Preparation of Aluminum Dross Non-Fired Bricks with High Nitrogen Concentration and Optimization of Process Parameters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sample Preparation

2.3. Characterization

3. Results and Discussion

3.1. Influence of Different Forming Pressures on Non-Fired Bricks

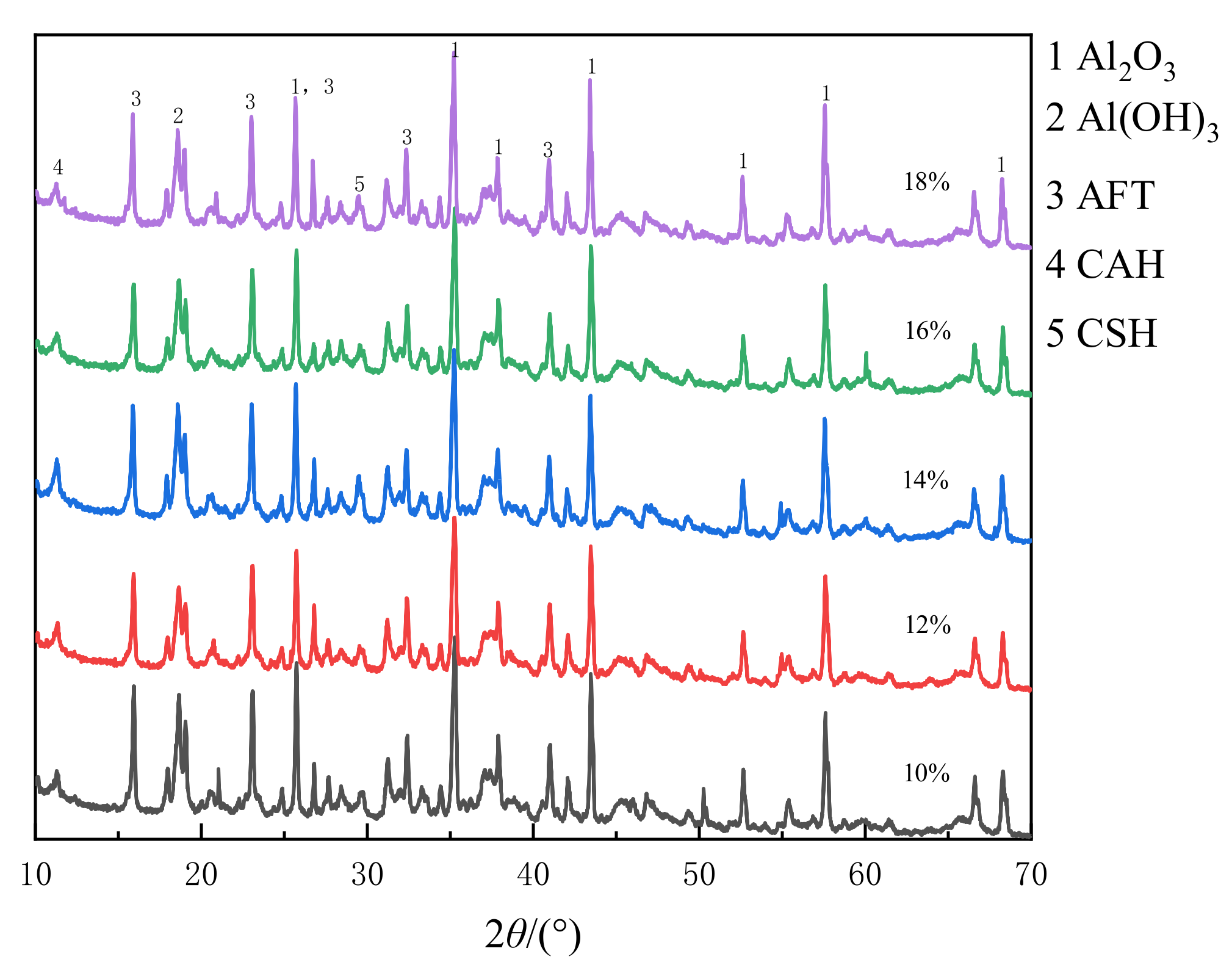

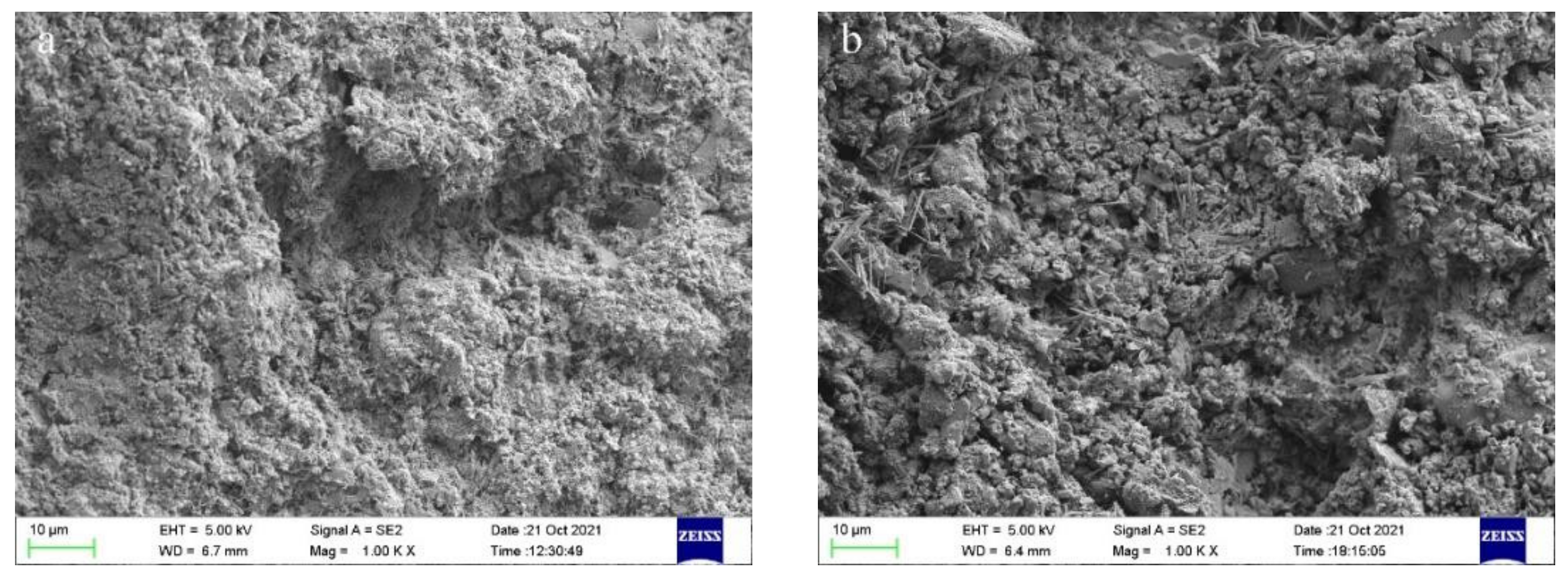

3.2. Influence of Mixing-Water Amount on Non-Fired Bricks

3.3. Influence of Aluminum Dross Particle Size on Non-Fired Bricks

3.4. Multi-Factor Optimization Experiment Based on Response Surface Method

4. Conclusions

- There is a positive correlation between the forming pressure and the mechanical properties of aluminum dross non-fired bricks, with a critical value of 18 MPa. When the forming pressure is greater than 18 MPa, the forming pressure continues to increase, which slightly improves the performance of non-fired bricks. The content of the main phases of non-fired bricks under different forming pressures does not change significantly.

- The mixing-water amount has a positive correlation with the mechanical properties of aluminum dross non-fired bricks before 14%, and has a negative correlation after 14%. When the mixing-water amount is 14%, the two hydration products CAH and CSH on the surface of the non-fired bricks are most abundant and intertwine, thereby increasing the strength of the non-fired bricks.

- When the particle size of aluminum dross is 100–150 mesh, the mechanical properties of non-fired bricks reach the maximum value and then decrease rapidly. This is because the active alumina is mainly distributed in the range larger than 200 mesh, which reacts with Ca(OH)2 and CaSO4 to generate excess AFt. Since there is no connection between the particles, the performance decreases overall.

- Through the multi-factor test based on the response surface method, the influence of different factors on the compressive strength of aluminum dross non-fired bricks is as follows: forming pressure > aluminum dross particle size > mixing-water amount. The optimal process parameters are as follows: forming pressure is 18 MPa, mixing-water amount is 15% and aluminum dross particle size range is 80–130 mesh. Under this condition, the compressive strength of non-fired bricks is 24.66 MPa, which is only 0.36% different from the model’s predicted value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, W.H.; Zhang, X.Y.; Zhang, J.J.; Shen, H.L.; Yang, J.J.; Liu, Y.; Liu, J.; Zhang, S.E.; Yang, J.L. Porous ceramics with near-zero shrinkage and low thermal conductivity from hazardous secondary aluminum dross. J. Am. Ceram. Soc. 2022, 105, 3197–3210. [Google Scholar] [CrossRef]

- Cinarli, U.; Turan, A. Investigation of Alumina-Based Ceramic Production from Aluminum Black Dross. Min. Metall. Explor. 2021, 38, 257–267. [Google Scholar] [CrossRef]

- Hong, J.P.; Wang, J.; Chen, H.Y.; Sun, B.D.; Li, J.J.; Chen, C. Process of aluminum dross recycling and life cycle assessment for Al-Si alloys and brown fused alumina. Trans. Nonferr. Met. Soc. 2010, 20, 2155–2161. [Google Scholar] [CrossRef]

- Gupta, N.; Gedam, V.V.; Moghe, C.; Labhasetwar, P. Investigation of characteristics and leaching behavior of coal fly ash, coal fly ash bricks and clay bricks. Environ. Technol. Innov. 2017, 7, 152–159. [Google Scholar] [CrossRef]

- Gao, Q.; Guo, Q.; Li, Y.L.; Ren, B.Z.; Fu, M.B.; Li, H.L.; Tian, D.C.; Ding, M. Innovative technology for defluorination of secondary aluminum dross by alkali leaching. Miner. Eng. 2021, 172, 107134. [Google Scholar] [CrossRef]

- Directory of National Hazardous Wastes (Version 2021); Ministry of Ecological Environment of the People’s Republic of China: Beijing, China, 2021. (In Chinese)

- Meshram, A.; Singh, K.K. Recovery of valuable products from hazardous aluminum dross: A review. Resour. Conserv. Recycl. 2018, 130, 95–108. [Google Scholar] [CrossRef]

- Xun, K.B. The Preparation of Flocculant PAFSC by Aluminium Waste Slag and Its Application Research. Master’s Thesis, Nanchang University, Nanchang, China, 2014. [Google Scholar]

- Zhou, Y.M.; Xie, G.; Yao, Y.; Tian, L.; Xie, T.J.; He, X.C. Preparation of aluminum hydroxide with aluminum ash by Alkali sintering method. Light Metals 2015, 09, 12–14. [Google Scholar] [CrossRef]

- David, E.; Kopac, J. Hydrolysis of aluminum dross material to achieve zero hazardous waste. J. Hazard. Mater. 2012, 209, 501–509. [Google Scholar] [CrossRef]

- Hu, S.Y.; Wang, D.Y.; Hou, D.; Zhao, W.; Li, X.L.; Qu, T.P.; Zhu, Q.D. Research on the Preparation Parameters and Basic Properties of Premelted Calcium Aluminate Slag Prepared from Secondary Aluminum Dross. Materials 2021, 14, 5855. [Google Scholar] [CrossRef]

- Yoshimura, H.N.; Abreu, A.P.; Molisani, A.L.; Camargo, A.C.D.; Portela, J.C.S.; Narita, N.E. Evaluation of aluminum dross waste as raw material for refractories. Ceram. Int. 2006, 34, 581–591. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, Z.H.; Han, Z.Y.; Xiao, X.Y.; Peng, C. Feasibility of aluminum recovery and MgAl2O4 spinel synthesis from secondary aluminum dross. Int. J. Min. Met. Mater. 2019, 26, 309–318. [Google Scholar] [CrossRef]

- Benkhelif, A.; Kolli, M. Synthesis of Pure Magnesium Aluminate Spinel (MgAl2O4) from Waste Aluminum Dross. Waste Biomass Valorization 2022, 13, 2637–2649. [Google Scholar] [CrossRef]

- Ewais, E.; Khalil, N.M.; Amin, M.S.; Ahmed, Y.; Barakat, M.A. Utilization of aluminum sludge and aluminum slag (dross) for the manufacture of calcium aluminate cement. Ceram. Int. 2009, 35, 3381–3388. [Google Scholar] [CrossRef]

- Mandal, A.K.; Verma, H.R.; Sinha, O.P. Utilization of aluminum plant’s waste for production of insulation bricks. J. Clean. Prod. 2017, 162, 949–957. [Google Scholar] [CrossRef]

- Ni, H.J.; Zhang, J.Q.; Lv, S.S.; Gu, T.; Wang, X.X. Performance Optimization of Original Aluminum Ash Coating. Coatings 2020, 10, 831. [Google Scholar] [CrossRef]

- Ni, H.J.; Zhang, J.Q.; Lv, S.S.; Wang, X.X.; Zhu, Y.; Gu, T. Preparation and Performance Optimization of Original Aluminum Ash Coating Based on Plasma Spraying. Coatings 2019, 9, 770. [Google Scholar] [CrossRef] [Green Version]

- Ni, H.J.; Wu, W.Y.; Lv, S.S.; Wang, X.X.; Tang, W.J. Formulation of Non-Fired Bricks Made from Secondary Aluminum Ash. Coatings 2022, 12, 2. [Google Scholar] [CrossRef]

- GB/T 17671-1999; Test Method for Cement Mortar Strength. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 1999. (In Chinese)

- Wu, H.; Lu, X.Y.; Luo, Z.J.; Yang, Y. Preparation and Mechanism Analysis of Activated Coal Gangue Unburned Bricks. Non-Met. Mines 2018, 41, 30–33. [Google Scholar]

- Xu, Q.Q. Development of Secondary Aluminum Ash Unburned. Master’s Thesis, Zhejiang Normal University, Jinhua, China, 2016. [Google Scholar]

- Zhou, J.; Gao, H.; Shu, Z.; Wang, Y.X.; Yan, C.J. Utilization of waste phosphogypsum to prepare non-fired bricks by a novel Hydration-Recrystallization process. Constr. Build. Mater. 2012, 34, 114–119. [Google Scholar] [CrossRef]

- Han, S.; Yan, P.Y.; Liu, R.G. Study on the hydration product of cement in early age using TEM. Sci. China Technol. Sci. 2012, 55, 2284–2290. [Google Scholar] [CrossRef]

- JC/T 422-2007; Non-Fired Rubbish Gangue Bricks. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2007. (In Chinese)

- Han, Y.M.; Xia, J.W.; Chang, H.F.; Xu, J. The Influence Mechanism of Ettringite Crystals and Microstructure Characteristics on the Strength of Calcium-Based Stabilized Soil. Materials 2021, 14, 1359. [Google Scholar] [CrossRef] [PubMed]

| Element | Na | Mg | Al | Si | S | Cl | K |

|---|---|---|---|---|---|---|---|

| Mass proportion % | 24.25 | 1.86 | 39.76 | 1.11 | 1.88 | 17.73 | 4.96 |

| Element | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A (forming pressure/MPa) | 12 | 15 | 18 |

| B (mixing-water amount/%) | 12 | 14 | 16 |

| C (aluminum dross particle size/mesh) | 50 | 100 | 150 |

| Experiment No. | A | B | C | Compressive Strength/MPa |

|---|---|---|---|---|

| 1 | 12 | 12 | 100 | 18.91 |

| 2 | 18 | 12 | 100 | 22.13 |

| 3 | 12 | 16 | 100 | 18.85 |

| 4 | 18 | 16 | 100 | 24.04 |

| 5 | 12 | 14 | 50 | 18.90 |

| 6 | 18 | 14 | 50 | 23.14 |

| 7 | 12 | 14 | 150 | 17.44 |

| 8 | 18 | 14 | 150 | 21.34 |

| 9 | 15 | 12 | 50 | 18.96 |

| 10 | 15 | 16 | 50 | 22.07 |

| 11 | 15 | 12 | 150 | 18.10 |

| 12 | 15 | 16 | 150 | 18.81 |

| 13 | 15 | 14 | 100 | 22.42 |

| 14 | 15 | 14 | 100 | 22.54 |

| 15 | 15 | 14 | 100 | 22.92 |

| Source | Sum of Squares | df | Mean Square | F-value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 65.84 | 9 | 7.32 | 50.60 | 0.0002 | significant |

| A | 34.24 | 1 | 34.24 | 236.80 | <0.0001 | significant |

| B | 4.02 | 1 | 4.02 | 27.79 | 0.0033 | significant |

| C | 6.81 | 1 | 6.81 | 47.09 | 0.0010 | significant |

| AB | 0.9702 | 1 | 0.9702 | 6.71 | 0.0488 | significant |

| AC | 0.0289 | 1 | 0.0289 | 0.1999 | 0.6735 | not significant |

| BC | 1.44 | 1 | 1.44 | 9.96 | 0.0252 | significant |

| A2 | 0.7884 | 1 | 0.7884 | 5.45 | 0.0668 | not significant |

| B2 | 5.16 | 1 | 5.16 | 35.68 | 0.0019 | significant |

| C2 | 14.18 | 1 | 14.18 | 98.06 | 0.0002 | significant |

| Residual | 0.7229 | 5 | 0.1446 | none | none | none |

| Lack of fit | 0.5867 | 3 | 0.1956 | 2.87 | 0.2690 | none |

| Pure Error | 0.1363 | 2 | 0.0681 | none | none | none |

| Cor Total | 66.57 | 14 | none | none | none | none |

| Item | Value | Item | Value |

|---|---|---|---|

| Std. Dev | 0.3802 | R2 | 0.9891 |

| Mean | 20.70 | Adjusted R2 | 0.9696 |

| C.V.% | 1.84 | Predicted R2 | 0.8544 |

| Adeq Precision | 22.3974 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, H.; Wu, W.; Lu, C.; Wang, X.; Zhu, Y.; Lv, S. Preparation of Aluminum Dross Non-Fired Bricks with High Nitrogen Concentration and Optimization of Process Parameters. Appl. Sci. 2022, 12, 6133. https://doi.org/10.3390/app12126133

Ni H, Wu W, Lu C, Wang X, Zhu Y, Lv S. Preparation of Aluminum Dross Non-Fired Bricks with High Nitrogen Concentration and Optimization of Process Parameters. Applied Sciences. 2022; 12(12):6133. https://doi.org/10.3390/app12126133

Chicago/Turabian StyleNi, Hongjun, Weiyang Wu, Chunyu Lu, Xingxing Wang, Yu Zhu, and Shuaishuai Lv. 2022. "Preparation of Aluminum Dross Non-Fired Bricks with High Nitrogen Concentration and Optimization of Process Parameters" Applied Sciences 12, no. 12: 6133. https://doi.org/10.3390/app12126133

APA StyleNi, H., Wu, W., Lu, C., Wang, X., Zhu, Y., & Lv, S. (2022). Preparation of Aluminum Dross Non-Fired Bricks with High Nitrogen Concentration and Optimization of Process Parameters. Applied Sciences, 12(12), 6133. https://doi.org/10.3390/app12126133