1. Introduction

The uncertainty of demand has led production systems to be increasingly complex. In this context, the production requires a strategic alignment with global company objectives and a high capacity on the part of plant operations and technology to respond to market needs [

1] and flexible equipment with many configurations for their machines [

2]. This can affect the availability of the machines and therefore their maintenance, which is why adequate management of the information is necessary to facilitate decision making. In fact, the academic literature shows tools that facilitate efficient maintenance management, such as Erozan [

3], the selection of an effective maintenance strategy, such as Srivastava et al. [

4], specific solutions for predictive maintenance in machining processes, such as Jimenez-Cortadi et al. [

5], or a devotion to synchronizing manufacturing and maintenance activities [

6]. All this shows that the problem of selecting the best maintenance strategy is conditioned by a high complexity and that multi-criteria decision systems must be used, as Aghaee et al. [

7] points out.

On the other hand, the reliability is presented as principal focus for the maintenance [

8]. However, in this current era of industry 4.0, according to Vrignat [

9], lean manufacturing policies are considered insufficient and must be complemented with other policies of sustainability. The same author also highlights the need to incorporate new maintenance strategies with prognostics and health management to make decisions in time, creating opportunities for scheduled maintenance intervention and avoiding unexpected failure. Therefore, a system for decision making regarding the design of customized maintenance plans could attend to an industry demand.

Although there is a recent concern among plant experts regarding expanding the capabilities of the Reliability-Centered Maintenance (RCM) method in order to improve it, according to the work of Melani [

10], these improvements involve the replacement of the RCM method by a sequential model of methodologies of Functional Analysis of Operability, Hazard and Operability Study (HAZOP), Analysis of Failure Modes, Effects and Criticalities, Failure Mode, Effect and Criticality Analysis (FMECA) and Analytic Network Process (ANP). Similarly, Ma et al. [

11] suggests performing a data-driven RCM process, which basically replaces the FMECA with a quantitative analysis on possible maintenance effects and replaces the original RCM decision logic with a quantitative decision model based on MonteCarlo Simulation. Both of the proposed models involve an enormous effort in preparing all the documentation and studies to carry out this philosophy, resulting in an increase in the effort and time devoted to the application of a classic RCM process.

In addition to the methodologies to select the best maintenance action according to the RCM process, Condition-Based Maintenance (CBM) technologies must be integrated with Computer Maintenance Management Systems (CMMS) to achieve the maximum capacity of the three aforementioned systems, as indicated by López-Campos et al. [

12], and include unified functional knowledge, as pointed out by Song [

13]. This even includes TPM, as proposed Kumtekar et al. [

14], and Failure Modes and Effects Analysis, as proposed by Mkalaf et al. [

15].

This work presents a system for decision making regarding the design of customized maintenance plans within a production plant whose general objective is the proposal of a system that assists an expert in the decision making for the design of maintenance plans tailored to the real productive context of an industrial plant, as based on the alignment of the company’s strategic objectives and tactical and maintenance operations, according to a customized concept.

As a result of the previously applied strategic definition, a productive area of the plant was selected to implement the improvements [

16]. This area was taken as the starting point for the tactical definition, in which sections of the machine tree were analyzed in detail within the cited area according to the works of Rodríguez-Padial et al. [

17,

18]. The present operational definition, in synthesis, will try to solve a reliability problem posed by the proven success methodology of Reliability-Centered Maintenance (hereafter RCM) and driven by Case-Based Reasoning algorithms (hereafter CBR) to offer an optimized maintenance solution adapted to a new problem presented, such as a new case. On the other hand, Ruschel [

19] considers it essential that the CBR methodology improves the various models used in decision making, seeking to anticipate maintenance actions before the failure occurs.

This maintenance solution will have a maintenance type or class format to be applied. Its frequency and specific instructions are to be developed in the future work order that will be programmed in the Computer Aided Maintenance Management software (hereafter CMMS).

As the state of the art on the integration of RCM and CBR methodologies, it is worth highlighting, as a background, the work of Cheng et al. [

20], who developed an intelligent system called IRCMA with a similar approach, although with a great difference in terms of the approach regarding the treatment of the RCM process. Fundamentally, the big difference is that it tries to apply the CBR paradigm only in the FMECA part of the RCM methodology, making it possible to recover cases for this part, which is more difficult to document and consumes more time by experts, according to Candea et al. [

21], in subsequently applying the decisional flowchart of the RCM process in the new context of the problem through consultation. In this way, it is possible to, on the one hand, group the advantages of the CBR algorithm—recovering similar cases of FMECA, achieving substantial savings in the time spent by the expert and maximizing human capacities in terms of remembering similar cases when there is an abundant base of cases—and, on the other hand, correctly apply the RCM criteria regarding the classification of the maintenance policy to be carried out, not by recovering a similar CBR case. This is intended to use only the recovery of cases in the FMECA part of the method, closely related to the functional failure and its root cause, a fact that depends more on the type of equipment but not on the maintenance policy, which depends more on the context where said team works by using the original RCM criteria established by Moubray. There is a remarkably small bibliography in which both RCM and CBR methodologies are integrated, as indicated by Kobbacy [

22], exclusively evidencing the IRCMA reference already cited Cheng et al. [

20] until 2012. In this sense, a current bibliographic search shows that there are no other related publications to date.

The objective of this work of operational definition, as a final part of the proposed global system, is to assist in the design of customized maintenance plans focused on reliability in a driven way—that is, to guide the maintenance expert in an ideal way according to RCM method. In this way, human error is minimized, as Rahman et al. [

23] suggested, and an adequate level of excellence is ensured in the applied methodology. On the other hand, the time spent by the maintenance expert in case recovery work, analysis and the adaptation of the same case to the new case or the reliability problem presented is drastically reduced, since it is carried out automatically by means of a software application developed for this purpose. A fundamental advantage resides in the fact of having a large number of historical cases, and the expert will only consider the most similar k-cases, kNN, where k is the number of similar cases that will be displayed by the application. All of this translates the operational objectives by integrating the RCM method with the CBR methodology. Therefore, the objective is the operational definition, allowing the expert or leader of the RCM group to be efficiently conducted in the RCM method with great savings in devoted time, specifically for the part of the method where failure modes, effects and criticalities—FMECA—are analyzed for the organization’s business.

2. Methodology

In the design of this decision support system and the planning of customized maintenance processes of any industrial plant, it has been decided to use the RCM method due to its proven effectiveness in the industrial environments where it is implemented and which are equipped with a knowledge-based system through CBR algorithms to endow the RCM process with faster decision making by a group of RCM experts in its implementation. In parallel, being a driving-assisted system, human errors caused by forgetfulness or carelessness in the correct implementation of the RCM method are minimized.

Finally, the system will be a computer support, as an independent application that implements the RCM method according to CBR algorithms, in such a way that results in a driven RCM method, assisting the expert from its inception to completion. The following sections very briefly describe the RCM and CBR methodologies.

2.1. RCM Method

The Reliability-Centered Maintenance (RCM) method was originally designed for the aviation industry by Nowlan and Heap [

24], Anderson and Neri [

25] and Smith [

26], and, later, an extension of the RCM concept was used by Moubray [

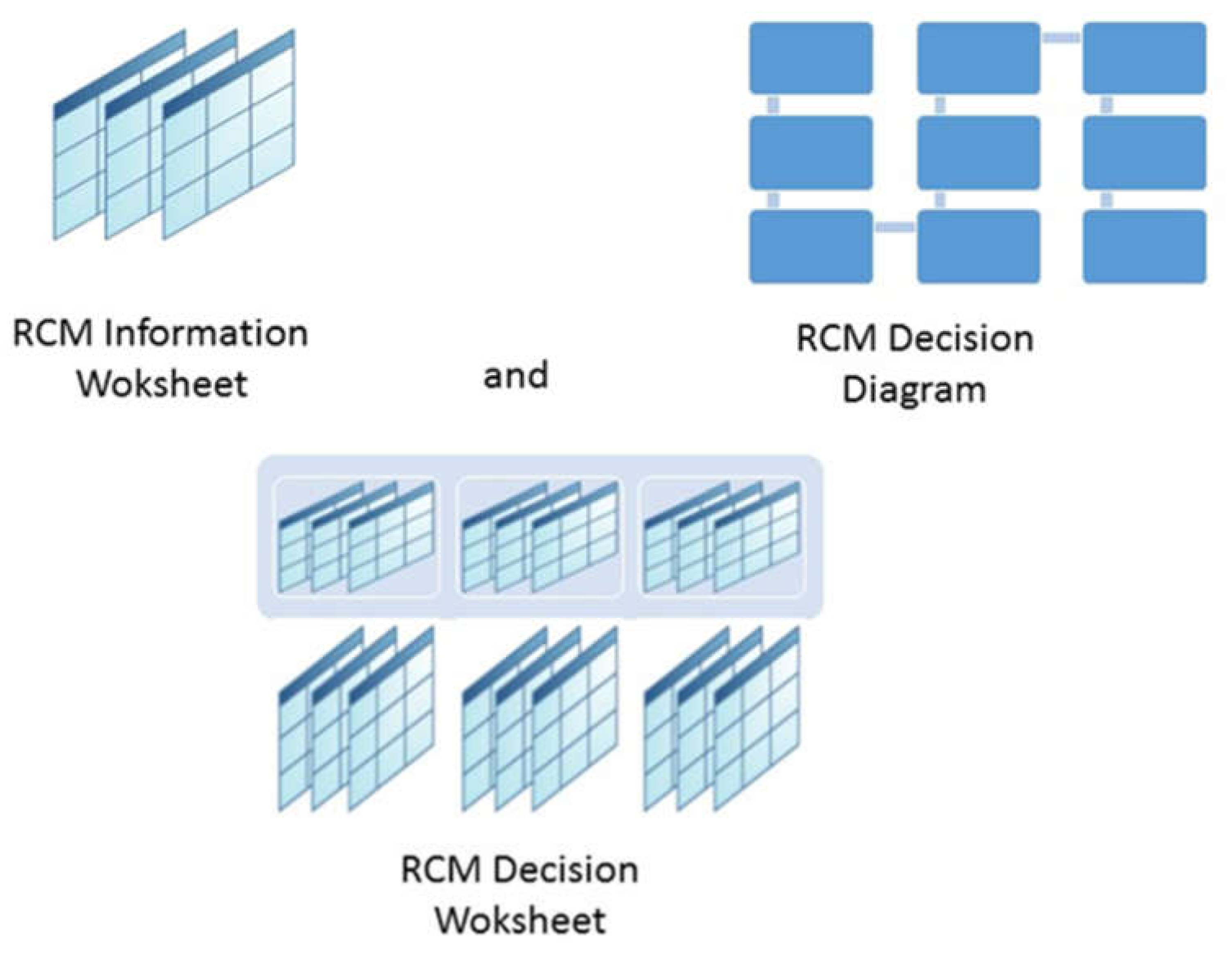

27] for a generic industrial environment. The concept is based on designing a maintenance plan based on the operational reliability of the plant. In summary, the functions required by the systems are defined; then, a Failure Modes, Effects and Criticalities Analysis (FMECA) is used, where they consider the possible functional failures being listed and link the different associated failure modes, their effects and their criticalities. The critical elements of the analyzed productive system are highlighted and located. The information is collected in an information worksheet, as shown in

Figure 1, adapted from Waeyenbergh and Pintelon [

28]. The next step indicates the use of a decision diagram, which helps in deciding the type of maintenance to apply, whose structure is shown in

Figure 1 and detailed in

Figure 2, the latter adapted from Saniuk et al. [

29]. This diagram helps in recording the decision worksheet.

Although RCM is a proven, successful method focused on increasing the plant reliability, strictly applied, it is a complex and costly method, justifiable in aeronautical and high-risk industries, where high reliability requirements are imperative, but too expensive for the general industry, where the maintenance problem is more economical than reliability. These disadvantages can be overcome by replacing the strict application of the method with a more flexible and customized approach to the maintenance to be applied.

2.2. CBR Method

The Case-Based Reasoning (CBR) method was originally pioneered by Schank [

30] from his research work on dynamic memory [

31], in which he discovered that memory recalls solved cases as similarity patterns to solve new problems posed. In this way, he defines reasoning based on cases as “the resolution of problems using or adapting the solutions of old problems” [

32]. Case-Based Reasoning (CBR) is an artificial intelligence paradigm that combines problem solving and learning, as established by Watson [

33]—that is, Case-Based Reasoning (CBR) is a method to describe a problem posed where various technologies can be used for its resolution. In this work, jCOLIBRÍ, developed by Díaz-Agudo [

34], has been used as a technology for the algorithmic implementation of the Case-Based Reasoning (CBR) methodology in the Java programming language [

35].

In summary, the Case-Based Reasoning (CBR) method is based on the hypothesis of human reasoning, where similar problems present similar solutions; therefore, it is about solving problems by adapting solutions to problems previously solved successfully and by describing them in a similar way to the new problem raised. In this sense, it is possible to differentiate two spaces: the space of the problem posed, called the description space, and the solution space. The CBR method is described as a cyclical process, as seen in

Figure 3, with four activities: Recover, Reuse, Review and Retain. Once a new problem arises, a new case is created in the description space, and the Retrieve activity makes it possible to obtain from the case base those problems that are most similar to the new case described. Once the most similar case is obtained, called the recovered case, the second activity is called Reuse—that is, the solution of the recovered case is used as an approximation of the solution of the new problem posed. This proposed solution, if necessary, is revised or better adapted to the problem initially raised, obtaining an adapted case with a new solution. If this solution is validated as good, the last activity consists of retaining the case as a new learned case and incorporating it as a new case added to the case base. As can be seen, the CBR method seeks to increase knowledge by incorporating new cases each time the CBR cycle is invoked.

Of the four activities, attention is focused on the recovery activity to establish that this methodology allows for the use of different technologies to recover cases due to similarity. In this work, the Nearest Neighbor algorithm (hereafter NN) has been used to model the similarity between the new case and the existing cases in order to obtain the recovered case. kNN is the most widely used recovery method in the CBR methodology [

36]; this has been evaluated as the most accurate method compared to other methodologies such as k-means clustering (k-means), FCM (Fuzzy C-Means) and SOM (Self-Organizing Map). According to Watson [

33], the similarity can be assessed as described in the following equation:

The similarity between an objective case, T, and a case of the base of cases, S, is evaluated with the similarity function, f, for the attribute, i, extending it from the first to the last, n, of each case. As can be seen in “(1)”, it is a sum weighted by the weight, wi, that marks the importance of each attribute, i. Extending this assessment between the objective case, T, and all the cases of the case base, Sj, of those existing, m, a normalized and ordered list can be obtained from the highest to the lowest, thus configuring from the most similar cases to those least close to the target. Finally, only a group of them will be taken from the entire list, the first k most similar to the objective. In this work, a value of k = 3 has been considered, according to the recommendation of an interval comprised of 1 to 4 according to the study by Salton and McGrill [

37]. It has been shown in some cases that the choice of the value of k influences the efficiency of the CBR process. Thus, a possible improvement of the method to increase the efficiency of the recovery activity could be to not tacitly decide a value of k, if not to calculate it automatically based on the optimization of the statistical disparity applied to the base of cases, avoiding human intervention and its associated error for choosing the value of k [

38].

2.3. Implementation of the CBR Method with jCOLIBRI

The driven design system for Reliability-Centered Maintenance (hereafter driven RCM) has been implemented in the Java programming language using specialized CBR libraries, for which the jCOLIBRI environment has been selected, according to Recio-García [

39]. In particular, jCOLIBRI version 2 or jCOLIBRI 2 has been used as a framework for the development and construction of CBR systems developed by Recio-García [

40] in Java. In this work, the development layer in Java has been used, whose architecture allows for the representation of cases and their handling by means of a specific library of CBR methods to be used in the dedicated CBR application that is the object of this work, called AIRCM.

The division of the application is modularized in the pre-cycle, cycle and post-cycle periods. The pre-cycle and post-cycle periods contain methods in charge of managing the resources required by the main cycle methods. There are two main methods of the cycle: (1) Recovery and Selection Methods. From this group of methods, the closest neighbor (NN) recovery method has been used, with global and local similarity metrics. The local metrics use the similarity function, f, of “(1)” to calculate the similarity value between the different attributes that describe the target case and those of the comparable cases in the case base, while the global metric calculates the weighted mean (wi) of the similarity values returned by the local metrics. Once the cases are retrieved, methods are used that select a group of the retrieved cases to present them to the end user. The simplest approach consisting of returning the k best cases has been used, the combination of which brings together the retrieval method of the k most neighbors next or kNN. (2) Reuse and Review Methods, which include basic methods for copying the solution of a case to the query or for copying the values from the attributes to the description of the solution.

Finally, the structure of the cases is defined in a series of classes that enable all the representations of the cases.

3. Application: Results and Discussion

The Case-Based Reasoning (CBR) and Reliability-Centered Maintenance (RCM) methodologies have been integrated with the ultimate objective of obtaining a customized design of maintenance plan adjusted to the real needs of industrial plants and assisting the person in charge of maintenance in its design. This integration of both methodologies, implemented in the Java programming language, results in the obtention of an independent computer application for the driven RCM model called Artificial Intelligence Reliability-Centered Maintenance (AIRCM) and designed for the effect to be applied in any industrial environment.

In particular, the AIRCM application has been conceived in two parts. The first part implements the FMECA, typical of the RCM method, with the CBR method using the jCOLIBRI environment and the second part, where the maintenance policy has been implemented according to the decisional flow chart in

Figure 2, using the operating context of the new case raised. Therefore, the maintenance policy adopted for the recovered case is discarded. This is because the maintenance policy depends more on the operational context where the equipment is located—that is, its effects and not the failure mode—as this is more related to the type of equipment and the maintenance policy with the productive context.

Every Knowledge-Based System (KBS), such as the CBR method, must have access to and the ability to modify a database where the different historical cases validated as successful are stored. This case base is made up of the worksheets (

Figure 1) of FMECA information once the classic RCM method has been successfully applied in a productive environment. These record sheets have been considered as already existing and will suppose that the input information for a record in the database is a base of cases that have been interconnected to the AIRCM application that is the object of this work. Since the data sheets are usually arranged in spreadsheets, it is easy to dump the information and its structure into a new spreadsheet that will make up the case record and therefore the case base that the AIRCM application needs. This case base is a Comma-Separated Values (CSV) file.

Figure 4 shows the values of the CSV file in tabular form, each column corresponding to the attributes specified in

Table 1.

This section has been divided into three phases, according to chronological order: the preparation of the case base used the design and implementation of the AIRCM application and the use of it to solve a new case raised, enabling the applicability of the driven RCM method through running the AIRCM application.

3.1. Case Base

For this work, a case base has been prepared with a total of 35 cases (

Figure 4) by means of the easy dumping of data from the worksheets corresponding to 35 problems that actually occurred and were successfully solved under the classic RCM method on a specific machine within the productive area as a result of a previous strategic definition.

The machine is identified with the Section code “EW”, the result of a previous tactical definition. This machine is divided according to a machine tree in hierarchical format (Section, Installation, Equipment) to locate the zone where the fault occurs.

3.2. Design and Implementation of Conductive RCM: Application

Once a database with structured attributes has been established, the implementation of the AIRCM computer application begins, using the Java programming language under the eclipse environment. In the first part of the code, the jCOLIBRI environment has been used to implement the CBR method with the specific libraries designed for this purpose. In the second part, the code has been implemented through conditional sentences to establish the maintenance policy according to the RCM decision diagram for the operational context of the new case presented. To implement the code, the Integrated Development Environment (IDE), eclipse [

41] has been used, since jCOLIBRI presents a framework prepared for this environment through a perspective intended for this purpose, as can be seen in

Figure 5.

The design has been divided into four phases: configuration, pre-cycle, cycle and post-cycle. In the configuration, a mapping has been established between the attributes of the case base of the CSV file and the computational variables of the computer application. The correspondence between the attributes of the case base,

Table 1, and the computational variables of the application, the central red box in

Figure 5, which distinguish between the descriptive variables of the problem “d.” and the descriptive variables of the solution “s.”, is noted. The complete mapping can be seen in

Table 2. This is done with the assistance of jCOLIBRI assigning headers through a drop-down of variables. Regarding persistence or memory storage, the location of the case base must be indicated by its memory address, as can be seen in

Figure 5 on the file that contains RCM_EW.csv. The last part of the configuration is based on the third XML file that can be seen inside the config folder of the same figure, called similarityConfig.xml, which is generated from the jCOLIBRI wizard, as can be seen in

Figure 6. In this figure, the similarity of the method used has been configured—in this case, Nearest Neighbors (NN). It can be seen that the variables to consider for the comparison of cases are the three inherent locations within the machine tree (Section, Installation, Equipment) and that of the problem description (Functional Failure). Likewise, these variables have been combined with each other to obtain a global mean according to the chosen variable, weighting them to give more emphasis to those variables that have been considered more important, according to “(1)”. In this case, it has been decided to weight the functional failure variable with 70%, considering it the most important, since it is what the application tries to solve; however, the equipment and its location within a machine must be taken into account to resolve a possible tie between similar descriptions. In this case, it involves a 30% weighting, each variable of the section, installation and equipment being distributed equally at 10%. The local similarity function used for all the variables is the MaxString function in order to compare the similarity between the texts of the new case raised (objective) and all the available cases in the case base.

In the pre-cycle and post-cycle phases, cases have been loaded before executing the cycle and the resources have been released once the cycle has been executed, respectively, through connectors to the case base. However, the corresponding cycle phase contains the logical functioning flow of the CBR method (

Figure 3) and is executed through queries. This cycle presents two stages. The first one applies the flow of CBR on the FMECA part of the RCM method; this is a recovery of failure modes within the base of cases, comparing them with the new problem raised through consultation. The second stage attempts to reapply the maintenance actions, re-evaluating the Risk Priority Number (NPR), the maintenance task instruction, the maintenance policy or class, the interval and the person assigned.

3.2.1. First Stage—CBR-Based FMECA

Recover: At this stage of the Java source code using jCOLIBRI libraries, the NN method has been implemented. In the first place, the similarity configuration seen in the configuration phase (

Figure 6) has been obtained to later use it in the retrieval of cases, according to a query introduced in the cycle method as an input parameter. This query corresponds to the description of the problem of the new case raised. In the second instance of the code, the collection of all retrieved cases has been stored in a variable, where a score has been added for each case based on its similarity to the query.

Reuse: In this stage of the code, the selection of the k closest cases has been implemented due to their similarity to the new case. In this work, it has been decided to select the k = 3 most similar cases, considered as the ideal value within the range [

1,

9], as justified previously. In this way, the user has been allowed to choose between the three most similar cases, making himself the final decision maker on the similarity of the new case presented with respect to the case base. In the first sentence, the selected cases variable stores the three closest cases in order of the similarity of the cases retrieved in the previous eval collection, while in the second sentence, the choice variable stores the three cases selected but orders them in a table to be presented on the screen to the application user by using a pop-up window.

However, this window, in addition to presenting the three most similar cases in descending order, allows the user to decide which case is finally selected from the three presented, allowing the user to decide which one best suits the problem, as seen in the third block of the code using the Buy or Quit conditional.

Review: At this stage of the code, the user has been allowed to review the selected case by creating a case using the bestCase variable and copying the selected one (choice). The revision itself is based on modifying the values contained in the attributes of the identifier, the newCaseID description and the newSolutionID solution of the bestCase case in such a way that a new case is prepared with sequential identification to the last case of the case base.

3.2.2. Second Stage—Driven RCM within the CBR Cycle Review Activity

In this second stage, being within the review activity within the CBR cycle, the code has been implemented to modify the values of those attributes that involve the operational context by the RCM method—that is, instead of retrieving the values of the attributes of the entire solution, only those associated with the FMECA are retrieved, and the rest of the attribute values will be modified (revised) by the user according to the RCM decision-making methodology through the decision diagram (

Figure 2), allowing the operational context to be reconsidered again when designing the solution of the new case raised. The aforementioned decision diagram has been implemented in Java code through conditional sentences so that the solution can be reviewed through established questions—hence the name of the conductive RCM method. The attributes whose values have been reviewed through the implementation of the driven RCM are: Risk Priority Number (NPR) (through its occurrence, severity and detection factors), Proposed Task (PT), Initial Interval (II) and Responsible (R). Finally, the new maintenance policy or Maintenance Classification (MC) has been applied, obeying the RCM decision diagram and leading the user through the questions to obtain the maintenance action to be applied in this context.

The final part of the cycle is the Retain activity. In this case, the code only presents a single sentence. Where the new case chosen and reviewed, bestCase has been stored in the case base by adding one more instance in the RCM_EW.CSV file.

3.3. Use of the Application to Resolve a New Failure Case by Assistance

Starting from a situation in which the complete planning and design assistance system has been launched (that is, a previous strategic definition has been applied) and obtaining as a result a productive area of interest to the management, for that productive area, a previous tactical definition by middle managers is later applied, resulting in a machine (section) to which the RCM design must be applied in order to improve its reliability and maintainability. At this moment, instead of applying a classic design using the RCM method, the use of driven RCM is made possible through the AIRCM application designed in a previous section for this purpose, with the advantages of minimizing the time spent by the users responsible for the design and the human errors inherent in handling extensive case databases.

At this point, the AIRCM application has been launched on the machine identified as section “EW”, the result of a previous tactical definition. Once the case base has been prepared, the data needed as input information will be fourfold, as can be seen in

Figure 7. The last three variables locate the area where the problem to be analyzed has occurred, while the textual description of the problem has been entered with the first input variable. This has been prepared in this way because users (machine operators) who request maintenance intervention must submit a work request, PT, which is nothing more than the start of a Work Order (OT) of the CMMS application used by the maintenance department. It takes advantage of the existing equivalence between the description of a work request and the functional failure of a device, attribute FF, in

Table 1.

The input information of the new problem posed in the query window of

Figure 8 has been introduced, describing the problem as a Functional Failure: “They do not center the axes”; for the AXIS equipment; for the Equipment: “AXIS”; within Installation: “RESMAS”; and Section: “EW”.

The three recovered cases similar to the problem raised have been obtained and ordered in descending order of similarity. As can be seen in the table in

Figure 8, the case identified as ID = 2 of the Cases Base is the most similar to the problem posed. As can be seen, the cases ID = 3 and ID = 1 will be the second and third most similar among those found in the case base. However, the user of the application can choose the case that best suits the three cases presented, since it also allows him to see other variables such as failure modes or failure effects, which complete the FMECA. In this way, it is possible to recover similar cases and carry out an analysis of failure modes, effects and criticalities faster and easier than doing it again, in addition to adding the existing knowledge of the previous analysis of proven success.

Once the user has chosen the case that best suits the needs of the new case or problem raised, he selects it himself by clicking on the Select attribute of the three cases presented on the screen. In this work, he has chosen the first one, ID = 2, since it is the most similar to the problem posed. Obtaining as an output the recovered case ID = 2, the review stage begins, assigning the case ID = 36 as an additional case to the 35 existing cases in the case base.

Continuing with the review process, the second stage of the driven RCM process begins immediately by reviewing the contextual information of the new problem, as shown in

Figure 9. With the occurrence, severity and undetectable data entered, the new Risk Priority Number (NPR) is automatically calculated.

The second revision stage comprises redefining the new maintenance policy or class by following the RCM diagram in a guided way—that is, the user has been guided through the questions in the diagram, as seen in

Figure 10, where the user answers the questions and the maintenance policy is obtained as an output. In this work, the maintenance classification obtained is Maintenance by Operator, thus completing the solution of the chosen case (see the last case in

Figure 11).

Finally, the retention activity is checked by verifying the persistence (that is, verifying that the new case is stored in the database)—in this case, in the RCM_EW.CSV file—and that a new case is added with the description identifiers and solutions IDP = 36 and IDS = 36, respectively, as evidenced in

Figure 11. The newly added case is also highlighted in

Figure 11, where it can be seen how the case number 36 has been added within the case identifier attribute as a consecutive number to the last existing case in the original case base. It is verified that all the registered attributes of case 36 contain all the values obtained in the solution process of the new case, according to the conductive process in

Figure 8,

Figure 9 and

Figure 10.

3.4. Achieved Development

A maintenance model focused on driven RCM has been developed in such a way that it assists the user responsible for the customized design of the maintenance plans of any industrial plant, making three great advantages possible: the first is the considerable saving of time involved in carrying out an FMECA; the second the minimization of human error regarding the treatment of an extensive series of historical cases; and the third advantage is that the AIRCM application created for this purpose is used as training for the inexperienced maintenance user, where they can be fully guided in the process, accessing all the historical cases stored and successfully resolved. In this way, an AIRCM application is available, which can be used as a training system through case simulation, providing a didactic component.

Once the AIRCM application has been validated, different input cases are entered and the corresponding solution is obtained. The advantages and benefits of the proposed driven RCM model have been successfully tested by raising a series of new cases in the EW section, where there is a base of success stories of RCM programs already implemented.

3.5. Results Analysis

A conductive RCM model has been developed in such a way that it assists the user responsible for the customized design of maintenance plans for an industrial plant, thus enabling three major advantages: the first is the considerable time savings involved in carrying out a Failure Modes, Effects and Criticalities Analysis (FMECA); the second is the minimization of human error in the treatment of an extensive series of historical cases; and the third advantage is that the AIRCM application created for this purpose is used as training for the inexperienced user of maintenance, where he can be totally guided in the process, accessing all the historical cases stored and successfully resolved. In this way, he has an AIRCM application that can be used as a training system through case simulation, providing a didactic component.

Once the AIRCM application has been validated, different input cases are entered and the corresponding solution is obtained. The advantages and benefits of the proposed conductive RCM model have been successfully tested by proposing a series of new cases in the EW section, where there is a database of successful cases of Reliability-Centered Maintenance (RCM) programs already implemented. The new cases have enabled the simulation in the AIRCM application environment, obtaining the results shown in

Table 3. The total number of simulated cases for each of the input variables {INSTALLATION, EQUIPMENT and FUNCTIONAL FAILURE} is shown with X.

It should be noted that the robustness of the proposed conductive RCM model has been verified, leaving some values corresponding to the input variables empty, as evidenced in

Table 3 for simulations 1 to 3, where only one input variable has been reported, for simulations 4 to 6, reporting two input variables, and for simulation 7, reporting all the input variables. For all the simulations carried out, it has been observed that the retrieved cases most similar to the problem posed are correctly displayed as results, even with a lack of input information, thus concluding the validation process. In the same way, the goodness of the system has been verified, introducing some input cases as a query to the problem. This only informs the FUNCTIONAL FAILURE (FF) input field in the query, approximately as what would be done in a real case, leaving the rest of the fields—EQUIPMENT, INSTALLATION and SECTION—empty, without input information. That is, it is about describing the problem of an existing case by means of a similar description to observe the response of the system.

Table 4 highlights this type of simulation to show the results, such as similar recovered cases, concluding that there is a good system response.

The use of the application developed in a maintenance design process in an industrial plant in operation has allowed us to observe the following improvements in the results.

Empirically, a notable reduction in the time devoted to applying the Reliability-Centered Maintenance (RCM) methodology has been achieved. Considering that a case like the one presented in this work requires a series of meetings of the RCM group created expressly, in addition to a documentary analysis of the specifications of the assets subject to maintenance and their operational context, the development of the Mode Analysis process of Failure, Effects and Criticalities (FMECA) and the correct application of the Reliability-Centered Maintenance (RCM) flowchart, a reduction of the four hours dedicated to the classic RCM process by the person responsible for the maintenance design is obtained—only thirty minutes is required to use the conductive RCM process through the AIRCM application developed and used in this work. This does not account for the time that has had to be devoted by the members of the RCM group in the different meetings organized.

Another advantage achieved with the execution of the AIRCM application has been the management of the knowledge acquired regarding the resolution of problems that have occurred in the plant. Starting from successfully executing the application of the conductive RCM program a vast number of times, a large number of effectively resolved historical cases will be obtained, which implies a large amount of information, which will be considered as stored intellectual capital. When a large number of cases are available in a database, it becomes difficult and arduous to manipulate it through direct consultation by a maintainer. This phenomenon is mitigated by similar case retrieval processes implemented in the application itself, so case retrieval is handled very precisely, and this problem is solved.

Special emphasis is placed on the use of the developed application as a knowledge manager in the broadest term, since, by hosting a large base of success stories regarding the solution of real plant problems, it enables its use a simulator to train novice or inexperienced users in the maintenance plan design processes.

4. Conclusions

The successful integration of both methods—Reliability-Centered Maintenance and Case-Based Reasoning (RCM-CBR)—for the scope of the improvement in the optimal management of the maintenance of assets of an industrial plant is the aim pursued in this work. Although the individual benefits of both methods have been shown to improve the efficiency of industrial processes, the union of both pointing to the single direction of designing maintenance plans produces a combined effect in terms of their efficiency, their precision and the minimization of the time devoted to obtaining it. An additional advantage of redirecting the time dedicated to customizing the maintenance plan has been achieved, since, by saving time in the use of the RCM method by using a driven process and the automatic recovery of solutions to the problem posed, it allows the person responsible for the design of the maintenance plan to invest his time in customizing, by adapting recovered cases, the new proposed solution, in addition to correctly monitoring the execution of the proposed solution.

As a conclusion of this operational definition, within the global process of assisting in the decision making and planning of maintenance processes, an independent application in the Java programming language has been developed and used to conduct the complete RCM process with the use of Case-Based Reasoning (CBR) algorithms in order to recover and explore similar failure cases from a base of historical cases that have occurred and whose solutions were successfully applied in equivalent industrial plants. This has meant an exploitation of the knowledge of historical problems and their solutions that occurred in industrial plants, and this has also made it possible to extend and pool the human intellectual capital inherent in all industries, such as experts from various areas; the middle management of maintenance, production, process and maintenance engineers; workshop personnel; mechanics and electricians; etc. This philosophy of the integration of both paradigms (RCM-CBR) has made it possible to group the different previously described agents that are involved in the reliability problems of the industrial plant in order to reduce the time spent applying a classic RCM process. This time saving is a competitive advantage as soon as the implementation of the corrective actions become part of the maintenance management program. The effects of their application are obtained earlier compared to the classic application of the RCM method, channeling the analysis effort into the following critical areas for improvement. Finally, this last part is much faster, more operational and its objectives are aligned with the two preceding objectives—tactical and strategic, respectively—whose joint effect has resulted in increasing the overall efficiency of the industrial company.

As a result of this operational definition, a solution has been established as a maintenance action or task to be applied in response to a reliability problem detected for the equipment from a chosen section of the previous tactical definition. This solution, carried out iteratively on the section under analysis, allows for the creation of a complete maintenance plan for it to be programmed in the CMMS. It should be noted that this methodology is based on a continuous improvement scheme, which allows it to be applied frequently according to the launch of the complete system together with the previous strategic and tactical definitions, or independently when a loss of reliability is detected.

Although the term “adaptive maintenance” (AdM) has not been coined, Burggräf [

42] suggested that the maintenance function should not only restore or maintain the operating condition of productive equipment and used the term “adaptive remanufacturing” (AdR) to suggest that the evolution towards intelligent and strategic maintenance should improve productive resources by increasing the life cycles of assets, monitoring their performance levels and considering the technical, economic and ecological aspects. It is considered relevant for future work to add this new concept of adaptive maintenance to this operational definition, where, in addition to re-establishing the required function of the high-impact asset to be maintained, the availability is ensured and the required function is increased—for example, when there is an increase in the speed of a machine due to the demands of the changing production context. In summary, it is suggested that scheduled maintenance interventions provide opportunities for the improvement or adaptation of the originally projected required functions of production systems in an increasingly demanding context.