Niger Seed Oil-Based Biodiesel Production Using Transesterification Process: Experimental Investigation and Optimization for Higher Biodiesel Yield Using Box–Behnken Design and Artificial Intelligence Tools

Abstract

:1. Introduction

2. Materials and Methods

2.1. NS Origin and Features

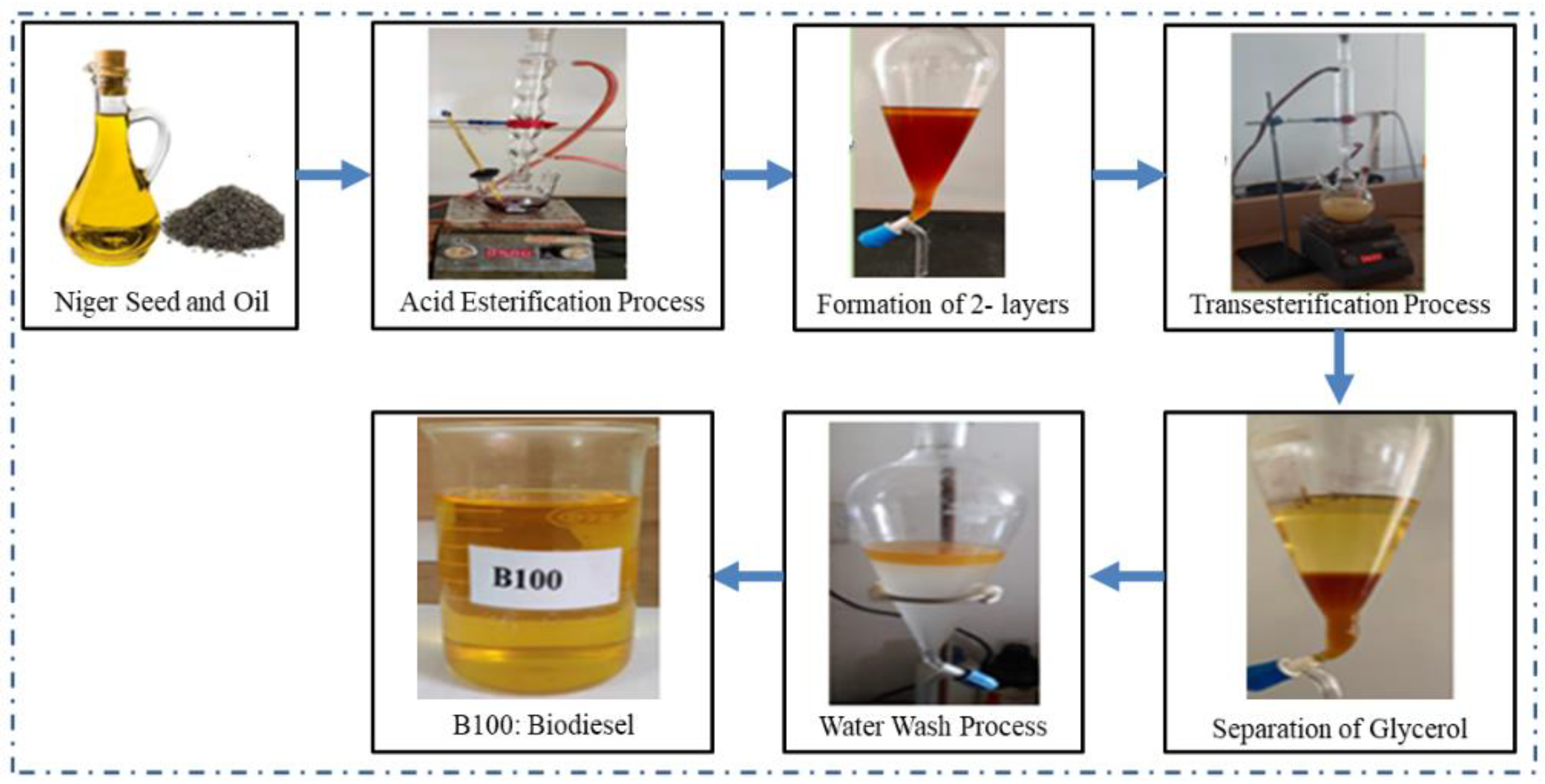

2.2. Biodiesel Production and Its Characterization

2.2.1. Free Fatty Acid and Acid Value of Niger Seed Oil

2.2.2. Design and Optimization of a Base-Catalyzed Transesterification Method

2.3. Artificial Intelligence Tools for Optimization

2.3.1. Firefly Algorithm

- Fireflies are unisex; regardless of sex, the fireflies attract each other.

- A brighter firefly attracts partners with less brightness (regardless of gender), which ensures an efficient approach to determining the best partner. The attractiveness toward the brightest (intensity of agent or insect) firefly ensures the best or optimal solution, whereas attractiveness decreases when the distance between two fireflies increases, according to Equation (2).

- 3.

- Fireflies show random movement when the firefly brightness remains identical or equal.

- 4.

- If the light is traveling through a material with light absorption coefficient , the light intensity at r from the source may be given by Equation (3).

- 5.

- The brightest firefly will conduct a local search by randomly traveling about its surroundings. As a result, if firefly j is brighter than firefly I, firefly I will travel towards firefly j using the updating formula in Equation (4).

2.3.2. Big-Bang Big-Crunch Algorithm

- The initial set of candidate solutions is distributed randomly according to the search space.

- The fitness function values corresponding to individual candidate solutions are determined.

- The center of mass based on the convergence operator is estimated, which has many inputs and generates a single output. The global fitness values are estimated according to the center of mass.

- As iteration proceeds, the computation of new or best candidate solutions (i.e., fitness function values) is generated by the addition/subtraction of a random number around the center of mass.

- The termination criterion has been tested for the pre-set goal. If the termination criterion has been met, the algorithm stops; otherwise, the above procedure will repeat.

2.3.3. Grey Wolf Optimization Algorithm

- Exploration: each member switches positions with the others in order to follow, chase, and approach the victim or prey.

- Encircling: grey wolf positions are updated based on the three best wolves (alpha, beta, and delta) in the search space around the prey.

- Hunting: grey wolves possess greater ability and knowledge and determine the prey’s location or position and encircle them. Alpha wolves lead the hunt, whereas delta and beta wolves join later. The positions of omega wolves are adjusted with reference to the top three fittest individuals of a population (α, β, and δ).

- Attacking the prey: grey wolves terminate the hunting process only after ensuring the prey stops moving.

3. Results and Discussion

3.1. Experimental Input–Output Data Collection and Analysis

3.2. Main Effect Parameter Analysis

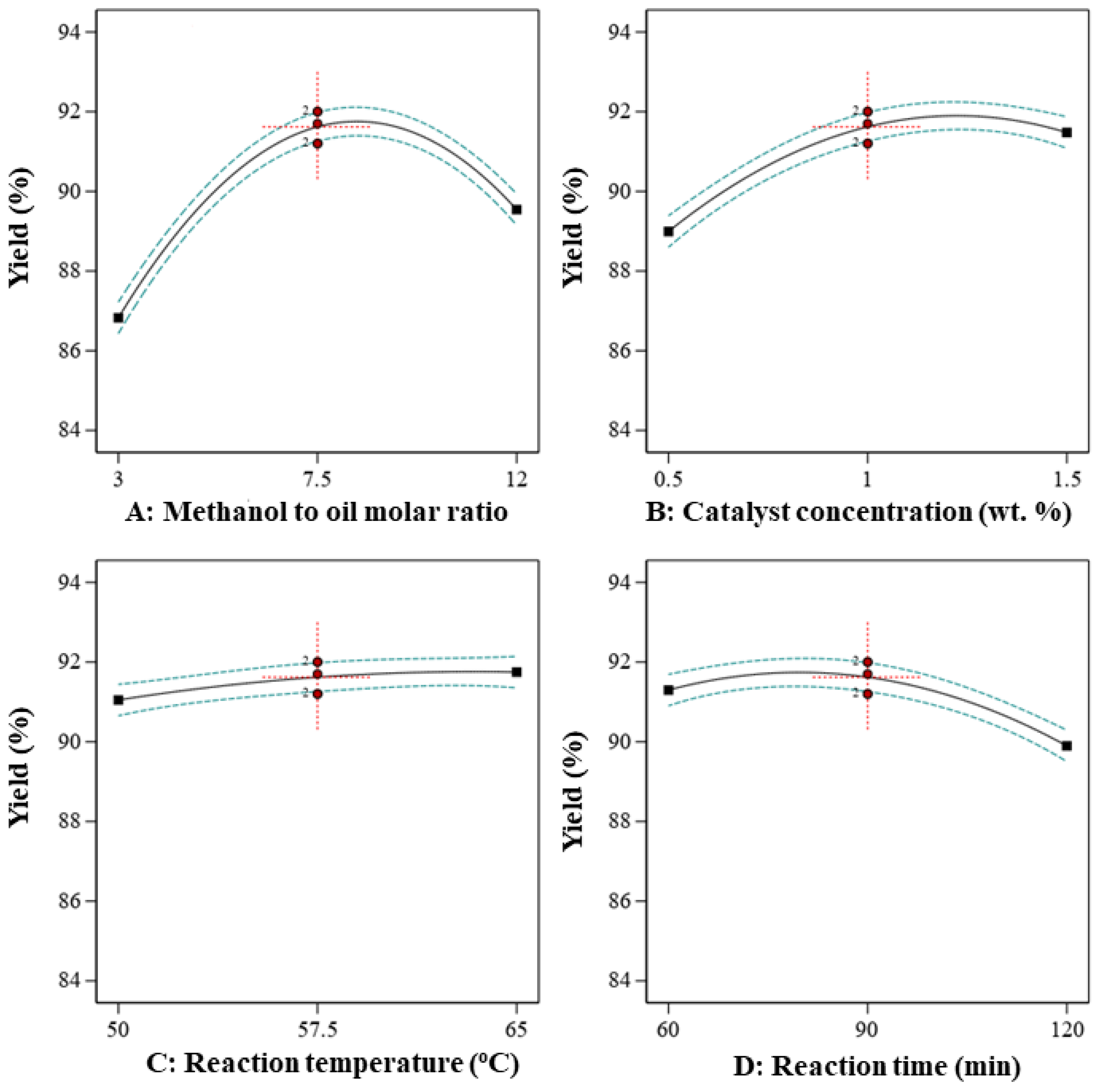

3.2.1. Effect of Methanol-to-Oil Molar Ratio

3.2.2. Effect of Catalyst Concentration

3.2.3. Effect of Reaction Temperature

3.2.4. Effect of Reaction Time

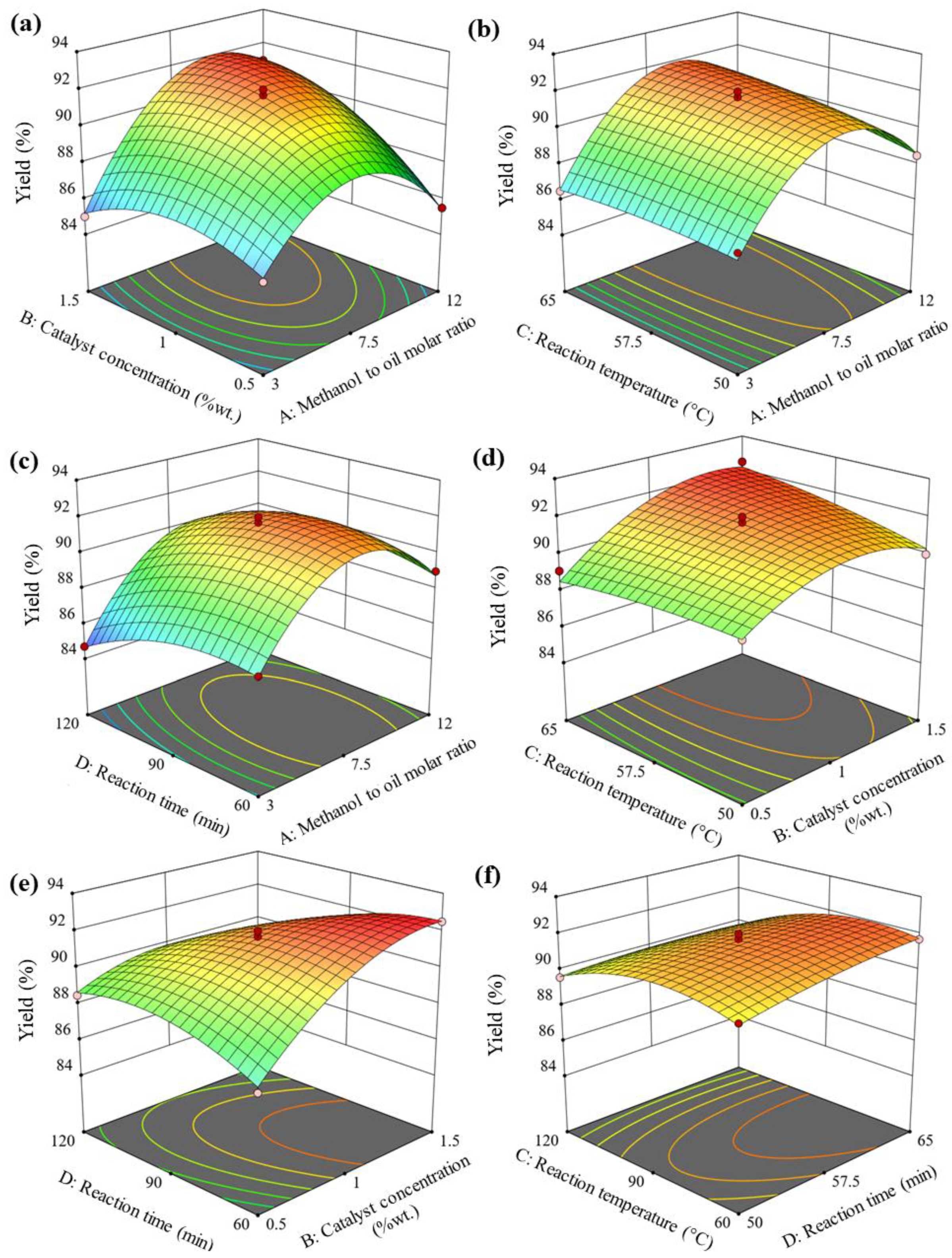

3.3. Surface Plot Analysis

- Figure 4a explains the interaction factor effects of M:O and CC, where a reaction time of 90 min and a temperature of 57.5 °C were kept at fixed mid-values. A gradual reduction in biodiesel yield was observed after the mid-point values of both M:O and CC. The desired higher biodiesel yield was found to be nearer the mid-values of M:O and CC. Excess quantity of M:O results in an increase in the glycerol solubility, whereas a higher amount of CC results in higher viscosity, which then affects the mixing ability and produces soap formation and emulsions, which ensures lower biodiesel yield. Similar observations are reported for Pithecellobium dulce seed oil [35] and flaxseed oil [45].

- The impact of two variables (such as M:O and RT) varied between their respective levels after the two parameters were held at respective mid-values (see Figure 4b). A simultaneous increase in M:O and RT, wherein the rate of reaction increases such that it pushes the reaction forward, could favor biodiesel yield. When compared to M:O, the impact of reaction temperature was found to be negligibly small. A similar effect was obtained corresponding to the transesterification of soyabean oil with ethanol [38].

- Figure 4c displays the interaction factor effects of M:O and Rt when two of the parameters (i.e., reaction temperature of 57.5 °C and catalyst concentration of 7.5 wt.%) are maintained constant. The biodiesel yield tends to increase with increased values of M:O and tends to decrease with an increase in reaction time. Higher biodiesel yield was obtained at a shortened duration corresponding to the middle level of the reaction temperature and catalyst concentration.

- The effect of CC and RT was analyzed after varying two factors simultaneously between their operating levels (refer to Figure 4d). The biodiesel yield tends to increase with increased values of catalyst concentration up to 1 wt.%, wherein the reaction temperature was found to have negligible impact. It was also observed that yield was found to decrease with high values of catalyst concentration and reaction temperatures that favor the triglyceride saponification reaction. The results are analogous to biodiesel yield production from jatropha seed oil [88].

- The impact on biodiesel yield by varying two variables simultaneously, such as CC and Rt (refer to Figure 4e). The combination of higher catalyst concentration and mid-values of reaction time resulted in higher biodiesel yield. An increase in weight percent of catalyst concentration ensures supplying more catalyst for the reacting samples that could accelerate the biodiesel yield. It was also observed that there was no significant improvement in the yield after ensuring a sufficient reaction time of 90 min.

- The effect of reaction time and reaction temperature when variables simultaneously varied between the operating levels were analyzed for the fixed values of CC of 1 wt.% and M:O of 7.5 (see Figure 4f). The resultant surface plot is seen to appear almost flat, which clearly indicates the biodiesel yield tends to have negligible influence on the interaction effect of reaction temperature and time. With increased values of reaction time, the biodiesel yield was found to have a negligible effect with an increasing trend (required time to attain the equilibrium point of a reaction wherein reaction rate increases), and beyond the limit, there might be a possibility to attain a reversible reaction when the reaction rate increases with the increased temperature [89].

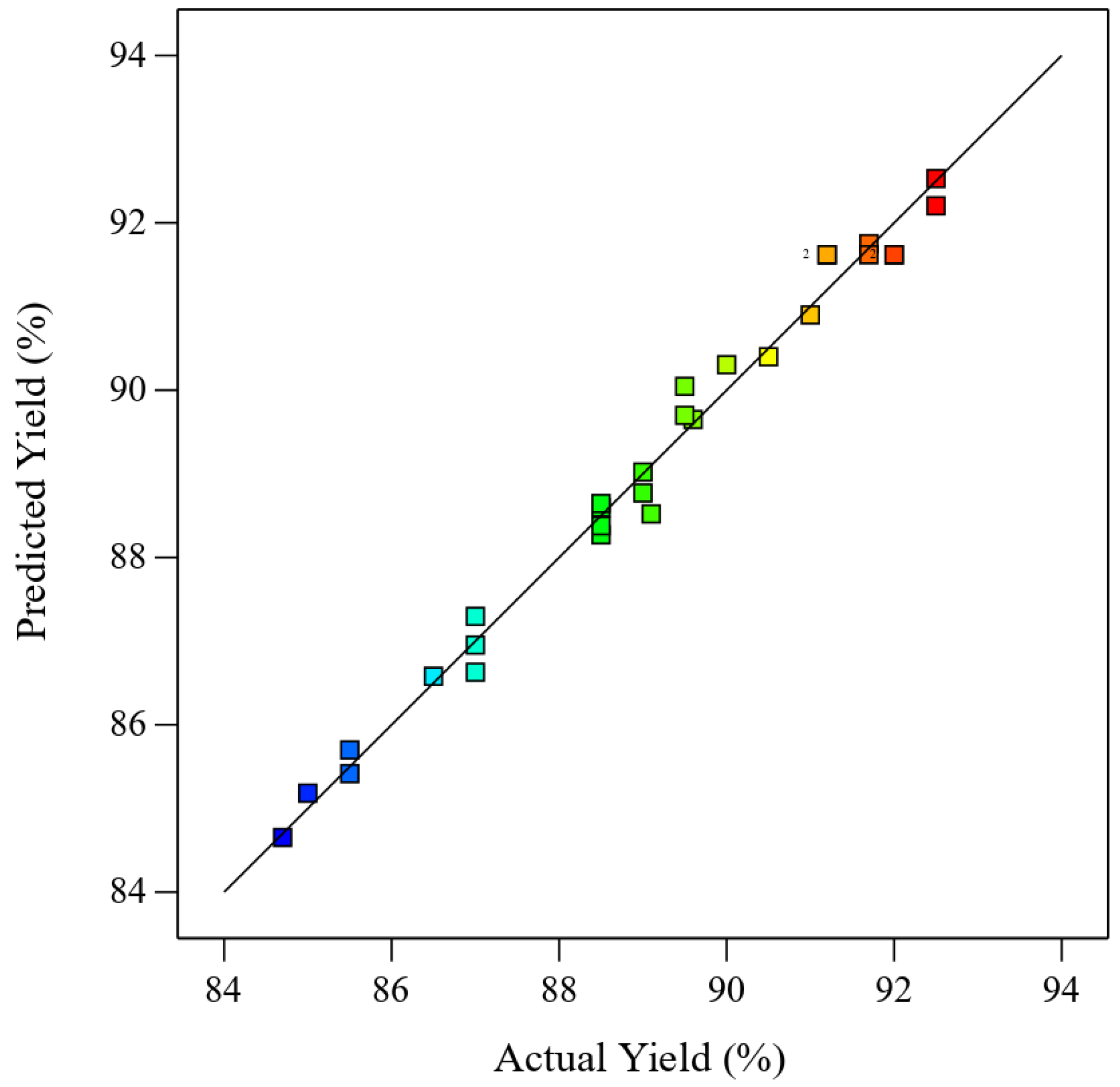

3.4. Regression Model for Biodiesel Yield

3.5. Summary Results of Optimization Algorithms

3.6. Physicochemical Properties Evaluation of Biodiesel Yield and NS Oil

4. Conclusions

- NS grown in hilly areas with less fertile soil, including the byproducts of seeds, has potential medicinal value. Niger seeds possess higher oil content (37–50%) and are therefore treated as cost-effective feedstock.

- Transesterification parameters (M:O, Rt, CC, and RT) were studied experimentally at reduced trials using BBD. The effect of all factors (linear + square + interaction) on the performance of biodiesel yield was studied. Among linear terms: M:O was the most contributing factor, followed by CC, Rt, and RT. The square terms of M:O, CC, and Rt were found to be significant, and thus, the relationship with biodiesel yield was found to be non-linear, whereas reaction temperature has a linear relationship with biodiesel yield. Two interaction terms (M:O × RT, RT × Rt) were found to be insignificant for biodiesel yield, whereas M:O with CC interaction term showed a dominant effect followed by CC with Rt, CC with RT, M:O with Rt, M:O with RT, respectively.

- The BBD-model-derived empirical equation predicted the biodiesel yield with the best fit and showed a good regression coefficient for the full quadratic model (terms: linear + square + interaction) found equal to 0.9869. The adjusted R2 (excluding insignificant terms: M:O × RT, RT × Rt, and RT2 from the model) value was found to be equal to 0.9737; therefore, model equations are statistically significant for conducting predictions (without performing the actual experiments) and optimization.

- Three artificial intelligence algorithms (BB-BC, GWO, FA) were applied to conduct optimization that could maximize the biodiesel yield. Transesterification parameters (M:O, Rt, CC, and RT) were optimized, and the resulting maximum fitness value (biodiesel yield) was found to be equal to 94.15% for both BB-BC and GWO, respectively, and 93.07% for FA. The confirmation experiments performed for optimized transesterification conditions (M:O = 9.32; CC = 1.5 wt.%; RT = 65 °C; Rt = 60 s) resulted in a biodiesel yield equal to 95.3 ± 0.5%.

- All three algorithms were tested for computational efficiency, and the results showed 0.8 s for BB-BC, 1.66 s for GWO, and 15.06 s for FA. Although BB-BC is computationally competent, it needs to compromise for solution accuracy; therefore, GWO is recommended to obtain a better solution accuracy and computation time.

- The physicochemical properties of biodiesel fuel were tested according to the ASTM standards; results were in good agreement (the kinematic viscosity, acid value, calorific value, copper strip corrosion, cloud point, pour point, flash point, sulfur content, and cetane number were found to be equal to 3.9 mm2/s, 0.36 mg KOH/g, 40,400 kJ/kg 1, 14 °C, 9 °C, 0.01% w/w, and 65.50) and were within the permissible limit corresponding to the biodiesel standard to use in diesel engines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Methanol-to-oil molar ratio |

| ASTM | American Society for Testing and Materials |

| B | Catalyst concentration |

| BBD | Box–Behnken design |

| BB-BC | Big-Bang Big-Crunch Algorithm |

| C | Reaction temperature |

| CC | Catalyst concentration |

| CCD | Central composite design |

| CCRD | Central composite rotatable design |

| D | Reaction time |

| FA | Firefly algorithm |

| GWO | Grey wolf optimization |

| MRAO | Methanol ratio of alcohol to oil |

| NaOH | Sodium hydroxide |

| NS | Niger seed |

| OMMR | Oil-to-methanol molar ratio |

| OMVR | Oil-to-methanol volume ratio |

| M: O | Methanol-to-oil molar ratio |

| NS | Niger seed |

| Rt | Reaction time |

| RT | Reaction temperature |

| RSM | Response surface methodology |

| α | Randomness |

| γ | Absorption coefficient |

| β | Randomness reduction |

| R2 | Regressor coefficient |

References

- Zakari, A.; Khan, I. Boosting economic growth through energy in Africa: The role of Chinese investment and institutional quality. J. Chin. Econ. Bus. Stud. 2022, 20, 1–21. [Google Scholar] [CrossRef]

- Muhammad, B.; Khan, M.K.; Khan, M.I.; Khan, S. Impact of foreign direct investment, natural resources, renewable energy consumption, and economic growth on environmental degradation: Evidence from BRICS, developing, developed and global countries. Environ. Sci. Pollut. Res. 2021, 28, 21789–21798. [Google Scholar] [CrossRef] [PubMed]

- Oyedepo, S.O. Energy and sustainable development in Nigeria: The way forward. Energy Sustain. Soc. 2012, 2, 15. [Google Scholar] [CrossRef] [Green Version]

- Olatomiwa, L.; Blanchard, R.; Mekhilef, S.; Akinyele, D. Hybrid renewable energy supply for rural healthcare facilities: An approach to quality healthcare delivery. Sustain. Energy Technol. Assess. 2018, 30, 121–138. [Google Scholar] [CrossRef] [Green Version]

- Banerjee, R.; Mishra, V.; Maruta, A.A. Energy poverty, health and education outcomes: Evidence from the developing world. Energy Econ. 2021, 101, 105447. [Google Scholar] [CrossRef]

- Sahoo, R.; Mondal, S.; Pal, S.C.; Mukherjee, D.; Das, M.C. Covalent-Organic Frameworks (COFs) as Proton Conductors. Adv. Energy Mater. 2021, 11, 2102300. [Google Scholar] [CrossRef]

- Tang, B.J.; Guo, Y.Y.; Yu, B.; Harvey, L.D. Pathways for decarbonizing China’s building sector under global warming thresholds. Appl. Energy 2021, 298, 117213. [Google Scholar] [CrossRef]

- Ntaribi, T.; Paul, D.I. The economic feasibility of Jatropha cultivation for biodiesel production in Rwanda: A case study of Kirehe district. Energy Sustain. Dev. 2019, 50, 27–37. [Google Scholar] [CrossRef]

- Thakur, A.K.; Kaviti, A.K.; Singh, R.; Gehlot, A. An overview of butanol as compression ignition engine fuel. Int. J. Energy Clean Environ. 2020, 21, 333–354. [Google Scholar] [CrossRef]

- Sarkar, A.; Sahu, D.; Das, D.; Behera, S.P.; Nayak, S.K.; Mandal, B.K. Effects of Ethanol as the Renewable fuel Blended with Gasoline on the Performance and Emission Characteristics of a Small Variable Compression Ratio Spark-Ignition Engine. Int. J. Energy Clean Environ. 2022, 23, 1–12. [Google Scholar] [CrossRef]

- Ahorsu, R.; Medina, F.; Constantí, M. Significance and challenges of biomass as a suitable feedstock for bioenergy and biochemical production: A review. Energies 2018, 11, 3366. [Google Scholar] [CrossRef] [Green Version]

- Miraculas, G.A.; Bose, N.; Raj, R.E. Process parameter optimization for biodiesel production from mixed feedstock using empirical model. Sustain. Energy Technol. Assess. 2018, 28, 54–59. [Google Scholar] [CrossRef]

- Ayoob, A.K.; Fadhil, A.B. Valorization of waste tires in the synthesis of an effective carbon based catalyst for biodiesel production from a mixture of non-edible oils. Fuel 2020, 264, 116754. [Google Scholar] [CrossRef]

- Nascimento, L.; Ribeiro, A.; Ferreira, A.; Valério, N.; Pinheiro, V.; Araújo, J.; Vilarinho, C.; Carvalho, J. Turning Waste Cooking Oils into Biofuels—Valorization Technologies: A Review. Energies 2021, 15, 116. [Google Scholar] [CrossRef]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Developments in the use of lipase transesterification for biodiesel production from animal fat waste. Appl. Sci. 2020, 10, 5085. [Google Scholar] [CrossRef]

- Binczarski, M.J.; Malinowska, J.Z.; Berlowska, J.; Cieciura-Wloch, W.; Borowski, S.; Cieslak, M.; Cieslak, M.; Puchowicz, D.; Witonska, I.A. Concept for the Use of Cotton Waste Hydrolysates in Fermentation Media for Biofuel Production. Energies 2022, 15, 2856. [Google Scholar] [CrossRef]

- Pasawan, M.; Chen, S.S.; Das, B.; Chang, H.M.; Chang, C.T.; Nguyen, T.X.Q.; Qu, H.M.; Chen, Y.F. Ultrasonication Assisted Catalytic Transesterification of Ceiba Pentandra (Kapok) Oil Derived Biodiesel Using Immobilized Iron Nanoparticles. Fuels 2022, 3, 113–131. [Google Scholar] [CrossRef]

- Maheswari, P.; Haider, M.B.; Yusuf, M.; Klemeš, J.J.; Bokhari, A.; Beg, M.; Othman, A.A.; Kumar, R.; Jaiswal, A.K. A review on latest trends in cleaner biodiesel production: Role of feedstock, production methods, and catalysts. J. Clean. Prod. 2022, 355, 131588. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Mariod, A.A.; Aroua, M.K.; Rahman, S.M.; Soudagar, M.E.M.; Fattah, I.M. Current state and perspectives on transesterification of triglycerides for biodiesel production. Catalysts 2021, 11, 1121. [Google Scholar] [CrossRef]

- Ge, J.C.; Yoon, S.K.; Song, J.H. Comparative Evaluation on Combustion and Emission Characteristics of a Diesel Engine Fueled with Crude Palm Oil Blends. Appl. Sci. 2021, 11, 11502. [Google Scholar] [CrossRef]

- Udayakumar, M.; Sivaganesan, S.; Sivamani, S. Process optimization of KOH catalyzed biodiesel production from crude sunflower-mahua oil. Biofuels 2022, 1–9. [Google Scholar] [CrossRef]

- Saravanan, A.; Murugan, M.; Reddy, M.S.; Parida, S. Performance and emission characteristics of variable compression ratio CI engine fueled with dual biodiesel blends of Rapeseed and Mahua. Fuel 2020, 263, 116751. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Khan, H.M.; Khan, T.M.; Razzaq, L.; Asif, T.; Mujtaba, M.A.; Hussain, A.; Farooq, M.; Ahmed, W.; Shahapurkar, K.; et al. Experimental analysis of engine performance and exhaust pollutant on a single-cylinder diesel engine operated using moringa oleifera biodiesel. Appl. Sci. 2021, 11, 7071. [Google Scholar] [CrossRef]

- Wategave, S.P.; Banapurmath, N.R.; Sawant, M.S.; Soudagar, M.E.M.; Mujtaba, M.A.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A.; et al. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- Ajith, B.S.; Math, M.C.; Patel, G.C.M.; Parappagoudar, M.B. Analysis and optimisation of transesterification parameters for high-yield Garcinia Gummi-Gutta biodiesel using RSM and TLBO. Aust. J. Mech. Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Jaikumar, S.; Bhatti, S.K.; Srinivas, V. Experimental investigations on performance, combustion, and emission characteristics of Niger (Guizotia abyssinica) seed oil methyl ester blends with diesel at different compression ratios. Arab. J. Sci. Eng. 2019, 44, 5263–5273. [Google Scholar] [CrossRef]

- Srikanth, H.V.; Godiganur, S.; Manne, B.; Bharath Kumar, S.; Spurthy, S. Niger seed oil biodiesel as an emulsifier in diesel–ethanol blends for compression ignition engine. Int. J. Ambient. Energy 2020, 1–11. [Google Scholar] [CrossRef]

- Quequeto, W.D.; Siqueira, V.C.; Nazario, C.E.D.; Junqueira, M.H.; Schoeninger, V.; Martins, E.A.S. Oil composition and physiological quality of Niger seeds after drying. Acta Sci. Agron. 2020, 42, e44398. [Google Scholar] [CrossRef]

- Deme, T.; Haki, G.D.; Retta, N.; Woldegiorgis, A.; Geleta, M. Mineral and Anti-Nutritional Contents of Niger Seed (Guizotia abyssinica (Lf) Cass., Linseed (Linumusitatissimum L.) and Sesame (Sesamumindicum L.) Varieties Grown in Ethiopia. Foods 2017, 6, 27. [Google Scholar] [CrossRef]

- Mohseni, N.M.; Mirzaei, H.; Moghimi, M. Optimized extraction and quality evaluation of Niger seed oil via microwave-pulsed electric field pretreatments. Food Sci. Nutr. 2020, 8, 1383–1393. [Google Scholar] [CrossRef]

- Melaku, E.T. Evaluation of Ethiopian Nigerseed (Guizotia abyssinica Cass) Production, Seed Storage and Virgin Oil Expression. Ph.D. Thesis, Humboldt Universität zu Berlin, Berlin, Germany, 2013; 187p. [Google Scholar]

- Shadangi, K.P.; Mohanty, K. Production and characterization of pyrolytic oil by catalytic pyrolysis of Niger seed. Fuel 2014, 126, 109–115. [Google Scholar] [CrossRef]

- Pradhan, K.; Mishra, R.; Paikary, R. Genetic variability and character association in niger. Indian J. Genet. Plant Breed. 1995, 44, 457–459. [Google Scholar]

- Alemaw, G.; Wold, A.T. An agronomic and seed-quality evaluation of noug (Guizotia abyssinica Cass.) germplasm in Ethiopia. Plant Breed. 1995, 114, 375–376. [Google Scholar] [CrossRef]

- Sekhar, S.C.; Karuppasamy, K.; Vedaraman, N.; Kabeel, A.E.; Sathyamurthy, R.; Elkelawy, M.; Bastawissi, H.A.E. Biodiesel production process optimization from Pithecellobium dulce seed oil: Performance, combustion, and emission analysis on compression ignition engine fuelled with diesel/biodiesel blends. Energy Convers. Manag. 2018, 161, 141–154. [Google Scholar] [CrossRef]

- Thoai, D.N.; Tongurai, C.; Prasertsit, K.; Kumar, A. Review on biodiesel production by two-step catalytic conversion. Biocatal. Agric. Biotechnol. 2019, 18, 101023. [Google Scholar] [CrossRef]

- Supraja, K.V.; Behera, B.; Paramasivan, B. Optimization of process variables on two-step microwave-assisted transesterification of waste cooking oil. Environ. Sci. Pollut. Res. 2020, 27, 27244–27255. [Google Scholar] [CrossRef]

- Silva, G.F.; Camargo, F.L.; Ferreira, A.L. Application of response surface methodology for optimization of biodiesel production by transesterification of soybean oil with ethanol. Fuel Process. Technol. 2011, 92, 407–413. [Google Scholar] [CrossRef] [Green Version]

- Parappagoudar, M.B.; Pratihar, D.K.; Datta, G.L. Linear and non-linear statistical modelling of green sand mould system. Int. J. Cast Met. Res. 2007, 20, 1–13. [Google Scholar] [CrossRef]

- Onoji, S.E.; Iyuke, S.E.; Igbafe, A.I.; Daramola, M.O. Transesterification of rubber seed oil to biodiesel over a calcined waste rubber seed shell catalyst: Modeling and optimization of process variables. Energy Fuels 2017, 31, 6109–6119. [Google Scholar] [CrossRef]

- Balajii, M.; Niju, S. A novel biobased heterogeneous catalyst derived from Musa acuminata peduncle for biodiesel production–Process optimization using central composite design. Energy Convers. Manag. 2019, 189, 118–131. [Google Scholar] [CrossRef]

- Rokni, K.; Mostafaei, M.; Soufi, M.D.; Kahrizi, D. Microwave-assisted intensification of transesterification reaction for biodiesel production from camelina oil: Optimization by Box-Behnken Design. Bioresour. Technol. Rep. 2022, 17, 100928. [Google Scholar] [CrossRef]

- Vahid, B.R.; Saghatoleslami, N.; Nayebzadeh, H.; Toghiani, J. Effect of alumina loading on the properties and activity of SO42−/ZrO2 for biodiesel production: Process optimization via response surface methodology. J. Taiwan Inst. Chem. Eng. 2018, 83, 115–123. [Google Scholar] [CrossRef]

- Mares, E.K.L.; Gonçalves, M.A.; da Luz, P.T.S.; da Rocha Filho, G.N.; Zamian, J.R.; da Conceição, L.R.V. Acai seed ash as a novel basic heterogeneous catalyst for biodiesel synthesis: Optimization of the biodiesel production process. Fuel 2021, 299, 120887. [Google Scholar] [CrossRef]

- Ahmad, T.; Danish, M.; Kale, P.; Geremew, B.; Adeloju, S.B.; Nizami, M.; Ayoub, M. Optimization of process variables for biodiesel production by transesterification of flaxseed oil and produced biodiesel characterizations. Renew. Energy 2019, 139, 1272–1280. [Google Scholar] [CrossRef]

- Qu, T.; Niu, S.; Zhang, X.; Han, K.; Lu, C. Preparation of calcium modified Zn-Ce/Al2O3 heterogeneous catalyst for biodiesel production through transesterification of palm oil with methanol optimized by response surface methodology. Fuel 2021, 284, 118986. [Google Scholar] [CrossRef]

- Sharma, A.; Kodgire, P.; Kachhwaha, S.S. Biodiesel production from waste cotton-seed cooking oil using microwave-assisted transesterification: Optimization and kinetic modeling. Renew. Sustain. Energy Rev. 2019, 116, 109394. [Google Scholar] [CrossRef]

- Sharma, A.; Kodgire, P.; Kachhwaha, S.S. Investigation of ultrasound-assisted KOH and CaO catalyzed transesterification for biodiesel production from waste cotton-seed cooking oil: Process optimization and conversion rate evaluation. J. Clean. Prod. 2020, 259, 120982. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Arslan, M.; Eryilmaz, T. Application of response surface methodology for the optimization of biodiesel production from yellow mustard (Sinapis alba L.) seed oil. Int. J. Green Energy 2019, 16, 60–71. [Google Scholar] [CrossRef]

- Milano, J.; Ong, H.C.; Masjuki, H.H.; Silitonga, A.S.; Chen, W.H.; Kusumo, F.; Dharma, S.; Sebayang, A.H. Optimization of biodiesel production by microwave irradiation-assisted transesterification for waste cooking oil-Calophyllum inophyllum oil via response surface methodology. Energy Convers. Manag. 2018, 158, 400–415. [Google Scholar] [CrossRef]

- Elango, R.K.; Sathiasivan, K.; Muthukumaran, C.; Thangavelu, V.; Rajesh, M.; Tamilarasan, K. Transesterification of castor oil for biodiesel production: Process optimization and characterization. Microchem. J. 2019, 145, 1162–1168. [Google Scholar] [CrossRef]

- Pooja, S.; Anbarasan, B.; Ponnusami, V.; Arumugam, A. Efficient production and optimization of biodiesel from kapok (Ceiba pentandra) oil by lipase transesterification process: Addressing positive environmental impact. Renew. Energy 2021, 165, 619–631. [Google Scholar] [CrossRef]

- Dehghan, L.; Golmakani, M.T.; Hosseini, S.M.H. Optimization of microwave-assisted accelerated transesterification of inedible olive oil for biodiesel production. Renew. Energy 2019, 138, 915–922. [Google Scholar] [CrossRef]

- Pascoal, C.V.P.; Oliveira, A.L.L.; Figueiredo, D.D.; Assunção, J.C.C. Optimization and kinetic study of ultrasonic-mediated in situ transesterification for biodiesel production from the almonds of Syagrus cearensis. Renew. Energy 2020, 147, 1815–1824. [Google Scholar] [CrossRef]

- Vishal, D.; Dubey, S.; Goyal, R.; Dwivedi, G.; Baredar, P.; Chhabra, M. Optimization of alkali-catalyzed transesterification of rubber oil for biodiesel production & its impact on engine performance. Renew. Energy 2020, 158, 167–180. [Google Scholar] [CrossRef]

- Adepoju, T.F. Optimization processes of biodiesel production from pig and neem (Azadirachta indica a. Juss) seeds blend oil using alternative catalysts from waste biomass. Ind. Crops Prod. 2020, 149, 112334. [Google Scholar] [CrossRef]

- Etim, A.O.; Betiku, E.; Ajala, S.O.; Olaniyi, P.J.; Ojumu, T.V. Potential of ripe plantain fruit peels as an ecofriendly catalyst for biodiesel synthesis: Optimization by artificial neural network integrated with genetic algorithm. Sustainability 2018, 10, 707. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, G.; Paul, A.K.; Goud, V.V. Optimization of non-catalytic transesterification of microalgae oil to biodiesel under supercritical methanol condition. Energy Convers. Manag. 2018, 156, 269–278. [Google Scholar] [CrossRef]

- Peng, Y.; Parsian, A.; Khodadadi, H.; Akbari, M.; Ghani, K.; Goodarzi, M.; Bach, Q.V. Develop optimal network topology of artificial neural network (AONN) to predict the hybrid nanofluids thermal conductivity according to the empirical data of Al2O3–Cu nanoparticles dispersed in ethylene glycol. Phys. A Stat. Mech. Its Appl. 2020, 549, 124015. [Google Scholar] [CrossRef]

- Ghasemi, A.; Hassani, M.; Goodarzi, M.; Afrand, M.; Manafi, S. Appraising influence of COOH-MWCNTs on thermal conductivity of antifreeze using curve fitting and neural network. Phys. A Stat. Mech. Appl. 2019, 514, 36–45. [Google Scholar] [CrossRef]

- Kumar, S. Comparison of linear regression and artificial neural network technique for prediction of a soybean biodiesel yield. Energy Sources A Recovery Util. Environ. Eff. 2020, 42, 1425–1435. [Google Scholar] [CrossRef]

- Betiku, E.; Osunleke, A.S.; Odude, V.O.; Bamimore, A.; Oladipo, B.; Okeleye, A.A.; Ishola, N.B. Performance evaluation of adaptive neuro-fuzzy inference system, artificial neural network and response surface methodology in modeling biodiesel synthesis from palm kernel oil by transesterification. Biofuels 2021, 12, 339–354. [Google Scholar] [CrossRef]

- Sarve, A.; Sonawane, S.S.; Varma, M.N. Ultrasound assisted biodiesel production from sesame (Sesamum indicum L.) oil using barium hydroxide as a heterogeneous catalyst: Comparative assessment of prediction abilities between response surface methodology (RSM) and artificial neural network (ANN). Ultrason. Sonochem. 2015, 26, 218–228. [Google Scholar] [CrossRef] [PubMed]

- Patel, G.C.M.; Shettigar, A.K.; Parappagoudar, M.B. A systematic approach to model and optimize wear behaviour of castings produced by squeeze casting process. J. Manuf. Process. 2018, 32, 199–212. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, W.; Wei, H.; Sun, C. Application of artificial intelligence for predicting reaction results in advanced oxidation processes. Environ. Technol. Innov. 2021, 23, 101550. [Google Scholar] [CrossRef]

- Patel, G.C.M.; Lokare, D.; Chate, G.R.; Parappagoudar, M.B.; Nikhil, R.; Gupta, K. Analysis and optimization of surface quality while machining high strength aluminium alloy. Measurement 2020, 152, 107337. [Google Scholar] [CrossRef]

- Patel, G.C.; Sibalija, T.V.; Mumtaz, J.; Li, Z. Abrasive water jet machining for a high-quality green composite: The soft computing strategy for modeling and optimization. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 83. [Google Scholar] [CrossRef]

- Sibalija, T.V.; Kumar, S.; Patel, G.C.M. A soft computing-based study on WEDM optimization in processing Inconel 625. Neural Comput. Appl. 2021, 33, 11985–12006. [Google Scholar] [CrossRef]

- Rangappa, R.; Patel, G.C.M.; Chate, G.R.; Lokare, D.; Lakshmikanthan, A.; Giasin, K.; Pimenov, D.Y. Coaxiality error analysis and optimization of cylindrical parts of CNC turning process. Int. J. Adv. Manuf. Technol. 2022, 120, 6617–6634. [Google Scholar] [CrossRef]

- Patel, G.C. Experimental modeling and optimization of surface quality and thrust forces in drilling of high-strength Al 7075 alloy: CRITIC and meta-heuristic algorithms. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 244. [Google Scholar] [CrossRef]

- Patel, G.C.M.; Krishna, P.; Parappagoudar, M.B. Squeeze casting process modeling by a conventional statistical regression analysis approach. Appl. Math. Model. 2016, 40, 6869–6888. [Google Scholar] [CrossRef]

- Chate, G.R.; Patel, G.C.M.; Deshpande, A.S.; Parappagoudar, M.B. Modeling and optimization of furan molding sand system using design of experiments and particle swarm optimization. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 232, 579–598. [Google Scholar] [CrossRef]

- Yang, X.S. Firefly algorithm, stochastic test functions and design optimisation. Int. J. Bio-Inspired Comput. 2010, 2, 78–84. [Google Scholar] [CrossRef]

- Johari, N.F.; Zain, A.M.; Noorfa, M.H.; Udin, A. Firefly algorithm for optimization problem. Appl. Mech. Mater. 2013, 421, 512–517. [Google Scholar] [CrossRef]

- Deo, R.C.; Ghorbani, M.A.; Samadianfard, S.; Maraseni, T.; Bilgili, M.; Biazar, M. Multi-layer perceptron hybrid model integrated with the firefly optimizer algorithm for windspeed prediction of target site using a limited set of neighboring reference station data. Renew. Energy 2018, 116, 309–323. [Google Scholar] [CrossRef]

- Yang, X.S. Multiobjective firefly algorithm for continuous optimization. Eng. Comput. 2013, 29, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Erol, O.K.; Eksin, I. A new optimization method: Big bang–big crunch. Adv. Eng. Softw. 2006, 37, 106–111. [Google Scholar] [CrossRef]

- Rezaee Jordehi, A. A chaotic-based big bang–big crunch algorithm for solving global optimisation problems. Neural. Comput. Appl. 2014, 25, 1329–1335. [Google Scholar] [CrossRef]

- Kaveh, A.; Talatahari, S. Size optimization of space trusses using Big Bang–Big Crunch algorithm. Comput. Struct. 2009, 87, 1129–1140. [Google Scholar] [CrossRef]

- Hatamlou, A.; Abdullah, S.; Hatamlou, M. Data clustering using big bang–big crunch algorithm. In Proceedings of the International Conference on Innovative Computing Technology, Tehran, Iran, 13–15 December 2011; Springer: Berlin/Heidelberg, Germany; pp. 383–388. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, H.; Bozorg-Haddad, O.; Chu, X. Grey wolf optimization (GWO) algorithm. In Advanced Optimization by Nature-Inspired Algorithms; Springer: Singapore, 2018; pp. 81–91. [Google Scholar] [CrossRef]

- Pradhan, M.; Roy, P.K.; Pal, T. Grey wolf optimization applied to economic load dispatch problems. Int. J. Electr. Power Energy Syst. 2016, 83, 325–334. [Google Scholar] [CrossRef]

- Salgotra, R.; Singh, U.; Sharma, S. On the improvement in grey wolf optimization. Neural. Comput. Appl. 2020, 32, 3709–3748. [Google Scholar] [CrossRef]

- Ilham, Z.; Saka, S. Two-step supercritical dimethyl carbonate method for biodiesel production from Jatropha curcas oil. Bioresour. Technol. 2010, 101, 2735–2740. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsiao, M.C.; Liao, P.H.; Lan, N.V.; Hou, S.S. Enhancement of biodiesel production from high-acid-value waste cooking oil via a microwave reactor using a homogeneous alkaline catalyst. Energies 2021, 14, 437. [Google Scholar] [CrossRef]

- Muro, C.; Escobedo, R.; Spector, L.; Coppinger, R. Wolf-pack (Canis Lupus) hunting strategies emerge from simple rules in computational simulations. Behav. Processes 2011, 88, 192–197. [Google Scholar] [CrossRef]

- Lee, H.V.; Yunus, R.; Juan, J.C.; Taufiq-Yap, Y.H. Process optimization design for jatrophabased biodiesel production using response surface methodology. Fuel Process. Technol. 2011, 92, 2420–2428. [Google Scholar] [CrossRef] [Green Version]

- Singh, V.; Belova, L.; Singh, B.; Sharma, Y.C. Biodiesel production using a novel heterogeneous catalyst, magnesium zirconate (Mg2Zr5O12): Process optimization through response surface methodology (RSM). Energy Convers. Manag. 2018, 174, 198–207. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Khalilpourazary, S. Optimization of production time in the multi-pass milling process via a Robust Grey Wolf Optimizer. Neural. Comput. Appl. 2018, 29, 1321–1336. [Google Scholar] [CrossRef]

- Belloufi, A.; Assas, M.; Rezgui, I. Intelligent selection of machining parameters in multipass turnings using firefly algorithm. Model. Simul. Eng. 2014, 2014, 8. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Cesur, C.; Aslan, V.; Yilbasi, Z. The production of biodiesel from safflower (Carthamus tinctorius L.) oil as a potential feedstock and its usage in compression ignition engine: A comprehensive review. Renew. Sustain. Energy Rev. 2020, 119, 109574. [Google Scholar] [CrossRef]

- Berchmans, H.J.; Hirata, S. Biodiesel production from crude Jatropha curcas L. seed oil with a high content of free fatty acids. Bioresour. Technol. 2008, 99, 1716–1721. [Google Scholar] [CrossRef]

- Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Nisar, J.; Iqbal, M. Biodiesel production from waste cooking oil: An efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Santya, G.; Maheswaran, T.; Yee, K.F. Optimization of biodiesel production from high free fatty acid river catfsh oil (Pangasius hypothalamus) and waste cooking oil catalyzed by waste chicken egg shells derived catalyst. SN Appl. Sci. 2019, 1, 152. [Google Scholar] [CrossRef] [Green Version]

- Awad, S.; Paraschiv, M.; Geo, V.E.; Tazerout, M. Effect of Free Fatty Acids and Short Chain Alcohols on Conversion of Waste Cooking Oil to Biodiesel. Int. J. Green Energy 2014, 11, 441–453. [Google Scholar] [CrossRef]

| Feedstock | Catalyst | Process Parameters | Optimization | Major Results | Ref. |

|---|---|---|---|---|---|

| Castor oil | KOH | Rt: 30–150 min, CC: 0.5–2 wt.%, RT: 50–70 °C, OMMR: 1:3–1:9 | CCD and RSM | 94.9% yield | [51] |

| Musa acuminata peduncle | CRBP | CC: 1.5–3.5 wt.%, OMMR: 6–14, Rt: 40–120 min | CCD and RSM | 98.73% yield | [41] |

| Waste cooking oil | NaOH | OMVR: 0.1–1, Rt: 10–60 s, MP: 100–400 w | CCRD and RSM | 94.6% yield | [37] |

| Rubber seed oil | RSS | Rt: 60–70 min, CC: 2.5–3.5 g, OMMR: 0.2–0.3 | CCD and RSM | 80% yield | [40] |

| Soybean oil | NaOH | Rt: 60–100 min, CC: 0.5–1.3 wt.%, RT: 50–70 °C, MR: 6:1–12:1 | CCRD and RSM | NR | [38] |

| Waste cooking oil | Sulfated zirconia | Rt: 30–120 min, CC: 2–4 wt.%, RT: 90–150 °C, OMMR: 9:1–21:1 | CCD and RSM | 93.5% yield | [43] |

| Flaxseed oil | KOH | Rt: 30–60 min, CC: 0.4–1 wt.%, RT: 35–65 °C, MR: 4:1–6:1 | CCD and RSM | 98% yield | [45] |

| Pithecellobium dulce seed oil | KOH | Rt: 60–120 min, CC: 0.4–1.2 wt.%, RT: 55–65 °C, MR: 1:3–1:9 | BBD and RSM | 93.24% yield | [35] |

| Waste cooking oil-Calophyllum inophyllum oil | KOH | Rt: 2–10 min, CC: 0.4–1 wt.%, SS: 600–1000 rpm, OMMR: 9:1–21:1 | BBD and RSM | 98.3% yield | [50] |

| Camelina oil | KOH | Rt: 5–8 min, CC: 0.5–1.5 wt.%, MRAO: 9:1–21:1 | BBD and RSM | 95.31% yield | [42] |

| Waste cotton-seed cooking oil | KOH | M:O: 6–10, CC: 0.3–0.7 wt.%, Rt: 6–12 min | FFD and RSM | 96.77% yield | [47] |

| CaO | M:O: 8–12, CC: 0.5–2 wt.%, Rt: 6–12 min | 90.5% yield | |||

| Waste cotton-seed cooking oil | KOH | M:O: 4.5–7.5, CC: 0.3–0.7 wt.%, RT: 40–60 °C | BBD and RSM | 97.76% yield | [48] |

| CaO | M:O: 6–12, CC: 0.5–1.5 wt.%, RT: 6–12 °C | 96.16% yield | |||

| Kapok (Ceiba pentandra) oil | Immobilized lipase | M:O: 4–20, WC: 2–22 vol.%, RT: 30–40 °C | CCD and RSM | 96.4% yield | [52] |

| Olive oil | KOH | M:O: 3–15, CC: 0.4–2 wt.%, PL: 100–900 W, Rt: 3–15 min | Try-error-method | 93.5% yield | [53] |

| Almonds of Syagrus cearensis | H2SO4 + KOH | M:O: 6–60, CC: 1–5 wt.%, Rt: 10–30 min | FFD and RSM | 99.99% yield | [54] |

| Rubber seed oil | H2SO4 | AOMR: 6–15, CC: 0.5–10.5 wt.%, Rt: 50–90 min, RT: 50–70 °C | BBD and RSM | 75.4% yield | [55] |

| Acai seeds and refined soybean oil | Acai seed ash catalyst | AOMR: 6–24, CC: 3–15 wt.%, Rt: 60–300 min, RT: 60–120 °C | CCD and RSM | 98.5% yield | [44] |

| Palm oil | Zn-Ce/Al2O3 | M:O: 12–24, CC: 5–10 wt.%, RT: 58–72 °C | CCD and RSM | 87.4% yield | [47] |

| Pig and neem seed | CaO | M:O: 12–24, CC: 2–4 g, Rt: 50–70 min, RT: 50–60 °C | CCD and RSM | 98.05% yield | [56] |

| Symbols | Factors | Levels | ||

|---|---|---|---|---|

| Low | Medium | High | ||

| A | Methanol-to-oil molar ratio | 3 | 7.5 | 12 |

| B | Catalyst concentration (wt.%) | 0.5 | 1.0 | 1.5 |

| C | Reaction temperature (°C) | 50 | 57.5 | 65 |

| D | Reaction time (min) | 60 | 90 | 120 |

| Run | A: Methanol-to-Oil Molar Ratio | B: Catalyst Concentration (wt.%) | C: Reaction Temperature (°C) | D: Reaction Time (min) | Experimental Biodiesel Yield (%) | Predicted Biodiesel Yield (%) |

|---|---|---|---|---|---|---|

| 1 | 7.5 | 1.5 | 57.5 | 60 | 92.5 ± 0.4 | 91.3 |

| 2 | 12.0 | 1.0 | 57.5 | 60 | 89.0 ± 0.8 | 88.8 |

| 3 | 3.0 | 1.0 | 57.5 | 60 | 87.0 ± 0.6 | 86.9 |

| 4 | 7.5 | 0.5 | 57.5 | 60 | 87.0 ± 0.3 | 87.3 |

| 5 | 7.5 | 1.0 | 50.0 | 60 | 90.5 ± 0.4 | 90.4 |

| 6 | 7.5 | 1.0 | 65.0 | 60 | 91.7 ± 0.7 | 91.8 |

| 7 | 12 | 1.5 | 57.5 | 90 | 91.0 ± 0.5 | 90.9 |

| 8 | 7.5 | 1.0 | 57.5 | 90 | 92.0 ± 0.4 | 91.6 |

| 9 | 3.0 | 0.5 | 57.5 | 90 | 85.5 ± 0.2 | 85.7 |

| 10 | 7.5 | 0.5 | 65.0 | 90 | 89.1 ± 0.4 | 88.5 |

| 11 | 12 | 0.5 | 57.5 | 90 | 85.5 ± 0.3 | 85.4 |

| 12 | 7.5 | 1.5 | 65.0 | 90 | 92.5 ± 0.8 | 92.2 |

| 13 | 3.0 | 1.0 | 50.0 | 90 | 87.0 ± 0.5 | 86.6 |

| 14 | 7.5 | 1.0 | 57.5 | 90 | 91.7 ± 0.4 | 91.6 |

| 15 | 7.5 | 1.5 | 50.0 | 90 | 90.0 ± 0.3 | 90.3 |

| 16 | 7.5 | 1.0 | 57.5 | 90 | 92.0 ± 0.4 | 91.6 |

| 17 | 3.0 | 1.0 | 65.0 | 90 | 86.5 ± 0.7 | 86.6 |

| 18 | 7.5 | 0.5 | 50.0 | 90 | 89.0 ± 0.7 | 89.0 |

| 19 | 7.5 | 1.0 | 57.5 | 90 | 91.2 ± 0.6 | 91.6 |

| 20 | 12 | 1.0 | 50.0 | 90 | 88.5 ± 0.5 | 88.6 |

| 21 | 12 | 1.0 | 65.0 | 90 | 89.5 ± 0.5 | 90.1 |

| 22 | 3.0 | 1.5 | 57.5 | 90 | 85.0 ± 0.8 | 85.2 |

| 23 | 7.5 | 1.0 | 57.5 | 90 | 91.2 ± 0.4 | 91.6 |

| 24 | 12 | 1.0 | 57.5 | 120 | 88.5 ± 0.2 | 88.3 |

| 25 | 7.5 | 0.5 | 57.5 | 120 | 88.5 ± 0.3 | 88.7 |

| 26 | 7.5 | 1.0 | 65.0 | 120 | 89.5 ± 0.3 | 89.7 |

| 27 | 3.0 | 1.0 | 57.5 | 120 | 84.7 ± 0.5 | 84.7 |

| 28 | 7.5 | 1.5 | 57.5 | 120 | 88.5 ± 0.7 | 88.4 |

| 29 | 7.5 | 1.0 | 50.0 | 120 | 89.6 ± 0.8 | 89.7 |

| Model | Regression Equation | Regression Coefficient |

|---|---|---|

| Linear | Yield = 83.78 + 0.302 A + 2.483 B + 0.047 C − 0.027 D | R2 = 0.3141, and Adj. R2 = 0.1998 |

| Linear + Interaction | Yield = 89.297 − 1.304 A − 3.467 B − 0.067 C + 0.1264 D + 0.667 AB + 0.011 AC + 0.0033AD + 0.16 BC − 0.0917 BD − 0.0014 CD | R2 = 0.4437, and Adj. R2 = 0.1347 |

| Linear + Interaction + Square | Yield = 54.44389 + 1.24074 A + 7.61333 B + 0.388222 C + 0.330889 D + 0.666667 AB + 0.011111 AC + 0.003333 AD + 0.16 BC − 0.0916670 BD − 0.001444 CD − 0.16963 A2 5.54 B2 − 0.003956 C2 − 0.001136 D2 | R2 = 0.9869, and Adj. R2 = 0.9737 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 150.77 | 14 | 10.77 | 75.62 | 0.0001 |

| M:O | 22.14 | 1 | 22.14 | 155.47 | 0.0001 |

| CC | 18.50 | 1 | 18.50 | 129.91 | 0.0001 |

| RT | 1.47 | 1 | 1.47 | 10.32 | 0.0063 |

| Rt | 5.88 | 1 | 5.88 | 41.29 | 0.0001 |

| M:O × CC | 9.00 | 1 | 9.00 | 63.19 | 0.0001 |

| M:O × RT | 0.5625 | 1 | 0.5625 | 3.95 | 0.0668 |

| M:O × Rt | 0.8100 | 1 | 0.8100 | 5.69 | 0.0318 |

| CC × RT | 1.44 | 1 | 1.44 | 10.11 | 0.0067 |

| CC × Rt | 7.56 | 1 | 7.56 | 53.10 | 0.0001 |

| RT × Rt | 0.4225 | 1 | 0.4225 | 2.97 | 0.1070 |

| M:O 2 | 76.54 | 1 | 76.54 | 537.41 | 0.0001 |

| CC 2 | 12.44 | 1 | 12.44 | 87.37 | 0.0001 |

| RT 2 | 0.3211 | 1 | 0.3211 | 2.25 | 0.1554 |

| Rt 2 | 6.78 | 1 | 6.78 | 47.62 | 0.0001 |

| Residual | 1.99 | 14 | 0.1424 | ||

| Lack of Fit | 1.35 | 10 | 0.1346 | 0.8308 | 0.6322 |

| Pure Error | 0.6480 | 4 | 0.1620 | ||

| Cor Total | 152.77 | 28 |

| Algorithms | Algorithm Specific Parameters | Fitness Value (Yield%) | Computation Time (seconds) | Transesterification Condition |

|---|---|---|---|---|

| GWO | Convergence constant = 0.5 | 94.15% | 1.66 | M:O = 9.32; CC = 1.5 wt.%; RT = 65 °C; Rt = 60 s |

| FA | Randomness, α = 0.9; Absorption coefficient, γ = 1; Randomness reduction, β = 0.6 | 94.15% | 15.06 | M:O = 9.32; CC = 1.5 wt.%; RT = 65 °C; Rt = 60 s |

| BB-BC | Exploration factor = 14 | 93.07% | 0.8 | M:O = 9.02; CC = 1.47 wt.%; RT = 63.8 °C; Rt = 86.1 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkataramana, S.H.; Shivalingaiah, K.; Davanageri, M.B.; Selvan, C.P.; Lakshmikanthan, A.; Chandrashekarappa, M.P.G.; Razak, A.; Anand, P.B.; Linul, E. Niger Seed Oil-Based Biodiesel Production Using Transesterification Process: Experimental Investigation and Optimization for Higher Biodiesel Yield Using Box–Behnken Design and Artificial Intelligence Tools. Appl. Sci. 2022, 12, 5987. https://doi.org/10.3390/app12125987

Venkataramana SH, Shivalingaiah K, Davanageri MB, Selvan CP, Lakshmikanthan A, Chandrashekarappa MPG, Razak A, Anand PB, Linul E. Niger Seed Oil-Based Biodiesel Production Using Transesterification Process: Experimental Investigation and Optimization for Higher Biodiesel Yield Using Box–Behnken Design and Artificial Intelligence Tools. Applied Sciences. 2022; 12(12):5987. https://doi.org/10.3390/app12125987

Chicago/Turabian StyleVenkataramana, Srikanth Holalu, Kanchiraya Shivalingaiah, Mahesh Basetteppa Davanageri, Chithirai Pon Selvan, Avinash Lakshmikanthan, Manjunath Patel Gowdru Chandrashekarappa, Abdul Razak, Praveena Bindiganavile Anand, and Emanoil Linul. 2022. "Niger Seed Oil-Based Biodiesel Production Using Transesterification Process: Experimental Investigation and Optimization for Higher Biodiesel Yield Using Box–Behnken Design and Artificial Intelligence Tools" Applied Sciences 12, no. 12: 5987. https://doi.org/10.3390/app12125987

APA StyleVenkataramana, S. H., Shivalingaiah, K., Davanageri, M. B., Selvan, C. P., Lakshmikanthan, A., Chandrashekarappa, M. P. G., Razak, A., Anand, P. B., & Linul, E. (2022). Niger Seed Oil-Based Biodiesel Production Using Transesterification Process: Experimental Investigation and Optimization for Higher Biodiesel Yield Using Box–Behnken Design and Artificial Intelligence Tools. Applied Sciences, 12(12), 5987. https://doi.org/10.3390/app12125987