Abstract

When the uniformity of the magnetization yoke is low, a mismatch occurs between the physical rotation center and the center due to the magnetic force after magnetization. This discrepancy in rotation can cause issues such as vibration and noise during high-speed rotation, which in the long term leads to a decrease in the lifespan of the motor. In addition, in order to minimize the problem of motor lifespan when a vehicle is used for more than 10 years after purchase, the problems caused by magnetization should be solved as far as possible. In this study, magnetization yokes were designed in various ways to optimize the factors that affect the magnetic properties after the magnetization of the Nd2Fe14B permanent magnets used in electric motors. In the case of a 50 µm deviation between the coils wound inside the magnetization yoke, the magnetic property imbalance of the Nd2Fe14B magnets and the motor characteristics are not significantly affected after magnetization. However, when the center of the coil wound inside the yoke is shifted from the center of the yoke, the magnetic field is generated unevenly, which degrades both the magnetic and motor characteristics of the Nd2Fe14B magnet. Therefore, it is very important to control the center of the coil that generates the external magnetic field in the magnetized yoke in order to magnetize the Nd2Fe14B magnet with excellent magnetic properties.

1. Introduction

Electric and hybrid vehicles use three times more motors than fossil-fueled vehicles [1,2]. The use of so many motors increases the weight of vehicles and their fuel consumption. To solve this problem, the ferrite magnets used in the motors should be replaced with Nd2Fe14B permanent magnets with superior magnetic characteristics to reduce the weight of the motors and improve overall fuel efficiency [3,4,5]. Nd2Fe14B permanent magnets have been recognized as the most energy-efficient hard magnets with excellent magnetic properties. Nd2Fe14B-based permanent magnets have been intensively studied due to their strategic importance for modern economies; these magnets are key components in sustainable mobility and energy conversion devices [6]. The Nd2Fe14B phase crystallizes in a tetragonal structure with space group P42/mnm. Nd2Fe14B ternary magnets exhibit excellent magnetic properties since they can be produced in fine crystalline grains (ca. 0.3 µm), close to a single domain size, using the hydrogenation–disproportionation–desorption–recombination (HDDR) process [7], which was first reported by Takeshita and Nakayama [8]. Permanent magnets used in motors must be magnetized to uniformly create flux in 4 to 24 poles for uniform motor torque. If non-uniform flux is emitted from the yoke and the permanent magnets are non-uniformly magnetized, an unstable flux is emitted from the permanent magnets that are magnetized when the motor is driven. Such non-uniform magnetic flux emission causes an unstable rotation when the motor is driven, which results in noise and deterioration in the motor performance [9,10]. Therefore, in this study, various magnetic yokes were designed and fabricated to analyze the magnetic characteristics of the permanent magnets in order to understand the factors that are related to the non-uniform rotation of the motor. A permanent magnet magnetized in each condition was mounted on a rotor to manufacture a motor, and the performance of the motor was evaluated. Finally, we propose an optimal yoke design for improving motor performance.

2. Experimental Procedure

2.1. Materials

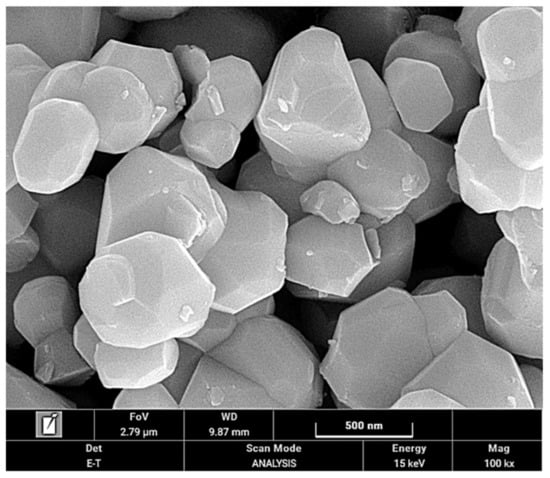

As a raw material, we used Nd2Fe14B powders with high residual inductance (9.15–9.35 kG) and low intrinsic coercivity (6.8–7.8 kOe), which were fabricated by employing a proprietary rapid solidification process followed by a milling process and heat treatment. Microstructures of specimens were examined with scanning electron microscopy (SEM). Figure 1 shows an SEM image of the Nd2Fe14B powders. The Nd2Fe14B powders have an irregular shape with an average particle size of approximately 500 nm.

Figure 1.

SEM image of as-received Nd2Fe14B powders.

Nd2Fe14B powders and epoxy resin were mixed manually, to which was added a hardener weighing approximately 0.5% of the epoxy resin. The mixed materials were pressed with an applied pressure of ~5 MPa, and we obtained a disk sample with diameter of 10 mm and thickness 7 mm. The pellet samples were cured using a drying oven at 200 °C.

A magnetometric study of Nd2Fe14B bonded magnets was performed. The magnetic properties of Nd2Fe14B had a strong temperature dependence. The (BH) max drops sharply once the temperature exceeds 100 °C. In order to achieve saturation magnetization, the power conditions of the magnetizing yoke were set to 950 V and 800 uF to generate 1.4 Tesla magnetic fields at room temperature. A magnetized yoke was designed to emit various magnetic fluxes.

Case 1: The center of the magnetization yoke core and the winding coil coincided with one another.

Case 2: The center of the yoke core and the winding coil matched, but the center of the wound coil had a 100 μm deviation.

Case 3: The center of the winding coil was shifted by 50 μm from the center of the yoke core.

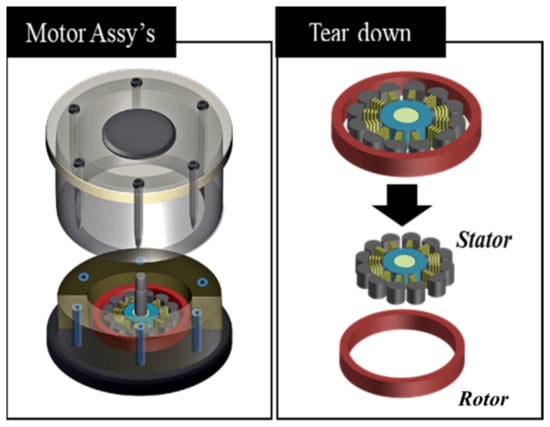

Nd2Fe14B bonded magnets with 100 ea were magnetized with a magnetized yoke to produce each condition. Each of the magnetized Nd2Fe14B magnets was used to manufacture a motor. The magnetized yoke was analyzed through a non-destructive analysis procedure. Additionally, magnetic properties of the magnetized yoke and magnetized magnet were analyzed using a surface flux meter. The motor was fabricated using the magnets magnetized with the respective magnetizing yokes, and the correlation between the magnetizing yoke and the motor characteristics was analyzed. Figure 2 shows the schematics of motor assays and tear-down images of motor indicating stator and rotor (Nd2Fe14B bonded magnets).

Figure 2.

Schematics of motor assays and tear-down images of motor indicating stator and rotor (Nd2Fe14B bonded magnet).

2.2. Testing Procedures

In this study, three designs of magnetization yokes were proposed to confirm the influence of the magnetic flux emitted from the yoke at the time of magnetization. Based on the three designs, the magnetization yoke was manufactured. The manufactured magnetization yoke was connected to the magnetizing power supply, and magnetization was performed under the conditions of 1500 V and 2000 uF.

The magnetized magnets were evaluated to determine their magnetization characteristics using a surface flux meter. Moreover, after the magnetized magnet was mounted on the motor and driven, total harmonic distortion analysis (THD) and back electromotive force (BEMF) were evaluated, respectively.

3. Results and Discussion

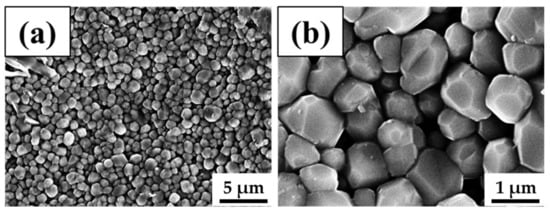

Figure 3 shows microstructures of the Nd2Fe14B bonded magnets fabricated in this research. The polished microstructures (Figure 3a,b) of the Nd2Fe14B bonded magnets show Nd2Fe14B particles uniformly and densely dispersed in the sample. The observed powder size from SEM images was approximately 500 μm.

Figure 3.

(a) Low- and (b) high-magnification SEM images of Nd2Fe14B bonded magnets.

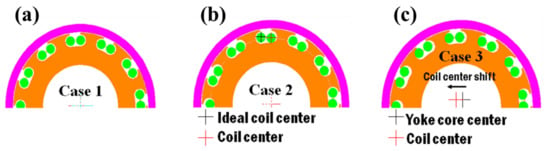

In order to confirm the influence of the magnetic flux emitted from the yoke at the time of magnetization, three kinds of magnetization yokes (cases 1 to 3) were designed and are shown in Figure 4. In case 1, the center of the yoke core and the center of the coil were designed to be the same and are shown in Figure 4a. In order to confirm the effect of the magnetizing coil that emits the magnetic field at the time of magnetization, the center of the yoke core and the coil were designed to be the same, and the center of each coil was designed to have a deviation of 100 μm in the radial direction. This condition is shown in Figure 4b. For case 3, the center of the coil was designed to have a deviation of 50 μm from the center of the yoke core and is shown in Figure 4c.

Figure 4.

Magnetization yoke design for (a) when the yoke center and coil center coincide; (b) when the center of the winding coil has a 100 μm deviation; (c) when the center of the winding coil has a 50 μm shift from the center of the yoke core.

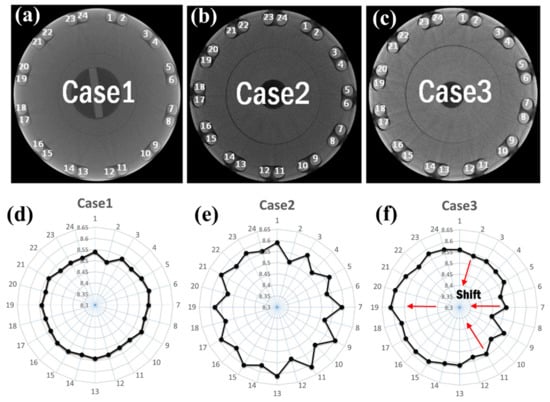

The designed yokes were fabricated and then subjected to 3D non-destructive analysis with an X-ray, as shown in Figure 5. In case 1, we can confirm that the yoke core and the coil core coincide with each other, as seen in Figure 5a,d. In case 2, the position deviation of each coil is 100 μm in the radial direction, and is shown in Figure 5b,e. In case 3, the center of the coil was shifted to the left by 50 μm, as shown in Figure 5c,f.

Figure 5.

Three-dimensional non-destructive analysis with magnetization yoke ((a,d) case 1, (b,e) case 2, and (c,f) case 3).

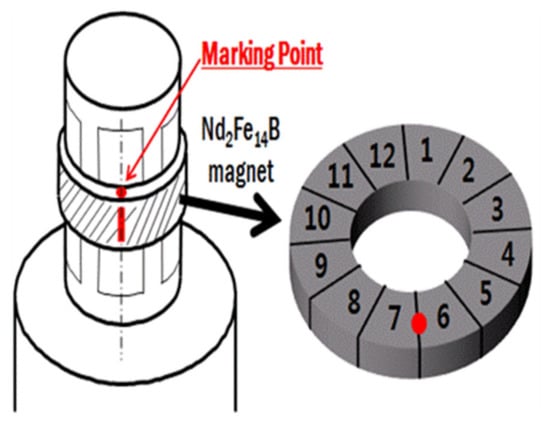

A Nd2Fe14B rare-earth bonded magnet was magnetized using a yoke in each of the three cases. In order to achieve saturation magnetization, the power condition of the magnetizing yoke was set to 950 V and 800 μF to generate 1.4 Tesla magnetic fields. To analyze the magnetic flux emitted from each pole of the magnetized yoke, the magnetic properties of each pole of the magnetized magnet were evaluated in the same manner, as shown in Figure 6.

Figure 6.

Schematic illustration of magnetization yoke and Nd2Fe14B permanent magnet used for the preparation of specimens.

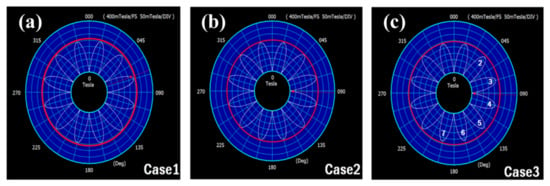

The surface magnetic flux density of the magnetized Nd2Fe14B magnet was measured [11,12]. Figure 7 shows the surface magnetic flux density of the Nd2Fe14B magnet with magnetizing yoke designs in all of the cases. In cases 1 and 2, it was confirmed that a uniform magnetic flux was generated in each pole as a whole. However, in case 3, a low magnetic flux was observed at the 2~7 poles.

Figure 7.

Surface flux analysis results of magnetized bonded permanent Nd2Fe14B magnet in (a) case 1; (b) case 2; and (c) case 3.

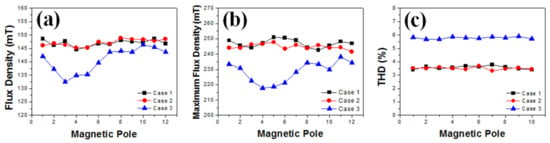

For a more accurate analysis, we analyzed the flux density, maximum flux peak value, and total harmonic distortion (THD) generated at each pole of the magnet magnetized using the magnetized yoke in cases 1 through 3, as shown in Figure 8 [13]. It can be seen that a constant flux density of 150 and 147 mT is generated in all the poles of the Nd2Fe14B bonded magnet magnetized with the yokes in cases 1 and 2, as seen in Figure 8a,b. However, in case 3, the magnet density of 135 mT can be observed at magnet poles 2~6, as in Figure 8c. As a result of the maximum flux peak analysis, it was confirmed that the maximum flux peaks of the magnets in cases 1 and 2 were similar. In case 3, we were able to confirm the low flux peak at the 2~7 pole. This finding is due to the non-uniform flux from the magnetized yoke because of the shift at the center of the coil. As a result of THD analysis, the THD value of the magnet that was magnetized with the yoke in case 3 (6.2%) is much higher than those magnetized with the yoke in cases 1 and 2 (3.5%). If the flux distortion of the magnetization of the magnet is increased, the efficiency of driving the motor for a long time is lowered, which can generate noise. The shift in the yoke coil creates a pole with a non-uniform magnetic flux of the Nd2Fe14B magnet, so that the deviation of flux peak and density becomes very high.

Figure 8.

Magnetic property and total harmonic distortion analysis results obtained with Nd2Fe14B magnets using a magnetized yoke in cases 1~3 ((a) flux density; (b) maximum flux; and (c) THD).

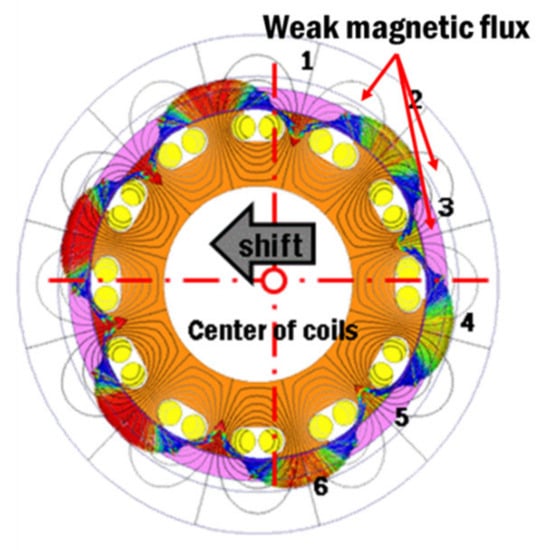

As a result of the magnetic field simulation for the design conditions in case 3 (Figure 9), it was confirmed that the low flux was emitted at poles 2 to 6. The simulation results are consistent with the surface magnetic flux density analysis results.

Figure 9.

Magnetic simulation of magnetized Nd2Fe14B rotor with a magnetizing yoke in case 3.

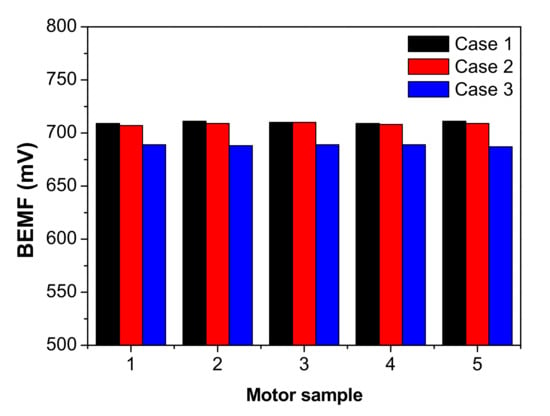

Figure 10 shows the results of the measurement of the back EMF of the motors manufactured using the Nd2Fe14B bonded magnets in cases 1 through 3 [13]. Generally, the power (P) of the motor can be expressed by the torque and angular velocity (ω) of the motor, as well as by the BEMF (e) and the stator core current (I) [14,15].

P = T × ω = (2 × r × F) × ω = (2 × r × B × I × ℓ) = e × I,

Figure 10.

Back electromotive force characteristic results of a motor with magnetized Nd2Fe14B magnets magnetized with yokes in cases 1 through 3.

From Equation (1), the BEMF (e) can be expressed as follows:

e = 2 × r × B × ℓ

If the current applied to the stator core is constant, the back electromotive force is correlated with B, the flux value of the rotor, which is the Nd2Fe14B permanent magnet magnetized in Equation (2). Therefore, in cases 1 and 2, where uniform flux is generated at each yoke pole, a uniform flux is formed in the entire rotor, and the equivalent BEMF value of 710 and 708.6 mV can be confirmed when the motor is mounted. However, when the magnets were magnetized with the yoke in case 3, which had low magnetic flux values at poles 2 to 7, and the forces were applied to the rotor, a low BEMF value of 688.4 mV was confirmed.

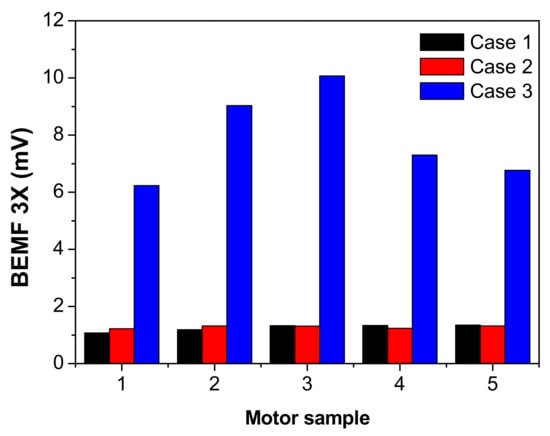

In addition, Figure 11 shows the measurement results for back EMF (3×) that were generated during the motor operation [16,17]. In general, the value of BEMF (3×) indicates the discrepancy between the physical rotation of the rotor and the electrical rotation. As a result of the analysis of the BEMF (3×) value of the motor using each rotor with a black rotor, it was confirmed that the motor using yokes in cases 1 and 2 measured 1.25 and 1.28 BEMF (3×). However, in case 3, where a non-uniform magnetic flux emission was confirmed, a high BEMF (3×) value of 7.87 was obtained.

Figure 11.

Back electromotive force (3×) characteristic results of a motor with Nd2Fe14B magnets magnetized with yokes in cases 1 through 3.

4. Conclusions

In order to analyze the correlation between the yoke and motor performance, we fabricated yokes as in cases 1, 2, and 3. The magnetic properties of the Nd2Fe14B rotor fabricated with each magnetized yoke were measured. In case 2, the good magnetic and motor characteristics of the rotor were confirmed. However, in case 3, the characteristics of the motor with a high BEMF were confirmed by the non-uniform magnetization characteristics of the rotor. Therefore, in order to fabricate a motor with excellent overall characteristics, the center of the yoke and the center of the winding coil must coincide with one another.

Author Contributions

Conceptualization, Y.-S.L., M.C. and I.J.; methodology, Y.-S.L., Y.S. and S.C.; formal analysis, Y.S. and S.C.; investigation, Y.S. and S.C.; resources, M.C.; data curation, Y.-S.L. and S.C.; writing—original draft preparation, Y.-S.L. and M.C.; writing—review and editing, S.C., M.C. and I.J.; visualization, S.C.; supervision, M.C. and I.J.; project administration, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the materials and parts technology developments (Grant No. 20010938), funded by the Ministry of Trade, Industry & Energy (MoTIE, South Korea).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Morrow, K.; Karner, D.; Francfort, J. Plug-in Hybrid Electric Vehicle Charging Infrastructure Review; US Department of Energy-Vehicle Technologies Program: Washington, DC, USA, 2008; p. 34. [Google Scholar]

- Chan, C. An overview of electric vehicle technology. Proc. IEEE 1993, 81, 1202–1213. [Google Scholar] [CrossRef]

- Chan, C.C.; Chau, K.; Jiang, J.; Xia, W.; Zhu, M.; Zhang, R. Novel permanent magnet motor drives for electric vehicles. IEEE Trans. Ind. Electron. 1996, 43, 331–339. [Google Scholar] [CrossRef] [Green Version]

- Chan, C.; Wong, Y. The state of the art of electric vehicles technology. In Proceedings of the 4th International Power Electronics and Motion Control Conference, Xi’an, China, 14–16 August 2004; pp. 46–57. [Google Scholar]

- Dhaliwal, A.; Nagaraj, S.C.; Ali, S. Hardware-in-the-Loop Simulation for Hybrid Electric Vehicles–An Overview, Lessons Learned and Solutions Implemented; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Choi, M.; Cho, S.; Song, Y.; Park, S.; Kim, Y. Simultaneous enhancement in coercivity and remanence of Nd2Fe14B permanent magnet by grain boundary diffusion process using NdHx. Curr. Appl. Phys. 2015, 15, 461–467. [Google Scholar] [CrossRef]

- Takeshita, T.; Morimoto, K. Anisotropic Nd–Fe–B bonded magnets made from HDDR powders. J. Appl. Phys. 1996, 79, 5040–5044. [Google Scholar] [CrossRef]

- Takeshita, T.; Nakayama, R. Development of HDDR process and anisotropic Nd-Fe-B bonded magnets. IEEE Transl. J. Magn. Jpn. 1993, 8, 692–700. [Google Scholar] [CrossRef]

- Hong, S.-P.; Cho, H.-S.; Lee, H.-S.; Cho, H.-R.; Lee, H.-Y. Effect of the magnetization direction in permanent magnet on motor characteristics. IEEE Trans. Magn. 1999, 35, 1231–1234. [Google Scholar] [CrossRef]

- Fenton, J.; Hodkinson, R. Lightweight Electric/Hybrid Vehicle Design; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Shmilovitz, D. On the definition of total harmonic distortion and its effect on measurement interpretation. IEEE Trans. Power Deliv. 2005, 20, 526–528. [Google Scholar]

- Damodharan, P.; Vasudevan, K. Sensorless brushless DC motor drive based on the zero-crossing detection of back electromotive force (EMF) from the line voltage difference. IEEE Trans. Energy Convers. 2010, 25, 661–668. [Google Scholar] [CrossRef]

- Murmann, J.P.; Frenken, K. Toward a systematic framework for research on dominant designs, technological innovations, and industrial change. Res. Policy 2006, 35, 925–952. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.; Ha, J. Design and analysis of analog filtering method for signal injection based sensorless control. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition-APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; pp. 1573–1578. [Google Scholar]

- Zhu, Z.; Almarhoon, A.; Ren, Y. Influence of back-EMF and current harmonics on sensorless control performance of single and dual three-phase permanent magnet synchronous machines. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2016, 35, 744–763. [Google Scholar] [CrossRef]

- van Dijken, S.; Gregg, J. Nanostructures for Spin Electronics. In Advanced Magnetic Nanostructures; Springer: Cham, Switzerland, 2006; p. 403. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).