Stator Design Method in Rotor–Stator Interference Flow Fields in Order to Suppress the Vibration of Bladed Disks

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Resonance Analysis Theory of Bladed Disk Systems

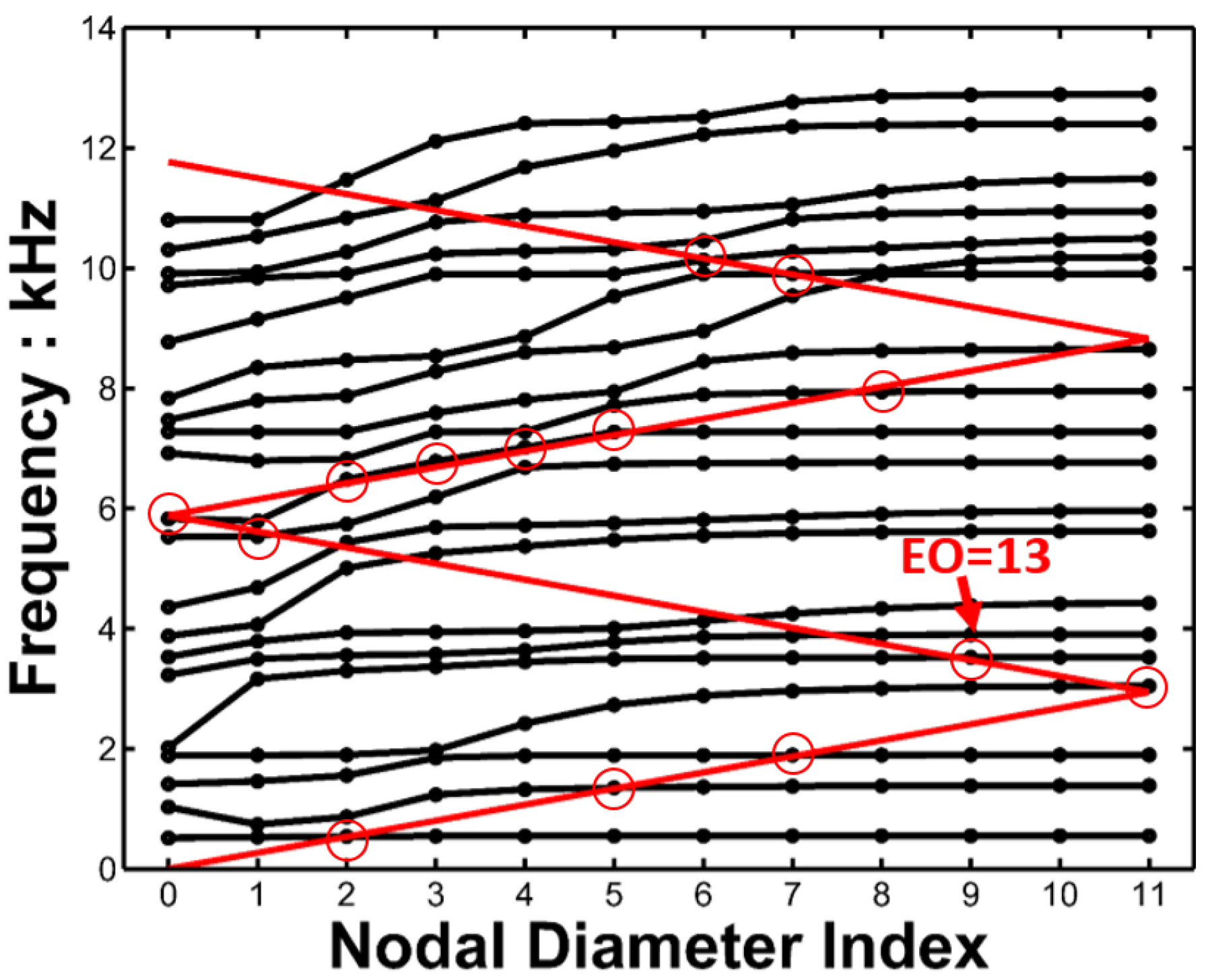

2.2. Resonance Conditions of Bladed Disk Systems

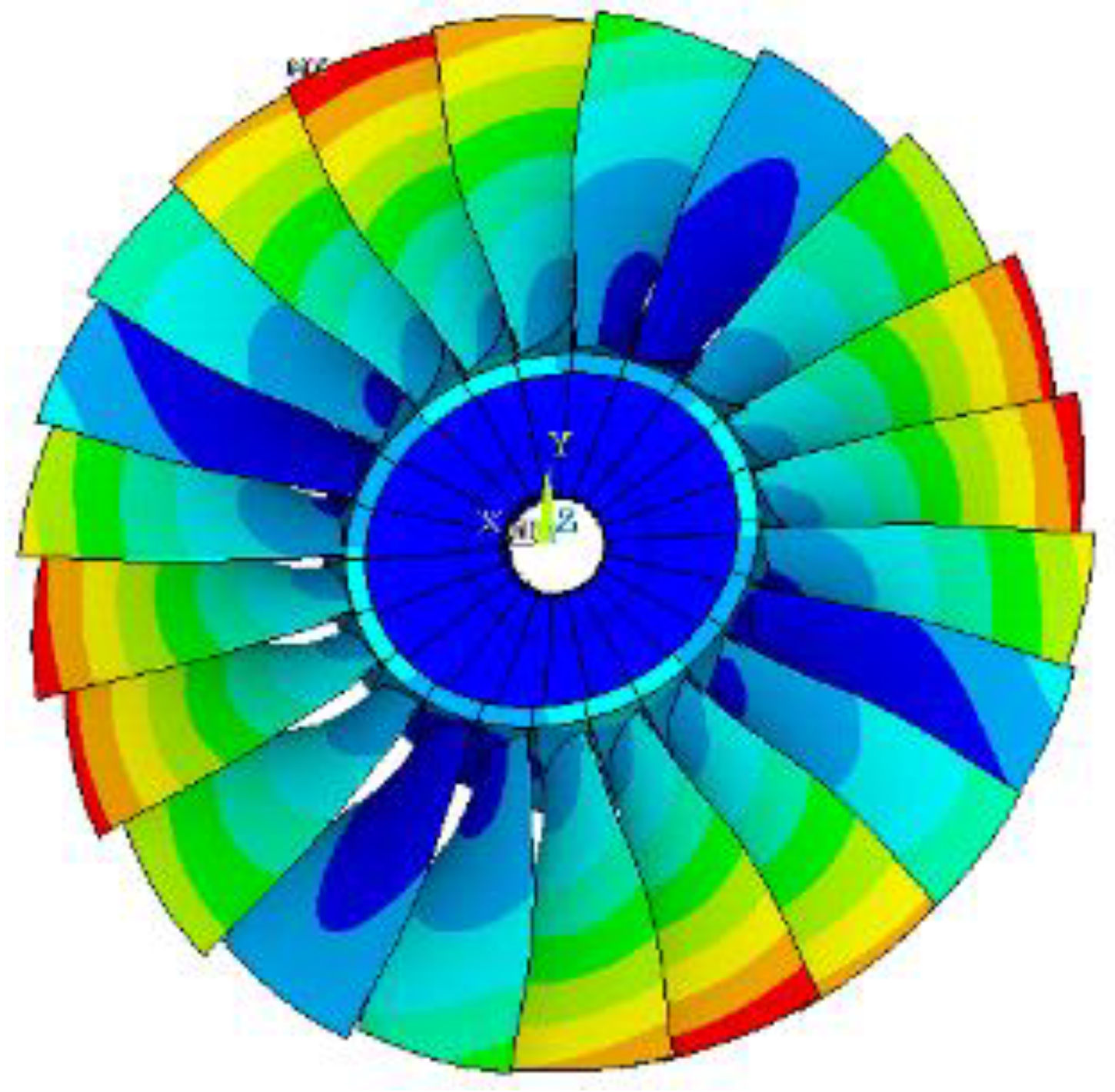

2.3. Resonance Analysis of Bladed Disk Systems

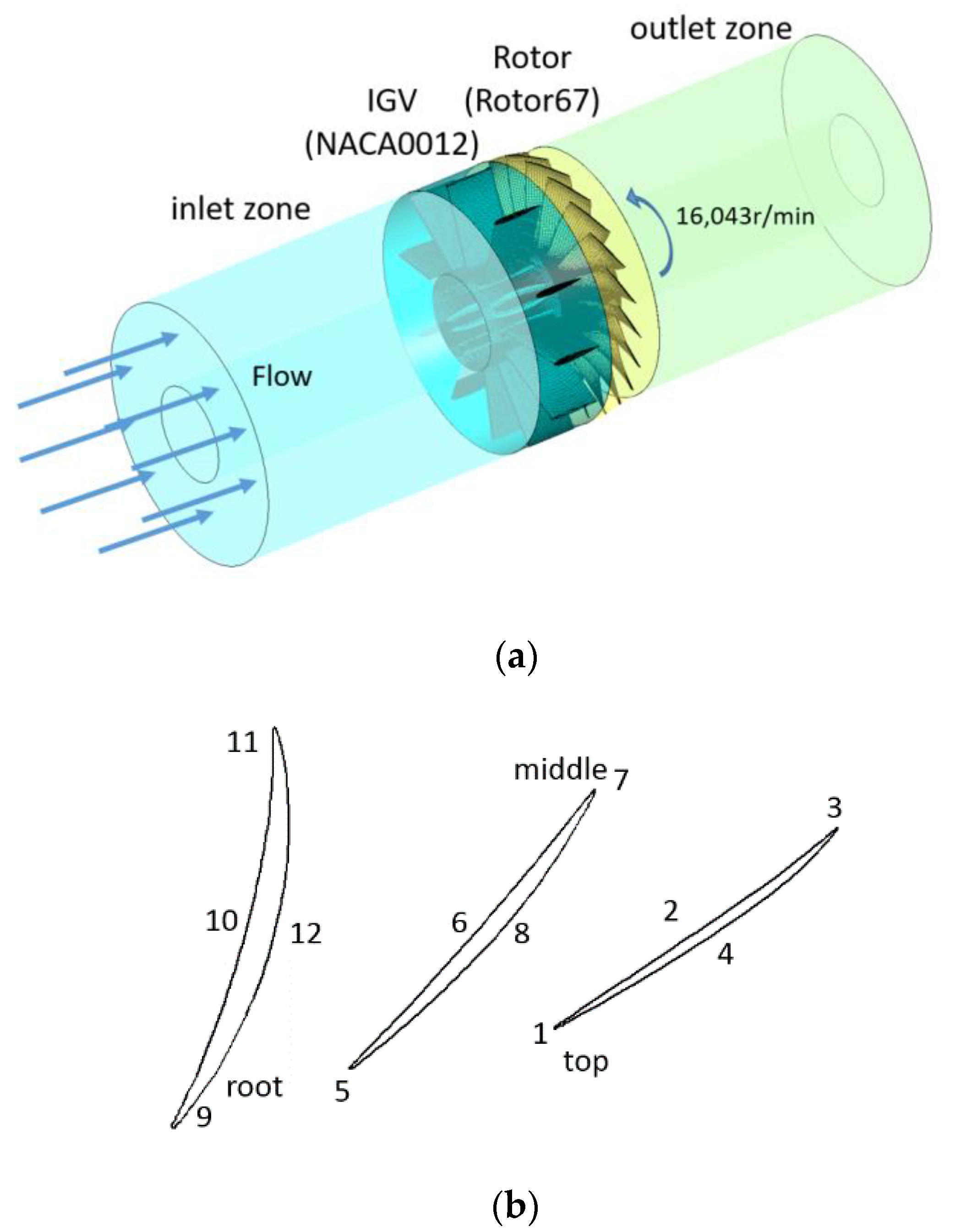

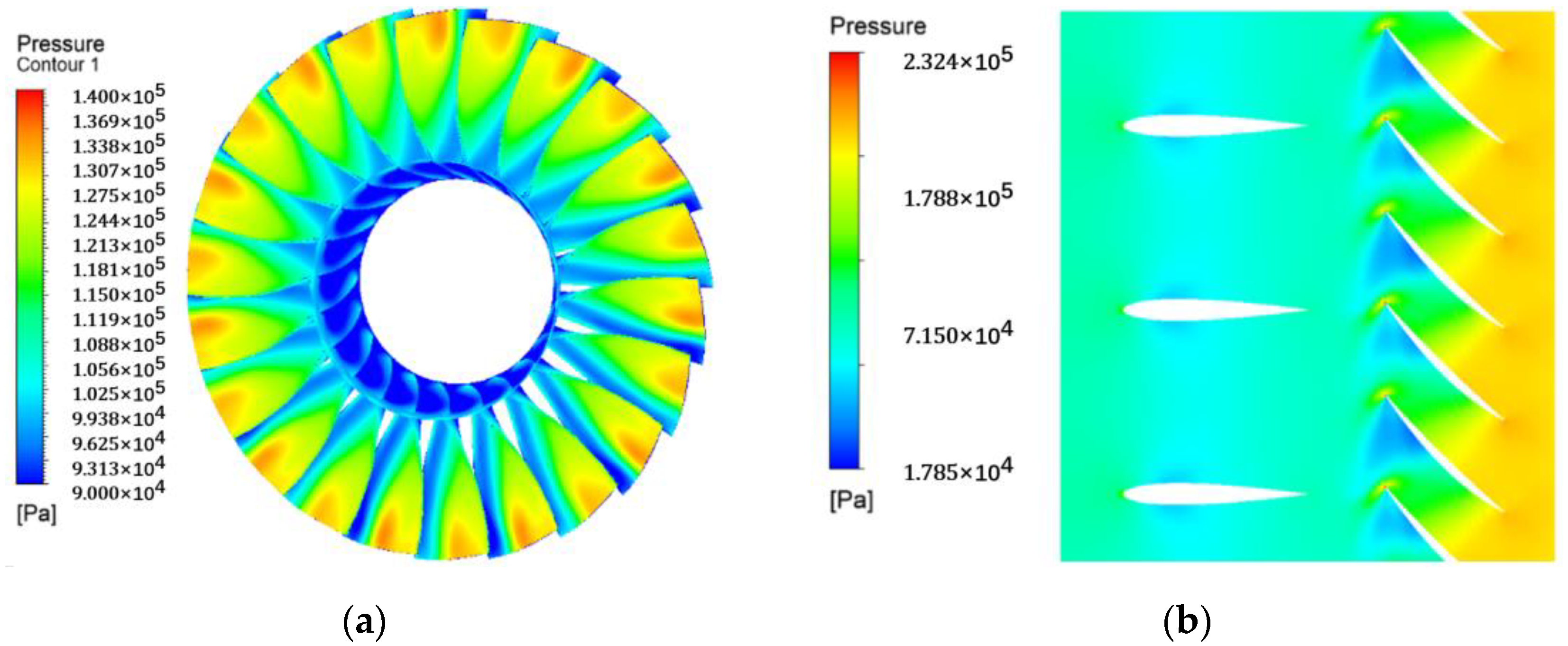

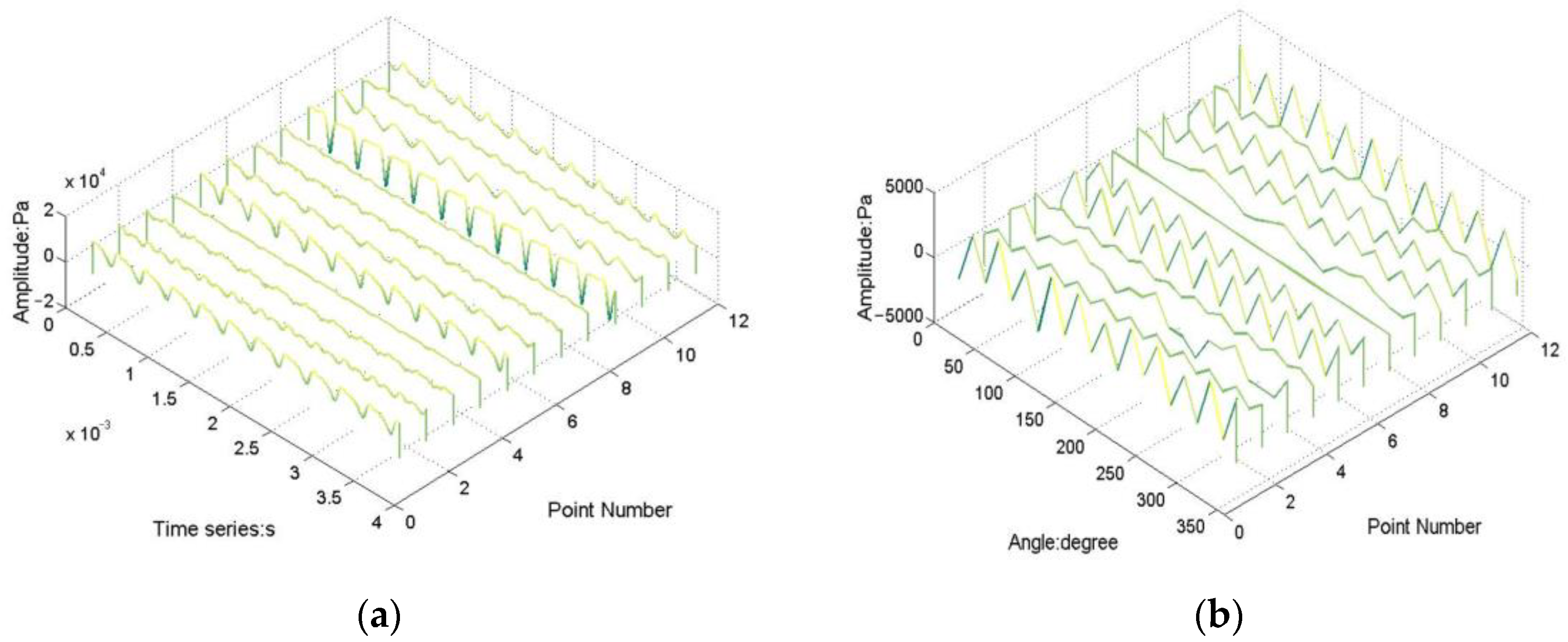

2.4. Unsteady Flow Field Calculations and Setting Excitation Monitor Points

3. Excitation Characteristics of Tuned Stators and Blade Period Design

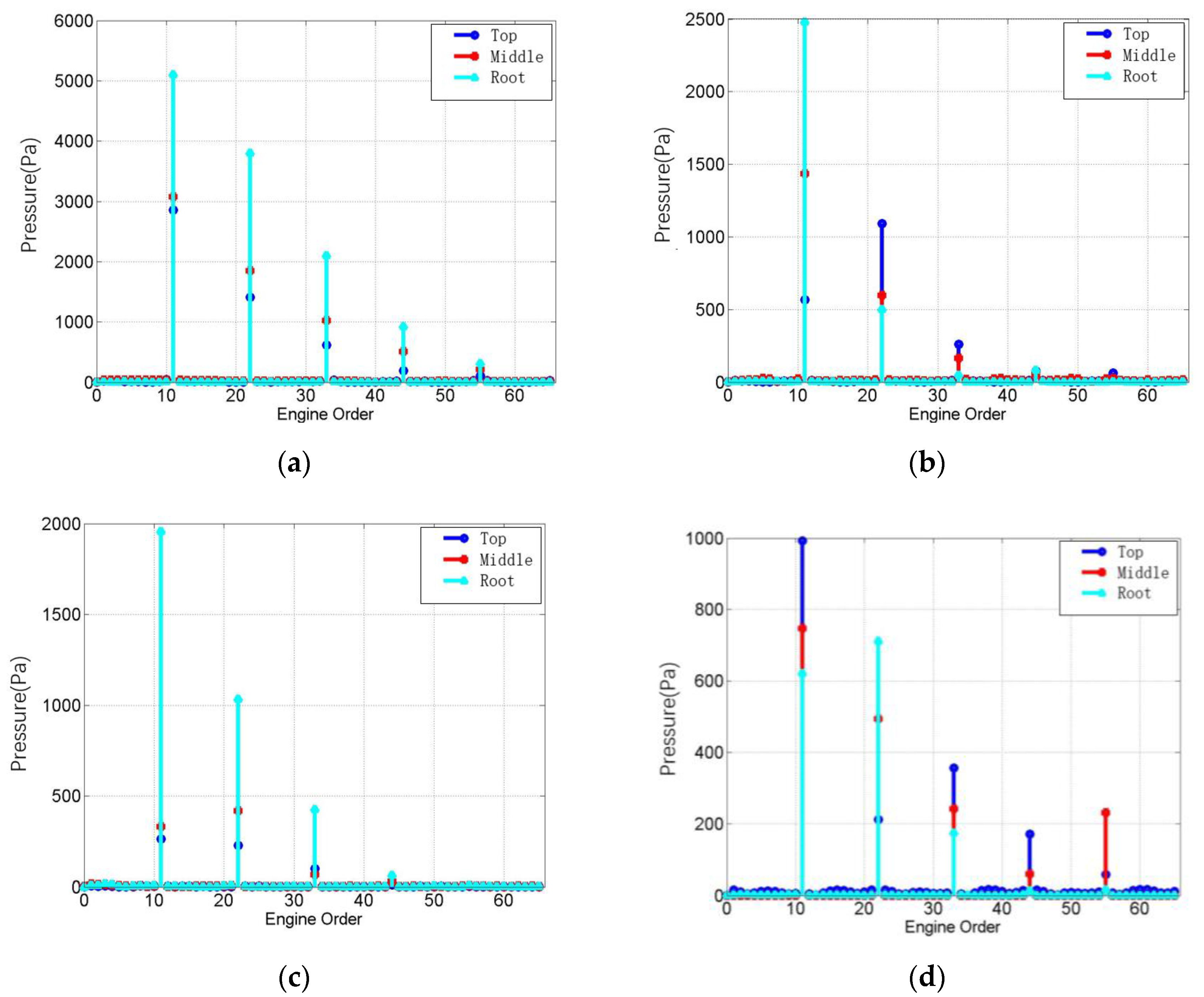

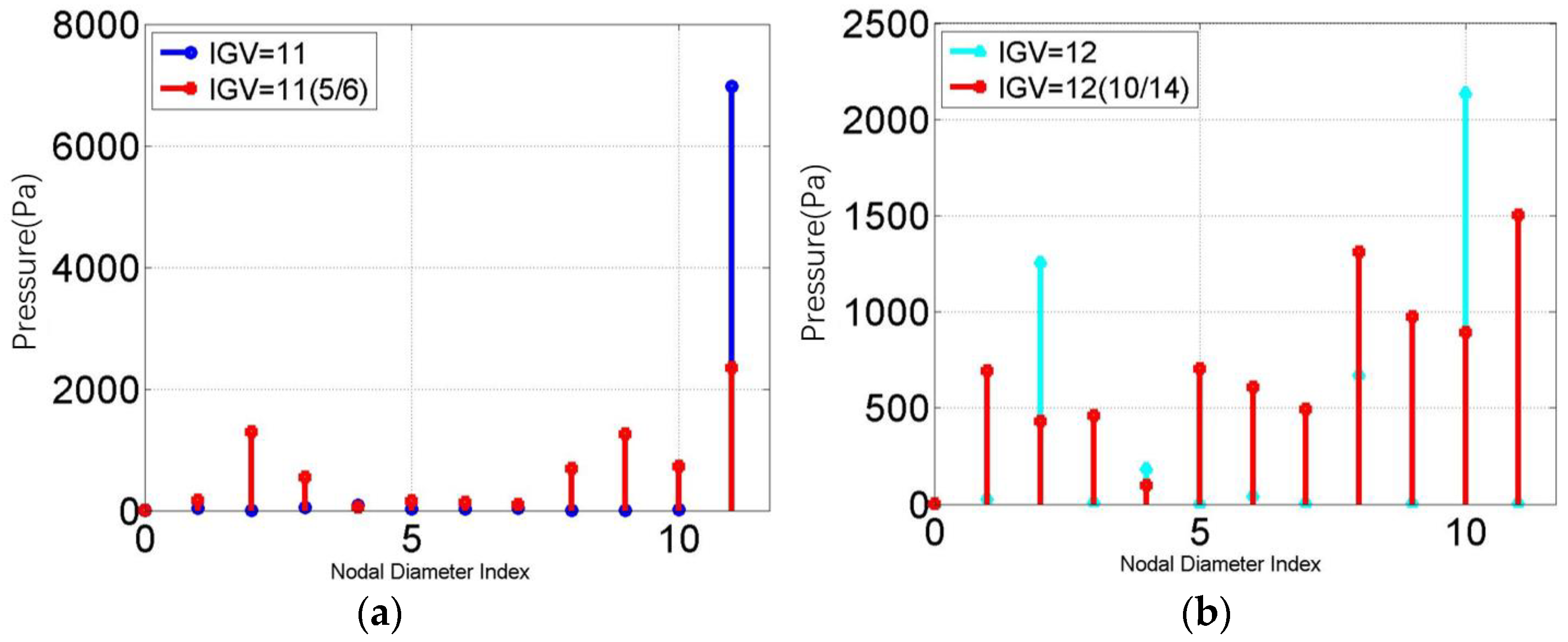

3.1. Effect of Stator Blade Number on Excitation towards the Bladed Disk

- (1)

- The excitation generated by the stator with the period number of on the downstream rotor blade includes each frequency component corresponding to the wake excitation order, namely, ;

- (2)

- Among all amplitudes of the frequency components, order is the largest, and the amplitude of the other component () decreases with the increase in ;

- (3)

- In general, the amplitude of is less than half that of the amplitude of the main excitation (), while the higher-order amplitude becomes smaller.

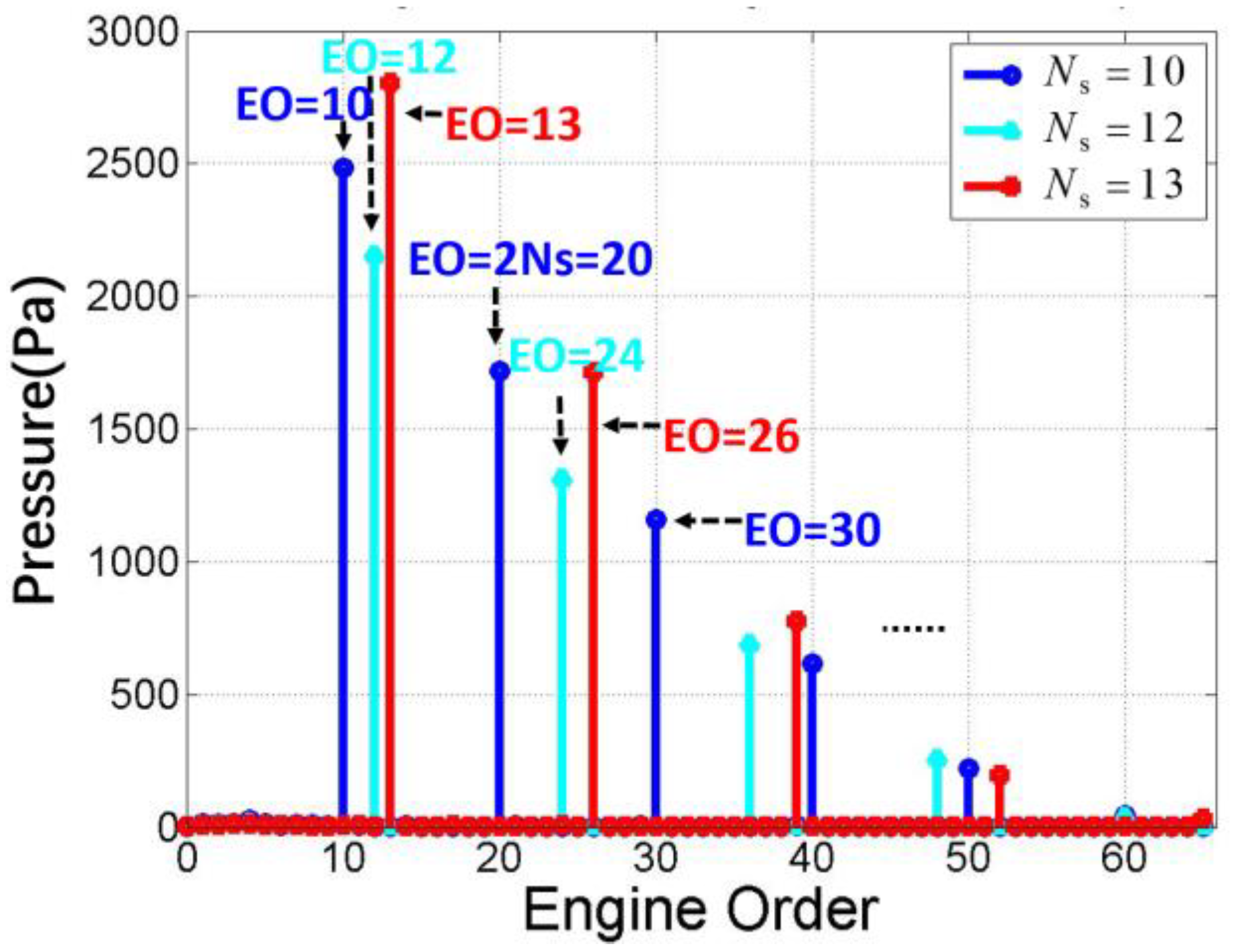

3.2. The Circumferential Wave Distribution Characteristics of Excitations and the Influence of the Stator Blade Number

3.3. Stator Number Design to Avoid Bladed Disk Resonance

- (1)

- When , the excitation component with excitation order 13 and circumferential wave number 9 will excite the modal resonance with nodal diameter ;

- (2)

- When , the excitation component with the excitation order of 30 and the circumferential wave number of 8 will excite the modal resonance with nodal diameter ;

- (3)

- When , the excitation does not contain the frequency component or circumferential wave component that causes resonance. Therefore, for the Rotor67 blade disk with 22 moving blades, resonance can be avoided with an upstream stator .

4. Excitation Characteristics of Mistuned Stators and Its Effect in Reducing Excitation Amplitude

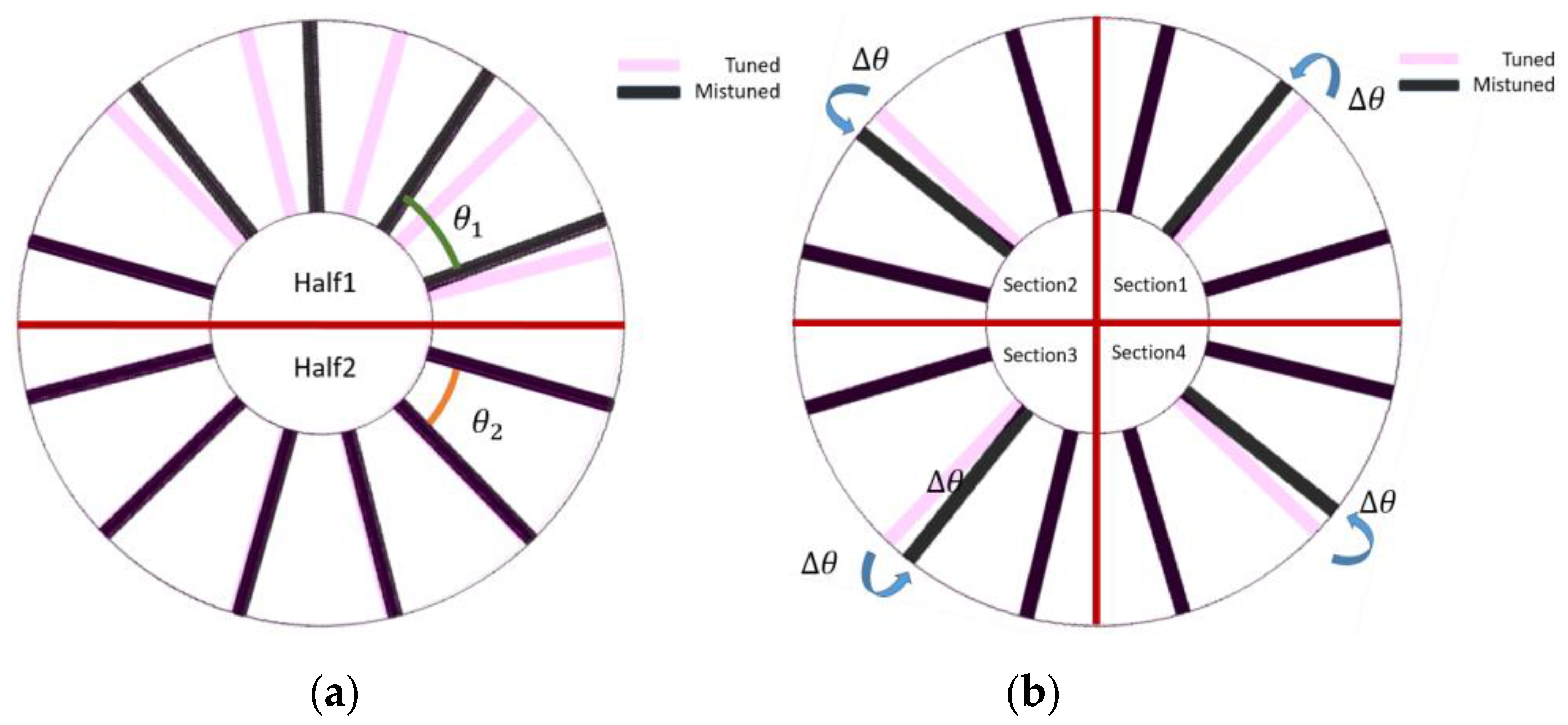

4.1. Mistuned Stator Pattern and Naming Rules

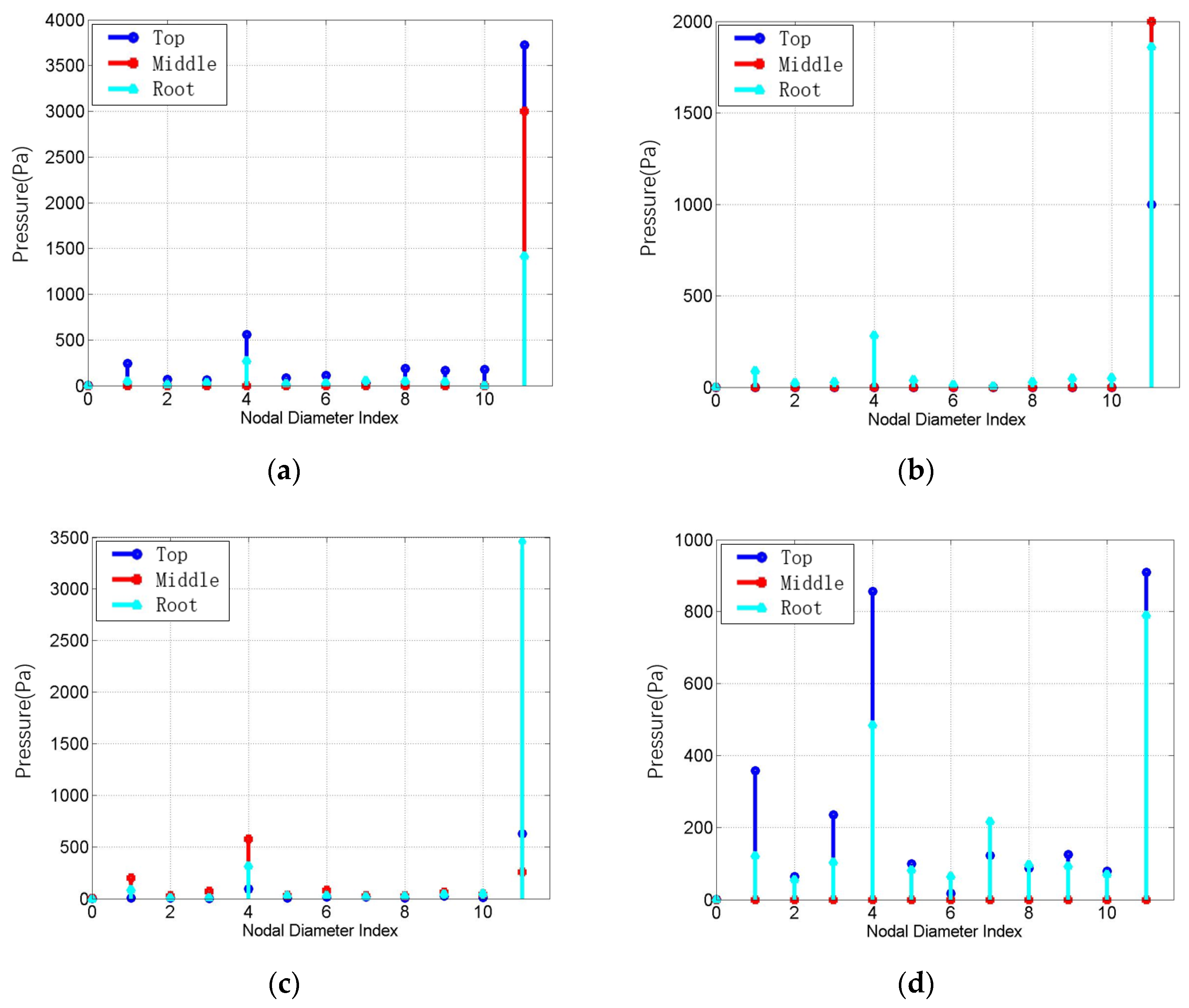

4.2. Asymmetric Mistuned Stators and Their Effect on Excitation towards Bladed Disks

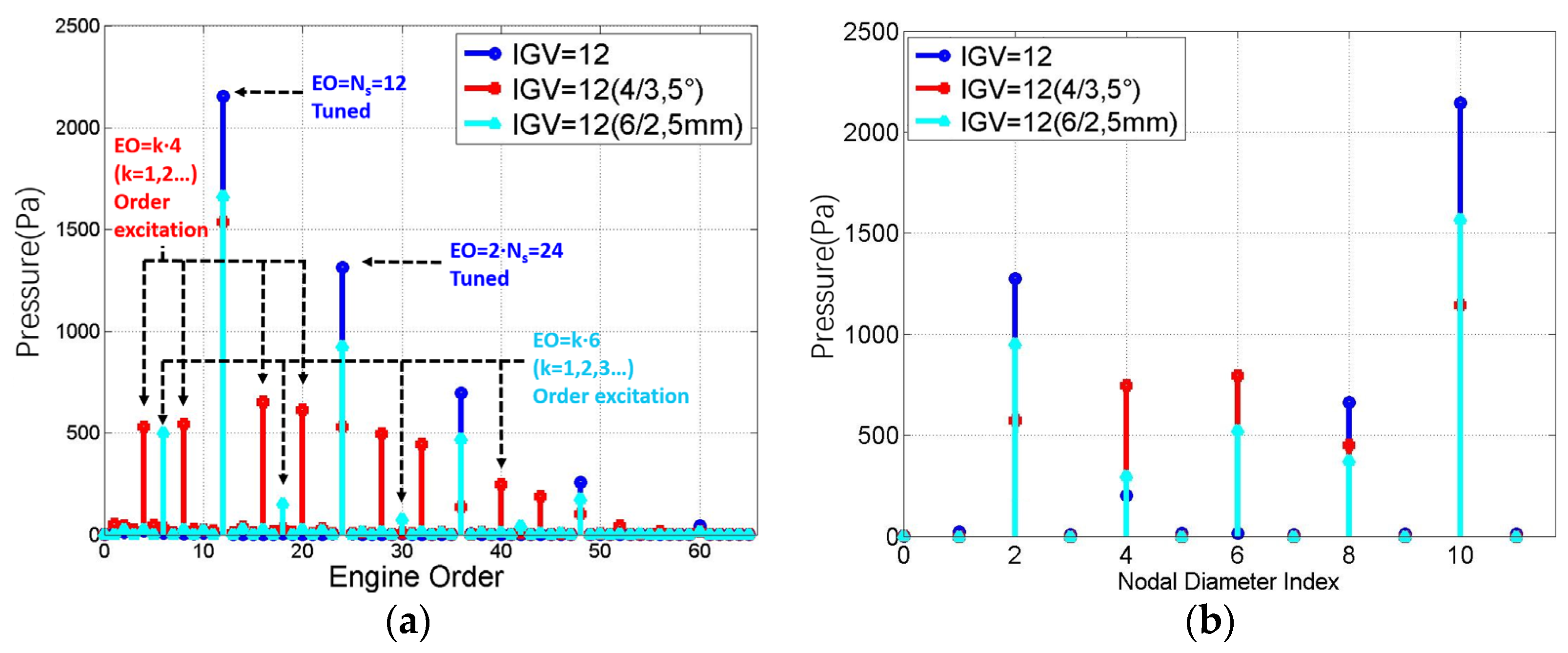

4.3. Sectional Non-Uniform Mistuned Stators and Their Effect on Excitation towards Bladed Disks

5. Conclusions

- (1)

- The excitation components of rotor–stator interference flow field on a bladed disk can be described by frequency components and circumferential wave components. The main frequency components can be written as , whereas the main circumferential wave components can be written as , among which . Components corresponding to are the main excitation, both for frequency and circumferential wave components, and the amplitude decreases with the increase in .

- (2)

- Referring to the Rotor67 bladed disk in this study, was chosen as the structural period number for stators; flow excitation here will not cause resonance. Through numerical analysis, it was shown that this method can determine the rationality of the stator–structural period without the need for performing numerical simulations of three-dimensional unsteady flow induced by rotor/stator interactions.

- (3)

- Compared with tuned stators, mistuned stators break up the wake energy by changing the topology of the blade. Therefore, the maximum amplitude of the wake excitation component decreases; however, the number of excitation components increases.

- (4)

- Two types of mistuned stators were studied: asymmetric mistuned and sectional non-uniform mistuned stators. Asymmetric mistuned stators decrease the excitation amplitude, although the components may induce resonance increases which renders them unsuitable for application. Sectional non-uniform mistuned stators can significantly reduce the amplitude of excitation without introducing too many new components, which shows potential in suppressing vibrations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kielb, J.J.; Abhari, R.S.; Dunn, M.G. Experimental and numerical study of forced response in a full-scaled rotating turbine. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001. [Google Scholar]

- Sayma, A.I.; Vahdati, M.; Imregun, M. An integrated nonlinear approach for turbomachinery forced response prediction. part I:formulation. J. Fluid Struct. 2000, 14, 87–101. [Google Scholar] [CrossRef]

- Kirkhope, J.; Wilson, G.J. A finite element analysis for the vibration modes of a bladed disc. J. Sound Vib. 1976, 49, 469–482. [Google Scholar] [CrossRef]

- Wang, P.-Y. Research on Vibration Suppression Theory of Bladed Disk of Aeroengine under Fluid Excitation; Beijing University of Aeronautics and Astronautics: Beijing, China, 2014. [Google Scholar]

- Xin, J.-Q. Researches on Typical Problems of Blisk Rotor Vibration in Turbomachinery; Beijing University of Aeronautics and Astronautics: Beijing, China, 2011. [Google Scholar]

- Yao, J.-Y. Forced Response Analysis of Bladed Disk under Fluid Excitation; Beijing University of Aeronautics and Astronautics: Beijing, China, 2010. [Google Scholar]

- Wildheim, S.J. Excitation of rotationally periodic structures. J. Appl. Mech. 1979, 46, 878–882. [Google Scholar] [CrossRef]

- Zhao, Z.; Song, W.; Jin, Y.; Lu, J. Effect of Rotational Speed Variation on the Flow Characteristics in the Rotor-Stator System Cavity. Appl. Sci. 2021, 11, 11000. [Google Scholar] [CrossRef]

- Faller, A.J. An experimental study of the instability of the laminar Ekman boundary layer. J. Fluid Mech. 1963, 15, 560. [Google Scholar] [CrossRef]

- Bayley, F.J.; Owen, J.M. Flow between a Rotating and a Stationary Disc. Aeronaut. Q. 1969, 20, 333–354. [Google Scholar] [CrossRef]

- Owen, J.M. Flow and Heat Transfer in Rotating-Disc Systems; JohnWiley Sons Inc.: New York, NY, USA, 1989; Volume 90, pp. 81–103. [Google Scholar]

- Bréard, C.; Green, J.S.; Imregun, M. Low-Engine-Order Excitation Mechanisms in Axial-Flow Turbomachinery. J. Propuls. Power 2015, 19, 704–712. [Google Scholar] [CrossRef]

- Bréard, C.; Vahdati, M.; Sayma, A.I.; Imregun, M. An Integrated Time-Domain Aeroelasticity Model for the Prediction of Fan Forced Response due to Inlet Distortion. J. Eng. Gas Turbines Power 2002, 124, 196–208. [Google Scholar] [CrossRef]

- Bladh, R.; Zhuang, Q.; Hu, J.; Hammar, J. Leakage-Induced Compressor Blade Excitation due to Inter-Segment Gaps. Asme Turbo Expo Turbine Tech. Conf. Expo. 2012, 44731, 1621–1632. [Google Scholar]

- Meng, Y.; Li, L.; Li, Q.-h. Asymmetry stator mistuned blade design and research. J. Aerosp. Power 2007, 22, 2083–2088. [Google Scholar]

- Meng, Y.; Li, L.; Li, Q.-h. Study on the influence of aerodynamic mistuned on unsteady aerodynamic force of blade. J. Aerosp. Power 2007, 22, 2083–2088. [Google Scholar]

- X, J.-Q.; Wang, J.-J. Forced response characteristic of bladed disk with aerodynamic mistuning. J. Aerosp. Power 2012, 27, 801–810. [Google Scholar]

- Kemp, R.H.; Hirschberg, M.H. Theoretical and Experimental Analysis of the Reduction of Rotor Blade Vibration in Turbomachinery Through the Use of Modified Stator Vane Spacing; NACA: Washington, DC, USA, 1958. [Google Scholar]

- Meng, Y.; Li, L.; Li, Q.-H. Transient analytical method of vane forcing response under stator-rotor wake influence. J. Beijing Univ. Aeronaut. Astronaut. 2007, 22, 2083–2088. (In Chinese) [Google Scholar]

- Yang, J.; Qiao, W.Y.; Hou, W.T.; Wei, Z.J. Numerical study on the stator solidity characteristics of axial turbine element stages. J. Aerosp. Power 2006, 32, 671–674. (In Chinese) [Google Scholar]

- Tan, J.; Wang, X.; Qi, D.; Wang, R. The effects of radial inlet with splitters on the performance of variable inlet guide vanes in a centrifugal compressor stage. Proc. Inst. Mech. Engineers. Part C J. Mech. Eng. Sci. 2011, 225, 2089–2105. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, W.; Hao, X. Experiment on treating block number of non-axisymmetric casing treatment. J. Propuls. Technol. 2009, 30, 434–438. [Google Scholar]

- Gottfried, D.; Fleeter, S. Passive detuning for HCF reduction. In Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Indianapolis, Indiana, 7–10 July 2002. [Google Scholar]

- Figaschewsky, F.; Giersch, T.; Kühhorn, A. Forced response prediction of an axial turbine rotor with regard to aero-dynamically mistuned excitation. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Sullivan, B.M.; Edwards, B.D.; Brentner, K.S. A subjective test of modulated blade spacing for helicopter main rotors. Am. Helicopter Soc. 2005, 50, 26–32. [Google Scholar] [CrossRef] [Green Version]

- Edwards, B.; Booth, E.R., Jr. Psychoacoustic Testing of Modulated Blade Spacing for Main Rotors; Contractor Report; NASA: Washington, DC, USA, 2002. [Google Scholar]

- Marshall, J.G.; Imergun, M. A Review of Aeroelasticity Methods with Emphasis on Turbomachinery Applications. J. Fluids Struct. 1996, 10, 237–267. [Google Scholar]

- Srinivasan, A.V. Flutter and Resonant Vibration Characteristics of Engine Blades. J. Eng. Gas Turbine Power 1997, 199, 742–775. [Google Scholar] [CrossRef]

- Sadeghi, M.; Liu, F. Investigation of Mistuning Effects on Cascade Flutter Using a Coupled Method. J. Propuls. Power 2007, 23, 266–272. [Google Scholar]

- Spara, K.M.; Fleeter, S. Supersonic turbomachinery rotor flutter control by aerodynamic detuning. J. Propuls. Power 1993, 9, 561–568. [Google Scholar] [CrossRef]

- Hoyniak, D.; Fleeter, S. Forced response analysis of an aerodynamically detuning supersonic turbomachine rotor. J. Vib. Acoust. Stress Reliab. Des. 1986, 108, 117–124. [Google Scholar] [CrossRef]

- Hoyniak, D.; Fleeter, S. The effect of circumferential aerodynamic detuning on coupled bending-torsion unstalled supersonic flutter. J. Turbomach. 1986, 108, 253–260. [Google Scholar] [CrossRef]

| EO | n | EO·Ω( Hz) | Ωn (Hz) |

|---|---|---|---|

| 2 | 2 | 535 | 539 |

| 5 | 5 | 1337 | 1350 |

| 7 | 7 | 1872 | 1893 |

| 11 | 11 | 2941 | 3043 |

| 13 | 9 | 3476 | 3519 |

| 21 | 1 | 5615 | 5533 |

| 22 | 0 | 5882 | 5828 |

| 24 | 2 | 6417 | 6483 |

| 25 | 3 | 6685 | 6784 |

| 26 | 4 | 6952 | 7015 |

| 27 | 5 | 7219 | 7271 |

| 30 | 8 | 8022 | 7939 |

| 37 | 7 | 9893 | 9903 |

| 38 | 6 | 10,161 | 10,132 |

| Set | Number of Mesh Nodes | P-Total at Point 5 (Pa) | Error |

|---|---|---|---|

| N1 | 2,086,376 | 163,347 | −4.5% |

| N2 | 3,138,914 | 168,072 | −1.75% |

| N3 | 5,031,256 | 170,223 | −0.05% |

| N4 | 8,122,370 | 171,066 | —— |

| EO | |||

|---|---|---|---|

| 13 | 13 | 26 | 39 |

| 14 | 14 | 28 | 42 |

| 15 | 15 | 30 | 45 |

| 13 | 13 | 26 | 39 |

| 14 | 14 | 28 | 42 |

| 15 | 15 | 30 | 45 |

| Case No. | Mistuned Type | Name |

|---|---|---|

| I | Asymmetric | |

| II | ||

| III | Sectional non-uniform | |

| IV |

| Excitation Order | Tuned | Mistuned Stator Case III | Mistuned Stator Case IV |

|---|---|---|---|

| 1313/Pa | 529/Pa | 925/Pa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Zhou, Z.; Li, L. Stator Design Method in Rotor–Stator Interference Flow Fields in Order to Suppress the Vibration of Bladed Disks. Appl. Sci. 2022, 12, 8495. https://doi.org/10.3390/app12178495

Ma H, Zhou Z, Li L. Stator Design Method in Rotor–Stator Interference Flow Fields in Order to Suppress the Vibration of Bladed Disks. Applied Sciences. 2022; 12(17):8495. https://doi.org/10.3390/app12178495

Chicago/Turabian StyleMa, Haoran, Zhou Zhou, and Lin Li. 2022. "Stator Design Method in Rotor–Stator Interference Flow Fields in Order to Suppress the Vibration of Bladed Disks" Applied Sciences 12, no. 17: 8495. https://doi.org/10.3390/app12178495

APA StyleMa, H., Zhou, Z., & Li, L. (2022). Stator Design Method in Rotor–Stator Interference Flow Fields in Order to Suppress the Vibration of Bladed Disks. Applied Sciences, 12(17), 8495. https://doi.org/10.3390/app12178495