Optimization Design and Analysis of Bionic Friction Reducing Nozzle in Oil Shale High-Pressure Jet Mining

Abstract

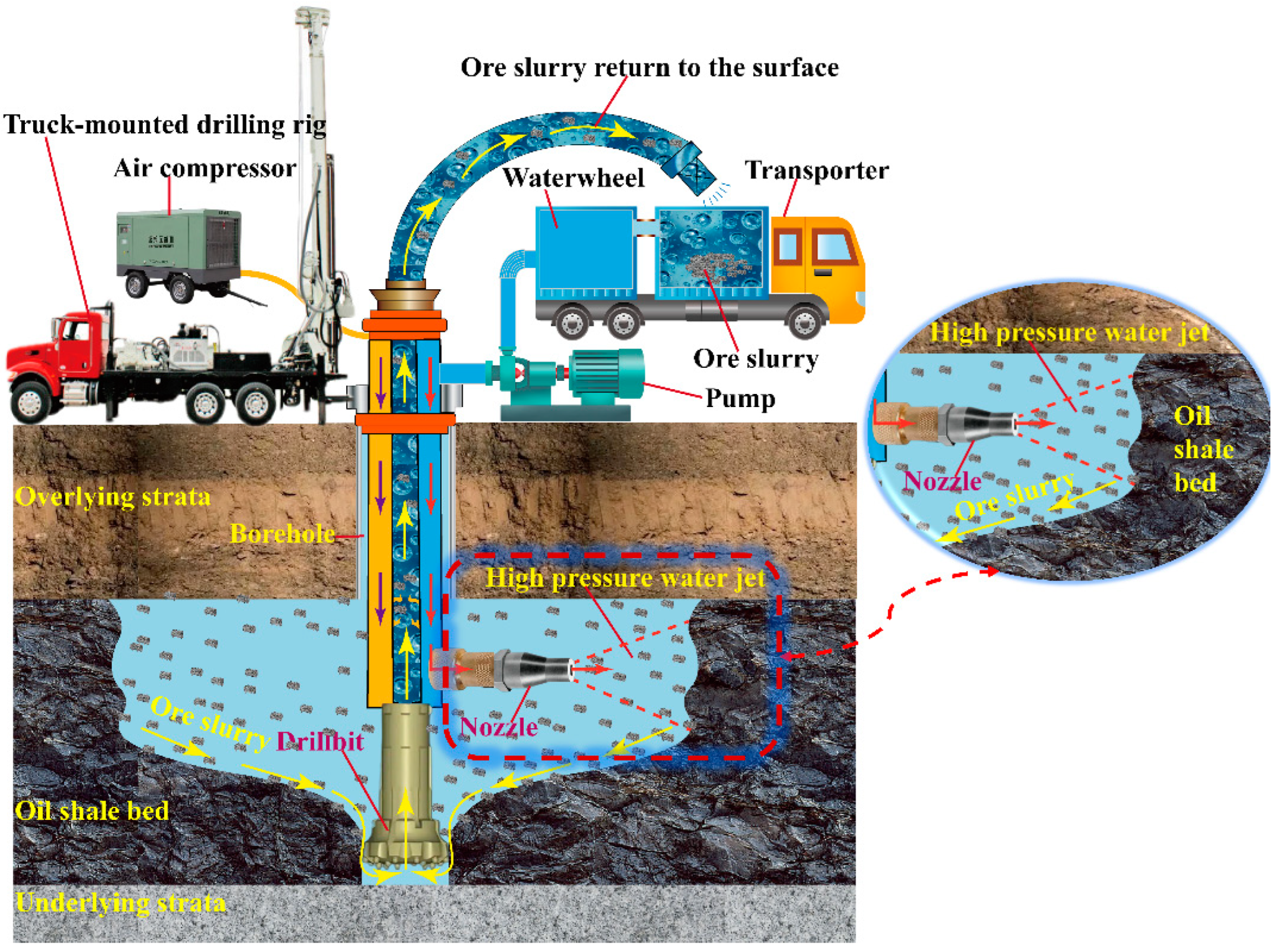

:1. Introduction

2. Modeling and Optimization Method

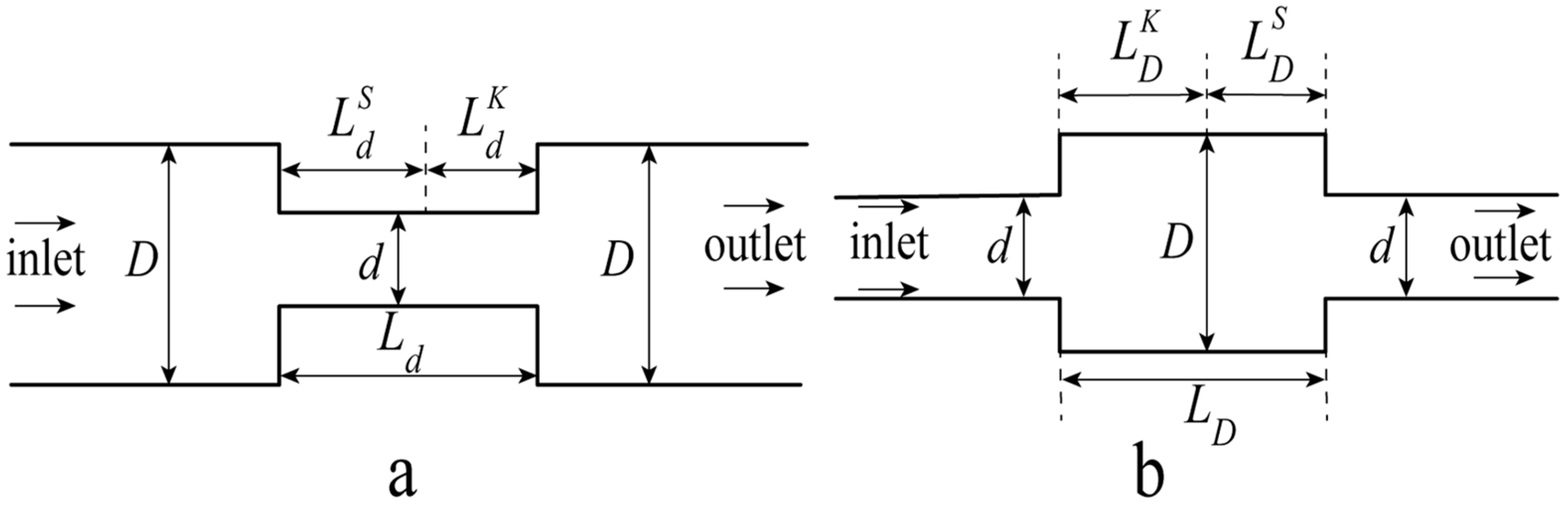

2.1. BCT Model and Pressure Drop Calculation

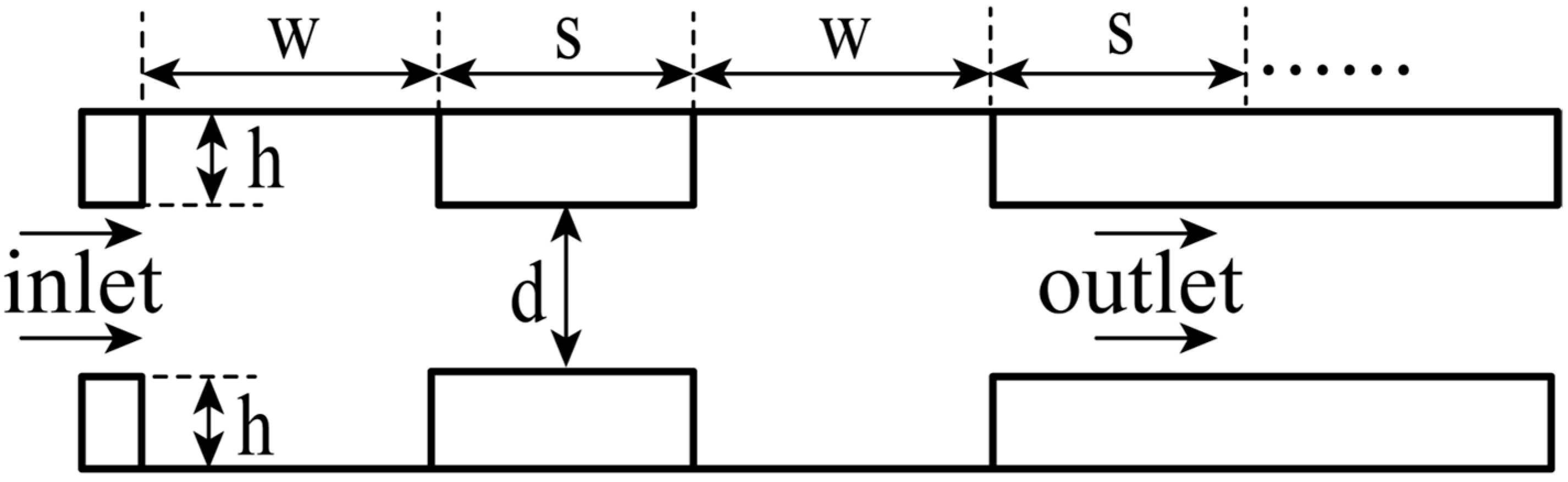

2.1.1. Conceptual Model of a BCT

2.1.2. Modeling for a Single-Type Variable Cross-Sectional Structure

2.1.3. Modeling for a Comprehensive-Type Variable Cross-Sectional Structure

2.1.4. Pressure Drop Calculation

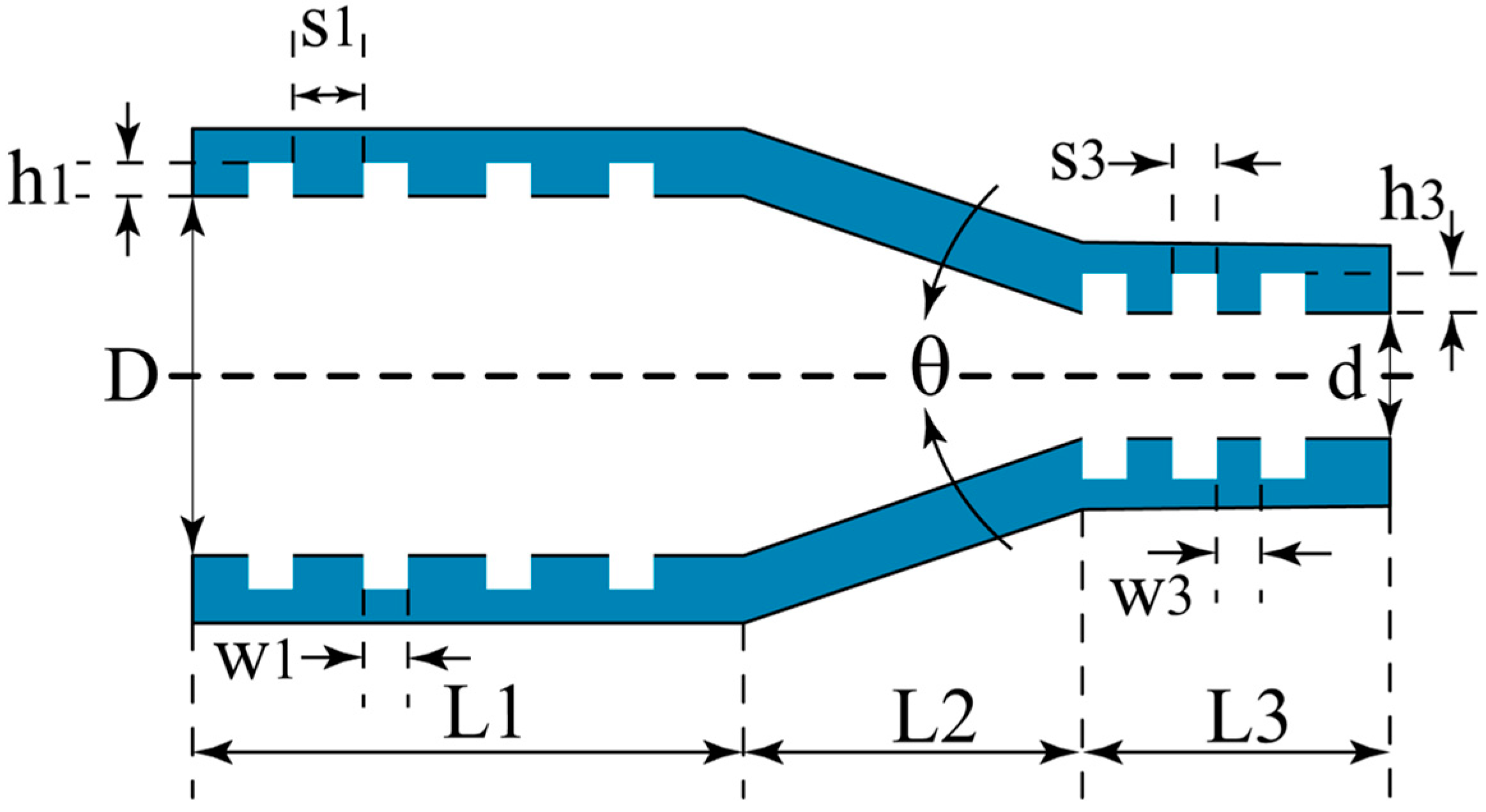

2.2. BSCN model and Optimization

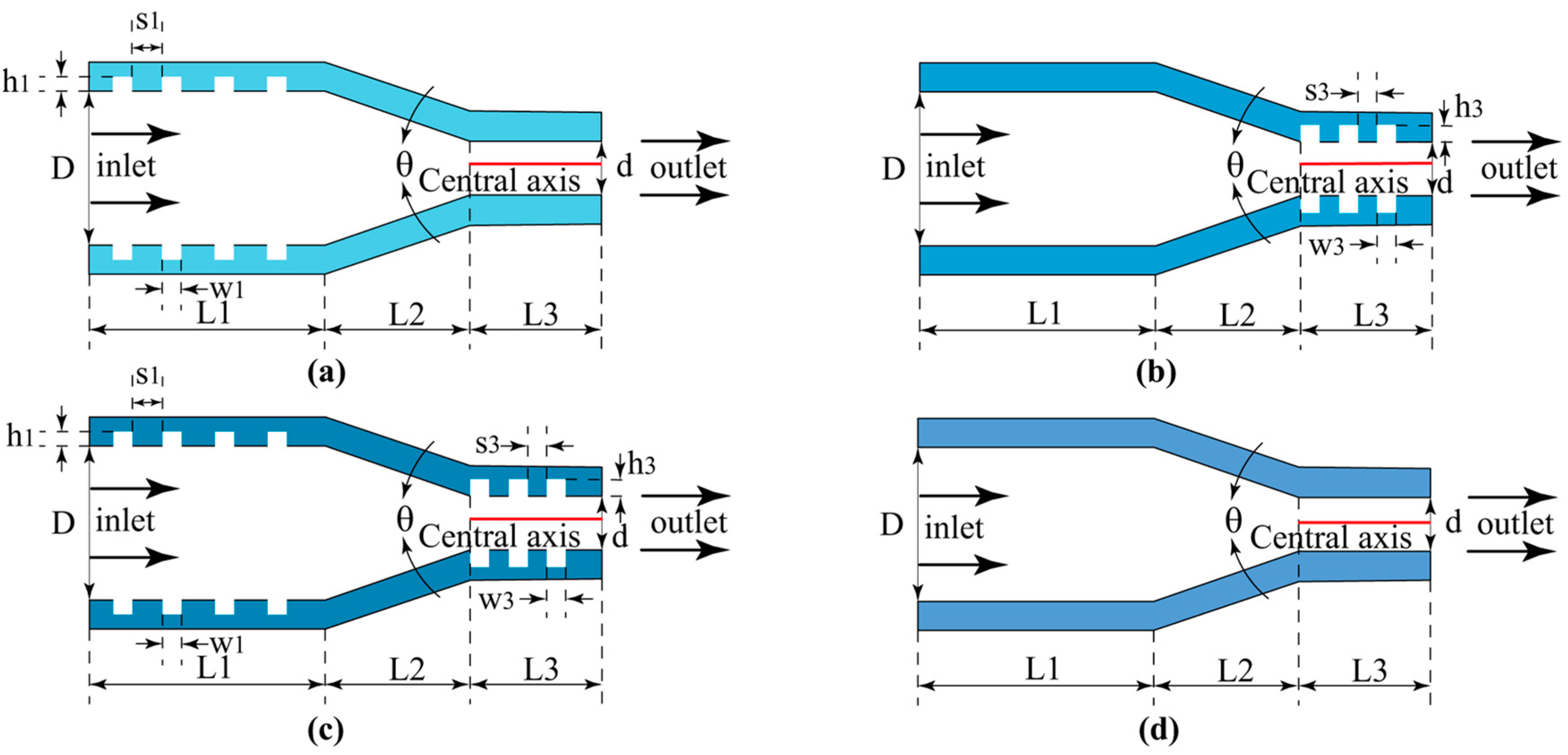

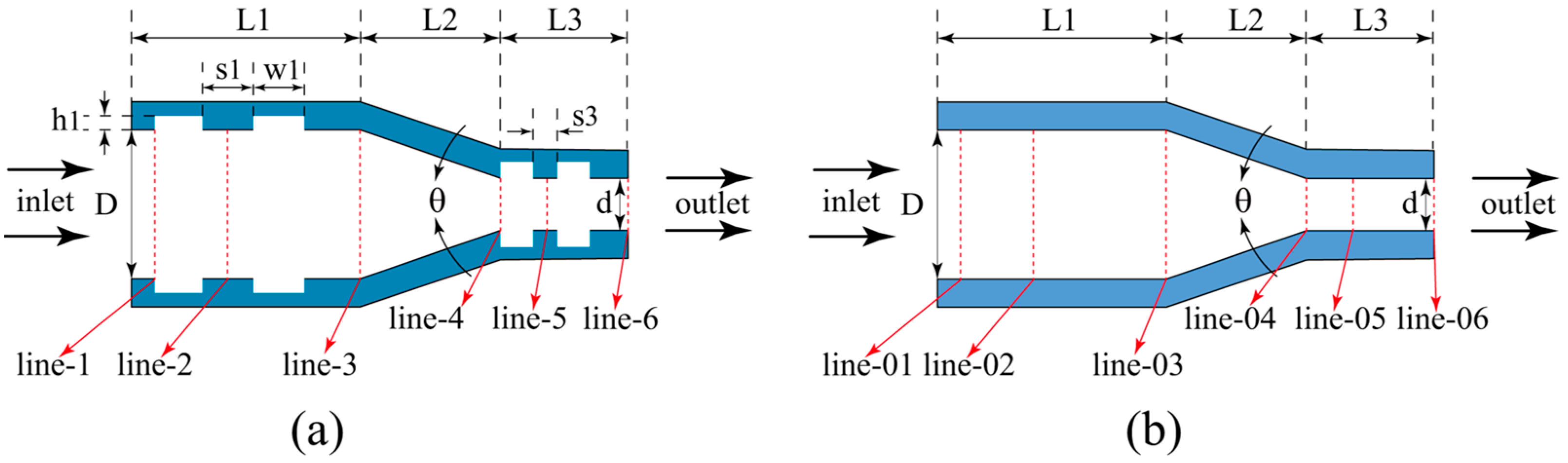

2.2.1. Conceptual Model of the BSCN

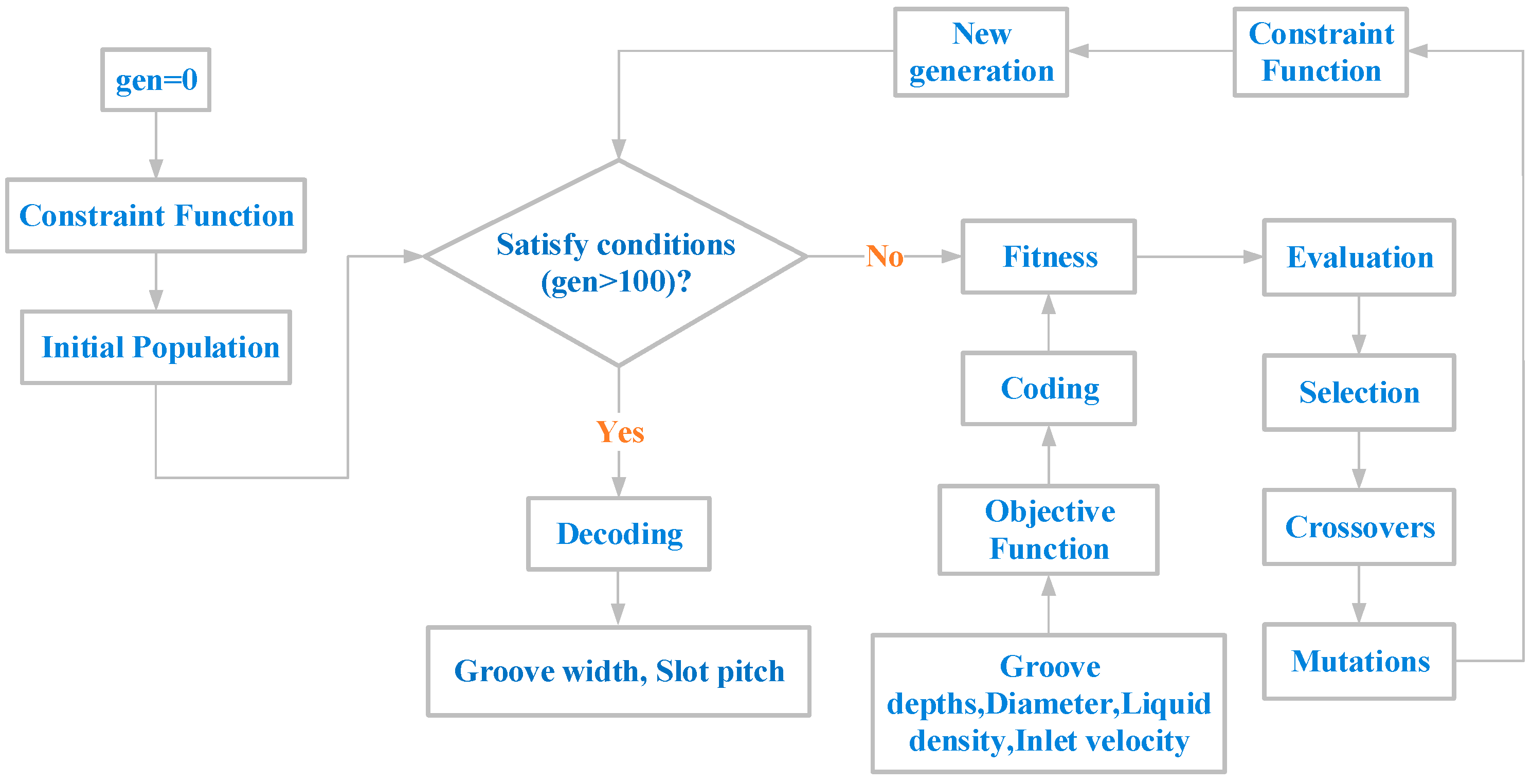

2.2.2. Optimization Process

2.2.3. Objective Function and Constraint Function

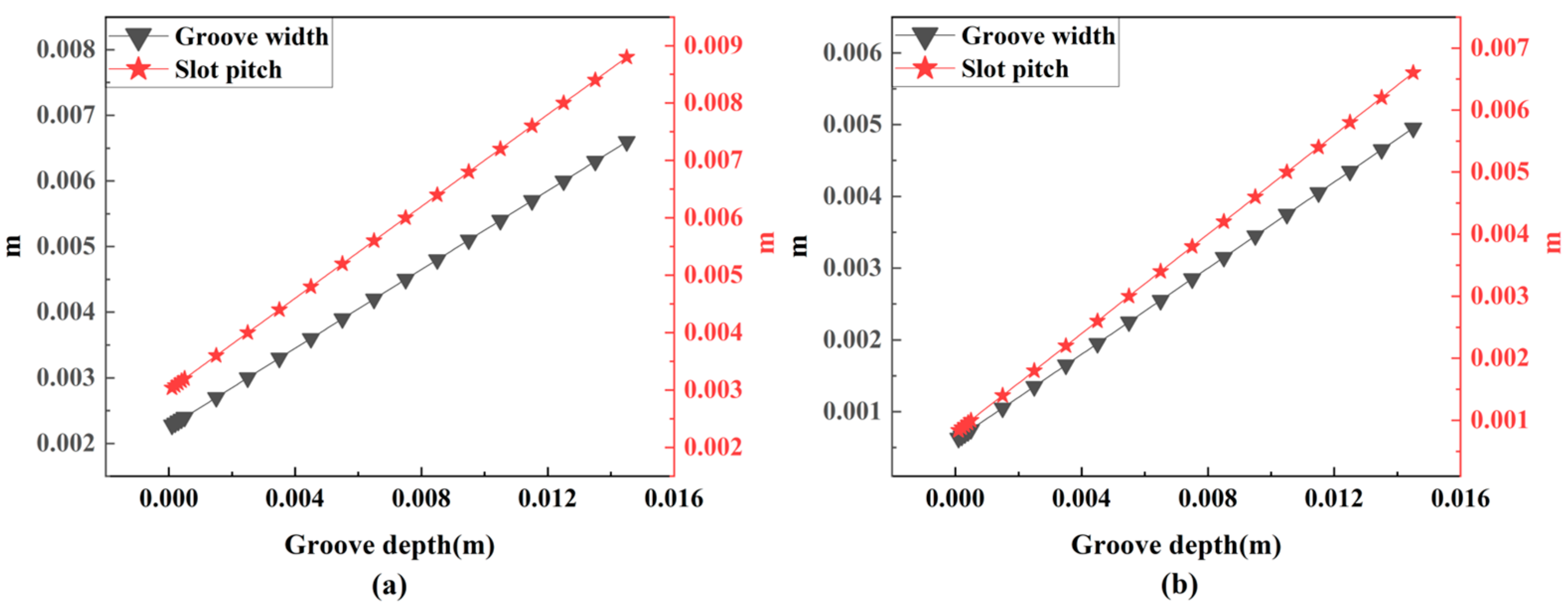

2.2.4. Basic Structure Parameters

2.2.5. Optimization Results

3. Case Study

3.1. CFD Numerical Simulation

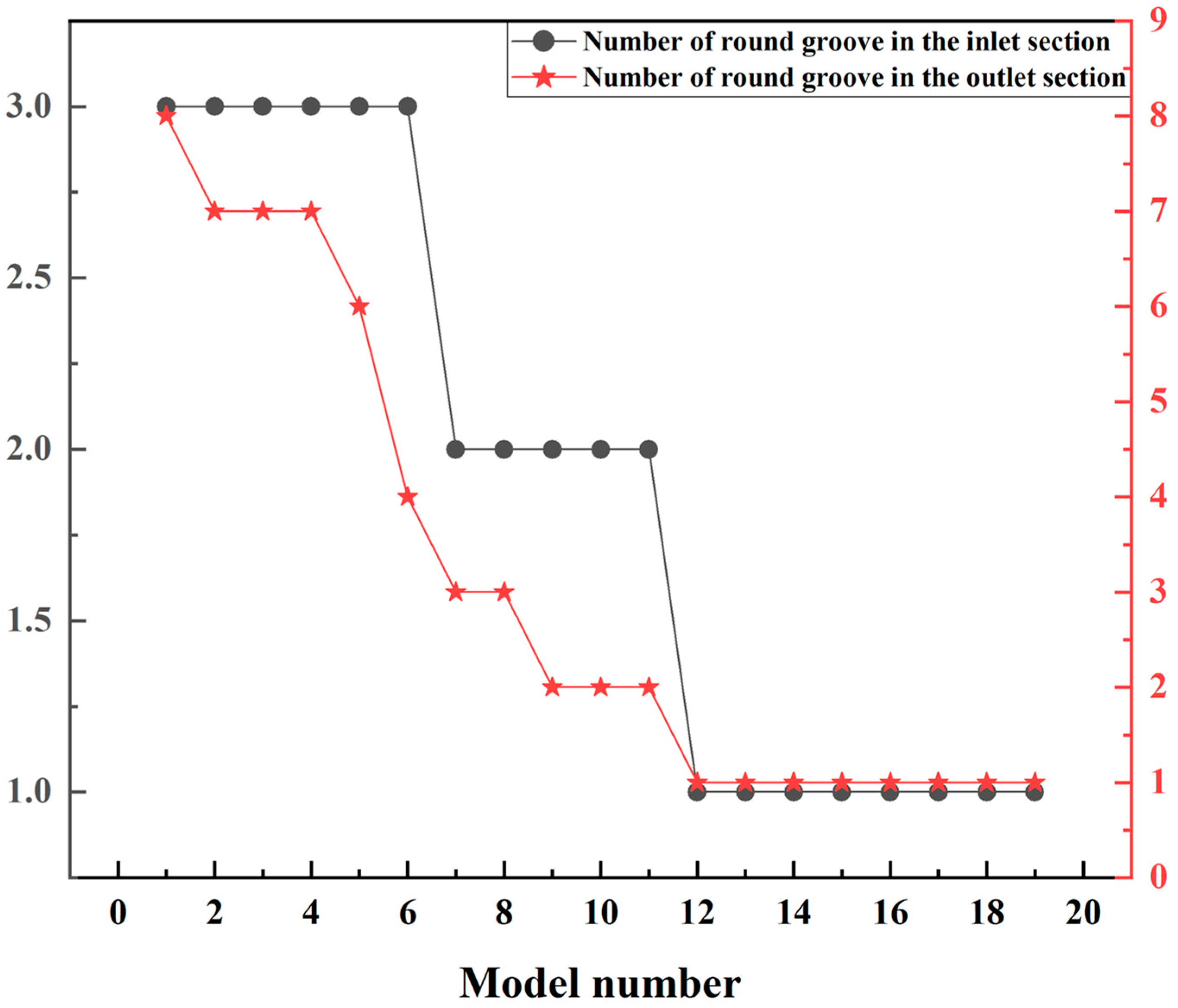

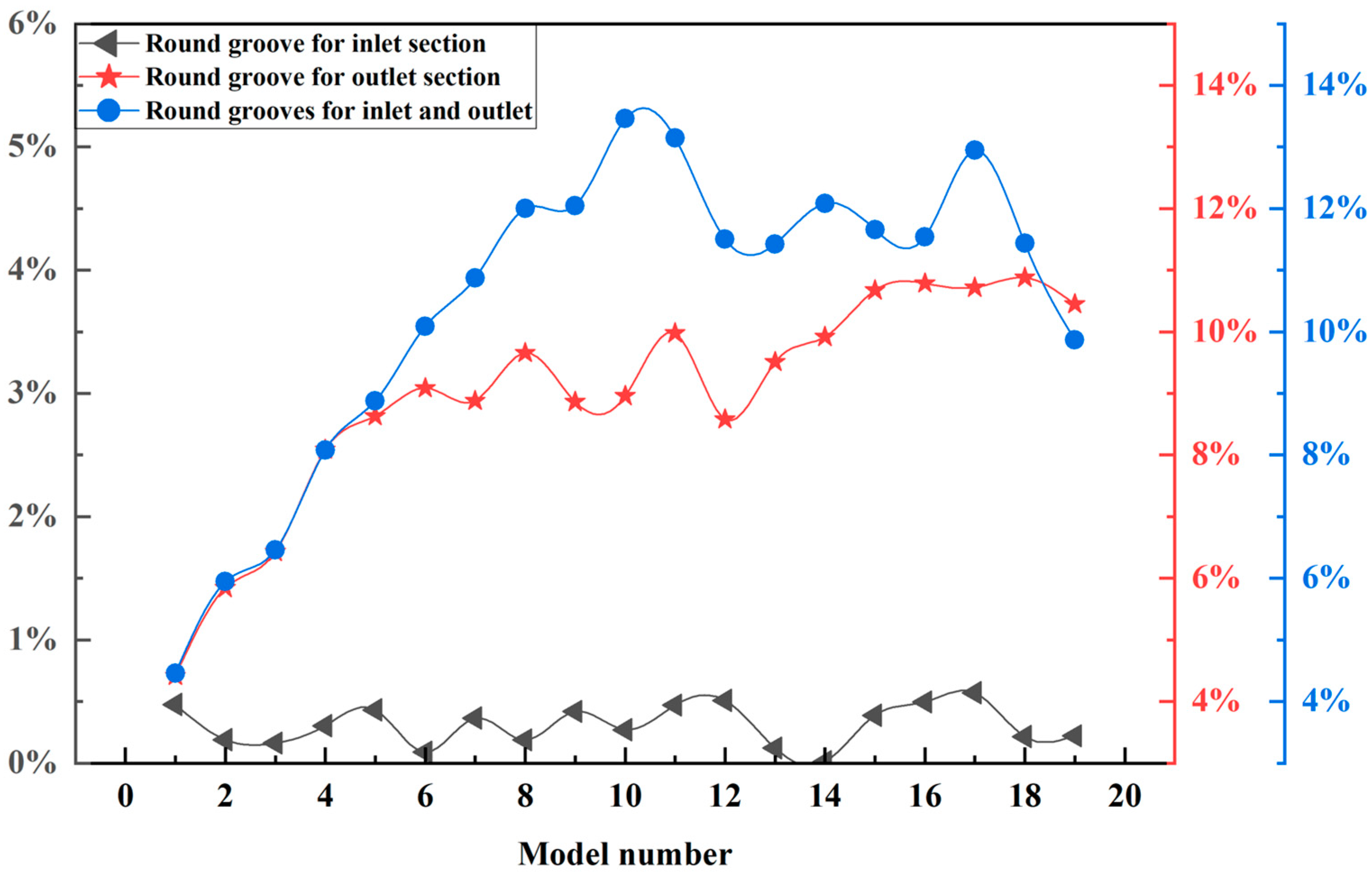

3.1.1. Determining the Number of BSCN Grooves

3.1.2. Basic Settings for Numerical Simulation

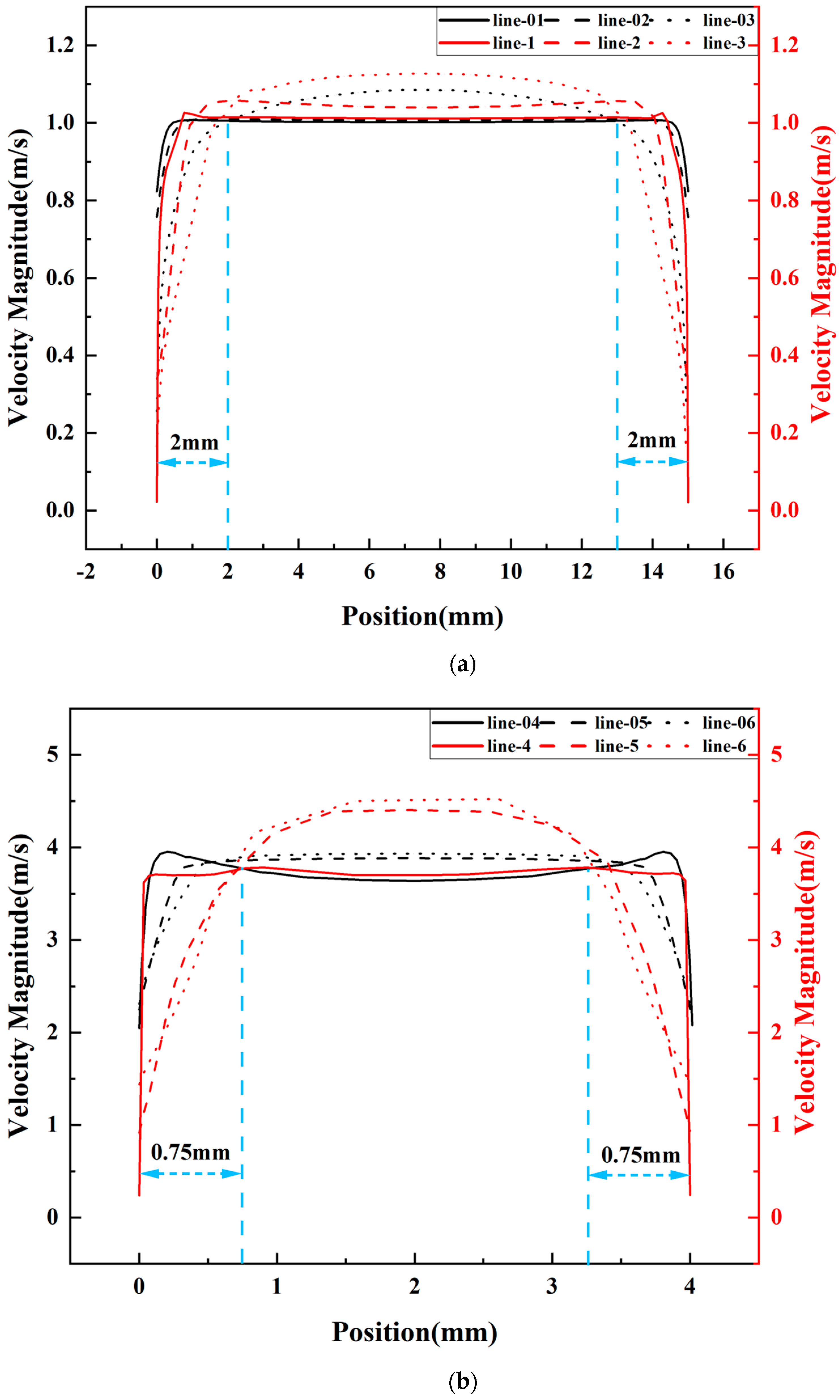

3.1.3. Analysis of Simulation Results

3.2. Analysis of the Effect

4. Conclusions

- (1)

- Under the same numerical simulation conditions, compared with the conventional straight cone nozzle, the velocity increase rate of the BSCN could reach 13.45%. This can provide valuable scientific references for the hydraulic mining of high-pressure water jets in oil shale drilling.

- (2)

- CFD numerical simulation results showed that the circular groove in the inlet and outlet sections could effectively reduce the fluid resistance. The drag reduction effect of the circular groove arranged in the outlet section of BSCN was better than that arranged in the inlet section.

- (3)

- Based on the results of genetic algorithm optimization analysis and CFD numerical simulation, the optimal structural parameters of the BSCN were as follows: Fixed values were inlet diameter D = 15 mm, inlet length L1 = 20 mm, outlet diameter d = 4 mm, L3/d = 3, and contraction angle θ = 30°. Variable values for the inlet section of L1, namely, the groove width, slot pitch, and groove depth, were 3.9 mm, 5.2 mm, and 5.5 mm, respectively, and the number of circular grooves was 2. In the outlet section of L3, the groove width, slot pitch, and groove depth were 2.25 mm, 3 mm, and 5.5 mm, respectively, and the number of circular grooves was 2.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, G.; Zhang, B.; Zhao, P.; Duan, C.; Zhao, Y.; Zhang, Z.; Yan, G.; Zhu, X.; Ding, W.; Rao, Z. Upgrading low-quality oil shale using high-density gas-solid fluidized bed. Fuel 2019, 252, 666–674. [Google Scholar] [CrossRef]

- Brendow, K. Global oil shale issues and perspectives (Synthesis of the Symposium on Oil Shale held in Tallinn (Estonia) on 18 and 19 November 2002). Oil Shale 2003, 20, 81–92. [Google Scholar]

- Knaus, E.A.; Killen, J.B.; Biglarbigi, K.A.; Crawford, P.A. An Overview of Oil Shale Resources; ACS Symposium Series: Washington, DC, USA, 23 February 2010; pp. 3–20. [Google Scholar]

- Dyni, J.R. Geology and Resources of Some World Oil-Shale Deposits. Oil Shale 2003, 20, 193–252. [Google Scholar]

- Kang, Z.; Zhao, Y.; Yang, D. Review of oil shale in-situ conversion technology. Appl. Energy 2020, 269, 115121–115139. [Google Scholar] [CrossRef]

- Jiwei, W.; Chen, C. Optimizing the Structure of the Straight Cone Nozzle and the Parameters of Borehole Hydraulic Mining for Huadian Oil Shale Based on Experimental Research. Energies 2017, 10, 2021–2035. [Google Scholar]

- Xu, Y.; Sun, P.; Yao, S.; Liu, Z.; Tian, X.; Li, F.; Zhang, J. Progress in exploration, development and utilization of oil shale in China. Oil Shale 2019, 36, 285–304. [Google Scholar] [CrossRef]

- Zhabin, A.; Polyakov, A.; Averin, E.; Khachaturian, W. Experimental studies on cutting oil shale by high-pressure water jets. Oil Shale 2019, 36, 32–42. [Google Scholar] [CrossRef]

- Dongqing, Z.; Jingbin, L.; Xiao, H.; Xin, L.; Kang, C. Flow field simulation of swirling abrasive jet nozzle for hard rock breaking. Geofluids 2022, 2022, 4681189. [Google Scholar] [CrossRef]

- Wen, J.; Chen, C.; Urso, C.; Yang, X.J. Experimental research on the performances of water jet devices and proposing the parameters of borehole hydraulic mining for oil shale. PLoS ONE 2018, 13, e0199027. [Google Scholar] [CrossRef]

- Pedchenko, L.; Pedchenko, N.; Manhura, A.; Pedchenko, M. Development of natural bitumen (bituminous sands) deposits based on the technology of hydraulic mining by boreholes. In Proceedings of the E3S Web of Conferences, Odesa, Ukraine, 22 October 2019; pp. 01036–01050. [Google Scholar]

- Jian, Z.; Zhang, G.; Xu, Y.; Lin, A.; Yang, D. Enhancing rate of penetration in a tight formation with high-pressure water jet (HPWJ) via a downhole pressurized drilling tool. J. Pet. Sci. Eng. 2019, 174, 1194–1207. [Google Scholar]

- Hja, C.; Hz, A.; Kg, B.; Ow, A.; Yw, A.; Dm, A. Numerical investigation of hard rock breakage by high-pressure water jet assisted indenter impact using the coupled SPH/FEM method. Powder Technol. 2020, 376, 176–186. [Google Scholar]

- Chen, S.; Yin, D.; Jiang, N.; Wang, F.; Zhao, Z. Mechanical properties of oil shale-coal composite samples. Int. J. Rock Mech. Min. Sci. 2019, 123, 104120–104130. [Google Scholar] [CrossRef]

- He, Q.; He, B.; Li, F.; Shi, A.; Chen, J.; Xie, L.; Ning, W. Fractal characterization of complex hydraulic fractures in oil shale via topology. Energies 2021, 14, 1123. [Google Scholar] [CrossRef]

- Spotts, N.G.; Guzik, S.; Gao, X. A CFD analysis of compressible flow through convergent-conical nozzles. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint PropulsionConference, San Jose, CA, USA, 15–17 July 2013; p. 3734. [Google Scholar]

- Mao, J.S.; Sun, Y.H.; Wen, J.W.; Chen, C. Research on Nong’an oil shale hydraulic breaking. Appl. Mech. Mater. 2013, 398, 7–10. [Google Scholar] [CrossRef]

- Shen, Y.; Huang, Y.Q.; Ye, R.F.; Ding, S.; Wang, L.; Lin, C.; Gu, Y. A new design of the laser-micro jet system. In Proceedings of the 2009 Symposium on Photonics and Optoelectronics, Wuhan, China, 14–16 August 2009; pp. 1–4. [Google Scholar]

- Chen, L.; Cheng, M.; Cai, Y.; Guo, L.; Gao, D. Design and Optimization of High-Pressure Water Jet for Coal Breaking and Punching Nozzle Considering Structural Parameter Interaction. Machines 2022, 10, 60. [Google Scholar] [CrossRef]

- Jiang, T.-W.; Huang, Z.-W.; Li, J.-B.; Zhou, Y.-S. Internal flow mechanism of cone-straight nozzle. Pet. Sci. 2021, 18, 1507–1519. [Google Scholar] [CrossRef]

- Jiang, T.; Huang, Z.; Li, J.; Zhou, Y.; Xiong, C. Effect of Nozzle Geometry on the Flow Dynamics and Resistance Inside and Outside the Cone-Straight Nozzle. ACS Omega 2022, 7, 9652–9665. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Chen, C.; Qi, Z.; Campos, U.; Pei, X. Bionic optimum design of straight cone nozzle and the effectiveness evaluation of reducing fluid resistance. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 358. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, J.; Peng, H.; Liu, D. Nature-Inspired Structures Applied in Heat Transfer Enhancement and Drag Reduction. Micromachines 2021, 12, 656. [Google Scholar] [CrossRef]

- Bhushan, B. Biomimetics: Lessons from nature–an overview. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2009, 367, 1445–1486. [Google Scholar] [CrossRef]

- Wilkinson, S.; Anders, J.; Lazos, B.; Bushnell, D. Turbulent drag reduction research at NASA Langley: Progress and plans. Int. J. Heat Fluid Fl. 1988, 9, 266–277. [Google Scholar] [CrossRef]

- Liu, C.; Sheng, C.; Yang, H.; Yuan, Z. Design and optimization of bionic janus blade in hydraulic torque converter for drag reduction. J. Bionic Eng. 2018, 15, 160–172. [Google Scholar] [CrossRef]

- Dean, B.; Bhushan, B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4775–4806. [Google Scholar] [CrossRef]

- Bechert, D.; Reif, W. On the drag reduction of the shark skin. In Proceedings of the 23rd Aerospace sciences meeting, Reno, NV, USA, 14–17 January 1985; p. 546. [Google Scholar]

- Walsh, M.; Lindemann, A. Optimization and application of riblets for turbulent drag reduction. In Proceedings of the 22nd Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1984; p. 347. [Google Scholar]

- Bechert, D.; Bruse, M.; Hage, W.; Meyer, R. Fluid mechanics of biological surfaces and their technological application. Naturwissenschaften 2000, 87, 157–171. [Google Scholar] [CrossRef]

- Bechert, D.; Bruse, M.; Hage, W.v.; Van der Hoeven, J.T.; Hoppe, G. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry. J. Fluid Mech. 1997, 338, 59–87. [Google Scholar] [CrossRef]

- Yunqing, G.; Tao, L.; Jiegang, M.; Zhengzan, S.; Peijian, Z. Analysis of drag reduction methods and mechanisms of turbulent. Appl. Bionics Biomech. 2017, 2017, 6858720. [Google Scholar] [CrossRef] [PubMed]

- Liu, E.; Li, L.; Wang, G.; Zeng, Z.; Zhao, W.; Xue, Q. Drag reduction through self-texturing compliant bionic materials. Sci. Rep. 2017, 7, 40038. [Google Scholar] [CrossRef] [PubMed]

- Chen, I.Y.; Wongwises, S.; Yang, B.-C.; Wang, C.-C. Two-phase flow across small sudden expansions and contractions. Heat Transf. Eng. 2010, 31, 298–309. [Google Scholar] [CrossRef]

- Liu, J.; Yao, L.; Zhang, Y.; Chen, J. The Calculation Method of Local Pressure Drop on Variable Cross-Section Circular Tube Structure. Mach. Des. Manuf. 2016, 5, 83–87. [Google Scholar]

- Zhao, B.-F.; Jin, Y.-Z.; Men, B.-H. The Study on Pipe Sudden Enlargement Local Resistant Coefficient. J. Northeast Agric. Univ. 1999, 6, 147–151. [Google Scholar]

- Roul, M.K.; Dash, S.K. Two-phase pressure drop caused by sudden flow area contraction/expansion in small circular pipes. Int. J. Numer. Methods Fluids 2011, 66, 1420–1446. [Google Scholar] [CrossRef]

- Hermany, L.; dos Santos, D.D.O.; Frey, S.; Naccache, M.F.; De Souza Mendes, P.R. Flow of yield-stress liquids through an axisymmetric abrupt expansion-contraction. J. Non-Newton. Fluid Mech. 2013, 201, 1–9. [Google Scholar] [CrossRef]

- Dos Santos, D.D.O.; Frey, S.L.; Naccache, M.F.; de Souza Mendes, P.R. Flow of elasto-viscoplastic liquids through a planar expansion–contraction. Rheol. Acta 2014, 53, 31–41. [Google Scholar] [CrossRef]

- Yao, L.; Liu, J.; Li, X.; Yue, Q.; Liu, Y.; Wang, H. Application of the building block approach to characterize the pressure loss of water and fracturing fluid in contraction-expansion pipe. J. Pet. Sci. Eng. 2019, 176, 51–61. [Google Scholar] [CrossRef]

- Wu, J.H.; Ai, W.Z. Flows through energy dissipaters with sudden reduction and sudden enlargement forms. J. Hydrodyn. 2010, 22, 360–365. [Google Scholar] [CrossRef]

- Mirjalili, S. Genetic algorithm. In Evolutionary algorithms and neural networks; Springer: Cham, Switzerland, 2019; pp. 43–55. [Google Scholar]

- Kumar, M.; Husain, D.; Upreti, N.; Gupta, D. Genetic algorithm: Review and application. Int. J. Inf. Technol. Knowl. Manag. 2010, 2, 451–454. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef] [PubMed]

| Parameter | D | d | L1 | L3 | θ | h | w | s |

|---|---|---|---|---|---|---|---|---|

| Value | 15 mm | 4 mm | 20 mm | 12 mm | 30° | -- | -- | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, Y.; Qin, X.; Dou, Z.; Xu, X.; Lv, J. Optimization Design and Analysis of Bionic Friction Reducing Nozzle in Oil Shale High-Pressure Jet Mining. Appl. Sci. 2022, 12, 8159. https://doi.org/10.3390/app12168159

Zhang J, Liu Y, Qin X, Dou Z, Xu X, Lv J. Optimization Design and Analysis of Bionic Friction Reducing Nozzle in Oil Shale High-Pressure Jet Mining. Applied Sciences. 2022; 12(16):8159. https://doi.org/10.3390/app12168159

Chicago/Turabian StyleZhang, Jiansong, Yongsheng Liu, Xing Qin, Zijun Dou, Xiaonan Xu, and Jianguo Lv. 2022. "Optimization Design and Analysis of Bionic Friction Reducing Nozzle in Oil Shale High-Pressure Jet Mining" Applied Sciences 12, no. 16: 8159. https://doi.org/10.3390/app12168159

APA StyleZhang, J., Liu, Y., Qin, X., Dou, Z., Xu, X., & Lv, J. (2022). Optimization Design and Analysis of Bionic Friction Reducing Nozzle in Oil Shale High-Pressure Jet Mining. Applied Sciences, 12(16), 8159. https://doi.org/10.3390/app12168159