Influence of Inlet Parameters on Power Characteristics of Bernoulli Gripping Devices for Industrial Robots

Abstract

:1. Introduction

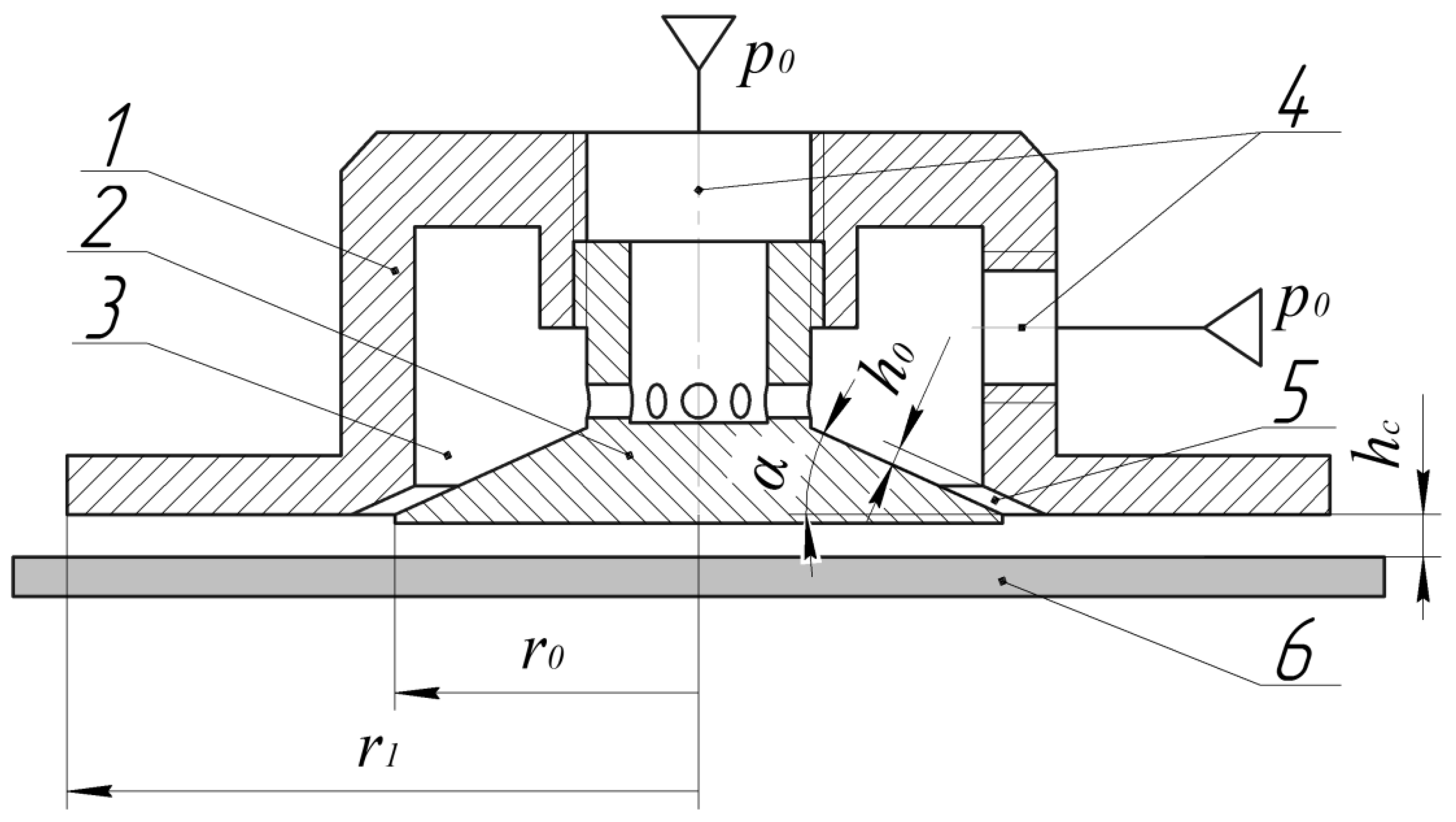

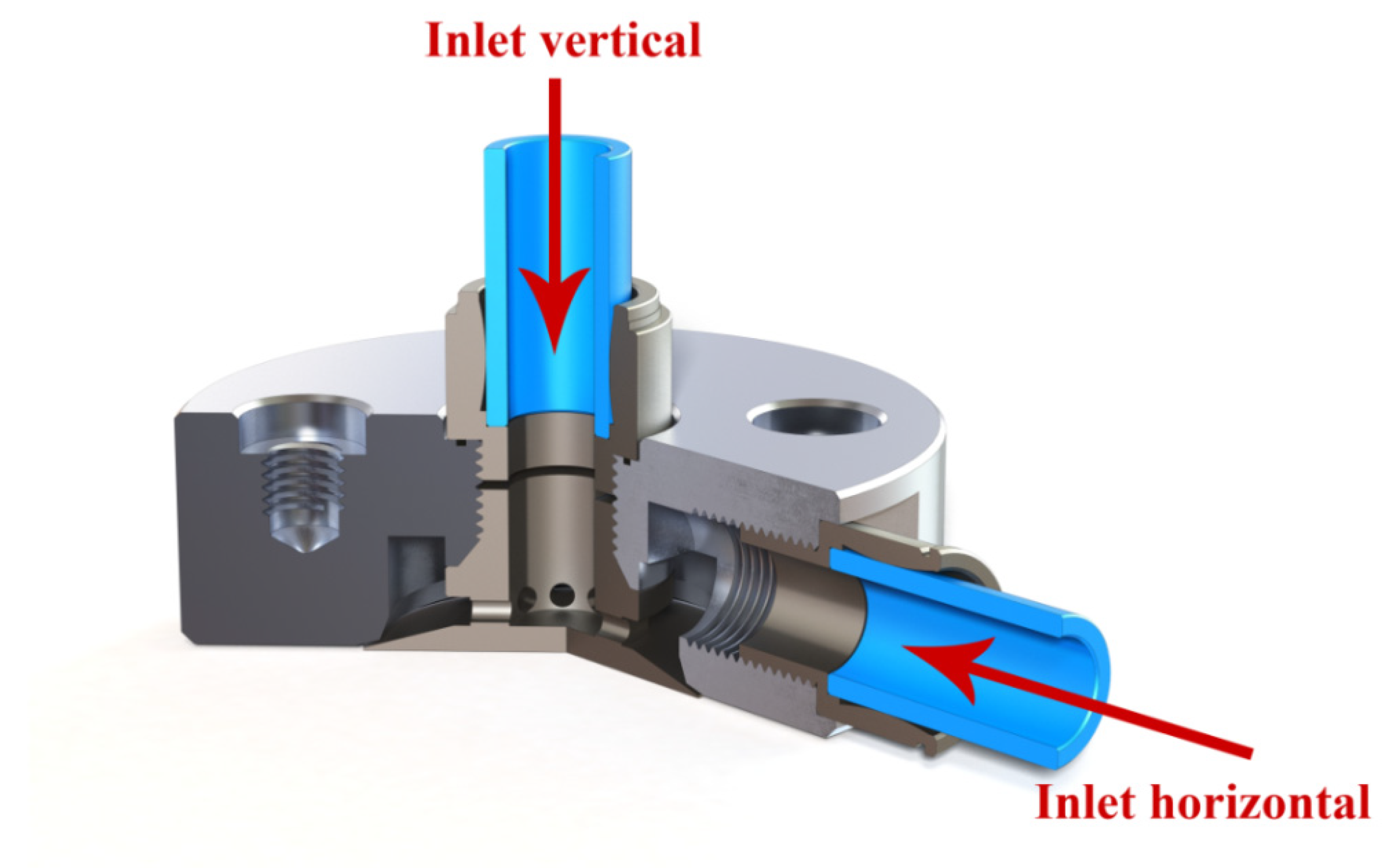

2. Materials and Methods

2.1. Theoretical Method

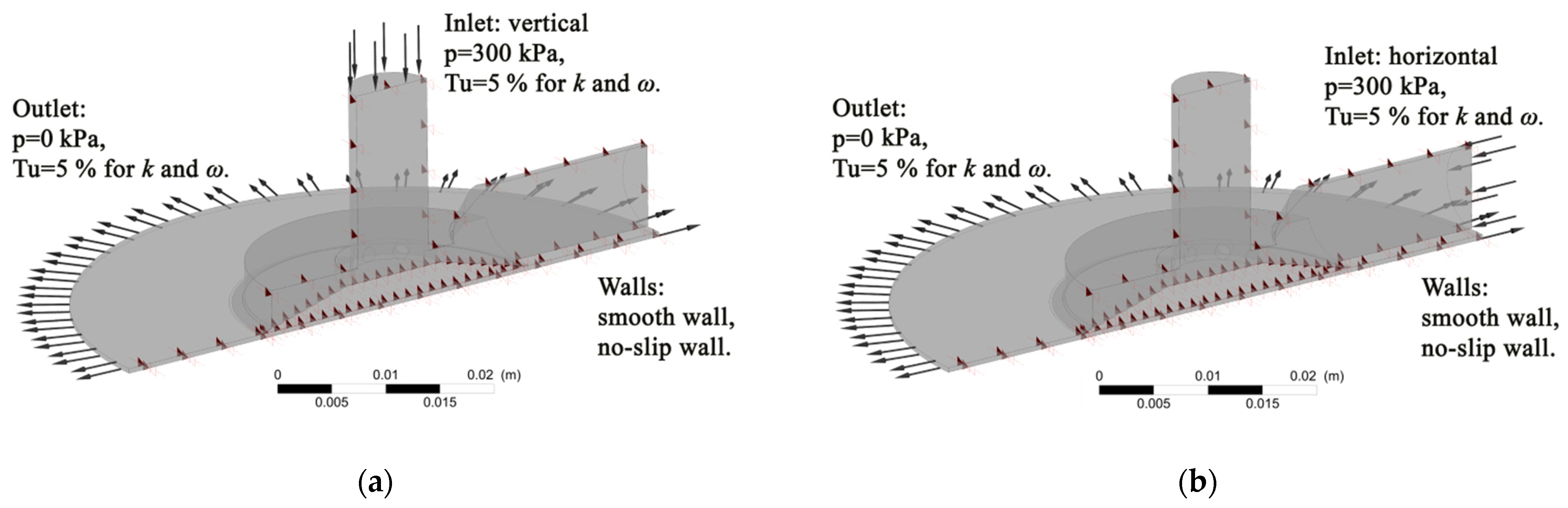

2.2. Finite Element Method

3. Results and Discussion

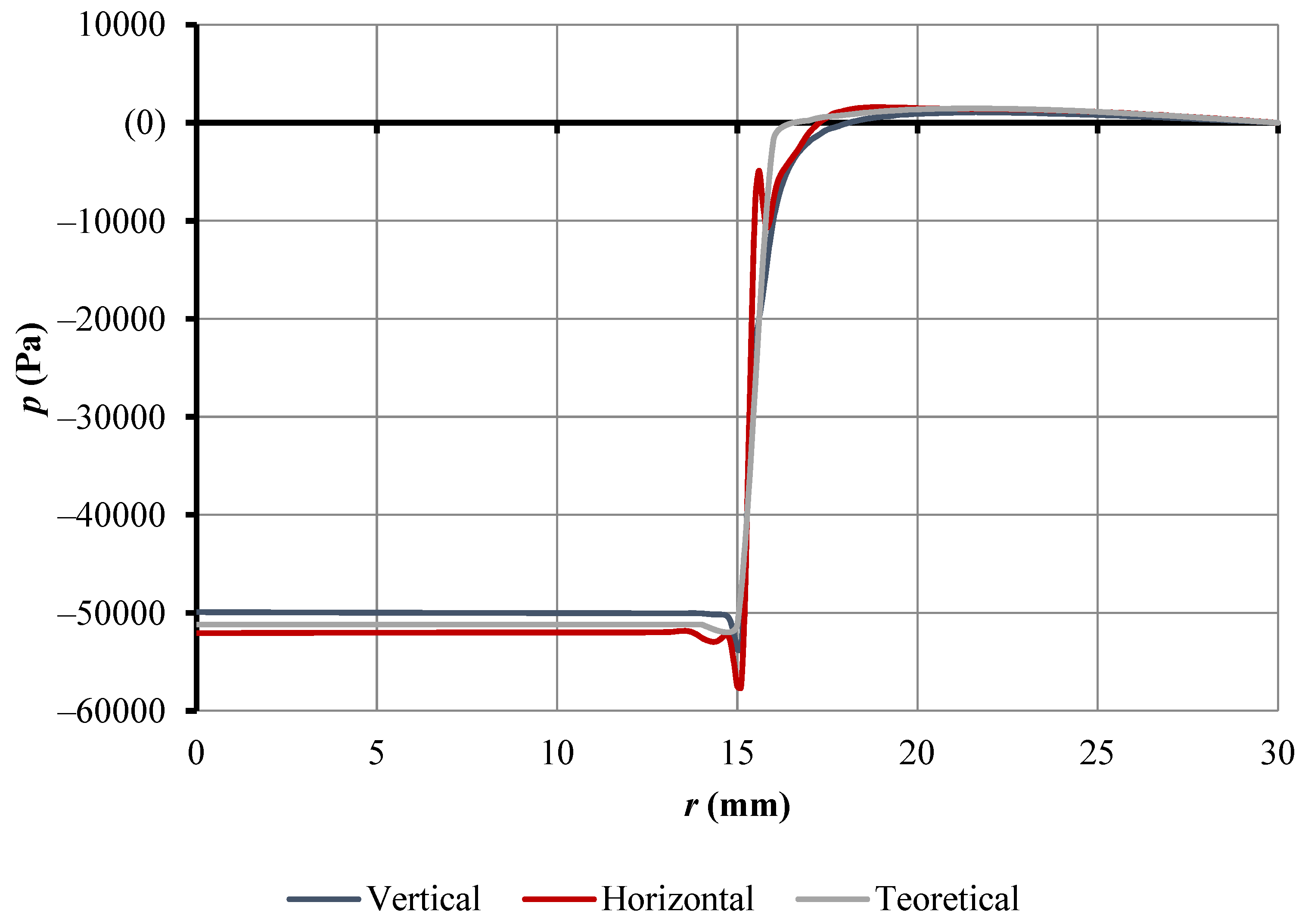

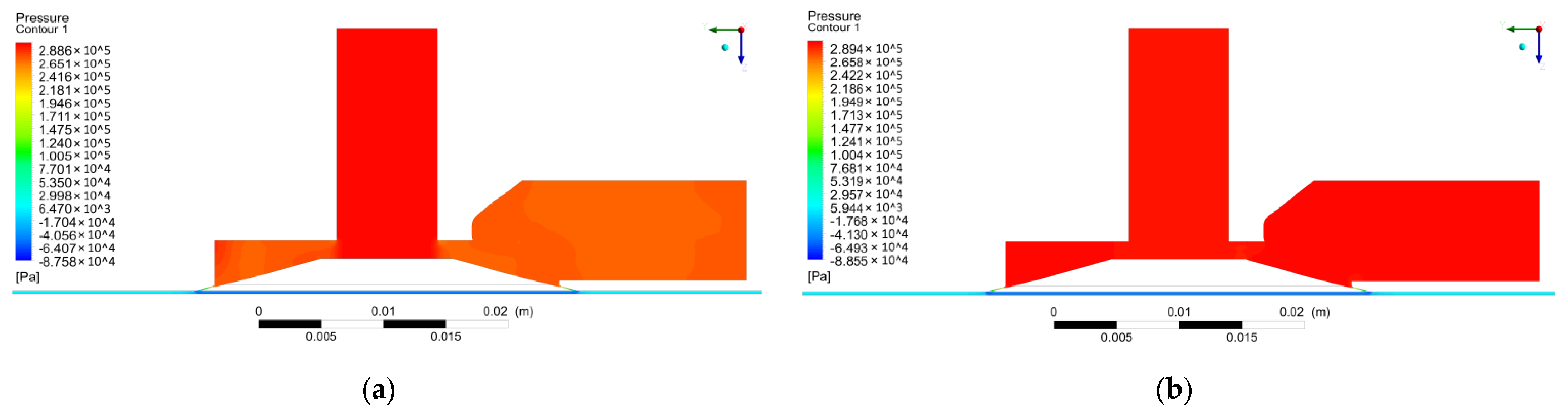

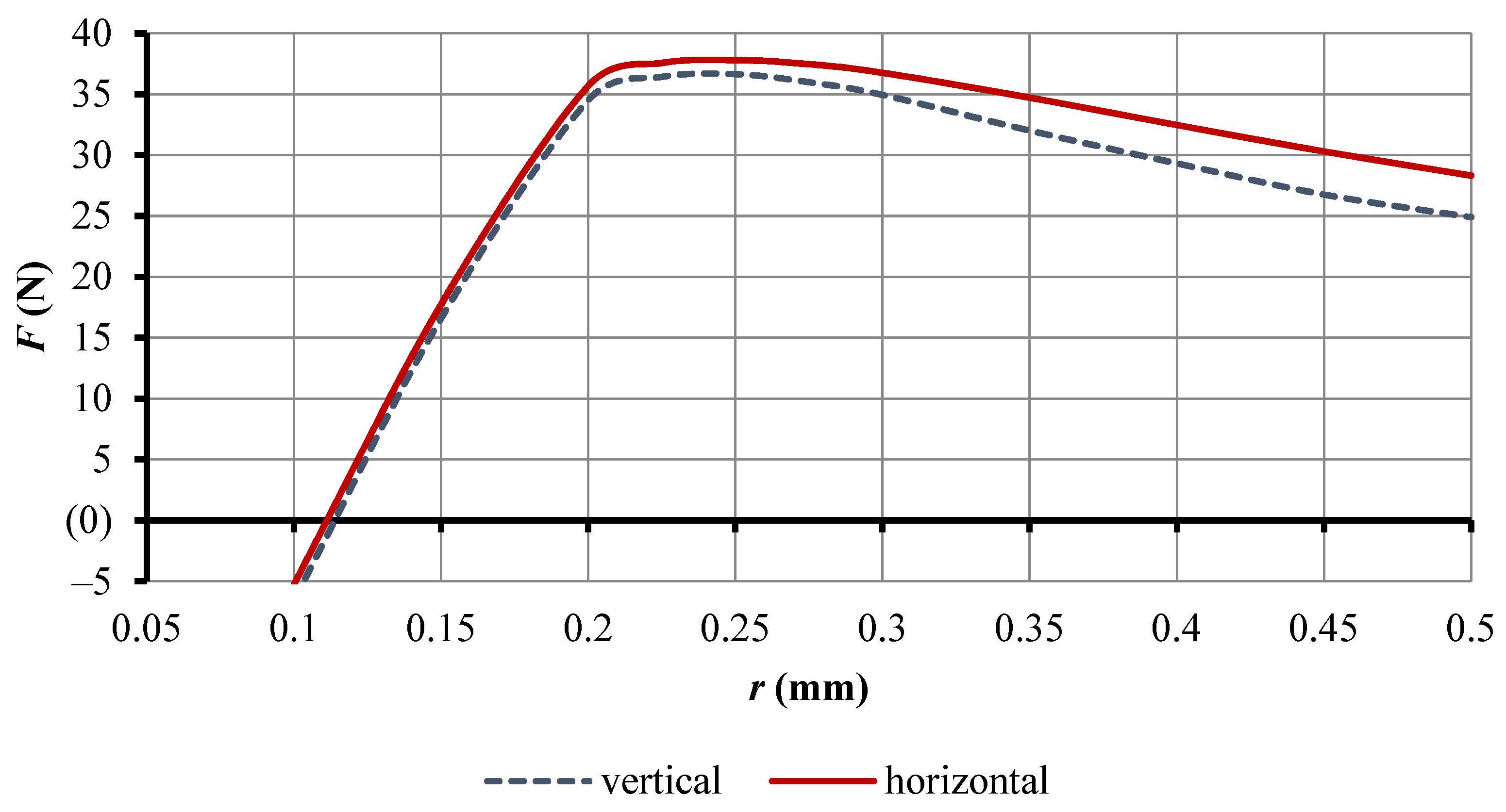

3.1. Influence of Compressed Air Supply Direction on BGD Power Characteristics

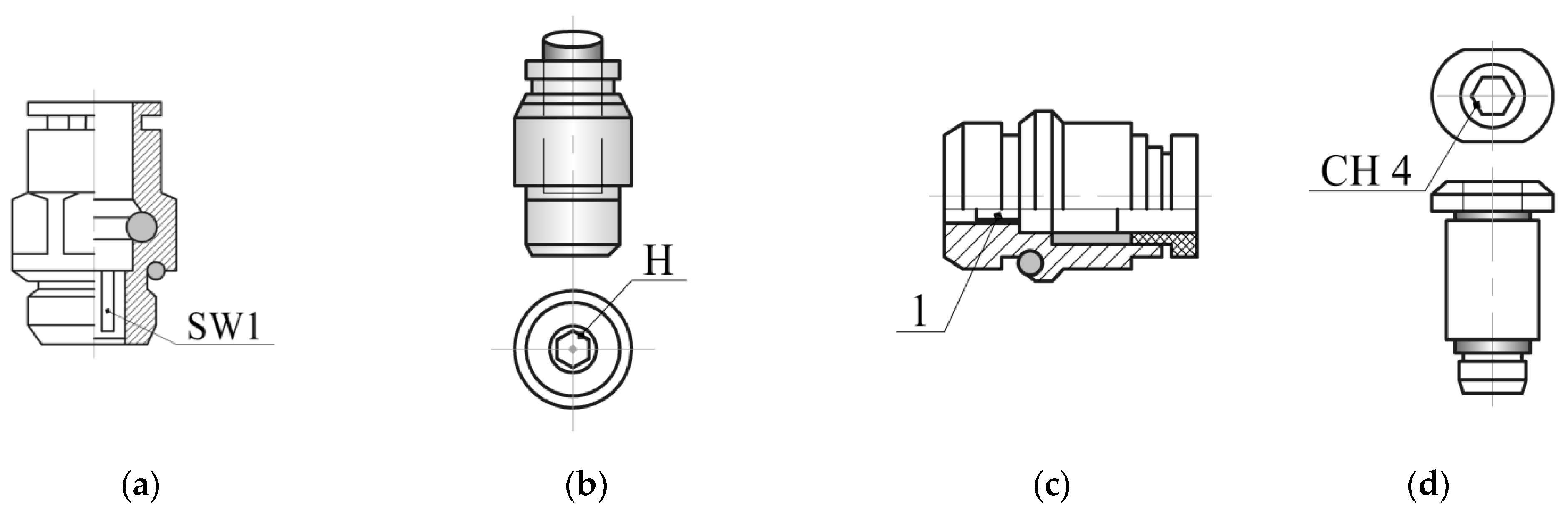

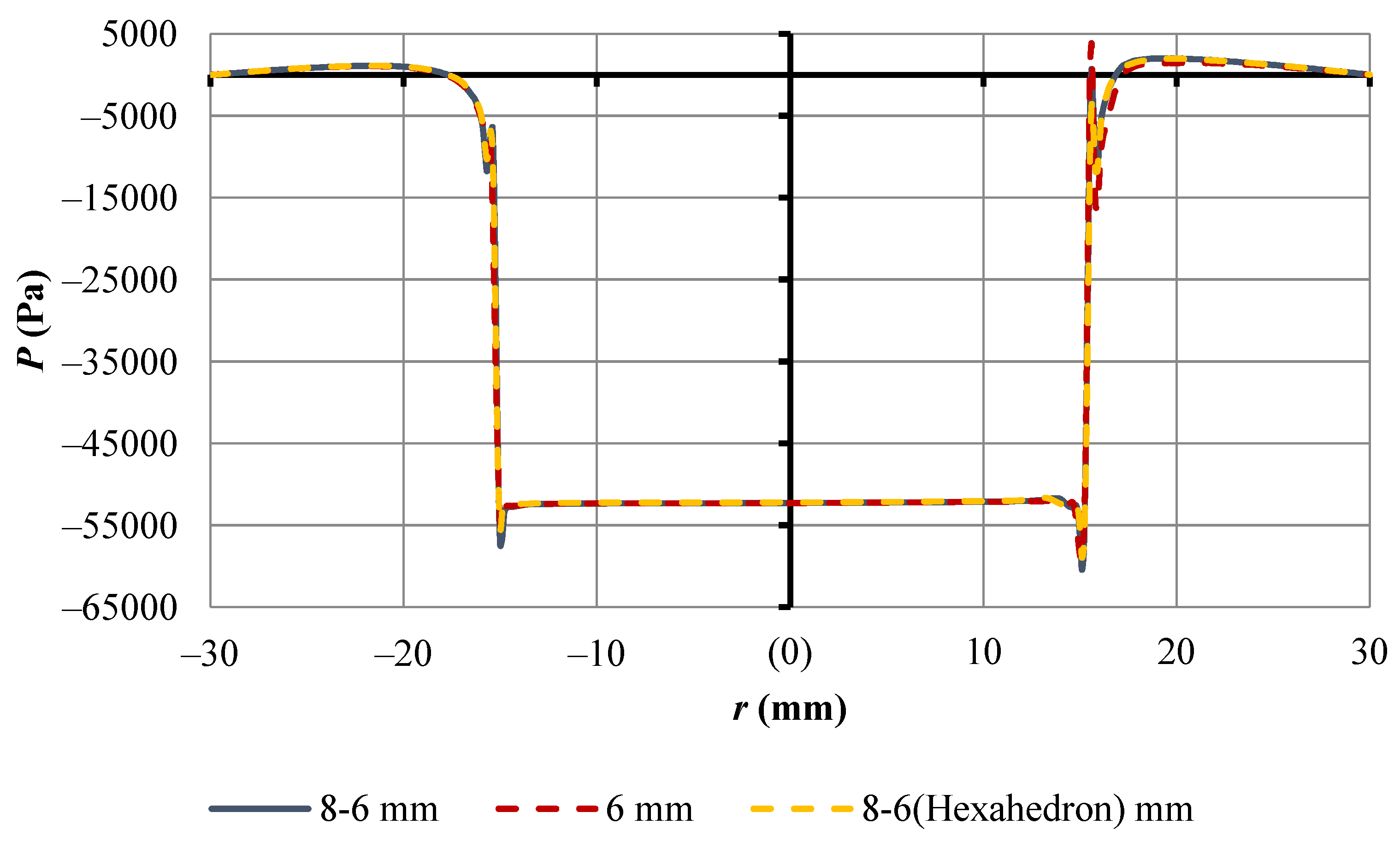

3.2. Impact of Internal Fitting Diameter on BGD Power Characteristics

4. Conclusions

- For the most common designs of air supply to the chamber of the gripping device, which are perpendicular to the fastening of gripping and horizontal to the fastening, finite element modeling in CFD was carried out. The adequacy of the obtained research results from the use the finite element method, namely, to the deviation of the theoretical results, which does not exceed 2%. It was determined that the theoretical method of research allows for the determination that only the influence of air pressure during air supply to the gripping device chamber affects its power characteristics. Therefore, it was further determined by the CFD finite element method that horizontal air supply to the gripping chamber should be used to provide the maximum possible lifting force. The constructed characteristic of the effect of the manipulation object gripping distance on its lifting force applies to both air supply structures.

- Structures and constriction in fittings are considered, which are used to supply compressed air to the chambers of Bernoulli gripping devices. Dependencies of the type of influence of the fittings narrowing on the power characteristics of the gripping devices are displayed. It was revealed that the difference in the lifting force of a Bernoulli gripping device that depends on the geometry of the fitting constriction is due to the pressure jump opposite the nozzle from the side of the compressed air supply, and for a supply pressure of 300 kPa, it affects the attraction force by only 0.05 N. Therefore, the design of the fittings from 8 mm to the diameter of the constriction was chosen in further studies.

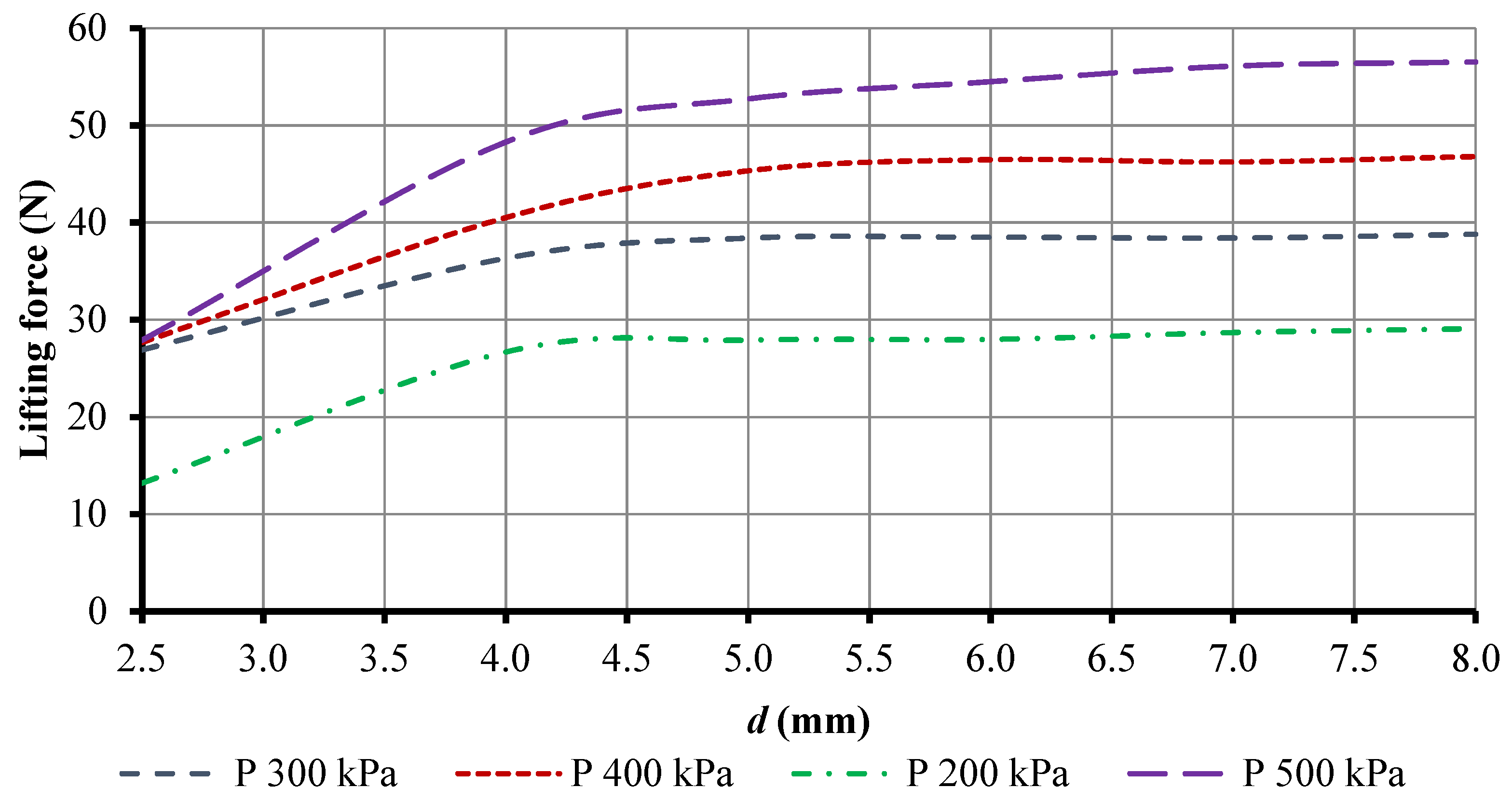

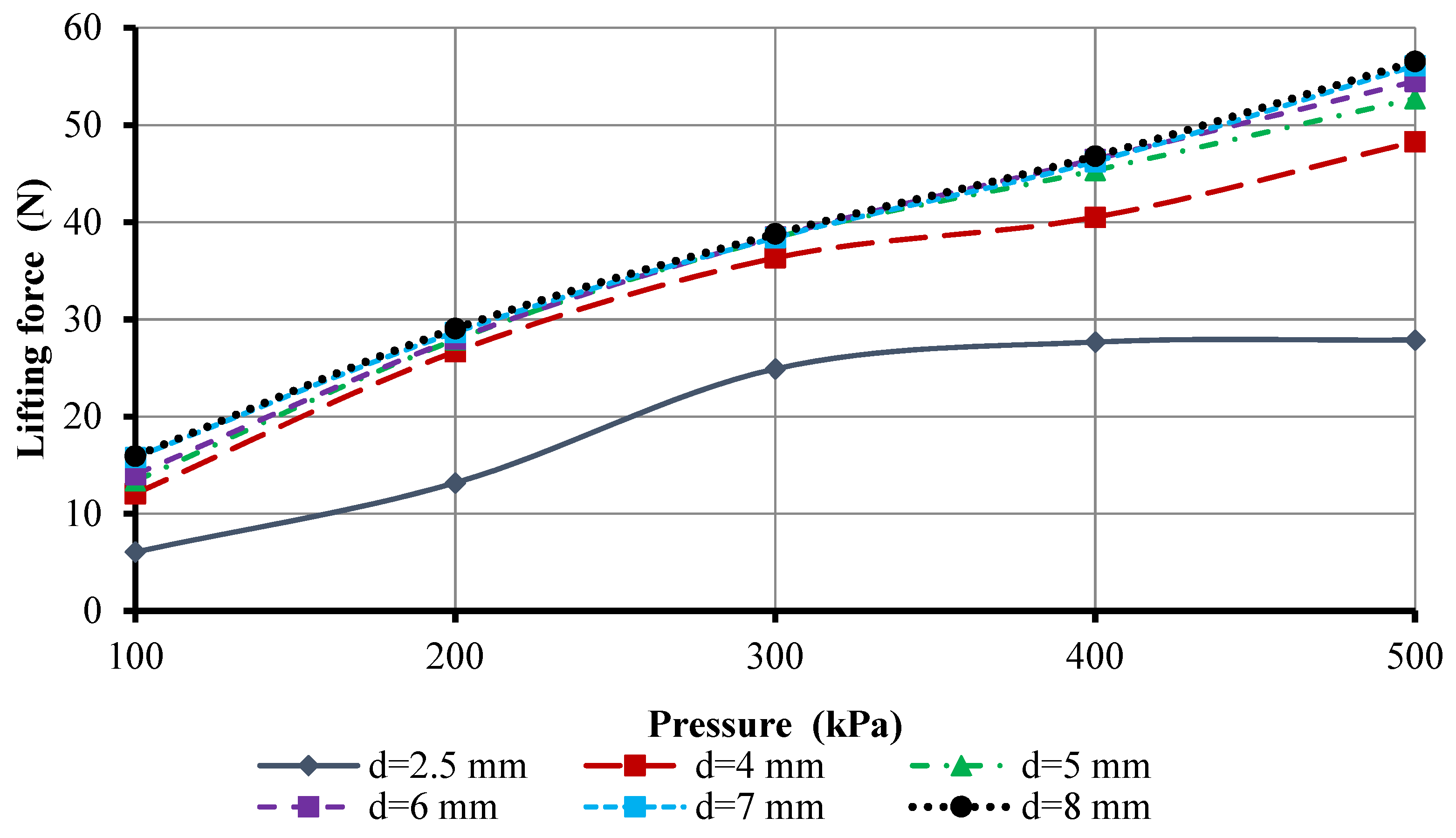

- For the most common diameters, the constrictions of the fittings at 2.5, 4, 5, 6, 7, and 8 mm shows the distribution of the lifting force at different supply pressures. It has been found that when the inlet diameter of the fitting decreases, the inlet air flow is throttled, which limits the compressed air flow rate of the gripping device and can reduce the lifting force by 55%. For a comprehensive study of the impact of consumption and power characteristics, the C-factor was used, and it was established that it is rational to use fittings with an internal diameter of 5 to 6 mm at a supply pressure of 200 to 300 kPa, and for 7 to 8 mm, a supply pressure of 100 and 400 to 500 kPa is used.

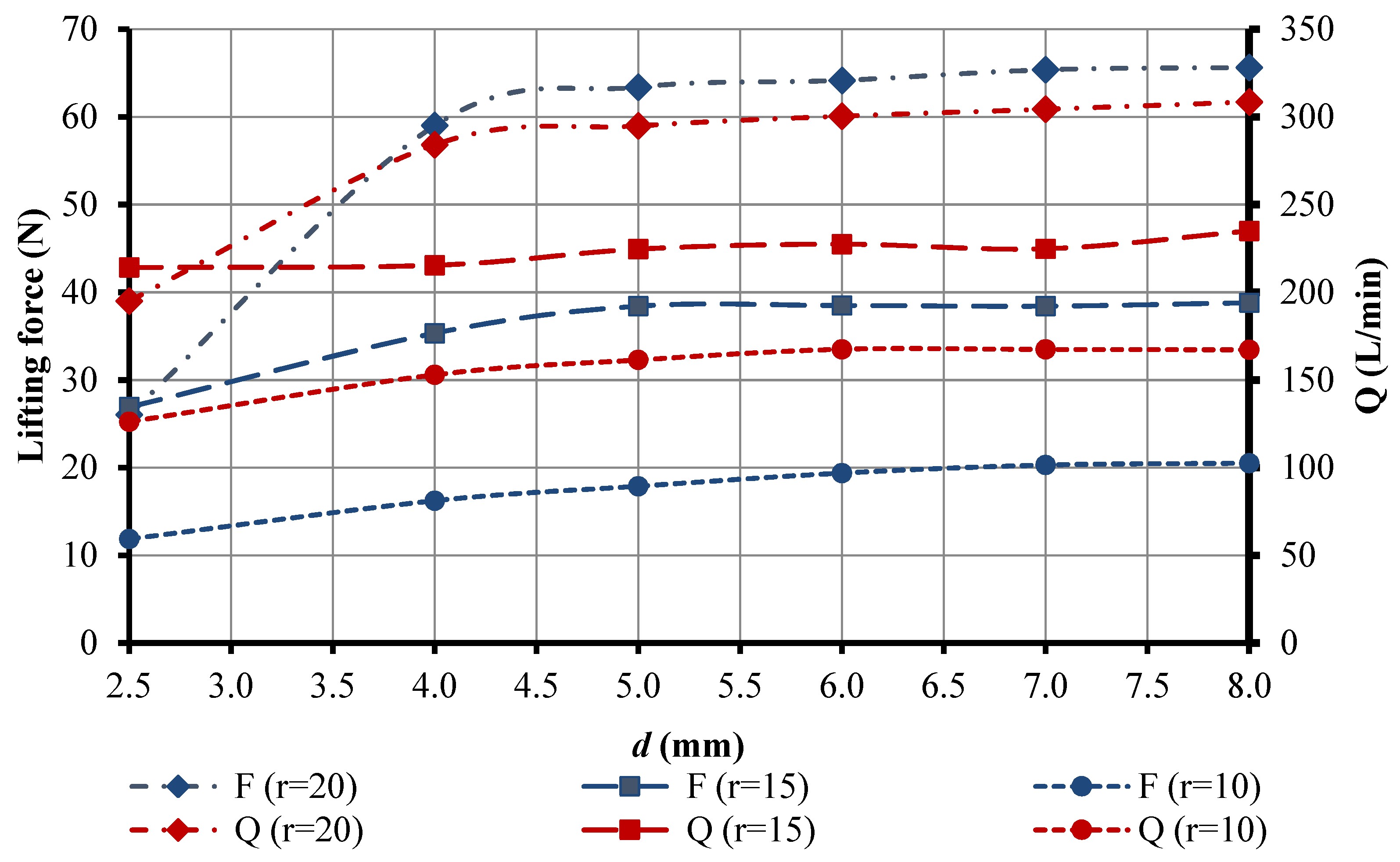

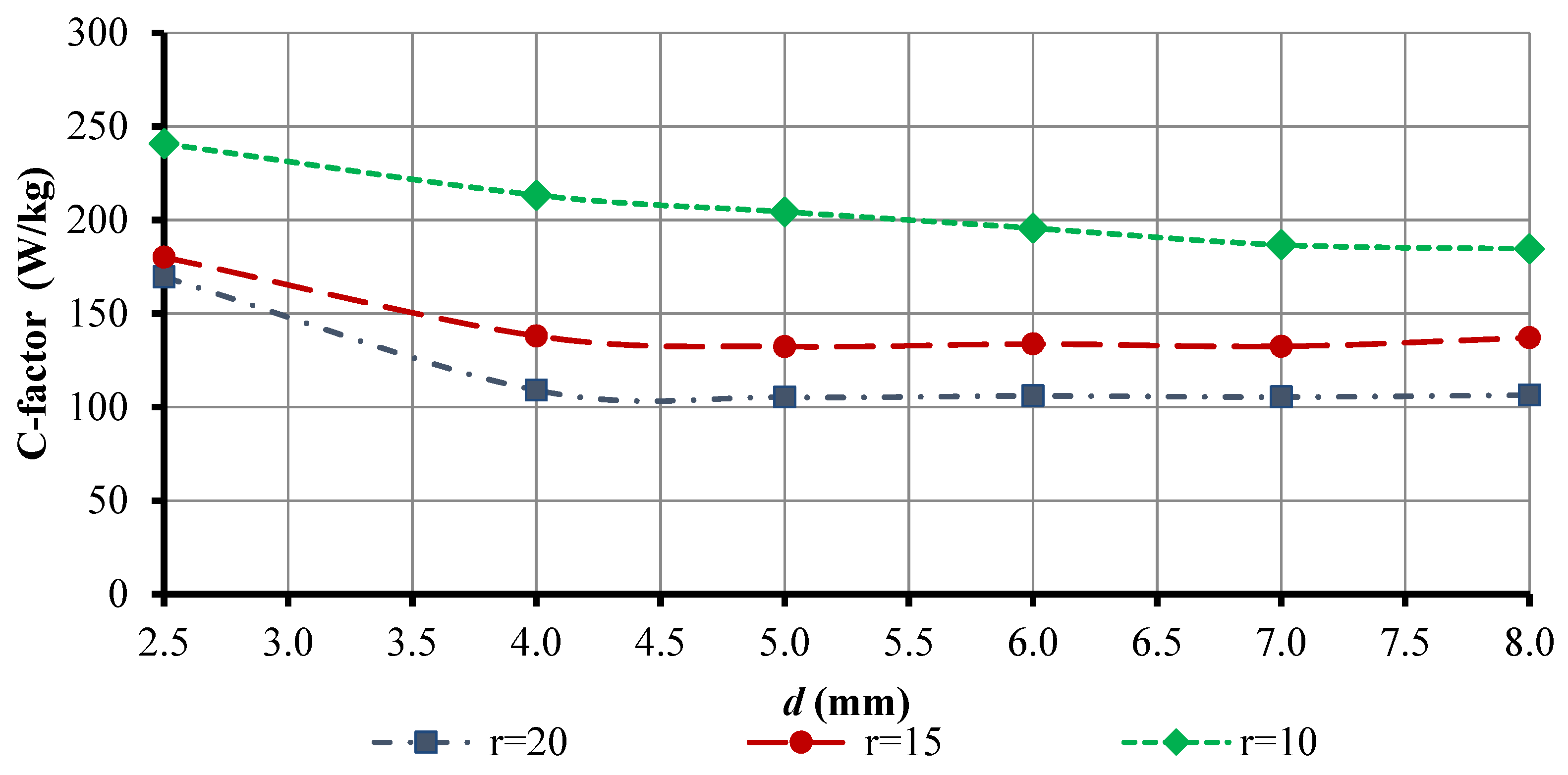

- It was revealed that the flow characteristics clearly correlate with the power characteristics at a different radius of the conical grip insert. In particular, it has been found that as the diameter of fitting constriction increases, the lifting force and flow rate increase throughout the study area. However, in the range of the inside diameter of the fitting of 6 to 8 mm, the lifting force remains practically unchanged with an increase in the flow rate of compressed air for the radii of the conical insert of the grip of 15 and 20 mm, and with a radius of the conical insert of the grip of 10 mm, the lifting force increases uniformly with increasing flow rate. To study the most effective radius of a conical insert, the C-factor was output at various input parameters, according to which, it was determined that the grip with a radius of the conical insert of 20 mm spends less energy to lift one kilogram of net weight. To provide a load capacity of one kilogram at a supply pressure of 300 kPa, a diameter of the fitting constriction of 5 to 7 mm for a Bernoulli gripping device uses an average of 105 W.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- McKerrow, P.J.; McKerrow, P. Introduction to Robotics; Addison-Wesley: Sydney, Australia, 1991; Volume 3. [Google Scholar]

- Nof, S.Y. (Ed.) Handbook of Industrial Robotics; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Garcia, E.; Jimenez, M.A.; De Santos, P.G.; Armada, M. The evolution of robotics research. IEEE Robot. Autom. Mag. 2007, 14, 90–103. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics: Modelling, Planning and Control; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Siciliano, B.; Khatib, O. Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Hägele, M.; Nilsson, K.; Pires, J.N.; Bischoff, R. Industrial Robotics. In Springer Handbook of Robotics; Springer: Cham, Switzerland, 2016; pp. 1385–1422. [Google Scholar]

- Lynch, K.M.; Frank, C.P. Modern Robotics; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Kurfess, T.R. (Ed.) Robotics and Automation Handbook; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Chan, F.T.S.; Ip, R.W.L.; Lau, H. Integration of expert system with analytic hierarchy process for the design of material handling equipment selection system. J. Mater. Process. Technol. 2001, 116, 137–145. [Google Scholar] [CrossRef]

- Kaya, O.; Tağlıoğlu, G.B.; Ertuğrul, Ş. The Series Elastic Gripper Design, Object Detection, and Recognition by Touch. ASMEJ. Mech. Robot. 2022, 14, 014501. [Google Scholar] [CrossRef]

- Yi, J.; Yumbla, F.; Auh, E.; Abayebas, M.; Luong, T.A.; Moon, H. Passive Aligning of Ribbon Cable in Sliding Surface Gripper for Assembly Task. ASMEJ. Mech. Robot. 2021, 13, 025001. [Google Scholar] [CrossRef]

- Henrich, D.; Wörn, H. Robot Manipulation of Deformable Objects; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Zoghlami, F.; Kurrek, P.; Jocas, M.; Masala, G.; Salehi, V. Design of a Deep Post Gripping Perception Framework for Industrial Robots. ASMEJ. Comput. Inf. Sci. Eng. 2021, 21, 021003. [Google Scholar] [CrossRef]

- Jin, L.; Duan, X.; Li, C.; Shi, Q.; Wen, H.; Wang, J.; Li, H. Design of a Novel Parallel Mechanism for Haptic Device. ASMEJ. Mech. Robot. 2021, 13, 045001. [Google Scholar] [CrossRef]

- Koustoumpardis, P.N.; Aspragathos, N.A. A review of gripping devices for fabric handling. In Proceedings of the International Conference on Intelligent Manipulation and Grasping IMG04, Genova, Italy, 1–2 July 2004. [Google Scholar]

- Zhang, M.T.; Goldberg, K. A Computer-Aided Design Tool in Java for Planar Gripper Design. J. Comput. Inf. Sci. Eng. 2004, 4, 43–48. [Google Scholar] [CrossRef]

- Martell, M.J.; Díaz, J.; Schultz, J.A. A Linear Multiport Network Approach for Elastically Coupled Underactuated Grippers. J. Mech. Robot. 2017, 9, 51012. [Google Scholar] [CrossRef]

- Reddy, P.V.P.; Suresh, V.V.N.S. A review on importance of universal gripper in industrial robot applications. Int. J. Mech. Eng. Robot. Res. 2013, 2, 255–264. [Google Scholar]

- Kumbla, N.B.; Thakar, S.; Kaipa, K.N.; Marvel, J.; Gupta, S.K. Handling Perception Uncertainty in Simulation-Based Singulation Planning for Robotic Bin Picking. ASMEJ. Comput. Inf. Sci. Eng. 2018, 18, 021004. [Google Scholar] [CrossRef]

- Suresh, S.A.; Christensen, D.L.; Hawkes, E.W.; Cutkosky, M. Surface and Shape Deposition Manufacturing for the Fabrication of a Curved Surface Gripper. ASMEJ. Mech. Robot. 2015, 7, 021005. [Google Scholar] [CrossRef]

- Long, Z.; Jiang, Q.; Shuai, T.; Wen, F.; Liang, C. A Systematic Review and Meta-analysis of Robotic Gripper. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 042055. [Google Scholar] [CrossRef]

- Birglen, L.; Schlicht, T. A statistical review of industrial robotic grippers. Robot. Comput.-Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Mikolajczyk, T. Indication of Machining Area with the Robot’s Camera using. Appl. Mech. Mater. 2013, 282, 146–151. [Google Scholar] [CrossRef]

- Gao, Y.; Huang, X.; Mann, I.S.; Su, H. A Novel Variable Stiffness Compliant Robotic Gripper Based on Layer Jamming. ASMEJ. Mech. Robot. 2020, 12, 051013. [Google Scholar] [CrossRef]

- Bogue, R. Artificial muscles and soft gripping: A review of technologies and applications. Ind. Robot. Int. J. 2012, 39, 535–540. [Google Scholar] [CrossRef]

- Boubekri, N.; Chakraborty, P. Robotic grasping: Gripper designs, control methods and grasp configurations–a review of research. Integr. Manuf. Syst. 2002, 13, 520–531. [Google Scholar] [CrossRef]

- Milojević, A.; Linß, S.; Ćojbašić, Ž.; Handroos, H. A Novel Simple, Adaptive, and Versatile Soft-Robotic Compliant Two-Finger Gripper With an Inherently Gentle Touch. ASMEJ. Mech. Robot. 2021, 13, 011015. [Google Scholar] [CrossRef]

- Chen, F.Y. Gripping mechanisms for industrial robots. In Robot Grippers; Springer: Berlin/Heidelberg, Germany, 1986; pp. 3–26. [Google Scholar] [CrossRef]

- Fantoni, G.; Santochi, M.; Dini, G.; Tracht, K.; Scholz-Reiter, B.; Fleischer, J.; Lien, T.K.; Seliger, G.; Reinhart, G.; Franke, J.; et al. Grasping devices and methods in automated production processes. CIRP Ann.-Manuf. Technol. 2014, 63, 679–701. [Google Scholar] [CrossRef]

- Raval, S.; Patel, B. A Review On Grasping Principle and Robotic Grippers. Int. J. Eng. Dev. Res. 2016, 4, 483–490. [Google Scholar]

- Lien, T.K. Gripper technologies for food industry robots. In Robotics and Automation in the Food Industry; Wood Head Publishing Limited: Sawston, UK, 2013; pp. 143–170. [Google Scholar] [CrossRef]

- Carbone, G. Grasping in Robotics; Springer: London, UK, 2012. [Google Scholar] [CrossRef]

- Bicchi, A.; Kumar, V. Robotic grasping and contact: A review. IEEE Int. Conf. Robot. Autom. 2000, 1, 348–353. [Google Scholar] [CrossRef]

- Wolf, A.; Schunk, H. Grippers in Motion; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2019. [Google Scholar] [CrossRef] [Green Version]

- Monkman, G.J.; Hesse, S.; Steinmann, R.; Schunk, H. Robot Grippers; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Prots, Y.I. Gripping Devices of Industrial Robots; TNTU: Ternopil, Ukraine, 2008. [Google Scholar]

- Fantoni, G.; Capiferri, S.; Tilli, J. Method for supporting the selection of robot grippers. Procedia CIRP 2014, 21, 330–335. [Google Scholar] [CrossRef]

- Schaffrath, R.; Jäger, E.; Winkler, G.; Doant, J.; Todtermuschke, M. Vacuum gripper without central compressed air supply. Procedia CIRP 2021, 97, 76–80. [Google Scholar] [CrossRef]

- Li, X.; Kagawa, T. Development of a new noncontact gripper using swirl vanes. Robot. Comput.-Integr. Manuf. 2013, 29, 63–70. [Google Scholar] [CrossRef]

- Ozcelik, B.; Erzincanli, F.; Findik, F. Evaluation of handling results of various materials using a non-contact end-effector. Ind. Robot. Int. J. 2003, 30, 363–369. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Duchon, F.; Fendo, O. Justification of design and parameters of Bernoulli–vacuum gripping device. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417741740. [Google Scholar] [CrossRef] [Green Version]

- Savkiv, V.; Mykhailyshyn, R.; Duchon, F. Gasdynamic analysis of the Bernoulli grippers interaction with the surface of flat objects with displacement of the center of mass. Vacuum 2019, 159, 524–533. [Google Scholar] [CrossRef]

- Festo AG & Co. Bernoulli Gripper OGGB. Available online: https://www.festo.com/net/sv_se/SupportPortal/default.aspx?cat=4564 (accessed on 10 July 2022).

- SMC. Available online: http://www.smcworld.com/products/en/vacuum/s.do?ca_id=1036 (accessed on 10 July 2022).

- Aventics. Non-Contact Transport System. Available online: https://www.aventics.com/en/products/pneumatic-products/vacuum-technology/non-contact-transport-system/ (accessed on 10 July 2022).

- Schmalz, J.; Schmalz, J. Floating Suction Cups SBS, Special Grippers. Available online: https://www.schmalz.com/en/vacuum-technology-for-automation/vacuum-components/special-grippers/floating-suction-cups/floating-suction-cups-sbs (accessed on 10 July 2022).

- Welanetz, L.F.; Syosset, N.Y. A suction device using air under pressure. J. Appl. Mech. Trans. Am. Soc. Mech. Eng. 1956, 78, 269. [Google Scholar] [CrossRef]

- Erzincanli, F.; Sharp, J.M. Development of a non-contact end effector for robotic handling of non-rigid materials. Robotica 1997, 15, 331–335. [Google Scholar] [CrossRef]

- Maruschak, P.; Savkiv, V.; Mykhailyshyn, R.; Duchon, F.; Chovanec, L. The analysis of influence of a nozzle form of the Bernoulli gripping devices on its energy efficiency. In Proceedings of the ICCPT 2019, Ternopil, Ukraine, 28–29 May 2019; pp. 66–74. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Duchon, F.; Maruschak, P. Justification of Influence of the Form of Nozzle and Active Surface of Bernoulli Gripping Devices on Its Operational Characteristics. In International Conference TRANSBALTICA; Springer: Cham, Switzerland, 2019; pp. 263–272. [Google Scholar] [CrossRef]

- Shi, K.; Li, X. Optimization of outer diameter of Bernoulli gripper. Exp. Therm. Fluid Sci. 2016, 77, 284–294. [Google Scholar] [CrossRef]

- Davis, S.; Gray, J.O.; Caldwell, D.G. An end effector based on the Bernoulli principle for handling sliced fruit and vegetables. Robot. Comput.-Integr. Manuf. 2008, 24, 249–257. [Google Scholar] [CrossRef]

- Petterson, A.; Ohlsson, T.; Caldwell, D.G.; Davis, S.; Gray, J.O.; Dodd, T.J. A Bernoulli principle gripper for handling of planar and 3D (food) products. Ind. Robot. Int. J. Robot. Res. Appl. 2010, 37, 518–526. [Google Scholar] [CrossRef]

- Sam, R.; Buniyamin, N. A Bernoulli principle based flexible handling device for automation of food manufacturing processes. In Proceedings of the2012 International Conference on Control, Automation and Information Sciences (ICCAIS), Saigon, Vietnam, 26–29 November 2012; pp. 214–219. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Maruschak, P.; Chovanec, L.; Prada, E.; Virgala, I.; Prentkovskis, O. Optimization of Design Parameters of Bernoulli Gripper with an Annular Nozzle. In Transport Means—Proceedings of the International Conference 2019; Kaunas University of Technology: Kaunas, Lithuania, 2019; pp. 423–428. [Google Scholar]

- Ertürk, Ş.; Samtaş, G. Design of grippers for laparoscopic surgery and optimization of experimental parameters for maximum tissue weight holding capacity. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 1125–1132. [Google Scholar] [CrossRef]

- Chettibi, T.; Lehtihet, H.; Haddad, M.; Hanchi, S. Minimum cost trajectory planning for industrial robots. Eur. J. Mech.-A/Solids 2004, 23, 703–715. [Google Scholar] [CrossRef]

- Saravanan, R.; Ramabalan, S. Evolutionary Minimum Cost Trajectory Planning for Industrial Robots. J. Intell. Robot. Syst. 2008, 52, 45–77. [Google Scholar] [CrossRef]

- Pellegrinelli, S.; Borgia, S.; Pedrocchi, N.; Villagrossi, E.; Bianchi, G.; Tosatti, L.M. Minimization of the energy consumption in motion planning for single-robot tasks. Procedia CIRP 2015, 29, 354–359. [Google Scholar] [CrossRef]

- Pellicciari, M.; Berselli, G.; Leali, F.; Vergnano, A. A method for reducing the energy consumption of pick-and-place industrial robots. Mechatronics 2013, 23, 326–334. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Duchon, F.; Maruschak, P.; Prentkovskis, O. Substantiation of bernoulli grippers parameters at non-contact transportation of objects with a displaced center of mass. In Transport Means-Proceedings of the International Conference; Kaunas University of Technology: Kaunas, Lithuania, 2018; pp. 1370–1375. [Google Scholar]

- Savkiv, V.; Mykhailyshyn, R.; Maruschak, P.; Diahovchenko, I.; Duchon, F.; Chovanec, Ľ.; Hutsaylyuk, V. Gripping Devices of Industrial Robots for Manipulating Offset Dish Antenna Billets. In Proceedings of the Forum on Innovative Technologies and Management for Sustainability—ITMS’2020, Panevėžys, Lithuania, 1–2 October 2020; pp. 75–83. [Google Scholar]

- Savkiv, V.; Mykhailyshyn, R.; Maruschak, P.; Kyrylovych, V.; Duchon, F.; Chovanec, Ľ. Gripping devices of industrial robots for manipulating offset dish antenna billets and controlling their shape. Transport 2021, 36, 63–74. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Fendo, O.; Mykhailyshyn, M. Orientation modeling of Bernoulli gripper device with off-centered masses of the manipulating object. Procedia Eng. 2017, 187, 264–271. [Google Scholar] [CrossRef]

- Mykhailyshyn, R.; Savkiv, V.; Mikhalishin, M.; Duchon, F. Experimental research of the manipulatiom process by the objects using bernoulli gripping devices. In Proceedings of the 2017 IEEE International Young Scientists Forum on Applied Physics and Engineering (YSF), Lviv, Ukraine, 17–20 October 2017; pp. 8–11. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Duchon, F.; Mikhalishin, M. Energy efficiency analysis of the manipulation process by the industrial objects with the use of Bernoulli gripping devices. J. Electr. Eng. 2017, 68, 496–502. [Google Scholar] [CrossRef] [Green Version]

- Savkiv, V.; Mykhailyshyn, R.; Duchoň, F.; Mikhalishin, M. Modeling of Bernoulli gripping device orientation when manipulating objects along the arc. Int. J. Adv. Robot. Syst. 2018, 15, 1729881418762670. [Google Scholar] [CrossRef]

- Mykhailyshyn, R.; Savkiv, V.; Duchon, F.; Koloskov, V.; Diahovchenko, I.M. Analysis of frontal resistance force influence during manipulation of dimensional objects. In Proceedings of the 2018 IEEE 3rd International Conference on Intelligent Energy and Power Systems (IEPS), Kharkiv, Ukraine, 10–14 September 2018; pp. 301–305. [Google Scholar] [CrossRef]

- Mykhailyshyn, R.; Savkiv, V.; Duchon, F.; Koloskov, V.; Diahovchenko, I.M. Investigation of the energy consumption on performance of handling operations taking into account parameters of the grasping system. In Proceedings of the 2018 IEEE 3rd International Conference on Intelligent Energy and Power Systems (IEPS), Kharkiv, Ukraine, 10–14 September 2018; pp. 295–300. [Google Scholar] [CrossRef]

- Mykhailyshyn, R.; Savkiv, V.; Duchon, F.; Trembach, R.; Diahovchenko, I.M. Research of Energy Efficiency of Manipulation of Dimensional Objects with the Use of Pneumatic Gripping Devices. In Proceedings of the 2019 IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON), Lviv, Ukraine, 2–6 July 2019; pp. 527–532. [Google Scholar] [CrossRef]

- Sanchez, J.; Corrales, J.A.; Bouzgarrou, B.C.; Mezouar, Y. Robotic manipulation and sensing of deformable objects in domestic and industrial applications: A survey. Int. J. Robot. Res. 2018, 37, 688–716. [Google Scholar] [CrossRef]

- Borras, J.; Alenya, G.; Torras, C. A Grasping-Centered Analysis for Cloth Manipulation. IEEE Trans. Robot. 2020, 36, 924–936. [Google Scholar] [CrossRef]

- Brun, X.F.; Melkote, S.N. Modeling and Prediction of the Flow, Pressure, and Holding Force Generated by a Bernoulli Handling Device. J. Manuf. Sci. Eng. 2009, 131, 031018. [Google Scholar] [CrossRef]

- Brun, X.; Melkote, S.N. Effect of Substrate Flexibility on the Pressure Distribution and Lifting Force Generated by a Bernoulli Gripper. J. Manuf. Sci. Eng. 2012, 134, 051010. [Google Scholar] [CrossRef]

- Toklu, E.; Erzincanli, F. Modeling of radial flow on a non-contact end effector for robotic handling of non-rigid material. J. Appl. Res. Technol. 2012, 10, 590–596. [Google Scholar] [CrossRef]

- Giesen, T.; Bürk, E.; Fischmann, C.; Gauchel, W.; Zindl, M.; Verl, A. Advanced gripper development and tests for automated photovoltaic wafer handling. Assem. Autom. 2013, 33, 334–344. [Google Scholar] [CrossRef]

- Liu, D.; Liang, W.; Zhu, H.; Teo, C.S.; Tan, K.K. Development of a distributed Bernoulli gripper for ultra-thin wafer handling. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Munich, Germany, 3–7 July 2017; pp. 265–270. [Google Scholar] [CrossRef]

- Liu, D.; Teo, C.S.; Liang, W.; Tan, K.K. Soft-Acting, Noncontact Gripping Method for Ultrathin Wafers Using Distributed Bernoulli Principle. IEEE Trans. Autom. Sci. Eng. 2018, 16, 668–677. [Google Scholar] [CrossRef]

- Liu, H.; Li, X.; Ma, Q.; Feng, W. Development non-contact gripper with flowrate-amplification using Coanda ejector. Vacuum 2021, 187, 110108. [Google Scholar] [CrossRef]

- Ertürk, Ş.; Erzincanlı, F. Design and development of a non-contact robotic gripper for tissue manipulation in minimally invasive surgery. Acta Bio Med. AteneiParm. 2020, 91, e2020071. [Google Scholar] [CrossRef]

- Trommelen, M.H.T. Development of a Medical Bernoulli Gripper. Available online: http://resolver.tudelft.nl/uuid:949e3227-9677-47c8-be16-3962ada7ebf8 (accessed on 10 July 2022).

- Mykhailyshyn, R.; Savkiv, V.; Boyko, I.; Prada, E.; Virgala, I. Substantiation of Parameters of Friction Elements of Bernoulli Grippers With a Cylindrical Nozzle. Int. J. Manuf. Mater. Mech. Eng. 2021, 11, 17–39. [Google Scholar] [CrossRef]

- Fendo, O.M. Substantiation of Parameters and Designs of Jet Grippers of Loading Devices. Ph.D. Thesis, Ternopil Ivan Puluy National Technical University, Sumy, Ukraine, 2012. [Google Scholar]

- Snegiryov, A.Y. High-performance computing in technical physics. In Numerical Simulation of Turbulent Flows; Polytechnic University Publ.: Saint Petersburg, Russia, 2009. [Google Scholar]

- Garbaruk, A.V. Modern Approaches to Modeling Turbulence; Polytechnic University Publ.: Saint Petersburg, Russia, 2016. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Menter, F.R.; Esch, T.; Kubacki, S. Transition modelling based on local variables. In Engineering Turbulence Modelling and Experiments 5; Elsevier: Amsterdam, The Netherlands, 2002; pp. 555–564. [Google Scholar] [CrossRef]

- Menter, F.R.; Langtry, R.; Völker, S. Transition modelling for general purpose CFD codes. Flow Turbul. Combust. 2006, 77, 277–303. [Google Scholar] [CrossRef]

- Menter, F.R.; Smirnov, P.E.; Liu, T.; Avancha, R. A One-Equation Local Correlation-Based Transition Model. Flow Turbul. Combust. 2015, 95, 583–619. [Google Scholar] [CrossRef]

- Langtry, R.B.; Menter, F.R. Correlation-Based Transition Modeling for Unstructured Parallelized Computational Fluid Dynamics Codes. AIAA J. 2009, 47, 2894–2906. [Google Scholar] [CrossRef]

- Li, X.; Li, N.; Tao, G.; Liu, H.; Kagawa, T. Experimental comparison of Bernoulli gripper and vortex gripper. Int. J. Precis. Eng. Manuf. 2015, 16, 2081–2090. [Google Scholar] [CrossRef]

- Metal Work Pneumatic. Available online: https://ecommerce.metalwork.it/store/mw/en/Catalogue/Fittings-and-accessories/Fittings/Automatic-fittings-mm-tubes-and-G-%28BSP%29-or-metric-thread/c/040101 (accessed on 10 July 2022).

- Camozzi Automation. Available online: http://catalogue.camozzi.com/Explorer.aspx?u_code=8_1&type=Context (accessed on 10 July 2022).

- Festo. Available online: https://www.festo.com/cat/en-gb_gb/products__01198 (accessed on 10 July 2022).

- SMC. Available online: https://www.smc.eu/en-eu/products/316-stainless-steel-kqg2~50214~nav#s (accessed on 10 July 2022).

- Wolf, A.; Schunk, H.A. Grippers in Motion: The Fascination of Automated Handling Tasks; Carl Hanser Verlag GmbH Co. KG: Munich, Germany, 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mykhailyshyn, R.; Xiao, J. Influence of Inlet Parameters on Power Characteristics of Bernoulli Gripping Devices for Industrial Robots. Appl. Sci. 2022, 12, 7074. https://doi.org/10.3390/app12147074

Mykhailyshyn R, Xiao J. Influence of Inlet Parameters on Power Characteristics of Bernoulli Gripping Devices for Industrial Robots. Applied Sciences. 2022; 12(14):7074. https://doi.org/10.3390/app12147074

Chicago/Turabian StyleMykhailyshyn, Roman, and Jing Xiao. 2022. "Influence of Inlet Parameters on Power Characteristics of Bernoulli Gripping Devices for Industrial Robots" Applied Sciences 12, no. 14: 7074. https://doi.org/10.3390/app12147074