A Hybrid Finite Element Method–Analytical Model for Classifying the Effects of Cracks on Gear Train Systems Using Artificial Neural Networks

Abstract

1. Introduction

1.1. Failure of Mechanical Systems

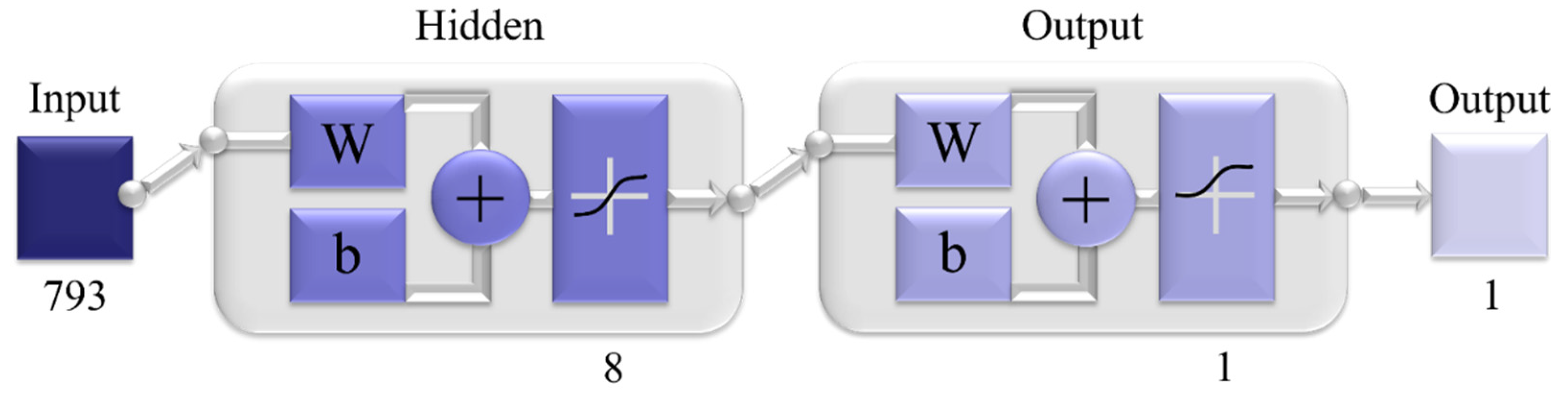

1.2. Vibration Analysis

1.3. Artificial Intelligence (AI)

1.4. Motivations of This Research

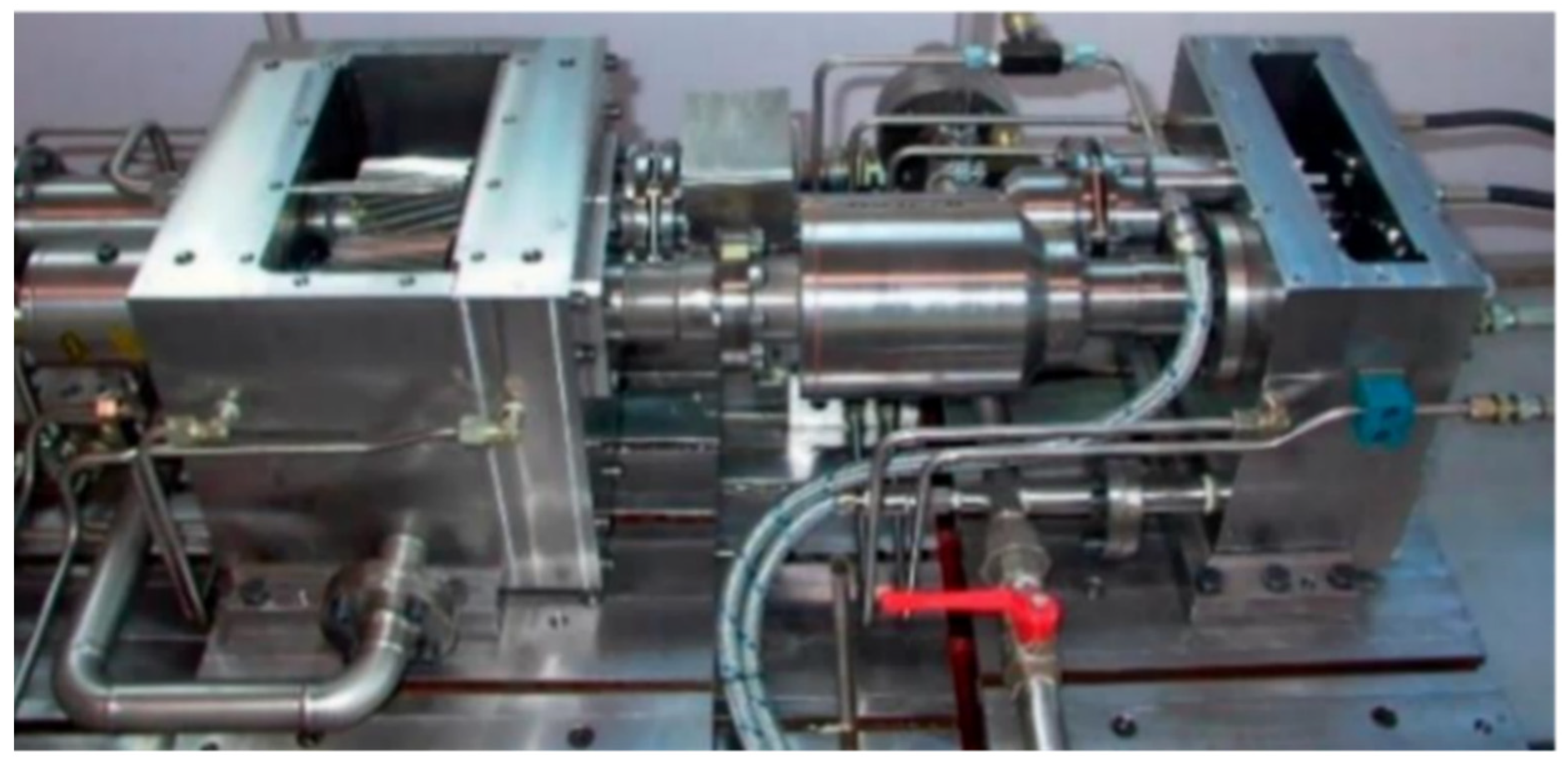

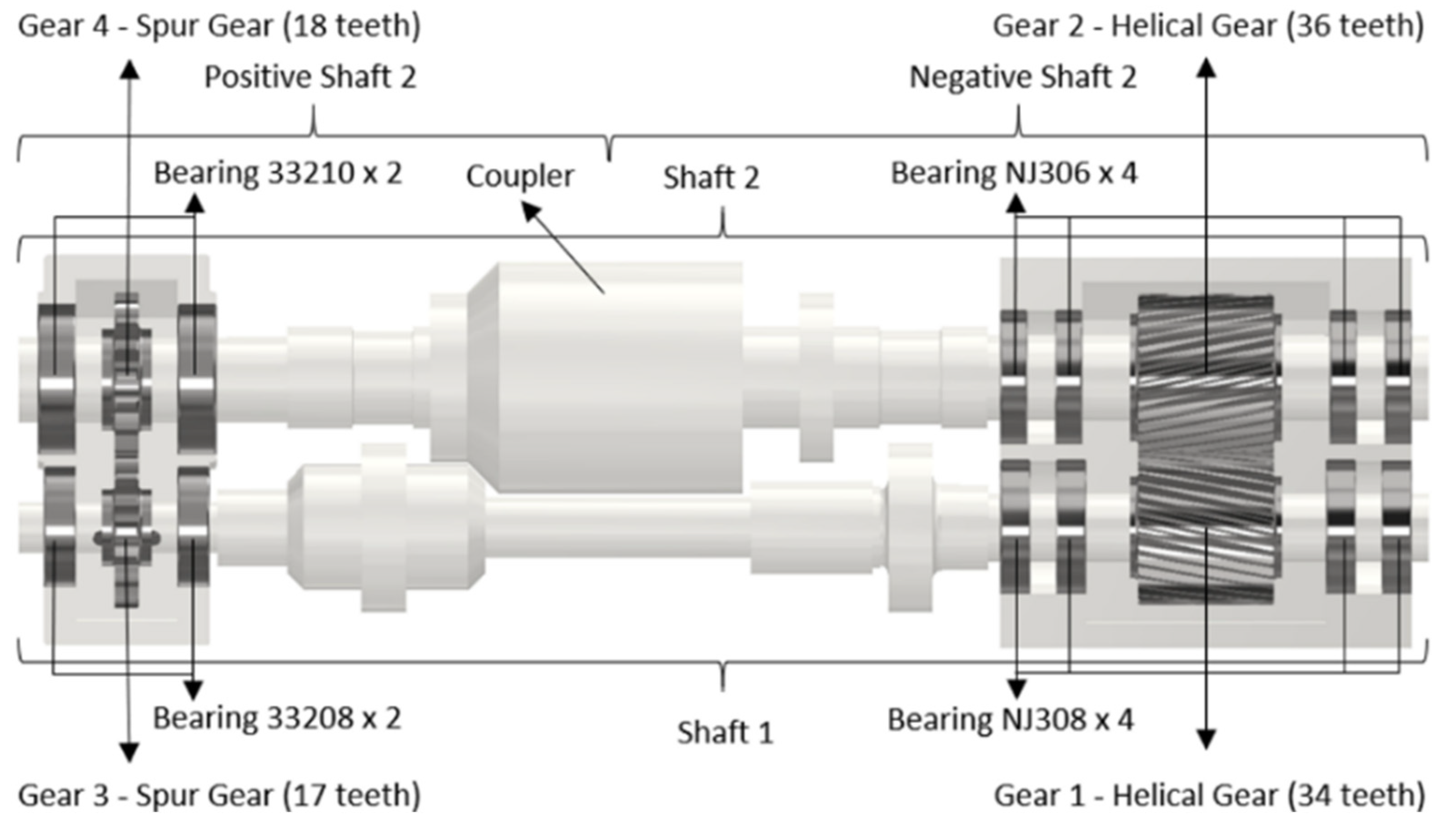

2. Gearbox Characteristics

3. Modeling, Implementation, and Numerical Simulation

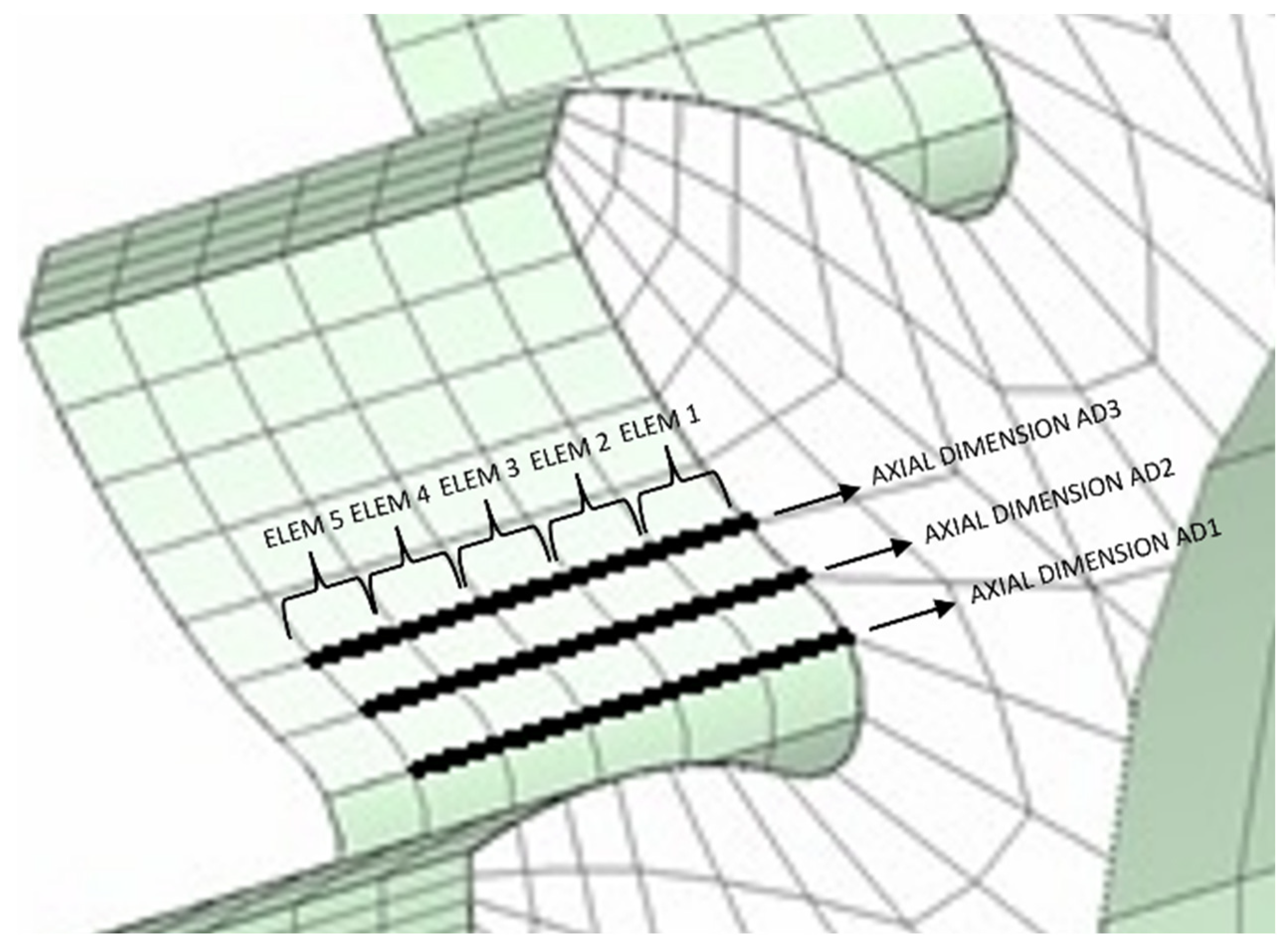

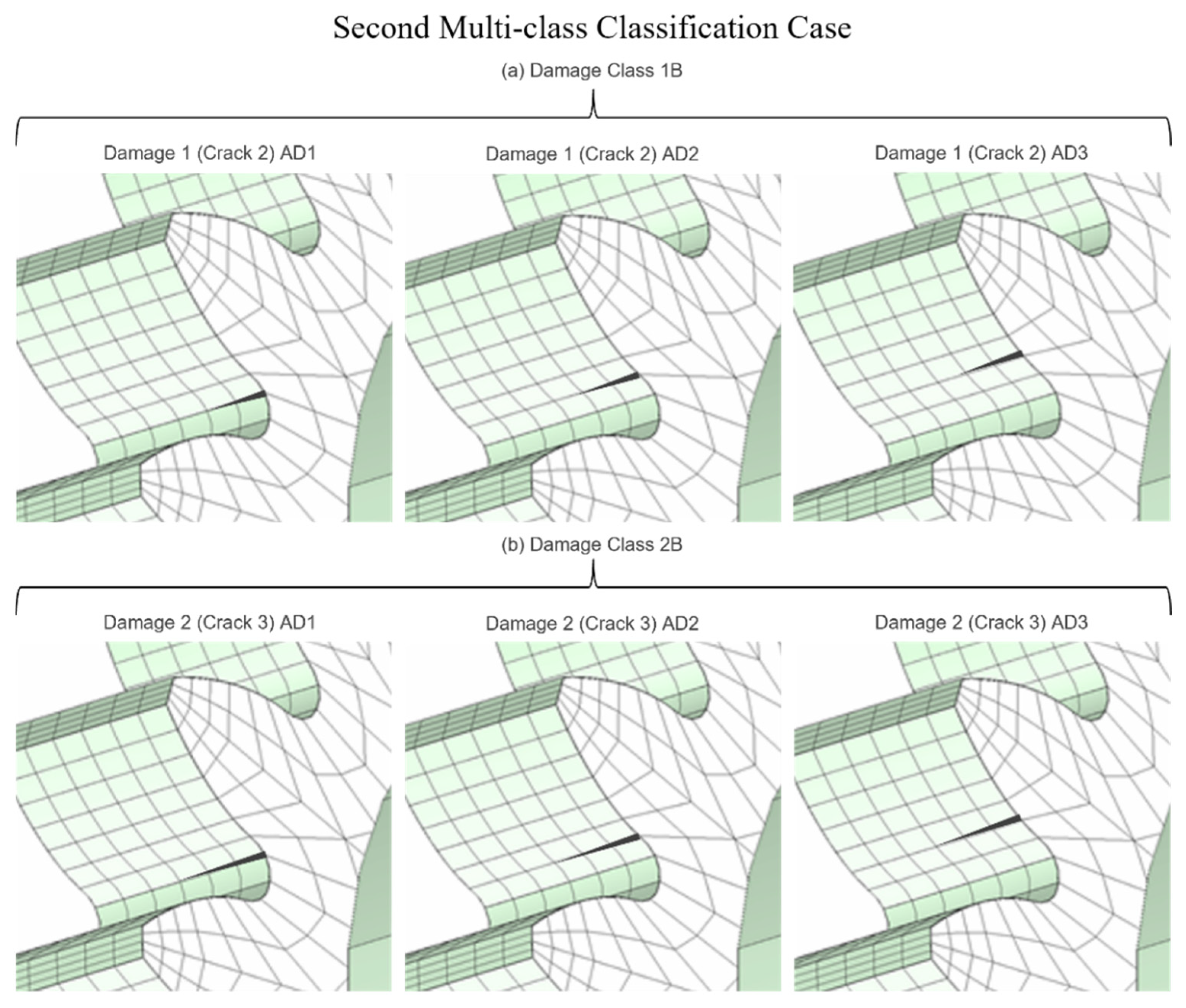

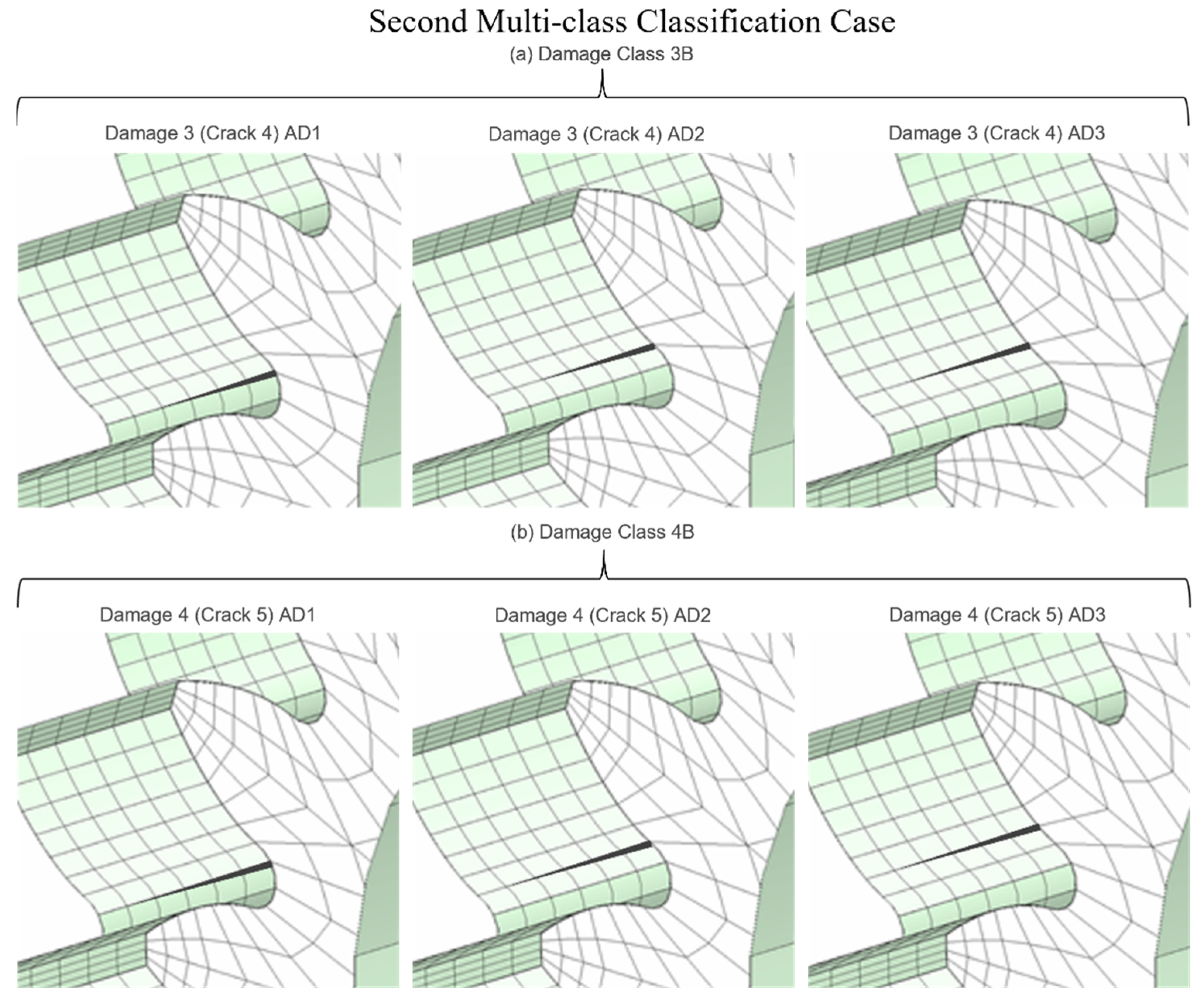

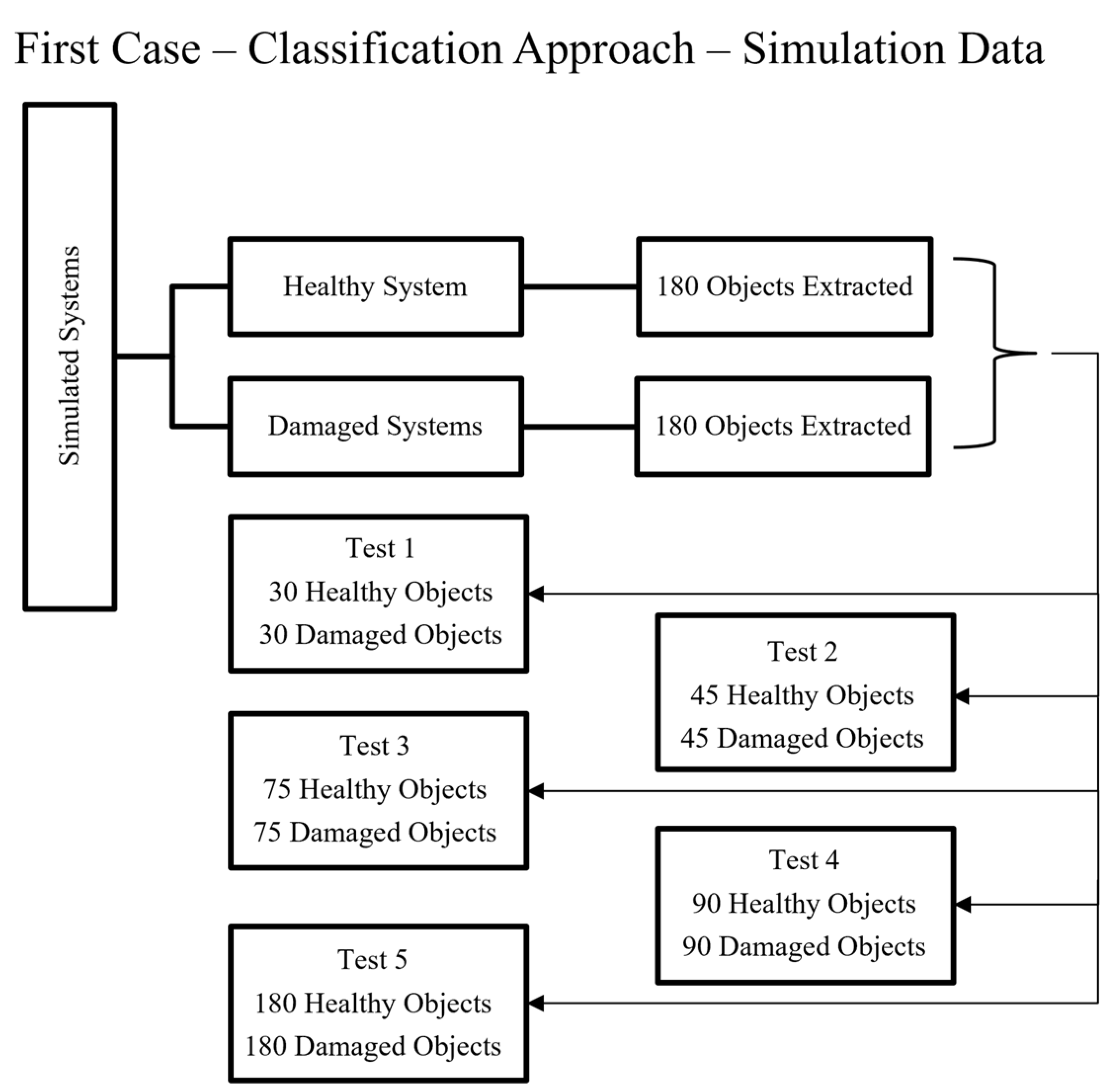

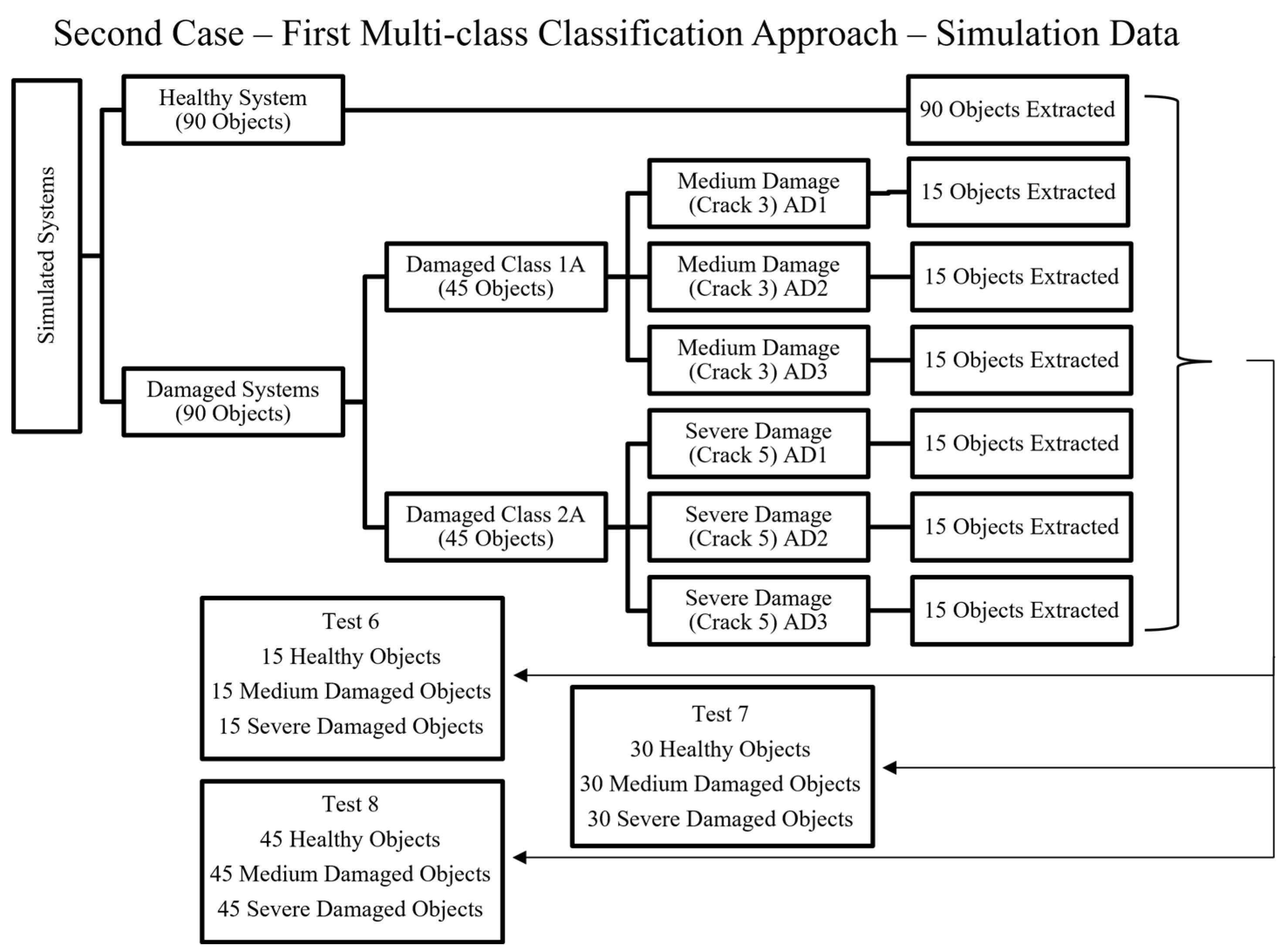

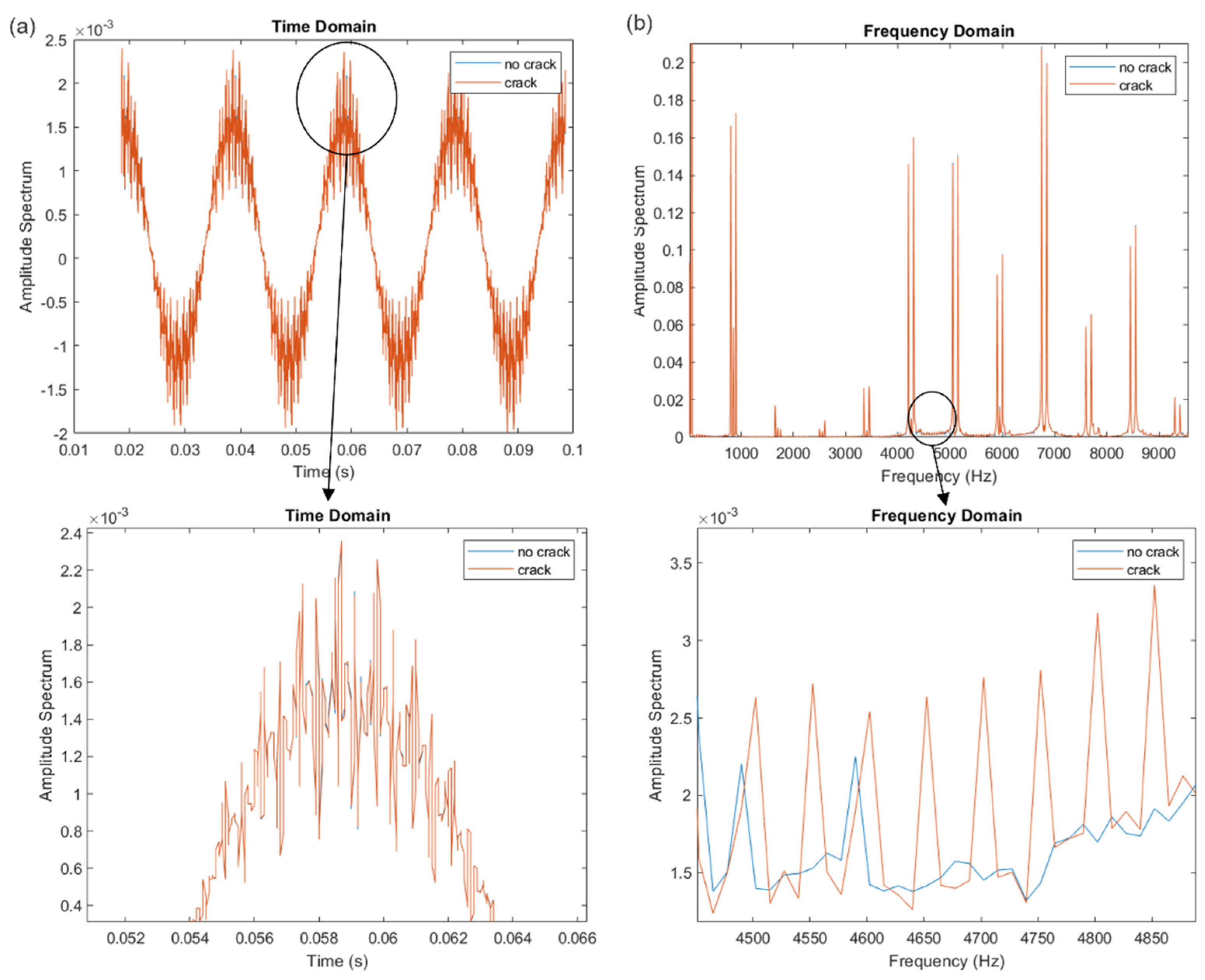

3.1. Numerical Simulation

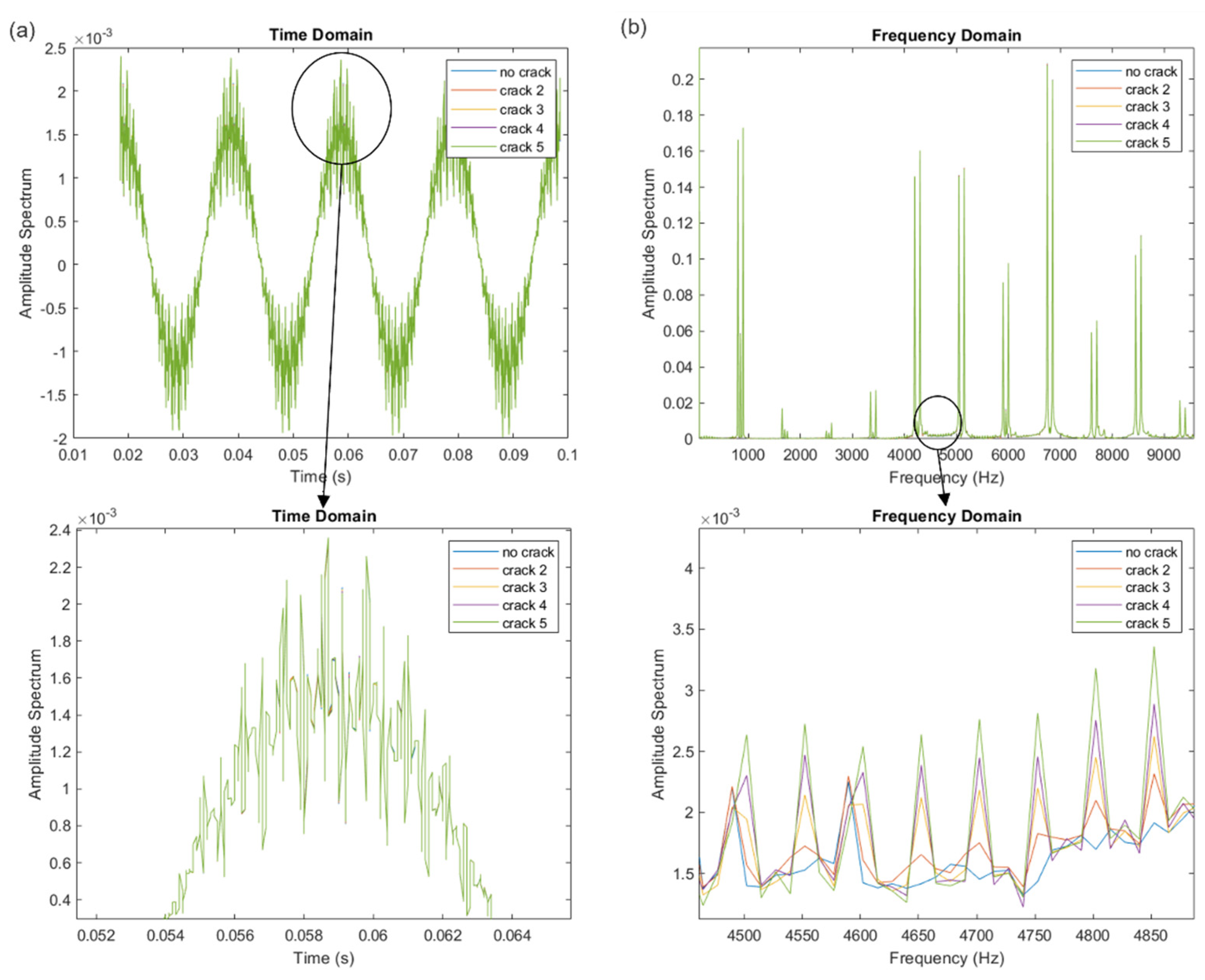

3.2. Post-Processing Approach

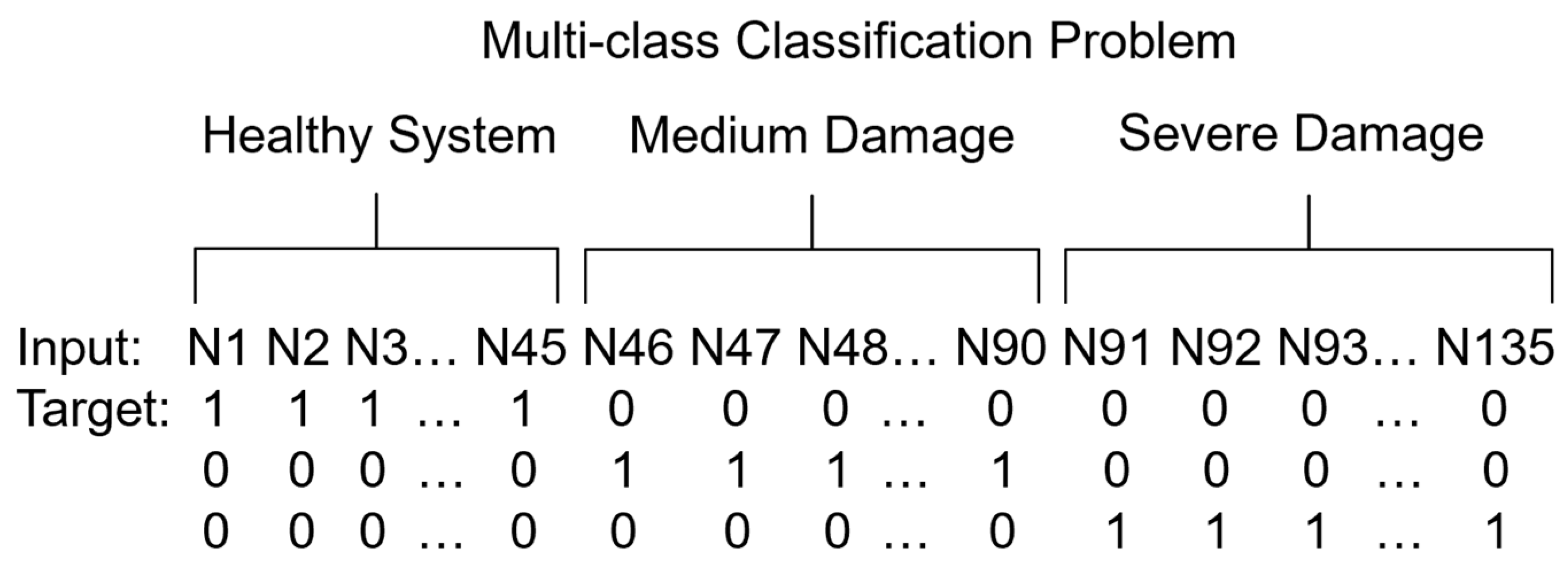

4. Artificial Neural Networks (ANNs)

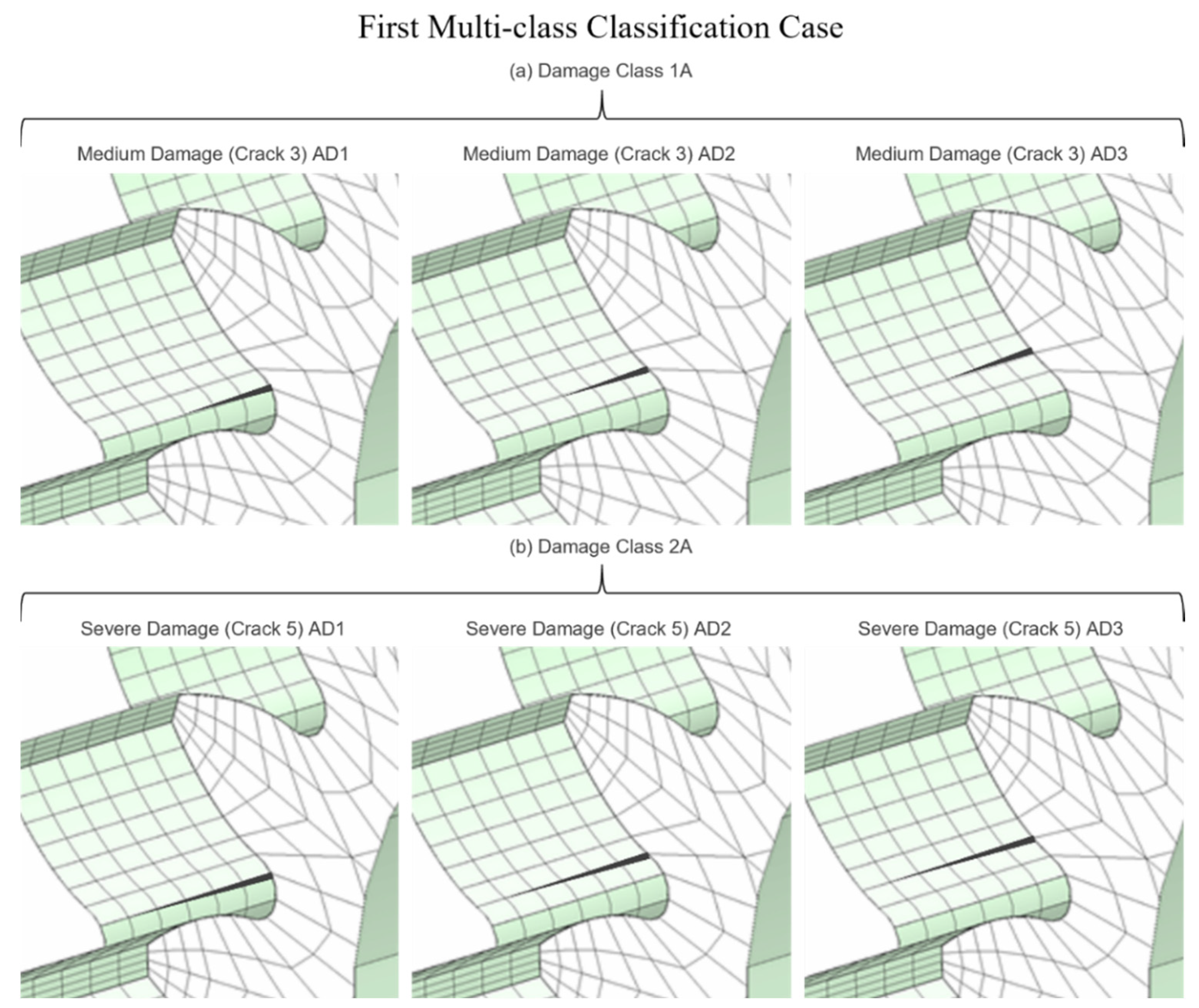

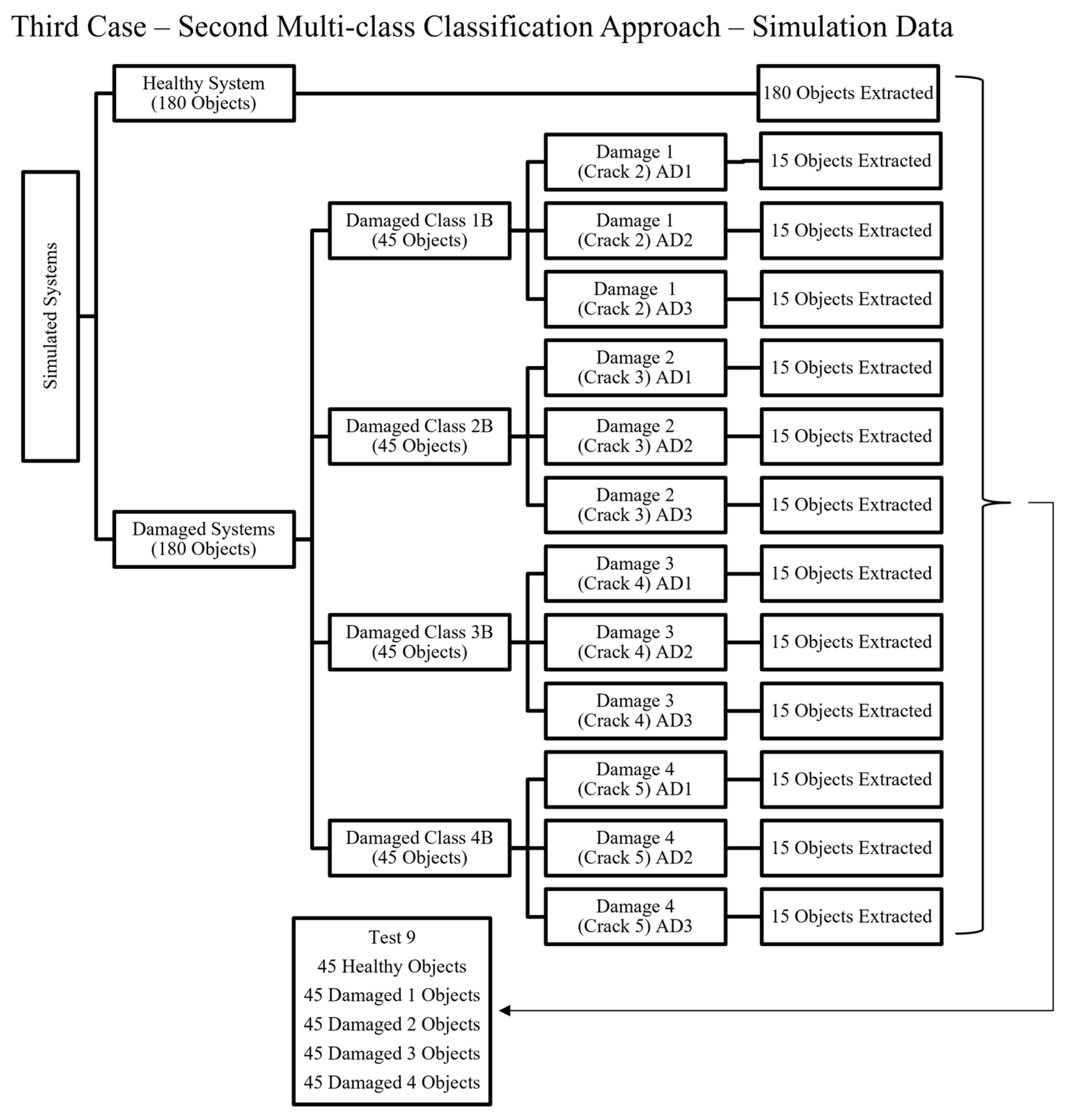

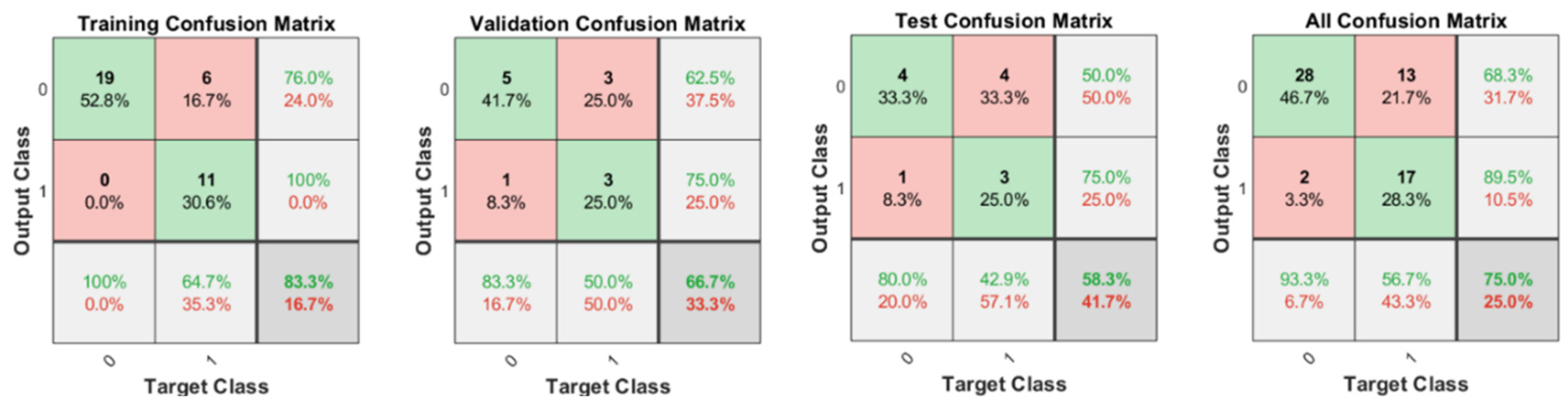

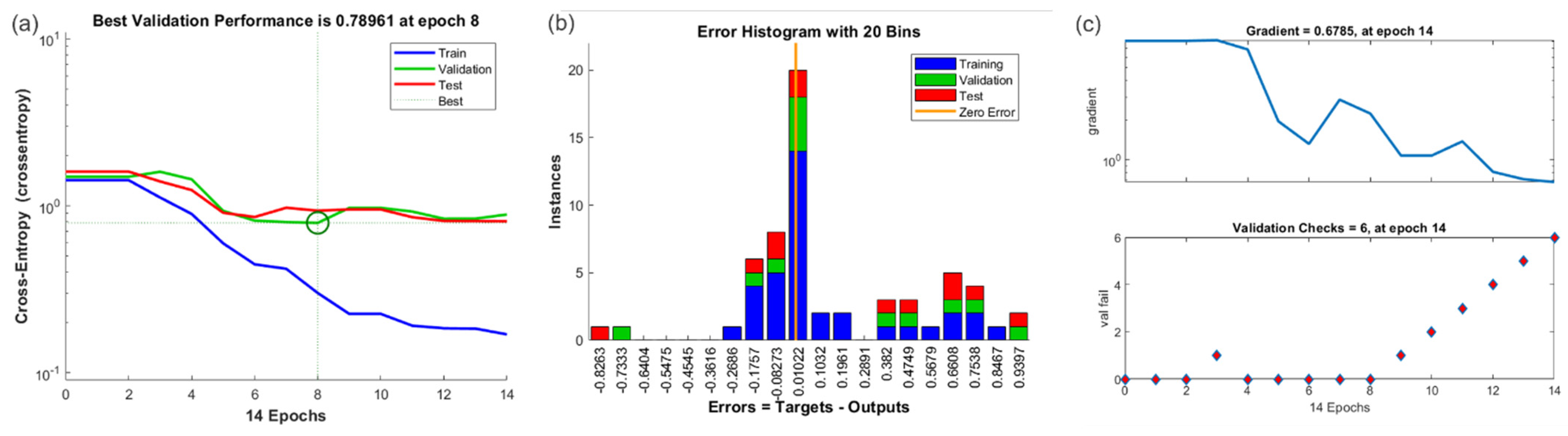

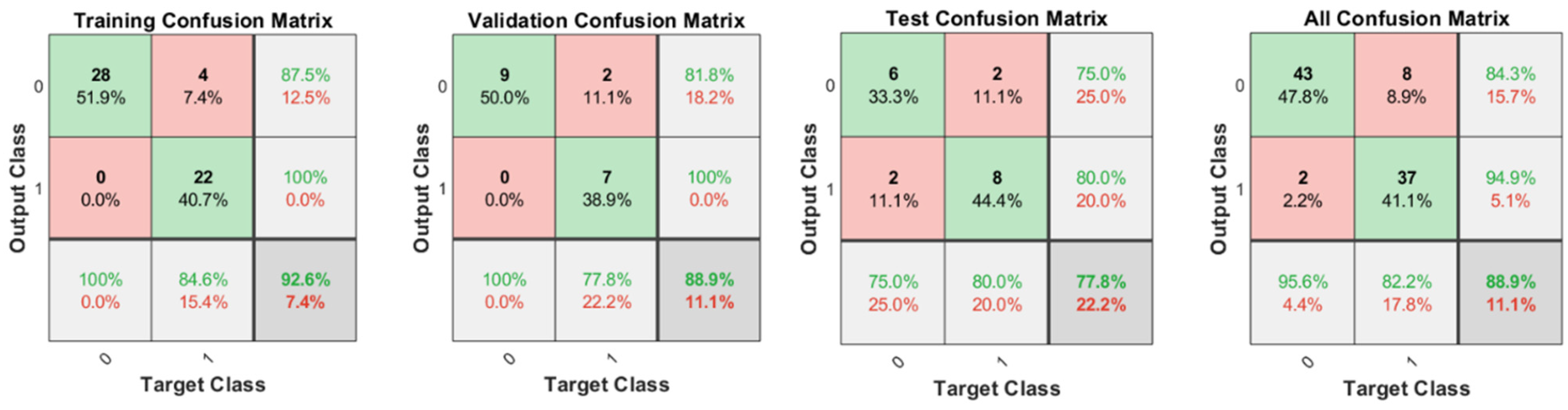

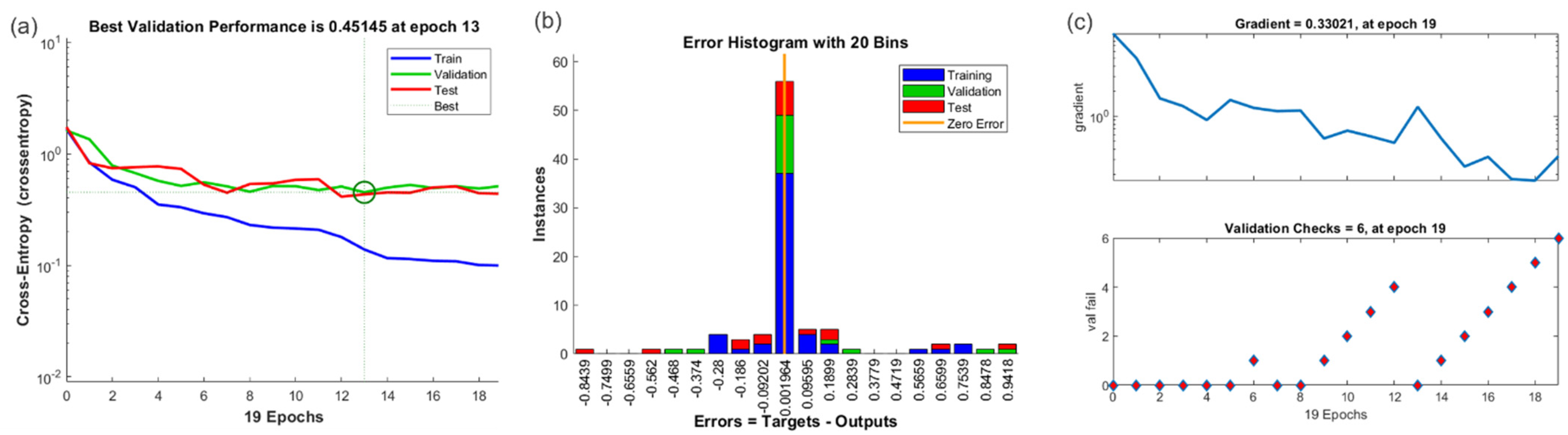

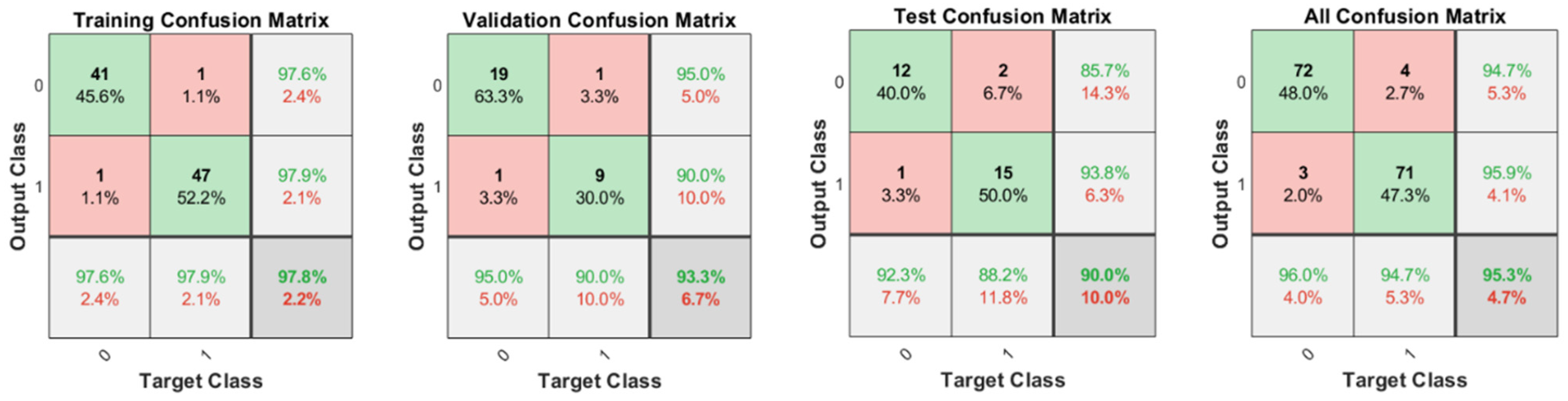

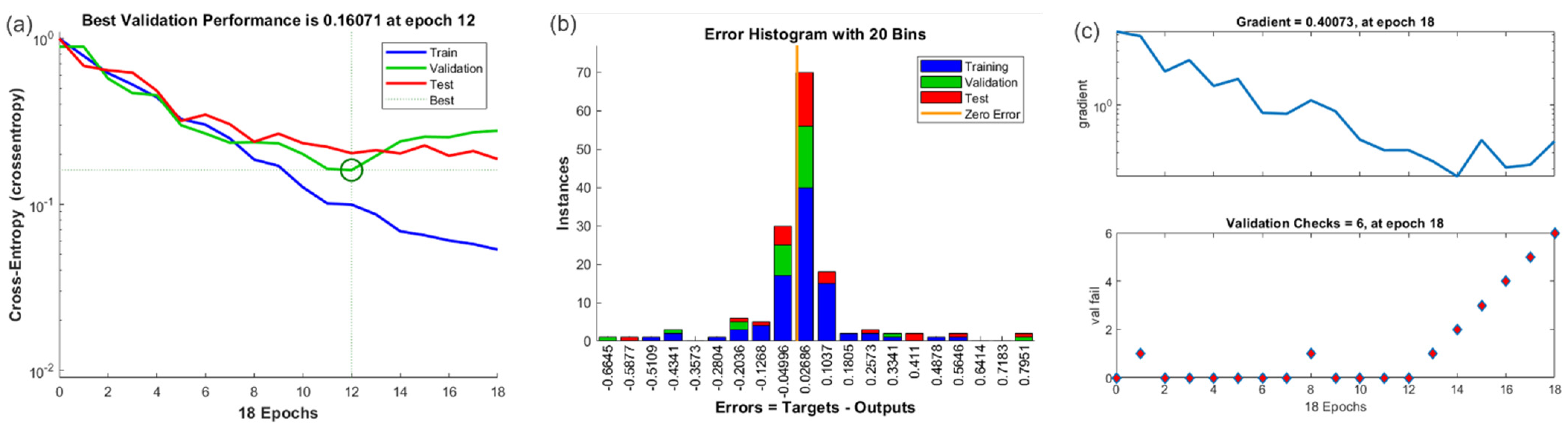

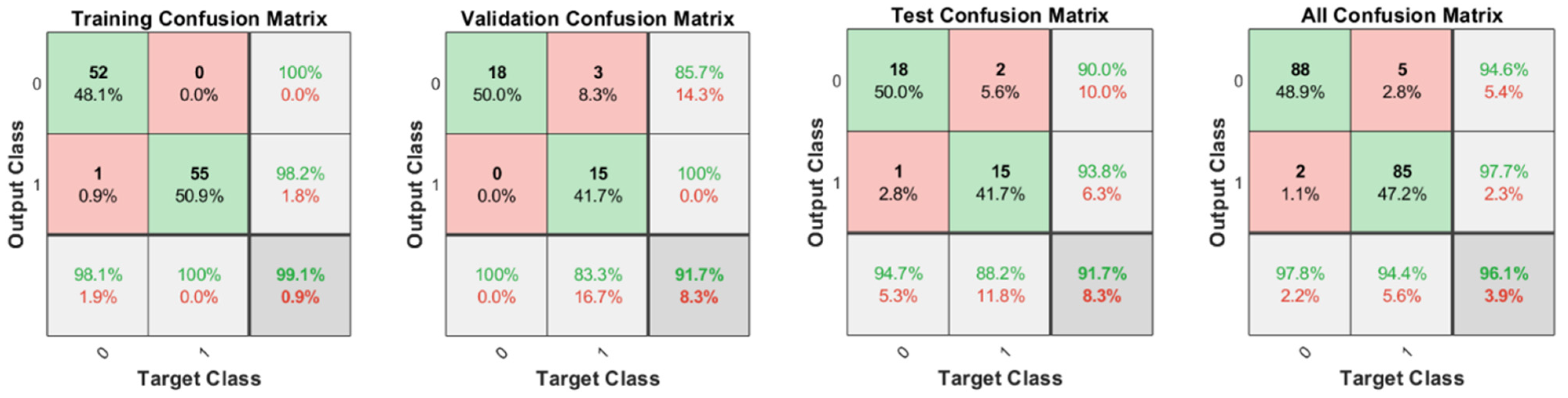

5. Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Axial Dimension |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| BP | Back Propagation |

| CE | Cross-Entropy |

| CM | Condition Monitoring |

| DL | Deep Learning |

| FD | Fault Diagnosis |

| FE | Finite Element |

| FEM | Finite Element Method |

| FFT | Fast Fourier Transform |

| FMD | False Medium Damage |

| FN | False Negative |

| FND | False No Damage |

| FP | False Positive |

| FSD | False Severe Damage |

| FZG | Forschungsstelle fur Zahnrader und Getriebebau |

| GMF | Gear Mesh Frequency |

| ML | Machine Learning |

| nprtool | Neural Network Pattern Recognition |

| RAM | Random Access Memory |

| RD | Radial Dimension |

| SHM | Structural Health Monitoring |

| TMD | True Medium Damage |

| TN | True Negative |

| TND | True No Damage |

| TP | True Positive |

| TSD | True Severe Damage |

| T3D | Transmission3D |

| %E | Percent Error |

| Nomenclature | |

| Actual objects | |

| b | Face width |

| Center distance | |

| Pitch circle diameter | |

| Young’s modulus | |

| Moment of inertia | |

| Neuron layer | |

| Mass | |

| Normal module | |

| Total number of objects | |

| Predicted objects | |

| Point inside the solid body | |

| Field point | |

| Surface grid point | |

| Rotational speed | |

| Displacement due to a load at the surface grid | |

| Poisson’s ratio | |

| Number of teeth | |

| Number of teeth | |

| Pressure angle | |

| Helix angle | |

| Contact ratio | |

References

- Monteiro, R.P.; Vidoni, R.; Concli, F. A Multibody Dynamic Model for Evaluating the Vibrating Modes of Gear Train Systems. Int. J. Transp. Dev. Integr. 2021, 5, 264–277. [Google Scholar] [CrossRef]

- Marra, A.L.; Juliani, R.; Garcia, C. Data Augmentation for Vibration Signals using System Identification Techniques. In Proceedings of the 2021 5th International Conference on System Reliability and Safety (ICSRS), Palermo, Italy, 24–26 November 2021. [Google Scholar] [CrossRef]

- Nentwich, C.; Reinhart, G. A Method for Health Indicator Evaluation for Condition Monitoring of Industrial Robot Gears. Robotics 2021, 10, 80. [Google Scholar] [CrossRef]

- Wang, D.; Tsui, K.-L.; Miao, Q. Prognostics and Health Management: A Review of Vibration Based Bearing and Gear Health Indicators. IEEE Access 2018, 6, 665–676. [Google Scholar] [CrossRef]

- Sendlbeck, S.; Fimpel, A.; Siewerin, B.; Otto, M.; Stahl, K. Condition Monitoring of Slow-speed Gear Wear using a Transmission Error-based Approach with Automated Feature Selection. Int. J. Progn. Health Manag. 2021, 12, 2. [Google Scholar] [CrossRef]

- Chen, X.; Semenov, S.; McGugan, M.; Madsen, S.H.; Yeniceli, S.C.; Berring, P.; Branner, K. Fatigue testing of a 14.3 m composite blade embedded with artificial defects Damage growth and structural health monitoring. Compos. Part A Appl. Sci. Manuf. 2020, 140, 106189. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, Z. Identification of Load Categories in Rotor System Based on Vibration Analysis. Sensors 2017, 17, 1676. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Lokesha, M.; Kumar, K.; Srinivas, K.R. Vibration based Fault Diagnosis Techniques for Rotating Mechanical Components: Review Paper. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012109. [Google Scholar] [CrossRef]

- Toh, G.; Park, J. Review of Vibration-Based Structural Health Monitoring Using Deep Learning. Appl. Sci. 2020, 10, 1680. [Google Scholar] [CrossRef]

- Woo, S. Reliability Design of Mechanical Systems. A Guide for Mechanical and Civil Engineers, 2nd ed.; Springer: Singapore, 2020; ISBN 978-981-13-7236-0. [Google Scholar] [CrossRef]

- Aherwar, A. An investigation on gearbox fault detection using vibration analysis techniques: A review. Aust. J. Mech. Eng. 2012, 10, 169–183. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, C.; Liu, H.; Bai, H.; Xu, X. Investigation on stress microcycles and mild wear mechanism in gear contact fatigue. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2265–2279. [Google Scholar] [CrossRef]

- Chen, X.; Yang, X.; Zuo, M.; Tian, Z. Planetary Gearbox Dynamic Modeling Considering Bearing Clearance and Sun Gear Tooth Crack. Sensors 2021, 21, 2638. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Liu, H.; Zhu, C.; Sun, Z.; Bai, H. Erratum to: Study on contact fatigue of a wind turbine gear pair considering surface roughness. Friction 2019, 10, 1135. [Google Scholar] [CrossRef]

- Xiao, Z.; Cao, J.; Yu, Y. Mathematical Modeling and Dynamic Analysis of Planetary Gears System with Time-Varying Parameters. Math. Probl. Eng. 2020, 2020, 3185624. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration based condition monitoring and fault diagnosis of wind turbine planetary gearbox: A review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Allam, A.; Moussa, M.; Tarry, C.; Veres, M. Detecting Teeth Defects on Automotive Gears Using Deep Learning. Sensors 2021, 21, 8480. [Google Scholar] [CrossRef]

- Li, D.; Zhang, S.; Yang, W.; Zhang, W. Corrosion Monitoring and Evaluation of Reinforced Concrete Structures Utilizing the Ultrasonic Guided Wave Technique. Int. J. Distrib. Sens. Netw. 2014, 10, 827130. [Google Scholar] [CrossRef]

- Sridhar, V.; Chana, K. Development of a Novel Sensor for Gear Teeth Wear and Damage Detection. Int. J. Progn. Health Manag. 2021, 12, 3. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Tang, S.; Xu, J.; Shi, B.; Liu, Y. Vibration Analysis for Fault Detection of Wind Turbine Drivetrains—A Comprehensive Investigation. Sensors 2021, 21, 1686. [Google Scholar] [CrossRef] [PubMed]

- Aherwar, A.; Khalid, S. Vibration analysis techniques for gearbox diagnostic: A review. Int. J. Adv. Eng. Technol. 2012, 3, 4–12. [Google Scholar]

- Alwadie, A.; Muhammad, I.; Nordin, S. The Fault Detection of Gear of Electromechanical Power Transmission System using Frequency Domain Approach. Renew. Energy Power Qual. J. 2021, 19. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. A Comparative Analysis of Signal Decomposition Techniques for Structural Health Monitoring on an Experimental Benchmark. Sensors 2021, 21, 1825. [Google Scholar] [CrossRef] [PubMed]

- Wah, W.S.L.; Chen, Y.-T.; Owen, J.S. A regression-based damage detection method for structures subjected to changing environmental and operational conditions. Eng. Struct. 2020, 228, 111462. [Google Scholar] [CrossRef]

- Chandrasekhar, K.; Stevanovic, N.; Cross, E.J.; Dervilis, N.; Worden, K. Damage detection in operational wind turbine blades using a new approach based on machine learning. Renew. Energy 2020, 168, 1249–1264. [Google Scholar] [CrossRef]

- Schmidt, S.; Heyns, P.S.; Gryllias, K.C. An informative frequency band identification framework for gearbox fault diagnosis under time-varying operating conditions. Mech. Syst. Signal Process. 2021, 158, 107771. [Google Scholar] [CrossRef]

- Cao, X.; Rembe, C. Non-Contact Damage Detection under Operational Conditions with Multipoint Laservibrometry. Sensors 2020, 20, 732. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Gu, J.X.; Fan, H.; Sun, X.; Li, B.; Gu, F. Acoustics Based Monitoring and Diagnostics for the Progressive Deterioration of Helical Gearboxes. Chin. J. Mech. Eng. 2021, 34, 1–12. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox condition monitoring in wind turbines: A review. Mech. Syst. Signal Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Ravikumar, K.; Madhusudana, C.; Kumar, H.; Gangadharan, K. Classification of gear faults in internal combustion (IC) engine gearbox using discrete wavelet transform features and K star algorithm. Eng. Sci. Technol. Int. J. 2022, 30, 101048. [Google Scholar] [CrossRef]

- Chen, W.; Dai, S.; Zheng, B. ARIMA-FEM Method with Prediction Function to Solve the Stress–Strain of Perforated Elastic Metal Plates. Metals 2022, 12, 179. [Google Scholar] [CrossRef]

- Rossi, M.; Renzi, M. A general methodology for performance prediction of pumps-as-turbines using Artificial Neural Networks. Renew. Energy 2018, 128, 265–274. [Google Scholar] [CrossRef]

- Surendran, R.; Khalaf, O.I.; Romero, C.A.T. Deep Learning Based Intelligent Industrial Fault Diagnosis Model. Comput. Mater. Contin. 2022, 70, 6323–6338. [Google Scholar] [CrossRef]

- Singh, V.; Gangsar, P.; Porwal, R.; Atulkar, A. Artificial intelligence application in fault diagnostics of rotating industrial machines: A state-of-the-art review. J. Intell. Manuf. 2021, 1–30. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Dworakowski, Z.; Dziedziech, K.; Jabłonski, A. A novelty detection approach to monitoring of epicyclic gearbox health. Metrol. Meas. Syst. 2018, 25, 459–473. [Google Scholar] [CrossRef]

- Cao, R.; Yunusa-Kaltungo, A. An Automated Data Fusion-Based Gear Faults Classification Framework in Rotating Machines. Sensors 2021, 21, 2957. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, R.; Pai, P.S.; Sriram, N.; Bhat, V. Comparison of wavelet based denoising schemes for gear condition monitoring: An Artificial Neural Network based Approach. IOP Conf. Ser. Mater. Sci. Eng. 2018, 310, 012010. [Google Scholar] [CrossRef]

- Strączkiewicz, M.; Barszcz, T. Application of Artificial Neural Network for Damage Detection in Planetary Gearbox of Wind Turbine. Shock Vib. 2016, 2016, 4086324. [Google Scholar] [CrossRef]

- Qiang, Z.; Jieying, G.; Junming, L.; Ying, T.; Shilei, Z. Gearbox fault diagnosis using data fusion based on self-organizing map neural network. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720923476. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.; Zhang, L.; Shao, S.; Bian, G. Multisignal VGG19 Network with Transposed Convolution for Rotating Machinery Fault Diagnosis Based on Deep Transfer Learning. Shock Vib. 2020, 2020, 886338. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Qu, Y.; He, D. Semi-supervised gear fault diagnosis using raw vibration signal based on deep learning. Chin. J. Aeronaut. 2020, 33, 418–426. [Google Scholar] [CrossRef]

- Concli, F.; Pierri, L.; Sbarufatti, C. A Model-Based SHM Strategy for Gears—Development of a Hybrid FEM-Analytical Approach to Investigate the Effects of Surface Fatigue on the Vibrational Spectra of a Back-to-Back Test Rig. Appl. Sci. 2021, 11, 2026. [Google Scholar] [CrossRef]

- Wehrle, E.; Palomba, I.; Vidoni, R. In-Operation Structural Modification of Planetary Gear Sets Using Design Optimization Methods. In MEDER 2018: Mechanism Design for Robotics; Gasparetto, A., Ceccarelli, M., Eds.; Mechanisms and Machine Science; Springer: Cham, Switzerland, 2019; Volume 66. [Google Scholar] [CrossRef]

- Richiedei, D.; Tamellin, I.; Trevisani, A. Simultaneous assignment of resonances and antiresonances in vibrating systems through inverse dynamic structural modification. J. Sound Vib. 2020, 485, 115552. [Google Scholar] [CrossRef]

- Xiang, J.; Zhong, Y. A Novel Personalized Diagnosis Methodology Using Numerical Simulation and an Intelligent Method to Detect Faults in a Shaft. Appl. Sci. 2016, 6, 414. [Google Scholar] [CrossRef]

- Gorla, C.; Conrado, E.; Rosa, F.; Concli, F. Contact and bending fatigue behaviour of austempered ductile iron gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 998–1008. [Google Scholar] [CrossRef]

- Colone, L.; Dimitrov, N.; Straub, D. Predictive repair scheduling of wind turbine drive-train components based on machine learning. Wind Energy 2019, 22, 1230–1242. [Google Scholar] [CrossRef]

- Vijayakar, S.; Marambedu, K.; Baker, B. TRANSMISSION3D User’ Manual; (v 2.5000/0.1300); ANSOL Advanced Numerical Solutions: Hilliard, OH, USA, 2020. [Google Scholar]

- Concli, F.; Gorla, C. Dynamic modeling of gears: An innovative hybrid FEM–analytical approach. Int. J. Comput. Methods Exp. Meas. 2020, 9, 117–125. [Google Scholar] [CrossRef]

- Concli, F.; Cortese, L.; Vidoni, R.; Nalli, F.; Carabin, G. A mixed FEM and lumped-parameter dynamic model for evaluating the modal properties of planetary gearboxes. J. Mech. Sci. Technol. 2018, 32, 3047–3056. [Google Scholar] [CrossRef]

- Concli, F.; Kolios, A. Preliminary Evaluation of the Influence of Surface and Tooth Root Damage on the Stress and Strain State of a Planetary Gearbox: An Innovative Hybrid Numerical–Analytical Approach for Further Development of Structural Health Monitoring Models. Computation 2021, 9, 38. [Google Scholar] [CrossRef]

- Integral, A.C.S.; Solution, E.; Problem, C. A combined surface integral and finite element solution. Int. J. Numer. Methods Eng. 1991, 31, 525–545. [Google Scholar]

- Prueter, P.E.; Parker, G.R.; Cunliffe, F. A Study of Gear Root Strains in a Multi-Stage Planetary Wind Turbine Gear Train Using a Three Dimensional Finite Element/Contact Mechanics Model and Experiments. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE 2011, Washington, DC, USA, 28–31 August 2011. [Google Scholar]

- Vijayakar, S.M.; Busby, H.R.; Houser, D.R. Linearization of multibody frictional contact problems. Comput. Struct. 1988, 29, 569–576. [Google Scholar] [CrossRef]

- Parker, R.G.; Vijayakar, S.M.; Imajo, T. Non-linear dynamic response of a spur gear pair: Modelling and experimental comparisons. J. Sound Vib. 2000, 237, 435–455. [Google Scholar] [CrossRef]

- Monteiro, R.P.; Vidoni, R.; Concli, F. Two Different Numerical Approaches for Supporting Vibration-Based Structural Health Monitoring of Gear Train Systems. In Managing and Implementing the Digital Transformation, Proceedings of the 1st International Symposium on Industrial Engineering and Automation ISIEA 2022; Matt, D.T., Vidoni, R., Rauch, V., Dallasega, P., Eds.; Lecture Notes in Networks and Systems; Springer: Bolzano-Bozen, Italy, 2022; Volume 525. [Google Scholar] [CrossRef]

- Karabacak, Y.E.; Özmen, N.G.; Gümüşel, L. Intelligent worm gearbox fault diagnosis under various working conditions using vibration, sound and thermal features. Appl. Acoust. 2022, 186, 108463. [Google Scholar] [CrossRef]

- Salla, A. Structural Health Monitoring of Mechanical Gearboxes: A FEM Based Approach. Bachelor’s Thesis, Free University of Bozen-Bolzano, Bolzano-Bozen, Italy, 2020. [Google Scholar]

- Biswal, S.; Sabareesh, G.R. Design and development of a wind turbine test rig for condition monitoring studies. In Proceedings of the 2015 International Conference on Industrial Instrumentation and Control (ICIC), Pune, India, 28–30 May 2015; pp. 891–896. [Google Scholar] [CrossRef]

- Amarnath, M. Local Fault Assessment in a Helical Geared System via Sound and Vibration Parameters Using Multiclass SVM Classifiers. Arch. Acoust. 2016, 41, 559–571. [Google Scholar] [CrossRef][Green Version]

- Jha, R.K.; Swami, P.D. Intelligent fault diagnosis of rolling bearing and gear system under fluctuating load conditions using image processing technique. J. Mech. Sci. Technol. 2020, 34, 4107–4115. [Google Scholar] [CrossRef]

- Wibowo, F.W.; Wihayati, W. Multi-classification of Alcohols using Quartz Crystal Microbalance Sensors based-on Artificial Neural Network Single Layer Perceptron. In Proceedings of the 2021 International Conference on Artificial Intelligence and Computer Science Technology (ICAICST), Yogyakarta, Indonesia, 29–30 June 2021; pp. 37–41. [Google Scholar] [CrossRef]

- Hameed, S.S.; Muralidharan, V.; Ane, B.K. Comparative analysis of fuzzy classifier and ANN with histogram features for defect detection and classification in planetary gearbox. Appl. Soft Comput. 2021, 106, 107306. [Google Scholar] [CrossRef]

- Gupta, S.; Meel, P. Inventive Communication and Computational Technologies. In Lecture Notes in Networks and Systems, Proceedings of the 4th International Conference on Inventive Communication and Computational Technologies (ICICCT 2020), Tamil Nadu, India, 28–29 May 2020; Springer: Singapore, 2021; Volume 145. [Google Scholar] [CrossRef]

| Parameters | Symbol | Stage 1 (Service Gearbox) | Stage 2 (Test Gearbox) | Units | ||

|---|---|---|---|---|---|---|

| Helical Gear 1 | Helical Gear 2 | Spur Gear 1 | Spur Gear 2 | |||

| Center distance | 91.5 | 91.5 | mm | |||

| Face width | 80 | 14 | mm | |||

| N° of teeth | 34 | 36 | 17 | 18 | - | |

| Normal module | 2.5 | 5.0 | mm | |||

| Mass | 3.1 | 3.3 | 3.1 | 3.3 | ||

| Moment of inertia | 0.0122 | 0.0146 | 0.0122 | 0.0146 | ||

| Pitch circle diameter | 0.0888 | 0.0941 | 0.0888 | 0.0941 | ||

| Pressure angle | 20 | 20 | ||||

| Helix angle | 12 | 0 | ||||

| Contact ratio | 1.0588 | 1.0588 | 1.0588 | 1.0588 | - | |

| Young’s modulus | 200 | 200 | GPa | |||

| Poisson’s ratio | 0.3 | 0.3 | - | |||

| Set of Simulations | ||

|---|---|---|

| Damage Index | Axial Dimension (AD) Longitudinal | Radial Dimension (RD) |

| Nº Elements | Clearance (0 mm) | |

| Crack 1 | 1 | ✓ |

| Crack 2 | 2 | ✓ |

| Crack 3 | 3 | ✓ |

| Crack 4 | 4 | ✓ |

| Crack 5 | 5 | ✓ |

| Simulated Systems | Damages | |

| 1 | No crack | - |

| 2 | Pos 1-AD1 | Crack 1 |

| 3 | Pos 2-AD1 | Crack 2 |

| 4 | Pos 3-AD1 | Crack 3 |

| 5 | Pos 4-AD1 | Crack 4 |

| 6 | Pos 5-AD1 | Crack 5 |

| 7 | Pos 6-AD2 | Crack 1 |

| 8 | Pos 7-AD2 | Crack 2 |

| 9 | Pos 8-AD2 | Crack 3 |

| 10 | Pos 9-AD2 | Crack 4 |

| 11 | Pos 10-AD2 | Crack 5 |

| 12 | Pos 11-AD3 | Crack 1 |

| 13 | Pos 12-AD3 | Crack 2 |

| 14 | Pos 13-AD3 | Crack 3 |

| 15 | Pos 14-AD3 | Crack 4 |

| 16 | Pos 15-AD3 | Crack 5 |

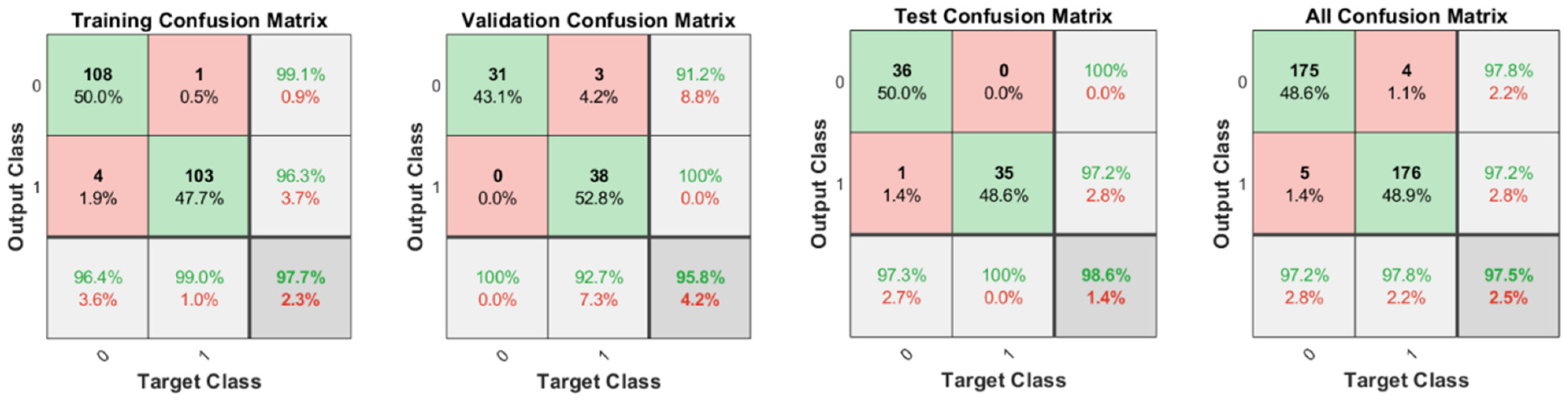

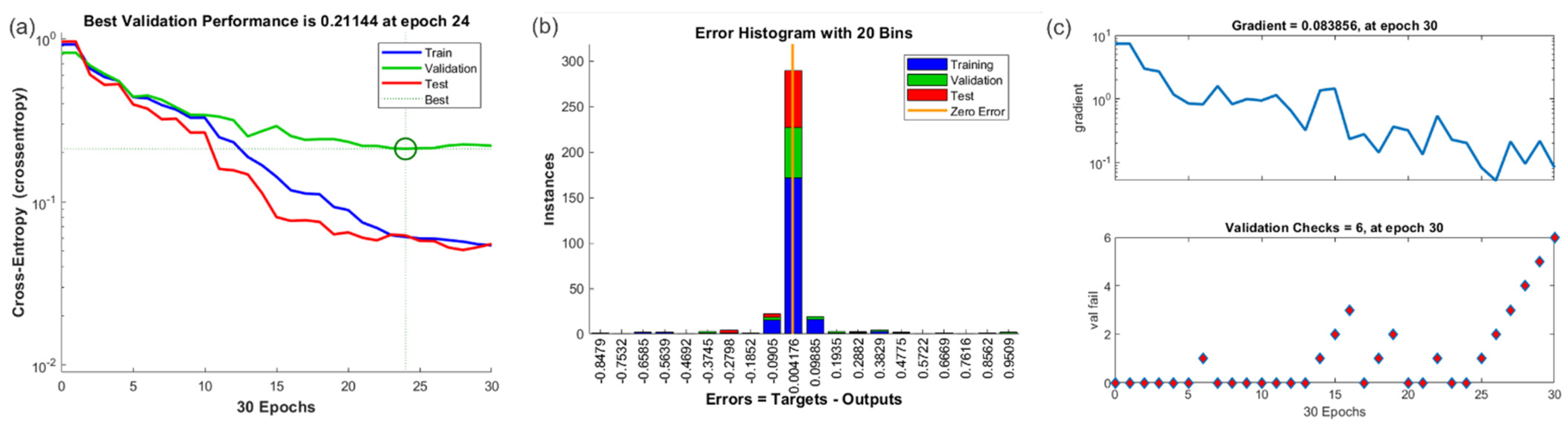

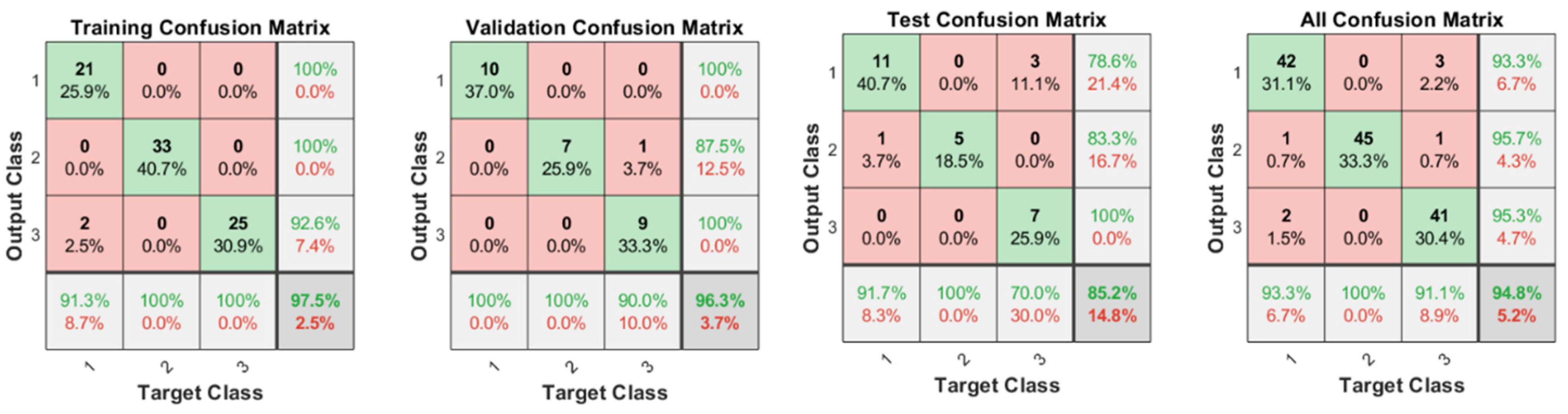

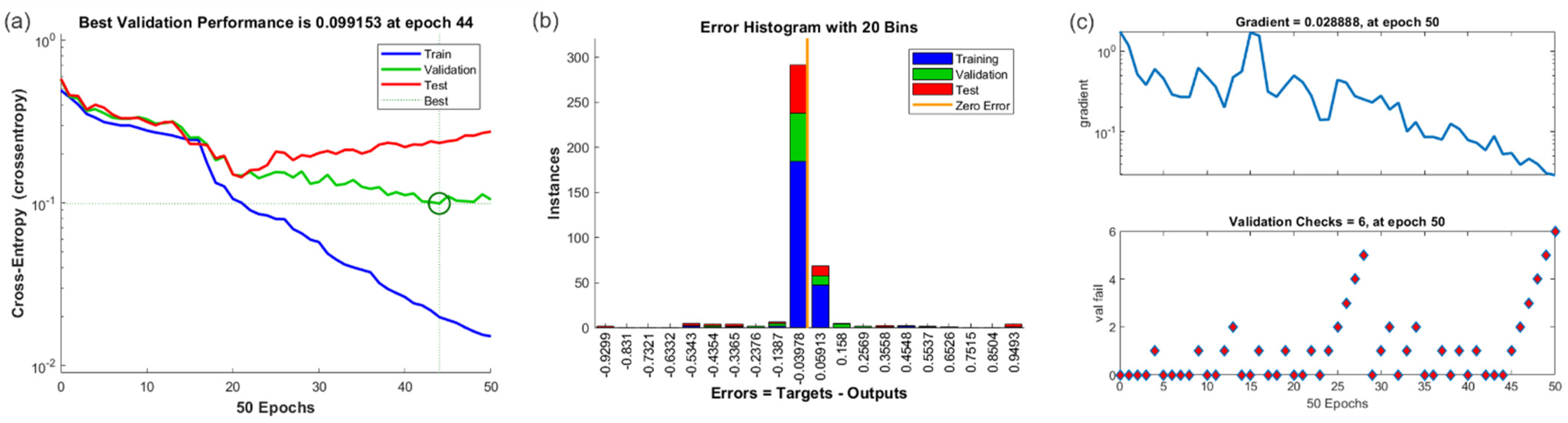

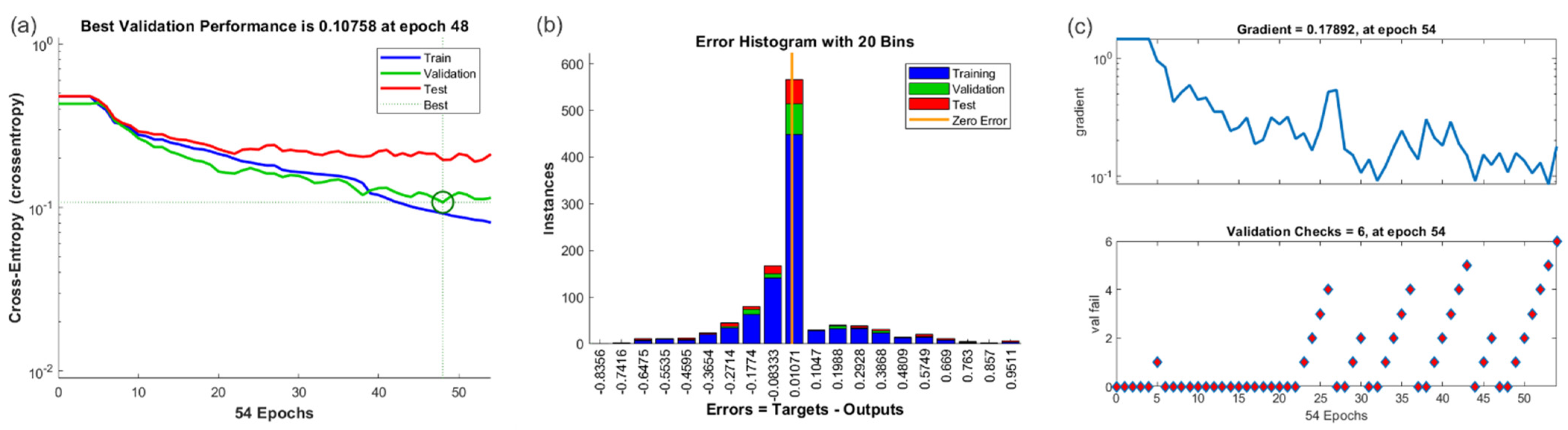

| Neural Pattern Recognition (nprtool) | |||

|---|---|---|---|

| Results | Samples | CE | %E |

| Training | 81 | 0.794494 | 1.60494 |

| Validation | 27 | 1.56895 | 1.85185 |

| Testing | 27 | 1.58625 | 3.33333 |

| Confusion Matrix Guide—Classification Method | ||||

|---|---|---|---|---|

| Total Number of Objects (n) = 360 | Predicted: No Damage (0) | Predicted: Damage (1) | Actual Objects (a) | |

| Actual (0) | TN = 175 | FP = 4 | a1 = TN + FP = 179 | a = a1 + a2 = n = 360 |

| Actual (1) | FN = 5 | TP = 176 | a2 = FN + TP = 181 | |

| Predicted Objects (p) | p1 = TN + FN = 180 | p2 = FP + TP = 180 | ||

| p = p1 + p2 = n = 360 | ||||

| Label 1 | ||||

| True Negative (TN) | Predicted no damage: yes, and there is no damage. | |||

| True Positive (TP) | Predicted damage: yes, and there is damage. | |||

| False Negative (FN) | Predicted no damage: yes, and there is damage. | |||

| False Positive (FP) | Predicted damage: yes, and there is no damage. | |||

| Label 2 | ||||

| Accuracy Index | What is the percentage of correct results for the classifier? | |||

| (TN + TP)/n = (175 + 176)/360 = 0.975 = 97.5% | ||||

| Misclassification Index | What is the percentage of wrong results for it? | |||

| (FP + FN)/n = (4 + 5)/360 = 0.025 = 2.5% | ||||

| True-Positive Index | When it is actually (1), what is the percentage of damage (1) prediction for it? | |||

| TP/a2 = 176/181 = 0.972 = 97.2% | ||||

| False-Positive Index | When it is actually (0), what is the percentage of damage (1) prediction for it? | |||

| FP/a1 = 4/179 = 0.022 = 2.2% | ||||

| True-Negative Index | When it is actually (0), what is the percentage of no damage (0) prediction for it? | |||

| TN/a1 = 175/179 = 0.978 = 97.8% | ||||

| False-Negative Index | When it is actually (1), what is the percentage of no damage (0) prediction for it? | |||

| FN/a2 = 5/181 = 0.028 = 2.8% | ||||

| Precision Index (0) | When it predicts no damage (0), what is the percentage of correct results for it? | |||

| TN/p1 = 175/180 = 0.972 = 97.2% | ||||

| No-Precision Index (0) | When it predicts no damage (0), what is the percentage of wrong results for it? | |||

| FN/p1 = 5/180 = 0.028 = 2.8% | ||||

| Precision Index (1) | When it predicts damage (1), what is the percentage of correct results for it? | |||

| TP/p2 = 85/90 = 0.978 = 97.8% | ||||

| No-Precision Index (1) | When it predicts damage (1), what is the percentage of wrong results for it? | |||

| FP/p2 = 5/90 = 0.022 = 2.2% | ||||

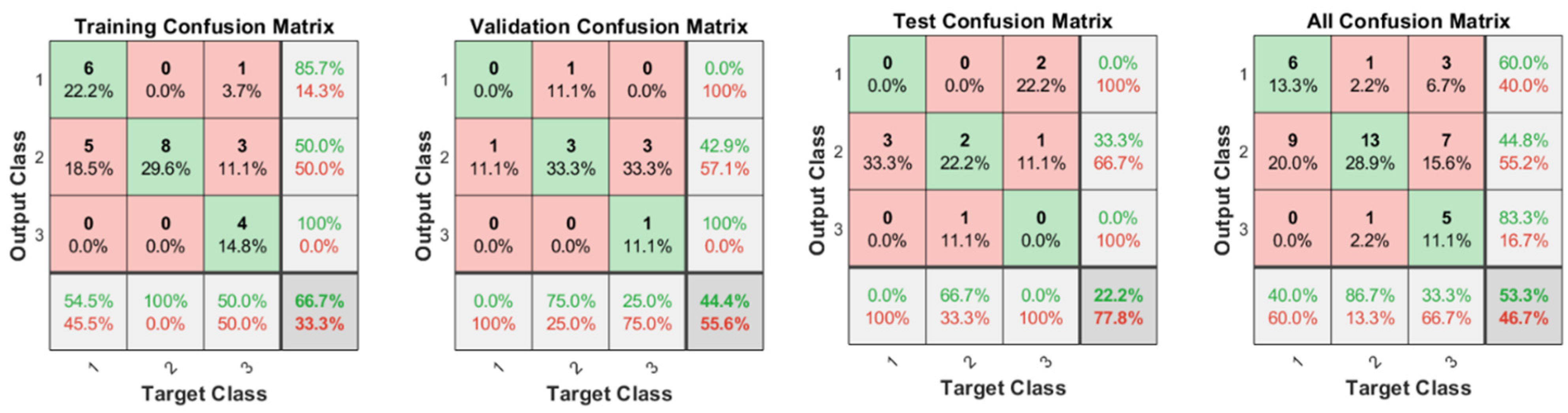

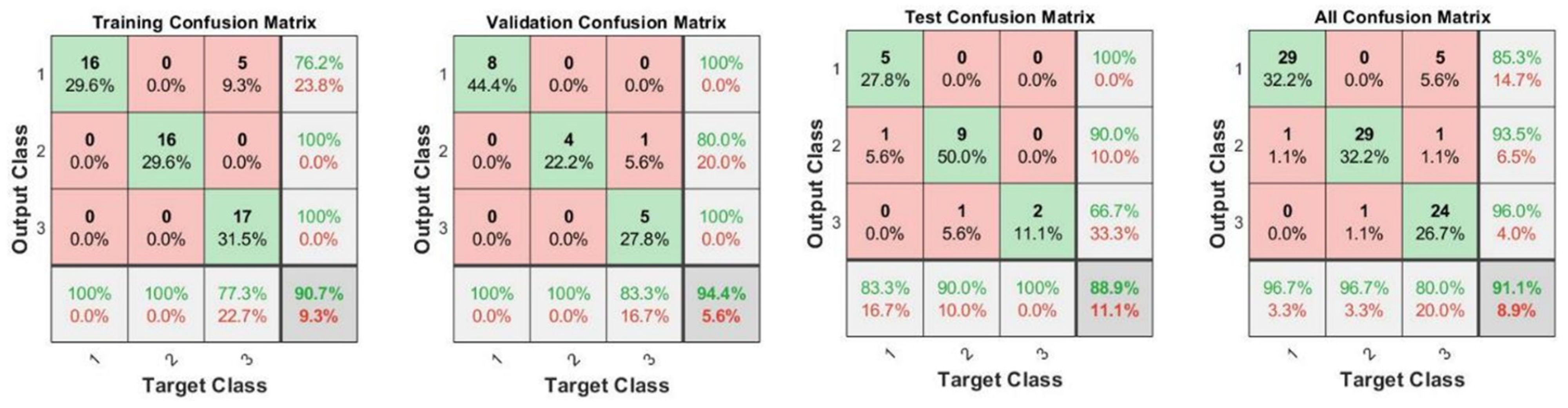

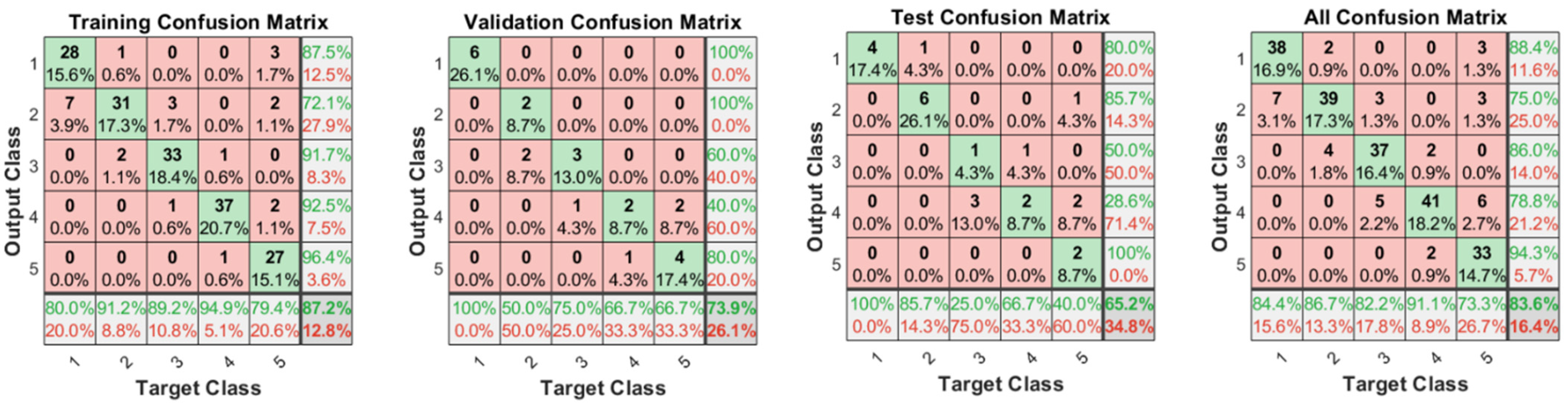

| Confusion Matrix Guide—Multi-Class Classification Method | |||||

|---|---|---|---|---|---|

| Number of Objects (n) = 135 | Predicted: No Damage (1) | Predicted: Medium Damage (2) | Predicted: Severe Damage (3) | Actual Objects (a) | |

| Actual (1) | TND11 = 42 | FMD12 = 0 | FSD13 = 3 | a1 = TND11 + FMD12 + FSD13 = 45 | a = a1 + a2 + a3 = n = 135 |

| Actual (2) | FND21 = 1 | TMD22 = 45 | FSD23 = 1 | a2 = FND21 + TMD22 + FSD23 = 47 | |

| Actual (3) | FND31 = 2 | FMD32 = 0 | TSD33 = 41 | a3 = FND31 + FMD32 + TSD33 = 43 | |

| Predicted Objects (p) | p1 = TND11 + FND21 + FND31 = 45 | p2 = FMD12 + TMD22 + FMD32 = 45 | p3 = FSD13 + FSD23 + TSD33 = 45 | ||

| p = p1 + p2 + p3 = n = 135 | |||||

| Label 1 | |||||

| True No Damage (TND11) | Predicted no damage: yes, and there is no damage. | ||||

| False No Damage (FND21) | Predicted no damage: yes, and there is damage. | ||||

| False No Damage (FND31) | Predicted no damage: yes, and there is damage. | ||||

| False Medium Damage (FMD12) | Predicted medium damage: yes, and there is no damage. | ||||

| True Medium Damage (TMD22) | Predicted medium damage: yes, and there is damage. | ||||

| False Medium Damage (FMD32) | Predicted medium damage: yes, and there is no damage. | ||||

| False Severe Damage (FSD13) | Predicted severe damage: yes, and there is no damage. | ||||

| False Severe Damage (FSD23) | Predicted severe damage: yes, and there is no damage. | ||||

| True Severe Damage (TSD33) | Predicted severe damage: yes, and there is damage. | ||||

| Label 2 | |||||

| Accuracy Index | What is the percentage of correct results for the classifier? | ||||

| (TND11 + TMD22 + TSD33)/n = (42 + 45 + 41)/135 = 0.948 = 94.8% | |||||

| Misclassification Index | What is the percentage of wrong results for it? | ||||

| (FND21 + FND31 + FMD12 + FMD32 + FSD13 + FSD23)/n = (1 + 2 + 0 + 0 + 3 + 1)/135 = 0.052 = 5.2% | |||||

| True No Damage Index | When it is actually (1), what is the percentage of no damage (1) prediction for it? | ||||

| TND11/a1 = 42/45 = 0.933 = 93.3% | |||||

| False No Damage Index | When it is actually (1), what is the percentage of medium damage (2) and severe damage (3) predictions for it? | ||||

| (FMD12 + FSD13)/a1 = (0 + 3)/45 = 0.067 = 6.7% | |||||

| True Medium Damage Index | When it is actually (2), what is the percentage of medium damage (2) prediction for it? | ||||

| TMD22/a2 = 45/47 = 0.957 = 95.7% | |||||

| False Medium Damage Index | When it is actually (2), what is the percentage of no damage (1) and severe damage (3) predictions for it? | ||||

| (FND21 + FSD23)/a2 = (1 + 1)/47 = 0.043 = 4.3% | |||||

| True Severe Damage Index | When it is actually (3), what is the percentage of severe damage (3) prediction for it? | ||||

| TSD33/a3 = 41/43 = 0.953 = 95.3% | |||||

| False Severe Damage Index | When it is actually (3), what is the percentage of no damage (1) and medium damage (2) predictions for it? | ||||

| (FND31 + FMD32)/a3 = (2 + 0)/43 = 0.047 = 4.7% | |||||

| Precision Index (1) | When it predicts no damage (1), what is the percentage of correct results for it? | ||||

| TND11/p1 = 42/45 = 0.933 = 93.3% | |||||

| No-Precision Index (1) | When it predicts no damage (1), what is the percentage of wrong results for it? | ||||

| (FND21 + FND31)/p1 = (1 + 2)/45 = 0.067 = 6.7% | |||||

| Precision Index (2) | When it predicts medium damage (2), what is the percentage of correct results for it? | ||||

| TMD22/p2 = 45/45 = 1.000 = 100.0% | |||||

| No-Precision Index (2) | When it predicts medium damage (2), what is the percentage of wrong results for it? | ||||

| (FMD12 + FMD32)/p2 = (0 + 0)/45 = 0.000 = 0.0% | |||||

| Precision Index (3) | When it predicts severe damage (3), what is the percentage of correct results for it? | ||||

| TSD33/p3 = 41/45 = 0.911 = 91.1% | |||||

| No-Precision Index (3) | When it predicts severe damage (3), what is the percentage of wrong results for it? | ||||

| (FSD13 + FSD23)/p3 = (3 + 1)/45 = 0.089 = 8.9% | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Paula Monteiro, R.; Lucatto Marra, A.; Vidoni, R.; Garcia, C.; Concli, F. A Hybrid Finite Element Method–Analytical Model for Classifying the Effects of Cracks on Gear Train Systems Using Artificial Neural Networks. Appl. Sci. 2022, 12, 7814. https://doi.org/10.3390/app12157814

de Paula Monteiro R, Lucatto Marra A, Vidoni R, Garcia C, Concli F. A Hybrid Finite Element Method–Analytical Model for Classifying the Effects of Cracks on Gear Train Systems Using Artificial Neural Networks. Applied Sciences. 2022; 12(15):7814. https://doi.org/10.3390/app12157814

Chicago/Turabian Stylede Paula Monteiro, Ronant, Amanda Lucatto Marra, Renato Vidoni, Claudio Garcia, and Franco Concli. 2022. "A Hybrid Finite Element Method–Analytical Model for Classifying the Effects of Cracks on Gear Train Systems Using Artificial Neural Networks" Applied Sciences 12, no. 15: 7814. https://doi.org/10.3390/app12157814

APA Stylede Paula Monteiro, R., Lucatto Marra, A., Vidoni, R., Garcia, C., & Concli, F. (2022). A Hybrid Finite Element Method–Analytical Model for Classifying the Effects of Cracks on Gear Train Systems Using Artificial Neural Networks. Applied Sciences, 12(15), 7814. https://doi.org/10.3390/app12157814