Rheology of Variable Viscosity-Based Mixed Convective Inclined Magnetized Cross Nanofluid with Varying Thermal Conductivity

Abstract

:1. Introduction

2. Viscosity Model of Cross Nanofluid

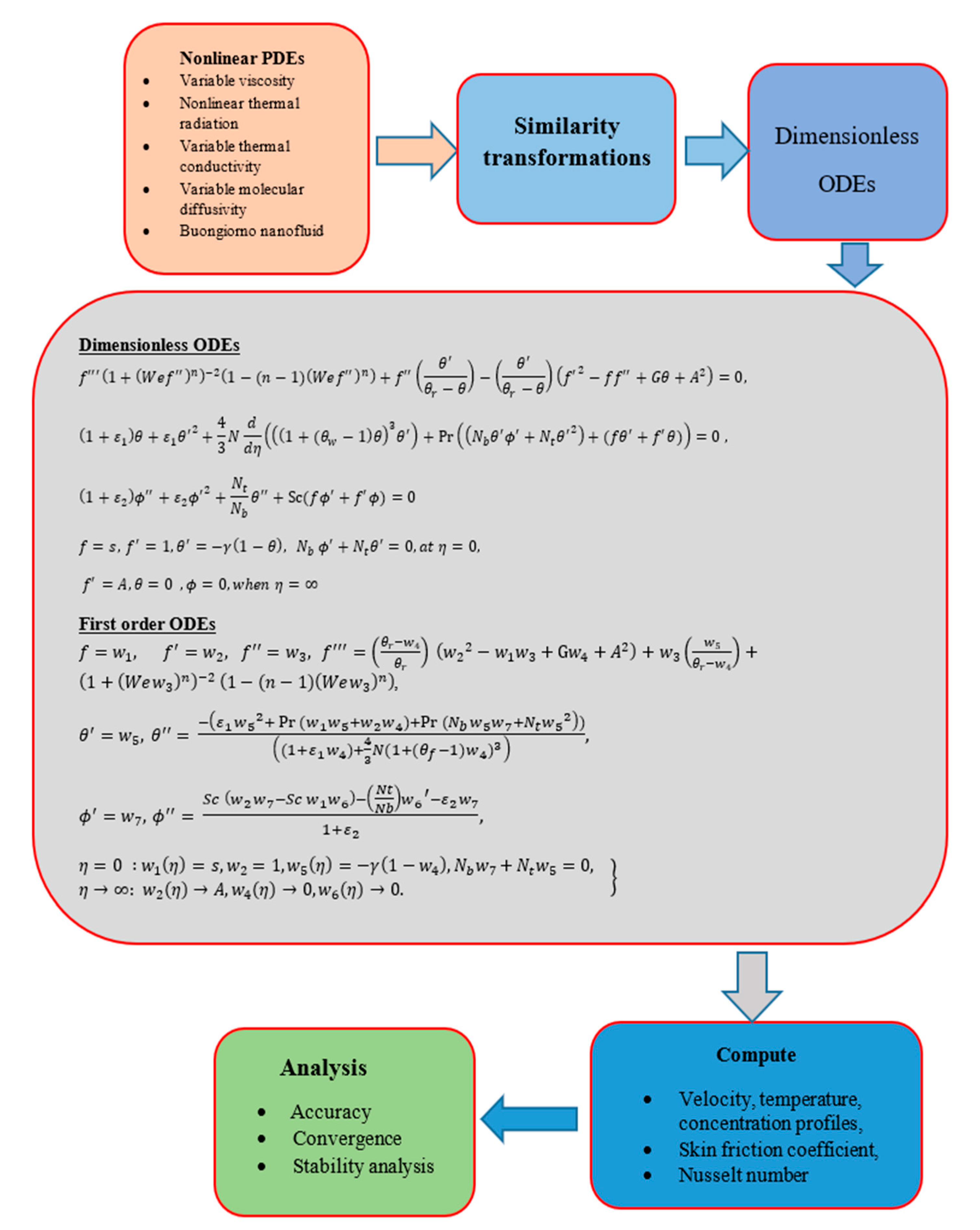

3. Orientation and Formulation of Physical Problem

4. Methodology

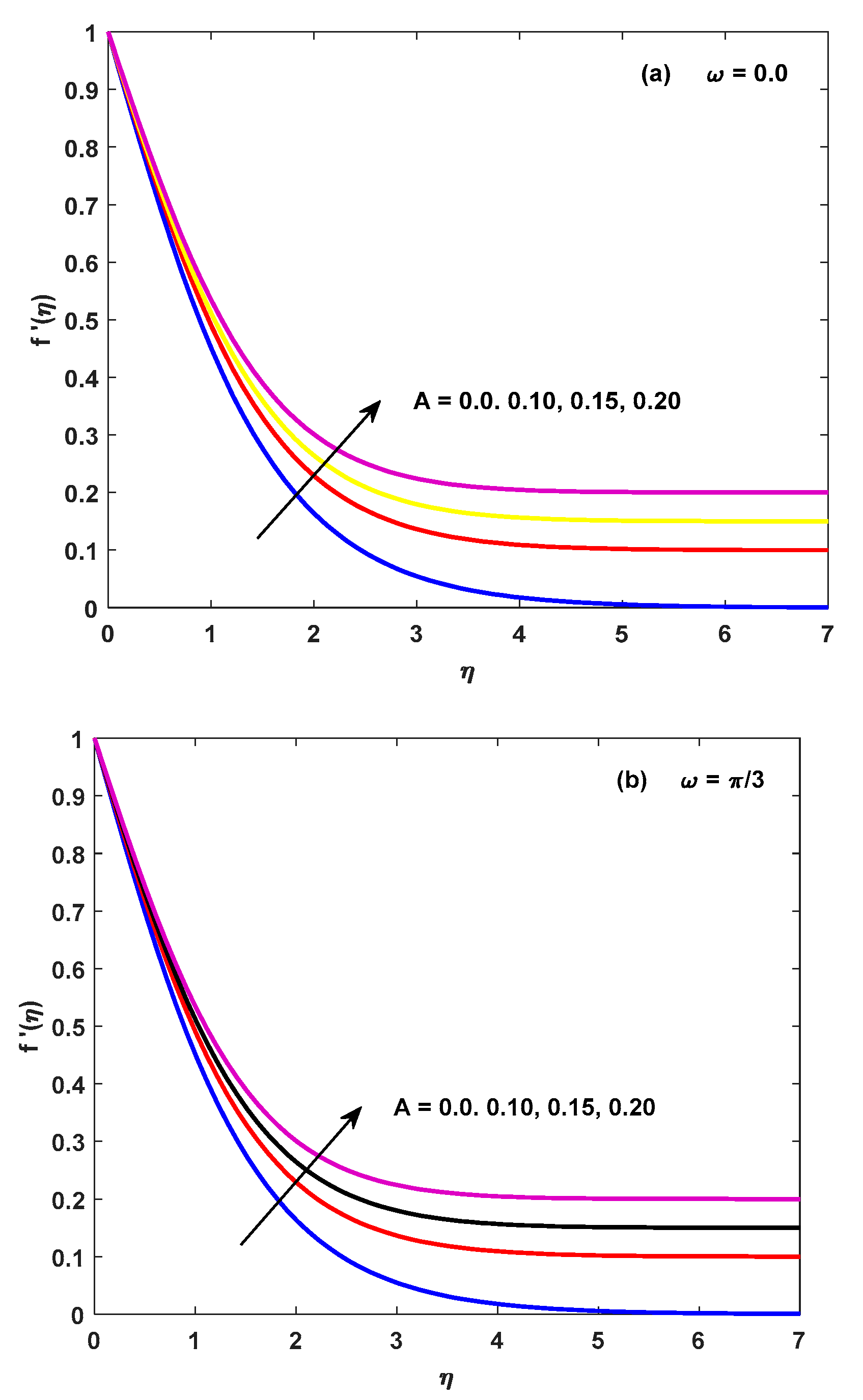

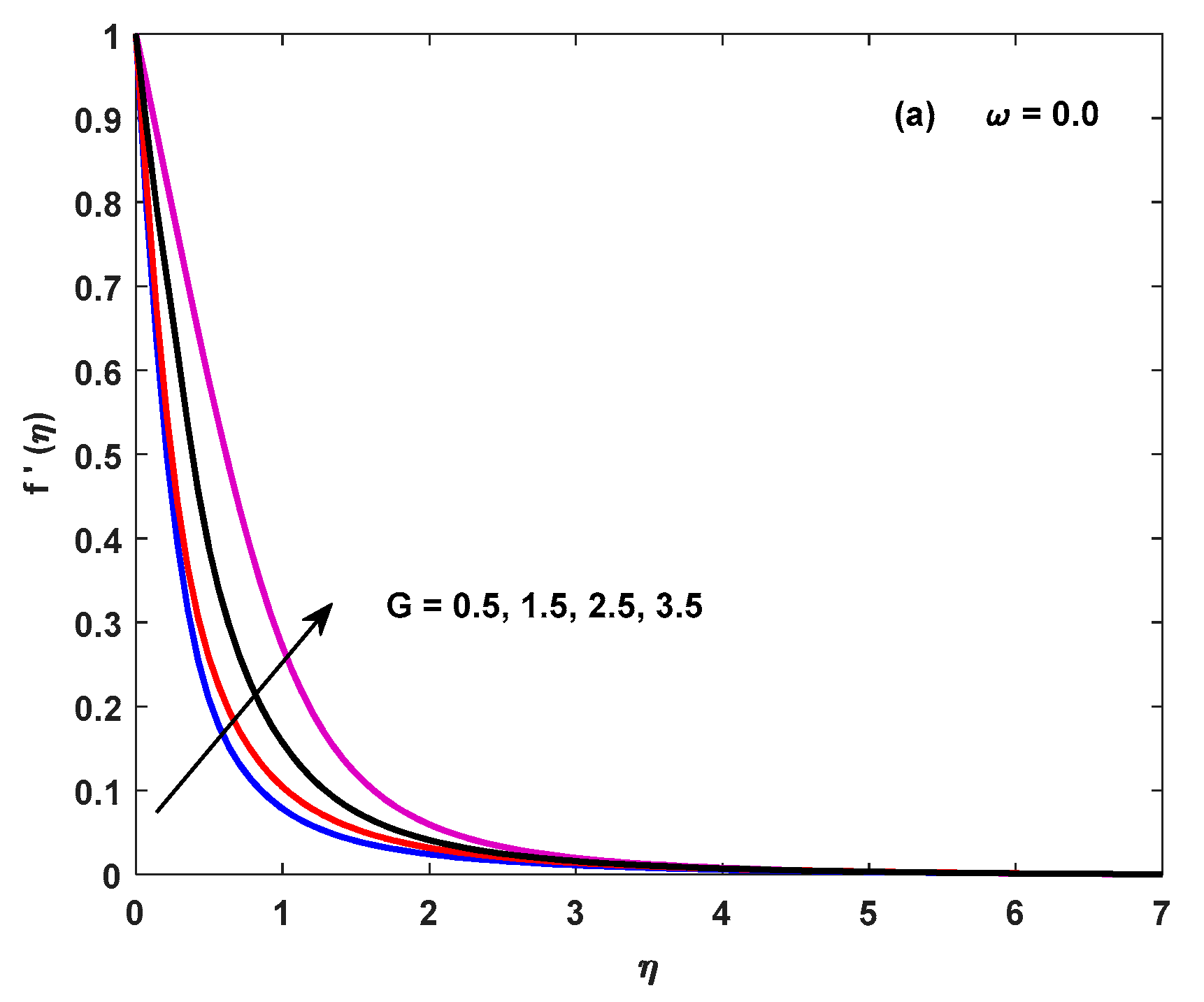

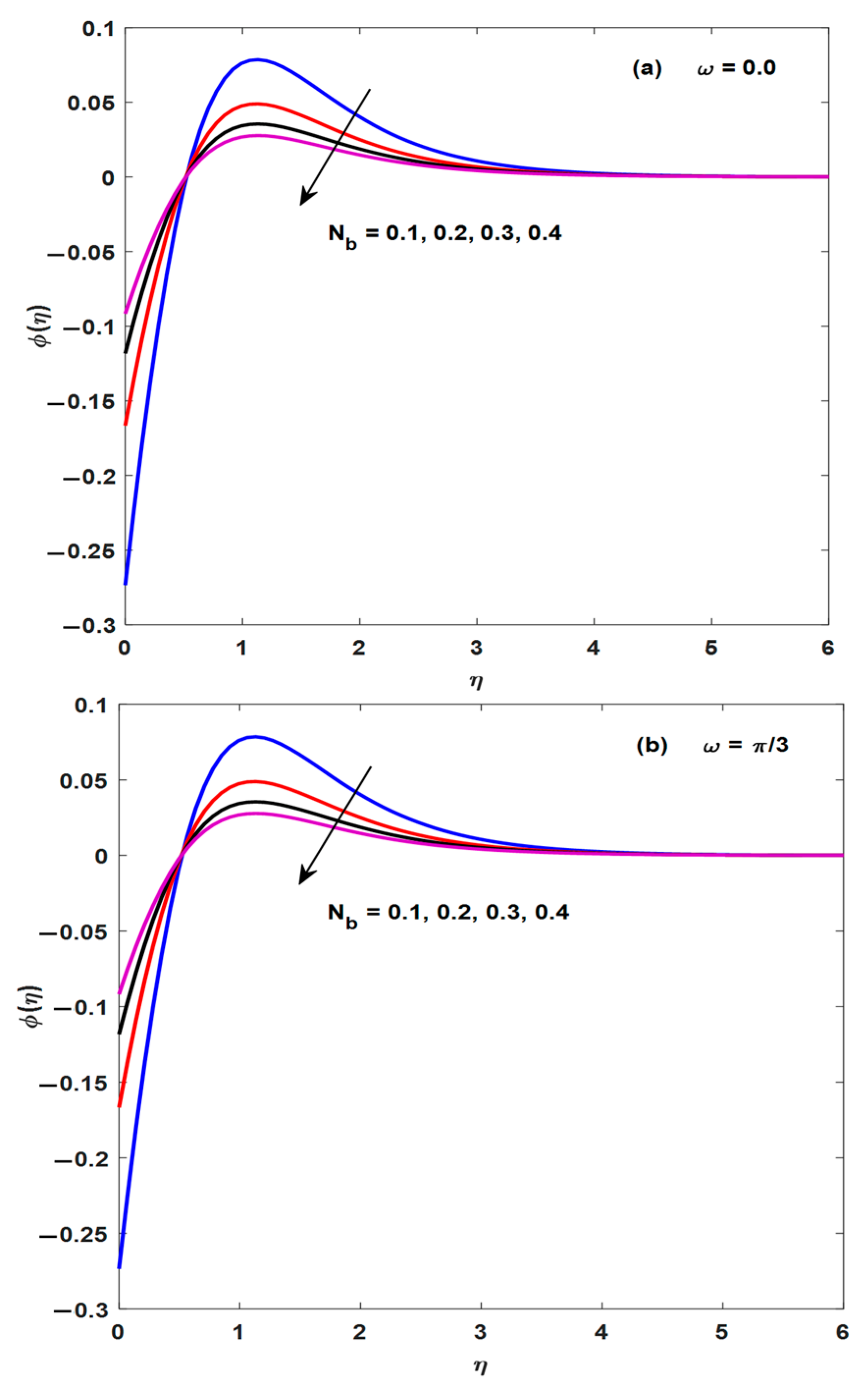

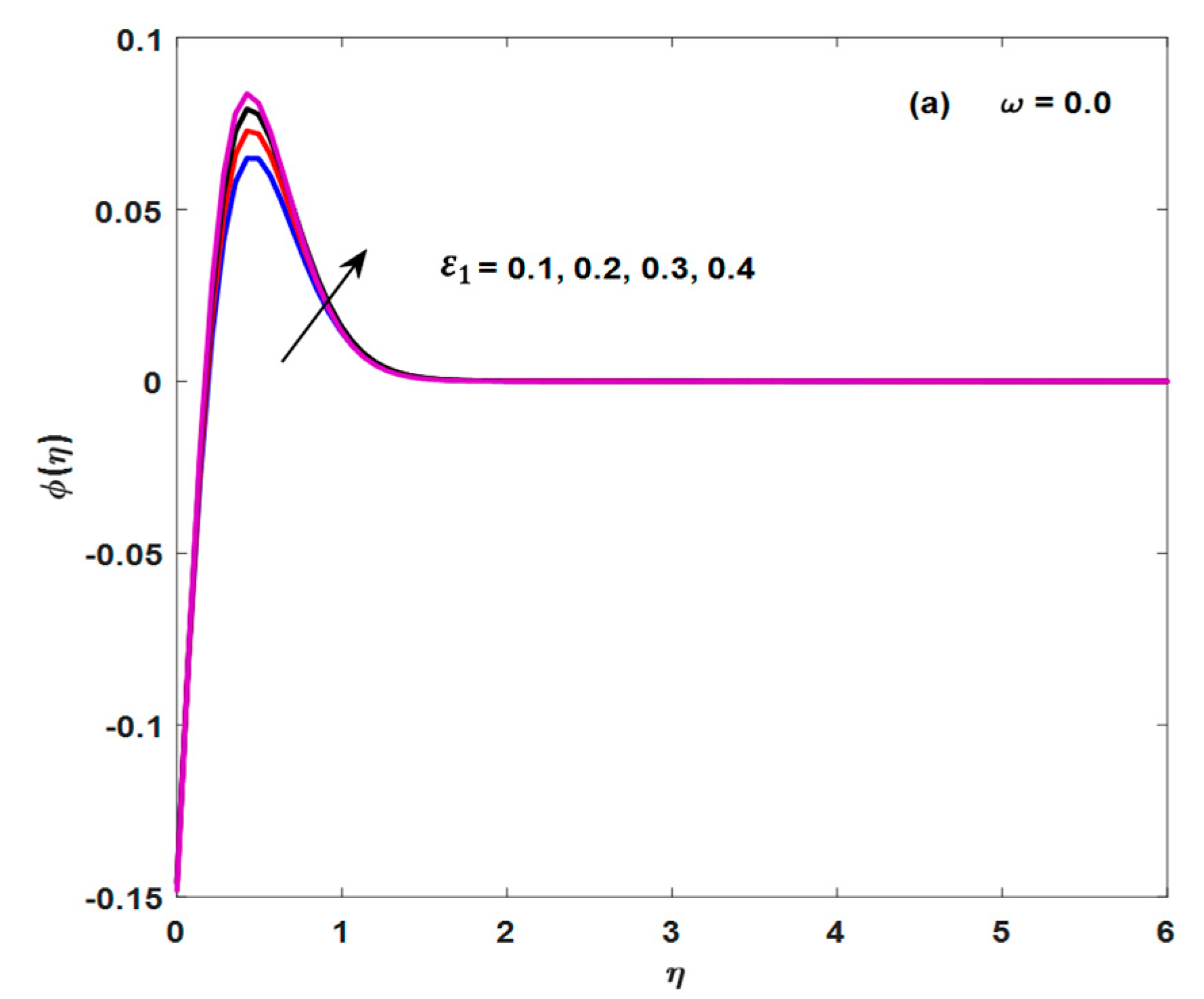

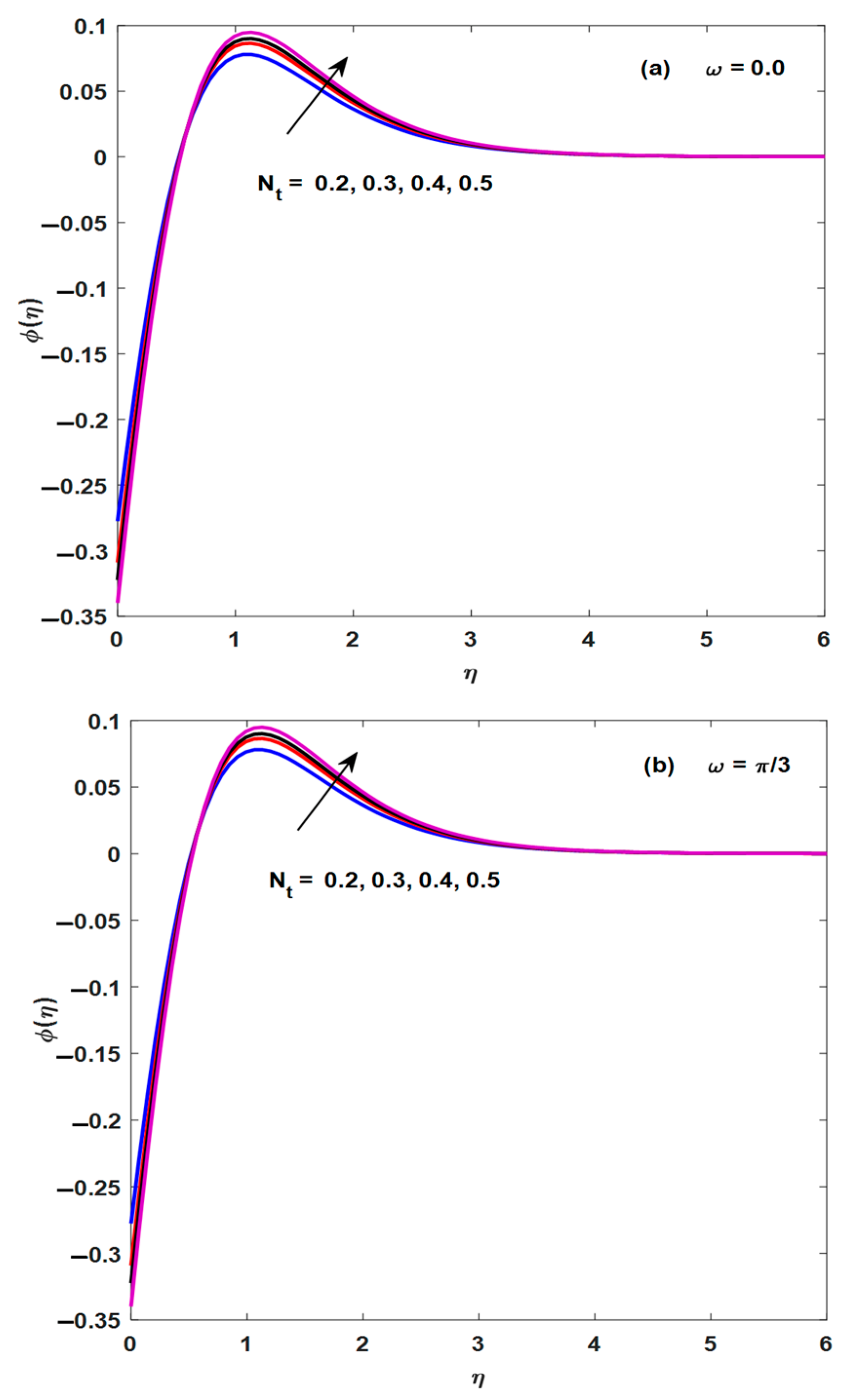

5. Comprehensive Debate Based on Numerical Results

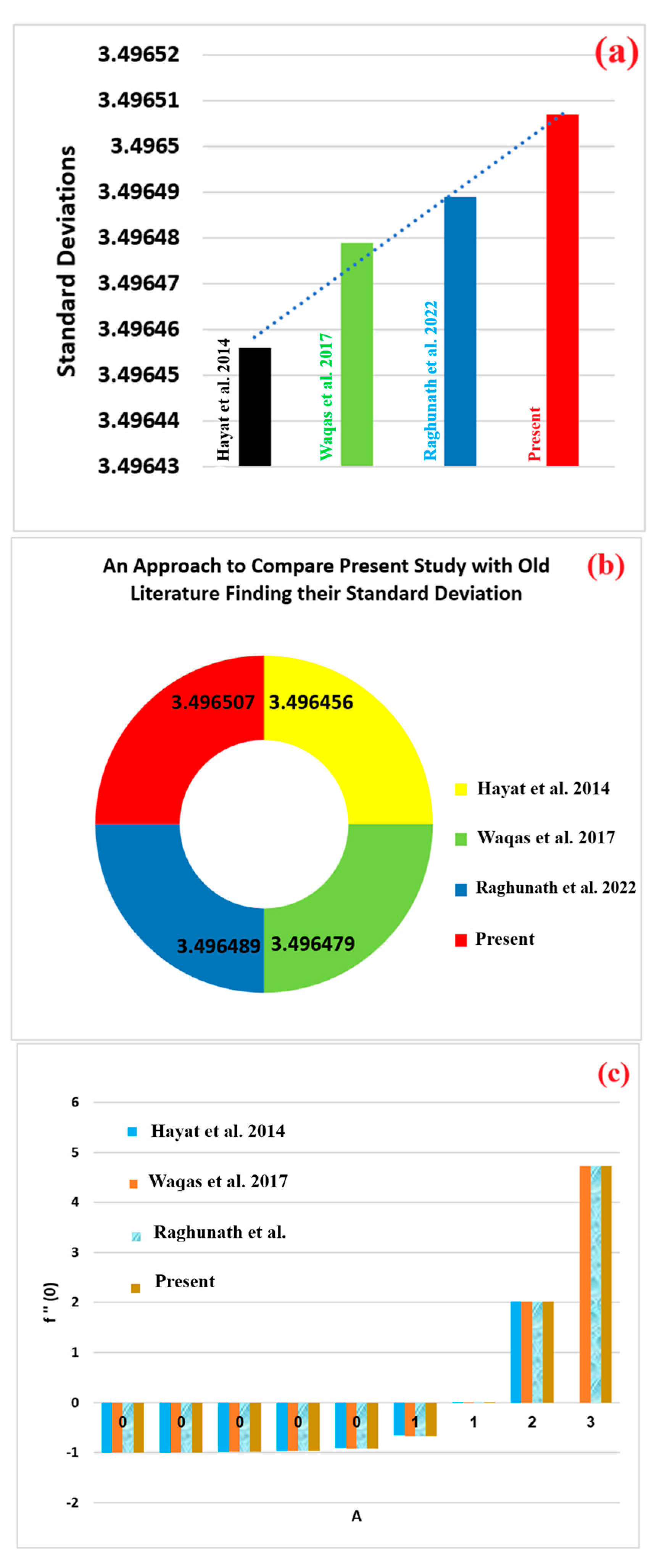

6. Validity of This Study

7. Conclusions

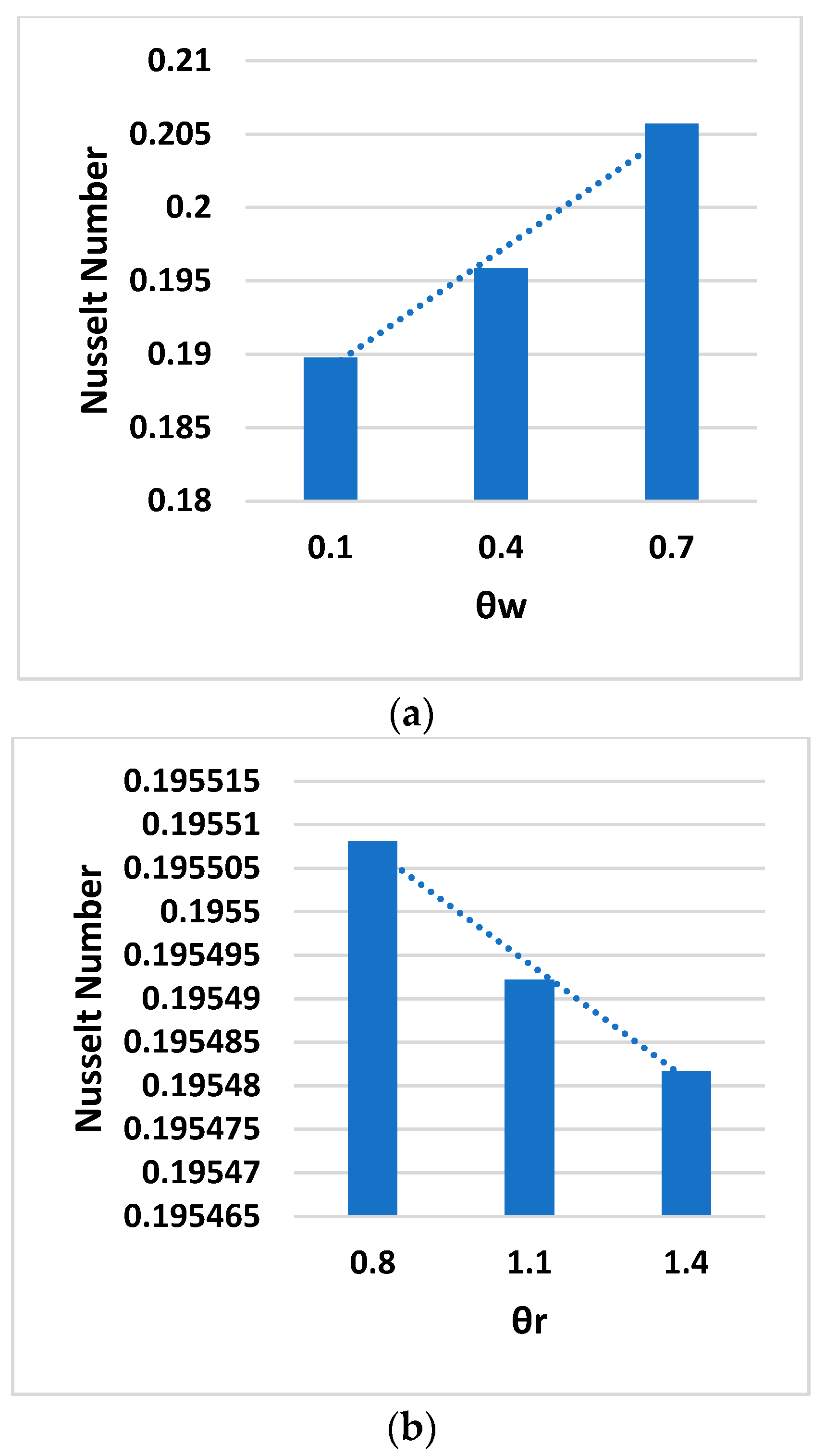

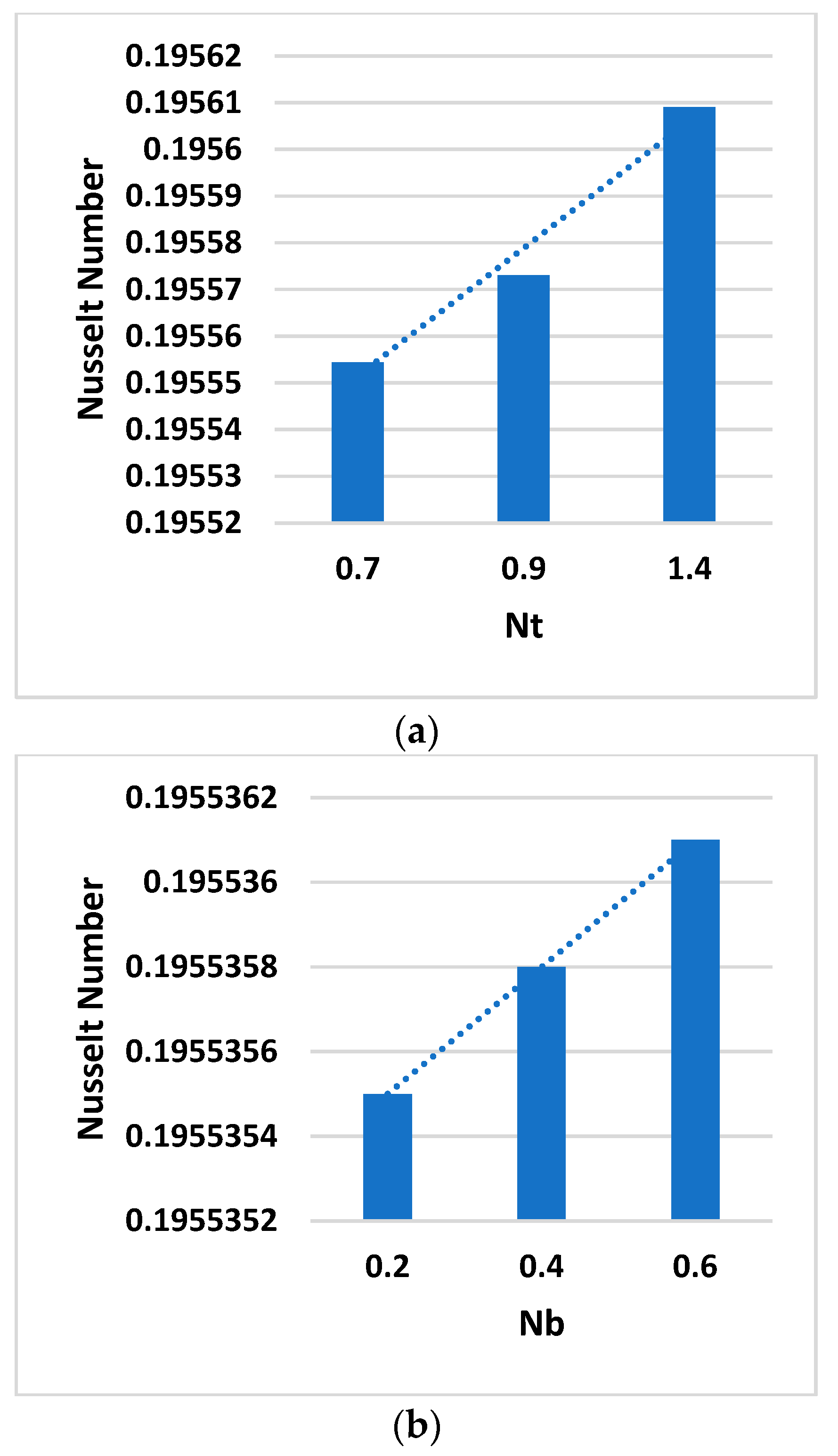

- An incremental change in variable temperature and molecular diffusivities diminishes the heat transfer rate.

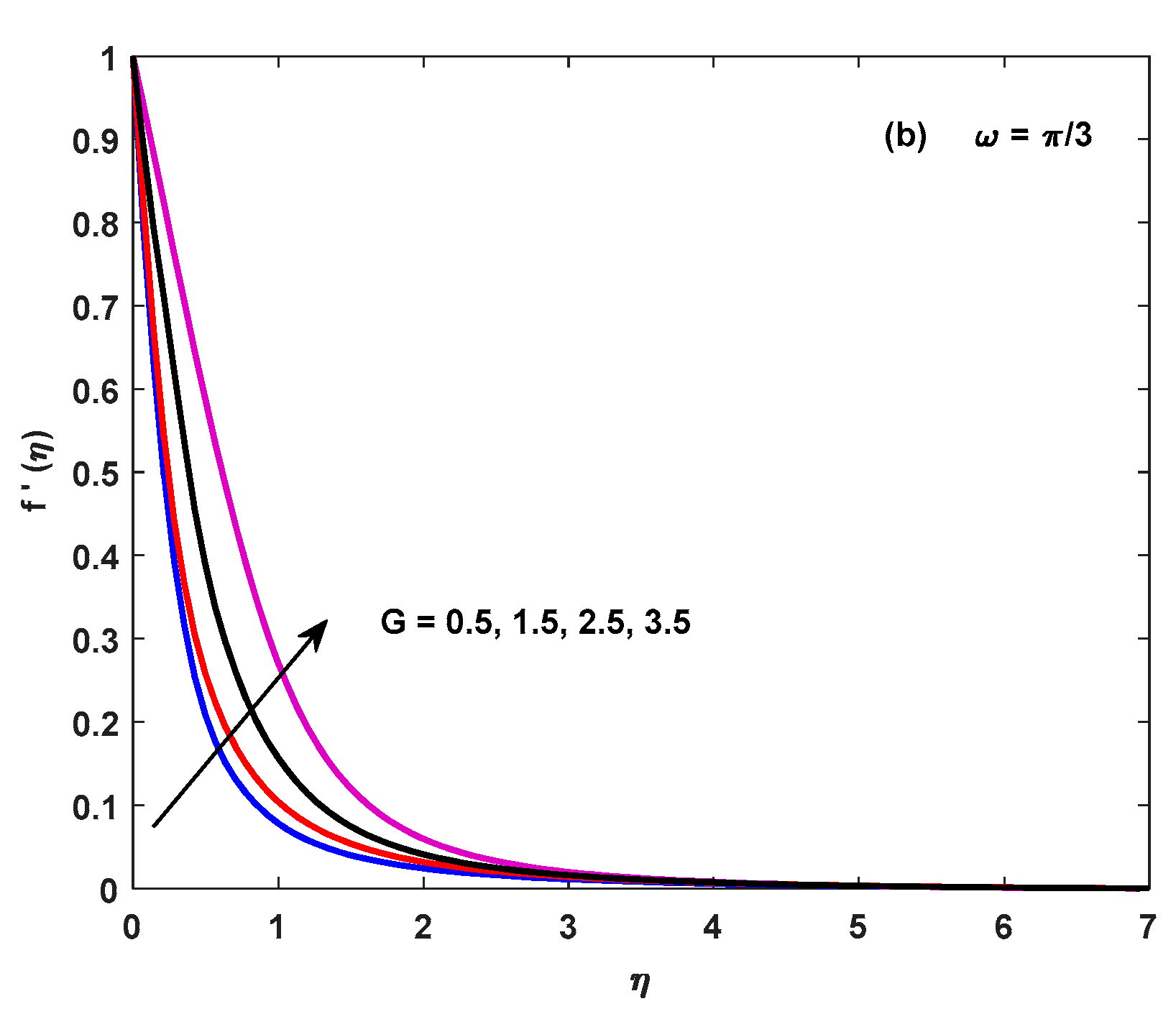

- An amplification in unsteady parameter improves the velocity field.

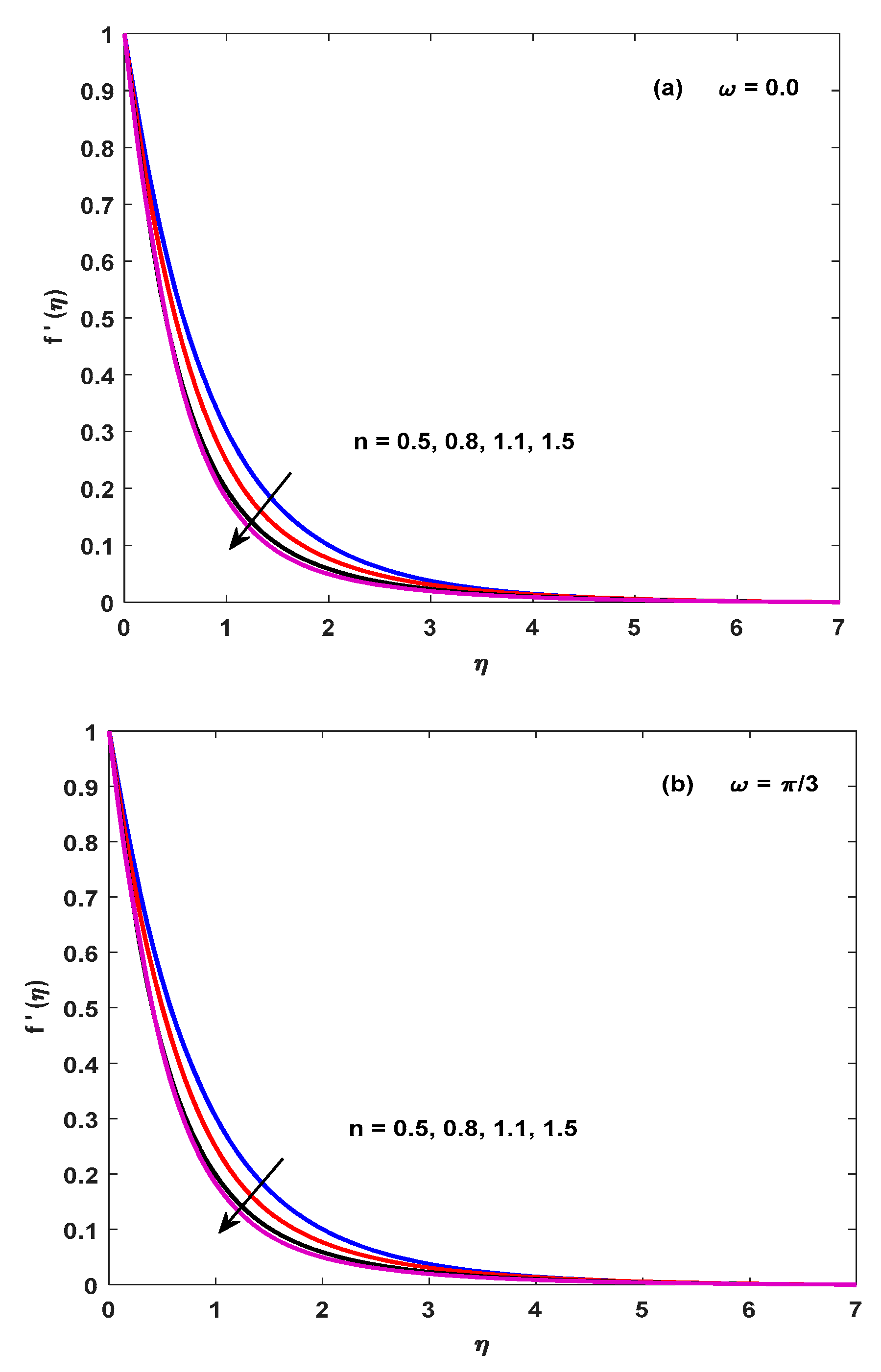

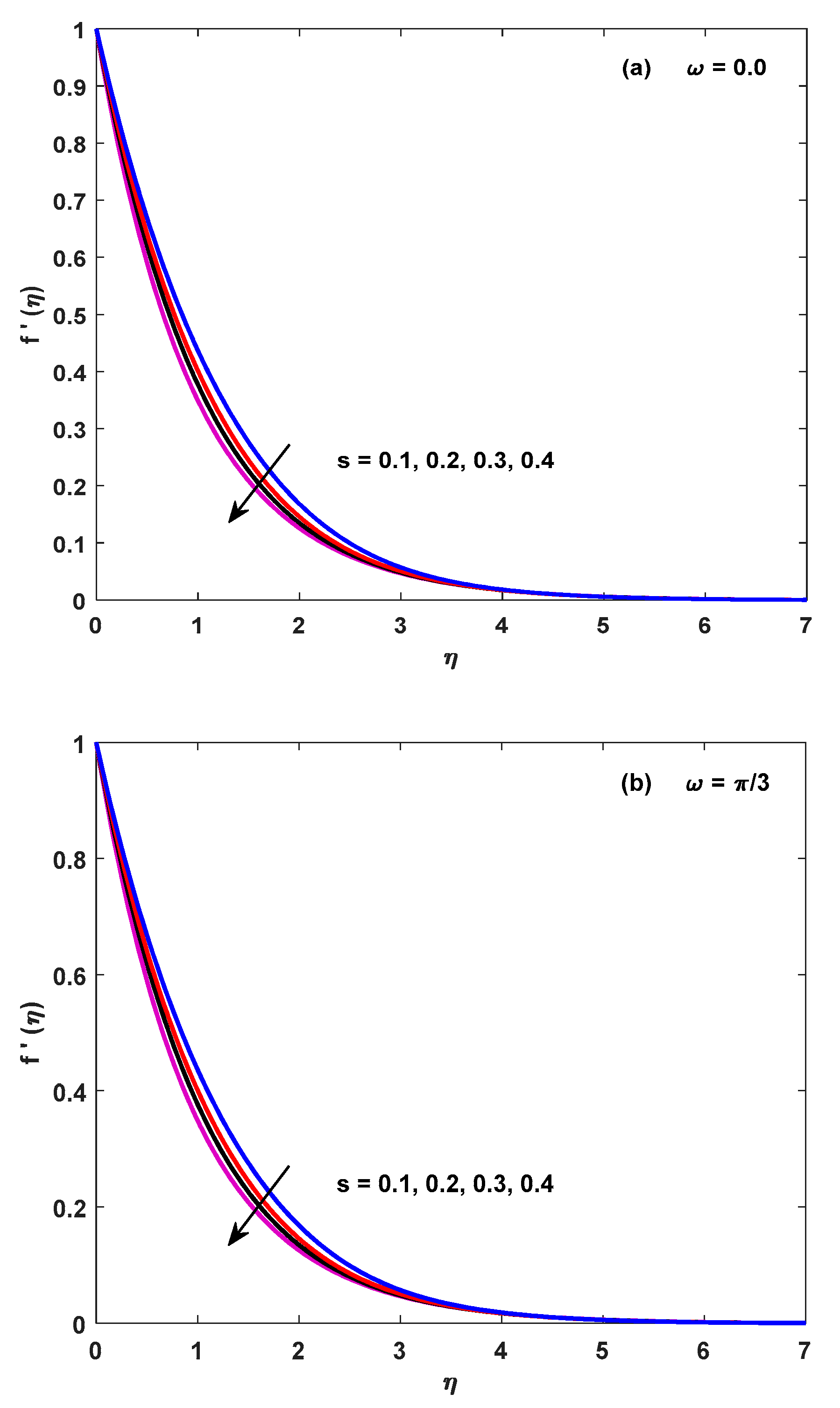

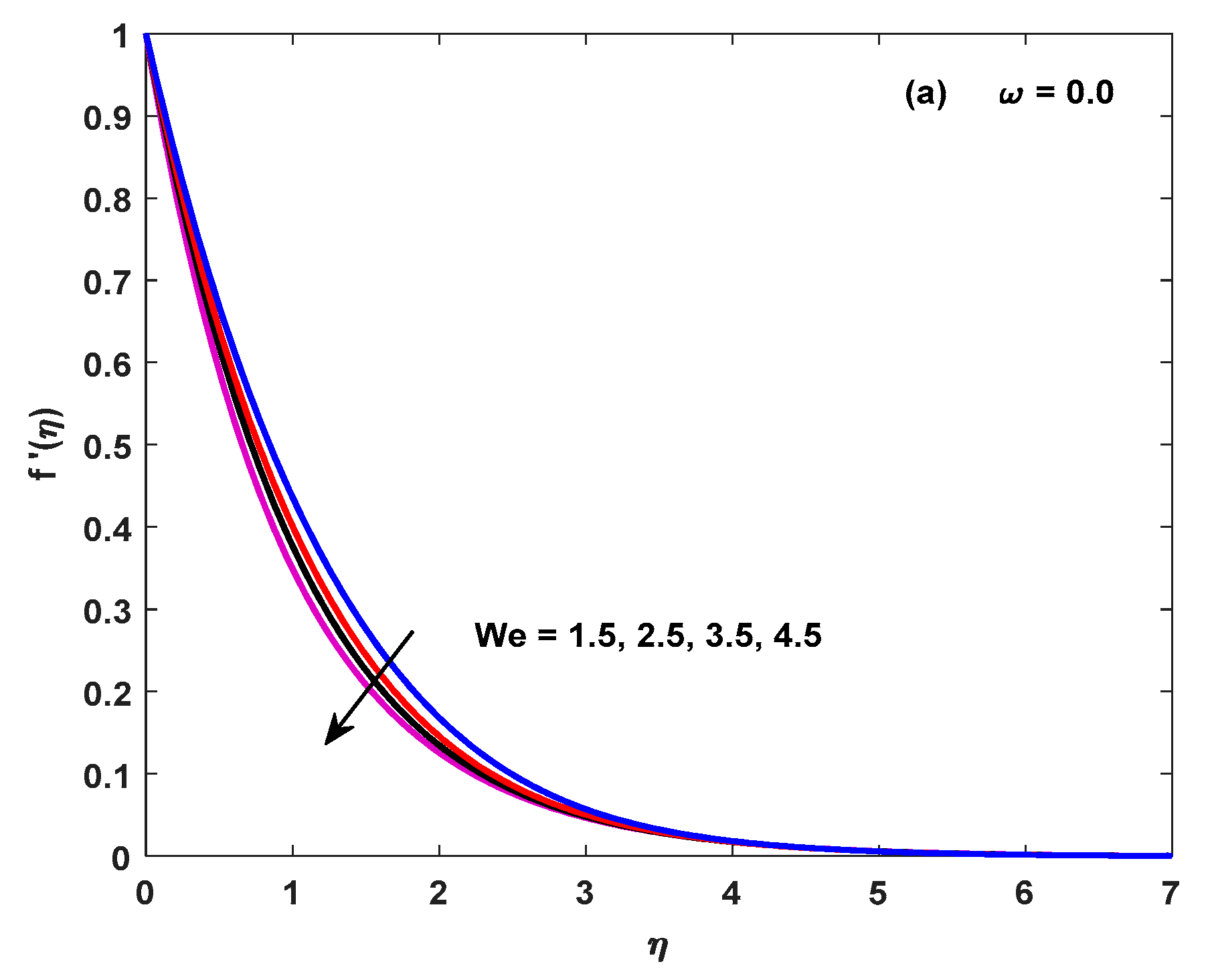

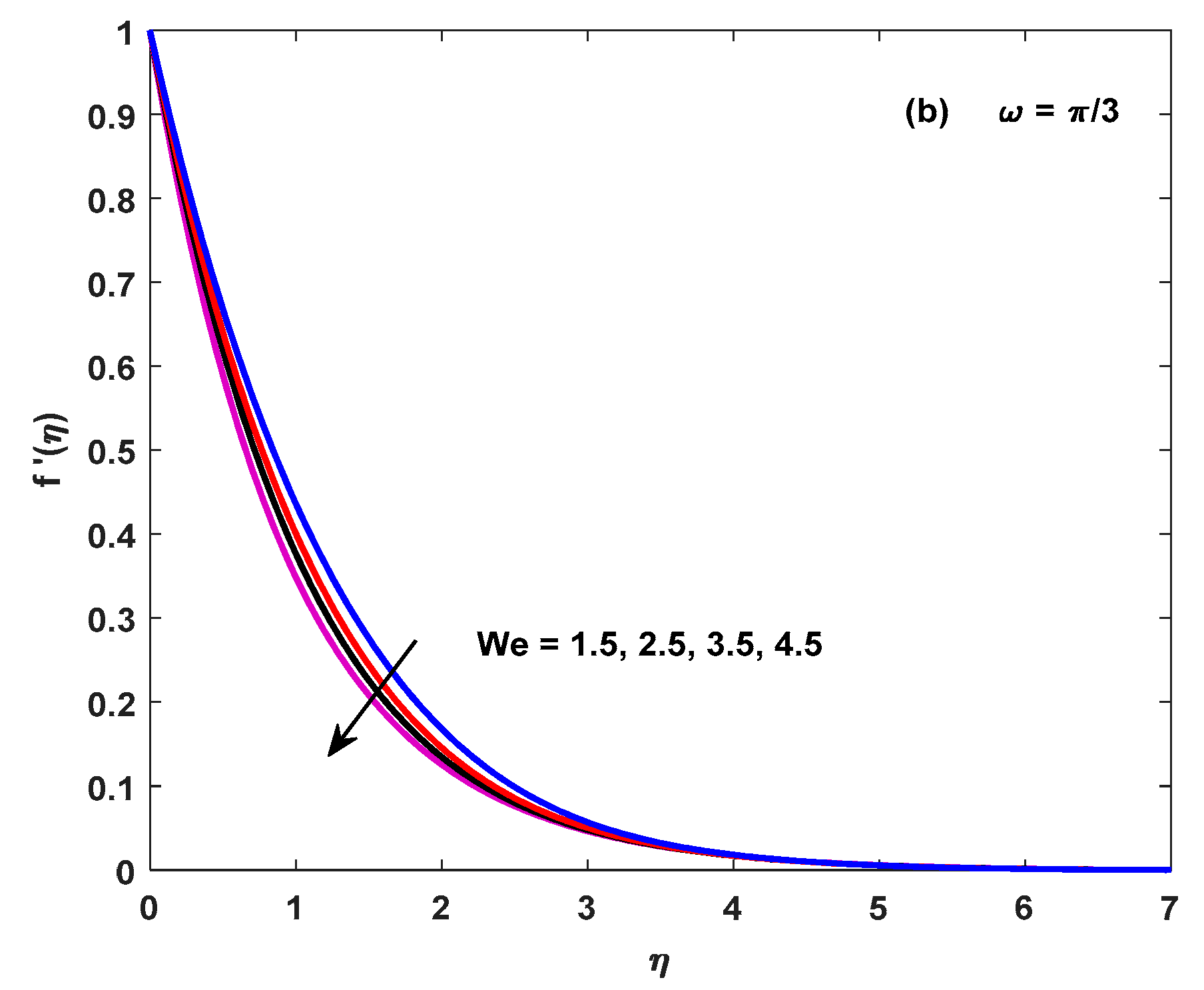

- The fluid velocity diminishes by escalating the Weissenberg number and power-law index .

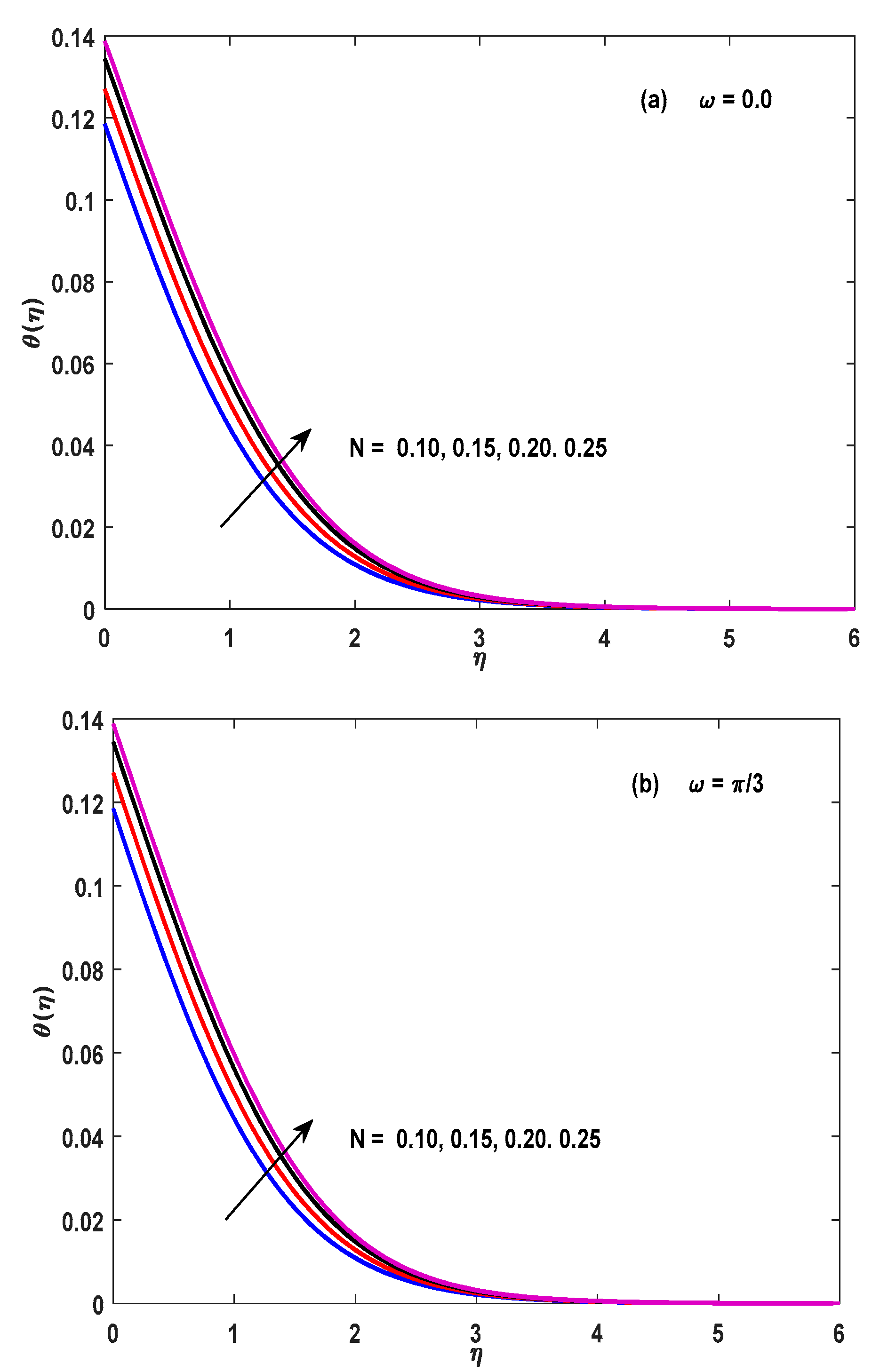

- A positive variation in the Grashoff number and thermal radiation amplifies the temperature field.

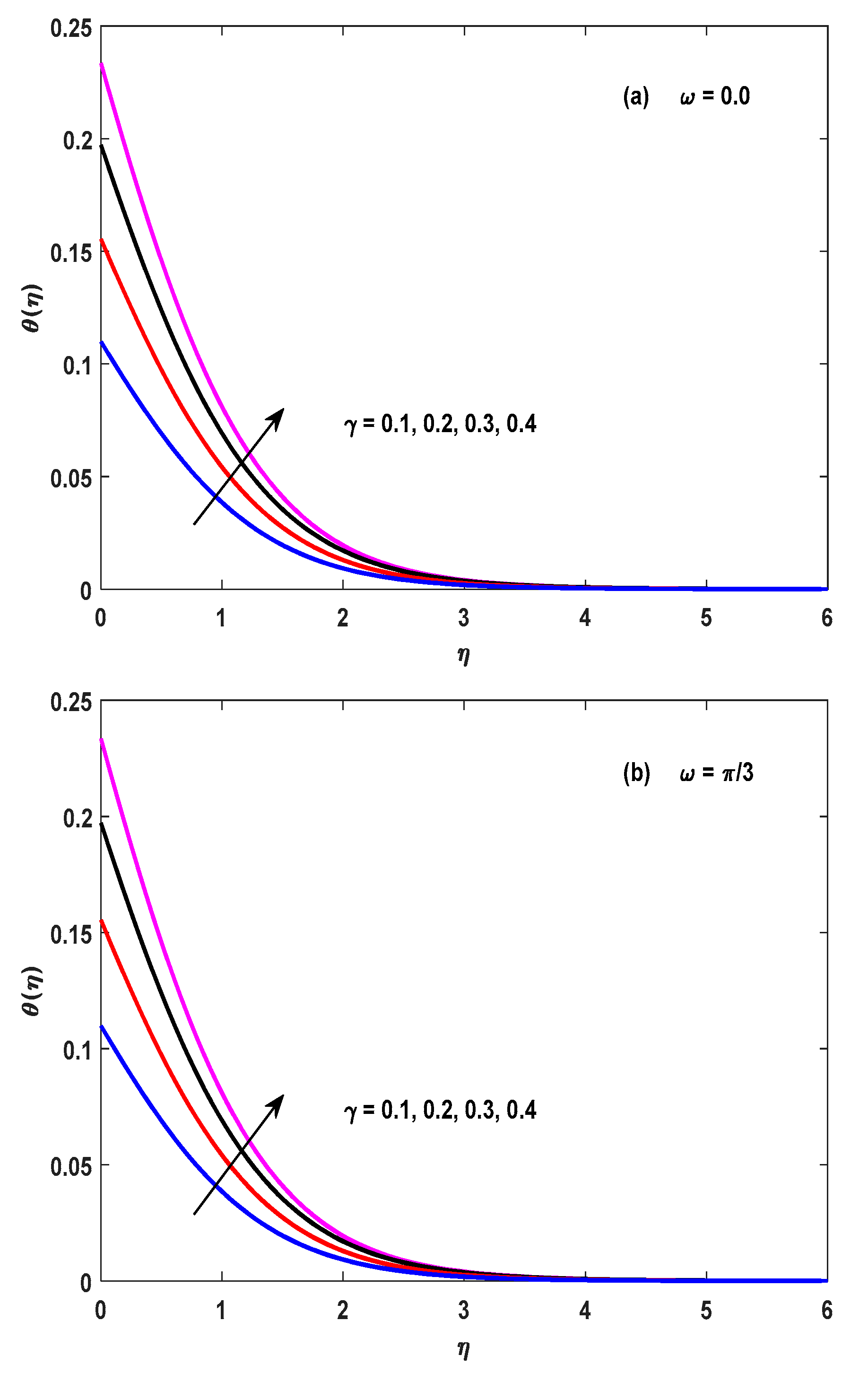

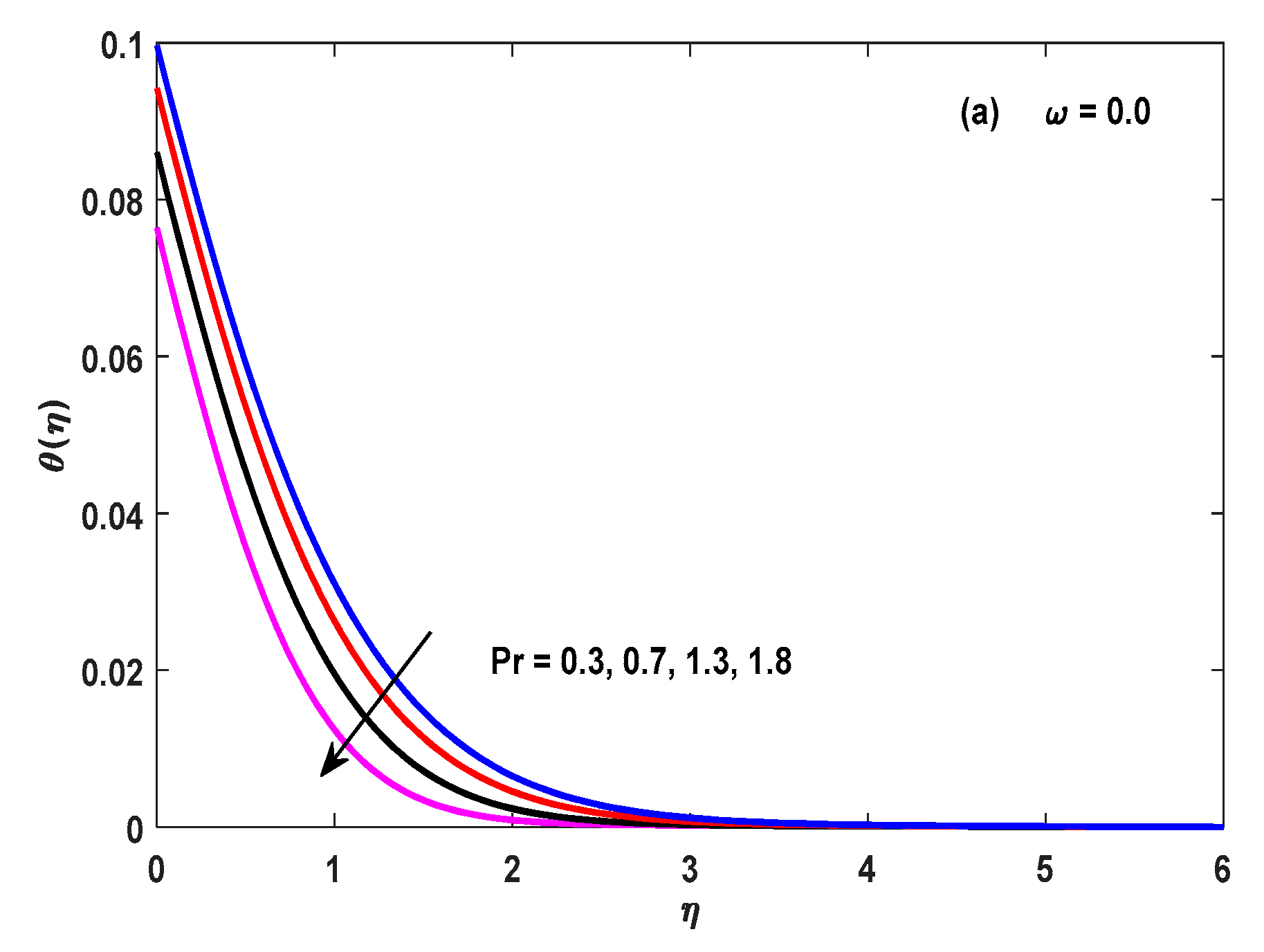

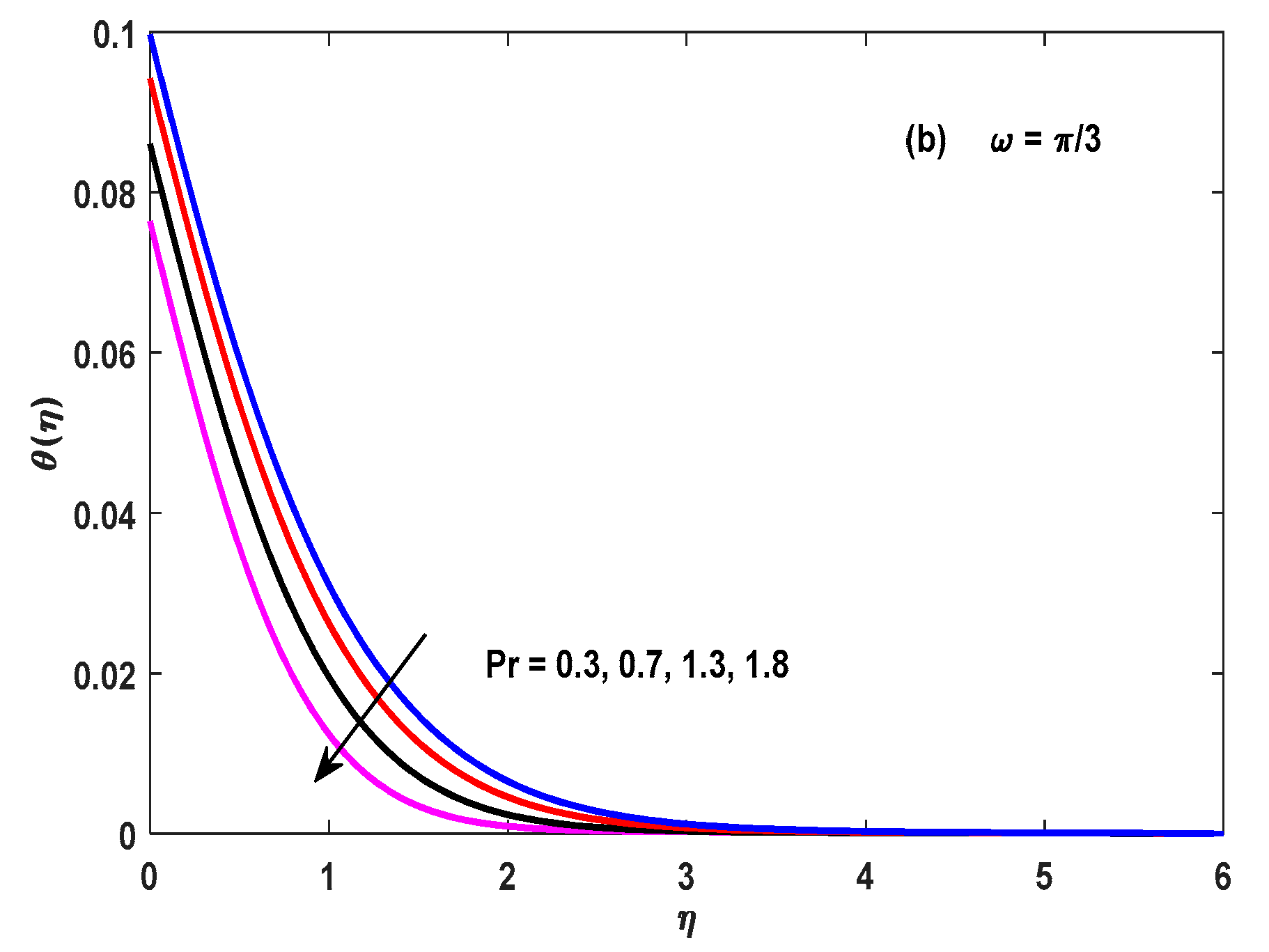

- The temperature of the fluid escalates by improving , and

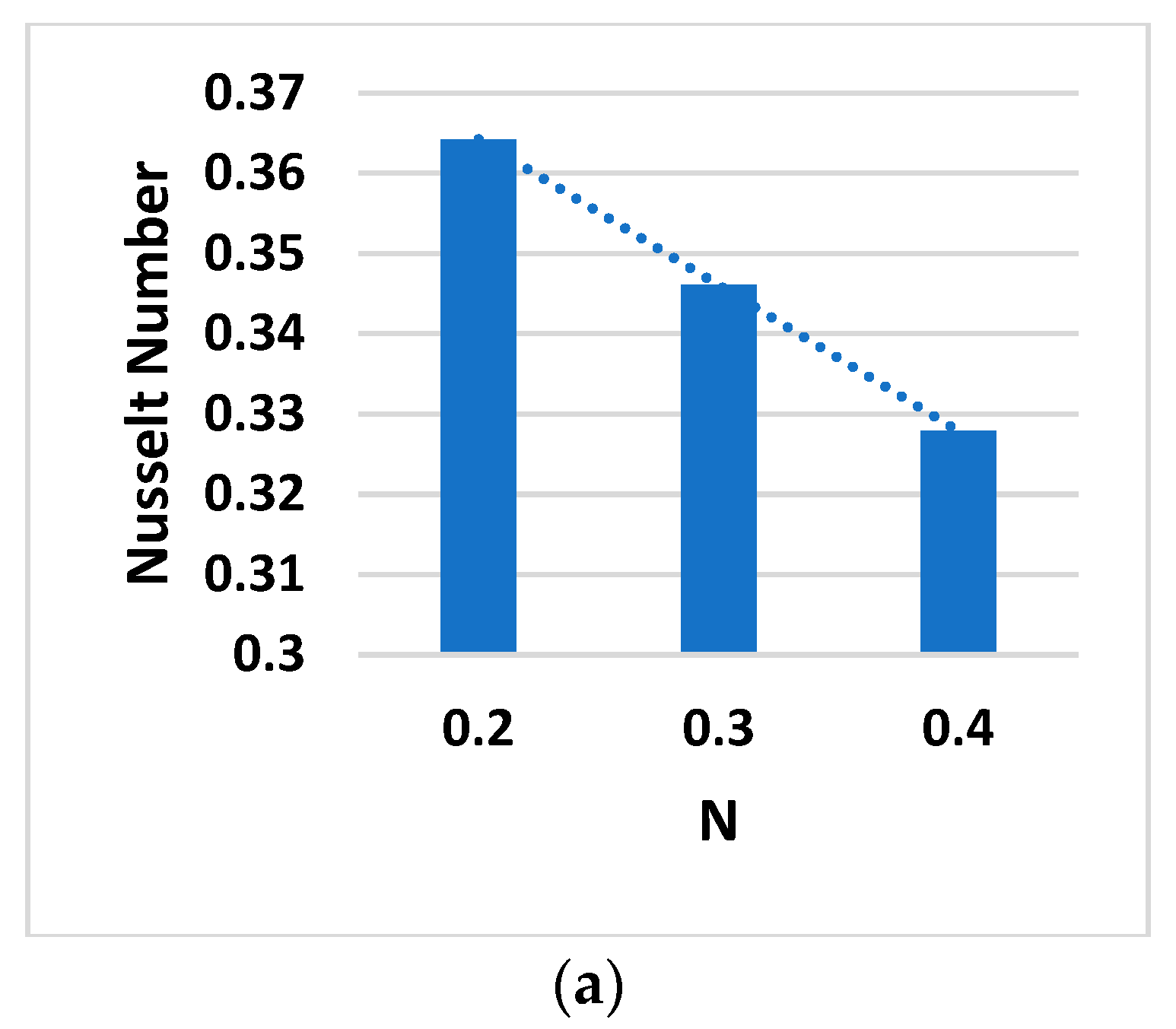

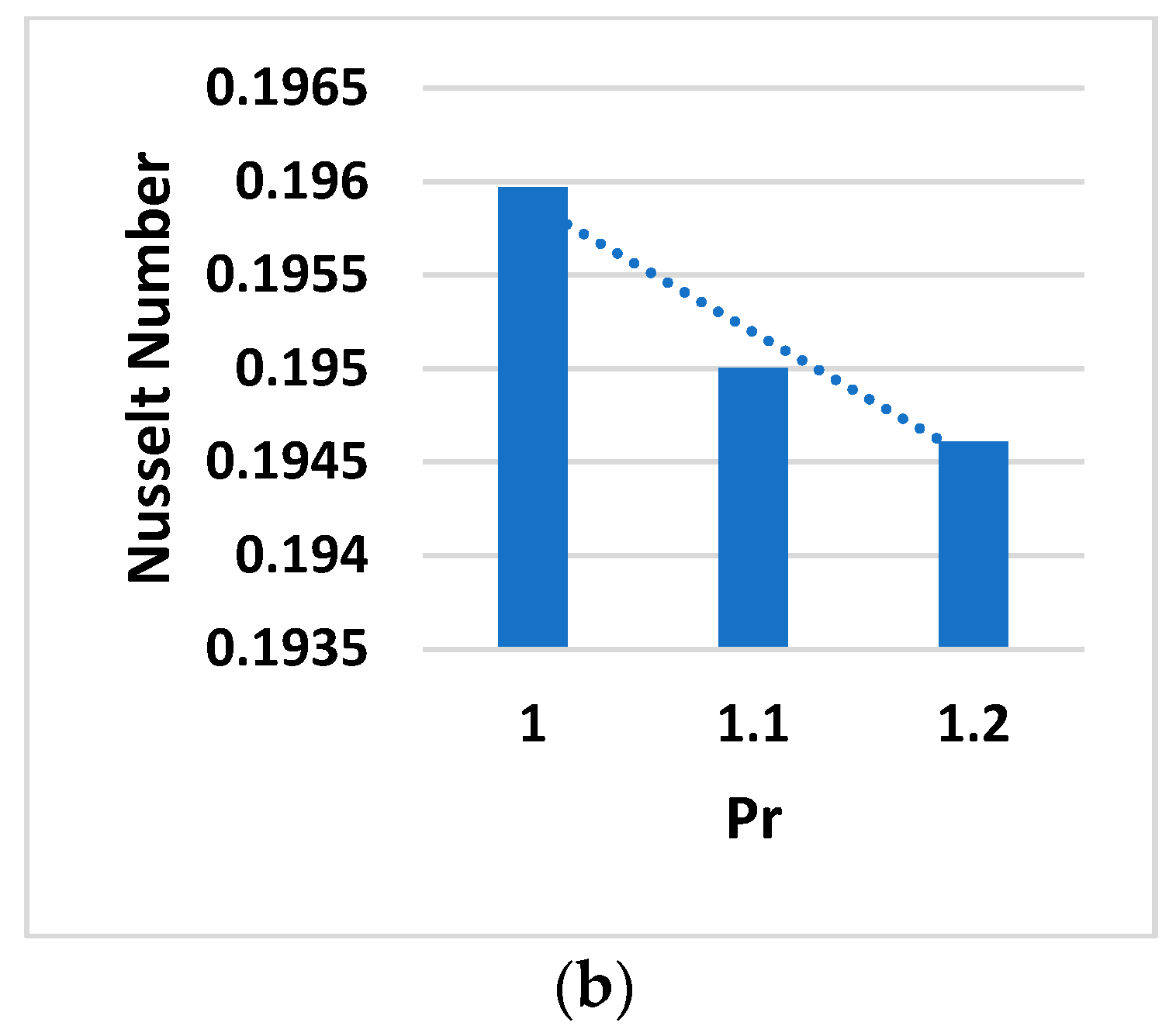

- Both and deteriorate the Nusselt number phenomenon.

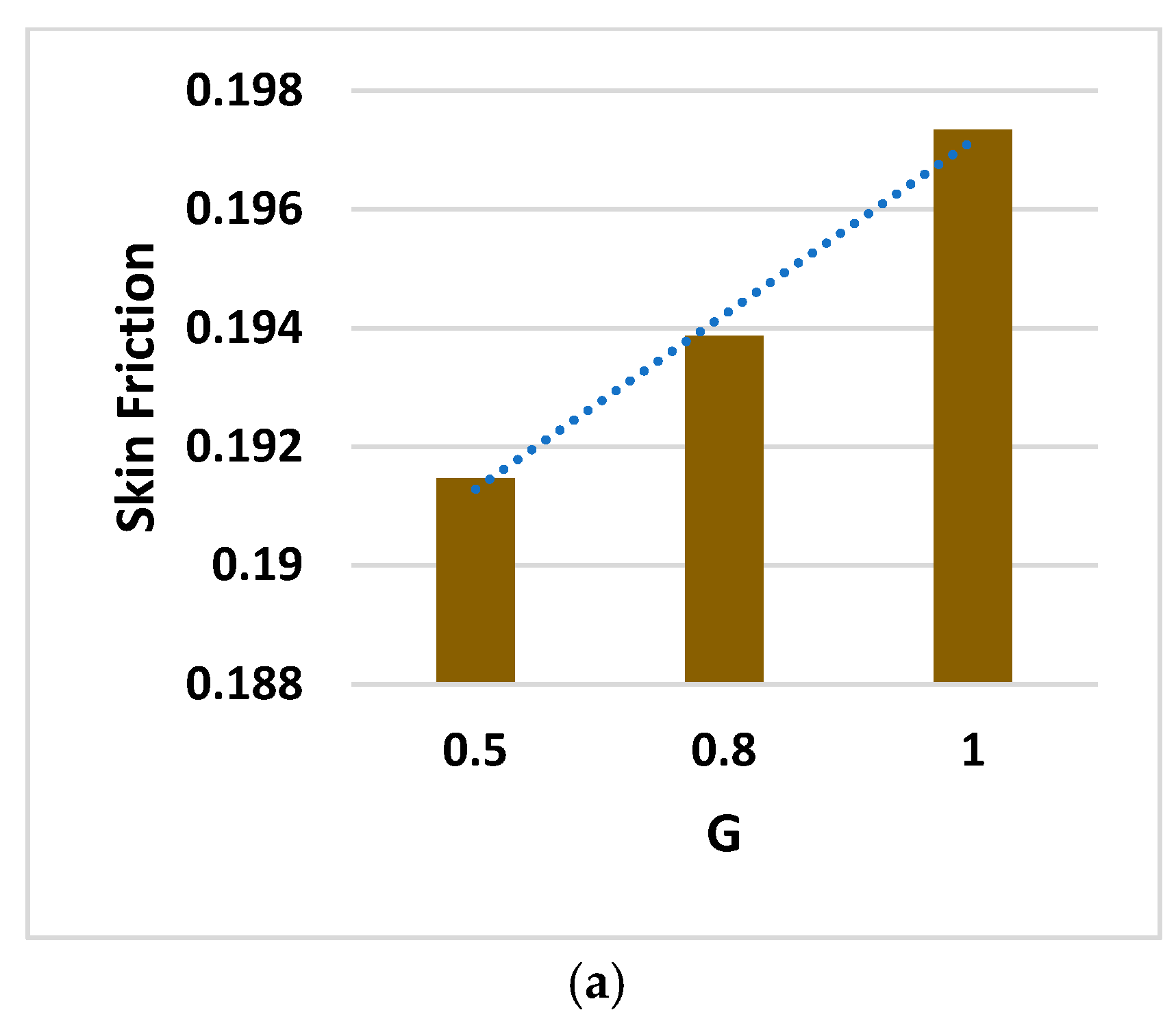

- The dimensionless parameters and magnify the surface drag coefficient.

8. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Unsteadiness parameter | Reference velocity | ||

| First Rivilin Erickson tensor | Stretching velocity | ||

| Dimensionless constants | Velocity profile | ||

| Chemotaxis constant | Blowing | ||

| Skin friction | Suction | ||

| Specific heat | space coordinates | ||

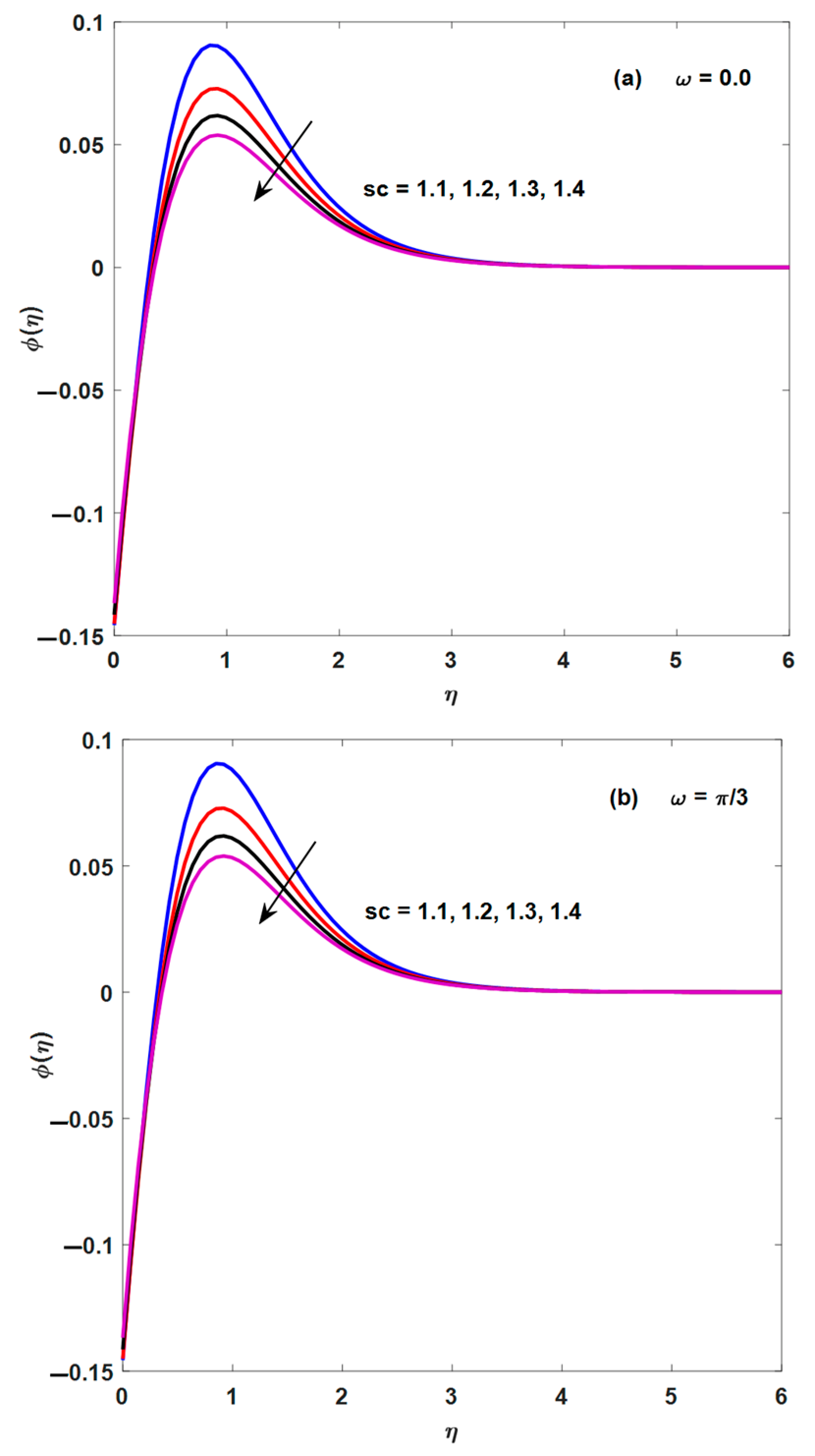

| Concentration profile | Weissenberg number | ||

| Solute diffusivity | Space variable | ||

| Diffusion coefficient of Brownian | Thermal expansion coefficient | ||

| Concentration diffusivity | Gases | ||

| Microorganisms’ diffusion coefficient | Liquids | ||

| Diffusion coefficient of thermophoresis | Thermal state and thermal property | ||

| Gravitational acceleration | Shear strain | ||

| Grashoff number (Mass) | Shear rate | ||

| Grashoff number (thermal) | Variable thermal conductivity | ||

| Thermal conductivity | Variable molecular diffusivity | ||

| Mean absorption coefficient | Dimensionless variable | ||

| Infinite conductivity | Dynamic viscosity | ||

| Characteristics length | Variable viscosity | ||

| Power law index | Temperature ratio parameter | ||

| Nusselt number | Viscosity | ||

| Pressure | Zero shear rate viscosity | ||

| Prandtl number | Infinite shear rate viscosity | ||

| Wall shear stress | Kinematic viscosity | ||

| Bioconvection Rayleigh number | Fluid density | ||

| Reynold number | Density of nanofluid | ||

| Schmidt number | Density of nanoparticles | ||

| Injection | Heat capacity of nanofluid | ||

| Suction | Heat capacity of nanoparticles | ||

| Temperature profile | Electrical conductivity | ||

| Wall temperature and concentration | Stefan-Boltzman constant | ||

| Ambient temperature and concentration | Cauchy stress tensor | ||

| Velocity components | Heat flux | ||

| ODEs | Ordinary differential equation | Stream function | |

| PDEs | Partial differential equation | Relaxation time constant |

References

- Sabir, Z.; Ayub, A.; Guirao, J.L.; Bhatti, S.; Shah, S.Z.H. The effects of activation energy and thermophoretic diffusion of nanoparticles on steady micropolar fluid along with Brownian motion. Adv. Mater. Sci. Eng. 2020, 2020, 2010568. [Google Scholar] [CrossRef]

- Ayub, A.; Wahab, H.A.; Shah, S.Z.; Shah, S.L.; Darvesh, A.; Haider, A.; Sabir, Z. Interpretation of infinite shear rate viscosity and a nonuniform heat sink/source on a 3D radiative cross nanofluid with buoyancy assisting/opposing flow. Heat Transf. 2021, 50, 4192–4232. [Google Scholar] [CrossRef]

- Ayub, A.; Wahab, H.A.; Sabir, Z.; Arbi, A. A note on heat transport with aspect of magnetic dipole and higher order chemical process for steady micropolar fluid. Comput. Overv. Fluid Struct. Interact. 2020, 97, 97–120. [Google Scholar]

- Shah, S.Z.H.; Ayub, A.; Sabir, Z.; Adel, W.; Shah, N.A.; Yook, S.J. Insight into the dynamics of time-dependent cross nanofluid on a melting surface subject to cubic autocatalysis. Case Stud. Therm. Eng. 2021, 27, 101227. [Google Scholar] [CrossRef]

- Wahab, H.A.; Hussain Shah, S.Z.; Ayub, A.; Sabir, Z.; Bilal, M.; Altamirano, G.C. Multiple characteristics of three-dimensional radiative Cross fluid with velocity slip and inclined magnetic field over a stretching sheet. Heat Transf. 2021, 50, 3325–3341. [Google Scholar] [CrossRef]

- Ayub, A.; Sabir, Z.; Altamirano, G.C.; Sadat, R.; Ali, M.R. Characteristics of melting heat transport of blood with time-dependent cross-nanofluid model using Keller–Box and BVP4C method. Eng. Comput. 2021, 38, 3705–3719. [Google Scholar] [CrossRef]

- Ayub, A.; Sabir, Z.; Le, D.N.; Aly, A.A. Nanoscale heat and mass transport of magnetized 3-D chemically radiative hybrid nanofluid with orthogonal/inclined magnetic field along rotating sheet. Case Stud. Therm. Eng. 2021, 26, 101193. [Google Scholar] [CrossRef]

- Ayub, A.; Wahab, H.A.; Balubaid, M.; Mahmoud, S.R.; Ali, M.R.; Sadat, R. Analysis of the nanoscale heat transport and Lorentz force based on the time-dependent Cross nanofluid. Eng. Comput. 2022, in press. [Google Scholar]

- Shah, S.Z.; Wahab, H.A.; Ayub, A.; Sabir, Z.; haider, A.; Shah, S.L. Higher order chemical process with heat transport of magnetized cross nanofluid over wedge geometry. Heat Transf. 2021, 50, 3196–3219. [Google Scholar] [CrossRef]

- Ayub, A.; Darvesh, A.; Altamirano, G.C.; Sabir, Z. Nanoscale energy transport of inclined magnetized 3D hybrid nanofluid with Lobatto IIIA scheme. Heat Transf. 2021, 50, 6465–6490. [Google Scholar] [CrossRef]

- Ayub, A.; Wahab, H.A.; Hussain Shah, S.Z.; Shah, S.L.; Sabir, Z.; Bhatti, S. On heated surface transport of heat bearing thermal radiation and MHD Cross flow with effects of nonuniform heat sink/source and buoyancy opposing/assisting flow. Heat Transf. 2021, 50, 6110–6128. [Google Scholar] [CrossRef]

- Ayub, A.; Sabir, Z.; Shah, S.Z.H.; Wahab, H.A.; Sadat, R.; Ali, M.R. Effects of homogeneous-heterogeneous and Lorentz forces on 3-D radiative magnetized cross nanofluid using two rotating disks. Int. Commun. Heat Mass Transf. 2022, 130, 105778. [Google Scholar] [CrossRef]

- Ayub, A.; Sabir, Z.; Shah, S.Z.H.; Mahmoud, S.R.; Algarni, A.; Sadat, R.; Ali, M.R. Aspects of infinite shear rate viscosity and heat transport of magnetized Carreau nanofluid. Eur. Phys. J. Plus 2022, 137, 247. [Google Scholar] [CrossRef]

- Ayub, A.; Shah, S.Z.H.; Sabir, Z.; Rao, N.S.; Sadat, R.; Ali, M.R. Spectral relaxation approach and velocity slip stagnation point flow of inclined magnetized cross-nanofluid with a quadratic multiple regression model. Waves Random Complex Media 2022, in press. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, S.; Ali, F.; Arif, M.; Khan, I.; Nisar, K.S. Couette flow of viscoelastic dusty fluid in a rotating frame along with the heat transfer. Sci. Rep. 2021, 11, 506. [Google Scholar] [CrossRef]

- Azam, M.; Xu, T.; Khan, M. Numerical simulation for variable thermal properties and heat source/sink in flow of Cross nanofluid over a moving cylinder. Int. Commun. Heat Mass Transf. 2020, 118, 104832. [Google Scholar] [CrossRef]

- Azam, M.; Xu, T.; Shakoor, A.; Khan, M. Effects of Arrhenius activation energy in development of covalent bonding in axisymmetric flow of radiative-Cross nanofluid. Int. Commun. Heat Mass Transf. 2020, 113, 104547. [Google Scholar] [CrossRef]

- Alshomrani, A.S.; Ullah, M.Z.; Baleanu, D. Importance of multiple slips on bioconvection flow of cross nanofluid past a wedge with gyrotactic motile microorganisms. Case Stud. Therm. Eng. 2020, 22, 100798. [Google Scholar] [CrossRef]

- Haq, F.; Saleem, M.; ur Rahman, M. Investigation of natural bio-convective flow of Cross nanofluid containing gyrotactic microorganisms subject to activation energy and magnetic field. Phys. Scr. 2020, 95, 105219. [Google Scholar] [CrossRef]

- Shi, Q.H.; Hamid, A.; Khan, M.I.; Kumar, R.N.; Gowda, R.J.; Prasannakumara, B.C.; Shah, N.A.; Khan, S.U.; Chung, J.D. Numerical study of bio-convection flow of magneto-cross nanofluid containing gyrotactic microorganisms with activation energy. Sci. Rep. 2021, 11, 16030. [Google Scholar] [CrossRef]

- Xiong, P.Y.; Hamid, A.; Chu, Y.M.; Khan, M.I.; Gowda, R.J.; Kumar, R.N.; Prasannakumara, B.C.; Qayyum, S. Dynamics of multiple solutions of Darcy–Forchheimer saturated flow of Cross nanofluid by a vertical thin needle point. Eur. Phys. J. Plus 2021, 136, 315. [Google Scholar] [CrossRef]

- Waqas, H.; Khan, S.A.; Khan, S.U.; Khan, M.I.; Kadry, S.; Chu, Y.M. Falkner-Skan time-dependent bioconvrction flow of cross nanofluid with nonlinear thermal radiation, activation energy and melting process. Int. Commun. Heat Mass Transf. 2021, 120, 105028. [Google Scholar] [CrossRef]

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; No. ANL/MSD/CP-84938; CONF-951135-29; Argonne National Lab. (ANL): Argonne, IL, USA, 1995. [Google Scholar]

- Said, Z.; Hachicha, A.A.; Aberoumand, S.; Yousef, B.A.; Sayed, E.T.; Bellos, E. Recent advances on nanofluids for low to medium temperature solar collectors: Energy, exergy, economic analysis and environmental impact. Prog. Energy Combust. Sci. 2021, 84, 100898. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Farshad, S.A.; Ebrahimpour, Z.; Said, Z. Recent progress on flat plate solar collectors and photovoltaic systems in the presence of nanofluid: A review. J. Clean. Prod. 2021, 293, 126119. [Google Scholar] [CrossRef]

- Marzougui, S.; Mebarek-Oudina, F.; Assia, A.; Magherbi, M.; Shah, Z.; Ramesh, K. Entropy generation on magneto-convective flow of copper–water nanofluid in a cavity with chamfers. J. Therm. Anal. Calorim. 2021, 143, 2203–2214. [Google Scholar] [CrossRef]

- Muhammad, T.; Waqas, H.; Khan, S.A.; Ellahi, R.; Sait, S.M. Significance of nonlinear thermal radiation in 3D Eyring–Powell nanofluid flow with Arrhenius activation energy. J. Therm. Anal. Calorim. 2021, 143, 929–944. [Google Scholar] [CrossRef]

- Said, Z.; Sundar, L.S.; Tiwari, A.K.; Ali, H.M.; Sheikholeslami, M.; Bellos, E.; Babar, H. Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys. Rep. 2021, 946, 1–94. [Google Scholar] [CrossRef]

- Meibodi, S.S.; Kianifar, A.; Mahian, O.; Wongwises, S. Second law analysis of a nanofluid-based solar collector using experimental data. J. Therm. Anal. Calorim. 2016, 126, 617–625. [Google Scholar] [CrossRef]

- Jalil, M.; Asghar, S.; Yasmeen, S. An exact solution of MHD boundary layer flow of dusty fluid over a stretching surface. Math. Probl. Eng. 2017, 2017, 2307469. [Google Scholar] [CrossRef]

- Raju, C.S.K.; Sandeep, N.; Sulochana, C.; Sugunamma, V.; Babu, M.J. Radiation, inclined magnetic field and cross-diffusion effects on flow over a stretching surface. J. Niger. Math. Soc. 2015, 34, 169–180. [Google Scholar] [CrossRef]

- Akinbobola, T.E.; Okoya, S.S. The flow of second grade fluid over a stretching sheet with variable thermal conductivity and viscosity in the presence of heat source/sink. J. Niger. Math. Soc. 2015, 34, 331–342. [Google Scholar] [CrossRef]

- Ahmad, N.; Siddiqui, Z.; Mishra, M. Boundary layer flow and heat transfer past a stretching plate with variable thermal conductivity. Int. J. Non-Linear Mech. 2010, 45, 306–309. [Google Scholar] [CrossRef]

- Okoya, S.S.; Hassan, A.R.; Salawu, S.O. On free convection flow of a moving vertical permeable plate with quadratic Boussinesq approximation and variable thermal conductivity. Heat Transf. Res. 2021, 52, 55–66. [Google Scholar] [CrossRef]

- Shoaib, M.; Raja, M.A.Z.; Sabir, T.; Awais, M.; Islam, S.; Shah, Z.; Kumam, P. Numerical analysis of 3-D MHD hybrid nanofluid over a rotational disk in presence of thermal radiation with Joule heating and viscous dissipation effects using Lobatto IIIA technique. Alex. Eng. J. 2021, 60, 3605–3619. [Google Scholar] [CrossRef]

- Ahmad, I.; Cheema, T.N.; Raja, M.A.Z.; Awan, S.E.; Alias, S.B.; Iqbal, S.; Shoaib, M. A novel application of Lobatto IIIA solver for numerical treatment of mixed convection nanofluidic model. Sci. Rep. 2021, 11, 4452. [Google Scholar] [CrossRef]

- Hayat, T.; Asad, S.; Mustafa, M.; Alsaedi, A. Radiation effects on the flow of Powell-Eyring fluid past an unsteady inclined stretching sheet with non-uniform heat source/sink. PLoS ONE 2014, 9, e103214. [Google Scholar]

- Waqas, H.; Rafique, S.; Khalid, S.; Ahmad, F.; Hussain, S. Thermal radiation effects on unsteady MHD flow of Casson fluids through porous medium over a permeable shrinking sheet. J. Appl. Environ. Biol. Sci. 2017, 7, 201–209. [Google Scholar]

- Raghunath, K.; Gulle, N.; Vaddemani, R.R.; Mopuri, O. Unsteady MHD fluid flow past an inclined vertical porous plate in the presence of chemical reaction with aligned magnetic field, radiation, and Soret effects. Heat Transf. 2022, 51, 2742–2760. [Google Scholar] [CrossRef]

- Hussain, S.M.; Jamshed, W.; Safdar, R.; Shahzad, F.; Mohd Nasir, N.A.A.; Ullah, I. Chemical reaction and thermal characteristiecs of Maxwell nanofluid flow-through solar collector as a potential solar energy cooling application: A modified Buongiorno’s model. Energy Environ. 2022, in press. [Google Scholar] [CrossRef]

- Hussain, S.M. Irreversibility Analysis of Time Dependent Magnetically Driven Flow of Sutterby Hybrid Nanofluid: A Thermal Mathematical Model. Waves Random Complex Media 2022. [Google Scholar] [CrossRef]

- Hussain, S.M. Thermal Enhanced Hybrid of Copper-Zirconium Dioxide/Ethylene Glycol nanofluid Flowing in Solar Collector of Water-Pump Application. Waves Random Complex Media 2022. [Google Scholar] [CrossRef]

- Sajid, T.; Jamshed, W.; Safdar, R.; Hussain, S.M.; Shahzad, F.; Bilal, M.; Rehman, Z.; Rahman, M.M.; Pasha, A.A. Features and aspects of radioactive flow and slippage velocity on rotating two-phase Prandtl nanofluid with zero mass fluxing and convective constraints. Int. Commun. Heat Mass Transf. 2022, 136, 106180. [Google Scholar] [CrossRef]

- Hussain, S.M.; Jamshed, W.; Eid, M.R. Solar-HVAC Thermal Investigation Utilizing (Cu-AA7075/C6H9NaO7) MHD-Driven Hybrid Nanofluid Rotating Flow via Second-Order Convergent Technique: A Novel Engineering Study. Arab. J. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Shahzad, F.; Jamshed, W.; Pasha, A.A.; Safdar, R.; Alam, M.M.; Arshad, M.; Hussain, S.M.; Krawczuk, M. Thermal Cooling Process by Nanofluid Flowing near Stagnating Point of Expanding Surface under Induced Magnetism Force: A Computational Case Study. Case Stud. Therm. Eng. 2022, 36, 102190. [Google Scholar] [CrossRef]

- Hussain, S.M.; Mishra, M.R.; Seth, G.S.; Chamkha, A.J. Dynamics of heat absorbing and radiative hydromagnetic nanofluids through a stretching surface with chemical reaction and viscous dissipation. Part-E J. Proc. Mech. Eng. 2022. [Google Scholar] [CrossRef]

- Hussain, S.M.; Sharma, R.; Chamkha, A.J. Numerical and statistical exploration on the dynamics of water conveying Cu-Al2O3 hybrid nanofluid flow over an exponentially stretchable sheet with Navier’s partial slip and thermal jump conditions. Chin. J. Phys. 2022, 75, 120–138. [Google Scholar] [CrossRef]

- Jamshed, W.; Devi, S.U.S.; Prakash MHussain, S.M.; Eid, M.R.; Nisar, K.S.; Muhammad, T. Entropy Amplified Solitary Phase Relative Probe on Engine Oil Based Hybrid Nanofluid. Chin. J. Phys. 2022, 77, 1654–1681. [Google Scholar] [CrossRef]

- Hussain, S.M.; Jamshed, W.; Pasha, A.A.; Adil, M.; Akram, M. Galerkin finite element solution for electromagnetic radiative impact on viscid Williamson two-phase nanofluid flow via extendable surface. Int. Commun. Heat Mass Transf. 2022, 137, 106243. [Google Scholar] [CrossRef]

- Hussain, S.M.; Goud, B.S.; Madheshwaran, P.; Jamshed, W.; Pasha, A.A.; Safdar, R.; Arshad, M.; Ibrahim, R.W.; Ahmad, M.K. Effectiveness of Nonuniform Heat Generation (Sink) and Thermal Characterization of a Carreau Fluid Flowing across a Nonlinear Elongating Cylinder: A Numerical Study. ACS Omega 2022, 7, 25309–25320. [Google Scholar] [CrossRef]

- Parvin, S.; Isa, S.S.P.M.; Al-Duais, F.S.; Hussain, S.M.; Jamshed, W.; Safdar, R.; Eid, M.R. The flow, thermal and mass properties of Soret-Dufour model of magnetized Maxwell nanofluid flow over a shrinkage inclined surface. PLoS ONE 2022, 17, e0267148. [Google Scholar] [CrossRef]

- Jamshed, W.; Eid, M.R.; Hussain, S.M.; Abderrahmane, A.; Safdar, R.; Younis, O.; Pasha, A.A. Physical Specifications of MHD Mixed Convective of Ostwald–de Waele Nanofluids in a Vented-Cavity with Inner Elliptic Cylinder. Int. Commun. Heat Mass Transf. 2022, 134, 106038. [Google Scholar] [CrossRef]

- Shahzad, F.; Jamshed, W.; Safdar, R.; Hussain, S.M.; Nasir, M.N.A.A.; Dhange, M.; Nisar, K.S.; Eid, M.R.; Sohail, M.; Alsehli, M.; et al. Thermal Analysis Characterization of Solar Powered Ship Using Oldroyd Hybrid Nanofluids in Parabolic Trough Solar Collector: An Optimal Thermal Application. Nanotech. Rev. 2022, 11, 2015–2037. [Google Scholar] [CrossRef]

| Ref. [37] | Ref. [38] | Ref. [39] | Present | |

|---|---|---|---|---|

| 0.01 | −0.9963 | −0.998024 | −0.99803 | −0.99803 |

| 0.02 | −0.993 | −0.995783 | −0.99578 | −0.99578 |

| 0.05 | −0.983 | −0.98758 | −0.98758 | −0.98759 |

| 0.1 | −0.9603 | −0.969386 | −0.96938 | −0.96938 |

| 0.2 | −0.908 | −0.918107 | −0.91811 | −0.91811 |

| 0.5 | −0.6605 | −0.66726 | −0.66726 | −0.66726 |

| 1 | 0.000001 | 0.000001 | 0.000001 | 0.000001 |

| 2 | 2.0181 | 2.01767 | 2.01762 | 2.01761 |

| 3 | 4.72000 | 4.72964 | 4.72967 | 4.72969 |

| Standard Deviation | 3.496456 | 3.496479 | 3.496489 | 3.496507 |

| Skin Friction | ||||

|---|---|---|---|---|

| 1.1 | 0.747311 | |||

| 1.3 | 0.675125 | |||

| 1.5 | 0.531447 | |||

| 0.1 | 0.511412 | |||

| 0.3 | 0.340778 | |||

| 0.5 | 0.293925 | |||

| 0.5 | 0.191472 | |||

| 0.8 | 0.193867 | |||

| 1 | 0.197345 | |||

| 0.1 | 0.318987 | |||

| 0.4 | 0.383099 | |||

| 0.6 | 0.421181 |

| Nusselt Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.5 | 0.3 | 0.3 | 0.1 | 0.7 | 0.1 | 0.2 | 0.189769 |

| 0.4 | 0.1958574 | |||||||

| 0.7 | 0.1967127 | |||||||

| 0.8 | 0.1955081 | |||||||

| 1.1 | 0.1954922 | |||||||

| 1.4 | 0.1954817 | |||||||

| 0.7 | 0.1955544 | |||||||

| 0.9 | 0.1955731 | |||||||

| 1.4 | 0.1956091 | |||||||

| 0.2 | 0.1965355 | |||||||

| 0.4 | 0.1985558 | |||||||

| 0.6 | 0.1995958 | |||||||

| 0.2 | 0.3642232 | |||||||

| 0.3 | 0.3460589 | |||||||

| 0.4 | 0.3278681 | |||||||

| 1.0 | 0.1959707 | |||||||

| 1.1 | 0.1930041 | |||||||

| 1.2 | 0.1956082 | |||||||

| 0.3 | 0.1954585 | |||||||

| 0.4 | 0.1955415 | |||||||

| 0.5 | 0.1957222 | |||||||

| 0.5 | 0.1955347 | |||||||

| 0.6 | 0.1955344 | |||||||

| 0.7 | 0.1955346 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darvesh, A.; Sajid, T.; Jamshed, W.; Ayub, A.; Shah, S.Z.H.; Eid, M.R.; Hussain, S.M.; Akram, M.; Hafeez, M.B.; Krawczuk, M. Rheology of Variable Viscosity-Based Mixed Convective Inclined Magnetized Cross Nanofluid with Varying Thermal Conductivity. Appl. Sci. 2022, 12, 9041. https://doi.org/10.3390/app12189041

Darvesh A, Sajid T, Jamshed W, Ayub A, Shah SZH, Eid MR, Hussain SM, Akram M, Hafeez MB, Krawczuk M. Rheology of Variable Viscosity-Based Mixed Convective Inclined Magnetized Cross Nanofluid with Varying Thermal Conductivity. Applied Sciences. 2022; 12(18):9041. https://doi.org/10.3390/app12189041

Chicago/Turabian StyleDarvesh, Adil, Tanveer Sajid, Wasim Jamshed, Assad Ayub, Syed Zahir Hussain Shah, Mohamed R. Eid, Syed M. Hussain, Mohammad Akram, Muhammad Bilal Hafeez, and Marek Krawczuk. 2022. "Rheology of Variable Viscosity-Based Mixed Convective Inclined Magnetized Cross Nanofluid with Varying Thermal Conductivity" Applied Sciences 12, no. 18: 9041. https://doi.org/10.3390/app12189041

APA StyleDarvesh, A., Sajid, T., Jamshed, W., Ayub, A., Shah, S. Z. H., Eid, M. R., Hussain, S. M., Akram, M., Hafeez, M. B., & Krawczuk, M. (2022). Rheology of Variable Viscosity-Based Mixed Convective Inclined Magnetized Cross Nanofluid with Varying Thermal Conductivity. Applied Sciences, 12(18), 9041. https://doi.org/10.3390/app12189041