1. Introduction

In robotic applications, it is crucial to reduce the overall operational cost and increase productivity, which usually results in the need to reduce the necessary cycle time of robotic tasks. Particular attention must be paid to the optimization of the robot end effector motion considering various criteria such as minimum execution time and/or energy consumption, smoothness, as well as robot constraints such as maximum joint velocity and acceleration, accuracy, workspace constraints such as obstacles and/or process constraints such as time window or end effector velocity and acceleration limits.

Among the most common methods to optimize robotic operations is the placement of the task to be executed at an optimal location with respect to the robot’s base or vice versa. In most cases, the proposed methods comprise three key aspects: (a) the introduction of a performance measure, (b) an optimization method and (c) an optimal search method.

Performance measures are at the core of such optimization methods. Their use allows for the quantification of different aspects of the manipulator’s operation targeted to be optimized. A wide range of different kinematic indices, either local, task based or global have been proposed in the relevant literature. Local indices are configuration dependent, i.e., dependent on the current posture of the manipulator at a given point. Task-based indices are usually formed by the algebraic manipulation of local indices along the given kinematic task, as such being dependent on the manipulator’s configurations during task execution. Global indices are configuration independent, since they represent the overall measure of a performance aspect across the whole manipulator’s workspace.

Among the well-established indices in the relevant literature is Yoshikawa’s manipulability index [

1], providing a measure of the manipulator’s ability to move in any given direction from a given configuration. However, it presents a number of inherit limitations, such as scale, order and dimensional dependency as well as the fact that in its general form is an unbounded index. Moreover, it does not take into account the direction of motion, since it examines all possible directions of motion from a given configuration. However, various improvements have been proposed to overcome its limitations [

2]. Other well-established indices include the Minimum Singular Value [

3] and the Jacobian condition number [

4]. The first examines the “most difficult” direction of motion of the end effector, providing a concise means to determine the manipulator’s posture distance from a singularity as well as a measure of the upper bound of the velocity the manipulator may move in all directions. The latter examines both the “most difficult” and the “easiest” motion directions from a given posture, providing a concise measure of accuracy of the transmission of joint speeds to end effector velocity. Similar indices of the latter are the Local Condition Number and the Reciprocal Local Condition Number [

2]. However, these indices retain the limitations of the manipulability index, due to being dependent on the manipulator’s Jacobian. In the case of the determination of the effectiveness of the transmission of joint speeds to the end effector velocity, Dubey and Luh proposed the Manipulator Velocity Ratio (MVR) [

5]. The measure examines the transmission in a given direction of motion of the end effector, providing a more concise view of the manipulator’s ability to move in a specific direction. Moreover, it also provides a measure of the required values of the latter in order to achieve a specified end effector velocity. A thorough and comprehensive review of performance indices may be found in [

2].

Optimal kinematic task placement methods utilize some of the above-mentioned indices depending on the manipulator’s performance aspect considered for optimization to formulate the optimization problem’s mathematical expression, i.e., the problem’s objective function. The formulated problem is then solved utilizing an optimal search method. Some of the most recent and characteristic examples from the relevant literature are the following.

As already stated, the chosen index is the cornerstone of any proposed optimal task placement problem. In the case of kinematic tasks, such as those addressed in this work, a kinematic index is used.

A local kinematic index provides quantifiable information of a selected aspect of the manipulator at a given point within the manipulator’s workspace. For example, Nguyen et al. in [

6] used Yoshikawa’s manipulability index as the index for their proposed method of optimal task placement within the workspace of a surgical robot.

One example of a task based kinematic index was the Approximation of the Minimum Manipulator Velocity Ratio (AMMVR) presented in [

7]. The index is formed by calculating the value of the Manipulator Velocity Ratio (MVR) [

5] at several end effector frames along a 3D curve representing a trajectory to be followed by the robot’s tool frame and selecting their minimum value as the task-based index value. The “approximation” description was used because the local index value (MVR) was calculated at a given number of frames along the trajectory.

In a similar fashion, Baizid et al. [

8] proposed a task-based index consisting of the minimum time required by the end effector of a manipulator to move between two task points within its workspace. The index was formed locally as the maximum value of the time required to traverse from one point to another. The index was then transformed to a task-based index by selecting the minimum value of all the local index valued determined for the given task. Liu and Cavunsoglu in [

9] used a task-based index based on the manipulability index to determine the optimal placement of a patient for the optimal execution of a robotic minimal evasive surgery task. The task-based index resulted from the integration of the local index value versus time along the required task trajectory divided by the total task execution time.

The problem of determining the optimal task placement may be reversed to the problem of determining the optimal robot base placement when the task(s) location(s) is(are) given. In such cases, usually a global kinematic index is proposed, in order to determine the overall best position for the robot’s placement, such as the reachability measure proposed in [

10]. The index was a measure of the reachability of different tasks in a given workspace that the manipulator must be able to reach. Dharmawan et al. on the other hand utilized a task-based index for the determination of the optimal location of a manipulator’s base for a given kinematic task [

11]. Their index was the sum of the mean manipulability index throughout the possible robot base locations.

In some cases, multi-criteria indices may be presented for providing a measurable function for the determination of the optimal location of the robot’s base. Doan and Lin in [

12] presented such an index formed by four criteria, all of which were expressed as a function of the robot’s kinematic and structural properties and constraints. The first one depicted the joint’s limitations, the second one was the possibility of the robot reaching a singular configuration, the third one depicted the possibility for the requirement of collision avoidance and the fourth was defined as the ratio of the distance between the robot’s base frame origin to the commanded target frame of the end effector by the theoretically reachable range from the origin of the robot’s base frame. Four weighting factors were introduced for each of the criteria and the index was defined either as the sole value of the fourth criterion or the maximum value of the other three criteria.

In the context of the proposed methods, it can be said that the approaches used are similar. An objective function is formed using the introduced or selected local, task based or global kinematic index and the objective function is then subject to minimization [

8] or maximization [

6,

7,

9,

10,

11,

12]. In all cases, the manipulator kinematics were at the core of the determination of the optimization process.

Due to the complexity of the problem, the search method is usually based on soft AI techniques such as Genetic Algorithms [

6,

7,

8,

10]. However, most of these proposed methods are applied offline and the results presented by the authors are based on simulations rather than experimental verification. From the presented works, only [

12] is verified using a physical system. As such, these results represent the upper limit of the ones expected from the physical system. One such simplification is that when kinematic tasks are simulated, the dynamics of a manipulator are either not considered or simplified to a degree that their influence is negligible.

The present work presents a method for the optimal placement of a kinematic robotic task inside the workspace of a manipulator. The presented approach presents similarities to previous work by the authors such as [

7]; however, its novelty is based on two respective points. Firstly, the optimal location of a kinematic task within the workspace takes into consideration the minimum singularity free paths that the manipulator’s end effector may utilize in its motion between different task points in the respective sequence that describes the task. This was not considered previously, and singularity avoidance was assumed on the basis of the index value at the considered task points. As such, there was no guarantee that the manipulator would not reach a singular posture during its motion between consecutive points. The consideration of the minimum singularity free paths allows for the derivation of a solution ensuring the execution of the task under the certainty that during the end effector motion the manipulator will not reach any singular configuration. This consideration was first presented in [

12]; however, in a global fashion. In this paper, the avoidance of singular postures during the end effector motion is conducted in a task-based fashion.

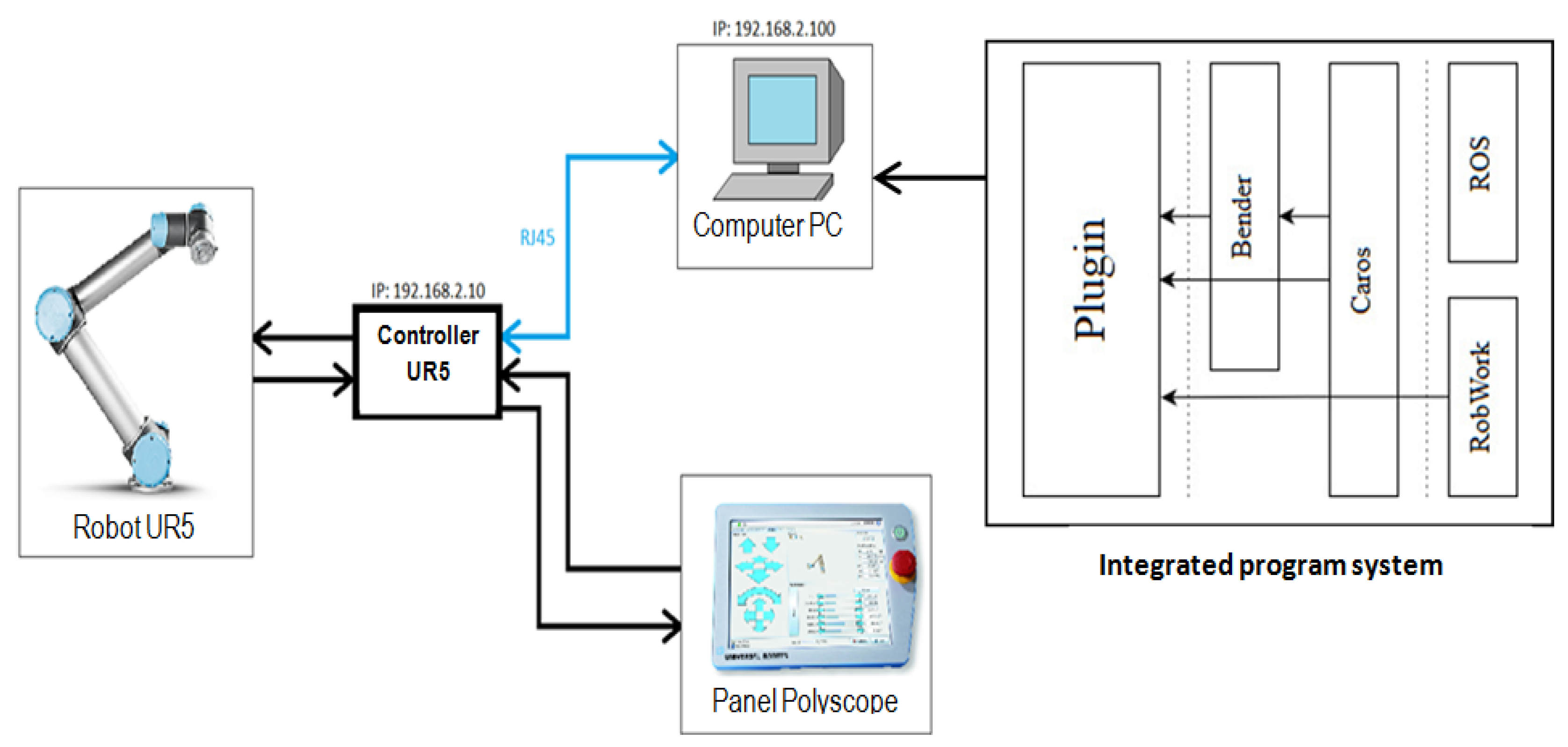

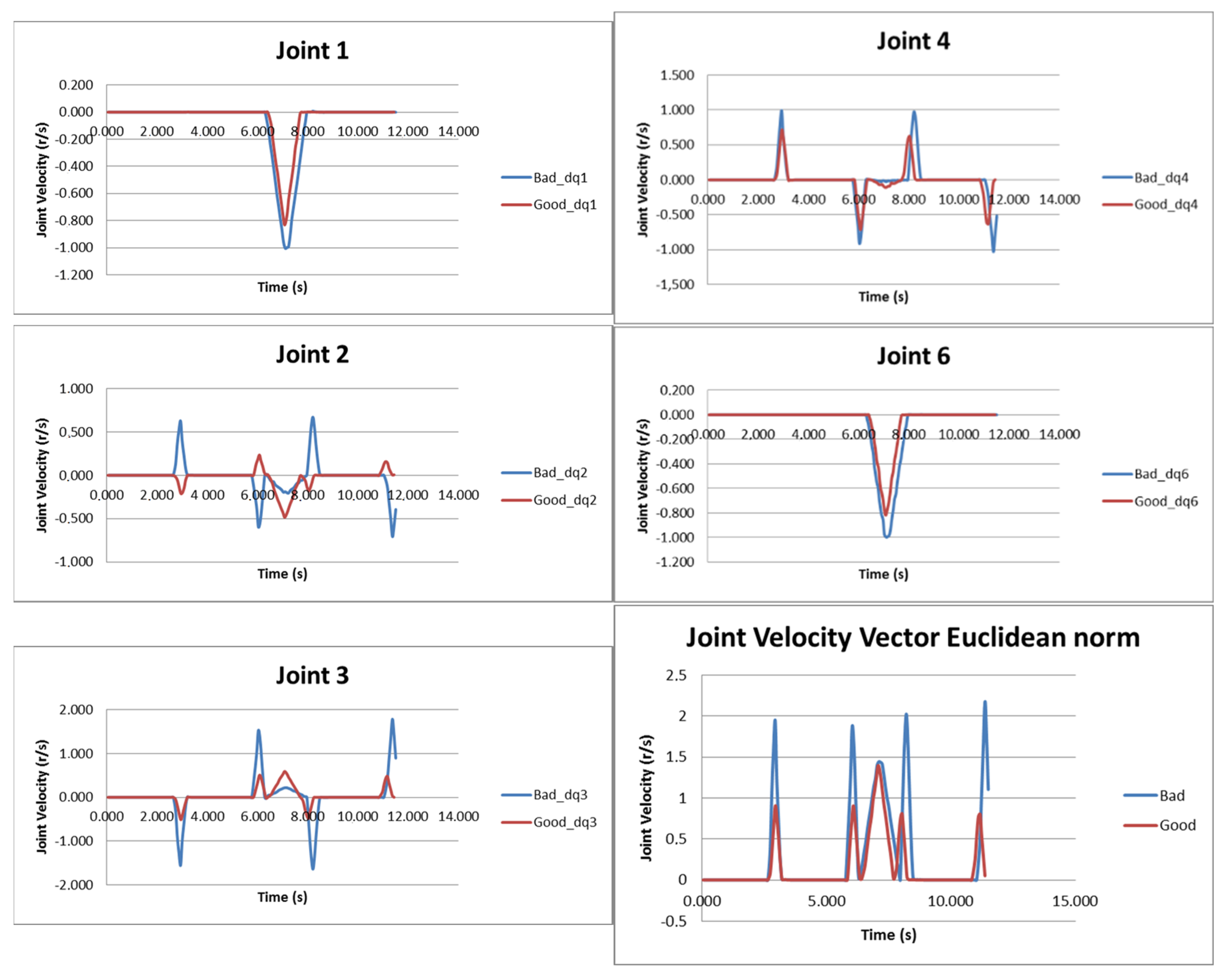

Moreover, the simulation results for the optimal task placement are experimentally verified in order to provide an insight on the validity of the computational results of the proposed method, i.e., the execution of a kinematic task under constant increases kinematic performance.

The main aim of the method presented is to allow the designer to derive the optimal location of a kinematic task within the robot’s workspace, so as the required joint speeds for the generation of the required end effector velocity will be minimized. As a process is proposed to develop task-based kinematic indices base on well-established local indices, such as the Manipulator Velocity Ratio [

5,

7]. In order to achieve the prescribed aims, the methodology presented aims for the maximization of the minimum value of the developed task-based kinematic performance indices. Given the computational results from the application of the proposed method, a physical experimental workcell is setup and the examined tasks are executed. Two types of robotic tasks are considered—a pick and place and a path-following task. The experimental workcell setup utilizes a UR-5 serial manipulator [

13]. Additionally, in order to determine the validity of the method both the optimal results as well as the results for a considered “bad” task placement location are utilized for the experiments, and in both cases end effector velocity and joint speeds along with the required time for task execution are measured. The experimental results for both the “bad” and “best” task placements are evaluated in contrast to examine the validity of the proposed method.

2. The Proposed Approach

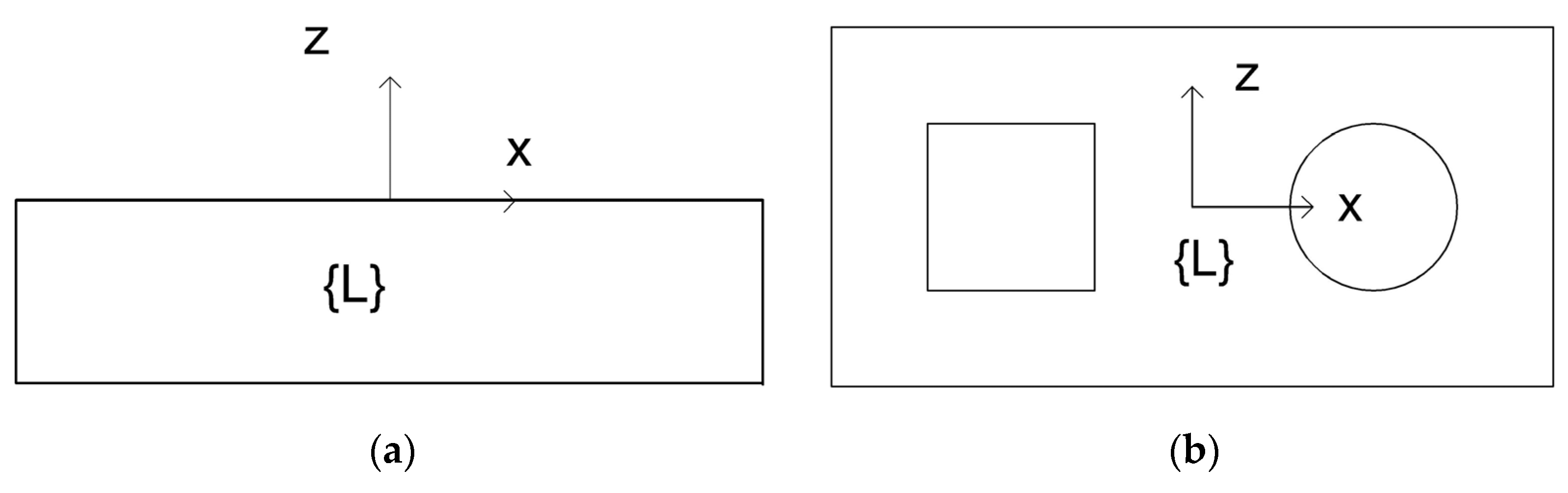

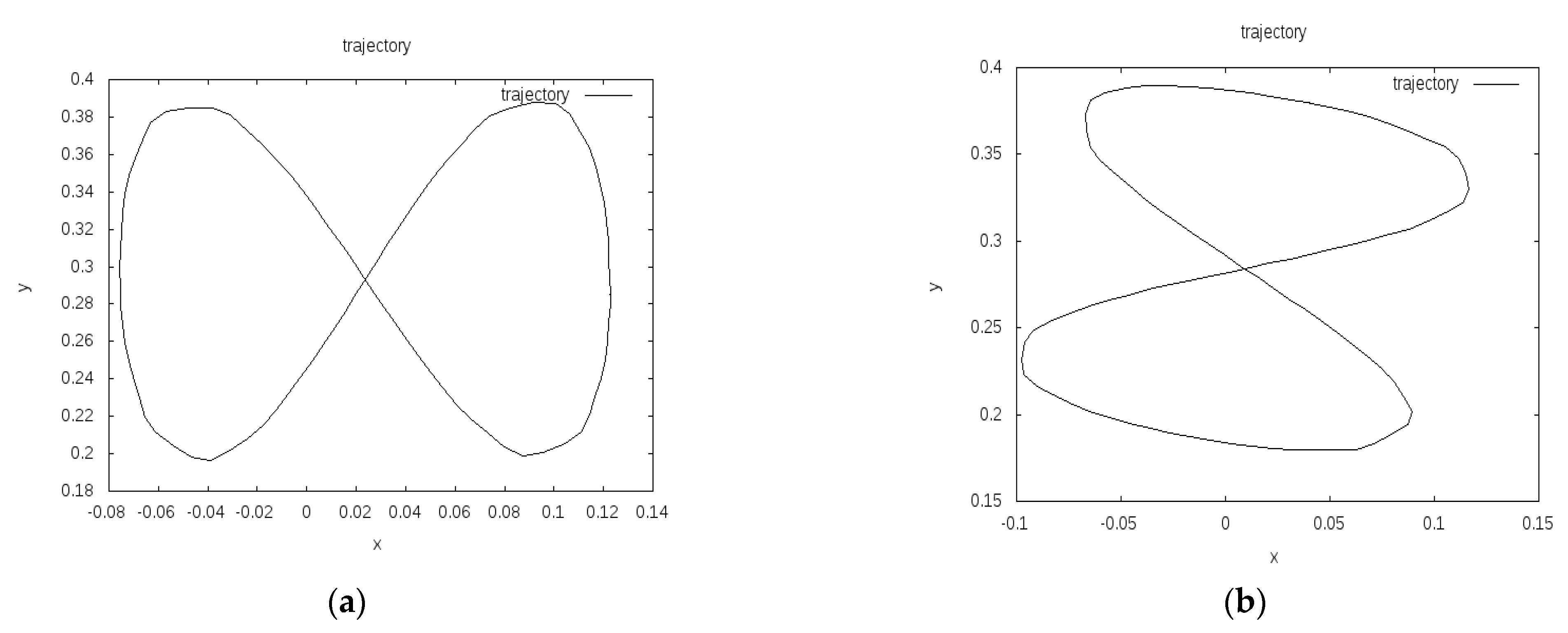

Generally, in kinematic robotic tasks, the end effector of a robot is required to reach a number of task points or to follow a given path with its end effector, presenting a prescribed orientation of the end effector local frame. These points may present task points where an action is executed or present intermediate task points along a curve/path to be followed by the robot’s tool in a specific sequence, while the end effector exhibits smooth motion along the path under prescribed acceleration and velocity requirements.

As such, a means to achieve an increased kinematic performance during task execution, commonly utilized, is the placement of the kinematic task to an optimal location within the robot’s workspace [

7]. In the case of the method presented, kinematic tasks are described as collections of task points that the end effector must visit and move along under given orientations.

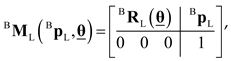

The presented methodology may be segmented to two parts that are interconnected: a part that enables the work cell’s layout design and a part where the experimental process takes place. The whole process is presented in

Figure 1.

- (1)

Layout Design

During this initial stage, the derivation of the kinematic tasks optimal location is computationally derived, having as an input the collection of the task points that compose the task. As such, a Local Coordinate System (LCS) is considered to be placed to the initial task point to be visited, which depicts the orientation and location of the end effector at it. All other task points are therefore referenced to the LCS. Therefore, the inputs for this stage are the position and orientation of the local coordinate systems, relative to the LCS, and the sequence with which they are to visited by the end effector during the execution of the task.

In order to the better interpolate the motion between the task points, intermediate points are initially determined between each consecutive task points pair. The designer is allowed to set the number of intermediate points to be placed as per task requirements.

Another process in the computational part involves the determination of the best possible paths between consecutive task frames. Therefore, a task-based kinematic performance index is developed so as to allow the quantification of the required kinematic performance aspect to be optimized during the execution of the task. The process is repeated for each pair of consecutive task frame and is listed as follows:

Initially, the possible configurations (postures) of the manipulator at each task and intermediate frame are determined by the solution of the inverse kinematics problem.

The possible singularity free paths with respect to the end effector’s motion between task frames are determined in the manipulator’s configuration space.

The task based index value is evaluated for the derived singular free paths.

Based on the index value along the path the best path is determined.

Finally, a Genetic Algorithm is employed to conduct the search for the optimal location of the kinematic task. At the end of the search process the optimal location of the kinematic task is determined.

- (2)

Experimental Implementation

The experimental implementation inputs are the determined optimal position and orientation of the LCS with respect to the BCS (Base Coordinate System of the Robot), the referencing of the task frames to the LCS and the sequence with which the end effector approaches the task frames. These are used to setup the task execution to the robotic workcell that will undertake the task execution.

2.1. Formulation of the Optimal Task Placement Problem

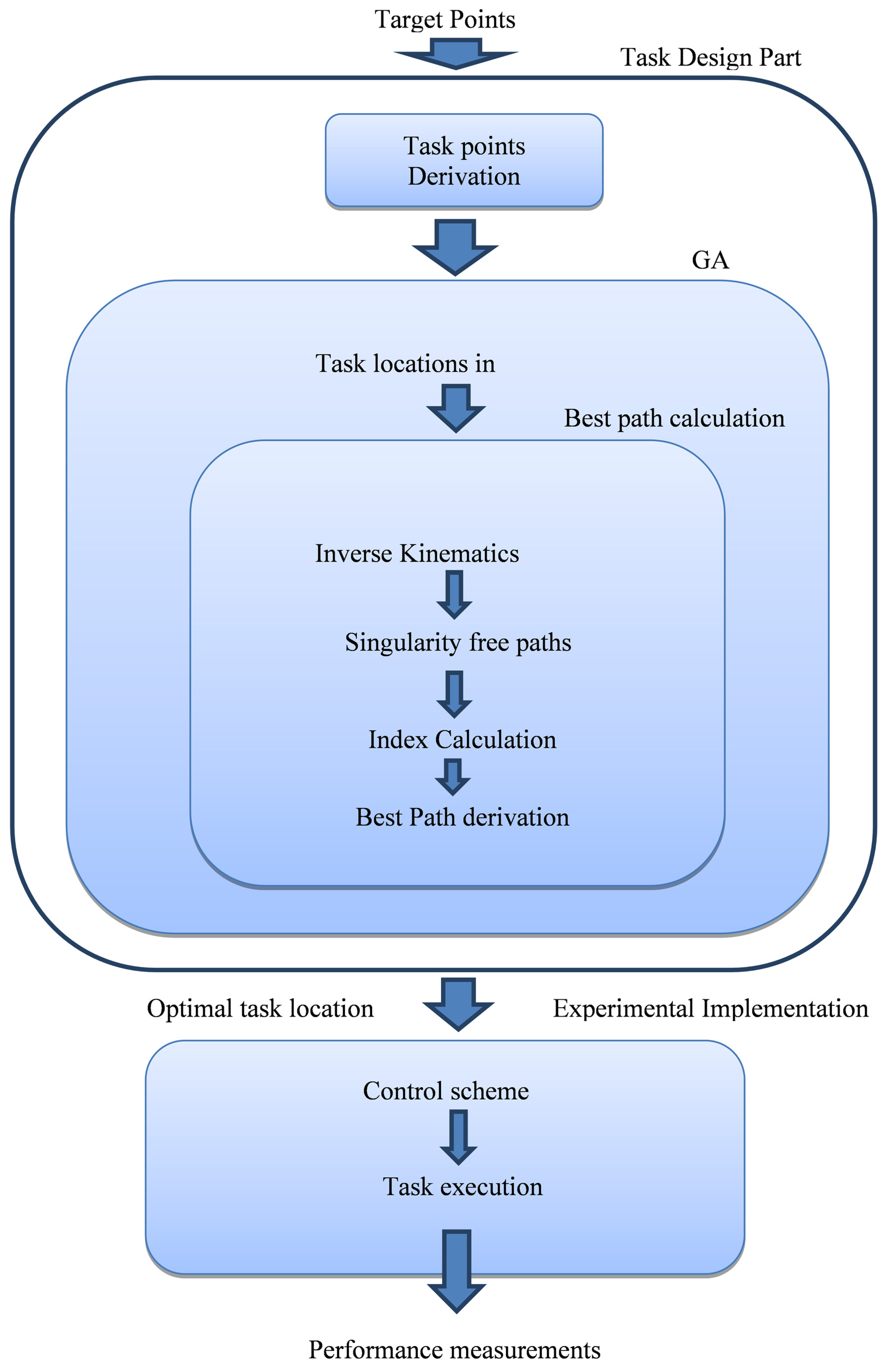

Formally, the kinematic task can be considered as one where the end effector of the robot is to reach k task frames under a required orientation requirement at each one with given orientation. The task frames respective location to each other are also given. A graphical representation of this consideration is illustrated in

Figure 2. In

Figure 2, the manipulator is placed at an arbitrary posture, and the kinematic task is represented by the collection of the respective task points presented. At each task frame the required orientation of the end effector’s frame is also depicted. As such, the task frame may be considered as as {P

i}, i = 2, …., k. In

Figure 2, the main coordinate systems required are that of the manipulator’s base (BCS) denoted as {B}, that of the end effector tool (TCS) denoted as {T} and that of the initial task frame of the kinematic task (to which all other task frames are referred to) (LCS) denoted as {L}. Therefore, for each task frame, it stands that:

where

LRi is the 3 × 3 matrix representing the orientation of the ith frame coordinate system relative to {L} and

Lpi is the 3 × 1 vector providing the location of the ith frame with respect to {L}. As such, it is possible to determine the overall task location with respect to the robot base {B}, as:

Considering this definition, the optimal task placement problem is transformed to the problem of the optimal placement of {L} relative to {B}.

The task frames can be utilized to determine k segments linear of motion that depicts the path to be followed by the end effector. Here, the selected kinematic performance aspect to be optimized is defined to be the transmission of the joint speeds to end effector velocity. Given that, the selected local kinematic performance index utilized for the task-based performance index is the Manipulator Velocity Ratio (MVR) [

5].

In order to determine the value of the index, the direction of motion of the end effector must be known. However, since a linear motion is considered to take place between frames in the cartesian space, it is quite simple to derive it for each path segment and, as such, for each segment, the index can be determined as:

where j is the index for the corresponding inverse kinematic solution for the ith frame. Vector

uvi is the unit vector depicting the direction of motion for the given segment,

J(vi,j) is the manipulator’s Jacobian evaluated at the ith frame with the jth configuration and r

(vi,j) is the MVR evaluated at the ith frame and jth configuration. However, the different solutions of the inverse kinematics to the ith and (i + 1)th frames provide a significant number of different motion paths between them in the manipulator’s joint space. Therefore, the selection of the best path is required and this selection is based on the determination of the shortest singular free path.

Figure 2.

UR-5 manipulator and the base {B}, end effector {T}, local {L} coordinate systems, and task frames {Pi}.

Figure 2.

UR-5 manipulator and the base {B}, end effector {T}, local {L} coordinate systems, and task frames {Pi}.

2.1.1. Shortest Singular Free Paths in the Configuration Space

As presented in [

14], no-generic geometries divide the space of 3R geometries into disjoint sets which have homogeneous topological properties. As such, given the maximum four solutions at a given point frame in the workspace of a 3R geometry, provided by the solution of the inverse kinematics problem, four disjoint sets can be produced. Therefore, in the case of non-cuspidal manipulators, the singularity locus separates the inverse kinematic solutions, forcing the manipulator to transverse singular points during the altering of its posture along the motion between task frames. The disjoint sets and their correspondence determination depend on the manipulator’s Jacobian matrix determinant |

J|. In previous work, it was shown that this value is independent to the value of the first joint variable [

15].

Here, the UR-5 robot is a 6 D.o.F manipulator and, as such, presents a maximum of eight postures at a given frame as resulting by the solution of the inverse kinematics problem. It is possible to derive the determinant of the Jacobian matrix of the UR-5:

In order to determine the singularity locus for the UR-5 robot, the equation considered is |

J| = 0. This results in the following solutions:

For the UR-5 robot’s eight aspects defined by [q2 q3 q4 q5] in the configuration space, there are eight solutions of the inverse kinematics problem included in each. The Jacobian matrix determinant sign, however, is preserved for each aspect. Given the above combinations, a total number of 64 available paths in the configuration space are present for the motion of the end effector between two given frames. These combinations stem from the possible configurations of each of the 6 joints of the manipulator as determined by the solution of its inverse kinematics. By the shortest path, the direct motion between two frames in the configuration space is considered. However, only eight of these paths allow the motion of the robot from the first to the second frame to proceed while not meeting a singularity point in the configuration space.

The determination of the singular free paths process is conducted utilizing the data in

Table 1. There, the sign of the Jacobian matrix determinant is evaluated at each frame and allocated to the corresponded aspect. Therefore, singular free paths are those that the sign of the determinant is preserved for both frames or in the case the frames configurations are existent in the same aspect.

2.1.2. Optimal Task Position Determination

The optimization process aims at improving the overall transmission of the joint speeds utilized, to achieve given end effector velocities.

The objective function is therefore defined as the maximum minimum overall value of the MVR in the k points of the 8 paths:

where R

v is the objective function.

Therefore, it is possible to derive the solution to the considered problem as:

As such, the method’s outputs are the orientation and position of {L} with respect to {B}. Since the required end effector postures for each of the task frames with respect to {L} are a priori given, deriving them requires a simple calculation of the respective transformation.

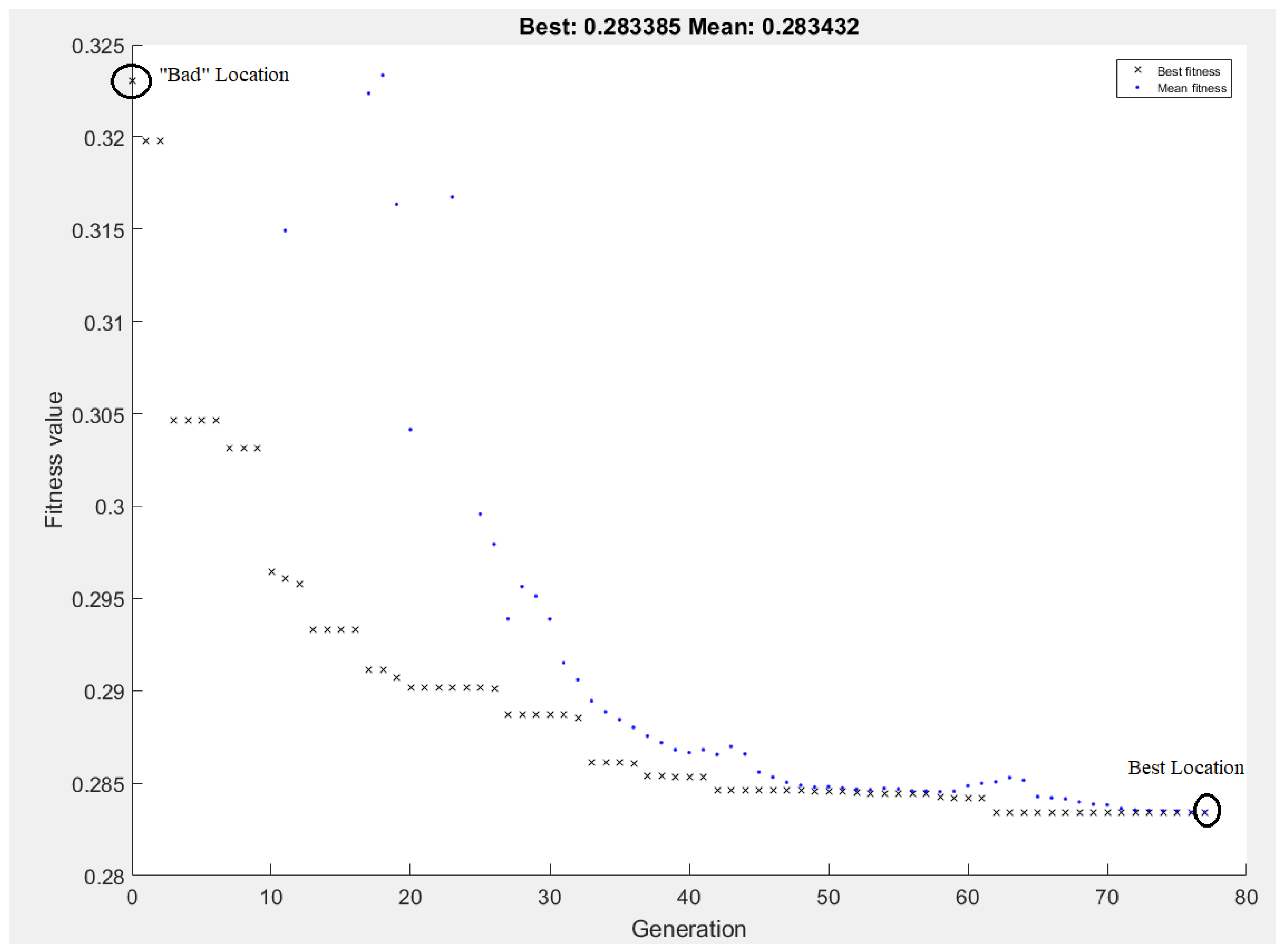

2.2. Derivation of the Optimal Solution to the Considered Problem

In the previous parts of the layout process described, the intermediate path segments along the motion between task frames were determined, and the task-based kinematic performance index was structured. Given these, the objective function of the considered problem was defined. In order to conduct the search for the optimal solution, a Genetic Algorithm is deployed.

In order to utilize the GA, the variables of the optimization problem must be appropriately represented. Here, a chromosome consisting of six digits of real numbers is utilized. These six digits correspond to the position of {L} with respect to {B} as [

x,

y,

z] coordinates and the Z-Y-Z Euler angles of {L} with respect to {B}. As such, the six digit chromosome is presented as:

The value ranges for the chromosome’s genes were: x, y, z ∈ [0.1, 0.5] (in meters) and φz = θy = 0, θz∈ [−π/2, π/2].

With respect to the GA operators utilized:

Reproduction was conducted in an elitist manner, ensuring the survival of the best individuals in the next generations (60% of the population).

Crossover was conducted using a one-point crossover method. The parents pairs were arbitrarily selected and the cut point was also arbitrarily defined. Here, the population selected corresponded to the 20% of the total population.

Mutation was conducted in a single point manner. A random digit was selected and reset to an arbitrary value. Again 20% of the population was selected to undergo mutation.

Given the objective function defined in Equation (8), the fitness function of the GA can be defined as:

Additionally, it is subject to minimization. Two conditions of search process termination were included, i.e., a maximum allowed generations number and a maximum number of iterations where there was no change in the fitness function value. The first was set to 100 generations and the second to 10 generations. A population of 40 individuals was utilized in each generation.

The outputs of the design part are the optimal location and orientation of all the task frames relative to {B}. These are the inputs to the experimental implementation (

Figure 1). The outputs of the experimental implementation are the manipulator’s joint velocities during task execution.