Towards Optimizing Garlic Combine Harvester Design with Logistic Regression

Abstract

:1. Introduction

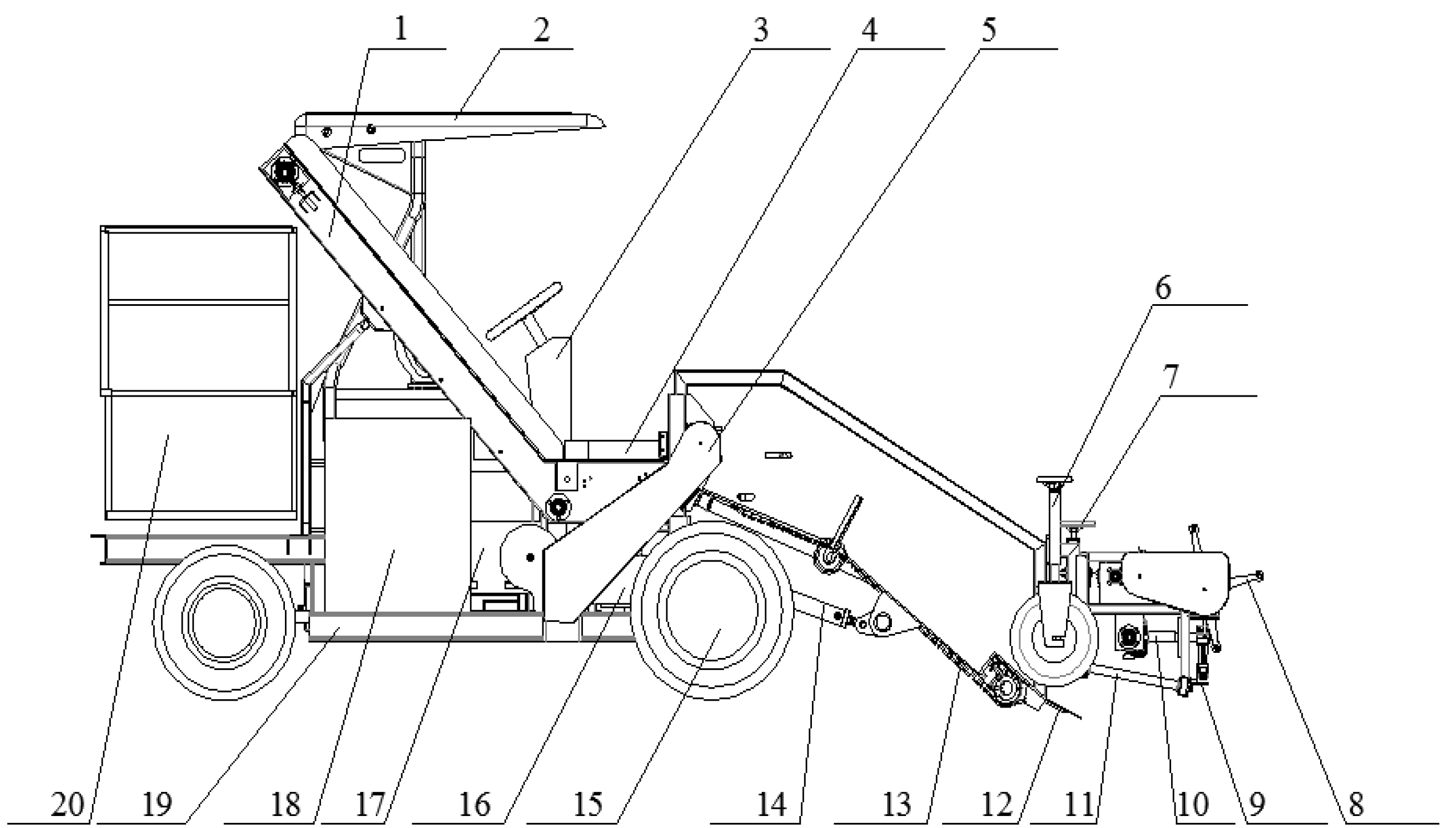

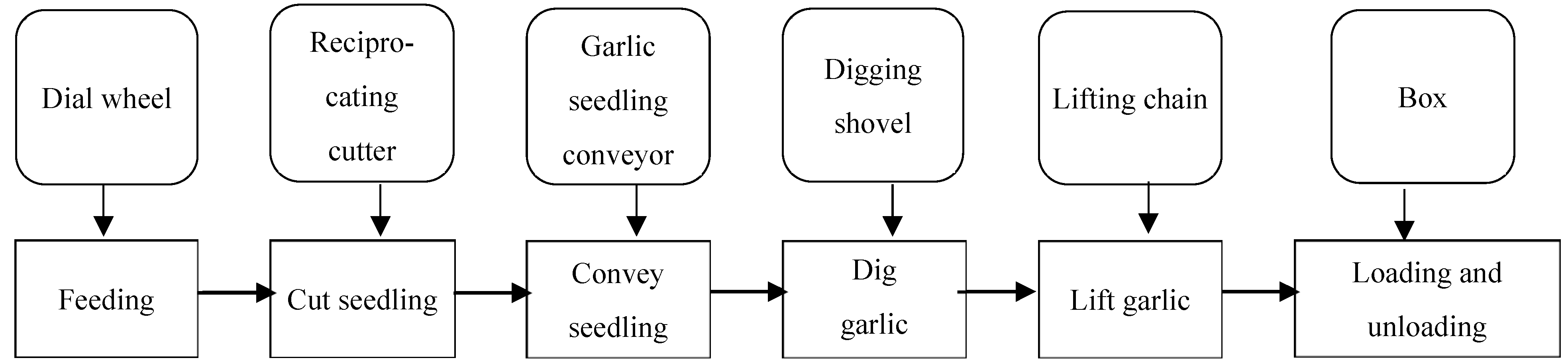

2. Complete Machine Structure and Working Principle

2.1. System Structure

2.2. Working Principle and Main Technical Parameters

3. Design and Analysis of Key Components

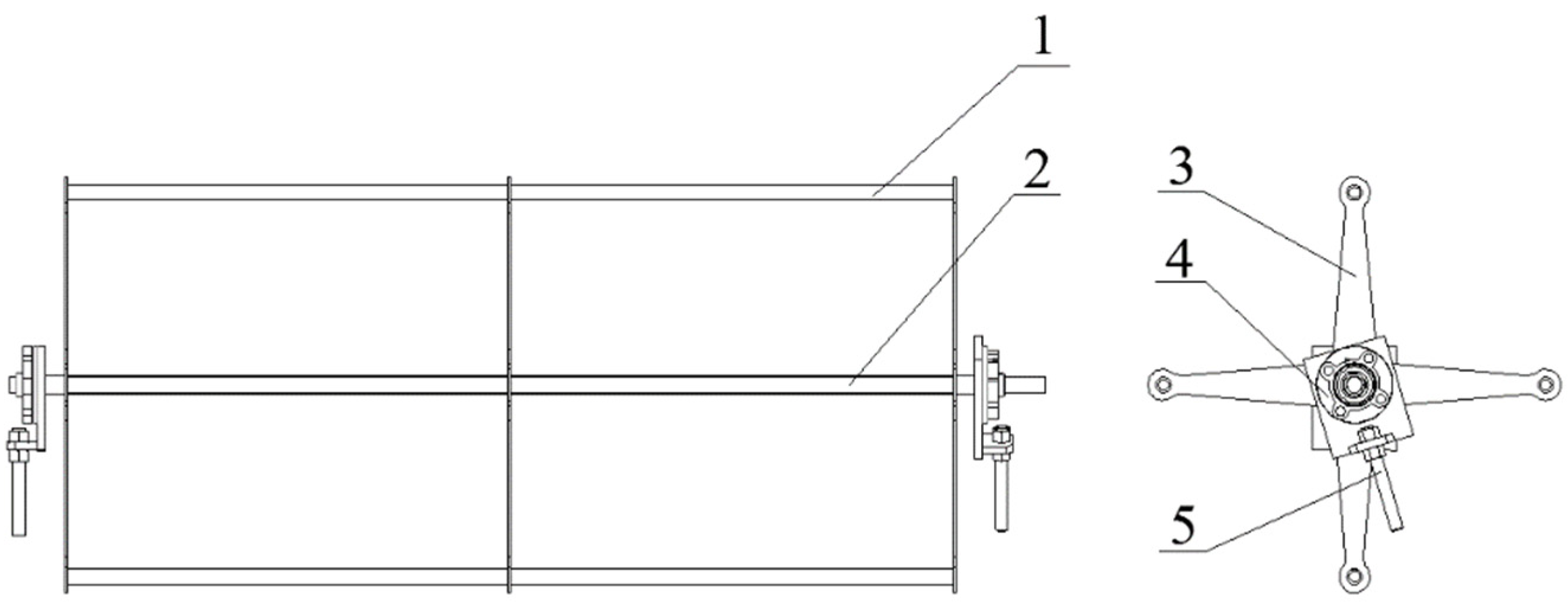

3.1. Dial Wheel Device

3.2. Reciprocating Cutter

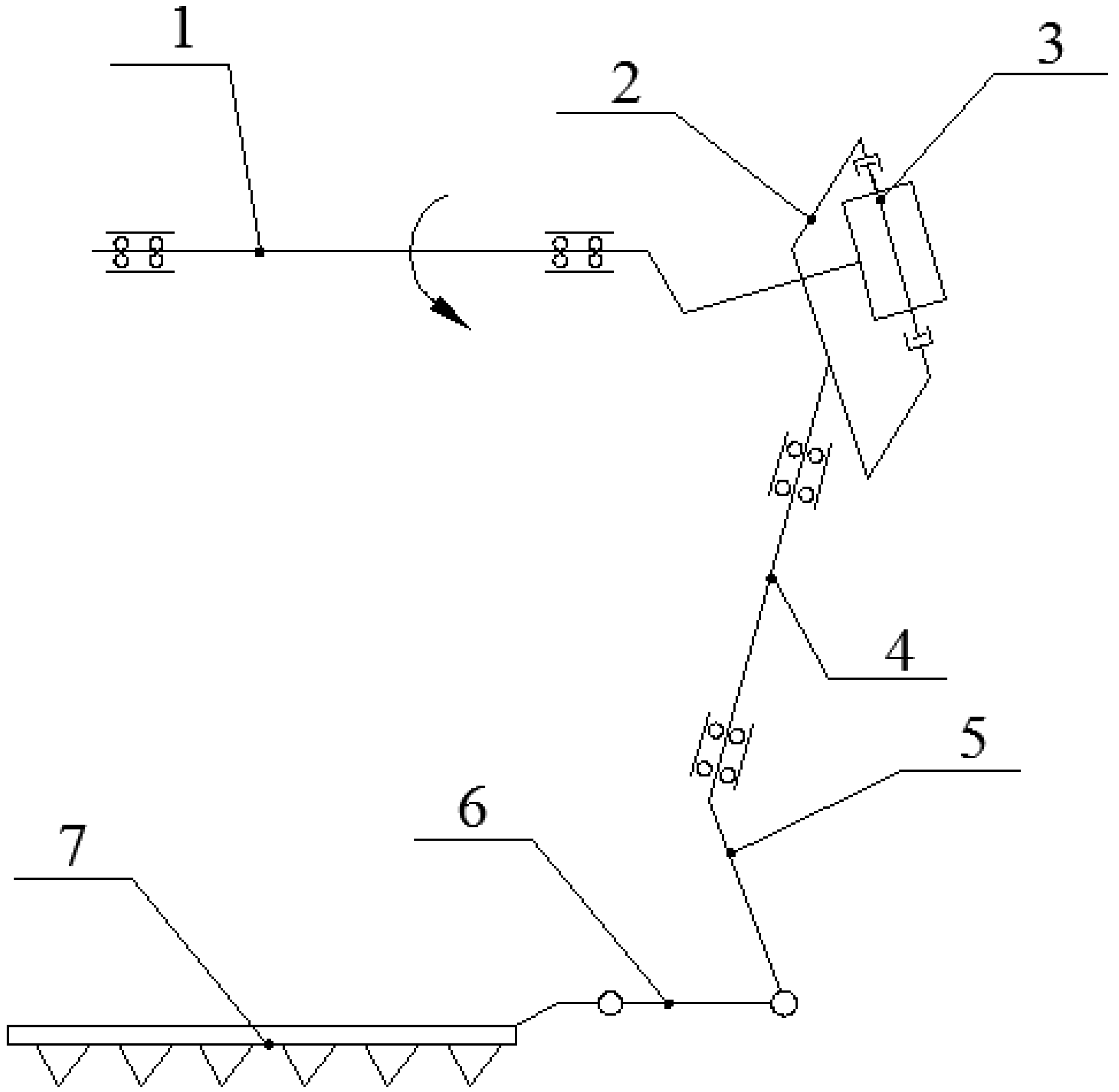

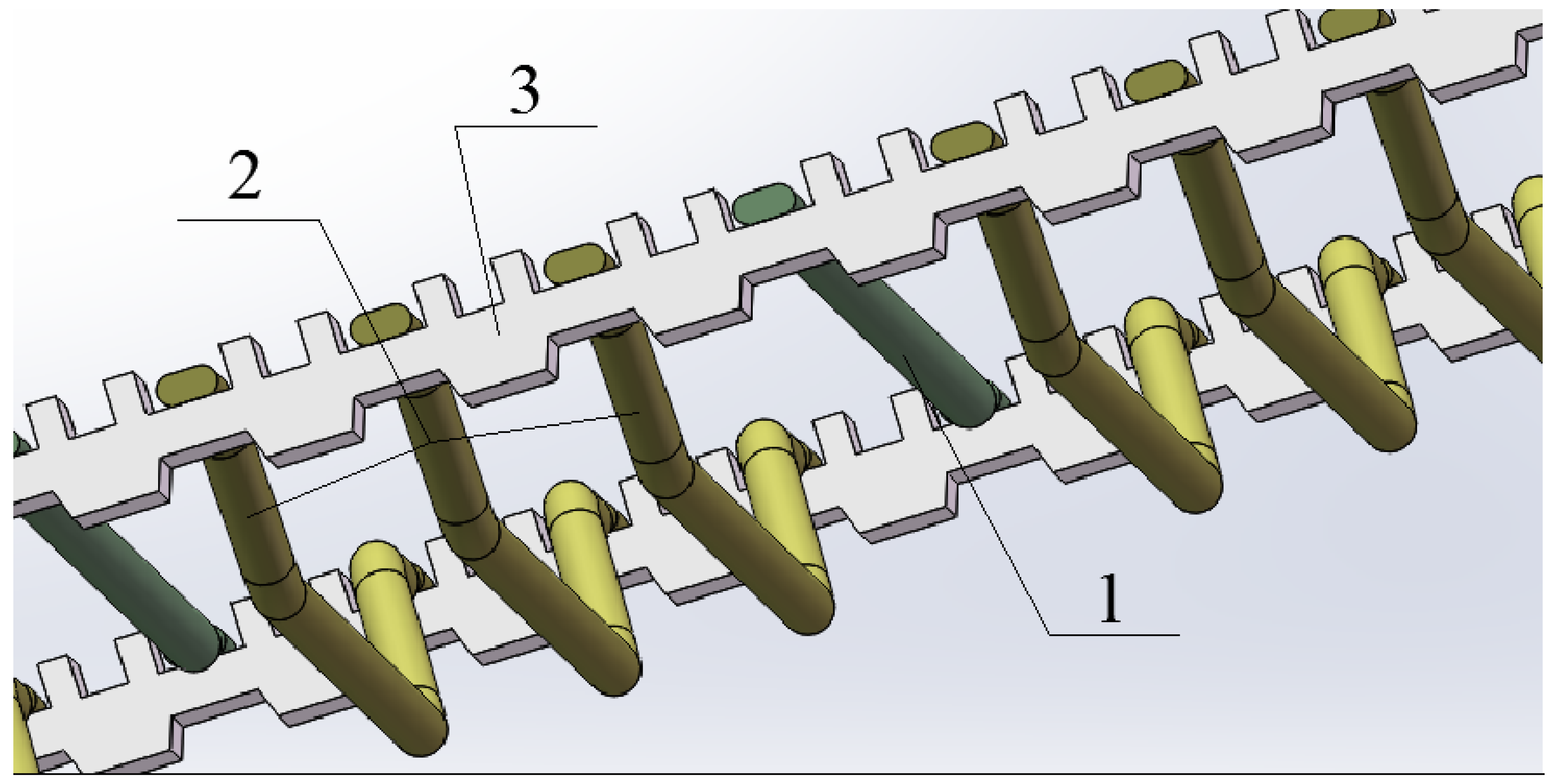

3.3. Elevating Chain

4. Field Test

4.1. Test Materials

4.2. Instrument Device

4.3. Test Method

4.4. Test Indicators

4.5. Test Design

4.5.1. Single-Factor Test Design

4.5.2. Orthogonal Experimental Design

5. Results and Analysis

5.1. Single-Factor Test

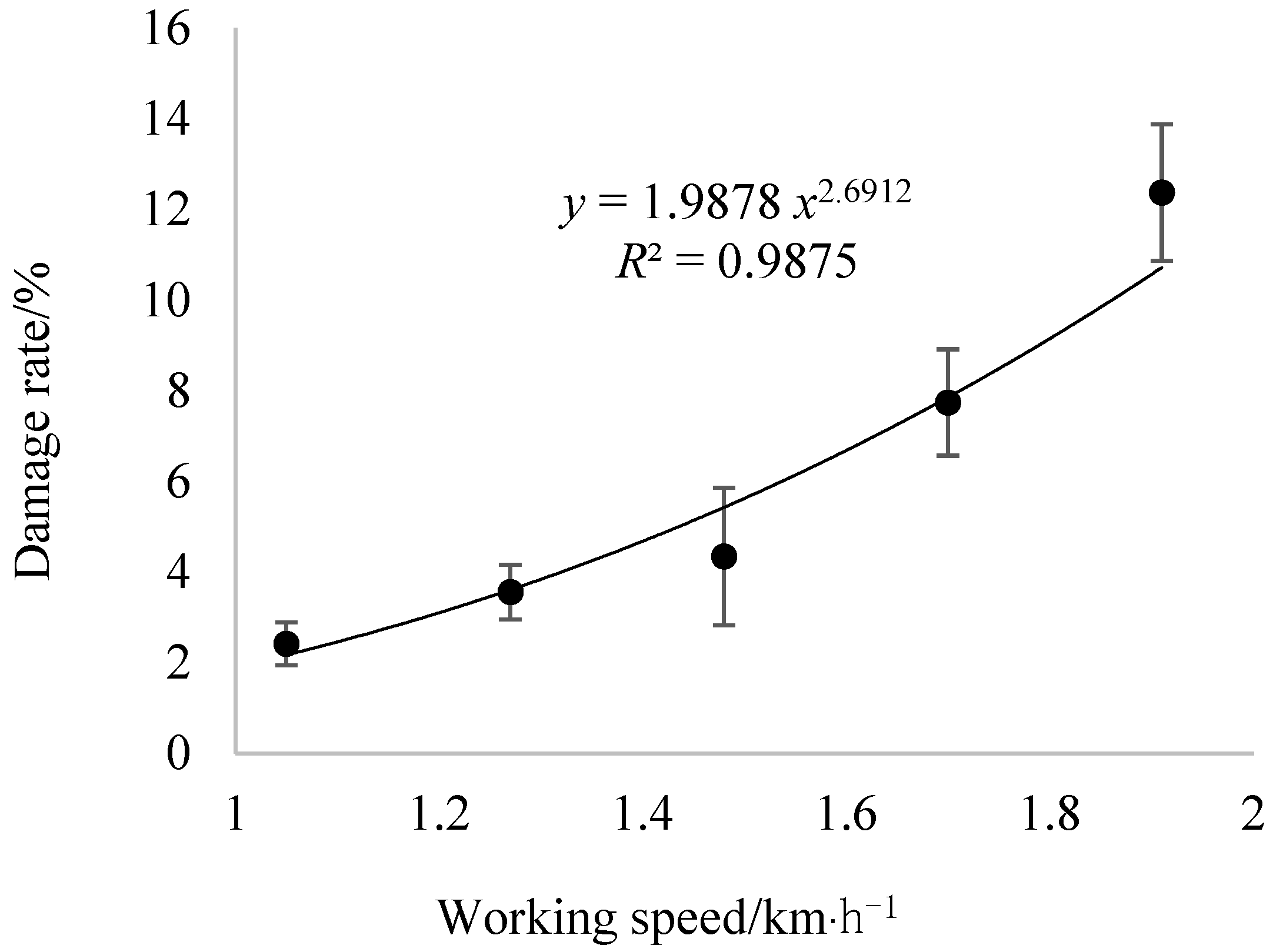

5.1.1. Effect of Operating Speed on Garlic Damage Rate

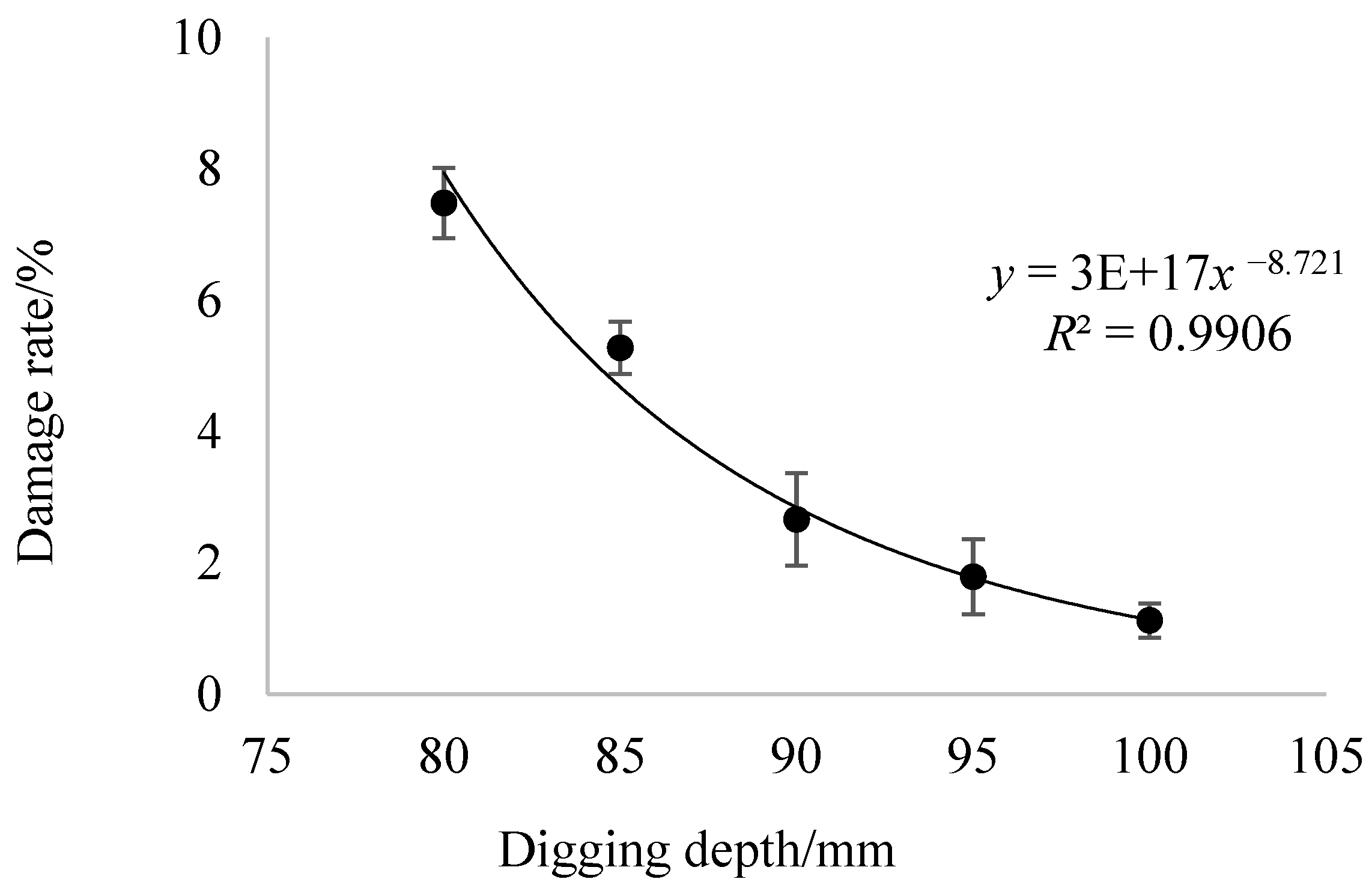

5.1.2. Effect of Excavation Depth on Garlic Damage Rate

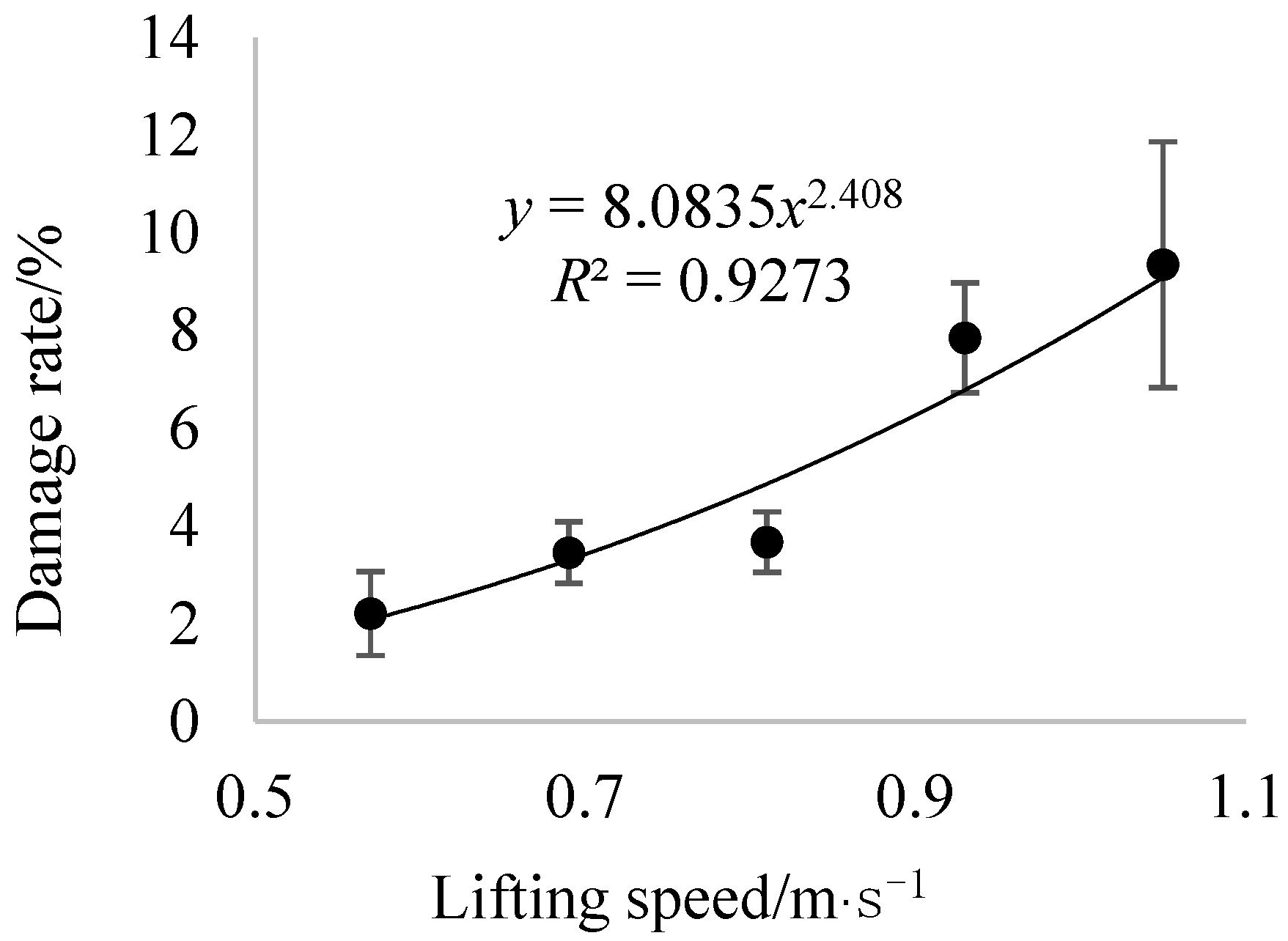

5.1.3. Effect of Lifting Speed on Garlic Damage Rate

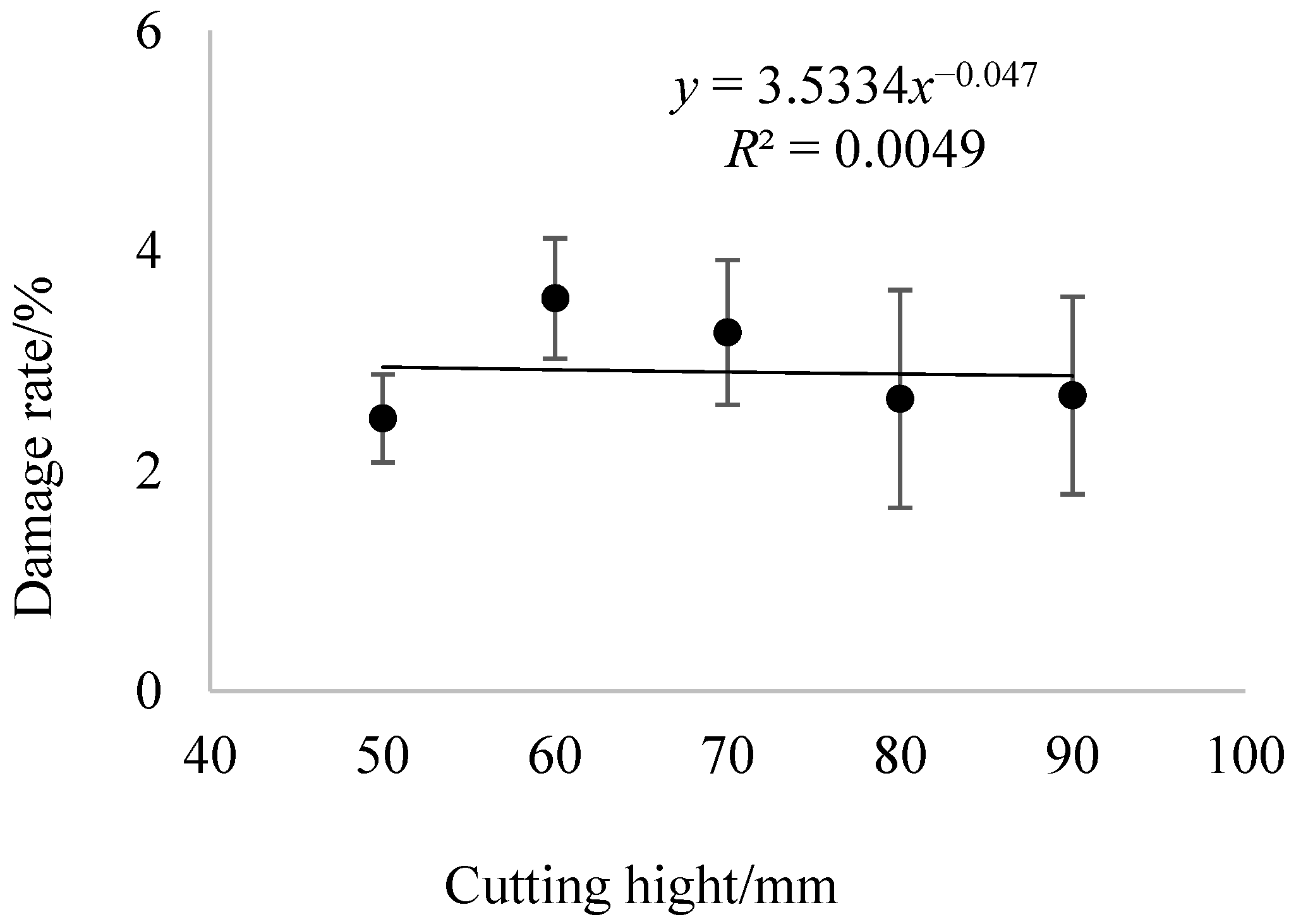

5.1.4. Effect of Cutting Height on Garlic Damage Rate

5.2. Multifactor Orthogonal Test

6. Conclusions and Discussion

6.1. Data Analysis

- (1)

- In this study, a theoretical analysis showed that when the operating speed was 0.55 to 1.01 m·s−1, the speed range of the reel was 23.3 to 42.5 r·min−1, the rotating speed range of the reciprocating cutter was 216.9 to 396.5 r·min−1 and the speed range of the lifting chain was 68.0 to 91.6 r·min−1. During the actual operation, the excavation depth was generally 80 to 100 mm.

- (2)

- The linear regression analysis of the orthogonal test results showed that when the operation speed was 1.05 km·h−1, the excavation depth was 100 mm and the lifting speed was 0.93 m·s−1, the garlic damage rate was the smallest, which was 0.18%, and the measured garlic damage rate was 0.83%.

- (3)

- In the single-factor test, the working speed, digging depth, lifting speed and cutting height were set as factors, and each factor had five levels. The results of the single-factor test showed that a reduction in the working speed, digging depth and lifting speed had a significant effect on the garlic damage rate, but a reduction in the cutting height had no significant effect on the garlic damage rate. In this section, we used Excel for the data analysis software.

- (4)

- In the orthogonal experiment, factors and levels were selected based on a single-factor test, and we chose L9(34) as the orthogonal table. According to the analysis of the R value, the order of the influence degree of the three factors on the garlic damage rate was as follows: excavation depth, operation speed and lifting speed. In other words, the excavation depth had the greatest influence on the garlic damage rate, and the lifting speed had the smallest influence on the garlic damage rate. In this section, we used the SPSS data analysis software.

6.2. Discussion

- (1)

- Garlic is a bulb crop with a shallow planting depth, and its maturity, diameter, weight, moisture content and other parameters vary greatly, which was the main reason for the test error. We further focused on the research of soil cleaning technology to effectively reduce the harvest impurity content rate.

- (2)

- Compared with scientific reports of the “Design and test of double-row walking garlic combine harvester” [31], the authors studied a garlic combine harvest too. Their optimal combination of parameters was achieved as follows: a working speed of 0.51 m·s−1, digging depth of 97.2 mm and clamping distance of 7.6 mm, corresponding to the damage and loss rates of 0.63% and 1.25%, respectively. In this paper, we reduced the working speed to 1.05 km·h−1 (0.29 m·s−1) and achieved a lower damage rate of 0.18% from our model, which is more meaningful for the research and optimization of the garlic combine harvester.

- (3)

- Compared with scientific reports of the “Design and Experiment of Modularized Garlic Combine Harvester” [32], the authors studied a modularized garlic combine harvester. The machine mainly consisted of a stem lifter, an arrow-shaped ripper, belt holding conveyor, stem aligning and cutting device and collector. The damage rate was 1.8%. In this study, our model achieved a lower damage rate of 0.18%, which is of great significance for the research and optimization of the garlic combine harvester.

6.3. Conclusions

- (1)

- This study carried out research on the 4DS-1200 garlic combine harvester under the garlic dense planting production mode in China, mainly including the design of functional components such as a reel, reciprocating cutter, garlic seedling conveyor, profiling depth-limiting device, digging shovel, lifting chain and box (which could complete the whole plant feeding), seedling cutting, garlic seedling conveying, garlic digging, soil cleaning and lifting at one time and operating steps such as loading and unloading.

- (2)

- The results of the single-factor test showed that the operation speed, excavation depth and lifting speed had a significant effect on the damage rate (p < 0.05), and the cutting height had no significant effect on the damage rate (p > 0.05). The results of the orthogonal test showed that the excavation depth and operation speed had an extremely significant influence on the index (p < 0.01), and the lifting speed had a significant influence on the index as well (p < 0.05).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manjunatha, M.; Samuel, D.V.K.; Anurag, R.K.; Gaikwad, N. Development and performance evaluation of a garlic peeler. J. Food Sci. Technol. 2014, 51, 3083–3093. [Google Scholar] [CrossRef] [Green Version]

- Dhingra, D.; Paul, S. Post–harvest technology of garlic—A review. J. Agric. Eng. 2005, 42, 1–18. [Google Scholar]

- Bakhtiari, M.R.; Ahmad, D. Determining physical and aerodynamic properties of garlic to design and develop of a pneumatic garlic clove metering system. Agric. Eng. Int. CIGR J. 2015, 17, 59–67. [Google Scholar]

- Degwale, A.; Dechassa, N.; Gedamu, F. Effects of vermicompost and inorganic NP fertilizers on growth, yield and quality of garlic (Allium sativum L.) in Enebse Sar Midir District, Northwestern Ethiopia. J. Biol. Agric. Healthc. 2016, 6, 2224–3208. [Google Scholar]

- Srivastava, S.C.; Sharma, U.C.; Singh, B.K.; Yadava, H.S. A profile of garlic production in India: Facts, trends and opportune ities. Int. J. Agric. Environ. Biotechnol. 2012, 5, 477–482. [Google Scholar]

- Feng, J. Research on Export Market Environment of Chinese Garlic Enterprises Based on Export Income Instability. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2014. [Google Scholar]

- Wang, H. Garlic export situation in 2011 and trend outlook in 2012. Chin. Fruit Veg. 2012, 4, 50–54. [Google Scholar]

- Zhang, H.; Yang, F.; Yun, Y. High yield cultivation techniques of garlic. Mod. Agric. 2018, 3, 4–5. [Google Scholar]

- Zhang, H.; Meng, L.; Wang, X.; Jia, R.; Fan, J. High quality and high yield cultivation techniques of film garlic in Xuzhou area. Vegetables 2016, 10, 41–43. [Google Scholar]

- Zhang, S.; Wang, Z.; Hu, S.; Cao, B. High-yield and high-quality cultivation techniques of garlic. Seed Ind. Guide 2015, 5, 20–22. [Google Scholar]

- Hu, L.; Hu, Z.; Wu, F.; Wang, J.; Cao, S.; Pang, B. Domestic garlic planting and production machinery. Jiangsu Agric. Sci. 2010, 6, 576–578. [Google Scholar]

- Hu, Z.; Wang, H.; Wu, F.; Hu, L. Overview of mechanized production and processing of garlic in the United States. Anhui Agric. Sci. 2007, 13, 4059–4061. [Google Scholar]

- Gao, X.; Zhao, D.; Xu, S.; Liu, C.; Huang, W. Application and research of modular design for general chassis of garlic machinery. J. Phys. Conf. Ser. 2019, 1237, 052037. [Google Scholar] [CrossRef]

- Yu, Z.; Hu, Z.; Hu, J.; Wang, H.; Peng, B. Research and development status of garlic harvesting machinery and influencing factors of operation quality. Agric. Mech. China 2012, 5, 68–71. [Google Scholar]

- Borkar, N.T.; Sahoo, P.K.; Barik, P.M. Design and development of tractor operated garlic harvester with oscillating soil separator. J. Agric. Eng. 2018, 55, 13–20. [Google Scholar]

- Noh, K.M.; Chang, Y.C.; Park, J.G. A fundamental study for developing a garlic harvester (I)-physical properties of live garlic at the harvesting season. J. Biosyst. Eng. 1999, 24, 1–8. [Google Scholar]

- Noh, K.M.; Chang, Y.C.; Park, J.G.; Yong, S.H. Development of a walking garlic harvester with pulling mechanism. J. Biosyst. Eng. 2002, 27, 513–520. [Google Scholar]

- So, J.D.; Kim, G.H.; Kwon, S.H. Mechanical Characteristics of Garlic Scapes for Developing Mechanical Garlic Bulbils Harvester. J. Biosyst. Eng. 2005, 30, 75–80. [Google Scholar] [CrossRef]

- Krishna, K.V. Studies on Design Parameters of Mechanical Harvesting of Garlic. Master’s Thesis, Agricultural Research Institute, New Delhi, India, 2012. [Google Scholar]

- Krishna, K.V.; De, D.; Sahoo, P.K. Design and development of a tractor operated garlic harvester. J. Agric. Eng. 2013, 50, 9–13. [Google Scholar]

- 21. Narender. Performance Evaluation of Root Crop Digger. Master’s Thesis, Chaudhary Charan Singh Haryana Agricultural University, Hisar, India, 2012.

- Zhang, H.; Hu, Z.; Wu, F.; Tian, L.; Peng, B. Overview of mechanized garlic planting and harvesting in China. Jiangsu Agric. Sci. 2010, 03, 460–461. [Google Scholar]

- Zhang, M.; Sun, Z.; Sun, Z.; Chen, Q. Research progress in crop mechanical harvesting technology. Anhui Agric. Sci. 2017, 45, 199–203. [Google Scholar]

- Wang, H.; Li, T.; Wu, Y.; Geng, A.; Li, Y.; Hou, J. Research status and prospect of garlic harvesting machinery. China J. Agric. Mach. Chem. 2018, 39, 102–107. [Google Scholar]

- Xin, J. Experimental Study on Physical and Mechanical Properties of Garlic and Design of Key Devices for Harvester. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2018. [Google Scholar]

- Qin, L. Research and Design of Garlic Combine Harvester. Master’s Thesis, Jinan University, Jinan, China, 2019. [Google Scholar]

- Tian, Z.; Zhao, Y.; Sui, Y.; Hou, J.; Sun, Q.; Wang, C.; Wang, Z.; Zhao, L. Design and experiment of a replant crops separating garlic harvester. Open Mech. Eng. J. 2018, 12, 67–80. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.; Sui, Y.; Zhao, L.; Hou, J.; Wang, C.; Ying, C.; Shangguan, J. Design and development of self-propelled garlic harvester. Agric. Res. 2018, 7, 495–505. [Google Scholar] [CrossRef]

- Han, K. Design and Test of Key Devices for 4DS-6 Garlic Combine Harvester. Master’s Thesis, Shandong Agricultural University, Taian, China, 2019. [Google Scholar]

- Wang, L. Development and Test of Vibration Parallel Orderly Clamping Garlic Harvester. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2019. [Google Scholar]

- Hou, J.; Li, C.; Zhang, Z.; Li, T.; Li, Y.; Wu, Y. Design and test of double-row walking garlic combine harvester. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–11. [Google Scholar]

- Zhao, D.; Cai, D.; Qin, L.; Gao, X.; Huang, W.; Liu, C. Design and Experiment of Modularized Garlic Combine Harvester. Trans. Chin. Soc. Agric. Mac. 2020, 51, 95–102. [Google Scholar]

| Item | Parameter | Unit |

|---|---|---|

| Type | Wheeled self-propelled | |

| Rated power | 47.5 | kW |

| Size | 5600 × 1500 × 2800 | mm |

| Weight | 3060 | kg |

| Working width | 1200 | mm |

| Digging depth | 0 to 100 | mm |

| Working speed I | 0 to 1.05 | km·h−1 |

| Working speed II | 0 to 2.71 | km·h−1 |

| Levels | Working Speed/ (km·h−1) | Digging Depth/ (mm) | Lifting Speed/ (m·s−1) | Cutting Height/ (mm) |

|---|---|---|---|---|

| 1 | 1.05 | 80 | 0.57 | 50 |

| 2 | 1.27 | 85 | 0.69 | 60 |

| 3 | 1.48 | 90 | 0.81 | 70 |

| 4 | 1.70 | 95 | 0.93 | 80 |

| 5 | 1.91 | 100 | 1.05 | 90 |

| Levels | Working Speed/ (km·h−1) | Digging Depth/ (mm) | Lifting Speed/ (m·s−1) |

|---|---|---|---|

| 1 | 1.05 | 80 | 0.69 |

| 2 | 1.48 | 90 | 0.81 |

| 3 | 1.91 | 100 | 0.93 |

| No. | A Working Speed/(km·h−1) | B Digging Depth/(mm) | C Lifting Speed/(m·s−1) | Damage Rate/(%) | ||

|---|---|---|---|---|---|---|

| Plot 1 | Plot 2 | Plot 3 | ||||

| 1 | 1.05 | 80 | 0.69 | 2.16 | 5.00 | 3.46 |

| 2 | 1.05 | 90 | 0.81 | 2.16 | 1.70 | 3.38 |

| 3 | 1.05 | 100 | 0.93 | 2.08 | 3.00 | 1.20 |

| 4 | 1.48 | 80 | 0.81 | 8.16 | 3.75 | 7.11 |

| 5 | 1.48 | 90 | 0.93 | 3.83 | 5.26 | 4.68 |

| 6 | 1.48 | 100 | 0.69 | 1.30 | 1.60 | 2.86 |

| 7 | 1.91 | 80 | 0.93 | 8.62 | 8.02 | 6.80 |

| 8 | 1.91 | 90 | 0.69 | 2.11 | 4.10 | 5.88 |

| 9 | 1.91 | 100 | 0.81 | 1.30 | 2.58 | 2.90 |

| 8.04 | 17.69 | 9.49 | ||||

| 12.85 | 11.03 | 11.01 | ||||

| 14.10 | 6.27 | 14.49 | ||||

| 6.06 | 11.42 | 5.00 | ||||

| Source | Sum of Squares | d f | Mean Square | Damage Rate/(%) | Sig. |

|---|---|---|---|---|---|

| Working speed/(km·h−1) | 20.442 | 2 | 10.221 | 6.204 | ** |

| Digging depth/(mm) | 65.810 | 2 | 32.905 | 19.972 | ** |

| Lifting speed/(m·s−1) | 13.174 | 2 | 6.587 | 3.998 | * |

| Error | 32.951 | 20 | 1.648 | ||

| Total | 540.710 | 27 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t | Sig. | 95.0% Confidence Interval for Beta | ||

|---|---|---|---|---|---|---|---|

| Beta | Std. Error | Lower Bound | Upper Bound | ||||

| Constant | 11.912 | 3.492 | 3.412 | 0.002 | 4.689 | 19.135 | |

| Working speed/(km·h−1) | 2.348 | 0.689 | 0.372 | 3.409 | 0.002 | 0.923 | 3.772 |

| Digging depth/(mm) | −0.190 | 0.030 | −0.702 | −6.428 | 0.000 | −0.252 | −0.129 |

| Lifting speed/(m·s−1) | 6.954 | 2.467 | 0.308 | 2.818 | 0.010 | 1.850 | 12.058 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Li, W.; Wen, F.; Chen, L.; Xu, Y. Towards Optimizing Garlic Combine Harvester Design with Logistic Regression. Appl. Sci. 2022, 12, 6015. https://doi.org/10.3390/app12126015

Zhu Z, Li W, Wen F, Chen L, Xu Y. Towards Optimizing Garlic Combine Harvester Design with Logistic Regression. Applied Sciences. 2022; 12(12):6015. https://doi.org/10.3390/app12126015

Chicago/Turabian StyleZhu, Zhengbo, Wei Li, Fujun Wen, Liangzhe Chen, and Yan Xu. 2022. "Towards Optimizing Garlic Combine Harvester Design with Logistic Regression" Applied Sciences 12, no. 12: 6015. https://doi.org/10.3390/app12126015

APA StyleZhu, Z., Li, W., Wen, F., Chen, L., & Xu, Y. (2022). Towards Optimizing Garlic Combine Harvester Design with Logistic Regression. Applied Sciences, 12(12), 6015. https://doi.org/10.3390/app12126015