Semi-Analytical Planetary Landing Guidance with Constraint Equations Using Model Predictive Control

Abstract

:1. Introduction

2. Problem Description and Decoupled Trajectory Planning

2.1. One-Dimensional Analytical Derivation

2.2. Three-Dimensional Extension

3. Motion Mode Analysis and Reachability Determination

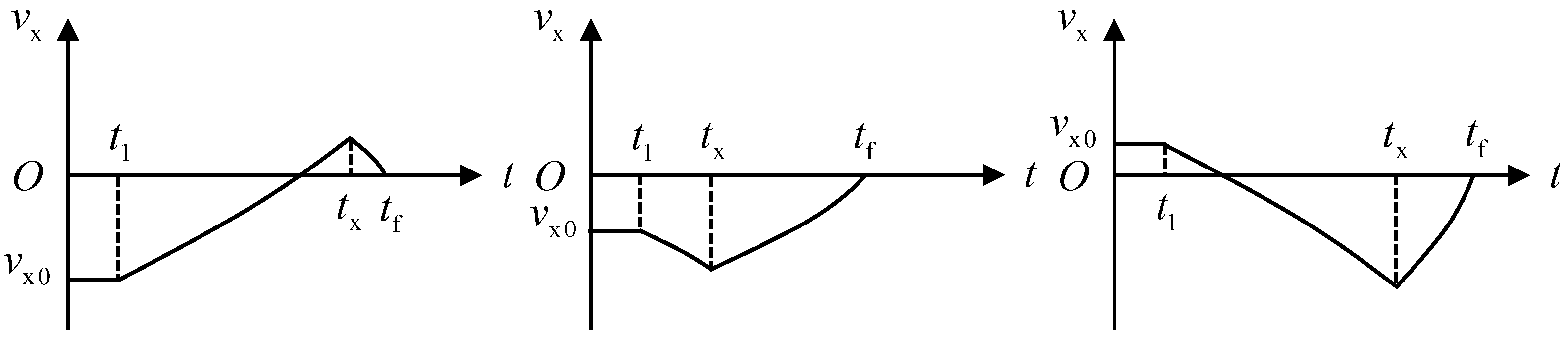

3.1. Motion Mode Analysis

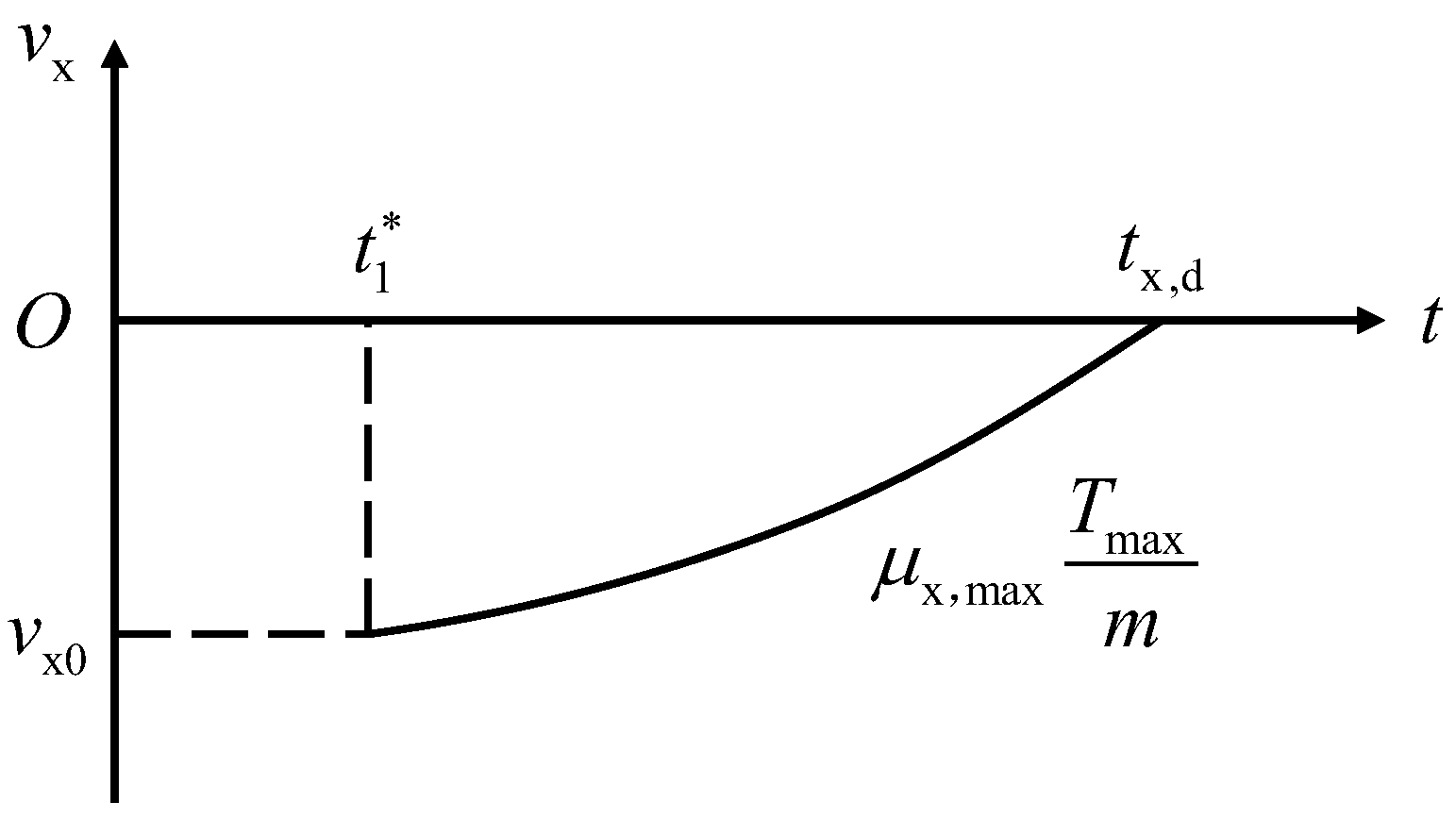

3.2. Reachability Analysis and Motion Mode Judgment

4. Model Predictive Control

5. Simulation Results

5.1. Optimality and Efficiency Evaluation

5.2. Controllability Set Analysis

5.3. MPC Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, H.; Tian, H.; Cai, G. Hybrid uncertainty-based design optimization and its application to hybrid rocket motors for manned lunar landing. Chin. J. Aeronaut. 2017, 30, 719–725. [Google Scholar] [CrossRef]

- Hao, Z.; Zhao, Y.; Chen, Y.; Zhang, Q. Orbital maneuver strategy design based on piecewise linear optimization for spacecraft soft landing on irregular asteroids. Chin. J. Aeronaut. 2020, 33, 2694–2706. [Google Scholar] [CrossRef]

- Ma, L.; Wang, K.; Xu, Z.; Shao, Z.; Song, Z.; Biegler, L.T. Multi-point powered descent guidance based on optimal sensitivity. Aerosp. Sci. Technol. 2019, 86, 465–477. [Google Scholar] [CrossRef]

- Li, S.; Jiang, X. RBF neural network based second-order sliding mode guidance for Mars entry under uncertainties. Aerosp. Sci. Technol. 2015, 43, 226–235. [Google Scholar] [CrossRef]

- Pagone, M.; Novara, C.; Martella, P.; Nocerino, C. GNC robustness stability verification for an autonomous lander. Aerosp. Sci. Technol. 2020, 100, 105831. [Google Scholar] [CrossRef]

- Zheng, Y.; Cui, H. Optimal nonlinear feedback guidance algorithm for Mars powered descent. Aerosp. Sci. Technol. 2015, 45, 359–366. [Google Scholar] [CrossRef]

- Lu, P. Propellant-Optimal Powered Descent Guidance. J. Guid. Control. Dyn. 2018, 41, 813–826. [Google Scholar] [CrossRef]

- Betts, J.T. Survey of Numerical Methods for Trajectory Optimization. J. Guid. Control. Dyn. 1998, 21, 193–207. [Google Scholar] [CrossRef]

- Zhang, B.; Tang, S.; Pan, B. Multi-constrained suboptimal powered descent guidance for lunar pinpoint soft landing. Aerosp. Sci. Technol. 2016, 48, 203–213. [Google Scholar] [CrossRef]

- Acikmese, A.B.; Ploen, S. A Powered Descent Guidance Algorithm for Mars Pinpoint Landing. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, San Francisco, CA, USA, 15–18 August 2005. [Google Scholar] [CrossRef]

- Acikmese, B.; Ploen, S.R. Convex Programming Approach to Powered Descent Guidance for Mars Landing. J. Guid. Control. Dyn. 2007, 30, 1353–1366. [Google Scholar] [CrossRef]

- Acikmese, B.; Scharf, D.; Blackmore, L.; Wolf, A. Enhancements on the Convex Programming Based Powered Descent Guidance Algorithm for Mars Landing. In Proceedings of the AIAA/AAS Astrodynamics Specialist Conference and Exhibit, Honolulu, Hawaii, 18–21 August 2008. [Google Scholar] [CrossRef] [Green Version]

- Blackmore, L.; Açikmeşe, B.; Scharf, D.P. Minimum-Landing-Error Powered-Descent Guidance for Mars Landing Using Convex Optimization. J. Guid. Control. Dyn. 2010, 33, 1161–1171. [Google Scholar] [CrossRef] [Green Version]

- Song, Z.Y.; Wang, C.; Theil, S.; Seelbinder, D.; Sagliano, M.; Liu, X.F.; Shao, Z.J. Survey of autonomous guidance methods for powered planetary landing. Front. Inf. Technol. Electron. Eng. 2020, 21, 652–674. [Google Scholar] [CrossRef]

- Lu, P.; Liu, X. Autonomous Trajectory Planning for Rendezvous and Proximity Operations by Conic Optimization. J. Guid. Control. Dyn. 2013, 36, 375–389. [Google Scholar] [CrossRef]

- Liu, X.; Lu, P. Solving Nonconvex Optimal Control Problems by Convex Optimization. J. Guid. Control. Dyn. 2014, 37, 750–765. [Google Scholar] [CrossRef]

- Pinson, R.M.; Lu, P. Trajectory Design Employing Convex Optimization for Landing on Irregularly Shaped Asteroids. J. Guid. Control. Dyn. 2018, 41, 1243–1256. [Google Scholar] [CrossRef]

- DONG, W.; WEN, Q.; XIA, Q.; YANG, S. Multiple-constraint cooperative guidance based on two-stage sequential convex programming. Chin. J. Aeronaut. 2020, 33, 296–307. [Google Scholar] [CrossRef]

- Mao, Y.; Szmuk, M.; Açıkmeşe, B. Successive convexification of non-convex optimal control problems and its convergence properties. In Proceedings of the 2016 IEEE 55th Conference on Decision and Control (CDC), Las Vegas, NV, USA, 12–14 December 2016; pp. 3636–3641. [Google Scholar] [CrossRef] [Green Version]

- Mao, Y.; Szmuk, M.; Xu, X.; Acikmese, B. Successive Convexification: A Superlinearly Convergent Algorithm for Non-convex Optimal Control Problems. arXiv 2019, arXiv:1804.06539. [Google Scholar]

- Szmuk, M.; Eren, U.; Acikmese, B. Successive Convexification for Mars 6-DoF Powered Descent Landing Guidance. In Proceedings of the AIAA Guidance, Navigation, and Control Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef]

- Szmuk, M.; Reynolds, T.P.; Açıkmeşe, B. Successive Convexification for Real-Time Six-Degree-of-Freedom Powered Descent Guidance with State-Triggered Constraints. J. Guid. Control. Dyn. 2020, 43, 1399–1413. [Google Scholar] [CrossRef]

- Sagliano, M. Pseudospectral Convex Optimization for Powered Descent and Landing. J. Guid. Control. Dyn. 2018, 41, 320–334. [Google Scholar] [CrossRef] [Green Version]

- Sagliano, M. Generalized hp Pseudospectral-Convex Programming for Powered Descent and Landing. J. Guid. Control. Dyn. 2019, 42, 1562–1570. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.; Miao, X.; Gong, S. Adaptive powered descent guidance based on multi-phase pseudospectral convex optimization. Acta Astronaut. 2020, 180, 386–397. [Google Scholar] [CrossRef]

- Meditch, J. On the problem of optimal thrust programming for a lunar soft landing. IEEE Trans. Autom. Control. 1964, 9, 477–484. [Google Scholar] [CrossRef]

- Klumpp, A.R. Apollo lunar descent guidance. Automatica 1974, 10, 133–146. [Google Scholar] [CrossRef]

- D’Souza, C.; D’Souza, C. An optimal guidance law for planetary landing. In Proceedings of the Guidance, Navigation, and Control Conference, New Orleans, LA, USA, 11–13 August 1997. [Google Scholar] [CrossRef]

- Rea, J.; Bishop, R. Analytical Dimensional Reduction of a Fuel Optimal Powered Descent Subproblem. In Proceedings of the AIAA Guidance, Navigation, and Control Conference, Toronto, ON, Canada, 2–5 August 2010. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Bai, X.; Baoyin, H. Rapid Trajectory Planning for Asteroid Landing with Thrust Magnitude Constraint. J. Guid. Control. Dyn. 2017, 40, 2713–2720. [Google Scholar] [CrossRef]

- Lu, P. Augmented Apollo Powered Descent Guidance. J. Guid. Control. Dyn. 2019, 42, 447–457. [Google Scholar] [CrossRef]

- Lu, P. Theory of Fractional-Polynomial Powered Descent Guidance. J. Guid. Control. Dyn. 2020, 43, 398–409. [Google Scholar] [CrossRef]

- Cheng, L.; Shi, P.; Gong, S.; Wang, Z. Real-time trajectory optimization for powered planetary landings based on analytical shooting equations. Chin. J. Aeronaut. 2021, 35, 91–99. [Google Scholar] [CrossRef]

- Izzo, D.; Märtens, M.; Pan, B. A survey on artificial intelligence trends in spacecraft guidance dynamics and control. Astrodynamics 2019, 3, 287–299. [Google Scholar] [CrossRef]

- Song, Y.; Miao, X.; Cheng, L.; Gong, S. The feasibility criterion of fuel-optimal planetary landing using neural networks. Aerosp. Sci. Technol. 2021, 116, 106860. [Google Scholar] [CrossRef]

- Bououden, S.; Chadli, M.; Karimi, H.R. A Robust Predictive Control Design for Nonlinear Active Suspension Systems. Asian J. Control. 2016, 18, 122–132. [Google Scholar] [CrossRef]

- Bououden, S.; Chadli, M.; Zhang, L.; Yang, T. Constrained model predictive control for time-varying delay systems: Application to an active car suspension. Int. J. Control. Autom. Syst. 2016, 14, 51–58. [Google Scholar] [CrossRef]

- Bououden, S.; Boulkaibet, I.; Chadli, M.; Abboudi, A. A Robust Fault-Tolerant Predictive Control for Discrete-Time Linear Systems Subject to Sensor and Actuator Faults. Sensors 2021, 21, 2307. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| 1905 kg | 13,258 N | ||

| 1505 kg | g | 3.7114 | |

| 6.8665 kg/s |

| Fuel Consumption | |||

|---|---|---|---|

| s | s | 236.5185 kg |

| Fuel Consumption | |||

|---|---|---|---|

| s | s | 377.0066 kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, X.; Cheng, L.; Song, Y.; Li, J.; Gong, S. Semi-Analytical Planetary Landing Guidance with Constraint Equations Using Model Predictive Control. Appl. Sci. 2022, 12, 6166. https://doi.org/10.3390/app12126166

Miao X, Cheng L, Song Y, Li J, Gong S. Semi-Analytical Planetary Landing Guidance with Constraint Equations Using Model Predictive Control. Applied Sciences. 2022; 12(12):6166. https://doi.org/10.3390/app12126166

Chicago/Turabian StyleMiao, Xinyuan, Lin Cheng, Yu Song, Junfeng Li, and Shengping Gong. 2022. "Semi-Analytical Planetary Landing Guidance with Constraint Equations Using Model Predictive Control" Applied Sciences 12, no. 12: 6166. https://doi.org/10.3390/app12126166