1. Introduction

“Hand tools” are regarded as tools that are held in the hand or manipulated by the human hand without the application of power or force from any other source of mechanical energy. In other words, the hand is the source of power for the operation of these tools. The term “evolution” refers to the development of various hand tools, from their primitive forms to their modern models. The use of these tools in connection with the processed material, respectively wood, is the only phase of their usefulness to be considered in this paper. On the other hand, we must recognize the possibility of using some of these tools in other areas of activity; for example, the prehistoric stone hammer and axe were most likely first used as weapons and as tools for killing animals for food. Perhaps these tools had been used for thousands of years for these hunting-related fields before they were ever adapted as woodworking tools. There is a relative lack of information in the history databases on the evolution of hand tools in the field of woodworking, which limits the sources of information consulted [

1].

The development and increasing use of tools and implements reflects the progress and increase in the level of civilization. It seems that the first inventions of man were tools to improve his living conditions and to provide new methods that would allow him to work more easily and efficiently. Every new tool that has come into permanent use has proven to be an important milestone in the development of humanity. This trend of progress has been slow, sporadic, and uncertain; people have learned slowly but steadily how to create better and more precise tools with which to build and arrange their houses, build bridges, and do everything that is necessary to enhance the comfort, security, and enrichment of life. Thus, it becomes clear that the woodworking tools used today represent many eras of experience gained by mankind, and a person who wants to handle these tools with expertise must acquire knowledge and skills in their use [

1].

It can be seen that a series of hand tools have been developed over time, have been perfected, and specialized versions have appeared for various purposes, types of materials, shapes, and sizes of the raw material; however, over time they have reduced significantly, their role being taken by other instruments, not necessarily hand tools. Thus, a significant number of hand tools have been made obsolete today by teams of workers trying to increase the quality and productivity of work. We can list several hand tools that will completely disappear from the equipment of workers specialized in certain manufacturing technologies, especially for the primary processing of wood or stone: saw, hammer, manual drill, chisel, and planer. At the moment, there are no such hand tools in the endowment of the specialized teams, they are being totally replaced with those with electric drive which bring added value to the manufacturing processes, related to precision, productivity, repeatability, and ease of use, low prices, and the elimination of some specializations of the workers. For example, nowadays, manual drills or planers for finishing wooden surfaces can hardly be found in stores.

Therefore, an important step for understanding the operation of old hand tools—which are part of cultural heritage—is, in addition to keeping the tools properly in physical format, the realization of equipment that can physically reproduce the sensations that occur when using these tools. More precisely, using the virtual reality (VR) technologies available today, it is proposed to create adjustable test benches that can generate haptic return forces, simulating the operation of hand tools.

Virtual reality in cultural heritage deals with digital reconstructions of historical artefacts and sites to enhance the users’ experience. New technologies have made possible the use of advanced tools to provide custom-made interfaces for virtual museums, artefacts, exhibition enhancements, and archaeological site reconstructions [

2]. Among these technologies, haptic devices bring more realism in an immersive virtual environment as a modality to touch and feel the sensation of force when exploring virtual artefacts.

Haptic force-feedback is generated by software-controlled forces and by feeding it to the users to provide them the sensation of interaction. Beside seeing the virtual objects, the sense of touch is also important to increase the sense of presence. With haptic devices, users can perform procedures and maneuvers that trigger both force and visual responses from the VE, creating tangible cultural heritage experiences [

3]. Visual and interactive content helps users comprehend and remember historical information [

4,

5]. Following the recommendation from [

6], we designed and developed a multi-modal virtual environment to present and preserve an antique carpentry tool via a visual and haptic interface.

The idea of this paper appeared when the authors noticed that in the endowment of the teams of workers in the field of wood processing, the tools and hand tools had started to disappear. Now, the vast majority of woodworking operations are achieved with power tools, reducing the physical effort of operators, and increasing accuracy and productivity. It is noticed that newcomers in the field no longer recognize the old tools and their uses. Therefore, in addition to the normal activities of storing these tools, we also propose an approach using virtual reality technologies, especially those related to haptic return.

This paper is structured as follows: in the

Section 2, we present background information about the use of the hand saw in history, as well as the use of mechanisms for generating haptic feedback in virtual reality applications. In the following section, a study is detailed regarding the kinematics and dynamics of the operation of a hand saw, with the aim of finding the trajectory of the handle and the cutting forces, as well as the vibrations in the handle.

Section 4 presents the operation of the custom-made mechanism, which is followed by the design, construction, programming, and realization of the virtual environment, and the connection between the physical mechanism and the components of the virtual environment.

Section 5 presents a user study that sought to obtain feedback from users regarding the quality of the interaction with the created equipment; this is followed by a discussion and conclusions.

2. Background Knowledge

2.1. History of the Hand Saw

According to historians Plutarch and Pliny, skilled workers have been recognized and organized into associations or guilds since a very early period (late eighth century BC). From such historical sources, as well as from inscriptions on various monuments, we know that woodworking in the Roman Empire belonged to a larger group of manual crafts practiced by craftsmen; Latin speakers called these skills

ars. The practitioner of an

ars was a person who, through training and experience, demonstrated a systematic knowledge of a technique to the point where he could live from it. The English derivative of

ars, art, can be used similarly in this broader sense [

7].

It can be understood from an examination of the Latin language found in literary sources and funerary inscriptions that there were a number of subspecialties included in the practice of the woodworker. The slave or soldier who dragged a log from the forest must not have followed the same preparation for its existence as the one who modeled the wood to make a finely crafted chest (the job of

arcularius). Such distinctions between skilled and unskilled can certainly be made, for the most part, on the basis of common sense and our own modern conception of mastery [

7].

Romans born into wealthy families did not have much chance of becoming skilled carpenters, but rather chose professions in the fields of medicine, acting, or painting. Most woodworkers, similar to their counterparts in other trades, such as metalworking, leatherworking, weaving, glass blowing, or inlay work were slaves (servants), freed slaves (freemen), or free-born common people without land. On the other hand, among these ordinary people, it is easy to imagine a stratification based on learned skills (arts), membership in guilds, and official positions within the guilds themselves. Woodworkers were, similar to other traditional craftsmen, individuals who earned their living by manual labor. The product of their trade was a physical object, always utilitarian, and sometimes of great aesthetic value [

7].

The Encyclopedia Britannica defines carpentry as “the art and trade of cutting, working, and joining timber”. The term includes both structural timberwork in framing and items such as doors, windows, and staircases [

8].

During the Roman Empire, carpentry progressed enormously, making people’s lives more comfortable through construction and products. Roman carpenters took huge steps in construction techniques that remained unmatched for over one thousand five hundred years. The carpenter’s tools have been improved, taking over features from the tools of colleagues in other trades, especially blacksmiths. Another important consideration for Roman carpenters was the population census, a mandatory activity for all Roman citizens, carried out every five years. Thus, registration was the only way a novelist could ensure that his or her identity and status as a citizen were recognized. A master who wanted to free his slave only had to put him on the censor’s list as a citizen. By this provision, many carpenters were promoted on the social ladder, moving from the status of slaves to that of free citizens [

9].

There is various evidence of the use of saws from ancient times to the present day. Artifacts have been found in very good condition, dating from the Egyptian [

10] or Roman [

11,

12] eras. At the same time, there is evidence recorded on the painted walls of various buildings in ancient Egypt, in scenes from the mortuary chambers of Egyptian kings [

13], or in the Roman Empire, in painted frescoes in Pompeii-“Casa del Falegname” [

14], or in bas-reliefs-stele at the Museo del Campidoglio. Closer to our times, in Westminster Cathedral, there are scenes painted with carpenters and using various tools, including saws [

15].

2.2. About Haptics, Mechanisms, and VR Technologies

Many higher education institutions are making rapid progress in the field of information technology, with an emphasis on reshaping students’ learning styles. Higher education institutions can increase pedagogical efficiency based on strategic investments in the use of these emerging educational technologies to meet the increasingly diverse learning needs of students [

16].

On the other hand, the models used in industry for the study of mechanical systems are becoming increasingly complex. Many learning situations require the student to mentally transform 2D objects into dynamic 3D objects. To easily understand scientific concepts, in order to describe the dynamics of a model, to anticipate how changes in parameters influence other factors, or to reason qualitatively about some physical processes, students could use models effectively in a 3D space. Today, the PC’s standard desktop interface is complemented by a multi-user virtual environment in which partners interact with each other.

Thus, the approach in [

17] is based on the interactions between the visual interface and haptic perception. This study refers to a simulation on the principles of articulated mechanisms using both visual equipment and haptic feedback. In [

18], a teaching method in which learning activities are performed in the virtual laboratory (VL) is presented.

All the research presented above demonstrates the attractiveness of the proposed concept, especially the advantages involved in haptic feedback [

17,

18]. The system proposed in this paper involves the use of dedicated haptic devices, which are not generic, being designed from the beginning for specific applications.

In this way, the aim is to minimize the volume occupied by the device itself, to use only the usual equipment found on the market. The user interface is flexible and easy to use, guaranteeing easy customization of the simulated mechanisms. Additionally, the decrease in the costs involved in the realization of the study equipment, as well as the action in the direction of the observance of the ecological norms, is considered.

Virtual reality is a field of study that aims to expose the user to an experience that mimics real life. The experience is considered synthetic, illusory, or virtual because the sensory stimulation of the user is generated by the system. In general practical cases, the system used consists of a series of equipment: sensors to detect user actions, a computer that processes user actions and generates output data, a display, and other additional devices to improve the perception of reality (speakers, force feedback devices).

To simulate and generate virtual experiences, developers create a virtual environment (VE) which is usually composed of spatially organized objects (called virtual objects), presented to the user through sensory displays. Virtual reality allows the user to ignore physical reality in order to experience a virtual change in time, space, and/or the type of interaction: interaction with a reality simulation environment or interaction with an imaginary world.

The theory of mechanisms and machines is a very opportune field of scientific education to implement haptic interfaces and one in which experiments can be performed where the student can both apply forces and be answered by feedback forces. Since there are very few examples of custom-made haptic systems in the literature, most systems use general haptic equipment from the market; several examples of mechanisms that can be used in VR applications with haptic feedback have been identified, which we present below.

Patent JP2008217260 [

19] discloses the operating algorithm of a force-response device. The problem here is to give a user who touches a virtual object the feeling of real touch. The suggested solution refers to determining the direction of the operating force (whether it is towards or away from the virtual object) and calculating, subsequently, the positions of the fingers in order to obtain the realistic touch sensation.

Patent CN201543166 [

20] discloses a force-generating apparatus. It consists of a reversible electric motor controlled by a driver, a direct current source, a speed sensor, a moment sensor, a current sensor, and a microprocessor. The motor is connected by a transmission to a moment-producing mechanism and transmits an active feedback force; the driver has the role of controlling the reversible engine; the speed sensor, torque sensor, and current sensor are used to acquire data on the rotational speed and output torque, which are transmitted to the microprocessor, which sends PWM signals to the driver and can adjust the motor outputs by modifying the PWM signals, thus being able to generate dynamic effects.

Patent US2011181405 [

21] discloses a haptic interface, consisting of a shaft of rotation with a longitudinal axis on which is fixed a user-operated lever, an interaction element with a rotating magneto-rheological fluid in solidarity with the shaft, a system for generating a magnetic field in the fluid, and a control unit capable of generating commands for changing the magnetic field. The system includes a coil-type mechanism that generates a variable magnetic field, and a permanent magnet mechanism that generates a permanent magnetic field. It is observed that this equipment can generate a resistance force, with an intensity that can be modified, to the action of the user of turning the lever.

Patent EP1598724 [

22] discloses a system consisting of an electric current source which supplies an electric motor, on the shaft of which an operative part is jointly mounted. A central unit calculates the rotational speed of the shaft according to the movement detected by an encoder and controls the torque generated by the motor according to the rotation of the operating part. All of these components are mounted in a housing so that moving parts slide into a high-viscosity environment to simulate strength.

2.3. VR Technologies in the Presentation of Artifacts

There are elements of cultural heritage that either are not in a suitable physical condition (they cannot be directly exposed in various exhibitions and museums within the reach of visitors or the general public), or no longer exist (having disappeared but for which we have a series of clear historical evidence and functional replicas can be reconstructed), or are part of intangible heritage (legends, dances, songs, etc.). For all these cases, there are various approaches, all of them aiming to identify methods using new technologies that can enhance these artifacts.

In this sense, the study from [

23] can be highlighted, which aims, based on an in-depth survey on the use of VR technologies and new interaction paradigms, to increase the public’s interest in cultural heritage. Thus, based on the characteristics of these methods in terms of interaction and immersion, it was aimed to achieve a clear classification of the technologies that can be used in this field, offering a tool for framing VR systems that suggests indications related to costs, usability, and quality sensory experience.

A series of virtual reality components have been identified that can be successfully used in the presentation of artifacts. Thus, augmented reality, a technology that allows the user to see a combination of a mixed scenario generated by a computer, in which virtual objects are combined with the real environment, is being studied by several researchers [

24]. In addition, for applications to present cultural heritage elements, in [

25] and [

26] multi-modal, mixed-reality technologies are used, which allow the real-time construction and interactive manipulation of photo-realistic virtual worlds based on real data sources. These applications have a high degree of interactivity and include provisions for other senses besides the visual (haptics and sound).

However, several researchers considered that the sense of touch, in the case of studying or observing an artifact, brings an important added value. Therefore, there are several ways to approach the problem. In [

27], it is proposed, before the construction of haptic equipment, to carry out a survey/studio to compare the experiences felt during the handling of a 3D-printed replica of the artifact with those experienced during the handling with the help of a gamified haptic interface based on the SUS scale and the AttrakDiff2 questionnaire. The obtained results showed that the proposed haptic interface is suitable for people who normally use mouse-based computer interaction, but without previous experience with haptic systems.

An area very much covered by research is that of museums and the exhibition for visitors of functional replicas or digital interfaces based on VR technologies, including haptic feedback. Thus, in [

28], a system is proposed that can be exhibited in “Museum of Pure Form” museums or displayed in a professional environment, such as CAVE.

Other experts use for artifacts interfaces based on dedicated equipment (e.g., Sensable™ Omni 6DoF, FALCON haptic device), which can be found on the market, developing only applications dedicated to specific artifacts whose digitally reconstructed 3D model is visualized on a computer display or in 3D glasses [

29,

30,

31,

32].

Another direction of research is the complex study of some elements of intangible heritage, an example being the “Gion Festival in Kyoto” [

33]. In this project, users can experience the things and events related to the Gion Festival with multiple virtual reality technologies, the interactive system being based on five human senses, such as the visual and haptic senses, the high-quality sounds of the festival music, and the virtual floating ceremony Yamahoko in the combined visual 3D environment.

Consequently, it can be said that there is a tendency to study the components of cultural heritage using VR technologies, including mechanisms with haptic feedback. It can be observed that most research of this type is carried out with the help of dedicated equipment on the market, less dedicated equipment, built especially for specific applications.

3. Kinematics and Dynamics of the Saw Handle

In this section, the operation of the hand saw is analyzed by conducting a user study on the trajectory of the handle together with the forces and vibration present during its operation. For this study, an extension of the handle was designed and various sensors were mounted on it.

To build haptic equipment that can be a close replica of a real saw, we must take into account its operating characteristics. We will have to take into account the trajectory (spatial position relative to the user) of the saw handle, as well as the reactions (forces) that occur during the operation of the saw.

3.1. The Trajectory of the Handle

To determine the trajectory of the saw handle, various films were analyzed, as well as operators in the activity of cutting a wooden log or board. It was found that the trajectory is almost rectilinear and there are also secondary movements (vibrations produced by the saw teeth) in the perpendicular direction to the main direction of the cutting movement. The length of the stroke is approximately equal to the toothed length of the saw blade.

Consequently, equipment that can replicate a rectilinear stroke in a horizontal plane having a stroke equal to the saw blade satisfies the operating requirements of the test bench (

Figure 1).

3.2. Measurement of Shear Forces

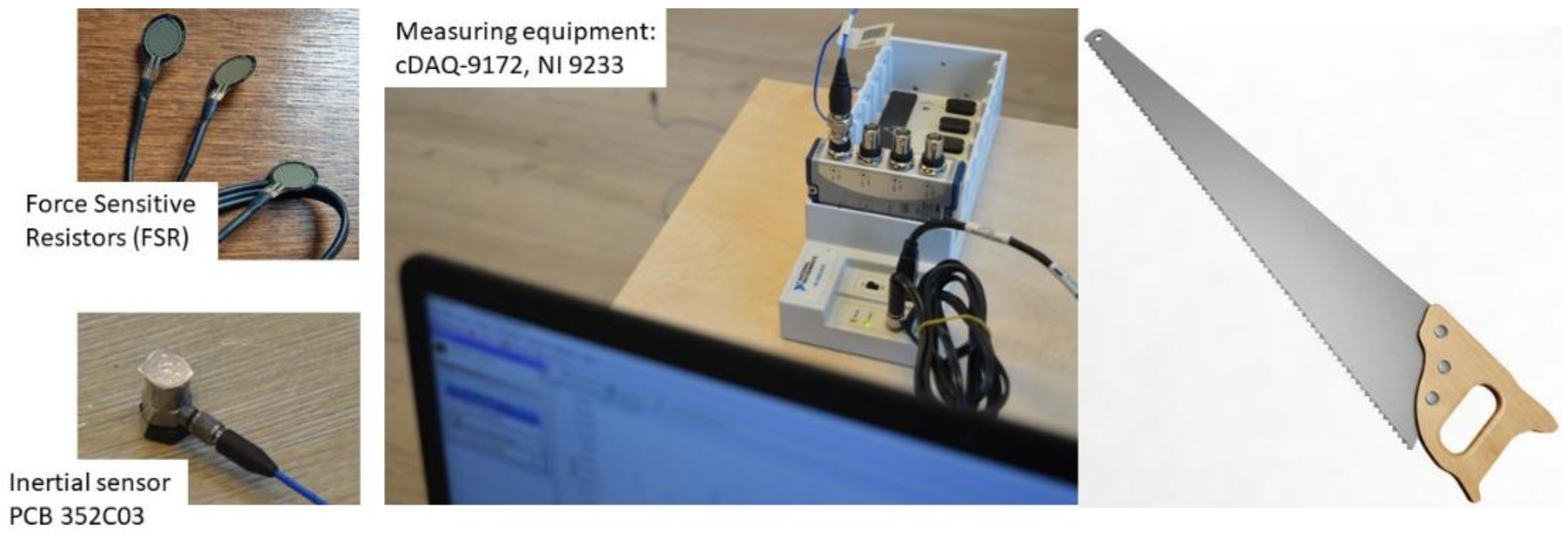

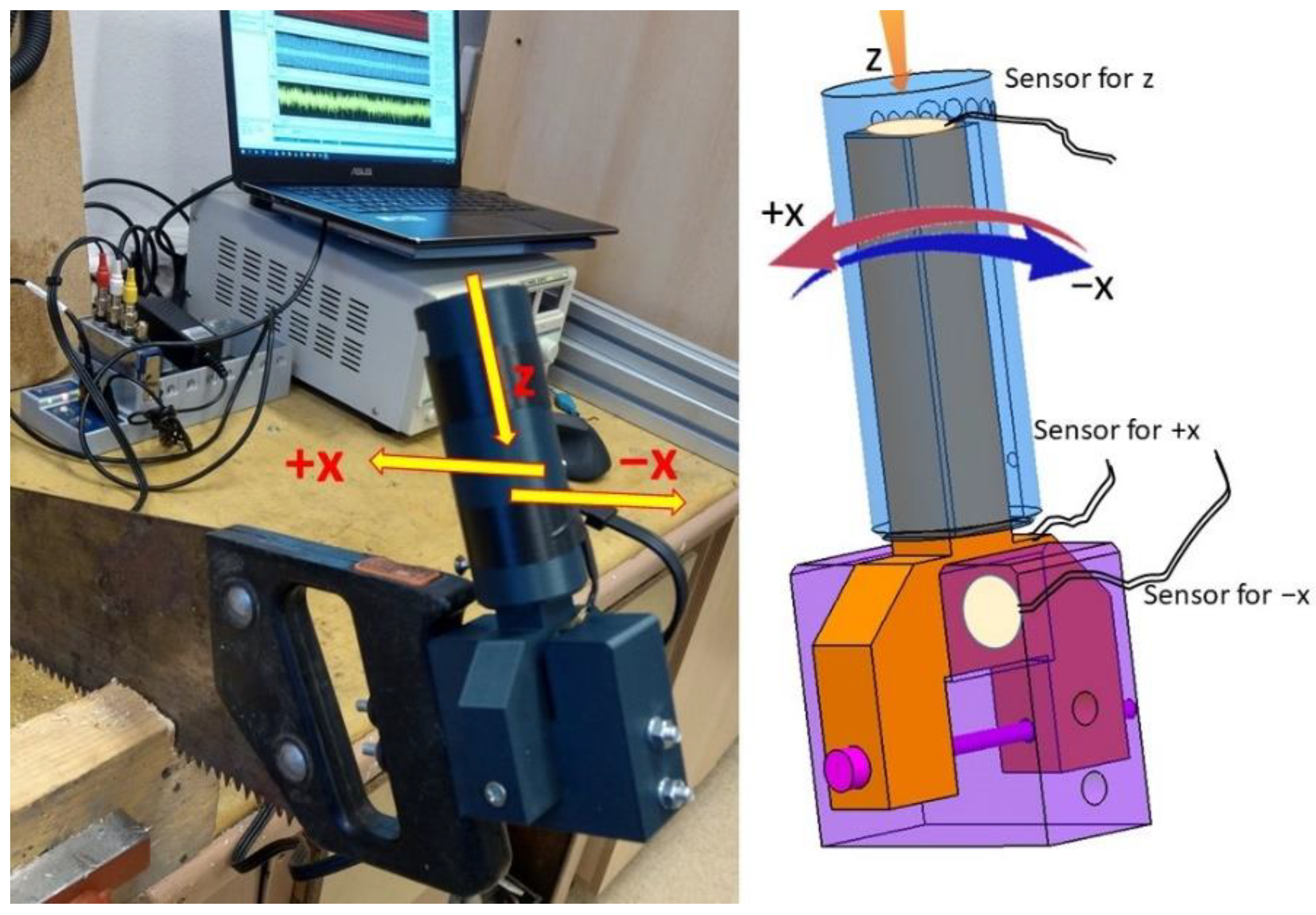

To determine the values of the reaction forces to be simulated in the saw handle, a measuring bench was prepared using a hand saw and measuring equipment for the forces and vibrations.

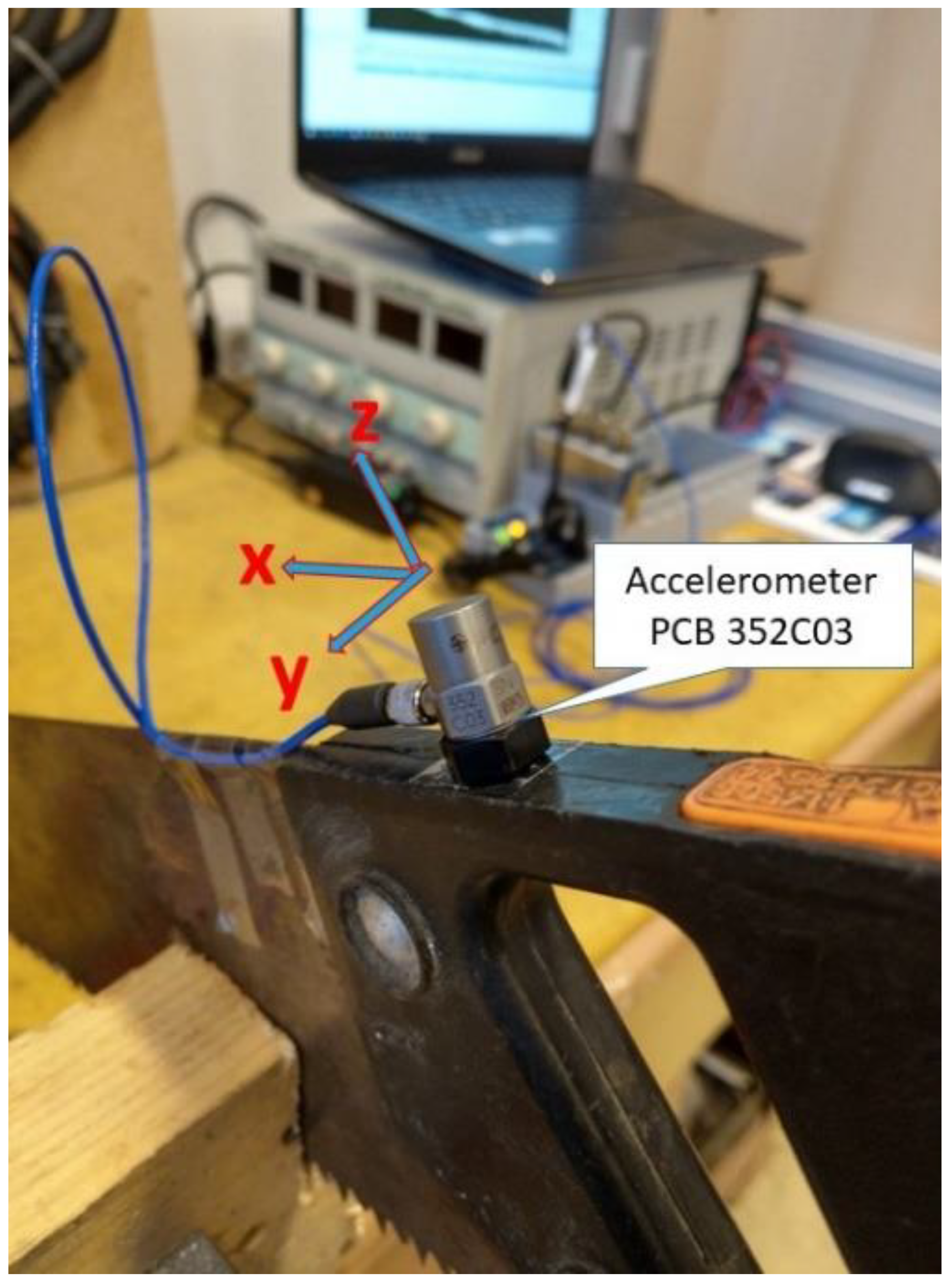

The entire measuring equipment, manufactured in Europe according to EU standards, is shown in

Figure 2 and consists of a chassis of type NI cDAQ-9172, an analog acquisition board NI 9233, a transducer (accelerometer) PCB 352C03, and a pressure sensors-force sensitive resistor (FSR), together with the LabView SignalExpress 2010 software.

In order to measure the forces required to cut a board of wood, a device has been designed and built that can measure the force exerted by the human operator by using three pressure sensors in the following situations: longitudinal push (+x), longitudinal retraction (−x), and push in the vertical direction (z).

These touch sensors are able to detect pressure, having a sensitive surface with a diameter of 1/2 inches (1.27 cm). The sensor has two connectors and the resistance measured between these two connectors varies with the pressure. When nothing presses on the sensor, its resistance is greater than 1 megaohm, and as pressure is applied, the electrical resistance decreases. The FSRs are basically a resistor that changes its resistive value depending on how much it is pressed. The force range is 0 to 20 lbs (0 to 100 Newtons) [

34].

Because these sensors are not specially designed to measure forces, having a rather low accuracy and repeatability, a calibration was performed using standard masses of 100 g, 200 g, 500 g, and combinations thereof. Based on the measurements, a graph was plotted representing the electrical voltage measured at the sensor terminals compared to the applied mass. The recorded values did not lead to a linear graph but, considering that a very precise determination is not followed, we extracted from the graph a linear trend, in the form of a one-degree equation. This dependence, electric voltage/force, will be used to calculate the values of forces during the sawing process for measuring the reactions in the saw handle, presented below.

An extension of the handle was built by 3D printing (

Figure 3). It was mounted on self-adhesive facets and the contact with the moving part was made by means of small silicone rubber elements, also self-adhesive, which approximately copy the shape and rigidity of human fingers.

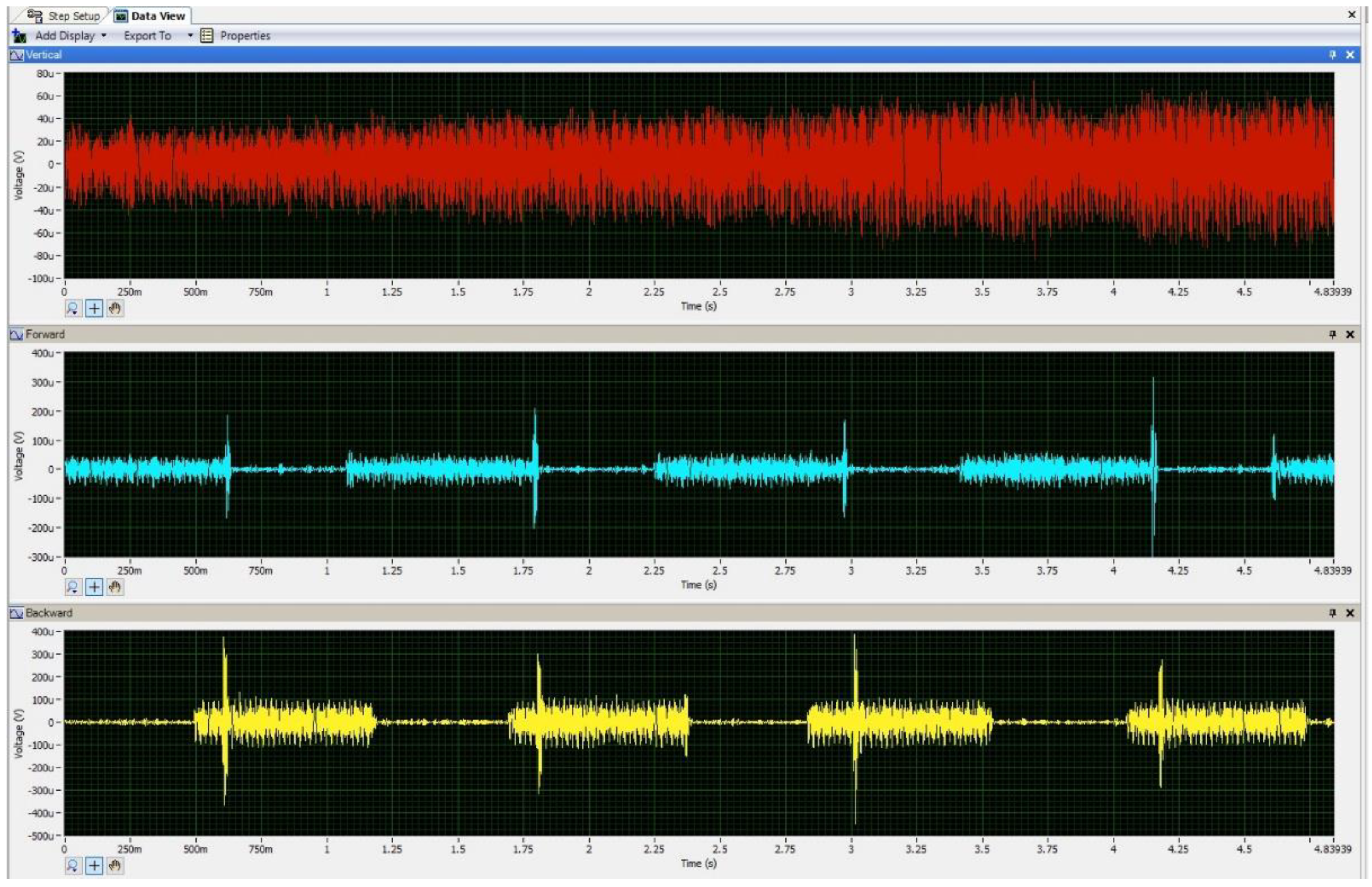

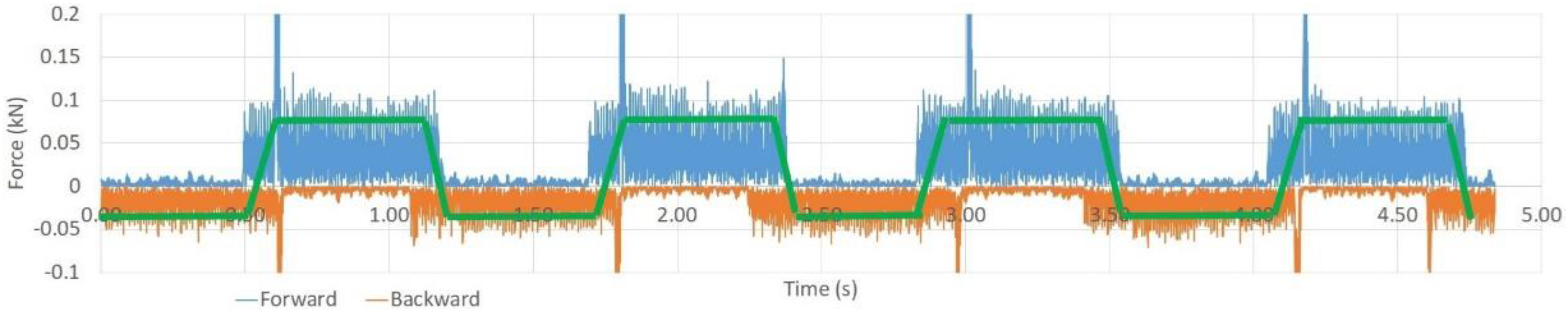

Five-second-long signals were captured with a frequency of 2 kHz. Approximately equal values were found for the movements in the longitudinal direction for pushing and pulling the saw (forwards and backwards), and for the vertical direction an approximately constant force was observed.

The recorded values (

Figure 4) were processed, the values of the measured forces were superimposed on the forward (blue color) and return movements (orange color) in

Figure 5, and, depending on the calibration curve, the distribution of forces was obtained in the process of using the saw.

The force values in

Figure 5, represented by the green line, which is an average of the measured values, which are in a very irregular shape, with many peaks, will be further used in the haptic system.

3.3. Vibration Measurement

Vibration measurements were performed with National Instruments vibration measurement equipment, LabView Signal Express data processing and analysis software, and a personal computer.

The three-directional piezoelectric vibration sensor PCB 352C03 was mounted by gluing on the saw handle, and the corresponding accelerations were measured during the operation of the manual saw (

Figure 6). The vibrations were recorded in batches of 5 s, with a frequency of 2000 Hz. The shapes of the recorded signals can be seen in the figure below (

Figure 7), where the main frequency that represents the change in direction of the saw was identified.

According to the graphs, in the measurement of 5 s, a cycle could be identified which was repeated about 15 times. Based on the recordings, it was estimated that a round-cut cutting cycle takes place in 0.6 s, we can say that the cutting frequency is around 1.67 Hz.

Vibrations have a complex harmful action on life, affecting the health of the human body, the quality of human work, the strength of the components of machines and constructions, the quality of operations and products made by different types of machines, etc.

The action of vibrations on the human body can be correctly assessed only if several of the mechanical parameters that characterize the movement are considered simultaneously such as the frequency, amplitude, and acceleration or vibration energy.

The vibration movement can have a single component at a certain frequency or several components existing simultaneously but at different frequencies.

Frequency analysis is the method by which the component frequencies are highlighted, the global signal being decomposed into a sum of frequencies, each corresponding to a certain level of vibration.

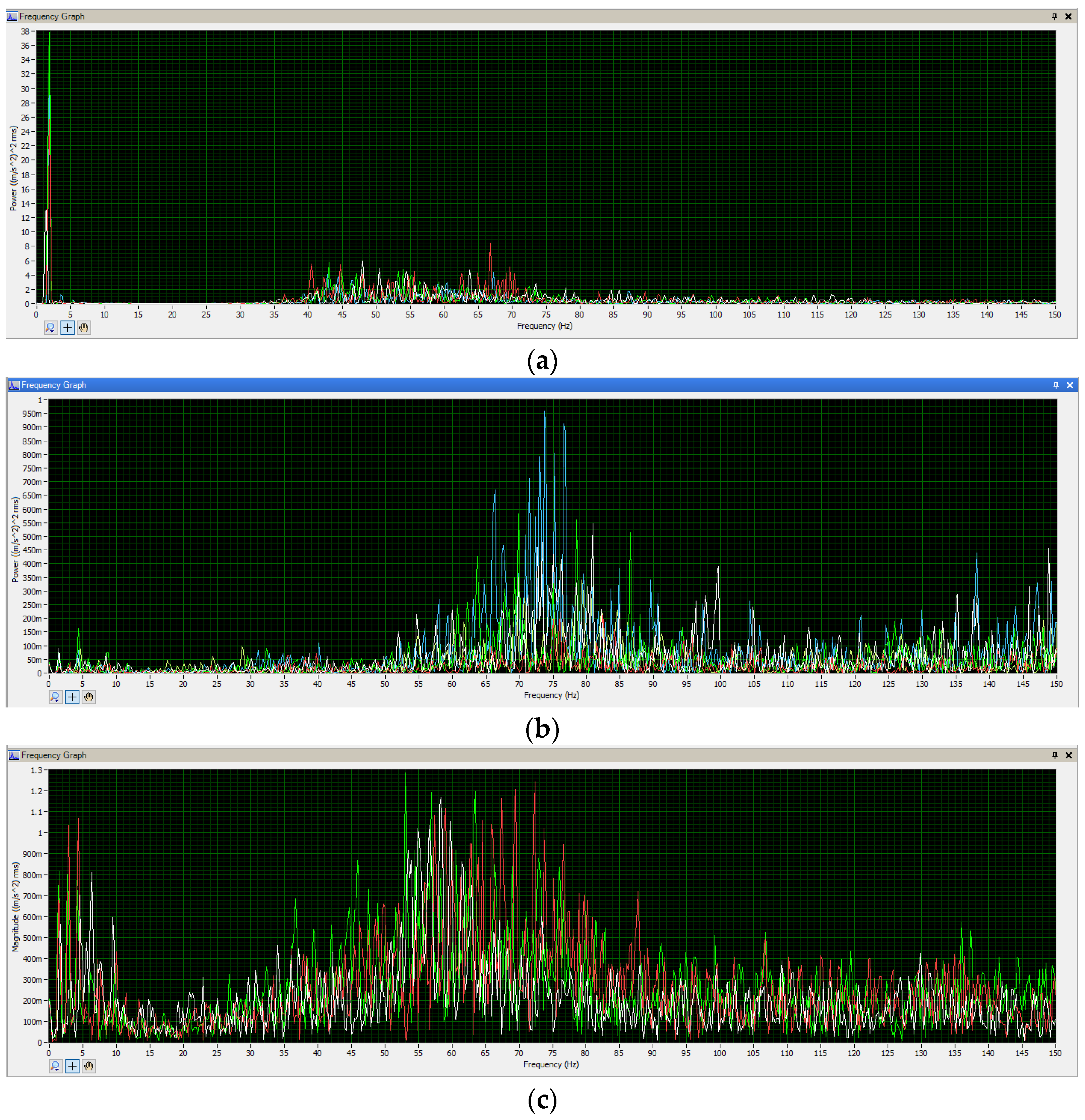

It is observed that there is a finite number of frequencies at which the signal amplitude is higher. The graphs obtained from the measurements were analyzed and the values of the amplitudes of the vibration acceleration depending on their frequency were highlighted, in the range of 0.5–150 Hz.

On all three graphs of the frequency spectrum (

Figure 8), in the three directions, two areas with a higher signal intensity can be observed: the first is located in the range 1–5 Hz and corresponds to the main cutting movements of the saw, i.e., the movements of pushing–pulling in the longitudinal direction (+ x and −x) and the second area, with lower values of intensity, is located in the range 45–80 Hz, which corresponds to the frequencies generated by the teeth of the saw in contact with the material that is cut. These frequencies also depend on the speed of use of the tool by the human operator. Next, in the design of the haptic tool, we will consider an average value of this frequency of about 60 Hz.

4. Construction and Operation of Haptic Equipment

In this section of the paper will be presented the steps we followed to design and build the haptic device. We started by constructing a planar mechanism that would be able to reproduce the movement of the saw handle in terms of the trajectory. Based on this theoretical mechanism, we designed and built the haptic equipment that was equipped with motors and sensors. An important stage was the programming of this equipment to properly reproduce the path and the force feedback of the handle, by calculating the trajectory and imposing the haptic force.

4.1. Design of the Haptic Equipment

4.1.1. Mechanism Design

The degree of freedom (DOF) of the haptic device is the number of directions of the allowed motion. The proposed haptic device must respond to the user’s action by providing the necessary force and vibration feedback as in the process of sawing and, at the same time, to guide the handle of the device on the required trajectory. Usually the force-feedback can be accomplished with admittance and impedance control, depending on how it is reacting to displacement or force. In this case, the two types of feedback (force and trajectory) have to be coupled: the device must respond to the user’s pulling and pushing movements with the proper force and trajectory. The solution is a haptic device with a kinematic structure with two DOF and with two actuators. This structure will couple the feedback from two directions. Other requirements are a small dimension of the parts to decrease the inertia, a reduced number of mechanical joins to reduce the friction (rotation joins are preferred), and a high structural stiffness to enable quick movements. The trajectory of the handle has to be close to linear, and the position and trajectory of the handle has to maximize the range of motions for the wrist and elbow.

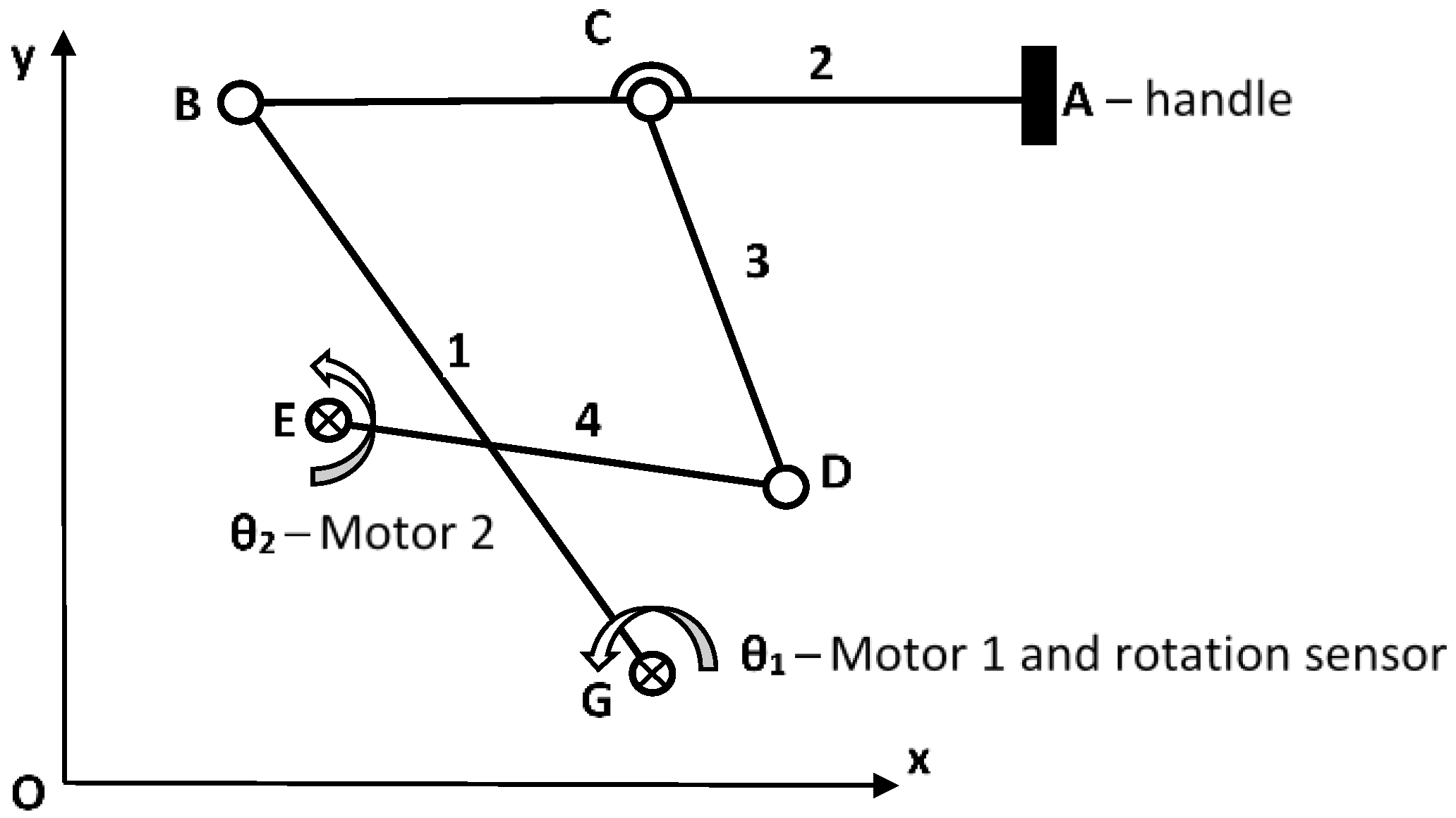

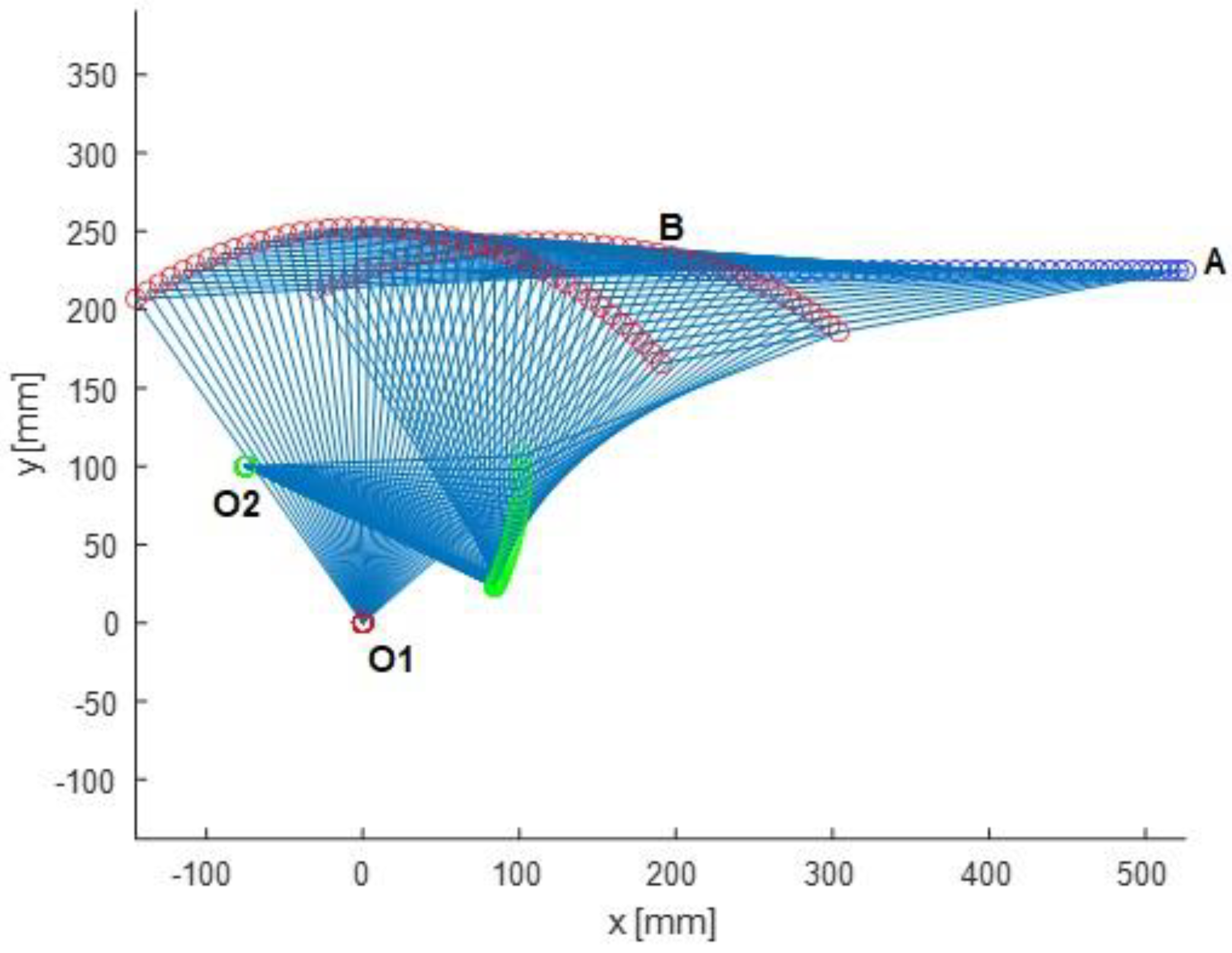

A close chain mechanism with two DOF can be designed with five pairs with one degree of freedom for each. The solution with only revolute joints is presented in

Figure 9. The pairs can be replaced one by one with translational joins, but this solution does not respect the requirements of low friction, low inertia, and high stiffness for quick response.

The proposed solution for the haptic device has five revolute joins (A–E) and four links (

Figure 9). Two motors electric motors are present in the haptic device, one in revolute G (Motor I) and one in E (Motor II). In addition, one rotational sensor is present for the measurement of the rotation in the joint G. Motor I is responsible for providing the force feedback.

The transmission angle is an indication of the efficiency of a power transmission. This is defined by the acute angle between the directions of the velocity-difference vector of the driving point and the absolute-velocity vector of the driven point. The maximum efficiency in the actuators’ torque transmission is in the position when link one is perpendicular to link two, and link four to link two. Due to the long stroke of the handle, these perpendicularity conditions were chosen to be fulfilled only at the middle of the handle’s path.

The horizontal displacement of the handle (xA) is imposed by the user. The task of Motor II is to guide the handle in the vertical direction by imposing the yA coordinate of the handle and to generate the vibrations in the vertical direction.

The angle

θ1 is measured by the rotational sensor, so the coordinates of revolute joint B (Equation (1)) can be easily found:

where

lBG is the length of the link one, the distance between the two revolute joints’ axis of rotation. By imposing the vertical position

yA of the handle, the coordinates of the revolute joint C will be as follows (Equation (2)):

The angle

θ2 which is imposed by the second motor and will generate the required trajectory can be computed as follows (Equation (3)):

where

and

lDE is the length of link four and

lCD is the length of link three.

In

Figure 10, a simulation of the handle’s displacement is shown on a straight path according to the designed mechanism (see

Figure 9), where O1, O2 are the centers of motors 1 and 2, and segment AB represents the trajectory of the handle in operation.

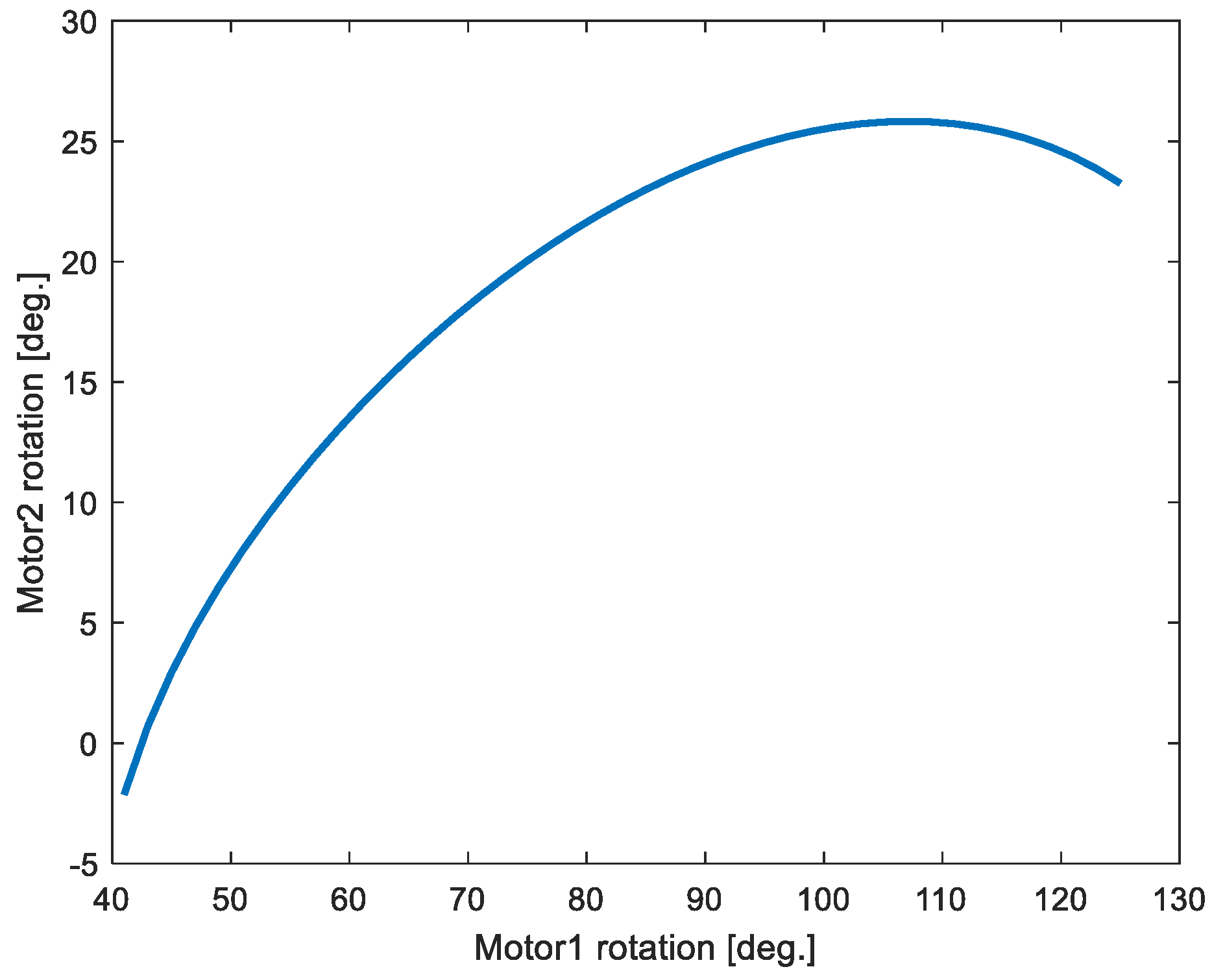

For a linear trajectory of the handle, the coupling of the two angles from Motor I (measured) and Motor II (imposed) is presented in

Figure 11. It can be observed that the point corresponding to the handle can follow a rectilinear trajectory of approximately 250–300 mm between points A and B (

Figure 10), sufficient to suggest the movement of a real saw. This movement will force the two motors to operate within their angular limits.

4.1.2. Equipment Design and Construction

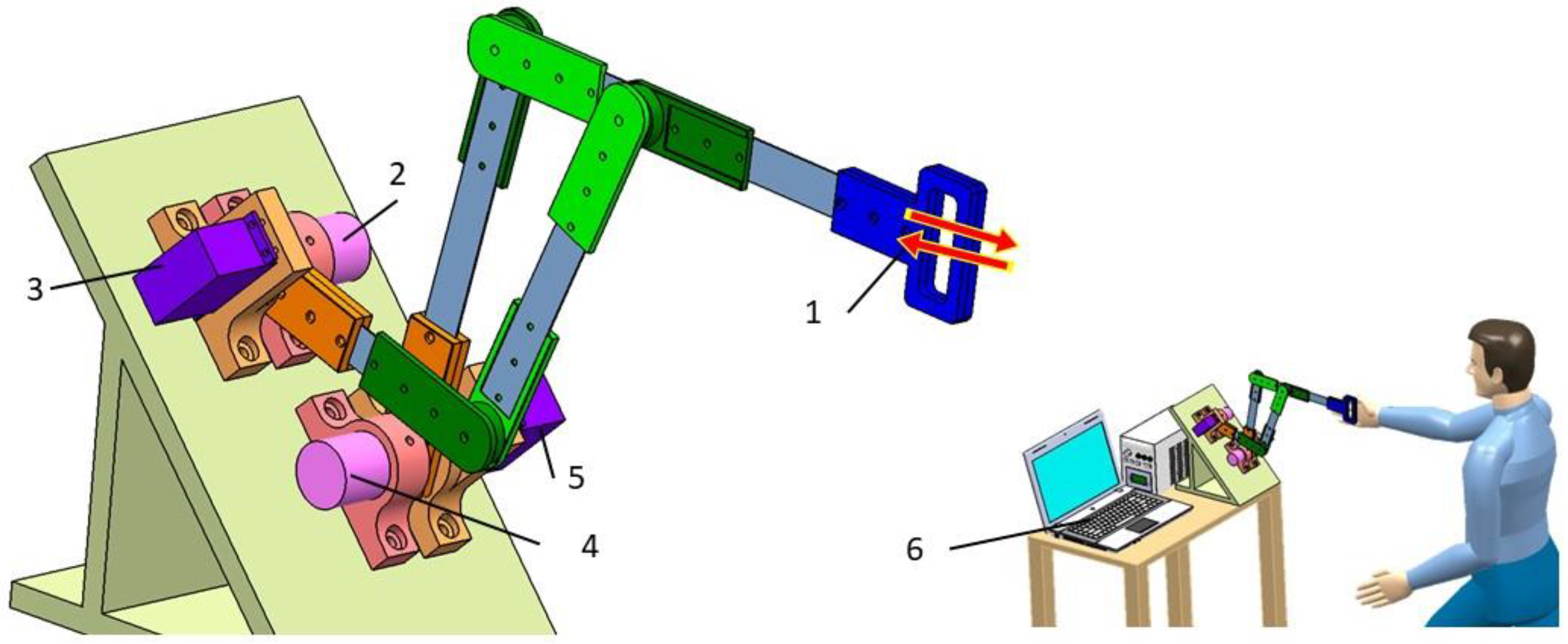

The force-feedback in the haptic device is induced by the torques generated by two gear motors on the shafts of the revolute joints G and E attached to links one and four. The whole assembly is mounted on a support at an ergonomically convenient height.

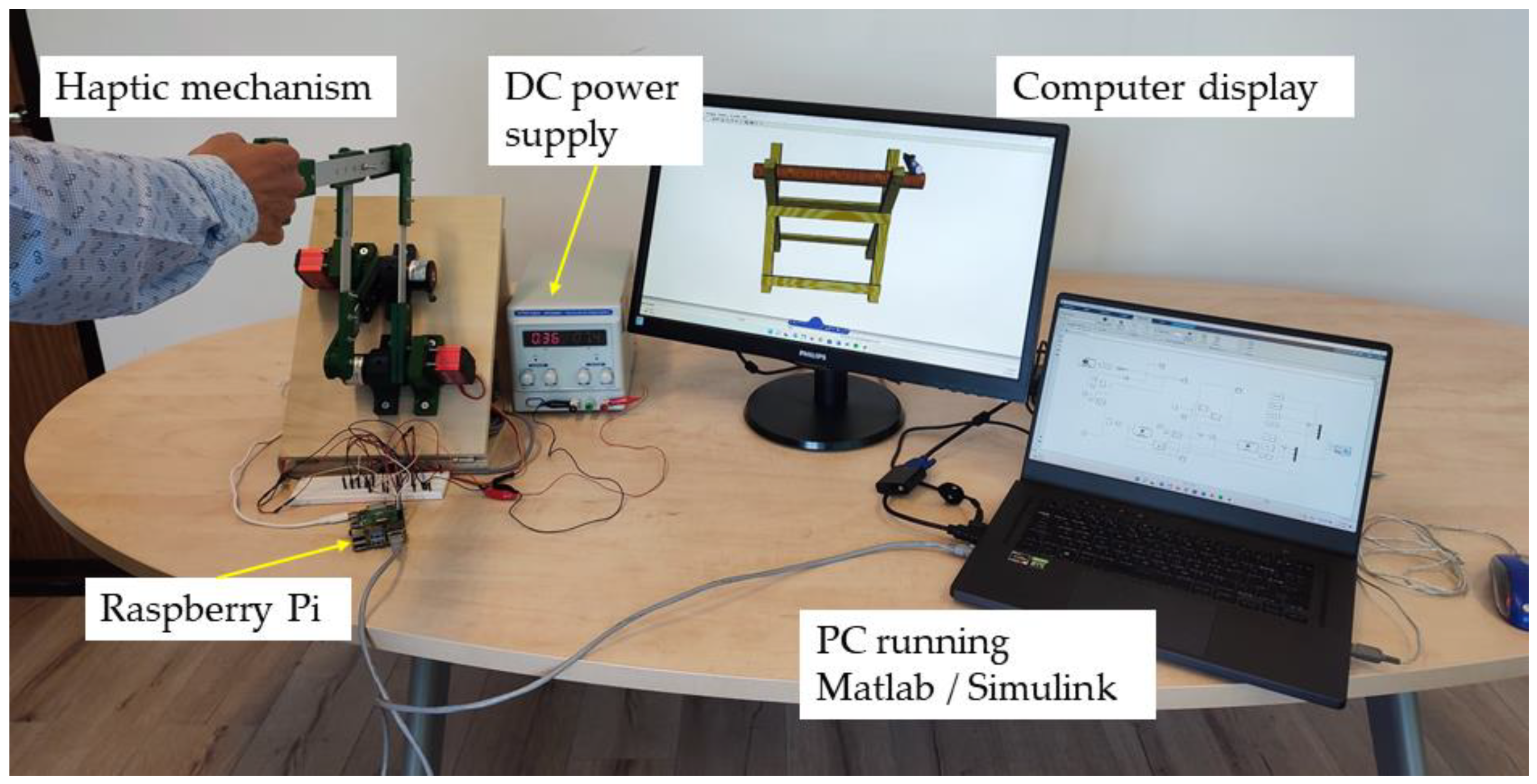

The equipment for haptic simulation, as well as its operation, is presented in the figure below (

Figure 12).

The operation of the equipment is carried out in the following sequence (see

Figure 12): (i) the user pulls the handle (1); (ii) the rotation sensors–encoders (2 and 4) located on the motors’ shafts (3 and 5) detect the time change in the angular position of the mechanism links and transmit the data to the calculation unit (6); (iii) the software application takes the value of the angular variation in the position of the links and introduces them into the calculation algorithm corresponding to the simulated articulated mechanism; (iv) depending on the current position, the value of the reaction force in this position is calculated; (v) depending on the dimensions of the components of the mechanism, the torque (Motor I) and position (Motor II) values are calculated and transmitted to the electric motor control to generate a force and position return; (vi) the user feels, at the handle, the force response of the system, watching, at the same time, the operation of the virtual mechanism on the subsystem of visualization, display, or virtual reality headset.

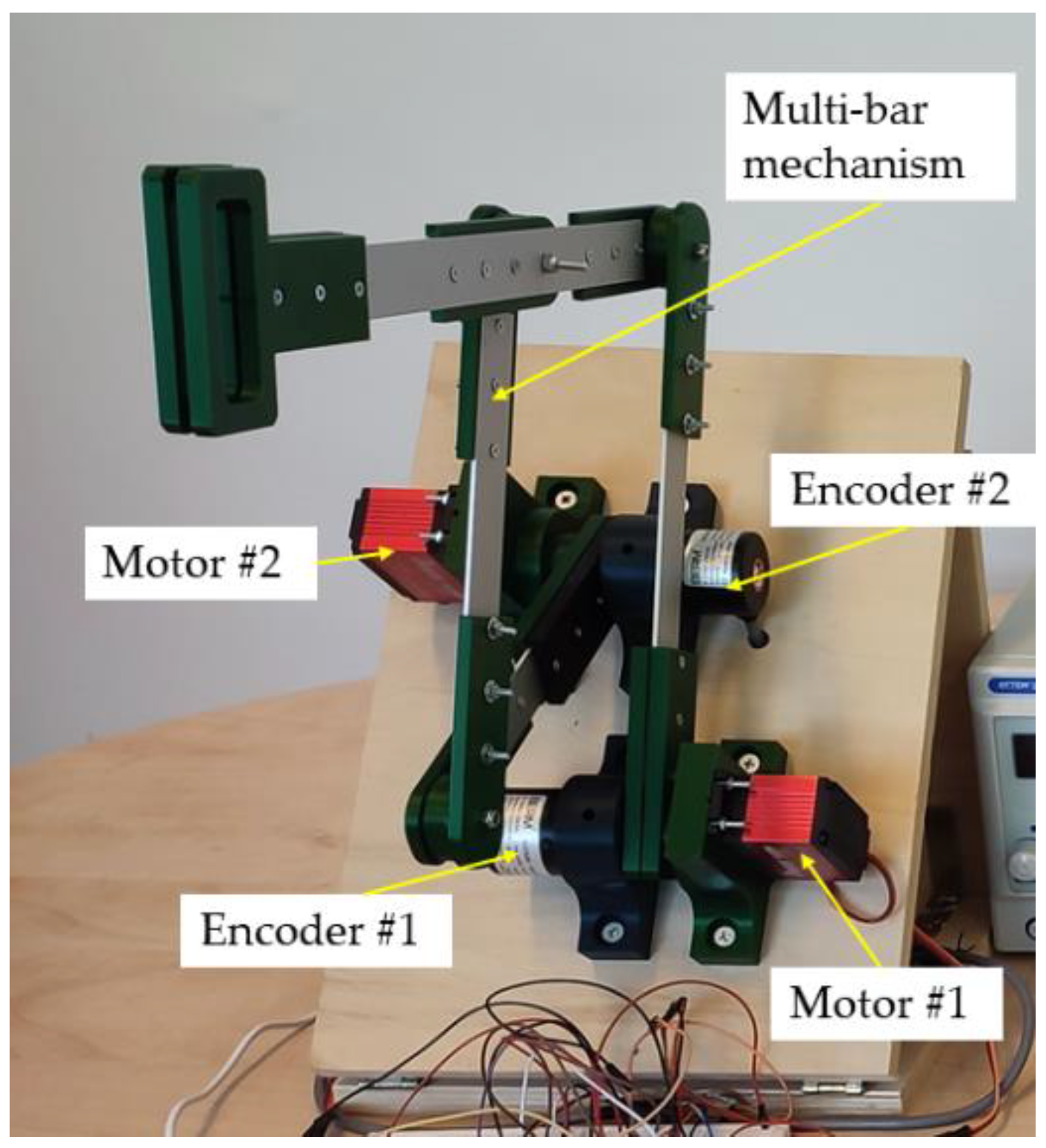

The equipment is shown in

Figure 13. The two gear motors are identical. The HD-1235 MG is a giant-scale (also called 1/4-scale or mega-scale) digital servo from Power HD that can deliver a stall torque up to 35–40 kg·cm (@ 7.4 V or 6 V), at a speed of 0.18–0.20 s/60°. The entire gear train is metal, and the output shaft is supported by two ball bearings for improved performance. This servo works with standard RC servo pulses at frequencies up to 333 Hz [

35].

Because the gearmotors do not have a control of the rotation angle, encoders (rotation sensors of type OMRON E6B2-CWZ6C) with a measuring accuracy of 2500 pulses/rotation were installed.

This assembly meets the specific conditions imposed by the ability of a standard user (operator) to detect movement (power, speed, angular position, torque) and has the possibility of controlling these values through the input data (dimensions of mechanisms, values of forces).

According to the specifications of the gear motors, the haptic device was designed with the linear stroke presented in

Figure 10, and it delivers maximum values of the haptic force in the range 30–50 N, values perfectly distinguishable by an operator.

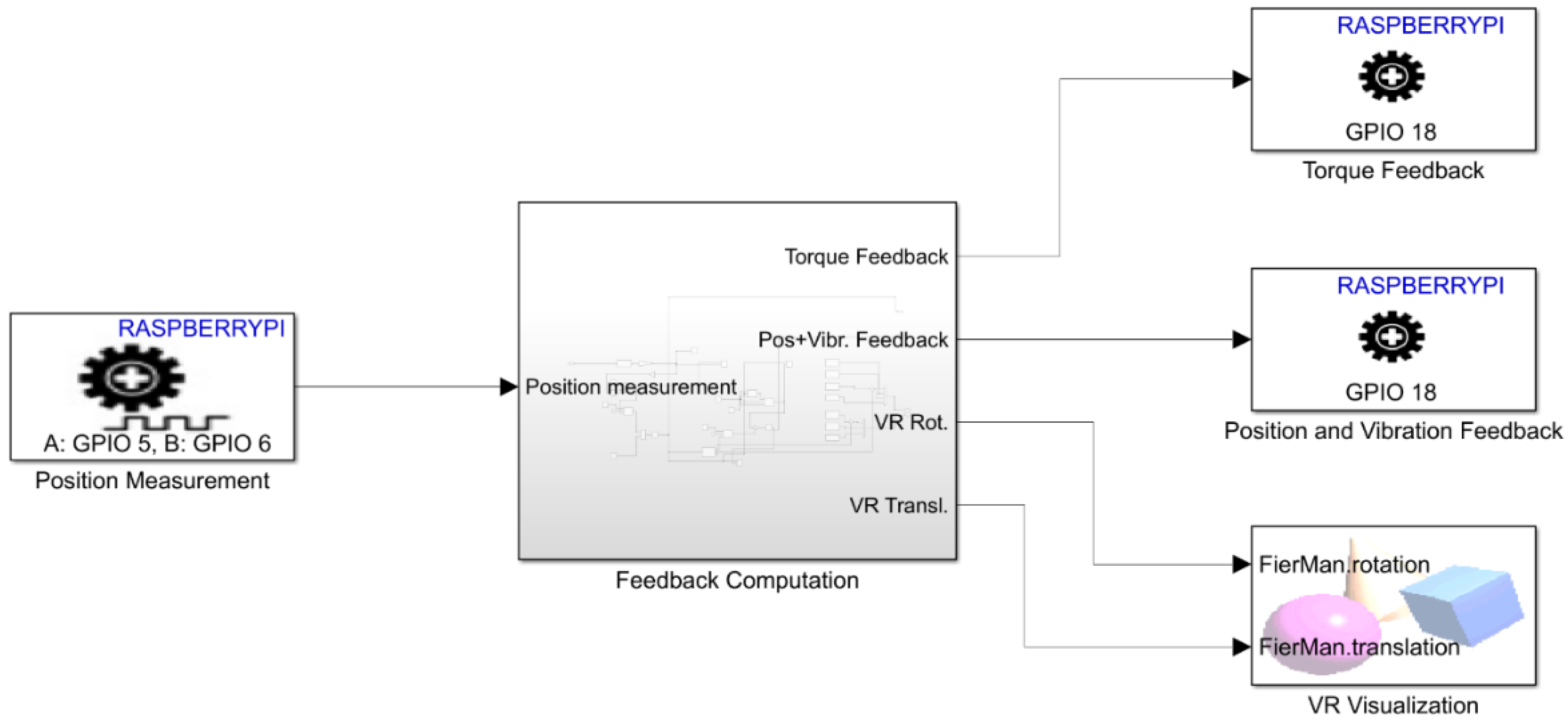

4.2. Equipment Programming

In order to program the equipment, several hypotheses were taken into account:

The handle will move in a complete cycle on the same trajectory; the thrust in the direction of pushing (cutting) is not necessarily identical with the return stroke.

The values of the shear forces, as well as the vibrations felt at the saw handle, are determined experimentally and then implemented in the software application that stimulates the operation and is based on the Raspberry controller.

The shear forces will be generated by the main motor, called the force-feedback motor (no. 5 in

Figure 12); the vibrations will be generated by the second motor, named the displacements and vibration feedback motor (no. 3 in

Figure 12); both motors will be controlled directly from the Raspberry controller, on a dedicated port.

The program made in the Matlab/Simulink software has the possibility to receive input data of various values and will require the introduction of some initial conditions:

Input of geometric data of the mechanism; these correspond to a certain type of saw, with known dimensions of the stroke length;

Imposing limits on the angles of the two main joints (at motors), corresponding to a complete stroke of the saw;

Calculating a dataset or creating a graph with the values of the resisting forces depending on the instantaneous position and the direction of operation, for generating the movements of the motor torques;

Setting the vibration characteristics according to the number of cutting teeth of the simulated saw; this will be done with the help of the secondary motor on which an additional vibration signal will be applied, in addition to the positioning commands.

The steps to follow in operation are as follows (

Figure 14):

Reading the angles from the two encoders to identify the position of the handle;

Reading a new set of angular values to identify the direction of movement;

Identification of the values corresponding to the instantaneous position and the direction of operation;

Sending commands to the motors to achieve the haptic torque and the position/vibration feedback.

Figure 14.

The basic block diagram of the operation of the haptic equipment made in Matlab software.

Figure 14.

The basic block diagram of the operation of the haptic equipment made in Matlab software.

In order to respect the imposed quasi-rectilinear trajectory, there must be a clear correspondence between the rotation angles of the two motors (see

Figure 11).

4.3. Operation of Haptic Equipment

For a good realistic and captivating 3D experience, we decided to create a virtual environment in which the sawing process is visible and a wooden log is to be cut (

Figure 15). The 3D models for logs, saws, and sawbucks were made using 3D-modelling software (CATIA v5 [

36]) and exported as

vrml files. The 3D graphics objects in the virtual reality scenes were connected to the Simulink model with the Simulink 3D Animation toolbox offered in Matlab (see

Figure 14) [

37].

The movement of the saw in the virtual environment is following the trajectory computed in the simulation and is presented in previous sections. The 3D environment uses the physical engine provided by Matlab/Simulink software (

Figure 15).

The virtual saw is related to the subject’s point of view (

Figure 16). The scene consists of several elements placed in a virtual environment with a reconstructed carpentry workshop, in which there is a wooden log on which the saw acts. The virtual scene is updated as soon as the user activates the haptic system.

5. User Study

One of the main goals of haptic systems is to transfer information from the system to the user [

38]. Haptic technology refers to any technology that can create a touching experience by applying user forces, vibrations, or movements.

These technologies can be used to create virtual objects in a computer simulation, to control virtual objects, and to improve the remote control of machines and devices (telerobotics).

In human–computer interaction, haptic feedback means both tactile feedback and force feedback. Touch feedback is the term applied to the sensations felt by the skin, it allows users to feel things such as the surface texture, temperature, and vibration.

Force feedback reproduces the directional forces that can result from various activities: the weight of the grabbed virtual objects, the mechanical conformity of an object, and the inertia [

39].

5.1. Conducting the Study

Evaluating haptic systems is not an easy task; however, there is a lot of work that addresses this issue [

40,

41]. We designed this user study based on some of the guidelines proposed in [

38], a study in which the authors explain in detail how haptic systems can be evaluated.

5.1.1. Experimental Setup

We have prepared and conducted two test sessions:

Tests were performed on a real saw, largely identical to the ancient ones referred to in the section regarding the state of the art. Two devices were built that were mounted on this saw in order to be able to identify and measure the pushing and pulling forces necessary for cutting with a saw, as well as to measure the vibrations that are generated in the operation. The measured values of forces and vibrations were used in the second stage, for programming the haptic system.

Using the haptic device, which can adjust various geometric features (stroke and trajectory) and haptic forces (pushing force and vibrations) in the handle in the VR scenario.

These two experimental sessions were designed to (i) measure the reactions from a real saw (trajectory, forces, and vibrations) in order to transfer these values of the operating characteristics to the haptic equipment, and for (ii) testing, adjusting, and optimizing the equipment.

5.1.2. Experimental Design and Procedure

For the study of the level of agreement, the following scenario was designed: two workbenches were prepared, the first being an application that uses a real saw and a log (see

Figure 1) and, at the second workbench, the haptic equipment is installed (see

Figure 15).

The participants in the user study start with workbench one, the one with the real saw, where they have to familiarize themselves with the handsaw and initiate the movements of cutting the log, in order to understand its operation. Then, in the second step, they will try to replicate the movements on the haptic equipment. Under the guidance of the authors, we proposed a time of 5–15 min (depending on the skill and experience of the participant) to carry out the activities at workbench one, the one with the real saw, to identify and familiarize with the actual movements of cutting the logs. For testing the haptic equipment, we considered 5 min to be enough, followed by filling out the questionnaires.

5.1.3. Measurements/Data Collection

A variety of methods are available to assist evaluators in collecting data. The most widely used of these involves the use of a scale (Likert) that can measure attitudes, knowledge, perceptions, values, and behavioral changes.

This scale involves a series of statements that respondents can choose from to rate their answers to the evaluative questions. There are various sets of answers, evaluated with one to seven points, for various indicators for which the study is to be carried out: level of acceptability, level of appropriateness, level of importance, level of agreement, knowledge of action, reflect me? my beliefs, priority. It is also used to evaluate other indicators and sets of five answers.

To evaluate the system proposed by us, we used the set of questions for evaluating the level of agreement, with the following possible answers: one—strongly disagree, two—disagree, three—somewhat disagree, four—neither agree or disagree, five—somewhat agree, six—agree, seven—strongly agree.

The questions are also divided into six categories: involvement, manipulability, pleasure, realism, use and general experience, to better assess the interaction with the haptic device. The values obtained are presented below, based on the questions in each category. Subjective questions could be answered on a scale of one to seven. There were some questions marked with “*” at the end that were expected to be answered in the negative. For negative items, we subtract the user’s response from value eight (for example, I think that interacting with this haptic device requires a lot of body muscle effort *).

5.1.4. Participants

The user study, based on a haptic device, involved 20 respondents aged between 19 and 67 years. Of these, 10 already had some experience in using haptic devices. After conducting two test sessions, respondents were asked to complete a questionnaire which followed a series of perceptual elements regarding the use of this equipment.

The questions ask users how much they agree or disagree with the statements. The questions used are widely used to evaluate haptic systems. The wording of these questionnaires is usually very close to a variety of haptic systems tested. Therefore, because they are presented in detail in the literature (see references), these specific questions are not presented in further detail in this article; however, the trends followed by the answers to these questions will be explained [

38,

40,

41,

42].

The subjects were also presented with a story about the hand rings used in antiquity to increase their interest. For both real and virtual saws, they performed 20 tests, separated in two sessions, with a short break between them. All users gave their informed consent at the beginning of the experiment.

5.2. Results and Discussion

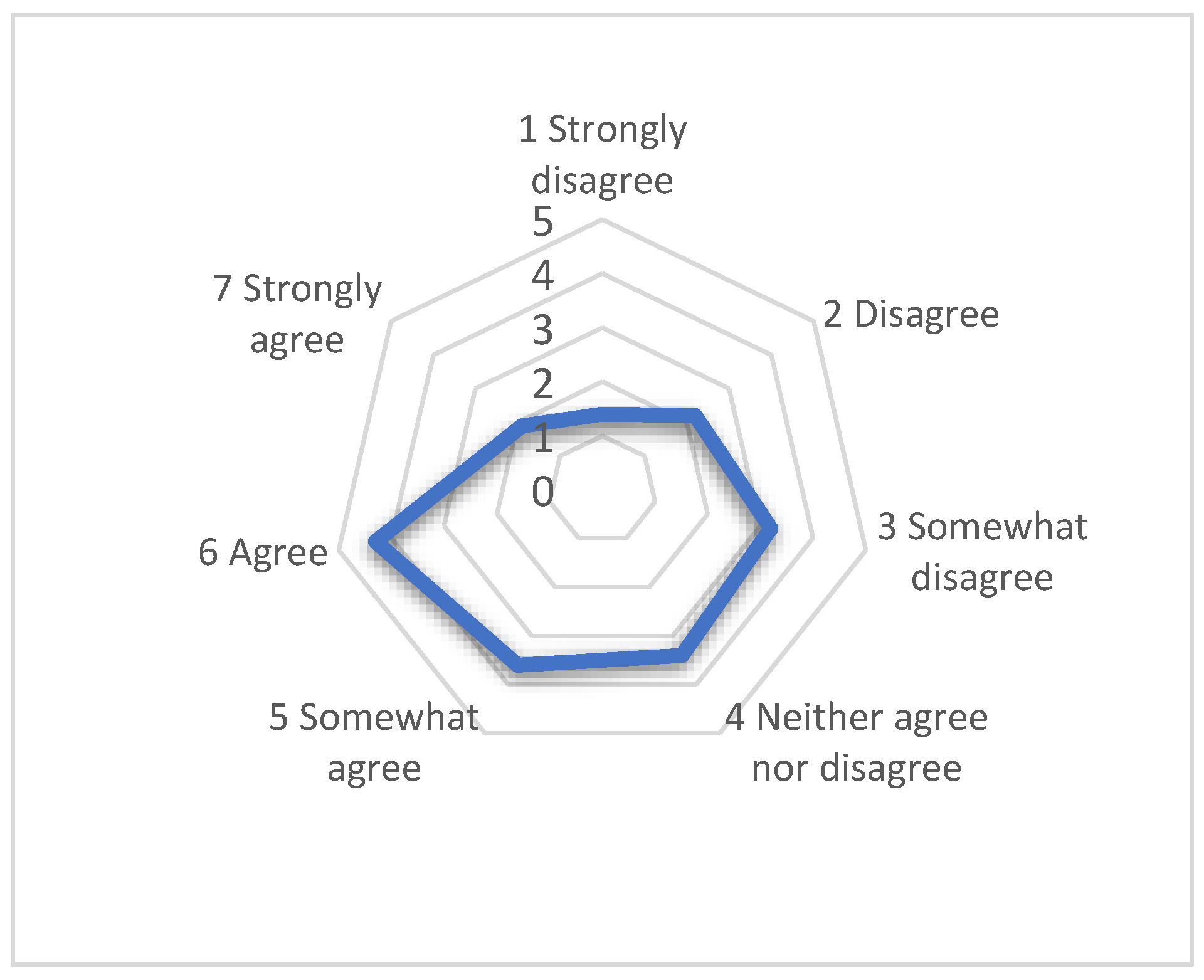

After conducting the practical tests, the users completed the questionnaires, giving marks for six monitored indicators. The data were analyzed and graphs were drawn with the final results, presented below.

5.2.1. Engagement

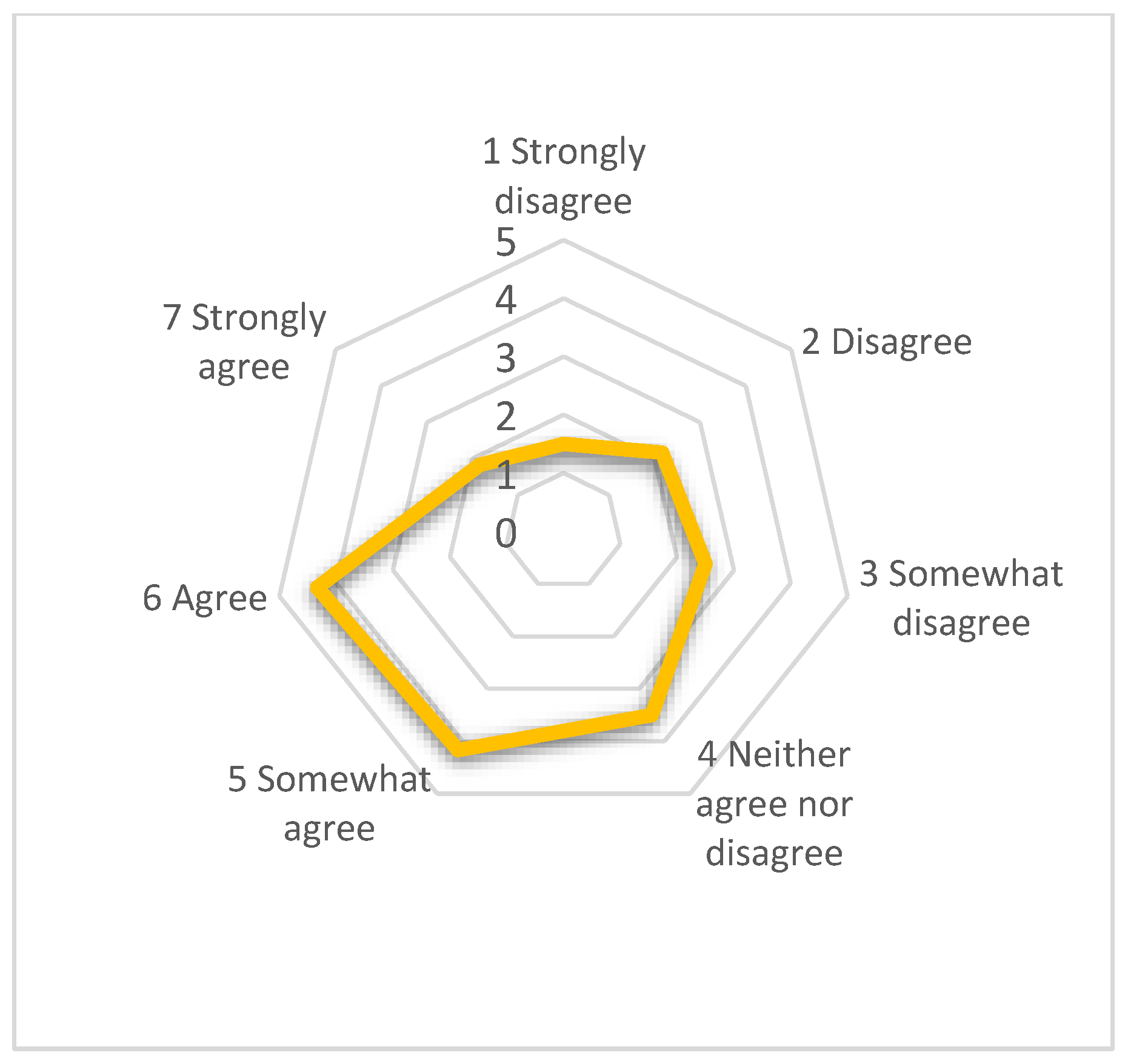

The aim was to record the answers regarding the ability, ease of use, pleasure, and interest of the subjects in using the tested device (

Figure 17).

The results processed in this section are shown in the figure above. The users had a great involvement in the experiment and they all wanted to successfully complete the tasks, reacting well to both the real and the haptic saw; they also found that the application was clear and easy to understand.

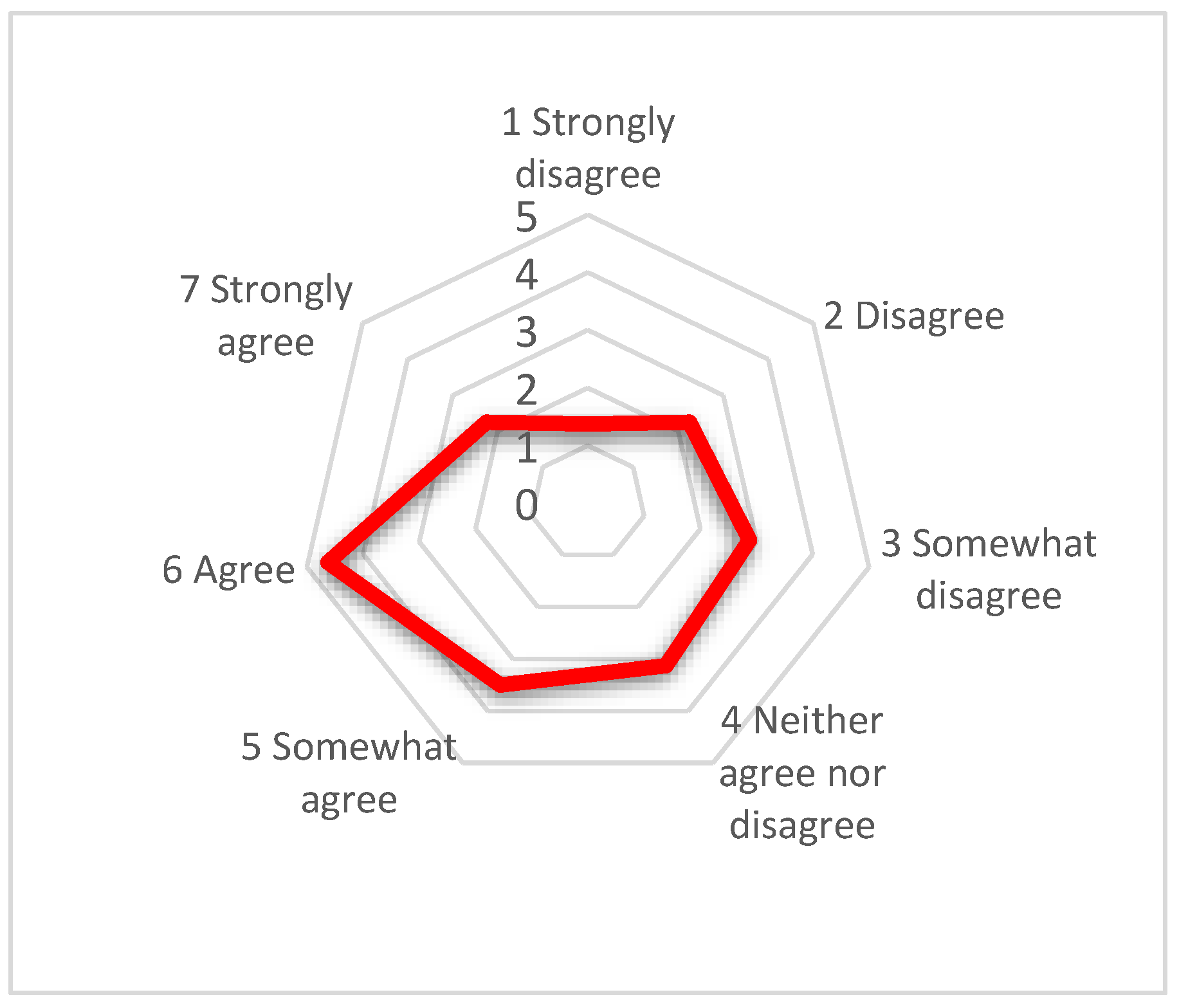

5.2.2. Manipulability

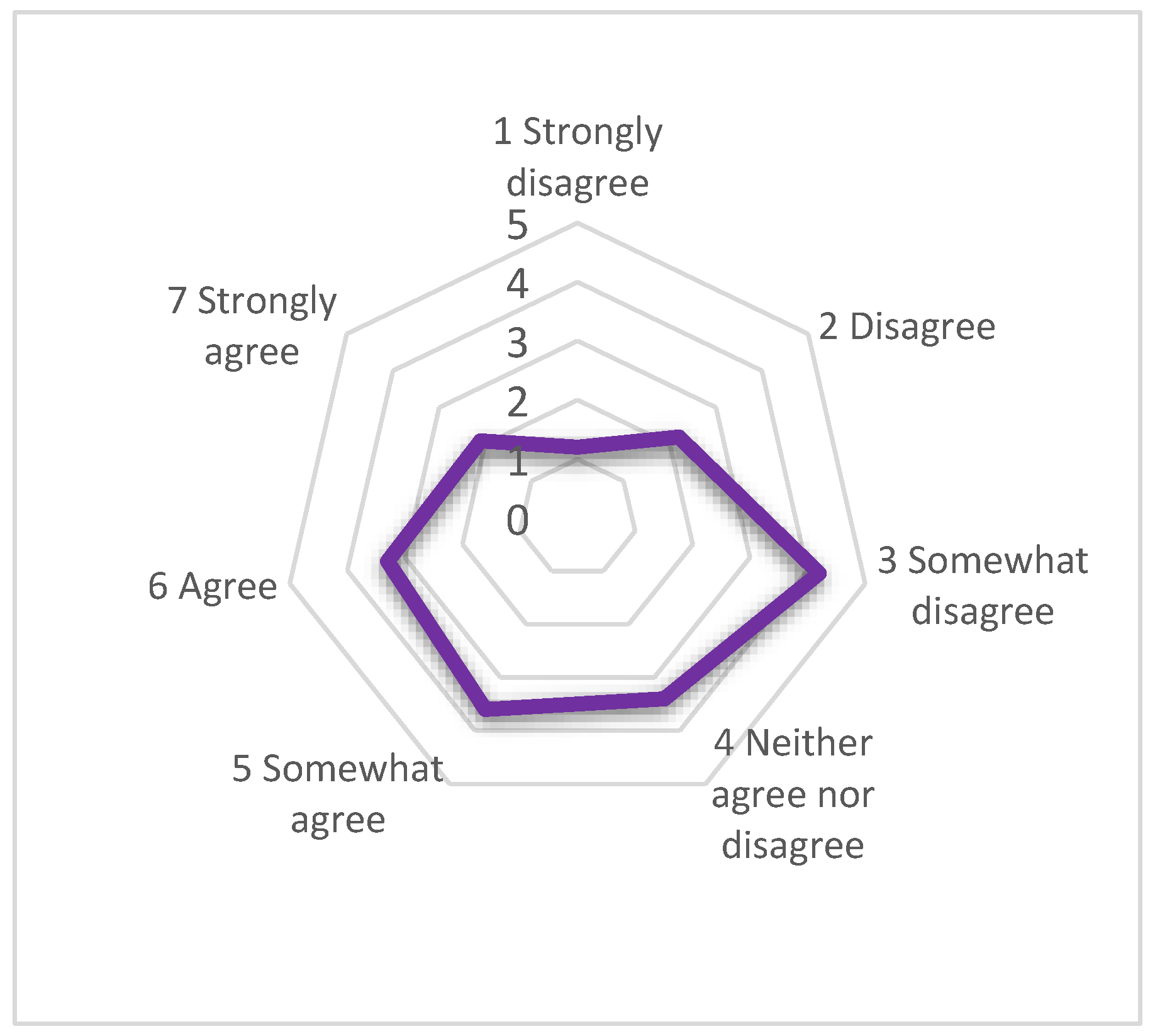

The questions in this section sought to verify that the proposed haptic system is ergonomic, comfortable, and easy to control in operation (

Figure 18).

According to the figure above, it can be observed that the users were satisfied with the haptic device in terms of maneuverability, having no difficulties in controlling the system.

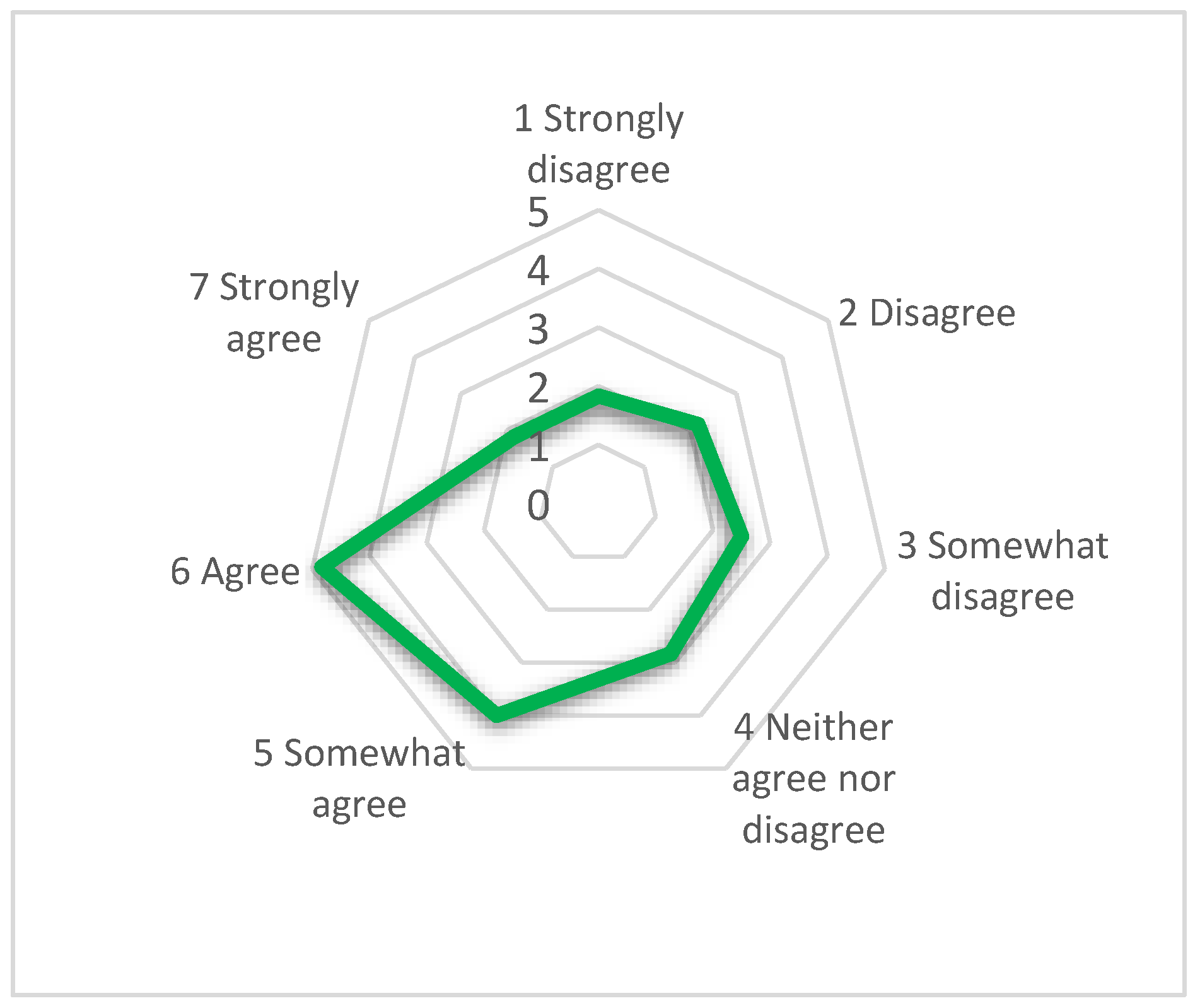

5.2.3. Enjoyment

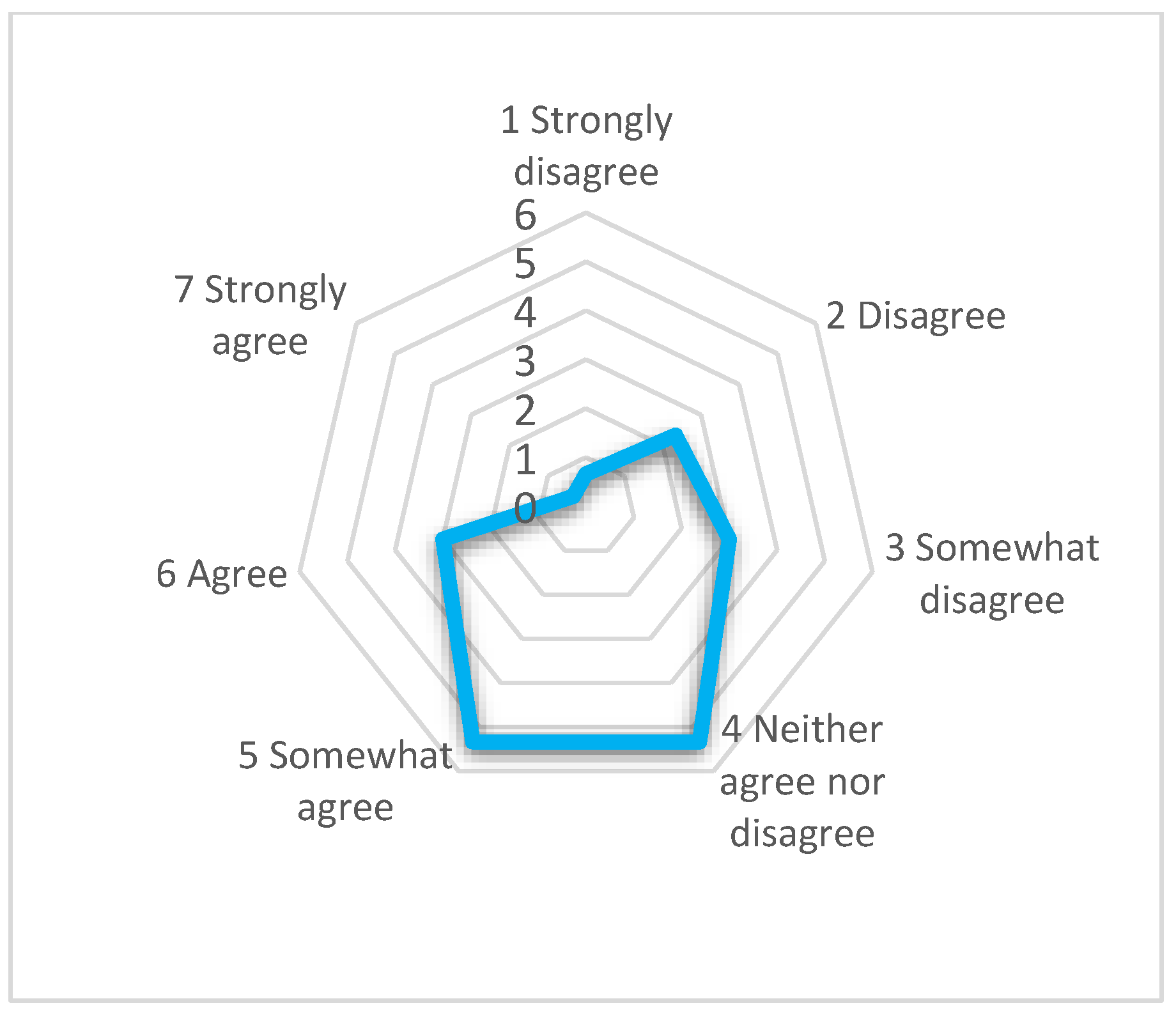

Questions were asked about the pleasure of using this haptic device, if it is interesting or boring, and if it helps to understand the operation of a real antique device (

Figure 19).

Most of the respondents were satisfied with the haptic device, described as pleasant and exciting, and learned new things about these hand tools used for thousands of years.

5.2.4. Realism

Questions were asked about the level of realism of haptic feedback and the existence of a similarity between the feelings of sawing using the haptic model with that of the real saw.

After analyzing the answers in this section (

Figure 20), we can say that users were generally satisfied with the haptic feedback of the user. The feeling of cutting was close to the real sensation, but everyone said they could easily identify if they used the real saw or the haptic system.

5.2.5. Usability

Here are recorded and processed the answers regarding the usability of the system, respectively the user’s desire to use the haptic device because it seemed easy to use, without having to learn other aspects beforehand.

The respondents seemed to be confident in using such a system and would like to reuse it in the near future (

Figure 21). Using the haptic saw was an easy task for them and many considered it a step further to allow everyone to use a saw without any safety issues.

5.2.6. Overall Experience

This section evaluates the general experience that the subjects had during the experiment, with the scoring of the positive and negative elements.

In conclusion, the experiment showed that users were really happy with the use of the virtual saw (

Figure 22). They liked it because there was absolutely no danger when using the haptic device. They also liked the fact that using a single device, you can actually simulate various saws just by loading a different software configuration.

5.3. Discussion

After running the tests, it was observed that people with higher practical skills—who usually carry out physical work with various hand tools in household work—had no problems in understanding the process or finding the correct position to manipulate the haptic system, and compared with the actions performed with classical tools.

The participants who had never used a manual saw—who had not performed physical work activities—had difficulties in understanding the operation of the proposed system. Even if they went to bench one before using the haptic equipment, using a classic saw, they were not familiar enough to be able to identify in detail the reactions and senses that should be followed in the simulator. The colleagues who participated in the tests—having extensive experience with virtual reality technologies, with newly created haptic equipment or classical ones from the market, some of them also having experience of physical work with hand tools—were able to make very pertinent observations on the proposed haptic system. Thus, some participants proposed improving the sensations of immersion in the virtual environment by adding sound and using 3D visualization systems. At the same time, those with experience noticed the fact that, when cutting in the virtual environment, the result of the work is not visible, that is, the partial or total cutting of the log.

We can mention some important moments of our work: (a) we offer a solution for reproducing the experience of using a saw in VR; (b) the developed system can reproduce the force characteristic of any type of hand saw; (c) we evaluate the degree of similarity of the haptic simulator with a real hand saw of the “foxtail” type; (d) a user study validates the system and shows that the prototype has been well received.

In conclusion, the proposed mechanism has several beneficial elements:

Technical—various sawing processes can be reproduced, no matter how complicated (high versatility);

Economic—low price;

Ecological—with a single system that can replace a very large amount of physical equipment;

Realism in operation, increasing the level of understanding of operation through visualization on the computer screen and through haptic feedback;

Possibility of adjustment during operation.

According to the results of this study, the opinion of the users must be taken into account, increasing the feeling of immersion by adding audio and 3D visualization systems. On the other hand, an improvement of the virtual environment will be pursued by adding various carpentry equipment.

6. Conclusions

Approaches to research in the field of cultural heritage preservation have been multilateral, ranging from simple 3D reconstructions of artifacts to demonstrating the functionality of certain equipment, weapons, and tools, and creating virtual museums, and communication interfaces, relying heavily on virtual reality technologies.

In this paper, we proposed, designed, and developed a planar mechanism, with a similar operation to a classic saw, capable of generating a haptic reaction at the level of the handle. The characteristics of this mechanism were estimated using a real saw in the wood-cutting process: the stroke and the trajectory of the handle were determined, the reactions felt by the operator were measured. These data became the initial data for the design of the haptic mechanism.

The multi-bar mechanism built for this application is based on two revolute joints driven by electric motors whose rotation angles are measured in real time by specialized encoders.

The connection of the motors and the encoders was made using a development board (Raspberry) and the programming and control were performed in the Matlab/Simulink software. Adjustments were made to obtain a haptic reaction as close to reality as possible, after which several attempts were made in order to estimate the validity of this type of system.

A virtual environment was developed that contains replicas of the main elements involved in the cutting operation with the classic saw: sawbuck, log, saw, and the operator’s hand. The movements of the saw in the operation of cutting the log in the virtual environment are connected in real time to the movements performed by the operator on the haptic mechanism. The user feels a resistant force through the handle of the mechanism, depending on the initial settings of the system, which simulates the cutting force, as well as a small vibration that simulates the vibrations generated by the teeth of the saw in operation.

In order to validate the concept of using an ancient saw in VR, two professional carpenters were consulted to give their opinions on the operation of the system. A user study was carried out to demonstrate the functionality of the concept and to investigate the level of agreement of the proposed haptic system.

Analyzing all the statements obtained in the user study, we can conclude that users generally had a good experience with the haptic device and would like to use it again in the future.

Further research can be conducted on enhancing the immersion on the visual and auditory levels. Thus, in order to improve the quality of users’ perceptions, we want to expand this project by creating a complex virtual environment that includes many more objects in the virtual scene (e.g., workshop equipped with several benches, several characters), as well as the use of 3D visualization devices (either 3D glasses or the CAVE system) and the inclusion of sound in the scene. This virtual scene can be expanded by adding new haptic devices developed by us or purchased from the market that will simulate the operation of other hand tools in the workshop.

Based on the results obtained, from the point of view of the quality of the equipment and the operating characteristics obtained, but also from the point of view of the perception of the users who tested it, we can say that this type of haptic system can be used successfully in the field to simulate the functioning of artifacts, and can give another dimension to the perception of cultural heritage elements.