Abstract

This paper presents the results of a survey on full-scale membrane biological reactors (MBRs) wastewater treatment plants (WWTPs) in Italy. Alongside the main technical characteristics of the Italian MBR plants, the opinions of the plant managers on the operational advantages and disadvantages are described. As reported by the MBR technology suppliers, approximately 290 MBR municipal or industrial WWTPs are in operation in Italy, out of which 242 were studied in this survey. Data from more than one hundred municipal WWTPs were collected; these account for a total capacity of about 2,000,000 population equivalent (PE), which corresponds to 3% of the total organic load treated by the Italian WWTPs with secondary and advanced treatment. Usually, small installations adopt the flat-sheet rather than hollow-fiber membrane configuration. The main reasons why the MBR technology has been preferred to other options are its potential to be used for increasing the treatment capacity of existing plants and its compactness. Moreover, the followed operational advantages have been highlighted: easiness to comply with the discharge limits, removal of pathogens without specific disinfection units, possibility of internal reuse of the effluent, and process automation. Membrane fouling and plant shutdown have been recorded as the most relevant troubles, the last one indeed occurring only occasionally or rarely.

1. Introduction

In membrane biological reactors (MBRs), the conventional activated sludge (CAS) process is combined with filtration on micro- or ultra-porous membranes. Final clarifiers are then replaced by membrane filtration units.

The main advantages of the MBR technology include [1,2,3,4,5]: (i) small footprint (due to both the elimination of sedimentation units and the increase of biomass concentration in the biological reactors); (ii) the complete separation of hydraulic retention time (HRT) and solid retention time (SRT); (iii) lower production of surplus activated sludge (if operated at higher SRT); (iv) the elimination of problems due to the poor sedimentation of activated sludge usually present in CAS; (v) high effluent quality, usually suitable for its reuse in agricultural and industrial sectors.

However, the performance and operational costs of MBR systems can be affected by several aspects [6,7,8]: maximum and sustainable flows of permeates; adequate preliminary treatments (to remove coarse and abrasive materials); membrane fouling and cleaning strategies; aeration and energy consumption; possible need of wastewater equalization; need of skilled personnel.

MBRs have been used for both municipal and industrial wastewater treatment [9]. Today, MBR technology has become an attractive solution also for medium-sized wastewater treatment plants (WWTPs) having capacity between 10,000 and 100,000 PE, mainly due to the significant membrane cost reduction in the last 15 years [4].

Alongside the “conventional” MBR process, new technological solutions are being developed. For instance, recent studies evaluated the coupling of membrane with the anaerobic biological reactors (AnMBRs) as an alternative solution to the conventional anaerobic digestion processes. This solution is presumed to reduce the overall energy demand and to facilitate the retention of microorganisms so as to operate with high biomass concentration. The advantage of this solution is related to the reduction in sludge volume and the increase in biogas production. However, the membrane fouling seems to be the main drawback of this process [10]. Another interesting application is the thermophilic aerobic membrane reactor (TAMR), which can be adopted for the treatment of high strength aqueous waste or industrial wastewater [11,12] and the minimization of sludge production [13,14].

According to [15], the MBR technology is being currently adopted in more than 5000 WWTPs around the world. The annual growth rate of MBR global market, from 2011 to 2018, is estimated around 15%. In particular, MBR plants are spreading a lot in China [16]. Currently, according to the MBR site [17], large MBR plants in the world (with capacity higher than 100,000 m3/day) are 63; more than 60% of these plants are present in China, 16% in USA and 11% in Europe.

The spreading of MBR technology has been favoured by the stringent environmental regulations, the reduced use of land and the ease of automation that MBRs provide; moreover, the reduction in both membrane cost and energy consumption and the longer membrane lifespan favoured the growth.

In the literature, topics of scientific interest have been deeply investigated. Relevant examples are (i) the studies to understand membrane fouling mechanisms [8]; (ii) the study of factors that could promote the removal of trace pollutants, such as presence of slow growing organisms, grater mass transfer efficiency due to presence of free-living bacteria and small flocs, adsorption and retention of hydrophobic compounds [18,19,20,21]; (iii) the use of advanced modeling for process optimization, in order to simulate greenhouse gas emissions depending on the control strategy adopted [22]; (iv) the comparison among MBR and other technologies based on the evaluation of their impacts and benefits on human health [23,24].

Although hundreds of papers have been published in scientific journals and a high number of full-scale MBR plants are operated worldwide, the opinion and valuable experience of practitioners, who are involved in the day-by-day conduction of the plants, can be rarely found in the scientific literature. This article intends to fill this gap by presenting a survey carried out in Italy, in which the salient technical characteristics of MBR plants as well as the judgment of the managers on the operational aspects are reported and discussed.

2. Methodology

The survey was performed in two steps. In the first one, the main MBR technology suppliers in Italy were asked to provide the following data for each Italian MBR plant equipped with their membranes:

- location of the plant;

- date of construction;

- type of wastewater treated;

- type of membrane (hollow-fiber, flat-sheet, hybrid);

- organic load (in terms of BOD5 and/or COD);

- average daily flowrate.

It must be noted that unfortunately not all the required data have been provided for all of the plants.

In the second step of the survey, a questionnaire was sent to the managers of the plants identified in the first step. The following data were requested in the questionnaire:

- effluent destination and threshold limits;

- treatment chain;

- dimensional and construction characteristics of the MBR section;

- raw wastewater and effluent properties;

- chemicals dosed in the plant;

- reasons that led to the MBR being installed;

- operational advantages obtained thanks to the installation of the MBR;

- operational problems concerning or related to the MBR.

The questionnaires used in the survey are reported in Supplementary Materials: Questionnaire S1 (first step of survey) and Questionnaire S2 (second step of survey).

3. Results and Discussion

3.1. MBR Plants in Italy

3.1.1. Number of MBR Plants, Capacity and Location

According to the most recent census, in Italy, in 2018, 18,140 municipal WWTPs were in operation, and the mean influent organic load to these plants was about 68 million of population equivalent (PE). A total of 65.5% of the civil and industrial pollutant load is treated by WWTPs with advanced treatment, 29.5% in secondary type WWTPs, and the remaining 5% in primary type WWTPs or Imhoff tanks [25].

In the first part of the survey reported in this paper, 242 MBR plants were identified: 124 plants treat municipal wastewater and 118 treat industrial wastewater. Further, 50 MBR plants treating industrial wastewater and equipped with flat-sheet membranes are present in Italy, but the owner of those plants denied the MBR technology suppliers the authorization to provide any data. It follows that, in total, about 290 MBR plants are in operation, of which about 70% treat industrial wastewater, and the remaining treat municipal wastewater.

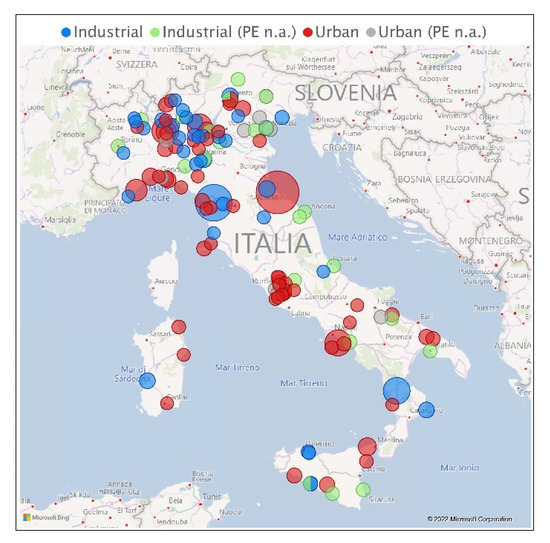

Most of the MBR plants are located in Northern Italy (62%), which is the most industrial area of the country; 21% and 17% of plants are located in the centre and in the south of Italy, respectively. The location of the MBR plants is reported in Figure 1.

Figure 1.

Location of MBR plants in Italy (the area of the circles is proportional to PE-if available) n.a.: not available.

The total capacity of 106 municipal MBR plants that provided this information is about 2,000,000 PE (see Table 1). This value accounts for mor than 3% of the total organic load treated by the Italian WWTPs with secondary and advanced treatments. The number of small and very small plants represents more than 70% of the total MBR plants, but the five plants with capacity higher than 100,000 PE treat more than 50% of the total organic load treated by all municipal MBR plants.

Table 1.

Italian MBR plants treating municipal wastewater.

Unfortunately, few data about the organic load of MBRs treating industrial wastewater were provided, so a classification based on the treated flowrate was adopted in this case. More than half of these plants treat mostly a flowrate between 100 and 500 m3/day, whereas 28% treat more than 500 m3/day (Table 2).

Table 2.

Italian MBR plants treating industrial wastewater.

3.1.2. Year of Construction

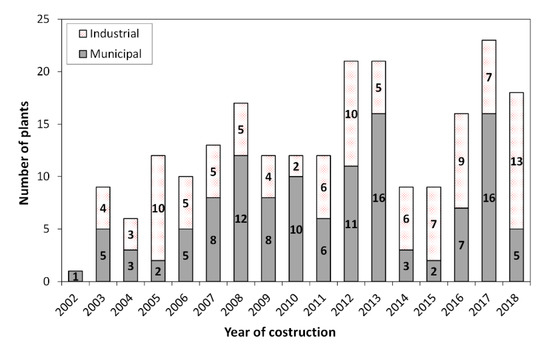

Figure 2 reports the number of Italian MBR plants by year of construction; the number of plants in the period 2018–2021 are not reported because the information is partial. It can be noted that, from 2002 to 2013, the number of plants increased up to 146 (that is the 64% of the 227 plants that provided this information). In the period 2014–2015 the number of MBR installations decreased, probably due to the economic crisis; since 2016, the number of plants has increased again.

Figure 2.

Number of MBR plants constructed in Italy (2002–2021).

As reported by Al-Asheh et al. [26], after 2008, the commercialization of MBR plants had decelerated due to the economic depression worldwide. Nevertheless, because of the necessity for a better water environment, MBR technology has a bright future to expand.

3.1.3. Type of Membrane

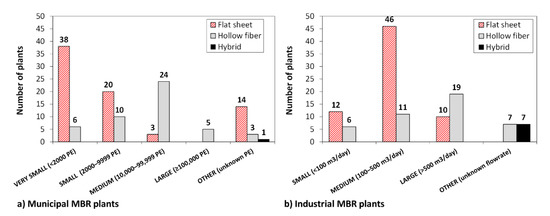

Regarding the type of membrane, 59% of all MBR plants analyzed in this survey use flat-sheet membrane, and 38% adopt hollow-fiber membranes. Recently, the hybrid membrane technology has been introduced on the market: this type is currently adopted by 3% of the MBR installations.

In municipal MBR plants, the flat-sheet membranes are mainly used for small and very small installations, and the hollow-fiber membranes are usually adopted for medium and large capacity (Figure 3a). Moreover, in the industrial applications, the flat-sheet membranes are prevalent in small and medium MBR plants (Figure 3b).

Figure 3.

Italian MBR plants split by type of membrane used.

This aspect is mainly related to the advantages and disadvantages of hollow-fiber membranes with respect to the flat-sheet ones. Hollow-fiber configurations, compared to the flat-sheet, are usually designed for higher fluxes, operated at lower mixed liquor suspended solid (MLSS) concentrations, cleaned more frequently (both mechanically—backwash—and chemically) and must be protected by more severe pre-treatment [27]. Moreover, the prevalent use of hollow-fiber membranes for larger installations is related to both their lower aeration energy demand and their higher specific surface with the possibility to reduce the tanks size/footprint [28,29]. As concerns this point, the average specific surface area is reported to be 292 m2/m3 and 118 m2/m3 for commercial hollow-fiber and flat-sheet membranes, respectively [30].

3.2. Operational Aspects and Judgement of the Plant Managers

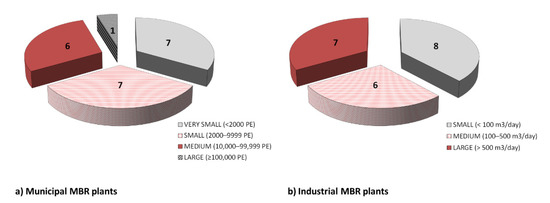

In the second part of the survey, 42 questionnaires were filled in by managers of 21 plants treating municipal wastewater and 21 plants treating industrial wastewater. Figure 4 shows the classification by capacity of the MBR plants analyzed (in terms of PE for municipal WWTPs and flowrate treated for the industrial ones). It can be noted that the total capacity of the 21 municipal MBR plants is 311,073 PE, which represents about 16% of the total capacity of Italian MBR.

Figure 4.

Classification of the MBR plants investigated in the second step of the survey.

3.2.1. Characteristics of the MBR Plants Analyzed

Regarding the treatment train, all municipal MBR plants include coarse screening, fine screening, grid and fat removal, denitrification, oxidation-nitrification, and membrane filtration. The effluent is always discharged in water bodies; the effluent of six plants is internally reused, as well. The treatment trains of the industrial MBR plants are very different as well as the effluent destination (Table 3).

Table 3.

Treatment train and effluent destination of the industrial MBR plants.

As concerns the type of membrane, the 67% of MBR plants investigated in the second part of the survey, both for municipal and industrial wastewater treatment, uses hollow-fiber membranes; in the other plants, flat-sheet membranes are adopted. A total of 80% of the municipal MBR plants adopt sodium hypochlorite and citric acid for membrane cleaning, whereas about 20% use sodium hypochlorite only. In few industrial MBR plants, sulphuric and hydrochloric acids are used as well.

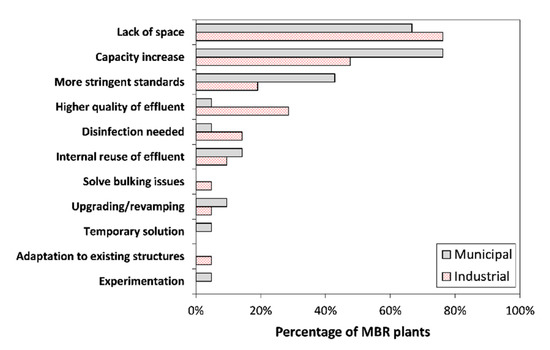

3.2.2. Driving Forces of MBR Installation

Figure 5 shows the driving forces that led to the installation of the MBR systems: the main ones are the lack of space and the possibility of increasing the treatment capacity, both for industrial and urban WWTPs. Furthermore, the higher quality of the effluent (in terms of low pollution), related both to operating authorizations and to the more stringent discharge limits, is a reason repeatedly mentioned by the managers of all MBR plants analyzed in the survey.

Figure 5.

Driving forces for installing MBR systems.

As reported by Kootenaei and Aminirad [31], the MBR are used with the aim to reuse the wastewater treated. The high robustness of MBR technology provides a fairly constant effluent with a large reduction of the pollutants, with a highly reliable operation.

The high effluent quality highlighted by several plant managers lead to an increase in the installation of MBRs in many regions suffering an acute lack of water (even in the south of Europe) to solve the hydric deficit. The treated wastewater can be reused in tasks where drinking water is not required, such as irrigation [32], cleaning or cooling water on industrial site, or domestic purposes (e.g., toilet flushing) [33]. Furthermore, the higher ability of MBR (with respect to CAS) to remove endocrine disrupting compounds (EDCs) [34] and trace pollutants [35] is documented.

In comparison with the CAS process, MBR has about a 50% higher annualized operating cost, mainly due to the need for replacing the membranes and the higher associated energy requirement. Therefore, MBR cannot compete with the CAS process unless a very high quality effluent is required, and for wider application of MBRs, the lower energy demand of the process is required. In fact, the MBR market is driven by the increased scarcity of water, ever stricter rules for water discharge and reuse quality legislation, decreasing investment cost, and the wide acceptance of the technology [36].

As reported in the introduction, the MBR market is growing significantly; this growth is led by the Asia–Pacific market. This is mainly due to the increasing demand for wastewater treatment from the Chinese market [36]. Concerning the Chinese situation, it is worth mentioning that Li et al. [37] highlighted that the primary driving forces in the last several decades were the water resource stress and the public policy related to resources and the environment. The future driving forces for MBR applications include declining capital investment and decreasing operating cost.

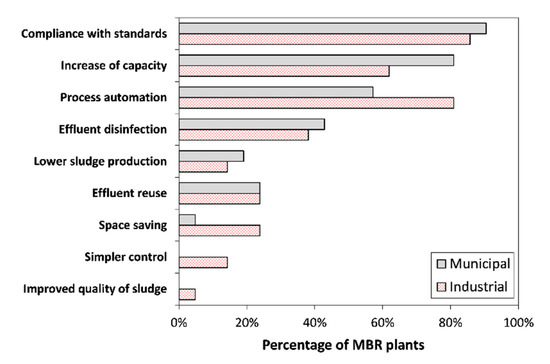

3.2.3. Operational Advantages

As concerns the operational advantages of MBRs, the plant managers highlight the easiness to comply with the discharge limits and to increase the treatment capacity of existing plants (Figure 6). In addition, the automation of the process (especially for hollow-fiber configuration), the possibility to remove pathogens without disinfection units (again especially for hollow-fiber configuration), the possible internal reuse of the effluent, and the reduction of sludge production are reported. The results obtained are similar between municipal and industrial plants, notwithstanding that the managers of the industrial ones highlight that process automation is more significant with respect to capacity increase. This aspect is very important, and it could represent a key factor to increase the diffusion of MBRs in industrial plants, where the choice of treatment solution, usually, is based on the simplification of the process operation.

Figure 6.

Operational advantages of MBR technology.

Moreover, the managers of MBRs underline that the process automation leads to high process reliability and cost reduction. In fact, according to Ferrero et al. [38], an automatic control system based on permeability trends without interfering with membrane fouling and biological nutrient removal can reduce the energy consumption due to membrane aeration up to 20%. Gabarrón et al. [39] studied modifications of the biological process (by means of the installation of control systems for biological aeration) and of the filtration process (reduction of the MLSS concentration or the flux and installation of control systems for membrane air scouring) to have a significant reduction in operational costs.

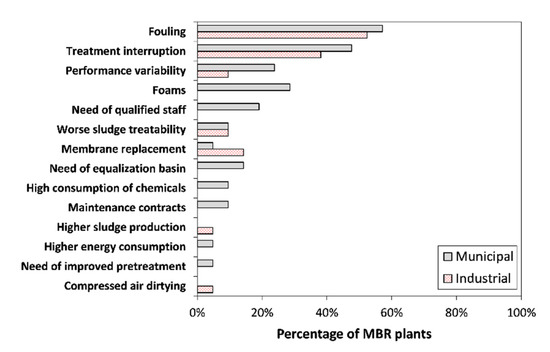

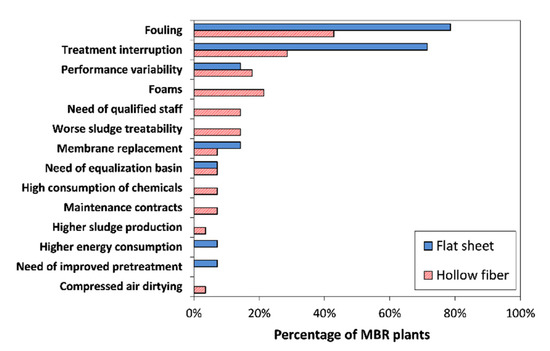

3.2.4. Critical Operational Aspects

Figure 7 shows the main operation troubles related to the MBR processes. Fouling of membranes and plant shutdown are the most relevant issues, even if, concerning the last aspect, the plant managers reported it as an occasional or rare event. Membrane fouling is a common problem in MBR plants, and in order to reduce its negative effects, collaboration between the membrane manufacturer and the plant manager is a key factor. The survey results highlight a significant difference between the membrane configurations: flat-sheet membranes are less affected by fouling issues with respect to the hollow-fiber configuration (Figure 8). In effect, according to [28], the advantages of the hollow-fiber configuration lie in the ability to induce movement of the membranes by mechanisms such as bubbling, and the feasibility of backwashing. Moreover, Hai et al. [40] showed that the hollow-fiber membrane exhibited fouling intensity proportional to the operating flux (0.05–0.3 m/day). Conversely, the flat-sheet membrane suffered from immediate internal pore blocking beyond a critical flux of 0.2 m/day.

Figure 7.

Operational troubles of MBR plants: comparison between municipal and industrial facilities.

Figure 8.

Operational troubles of MBR plants: comparison between flat-sheet and hollow-fiber membranes.

The most important operation and maintenance routine in MBRs is the membrane cleaning. If the membranes are not kept clean, the fouling problems can lead to plant shutdown, as well as cost increase, performance reduction and briefer membrane lifespan [41].

According to the opinion of MBR managers and the scientific literature, fouling preventive-control strategies are an important issue that strongly concern not only the research but the industry as well [42].

Fouling phenomena depend on many factors such as operating conditions, membrane cleaning strategies, characteristics of wastewater influent, and membrane properties. Fouling is associated with four successive steps. Initially smallest pores are blocked, followed by obscuring the inner surface of larger pores. Direct blockage and accumulation of particles on the larger pores is the next step, and finally the formation of the cake layer is followed. However, the identification of each step is not easy [26]. Fouling issue is strongly influenced by extra extracellular polymeric substances (EPSs), biological substances which largely determine properties of sludge flocs, including hydrophobicity, adhesion, flocculation, settling and dewatering properties. Several developments in fouling prevention and control strategies were identified [4,42]: suitable feed pre-treatment, physical/chemical cleaning, flux reduction, aeration increase, ultrasound or ozone application, and membrane surface modification. Moreover, the operating conditions modification (e.g., MLSS concentration, HRT, SRT, Food/Mass ratio) affects the fouling: increasing SRT leads to a decrease in the EPS level which provides lower fouling on the membrane surface. On the other hand, the increase in the MLSS concentration results in the elevation of the mixed liquor’s viscosity that may worsen fouling and also require more demand for aeration. Hence, assessing optimum SRT is essential to control fouling phenomena [26].

Even the problem of plant shutdown can be avoided, or at least reduced, with regular recovery and cleaning operation. This aspect has led to the need of qualified staff: the acquisition of suitable skills to solve the several troubles and to obtain the knowledge of a new process takes time, but this aspect could also represent an opportunity for the technical growth of the plant human resources.

The weather conditions affect the variability of the treatment performance in terms of energy and reagent consumption (e.g., the lower the water temperature, the higher the water viscosity, the higher the energy consumption for membrane cleaning) but does not involve a reduction in process yields. This aspect, combined with the foaming issue, which is instead related to the biomass conditions and to the input load, underlines the great importance of pre-treatments and equalization. Thus, the possibility to maintain a more constant quality of influent wastewater allows us to increase the lifespan of the membranes. Moreover, the concomitant improvement of the membrane materials has allowed a significant increase in their useful life up to over a decade with guarantees offered by some manufacturers even up to 10 years [43].

A future challenge will be the higher cost effectiveness of MBR, mainly due to the energy cost increasing. Constant efforts will be essential to extend the membrane lifetime which will reduce the depreciation cost. A development of more efficient membranes, bioreactor combination modes, sharpness in designing of membrane scouring, and biological aeration systems are essential to higher cost effectiveness [36].

Regarding the comparison between CAS and MBR, Wang et al. [44] proposed the application of a sustainability index that takes into account economic, technological and managerial factors. The authors showed that the sustainability of full-scale MBR process is lower than CAS process, in agreement with the findings of Bertanza et al. [7]. However, MBR is extensively an alternative solution to replace CAS process when influent volume is below 50,000 m3/day. For a comprehensive comparison, local economic conditions need to be given top priority, and it is necessary to understand the current situation of local water pollution, influent quality and land resources.

4. Conclusions

The survey leads to the following main conclusions:

- There are about 290 MBR plants in Italy, and they are located mainly in the most industrial area of the country. The number of municipal plants that provided information is 106, and they serve about 2 million PE, corresponding to approximately 3% of the total organic load treated by the Italian WWTPs with secondary and advanced treatments;

- Flat-sheet membranes are more spread than hollow-fiber ones, above all in small installations. In the case of hollow-fiber membranes, high area per unit volume, cost effective fabrication process, and capability to withstand severe operating conditions make them attractive. Recently, hybrid membranes were utilized in few plants;

- The main drivers for the installation of the MBR system are the lack of space and the necessity to increase the treatment capacity of existing plants, both in the case of industrial and municipal wastewater;

- The opinion of the plant managers is substantially positive. In particular, the reliability in the compliance with the discharge limits, the improvement of the plant capacity and, above all, in the industrial installations and the automation of the process are very appreciated features. However, some critical aspects remain, such as membrane fouling and plant shutdown, on which the MBR technology producers are required to give effective answers.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/app12136559/s1, Questionnaire S1: Questionnaire used for the census of MBR plants; Questionnaire S2: Questionnaire used for the survey on operational aspects.

Author Contributions

Conceptualization, M.V. and C.C.; methodology, A.A.; validation, M.V. and G.B.; data curation, A.A.; writing—original draft preparation, A.A.; writing—review and editing, M.V.; visualization, G.B.; supervision, M.V., G.B. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank the MBR technology suppliers and the managers of the MBR plants which provided information in this survey. A2A Ciclo Idrico, Acea, Arpa Lombardia, ASM Voghera, Bema, CAP Holding, Depurazione Trentino Centrale, Depurazione Trentino Occidentale, Emilia Ambiente, Evoqua, General Electric, Ghezz International, Hera, Idroclean, Idrotigullio, Ingeco, Iren, Koch, Kubota, Latte Arborea, M.G., Microdyn Nadir, Multiservizi, Padania Acque Gestione, Pavia Acque, Provincia Autonoma di Trento, Setam, Siba, Sifagest.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Meng, F.; Chae, S.R.; Drews, A.; Kraume, M.; Shin, H.-S.; Yang, F. Recent advances in membrane bioreactors (MBRs): Membrane fouling and membrane material. Water Res. 2009, 43, 1489–1512. [Google Scholar] [CrossRef] [PubMed]

- Judd, S.; Judd, C. The MBR Book: Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment, 2nd ed.; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Wang, Z.; Ma, J.; Tang, C.Y.; Kimura, K.; Wang, Q.; Han, X. Membrane cleaning in membrane bioreactors: A review. J. Membr. Sci. 2014, 468, 276–307. [Google Scholar] [CrossRef]

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane bioreactors—A review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects. J. Membr. Sci. 2017, 527, 207–227. [Google Scholar] [CrossRef] [Green Version]

- Meng, F.; Zhang, S.; Oh, Y.; Zhou, Z.; Shin, H.-S.; Chae, S.-R. Fouling in membrane bioreactors: An updated review. Water Res. 2017, 114, 151–180. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.-H.; Kim, H.-S.; Yeom, I.-T. The optimum operational condition of membrane bioreactor (MBR): Cost estimation of aeration and sludge treatment. Water Res. 2004, 38, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Bertanza, G.; Canato, M.; Laera, G.; Vaccari, M.; Svanström, M.; Heimersson, S. A comparison between two full-scale MBR and CAS municipal wastewater treatment plants: Techno-economic-environmental assessment. Environ. Sci. Pollut. Res. 2017, 24, 17383–17393. [Google Scholar] [CrossRef] [Green Version]

- Hamedi, H.; Ehteshami, M.; Mirbagheri, S.A.; Rasouli, S.A.; Zendehboudi, S. Current Status and Future Prospects of Membrane Bioreactors (MBRs) and Fouling Phenomena: A Systematic Review. Can. J. Chem. Eng. 2019, 97, 32–58. [Google Scholar] [CrossRef] [Green Version]

- Iorhemen, O.T.; Hamza, R.A.; Tay, J.H. Membrane Bioreactor (MBR) Technology for Wastewater Treatment and Reclamation: Membrane Fouling. Membranes 2016, 6, 33. [Google Scholar] [CrossRef] [Green Version]

- Musa, M.A.; Idrus, S.; Che Man, H.; Nik Daud, N.N. Wastewater Treatment and Biogas Recovery Using Anaerobic Membrane Bioreactors (AnMBRs): Strategies and Achievements. Energies 2018, 11, 1675. [Google Scholar] [CrossRef] [Green Version]

- Collivignarelli, M.C.; Abbà, A.; Bertanza, G.; Setti, M.; Barbieri, G.; Frattarola, A. Integrating novel (thermophilic aerobic membrane reactor-TAMR) and conventional (conventional activated sludge-CAS) biological processes for the treatment of high strength aqueous wastes. Bioresour. Technol. 2018, 255, 213–219. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Frattarola, A.; Manenti, S.; Todeschini, S.; Bertanza, G.; Pedrazzani, R. Treatment of aqueous wastes by means of Thermophilic Aerobic Membrane Reactor (TAMR) and nanofiltration (NF): Process auditing of a full-scale plant. Environ. Monit. Assess. 2019, 191, 708. [Google Scholar] [CrossRef] [PubMed]

- Collivignarelli, M.C.; Abbà, A.; Castagnola, F.; Bertanza, G. Minimization of municipal sewage sludge by means of a thermophilic membrane bioreactor with intermittent aeration. J. Clean. Prod. 2017, 143, 369–376. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Bertanza, G.; Frattarola, A. The upgrading of conventional activated sludge processes with thermophilic aerobic membrane reactor: Alternative solutions for sludge reduction. J. Environ. Manag. 2020, 264, 110490. [Google Scholar] [CrossRef] [PubMed]

- Hai, F.I.; Yamamoto, K.; Lee, C.-H. Membrane Biological Reactors: Theory, Modeling, Design, Management and Applications to Wastewater Reuse, 2nd ed.; IWA Publishing: London, UK, 2019. [Google Scholar]

- Xiao, K.; Liang, S.; Wang, X.; Chen, C.; Huang, X. Current state and challenges of full-scale membrane bioreactor applications: A critical review. Bioresour. Technol. 2019, 271, 473–481. [Google Scholar] [CrossRef] [PubMed]

- The Mbr Membrane Bioreactor Site. Available online: https://www.thembrsite.com/largest-mbr-plants/largest-membrane-bioreactor-plants-worldwide/ (accessed on 22 April 2022).

- Alvarino, T.; Torregrosa, N.; Omil, F.; Lema, J.M.; Suarez, S. Assessing the feasibility of two hybrid MBR systems using PAC for removing macro and micropollutants. J. Environ. Manag. 2017, 203, 831–837. [Google Scholar] [CrossRef] [PubMed]

- Grandclément, C.; Seyssiecq, I.; Piram, A.; Wong-Wah-Chung, P.; Vanot, G.; Tiliacos, N.; Roche, N.; Doumenq, P. From the conventional biological wastewater treatment to hybrid processes, the evaluation of organic micropollutant removal: A review. Water Res. 2017, 111, 297–317. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Becerra, F.Y.; Ortiz, I. Biodegradation of emerging organic micropollutants in nonconventional biological wastewater treatment: A critical review. Environ. Eng. Sci. 2018, 35, 1012–1036. [Google Scholar] [CrossRef]

- Rizzo, L.; Malato, S.; Antakyali, D.; Vasiliki, G.; Beretsou, V.G.; Dolić, M.B.; Gernjak, W.; Heath, E.; Ivancev-Tumbas, I.; Karaolia, P.; et al. Consolidated vs new advanced treatment methods for the removal of contaminants of emerging concern from urban wastewater. Sci. Total Environ. 2019, 655, 986–1008. [Google Scholar] [CrossRef]

- Mannina, G.; Cosenza, A.; Ekama, G. A comprehensive integrated membrane bioreactor model for greenhouse gas emissions. Chem. Eng. J. 2018, 334, 1563–1572. [Google Scholar] [CrossRef]

- Papa, M.; Pedrazzani, R.; Bertanza, G. How green are environmental technologies? A new approach for a global evaluation: The case of WWTP effluents ozonation. Water Res. 2013, 47, 3679–3687. [Google Scholar] [CrossRef]

- Papa, M.; Alfonsín, C.; Moreira, M.T.; Bertanza, G. Ranking wastewater treatment trains based on their impacts and benefits on human health: A “Biological Assay and Disease” approach. J. Clean. Prod. 2016, 113, 311–317. [Google Scholar] [CrossRef]

- ISTAT Water Statistics—Years 2018–2020. Available online: https://www.istat.it/it/files/2021/03/Report-Giornata-mondiale-acqua.pdf (accessed on 22 April 2022). (In Italian).

- Al-Asheh, S.; Bagheri, M.; Aidan, A. Membrane bioreactor for wastewater treatment: A review. Case Stud. Chem. Environ. Eng. 2021, 4, 100109. [Google Scholar] [CrossRef]

- Krzeminski, P.; Gil, J.A.; van Nieuwenhuijzen, A.; van der Graaf, J.H.J.M.; van Lier, J.B. Flat Sheet or hollow fibre—Comparison of full-scale membrane bio-reactor configurations. Desalination Water Treat. 2012, 42, 100–106. [Google Scholar] [CrossRef]

- Akhondi, E.; Zamani, F.; Tng, K.H.; Leslie, G.; Krantz, W.B.; Fane, A.G.; Chew, J.W. The Performance and Fouling Control of Submerged Hollow Fiber (HF) Systems: A Review. Appl. Sci. 2017, 7, 765. [Google Scholar] [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane Technologies in Wastewater Treatment: A Review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Yoon, S.-H. Membrane Bioreactor Processes: Principles and Applications; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Kootenaei, F.G.; Aminirad, H. Membrane Biological Reactors (MBR) and Their Applications for Water Reuse. Int. J. Adv. Biol. Biomed. Res. 2014, 2, 2208–2216. [Google Scholar]

- Lonigro, A.; Montemurro, N.; Rubino, P.; Vergine, P.; Pollice, A. Reuse of treated municipal wastewater for irrigation in Apulia Region: The “IN.TE.R.R.A.” project. Environ. Eng. Manag. J. 2015, 14, 1665–1674. [Google Scholar] [CrossRef]

- Wisniewski, C. Membrane bioreactor for water reuse. Desalination 2007, 203, 15–19. [Google Scholar] [CrossRef]

- Spring, A.J.; Bagley, D.M.; Andrews, R.C.; Lemanik, S.; Yang, P. Removal of endocrine disruptors using a membrane bioreactor and disinfection. J. Environ. Eng. Sci. 2007, 6, 131–137. [Google Scholar] [CrossRef]

- Bertanza, G.; Pedrazzani, R.; Dal Grande, M.; Papa, M.; Zambarda, V.; Montani, C.; Steimberg, N.; Mazzoleni, G.; Di Lorenzo, D. Effect of biological and chemical oxidation on the removal of estrogenic compounds (NP and BPA) from wastewater: An integrated assessment procedure. Water Res. 2011, 45, 2473–2484. [Google Scholar] [CrossRef]

- Helmi, A.; Gallucci, F. Latest Developments in Membrane (Bio)Reactors. Processes 2020, 8, 1239. [Google Scholar] [CrossRef]

- Li, P.; Liu, L.; Wu, J.; Cheng, R.; Shi, L.; Zheng, X.; Zhang, Z. Identify driving forces of MBR applications in China. Sci. Total Environ. 2019, 647, 627–638. [Google Scholar] [CrossRef]

- Ferrero, G.; Rodríguez-Roda, I.; Comas, J. Automatic control systems for submerged membrane bioreactors: A state-of-the-art review. Water Res. 2012, 46, 3421–3433. [Google Scholar] [CrossRef]

- Gabarrón, S.; Ferrero, G.; Dalmau, M.; Comas, J.; Rodríguez-Roda, I. Assessment of energy-saving strategies and operational costs in full-scale membrane bioreactors. J. Environ. Manag. 2014, 134, 8–14. [Google Scholar] [CrossRef]

- Hai, F.I.; Yamamoto, K.; Fukushi, K. Different fouling modes of submerged hollow-fiber and flat-sheet membranes induced by high strength wastewater with concurrent biofouling. Desalination 2005, 180, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Park, H.-D.; Chang, I.-S.; Lee, K.-J. Principles of Membrane Bioreactors for Wastewater Treatment; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Gkotsis, P.K.; Banti, D.C.; Peleka, E.N.; Zouboulis, A.I.; Samaras, P.E. Fouling Issues in Membrane Bioreactors (MBRs) for Wastewater Treatment: Major Mechanisms, Prevention and Control Strategies. Processes 2014, 2, 795–866. [Google Scholar] [CrossRef]

- Cote, P.; Alam, Z.; Penny, J. Hollow fiber membrane life in membrane bioreactors (MBR). Desalination 2012, 288, 145–151. [Google Scholar] [CrossRef]

- Wang, S.; Zou, L.; Li, H.; Zheng, K.; Wang, Y.; Zheng, G.; Li, J. Full-scale membrane bioreactor process WWTPs in East Taihu basin: Wastewater characteristics, energy consumption and sustainability. Sci. Total Environ. 2020, 723, 137983. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).