Pollutants Concentration during the Construction and Operation Stages of a Long Tunnel: A Case Study of Lowari Tunnel, (Dir–Chitral), Khyber Pakhtunkhwa, Pakistan

Abstract

:1. Introduction

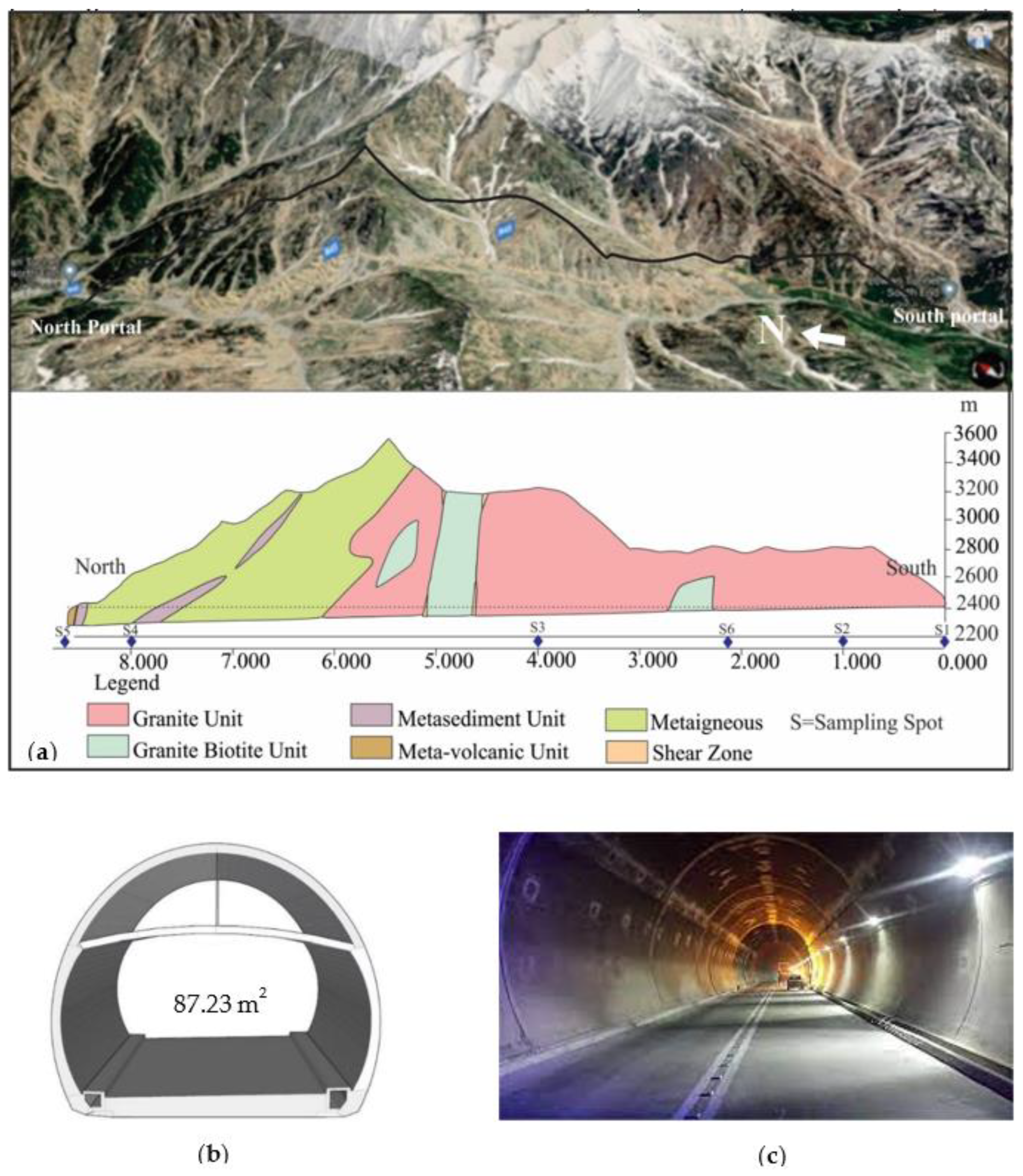

2. Materials and Methods

2.1. Construction Stage

2.2. Operational Stage

3. Results and Discussion

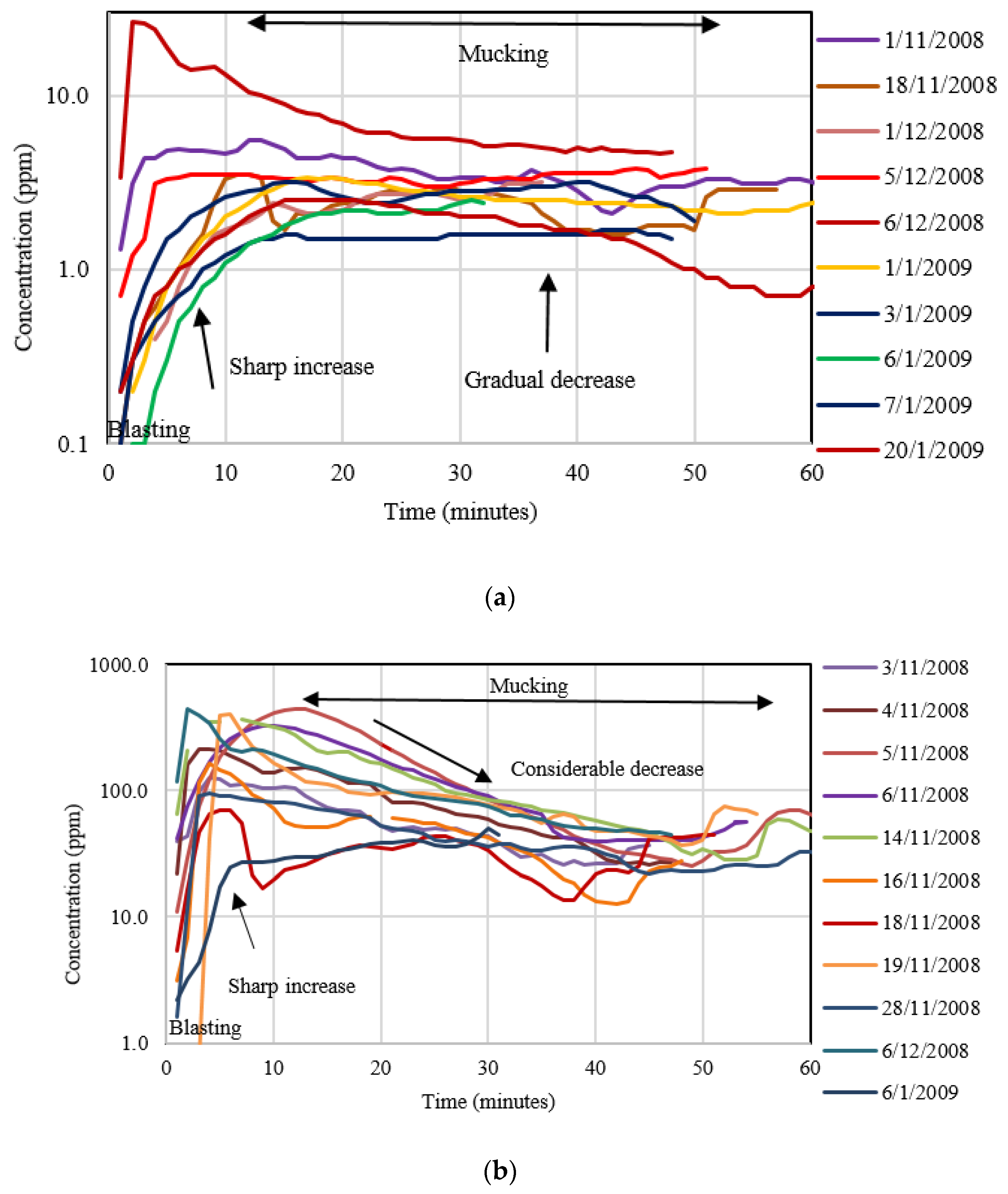

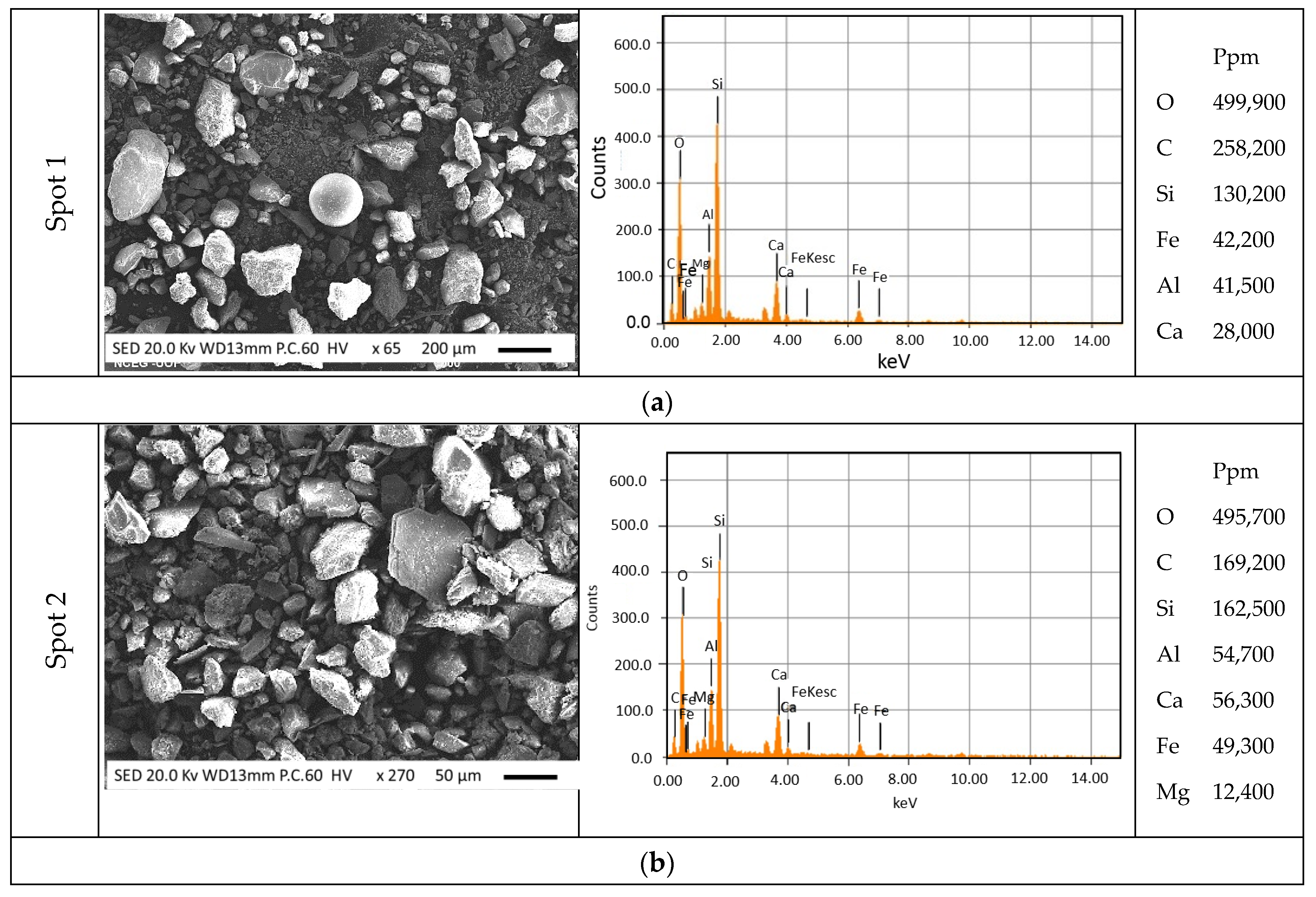

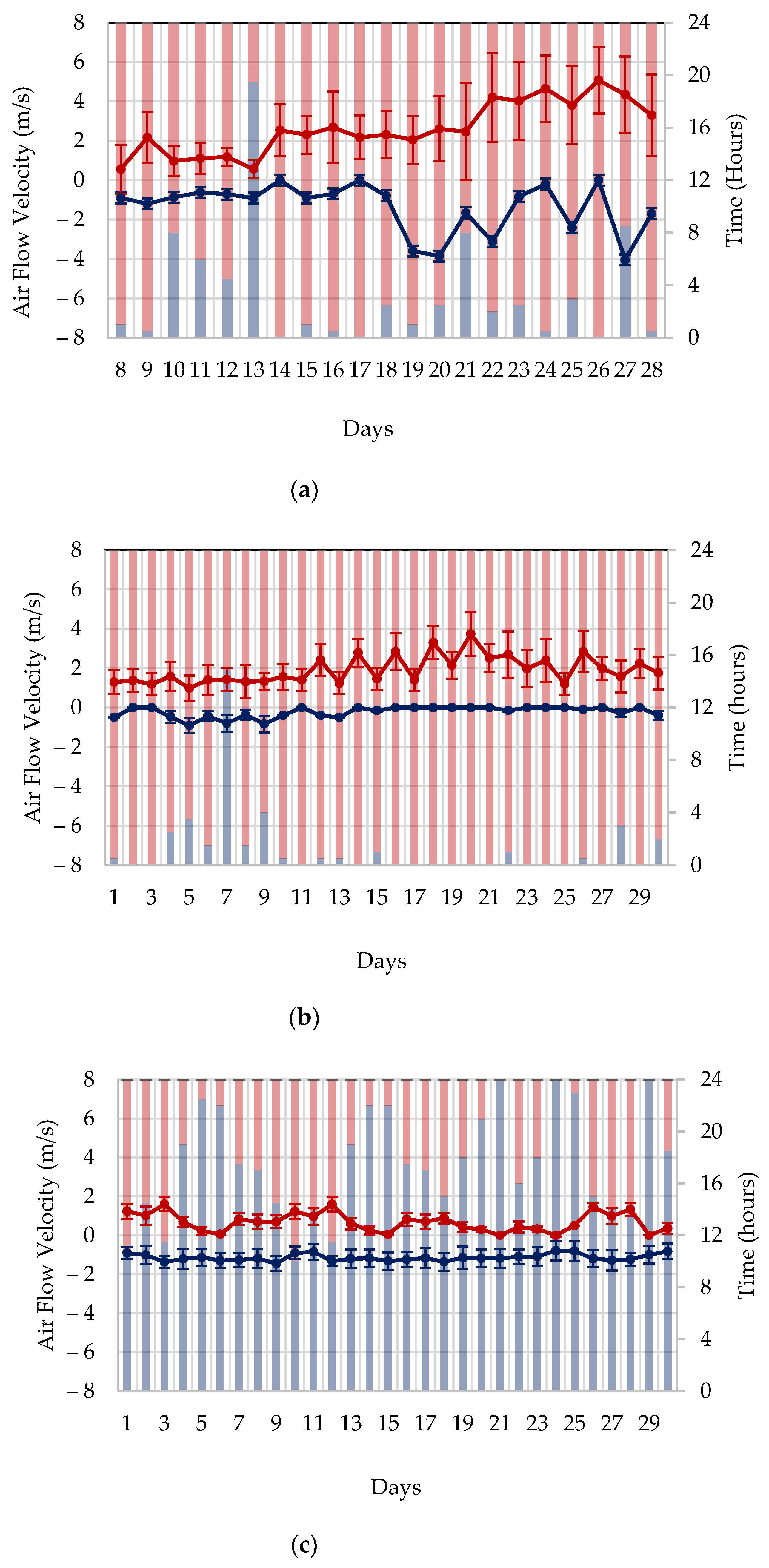

3.1. Construction Stage

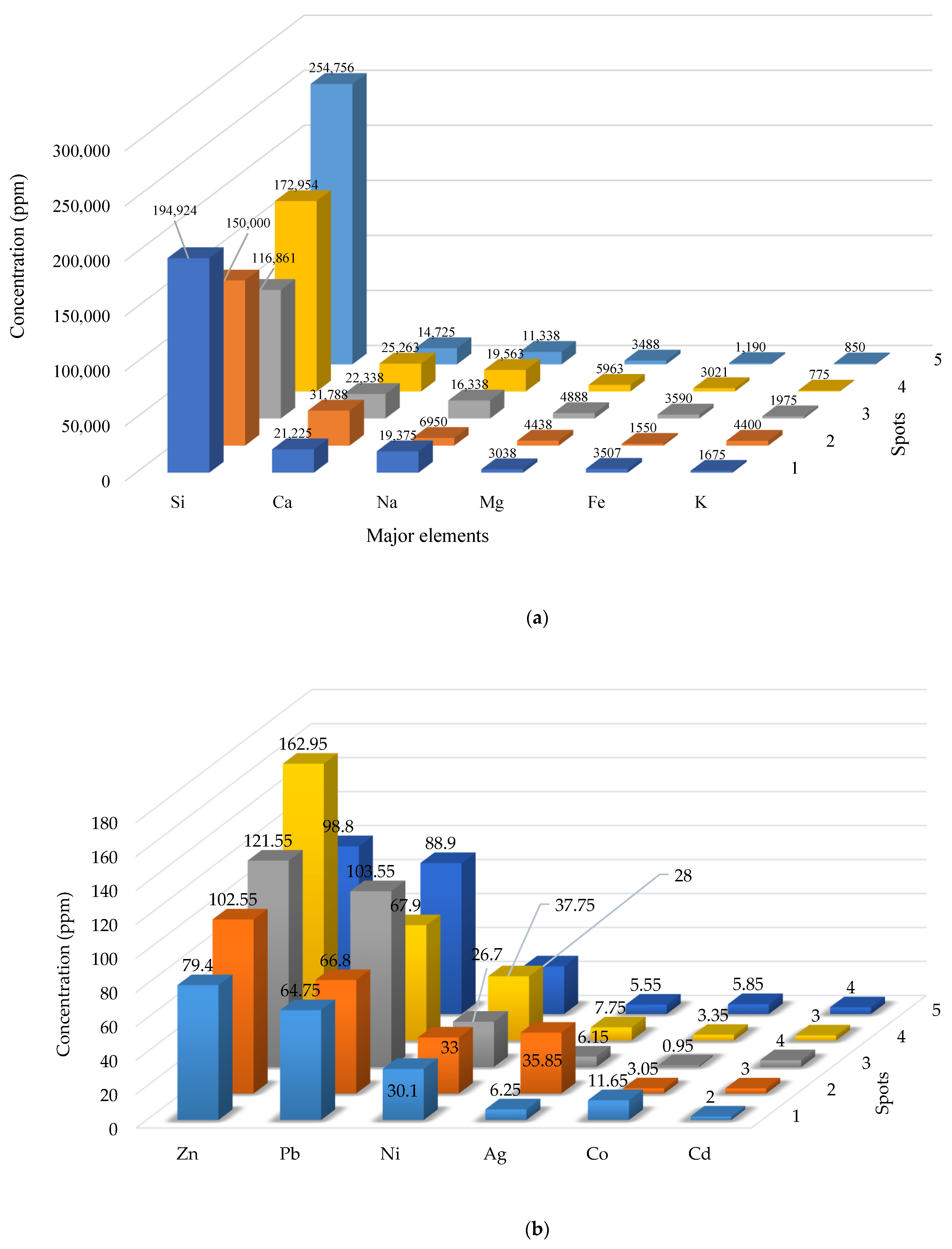

3.2. Operational Stage

4. Summary and Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, X.; Chai, J.; Liu, Z.; Qin, Y.; Xu, Z. Comparison of ventilation methods used during tunnel construction. Eng. Appl. Comput. Fluid Mech. 2020, 14, 107–121. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.; Bohne, R.A.; Bruland, A.; Jakobsen, P.D.; Lohne, J. Environmental impact of drill and blast tunnelling: Life cycle assessment. J. Clean. Prod. 2015, 86, 110–117. [Google Scholar] [CrossRef]

- Liu, S.; Luo, Z.; Zhang, K.; Hang, J. Natural ventilation of a small-scale road tunnel by wind catchers: A CFD simulation study. Atmosphere 2018, 9, 411. [Google Scholar] [CrossRef] [Green Version]

- Qian, C.; Chen, J.; Luo, Y.; Zhao, Z. Monitoring and analysis of the operational environment in an extra-long highway tunnel with longitudinal ventilation. Tunn. Undergr. Space Technol. 2019, 83, 475–484. [Google Scholar] [CrossRef]

- Yang, Q.; Shen, H.; Liang, Z. Analysis of particulate matter and carbon monoxide emission rates from vehicles in a Shanghai tunnel. Sustain. Cities Soc. 2020, 56, 102104. [Google Scholar] [CrossRef]

- Zhao, D.; Chen, H.; Shao, H.; Sun, X. Vehicle emission factors for particulate and gaseous pollutants in an urban tunnel in Xi’an, China. J. Chem. 2018, 2018, 8964852. [Google Scholar] [CrossRef] [Green Version]

- Bein, K.J.; Wallis, C.D.; Silverman, J.L.; Lein, P.J.; Wexler, A.S. Emulating Near-Roadway Exposure to Traffic-Related Air Pollution via Real-Time Emissions from a Major Freeway Tunnel System. Environ. Sci. Technol. 2022, 56, 7083–7095. [Google Scholar] [CrossRef]

- Piscitello, A.; Bianco, C.; Casasso, A.; Sethi, R. Non-exhaust traffic emissions: Sources, characterization, and mitigation measures. Sci. Total Environ. 2021, 766, 144440. [Google Scholar] [CrossRef]

- Harrison, R.M.; Allan, J.; Carruthers, D.; Heal, M.R.; Lewis, A.C.; Marner, B.; Murrells, T.; Williams, A. Non-exhaust vehicle emissions of particulate matter and VOC from road traffic: A review. Atmos. Environ. 2021, 262, 118592. [Google Scholar] [CrossRef]

- Lima, B.D.; Teixeira, E.C.; Hower, J.C.; Civeira, M.S.; Ramírez, O.; Yang, C.-X.; Oliveira, M.L.; Silva, L.F. Metal-enriched nanoparticles and black carbon: A perspective from the Brazil railway system air pollution. Geosci. Front. 2021, 12, 101129. [Google Scholar] [CrossRef]

- Zhao, Y.; Jia, C. Risk Analysis of Harmful Gas in Deep Buried Long Tunnel Construction. In Proceedings of the International Conference on Advances in Energy, Environment and Chemical Engineering, San Francisco, CA, USA, 10–14 July 2015; pp. 655–658. [Google Scholar]

- Safety, O.; Administration, H. Underground Construction (Tunneling):(osha 3115). US Dep. Labor 2003, 30, 35–44. [Google Scholar]

- Balne, P.K.; Sinha, N.R.; Hofmann, A.C.; Martin, L.M.; Mohan, R.R. Characterization of hydrogen sulfide toxicity to human corneal stromal fibroblasts. Ann. N. Y. Acad. Sci. 2020, 1480, 207–218. [Google Scholar] [CrossRef] [PubMed]

- Spagnolo, E.V.; Romano, G.; Zuccarello, P.; Laudani, A.; Mondello, C.; Argo, A.; Zerbo, S.; Barbera, N. Toxicological investigations in a fatal and non-fatal accident due to hydrogen sulphide (H2S) poisoning. Forensic Sci. Int. 2019, 300, e4–e8. [Google Scholar] [CrossRef] [PubMed]

- Langrish, J.; Bosson, J.; Unosson, J.; Muala, A.; Newby, D.; Mills, N.; Blomberg, A.; Sandström, T. Cardiovascular effects of particulate air pollution exposure: Time course and underlying mechanisms. J. Intern. Med. 2012, 272, 224–239. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Yu, X.; Gu, H.; Miao, B.; Wang, M.; Huang, H. Commuters’ exposure to PM2.5 and CO2 in metro carriages of Shanghai metro system. Transp. Res. Part D Transp. Environ. 2016, 47, 162–170. [Google Scholar] [CrossRef]

- Pant, P.; Harrison, R.M. Estimation of the contribution of road traffic emissions to particulate matter concentrations from field measurements: A review. Atmos. Environ. 2013, 77, 78–97. [Google Scholar] [CrossRef]

- Ishtiaq, M.; Jehan, N.; Khan, S.A.; Muhammad, S.; Saddique, U.; Iftikhar, B. Potential harmful elements in coal dust and human health risk assessment near the mining areas in Cherat, Pakistan. Environ. Sci. Pollut. Res. 2018, 25, 14666–14673. [Google Scholar] [CrossRef]

- Khan, S.A.; Muhammad, S.; Nazir, S.; Shah, F.A. Heavy metals bounded to particulate matter in the residential and industrial sites of Islamabad, Pakistan: Implications for non-cancer and cancer risks. Environ. Technol. Innov. 2020, 19, 100822. [Google Scholar] [CrossRef]

- Lu, H.; Zhu, Y.; Qi, Y.; Yu, J. Do urban subway openings reduce PM2. 5 concentrations? Evidence from China. Sustainability 2018, 10, 4147. [Google Scholar] [CrossRef] [Green Version]

- Bedogni, M.; Crapanzano, S.; Lavecchia, C.; Parrella, L. Measurements, model simulations and reduction of CO concentrations inside an urban road tunnel in Milan. Int. J. Environ. Pollut. 2001, 16, 374–385. [Google Scholar] [CrossRef]

- Caliendo, C.; Genovese, G.; Russo, I. Risk analysis of road tunnels: A computational fluid dynamic model for assessing the effects of natural ventilation. Appl. Sci. 2020, 11, 32. [Google Scholar] [CrossRef]

- Du, T.; Yang, D.; Peng, S.; Xiao, Y. A method for design of smoke control of urban traffic link tunnel (UTLT) using longitudinal ventilation. Tunn. Undergr. Space Technol. 2015, 48, 35–42. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, J.; Kenneally, B.; Mooney, M. Air flow behavior and gas dispersion in the recirculation ventilation system of a twin-tunnel construction. Tunn. Undergr. Space Technol. 2016, 58, 30–39. [Google Scholar] [CrossRef]

- Han, J.; Liu, F.; Wang, F.; Weng, M.; Wang, J. Study on the smoke movement and downstream temperature distribution in a sloping tunnel with one closed portal. Int. J. Therm. Sci. 2020, 149, 106165. [Google Scholar] [CrossRef]

- Liu, R.; He, Y.; Zhao, Y.; Jiang, X.; Ren, S. Tunnel construction ventilation frequency-control based on radial basis function neural network. Autom. Constr. 2020, 118, 103293. [Google Scholar] [CrossRef]

- Moreno, T.; Perez, N.; Reche, C.; Martins, V.; De Miguel, E.; Capdevila, M.; Centelles, S.; Minguillón, M.C.; Amato, F.; Alastuey, A. Subway platform air quality: Assessing the influences of tunnel ventilation, train piston effect and station design. Atmos. Environ. 2014, 92, 461–468. [Google Scholar] [CrossRef]

- Nie, W.; Wei, W.; Ma, X.; Liu, Y.; Peng, H.; Liu, Q. The effects of ventilation parameters on the migration behaviors of head-on dusts in the heading face. Tunn. Undergr. Space Technol. 2017, 70, 400–408. [Google Scholar] [CrossRef]

- Lokhandwala, S.; Gautam, P. Indirect impact of COVID-19 on environment: A brief study in Indian context. Environ. Res. 2020, 188, 109807. [Google Scholar] [CrossRef]

- Beslic, I.; Sega, K.; Sisovic, A.; Klaic, Z.B. PM10, CO and NOx concentrations in the Tuhobic road tunnel, Croatia. Int. J. Environ. Pollut. 2005, 25, 251–262. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, W.; Simpson, I.; Huang, X.; Yu, J.; Huang, Z.; Wang, Z.; Zhang, Z.; Liu, D.; Huang, Z. Decadal changes in emissions of volatile organic compounds (VOCs) from on-road vehicles with intensified automobile pollution control: Case study in a busy urban tunnel in south China. Environ. Pollut. 2018, 233, 806–819. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Yao, Z.; Lei, S. Air flow and gas dispersion in the forced ventilation of a road tunnel during construction. Undergr. Space 2019, 4, 168–179. [Google Scholar] [CrossRef]

- Hung-Lung, C.; Yao-Sheng, H. Particulate matter emissions from on-road vehicles in a freeway tunnel study. Atmos. Environ. 2009, 43, 4014–4022. [Google Scholar] [CrossRef]

- Nan, C.; Ma, J.; Luo, Z.; Zheng, S.; Wang, Z. Numerical study on the mean velocity distribution law of air backflow and the effective interaction length of airflow in forced ventilated tunnels. Tunn. Undergr. Space Technol. 2015, 46, 104–110. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Bu, R.; Ma, F.; Shen, Y. Effect of press-in ventilation technology on pollutant transport in a railway tunnel under construction. J. Clean. Prod. 2020, 243, 118590. [Google Scholar] [CrossRef]

- Hua, Y.; Nie, W.; Liu, Q.; Yin, S.; Peng, H. Effect of wind curtain on dust extraction in rock tunnel working face: CFD and field measurement analysis. Energy 2020, 197, 117214. [Google Scholar] [CrossRef]

- Zamorategui-Molina, A.; Gutiérrez-Ortega, N.; Baltazar-Vera, J.C.; Del Angel, J.; Tirado-Torres, D. Carbon Monoxide and Particulate Matter Concentration inside the Road Tunnels of Guanajuato City, Mexico. Aerosol Air Qual. Res. 2021, 21, 210039. [Google Scholar] [CrossRef]

- Shahne, M.Z.; Arhami, M.; Hosseini, V.; El Haddad, I. Particulate emissions of real-world light-duty gasoline vehicle fleet in Iran. Environ. Pollut. 2022, 292, 118303. [Google Scholar] [CrossRef]

- Yan, G.; Wang, M.; Qin, P.; Yan, T.; Li, K.; Wang, X.; Han, C. Field measurements of vehicle pollutant emissions in road tunnels at different altitudes. Tunn. Undergr. Space Technol. 2021, 118, 104187. [Google Scholar] [CrossRef]

- Ur Rehman, Z.; Mohammad, N.; Hussain, S.; Tahir, M. Numerical modeling for the engineering analysis of rock mass behaviour due to sequential enlargement of Lowari tunnel Chitral Khyber Pakhtunkhwa, Pakistan. Int. J. Geotech. Eng. 2019, 13, 54–60. [Google Scholar] [CrossRef]

- Cornelis, R. Handbook of Elemental Speciation II: Species in the Environment, Food, Medicine and Occupational Health; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Belis, C.; Karagulian, F.; Larsen, B.R.; Hopke, P. Critical review and meta-analysis of ambient particulate matter source apportionment using receptor models in Europe. Atmos. Environ. 2013, 69, 94–108. [Google Scholar] [CrossRef]

- Klöckner, P.; Seiwert, B.; Weyrauch, S.; Escher, B.I.; Reemtsma, T.; Wagner, S. Comprehensive characterization of tire and road wear particles in highway tunnel road dust by use of size and density fractionation. Chemosphere 2021, 279, 130530. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.C. Characteristics of trace metals in traffic-derived particles in Hsuehshan Tunnel, Taiwan: Size distribution, potential source, and fingerprinting metal ratio. Atmos. Chem. Phys. 2015, 15, 4117–4130. [Google Scholar] [CrossRef] [Green Version]

- Masiol, M.; Hofer, A.; Squizzato, S.; Piazza, R.; Rampazzo, G.; Pavoni, B. Carcinogenic and mutagenic risk associated to airborne particle-phase polycyclic aromatic hydrocarbons: A source apportionment. Atmos. Environ. 2012, 60, 375–382. [Google Scholar] [CrossRef]

- Rissler, J.; Swietlicki, E.; Bengtsson, A.; Boman, C.; Pagels, J.; Sandström, T.; Blomberg, A.; Löndahl, J. Experimental determination of deposition of diesel exhaust particles in the human respiratory tract. J. Aerosol Sci. 2012, 48, 18–33. [Google Scholar] [CrossRef] [Green Version]

- Thorpe, A.; Harrison, R.M. Sources and properties of non-exhaust particulate matter from road traffic: A review. Sci. Total Environ. 2008, 400, 270–282. [Google Scholar] [CrossRef]

- Tervahattu, H.; Kupiainen, K.J.; Räisänen, M.; Mäkelä, T.; Hillamo, R. Generation of urban road dust from anti-skid and asphalt concrete aggregates. J. Hazard. Mater. 2006, 132, 39–46. [Google Scholar] [CrossRef]

- Cheng, Y.; Zou, S.; Lee, S.; Chow, J.; Ho, K.; Watson, J.; Han, Y.; Zhang, R.; Zhang, F.; Yau, P. Characteristics and source apportionment of PM1 emissions at a roadside station. J. Hazard. Mater. 2011, 195, 82–91. [Google Scholar] [CrossRef]

- Qiao, T.; Xiu, G.; Zheng, Y.; Yang, J.; Wang, L.; Yang, J.; Huang, Z. Preliminary investigation of PM1, PM2. 5, PM10 and its metal elemental composition in tunnels at a subway station in Shanghai, China. Transp. Res. Part D Transp. Environ. 2015, 41, 136–146. [Google Scholar] [CrossRef]

- Grivas, G.; Cheristanidis, S.; Chaloulakou, A.; Koutrakis, P.; Mihalopoulos, N. Elemental composition and source apportionment of fine and coarse particles at traffic and urban background locations in Athens, Greece. Aerosol Air Qual. Res. 2018, 18, 1642–1659. [Google Scholar] [CrossRef] [Green Version]

- Sommer, F.; Dietze, V.; Baum, A.; Sauer, J.; Gilge, S.; Maschowski, C.; Gieré, R. Tire abrasion as a major source of microplastics in the environment. Aerosol Air Qual. Res. 2018, 18, 2014–2028. [Google Scholar] [CrossRef]

- Candeias, C.; Vicente, E.; Tomé, M.; Rocha, F.; Ávila, P.; Célia, A. Geochemical, mineralogical and morphological characterisation of road dust and associated health risks. Int. J. Environ. Res. Public Health 2020, 17, 1563. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- World Health Organization. Hazard Prevention and Control in the Work Environment: Airborne Dust; World Health Organization: Geneva, Switzerland, 2002.

- Celo, V.; Yassine, M.M.; Dabek-Zlotorzynska, E. Insights into Elemental Composition and Sources of Fine and Coarse Particulate Matter in Dense Traffic Areas in Toronto and Vancouver, Canada. Toxics 2021, 9, 264. [Google Scholar] [CrossRef] [PubMed]

- Penkała, M.; Ogrodnik, P.; Rogula-Kozłowska, W. Particulate matter from the road surface abrasion as a problem of non-exhaust emission control. Environments 2018, 5, 9. [Google Scholar] [CrossRef] [Green Version]

- Kreutzmann, H. Accessibility for High Asia: Comparative perspectives on northern Pakistan’s traffic infrastructure and linkages with its neighbours in the Hindukush-Karakoram-Himalaya. J. Mt. Sci. 2004, 1, 193–210. [Google Scholar] [CrossRef]

- Li, H.-C.; Chen, K.-S.; Lai, C.-H.; Wang, H.-K. Measurements of gaseous pollutant concentrations in the Hsuehshan Traffic Tunnel of Northern Taiwan. Aerosol Air Qual. Res. 2011, 11, 776–782. [Google Scholar] [CrossRef]

- Cheng, Y.-H.; Liu, Z.-S.; Yan, J.-W. Comparisons of PM10, PM2.5, particle number, and CO2 levels inside metro trains between traveling in underground tunnels and on elevated tracks. Aerosol Air Qual. Res. 2012, 12, 879–891. [Google Scholar] [CrossRef] [Green Version]

- Gillies, J.; Gertler, A.; Sagebiel, J.; Dippel, N.W. On-road particulate matter (PM2.5 and PM10) emissions in the Sepulveda Tunnel, Los Angeles, California. Environ. Sci. Technol. 2001, 35, 1054–1063. [Google Scholar] [CrossRef]

| Month | Date | H2S (ppm) | SO2 (ppm) | NO (ppm) | CO (ppm) | CO2 (ppm) | Oxy (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Range | Ave. | Range | Ave. | Range | Ave. | Range | Ave. | Range | Ave. | Range. | Ave. | ||

| November 2008 | 1 November 2008 | 0.0 to 0.3 | 0.1 | 0.0 to 0.0 | 0.0 | 1.2 to 5.5 | 3.3 | - | - | - | - | - | - |

| 3 November 2008 | - | - | - | - | - | - | 0.3 to 126.5 | 49.2 | 367.0 to 1670.0 | 771.9 | 30.0 to 30.0 | 30.0 | |

| 4 November 2008 | 0.0 to 0.3 | 0.1 | 0.0 to 0.0 | 0.0 | 1.1 to 11.7 | 5.7 | 3.4 to 215.4 | 77.2 | 616.0 to 915.0 | 772.9 | 30.0 to 30.0 | 30.0 | |

| 5 November 2008 | 0.0 to 0.3 | 0.0 | 0.0 to 0.0 | 0.0 | 0.0 to 16.7 | 5.0 | 0.0 to 446.2 | 103.8 | 185.0 to 2151.0 | 611.2 | 30.0 to 30.0 | 30.0 | |

| 6 November 2008 | 0.0 to 0.3 | 0.0 | 0.0 to 0.0 | 0.0 | 0.3 to 18.0 | 6.2 | 0.0 to 327.0 | 79.0 | 111.0 to 2182.0 | 662.8 | 30.0 to 30.0 | 30.0 | |

| 9 November 2008 | 0.0 to 0.3 | 0.1 | 0.0 to 0.0 | 0.0 | 0.3 to 4.2 | 3.3 | 0.0 to 22.4 | 15.3 | 116.0 to 1880.0 | 785.6 | 30.0 to 30.0 | 30.0 | |

| 10 November 2008 | 0.0 to 0.2 | 0.1 | 0.0 to 0.0 | 0.0 | 1.8 to 5.1 | 3.4 | 21.7 to 28.8 | 24.5 | 617.0 to 816.0 | 687.3 | - | - | |

| 11 November 2008 | 0.0 to 0.1 | 0.0 | 0.0 to 0.0 | 0.0 | 1.8 to 3.1 | 2.5 | 12.1 to 50.4 | 26.2 | 352.0 to 693.0 | 526.4 | 30.0 to 30.0 | 30.0 | |

| 12 November 2008 | 0.0 to 0.3 | 0.0 | 0.0 to 0.0 | 0.0 | 0.7 to 6.1 | 2.6 | 6.0 to 59.7 | 22.9 | 417.0 to 1237.0 | 669.5 | 30.0 to 30.0 | 30.0 | |

| 14 November 2008 | 0.0 to 1.5 | 0.2 | 0.0 to 0.0 | 0.0 | 0.2 to 20.4 | 6.6 | 0.0 to 367.0 | 95.6 | 1559.0 to 3240.0 | 2103.9 | 29.6 to 30.0 | 29.9 | |

| 15 November 2008 | - | - | - | - | - | - | 0.0 to 77.6 | 45.6 | 1192.0 to 2942.0 | 1598.7 | 29.6 to 30.0 | 29.9 | |

| 16 November 2008 | 0.0 to 0.5 | 0.1 | 0.0 to 0.0 | 0.0 | 0.0 to 6.2 | 2.6 | 0.2 to 164.4 | 42.7 | 380.0 to 1641.0 | 759.2 | 30.0 to 30.0 | 30.0 | |

| 17 November 2008 | 0.0 to 0.2 | 0.0 | 0.0 to 0.0 | 0.0 | 0.5 to 4.8 | 2.2 | 1.4 to 32.6 | 11.6 | 397.0 to 2453.0 | 1431.4 | 29.7 to 30.0 | 29.9 | |

| 18 November 2008 | 0.0 to 0.2 | 0.0 | 0.0 to 0.0 | 0.0 | 0.1 to 3.5 | 2.2 | 0.9 to 69.4 | 29.6 | 487.0 to 2121.0 | 972.4 | 29.7 to 30.0 | 29.9 | |

| 19 November 2008 | - | - | - | - | - | - | 0.5 to 403.0 | 92.2 | 434.0 to 2463.0 | 831.6 | 29.8 to 30.0 | 30.0 | |

| 28 November 2008 | - | - | - | - | - | - | 0.0 to 94.8 | 30.3 | 1295.0 to 2692.0 | 2077.6 | 30.0 to 30.0 | 30.0 | |

| 30 November 2008 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 0.4 to 3.9 | 2.6 | 0.0 to 19.5 | 13.2 | 2836.0 to 5888.0 | 5275.1 | 29.8 to 30.0 | 29.9 | |

| December 2008 | 1 December 2008 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 0.0 to 3.2 | 2.0 | 9.3 to 48.0 | 30.8 | 2935.0 to 11,777.0 | 7911.5 | 29.3 to 30.0 | 29.4 |

| 2 December 2008 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 1.4 to 4.3 | 3.2 | 4.6 to 33.6 | 14.5 | 183.0 to 1946.0 | 879.6 | 29.0 to 30.0 | 29.9 | |

| 4 December 2008 | 0.0 to 0.2 | 0.0 | 0.0 to 0.0 | 0.0 | 0.6 to 4.1 | 3.4 | 3.9 to 28.8 | 22.4 | 1402.0 to 3499.0 | 2070.2 | 30.0 to 30.0 | 30.0 | |

| 5 December 2008 | 0.0 to 0.2 | 0.0 | 0.0 to 0.0 | 0.0 | 0.7 to 3.8 | 3.3 | 13.5 to 31.4 | 21.0 | 647.0 to 1692.0 | 860.3 | 30.0 to 30.0 | 30.0 | |

| 6 December 2008 | 0.0 to 2.8 | 0.2 | 0.0 to 0.0 | 0.0 | 1.3 to 26.3 | 7.7 | 4.8 to 450.0 | 109.6 | 534.0 to 1109.0 | 667.7 | 30.0 to 30.0 | 30.0 | |

| 25 December 2008 | 0.0 to 1.9 | 1.0 | 0.0 to 0.0 | 0.0 | 0.0 to 9.5 | 5.6 | 0.0 to 203.9 | 98.2 | 1319.0 to 4934.0 | 3941.4 | 29.7 to 30.0 | 29.9 | |

| 26 December 2008 | 0.0 to 0.2 | 0.0 | 0.0 to 0.0 | 0.0 | 0.0 to 3.0 | 1.4 | 0.1 to 47.4 | 6.6 | 0.1 to 47.4 | 6.7 | 29.6 to 30.0 | 29.9 | |

| 27 December 2008 | 0.0 to 0.3 | 0.1 | 0.0 to 0.0 | 0.0 | 0.0 to 3.9 | 1.8 | 0.0 to 100.4 | 45.3 | 273.0 1072.0 | 630.7 | 29.9 to 30.0 | 30.0 | |

| 28 December 2008 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 0.4 to 1.3 | 0.6 | - | - | - | - | - | - | |

| 29 December 2008 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 0.0 to 2.7 | 1.4 | 0.0 to 10.1 | 3.9 | 659.0 to 2454.0 | 1875.5 | 29.6 to 30.0 | 29.9 | |

| 31 December 2008 | 0.0 to 0.2 | 0.0 | 0.0 to 0.0 | 0.0 | 1.7 to 2.8 | 2.3 | 41.3 to 95.0 | 75.1 | 3040.0 to 7389.0 | 4961.4 | 29.4 to 30.0 | 29.7 | |

| January 2009 | 1 January 2009 | 0.0 to 0.2 | 0.1 | 0.0 to 0.0 | 0.0 | 0.0 to 8.1 | 3.7 | 1.8 to 228.3 | 65.6 | 1684.0 to 7632.0 | 5906.0 | 29.6 to 30.0 | 29.9 |

| 3 January 2009 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 0.1 to 1.7 | 1.4 | 0.6 to 56.6 | 29.9 | 1755.0 to 8690.0 | 5880.0 | 29.5 to 30.0 | 29.8 | |

| 5 January 2009 | - | - | - | - | - | - | 0.7 to 52.7 | 38.4 | 6438.0 to 14,333.0 | 7803.9 | 29.3 to 30.0 | 29.4 | |

| 6 January 2009 | 0.0 to 0.0 | 0.0 | 0.0 to 0.0 | 0.0 | 0.0 to 2.5 | 1.5 | 7.8 to 15.6 | 33.2 | 882.0 to 1771.0 | 1528.3 | 29.7 to 29.9 | 29.8 | |

| 7 January 2009 | 0.0 to 0.1 | 0.0 | 0.0 to 0.0 | 0.0 | 0.2 to 3.2 | 2.5 | 0.0 to 78.2 | 48.4 | 473.0 to 2886.0 | 2220.5 | 29.2 to 30.0 | 29.5 | |

| 9 January 2009 | 0.0 to 0.1 | 0.0 | 0.0 to 0.0 | 0.0 | 0.0 to 3.9 | 1.5 | 2.4 to 149.0 | 30.7 | 1046.0 to 2792.0 | 1668.4 | 29.3 to 29.9 | 29.6 | |

| 20 January 2009 | 0.0 to 0.2 | 0.1 | 0.0 to 0.0 | 0.0 | 0.2 to 2.5 | 1.4 | - | - | - | - | - | - | |

| Spot | Chainage | NO | CO | H2S | CO2 | O2 | O3 | NH3 | NO2 | PM10 | PM2.5 | PM1 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (ppm) | |||||||||||||

| 30 June 2021 | 1 | S. Portal | - | 1.94 | - | 459 | 24.0 | - | - | 0.002 | 0.010 | 0.049 | 0.104 |

| 2 | 1 + 000 | - | - | - | 369 | 24.0 | - | - | 0.002 | 0.515 | 0.076 | 0.094 | |

| 3 | 4 + 000 | - | 5.80 | - | 525 | 23.1 | - | - | 0.002 | 0.298 | 0.054 | 0.342 | |

| 4 | 8 + 000 | - | - | - | 484 | 22.0 | - | - | 0.002 | 0.371 | 0.208 | 0.061 | |

| Limit | 22.5 max | 35 max | 10 max | 5000 max | 19.5 min | 0.1 max | 50 max | 0.2 max | 0.054 max | 0.06 max | |||

| Study | Tunnel | Length (m) | Slope % | CO (ppm) | PM10 (ppm) | PM2.5 (ppm) |

|---|---|---|---|---|---|---|

| This study | Lowari Tunnel | 8509 | 1.8 | 5.80 | 0.40 | 0.11 |

| Li et al., 2011 | Hsuehshan Tunnel | 12,900 | 1.3 | 5.21 | - | - |

| Qian et al., 2019 | Xihan ESA1 Tunnel | 6102 | - | 5.10 | - | - |

| Zamorategui-Molina et al., 2021 | Calle Hidalgo Tunnel | 1100 | 2.1 | 0.01 | 0.08 | 0.08 |

| Ponciano Aguilar Tunnel | 1100 | - | 0.02 | - | - | |

| Tiburcio Tunnel | 0950 | 1.7 | 0.02 | - | -- | |

| Barretero Tunnel | 0800 | 2.6 | 0.03 | 0.10 | 0.09 | |

| Galerena Tunnel | 0700 | 6.7 | 0.02 | 0.08 | 0.08 | |

| Los angeles Tunnel | 0600 | 6.9 | 0.07 | 0.18 | 0.16 | |

| Santa F Tunnel | 0500 | 1.6 | 0.03 | 0.08 | 0.08 | |

| Tamazuca Tunnel | 0110 | 2.1 | 0.02 | - | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, J.; Ahmed, W.; Yasir, M.; Islam, I.; Janjuhah, H.T.; Kontakiotis, G. Pollutants Concentration during the Construction and Operation Stages of a Long Tunnel: A Case Study of Lowari Tunnel, (Dir–Chitral), Khyber Pakhtunkhwa, Pakistan. Appl. Sci. 2022, 12, 6170. https://doi.org/10.3390/app12126170

Khan J, Ahmed W, Yasir M, Islam I, Janjuhah HT, Kontakiotis G. Pollutants Concentration during the Construction and Operation Stages of a Long Tunnel: A Case Study of Lowari Tunnel, (Dir–Chitral), Khyber Pakhtunkhwa, Pakistan. Applied Sciences. 2022; 12(12):6170. https://doi.org/10.3390/app12126170

Chicago/Turabian StyleKhan, Jehanzeb, Waqas Ahmed, Muhammad Yasir, Ihtisham Islam, Hammad Tariq Janjuhah, and George Kontakiotis. 2022. "Pollutants Concentration during the Construction and Operation Stages of a Long Tunnel: A Case Study of Lowari Tunnel, (Dir–Chitral), Khyber Pakhtunkhwa, Pakistan" Applied Sciences 12, no. 12: 6170. https://doi.org/10.3390/app12126170

APA StyleKhan, J., Ahmed, W., Yasir, M., Islam, I., Janjuhah, H. T., & Kontakiotis, G. (2022). Pollutants Concentration during the Construction and Operation Stages of a Long Tunnel: A Case Study of Lowari Tunnel, (Dir–Chitral), Khyber Pakhtunkhwa, Pakistan. Applied Sciences, 12(12), 6170. https://doi.org/10.3390/app12126170