Jointed Rock Failure Mechanism: A Method of Heterogeneous Grid Generation for DDARF

Abstract

:1. Introduction

1.1. Automatic Generation of Random Joint Networks

1.2. Automatic Generation of Triangular Block Grid

1.3. Analysis of Block Boundary Cracking

1.4. Simulated Material Inhomogeneity

- (1)

- is any non-negative integer;

- (2)

- meets:

- (3)

- is odd, and

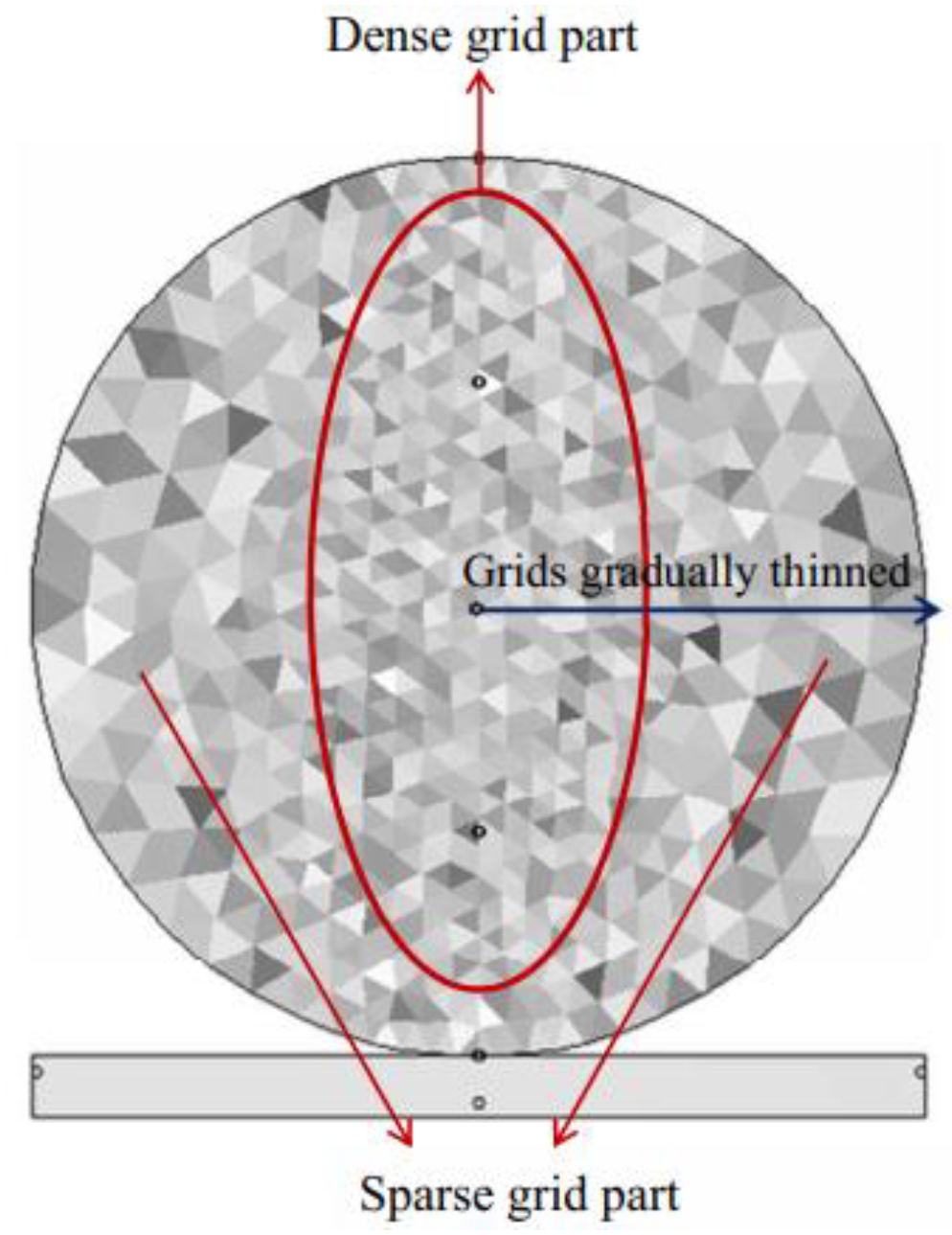

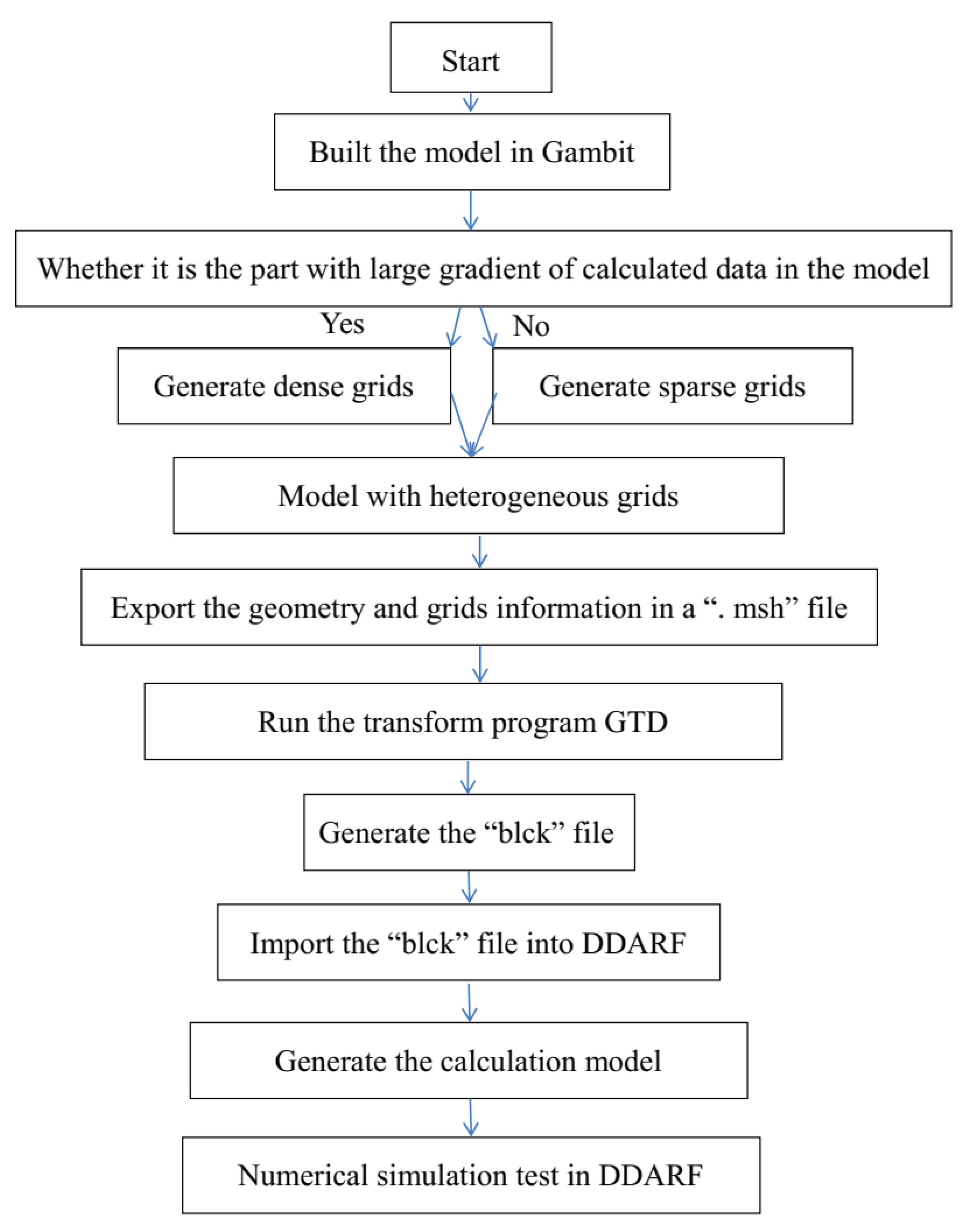

2. The Methodology of Heterogeneous Grid Generation for DDARF

2.1. Gambit Modeling and Generation of Heterogeneous Grids

2.2. Transform Program GTD (Gambit to DDARF)

3. Results and Discussion

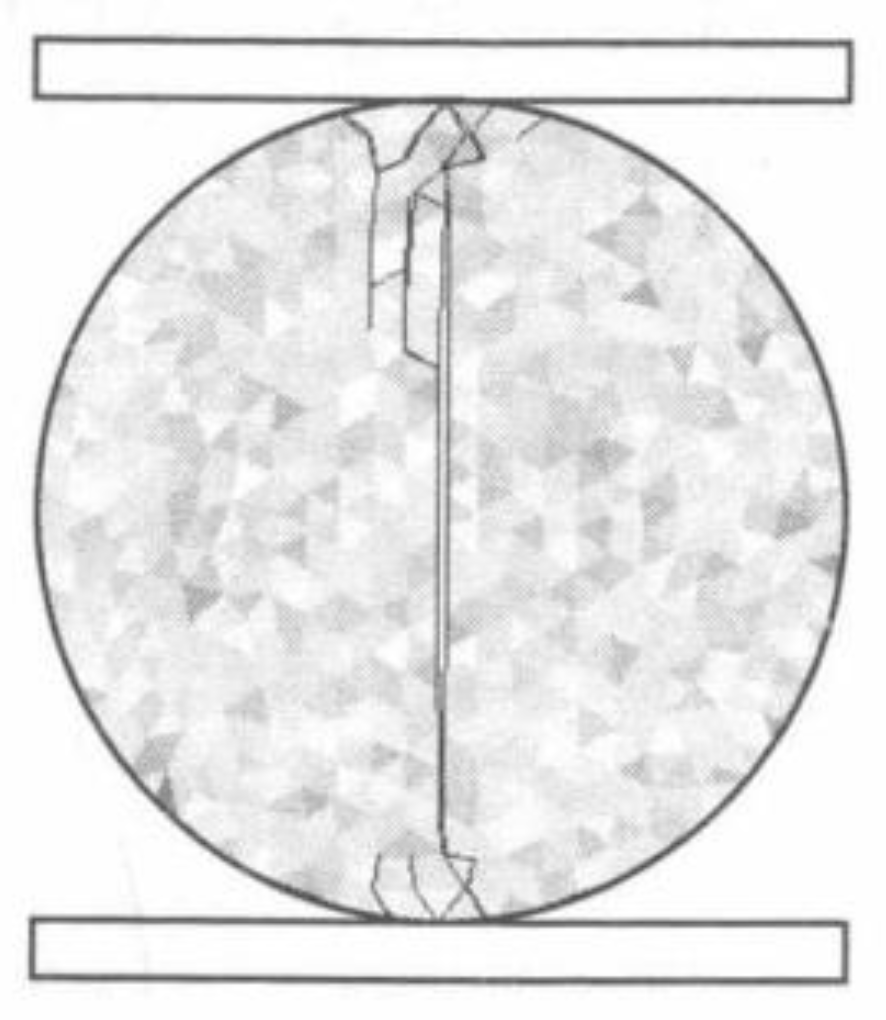

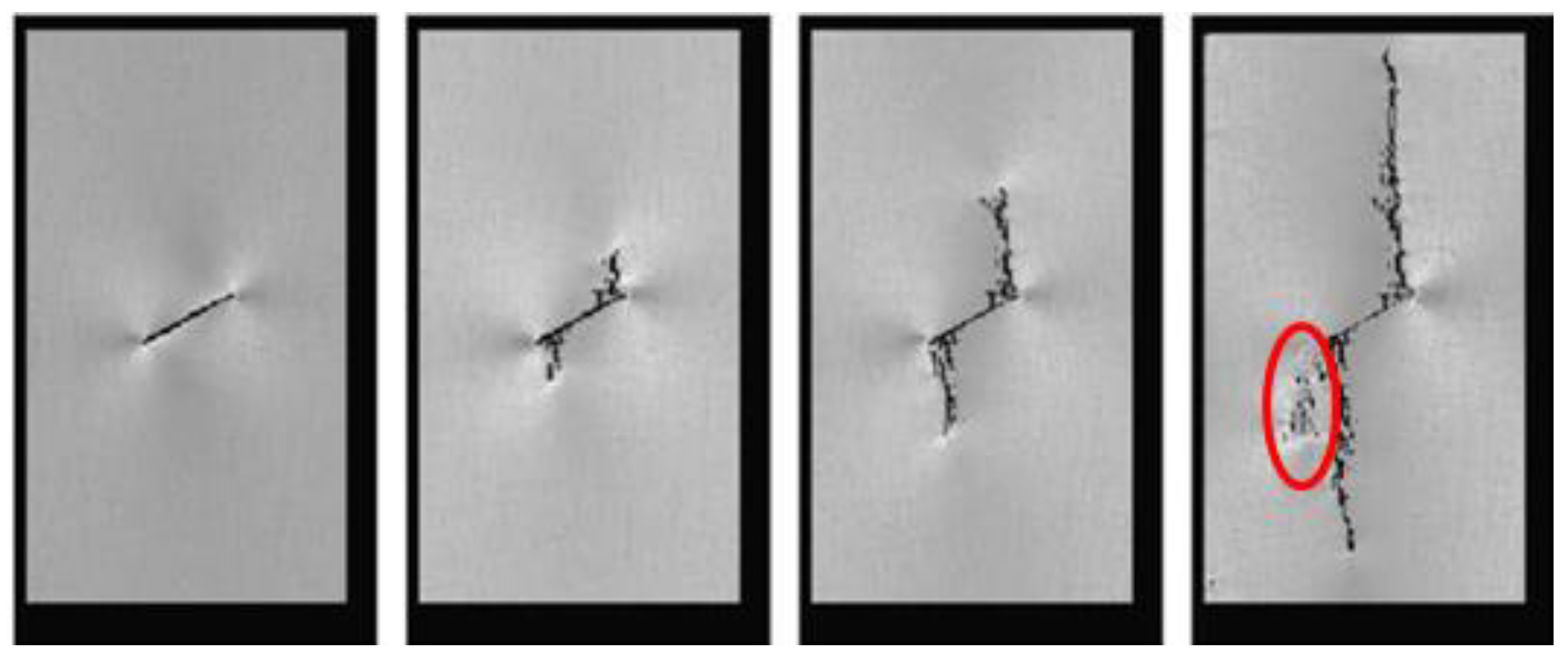

3.1. Accuracy Verification of the Optimized DDARF Program

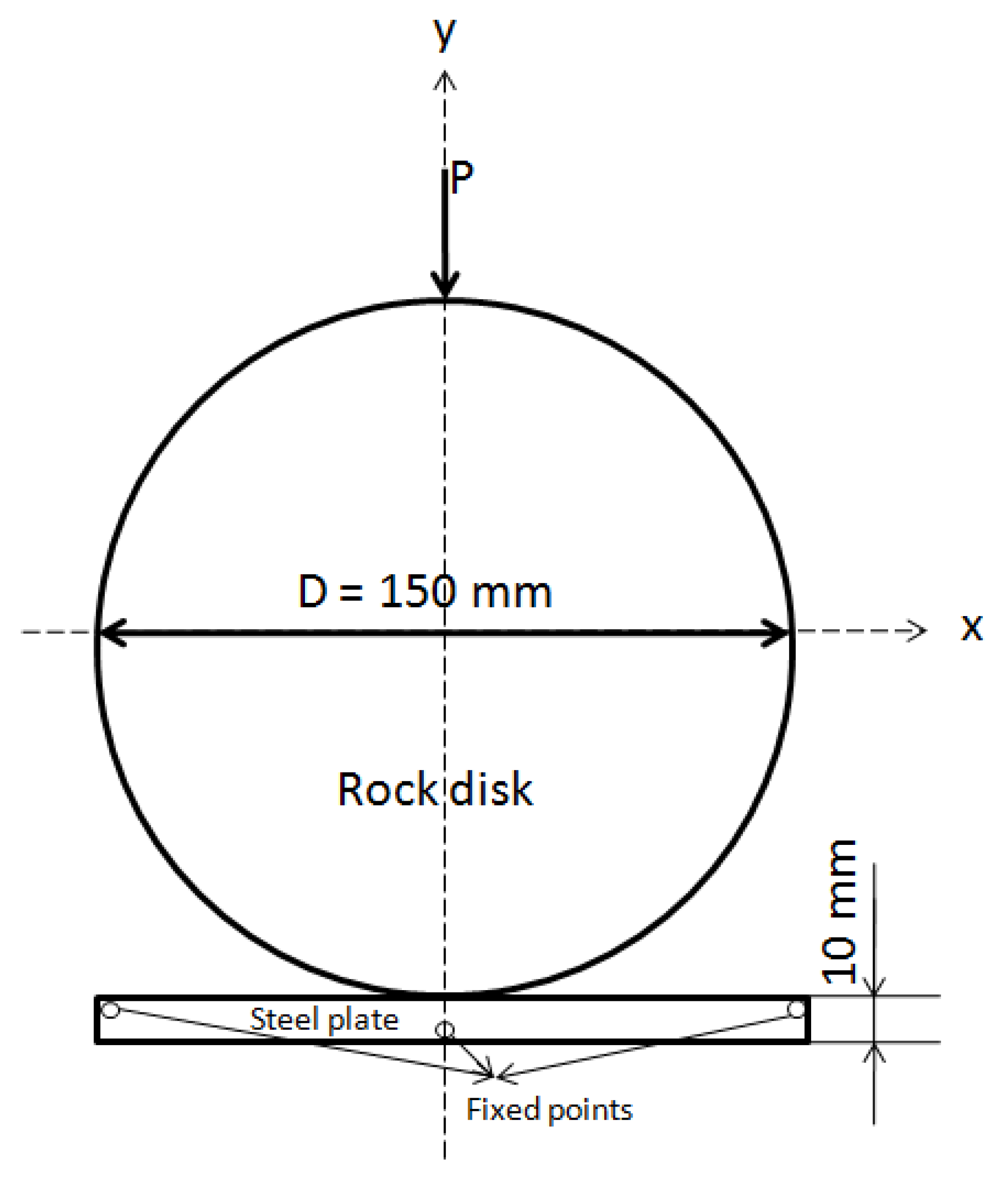

3.1.1. Model Parameters and Loading Mode

3.1.2. Analysis and Comparison of Results

3.2. Superiority Verification of the Optimized DDARF Program

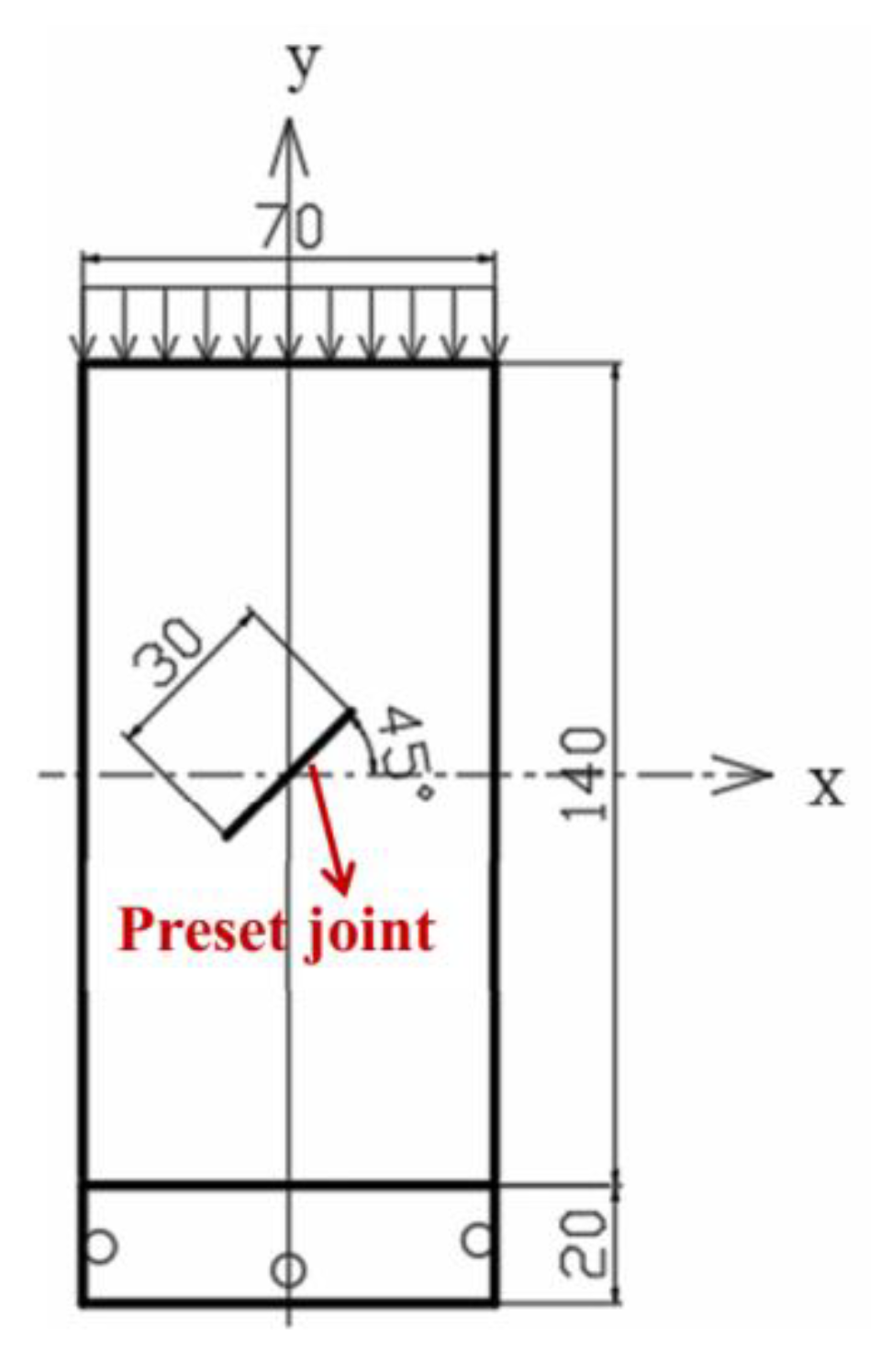

3.2.1. Model Building and Loading Mode

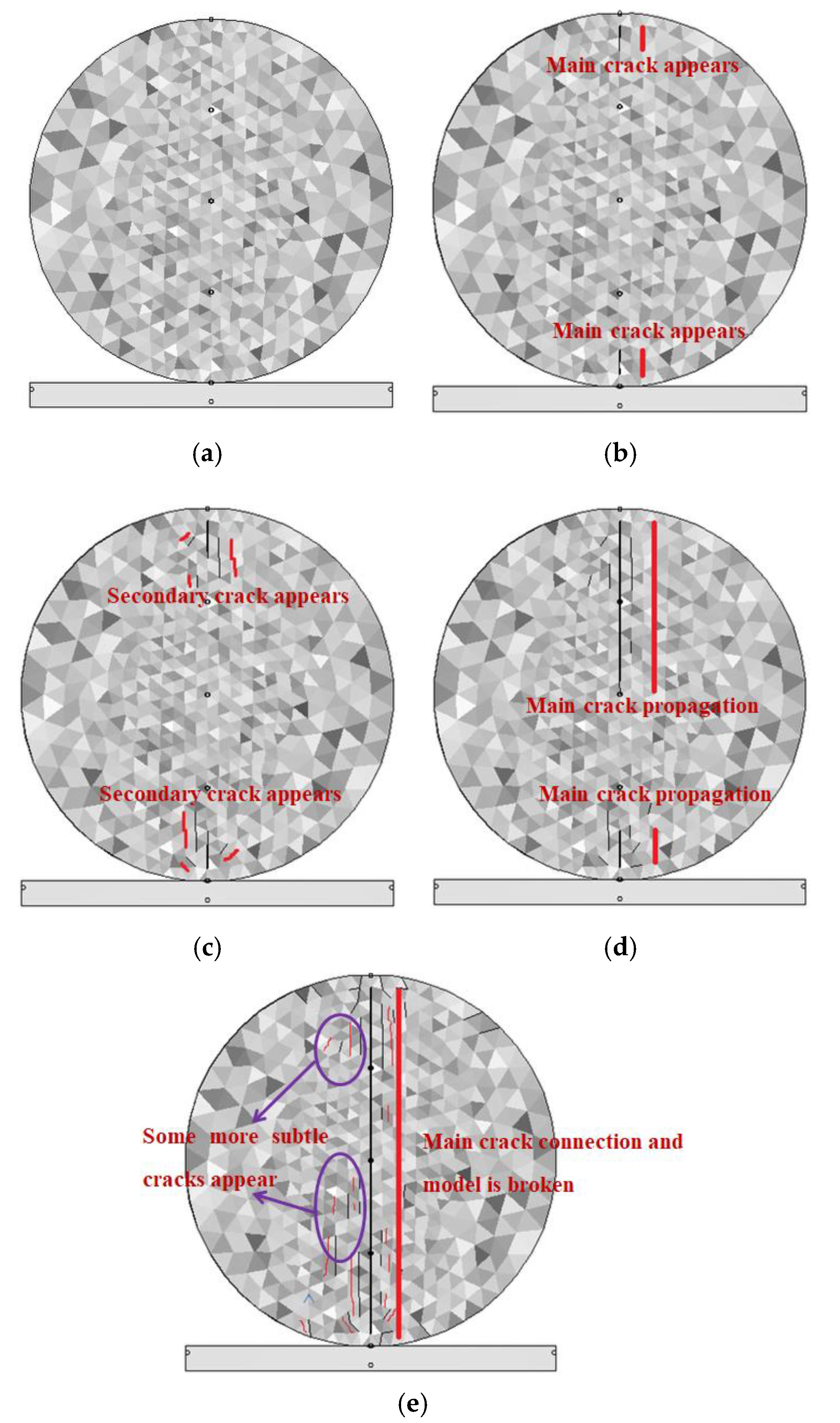

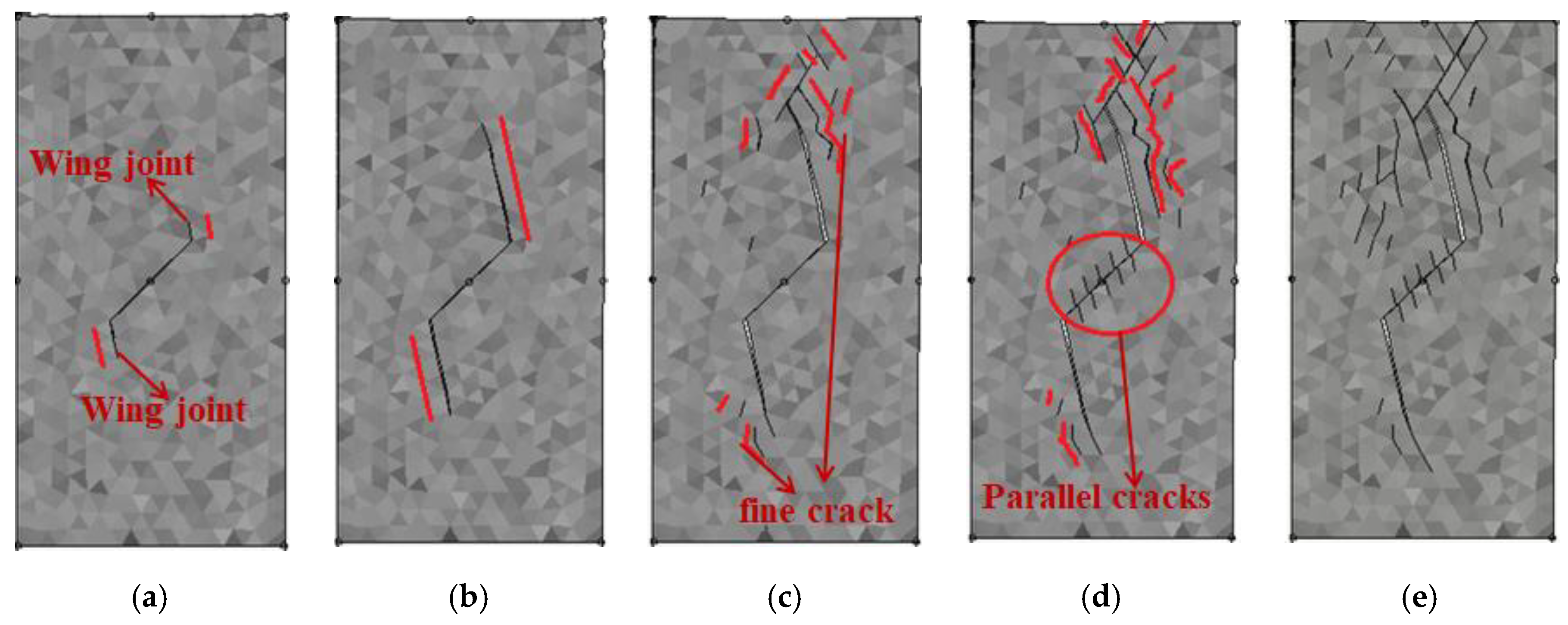

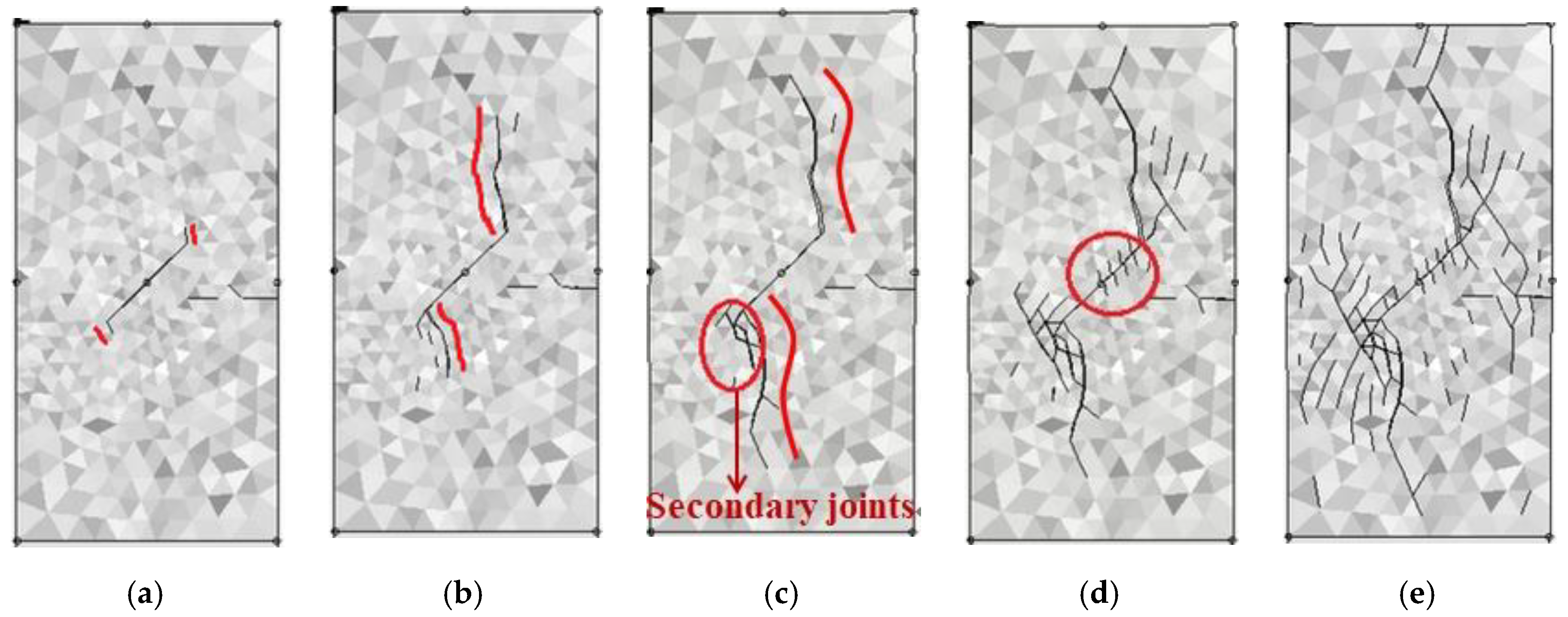

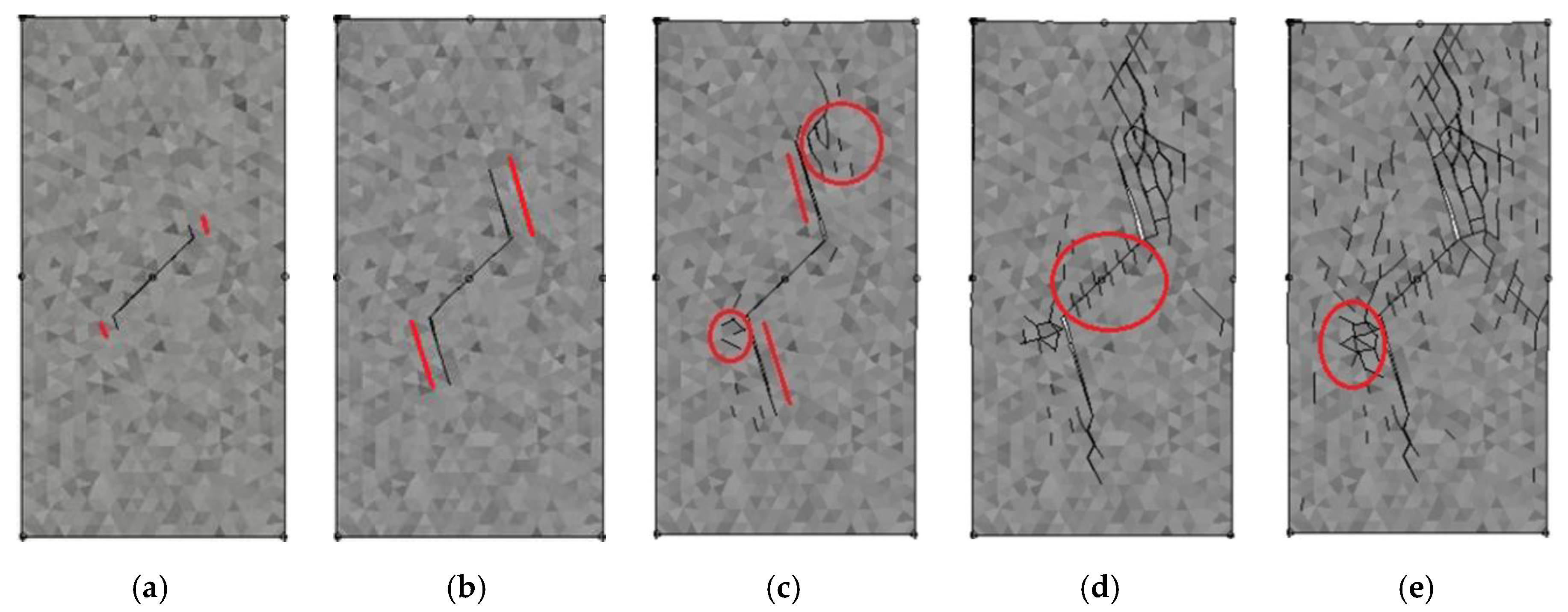

3.2.2. Analysis of Model Cracking Process

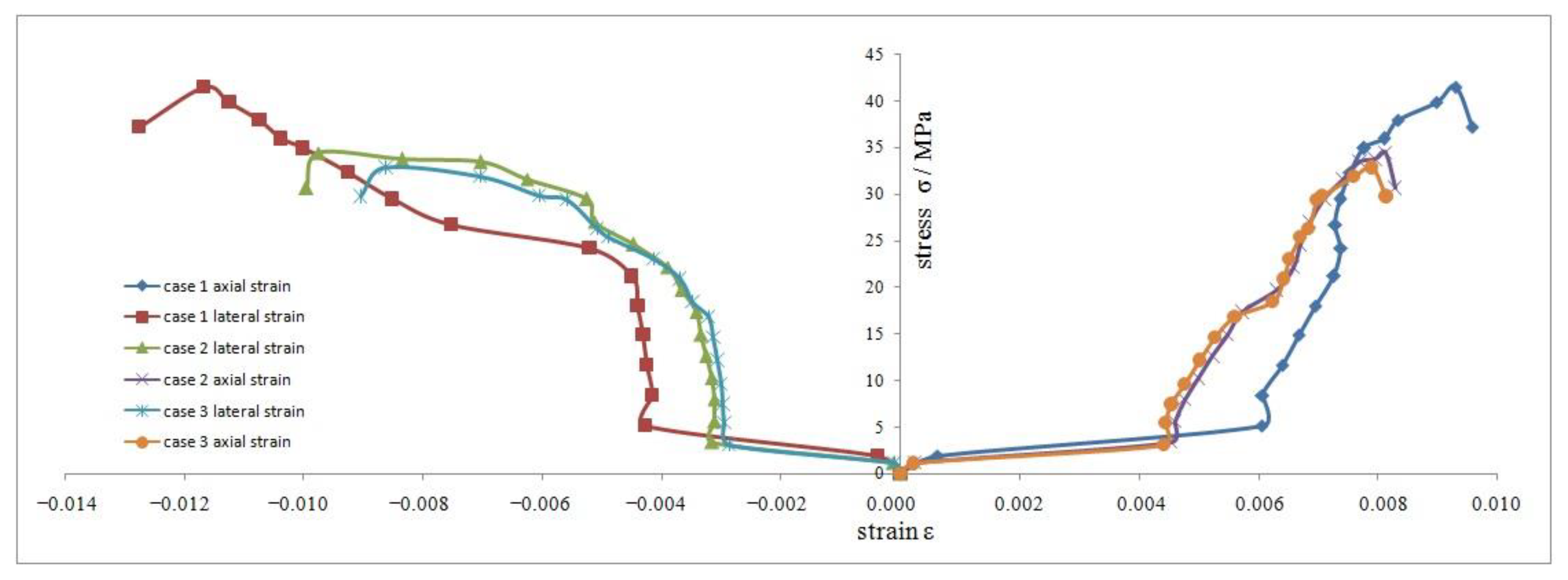

3.2.3. Stress Comparison

- 1.

- Compaction stage

- 2.

- Elastic deformation stage

- 3.

- Steady crack growth stage

3.2.4. Computing Efficiency Comparison

4. Conclusions

- The optimization method proposed in this paper can effectively generate heterogeneous grids in DDARF, which solves the problem that the original DDARF could only generate uniform grids and overcomes the problem that the number of model grids in DDARF simulations for geotechnical engineering processes is too large to be calculated.

- The Brazilian splitting experiment can be simulated effectively by using the optimized DDARF program. Compared with the original DDARF program, the simulation results are more consistent with the physical experiment results.

- The optimized DDARF program was used to simulate the uniaxial compression experiment of rock blocks. Compared with the original DDARF program, it is more accurate in the cracking and expansion of joints and more consistent with the simulation results of the other software. At the same time, it can improve the calculation efficiency—that is to say, the optimized DDARF program has advantages in calculation accuracy and efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Liu, Y.; Tang, H. Rock Mass Mechanics; Chemical Industrial Press: Beijing, China, 2008; pp. 9–10. (In Chinese) [Google Scholar]

- He, P.; Li, S.C.; Li, L.P.; Zhang, Q.Q.; Xu, F.; Chen, Y.J. Discontinuous Deformation Analysis of Super Section Tunnel Surrounding Rock Stability Based on Joint Distribution Simulation. Comput. Geotech. 2017, 91, 218–229. [Google Scholar] [CrossRef]

- Wang, P.; Liu, C.; Qi, Z.; Liu, Z.; Cai, M. A Rough Discrete Fracture Network Model for Geometrical Modeling of Jointed Rock Masses and the Anisotropic Behaviour. Appl. Sci. 2022, 12, 1720. [Google Scholar] [CrossRef]

- Pavičić, I.; Galić, I.; Kucelj, M.; Dragičević, I. Fracture System and Rock-Mass Characterization by Borehole Camera Surveying: Application in Dimension Stone Investigations in Geologically Complex Structures. Appl. Sci. 2021, 11, 764. [Google Scholar] [CrossRef]

- Yan, C.; Xu, J.; Bao, H. Rock Mass Mechanics; People’s Communications Publishing House Co., Ltd.: Beijing, China, 2017; pp. 49–50. (In Chinese) [Google Scholar]

- Dong, Z.; Hong, W.J.; Qian, Y.; Yi, J.Z.; Xiang, L.T. Experimental Study on Mechanical Characteristics of Sandstone Containing Arc Fissures. Arab. J. Geosci. 2018, 11, 637. [Google Scholar]

- Liu, X.; Liang, Z.; Meng, S.; Tang, C.; Tao, J. Numerical Simulation Study of Brittle Rock Materials from Micro to Macro Scales Using Digital Image Processing and Parallel Computing. Appl. Sci. 2022, 12, 3864. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, X.; Li, T. DDARF Method to Simulate the Whole Process of Jointed Rock Mass Failure; Science Press: Beijing, China, 2009; pp. 1, 29–40, 63–66, 80–82. (In Chinese) [Google Scholar]

- Zhu, W.S.; Chen, Y.J.; Li, S.C.; Yin, F.Q.; Yu, S.; Li, Y. Rock Failure and its Jointed Surrounding Rocks: A Multi-scale Grid Meshing Method for DDARF. Tunn. Undergr. Space Technol. 2014, 43, 370–376. [Google Scholar] [CrossRef]

- Gao, Z.; Luo, J.; Wu, X.; Li, K. Deformation Analysis of the Rock Surrounding a Tunnel Excavated through a Gently Dipping Bed. Appl. Sci. 2022, 12, 1960. [Google Scholar] [CrossRef]

- Wang, W.; Liu, G.W.; Su, Q.; Han, R. Analysis of Excavation Procedure and Stability in Jointed Rock Masses of the Large Underground Caverns. In Application of Intelligent Systems in Multi-modal Information Analytics; MMIA 2019; Advances in Intelligent Systems and Computing; Sugumaran, V., Xu, Z.P.S., Zhou, H., Eds.; Springer: Cham, Switzerland, 2019; p. 929. [Google Scholar] [CrossRef]

- Zhang, C.L.; Feng, R.M.; Zhang, X.B.; Shen, W. Numerical Study on Stress Relief and Fracture Distribution Law of Floor in Short-Distance Coal Seams Mining: A Case Study. Geotech. Geol. Eng. 2020, 39, 437–450. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, M. Rock Mechanics; China Construction Industry Press: Beijing, China, 2015; pp. 206–208. (In Chinese) [Google Scholar]

- Wang, L.G. Experimental and Numerical Study on Failure Mechanism of Fractured Rock Mass. Ph.D. Thesis, Shandong University, Jinan, China, 2012. [Google Scholar]

- Young, M. Discontinuous Deformation Method for Fracture Mechanism of Fractured ROCK Mass. Ph.D. Thesis, Shandong University, Jinan, China, 2011. [Google Scholar]

- Wang, Z.Y. Numerical Simulation of Mechanical Properties and Fracture Mechanism of Fractured Rock Mass with Granular Flow. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2016. [Google Scholar]

- Golsanami, N.; Jayasuriya, M.N.; Yan, W.C.; Fernando, S.G.; Liu, X.F.; Cui, L.K.; Zhang, X.P.; Yasin, Q.; Dong, H.; Dong, X. Characterizing clay textures and their impact on the reservoir using deep learning and Lattice-Boltzmann simulation applied to SEM images. Energy 2022, 240, 122599. [Google Scholar] [CrossRef]

- Shi, G.H. Discontinuous Deformation Analysis—A New Numerical Model for the Statics and Dynamics of Block System. Ph.D. Thesis, Department of Civil Engineering, University of California, Berkeley, CA, USA, 1988. [Google Scholar]

- Shi, G.H. Applications of Discontinuous Deformation Analysis and Manifold Method. In Proceedings of the 42nd U.S. Rock Mechanics Symposium (USRMS), San Francisco, CA, USA, 29 June–2 July 2008; pp. 3–15. [Google Scholar]

- Jiao, Y.Y.; Zhang, X.L.; Zhang, H.Q.; Huang, G.H. A Discontinuous Numerical Model to Simulate Rock Failure Process. Geomech. Geoengin. 2014, 9, 133–141. [Google Scholar] [CrossRef]

- Folino, G.; Spezzano, G. An Autonomic Tool for Building Self-Organizing Grid Enabled Applications. Future Gener. Comput. Syst. 2007, 23, 671–679. [Google Scholar] [CrossRef] [Green Version]

- Jing, L. A Review of Techniques, Advances and Outstanding Issues in Numerical Modeling for Rock Mechanics and Rock Engineering. Int. J. Rock Mech. Min. Sci. 2003, 40, 283–353. [Google Scholar] [CrossRef]

- Mancini, E.; Rak, M.; Torella, R.; Villano, U. Predictive Autonomicity of Web Services in the Mawes Framework. J. Comput. Sci. 2006, 2, 513–520. [Google Scholar] [CrossRef] [Green Version]

- Mancini, E.P.; Villano, U.; Rak, M.; Moscato, F. Simulation-Based Optimization of Multiple-Task Grid Applications. Future Gener. Comput. Syst. 2008, 24, 594–604. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.S. Study on Mechanism and Discontinuous Deformation Analysis of Hydraulic Fracturing of Rock. Ph.D. Thesis, Shandong University, Jinan, China, 2019. [Google Scholar]

- Wang, L.M. Finite Element Meshing Automation System for Specific Component. Ph.D. Thesis, Shandong University, Jinan, China, 2017. [Google Scholar]

- Fluent Inc. GAMBIT 2.3 User’s Guide. 2006. Available online: https://wenku.baidu.com/view/21d118d628ea81c758f5785c.html (accessed on 15 May 2022).

- Zhang, X.L. Study on Numerical Methods for Modeling Failure Process of Semi continuous Jointed Rock Mass. Ph.D. Thesis, Institute of Rock and Soil Mechanics Chinese Academy of Sciences, Wuhan, China, 2007. [Google Scholar]

- Sheng, G.L.; Su, Y.L.; Wang, W.D. A new fractal approach for describing induced-fracture porosity/permeability/compressibility in stimulated unconventional reservoirs. J. Pet. Sci. Eng. 2019, 179, 855–866. [Google Scholar] [CrossRef]

- Li, Y.P.; Chen, L.Z.; Wang, Y.H. Experimental Research on Pre-Cracked Marble under Compression. Int. J. Solids Struct. 2005, 42, 2505–2516. [Google Scholar] [CrossRef]

- Zhou, X.P.; Bi, J.W.; Deng, R.S.; Li, B. Effects of Brittleness on Crack Behaviors in Rock-Like Materials. J. Test. Eval. 2020, 48, 20170595. [Google Scholar] [CrossRef]

- Gao, M.B.; Li, T.B.; Meng, L.B.; Ma, C.C.; Xing, H.L. Identifying crack initiation stress threshold in brittle rocks using axial strain stiffness characteristics. J. Mt. Sci. 2018, 15, 1371–1382. [Google Scholar] [CrossRef]

- Sun, W.; Wu, S.C.; Zhou, Y.; Zhou, J.X. Comparison of crack processes in single-flawed rock-like material using two bonded–particle models under compression. Arab J. Geosci. 2019, 12, 156. [Google Scholar] [CrossRef]

- Fan, X.; Li, K.H.; Lai, H.P.; Xie, Y.L.; Cao, R.H.; Zheng, J. Internal Stress Distribution and Cracking Around Flaws and Openings of Rock Block under Uniaxial Compression: A Particle Mechanics Approach. Comput. Geotech. 2018, 102, 28–38. [Google Scholar] [CrossRef]

| Density (kg/m3) | Elastic Modulus (GPa) | Elastic Modulus Uniformity Coefficient | Poisson’s Ratio | Poisson’s Ratio Uniformity Coefficient | Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 2500 | 70 | 15 | 0.3 | 100 | 30 | 40 | 15 |

| Density (kg/m3) | Elastic Modulus (GPa) | Elastic Modulus Uniformity Coefficient | Poisson’s Ratio | Poisson’s Ratio Uniformity Coefficient | Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 2310 | 10 | 15 | 0.25 | 20 | 30 | 40 | 25 |

| Case | Crack Initiation Stress (MPa) | Peak Stress (MPa) | Crack Initiation Stress/Peak Stress (%) |

|---|---|---|---|

| 1 | 21.19 | 41.56 | 50.99% |

| 2 | 17.36 | 34.43 | 50.42% |

| 3 | 16.84 | 32.87 | 51.23% |

| Case | Crack Initiation Time | Failure Time |

|---|---|---|

| 1 | 1:14 | 8:45 |

| 2 | 1:35 | 8:33 |

| 3 | 2:27 | 17:46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.-P.; Daud, N.N.N. Jointed Rock Failure Mechanism: A Method of Heterogeneous Grid Generation for DDARF. Appl. Sci. 2022, 12, 6095. https://doi.org/10.3390/app12126095

Ma H-P, Daud NNN. Jointed Rock Failure Mechanism: A Method of Heterogeneous Grid Generation for DDARF. Applied Sciences. 2022; 12(12):6095. https://doi.org/10.3390/app12126095

Chicago/Turabian StyleMa, Hai-Ping, and Nik Norsyahariati Nik Daud. 2022. "Jointed Rock Failure Mechanism: A Method of Heterogeneous Grid Generation for DDARF" Applied Sciences 12, no. 12: 6095. https://doi.org/10.3390/app12126095

APA StyleMa, H.-P., & Daud, N. N. N. (2022). Jointed Rock Failure Mechanism: A Method of Heterogeneous Grid Generation for DDARF. Applied Sciences, 12(12), 6095. https://doi.org/10.3390/app12126095