Cavitation Erosion Characteristics for Different Metal Surface and Influencing Factors in Water Flowing System

Abstract

:1. Introduction

2. Materials and Methods

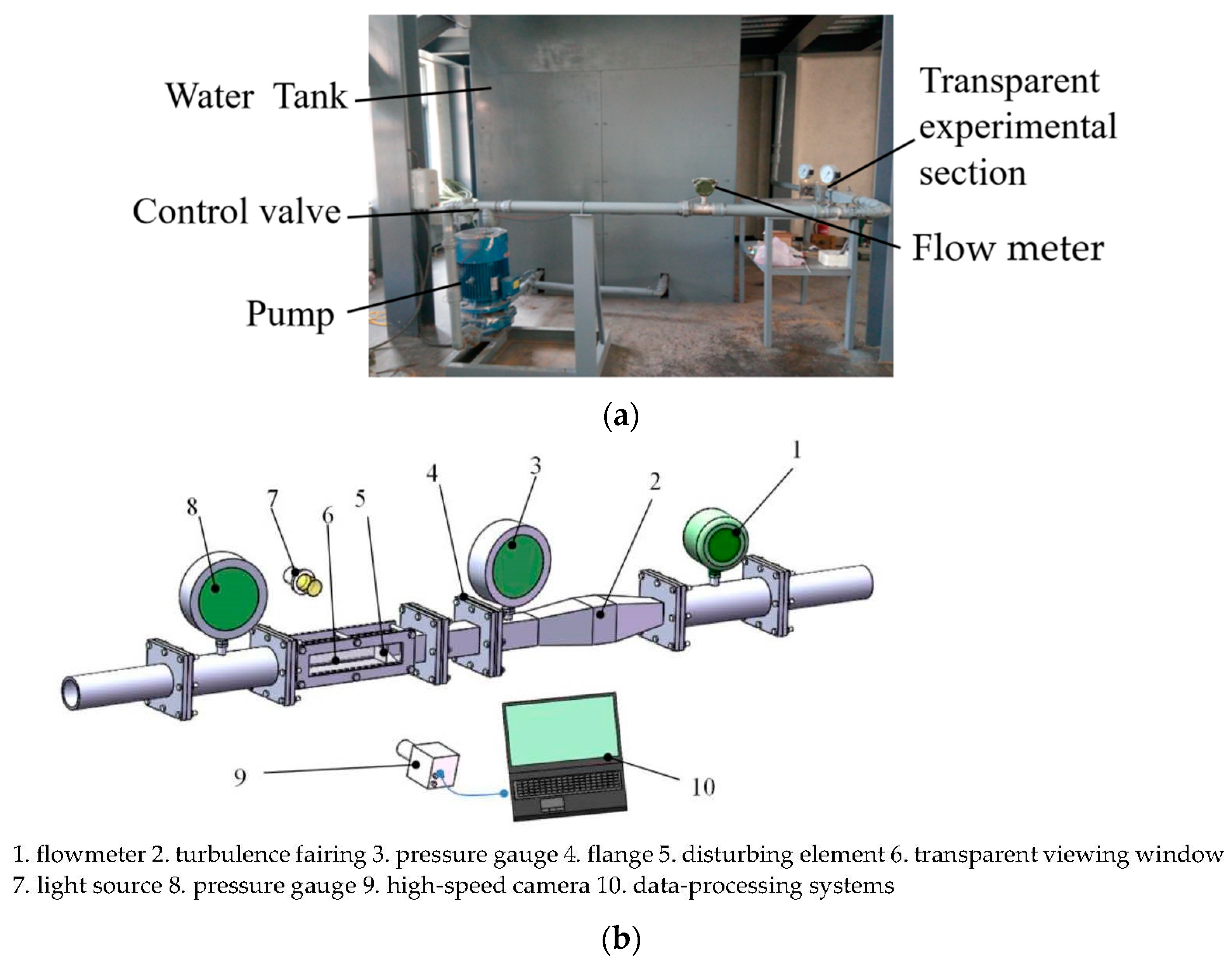

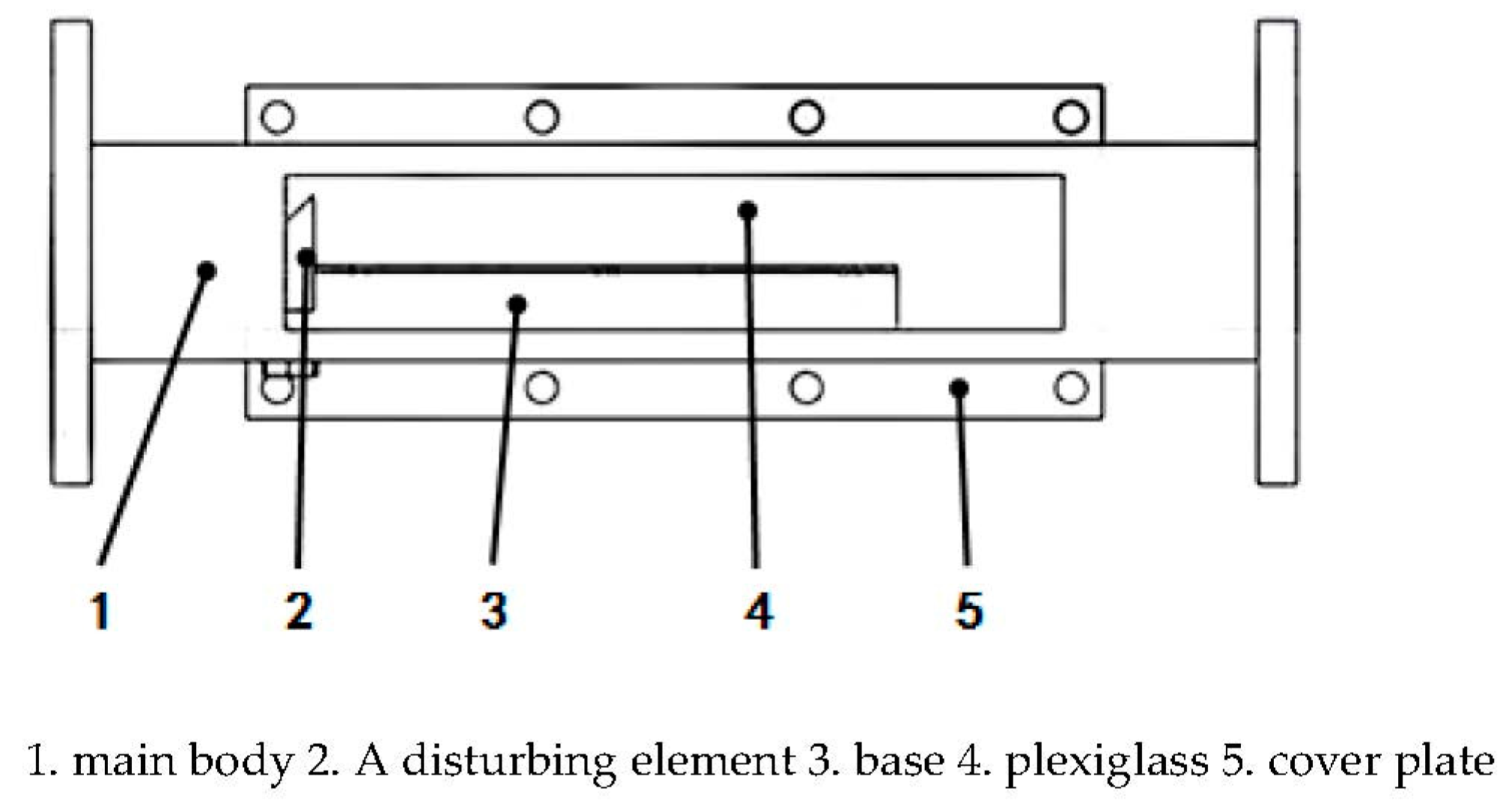

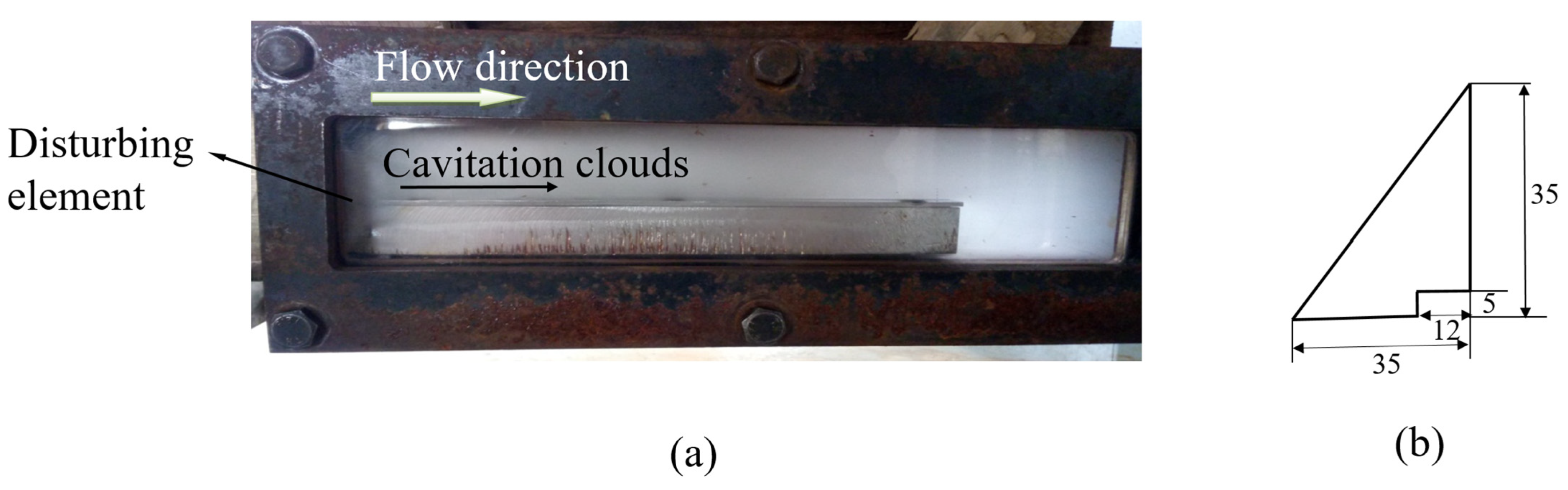

2.1. Experimental Device

2.2. Test Material Preparation

3. Results

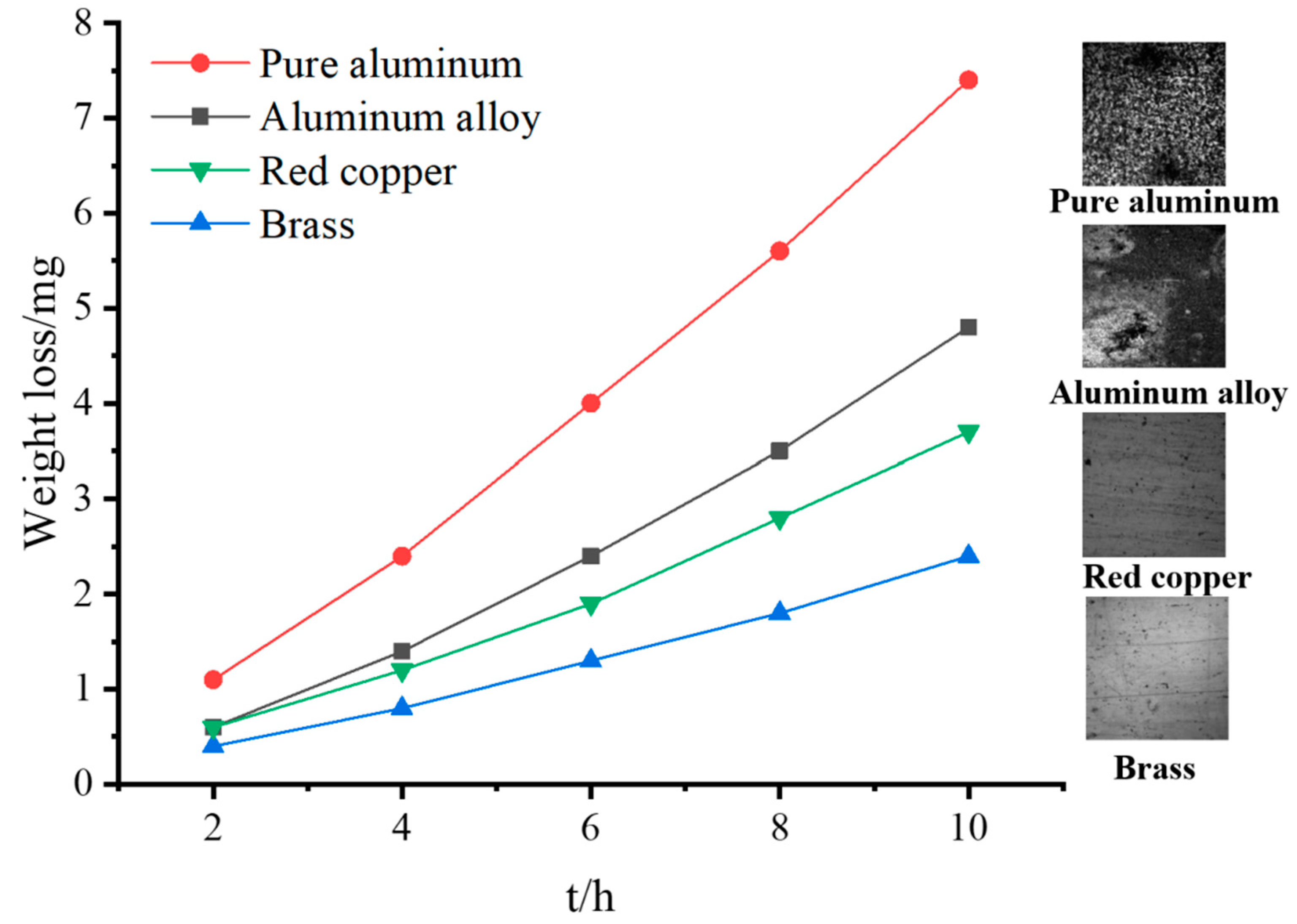

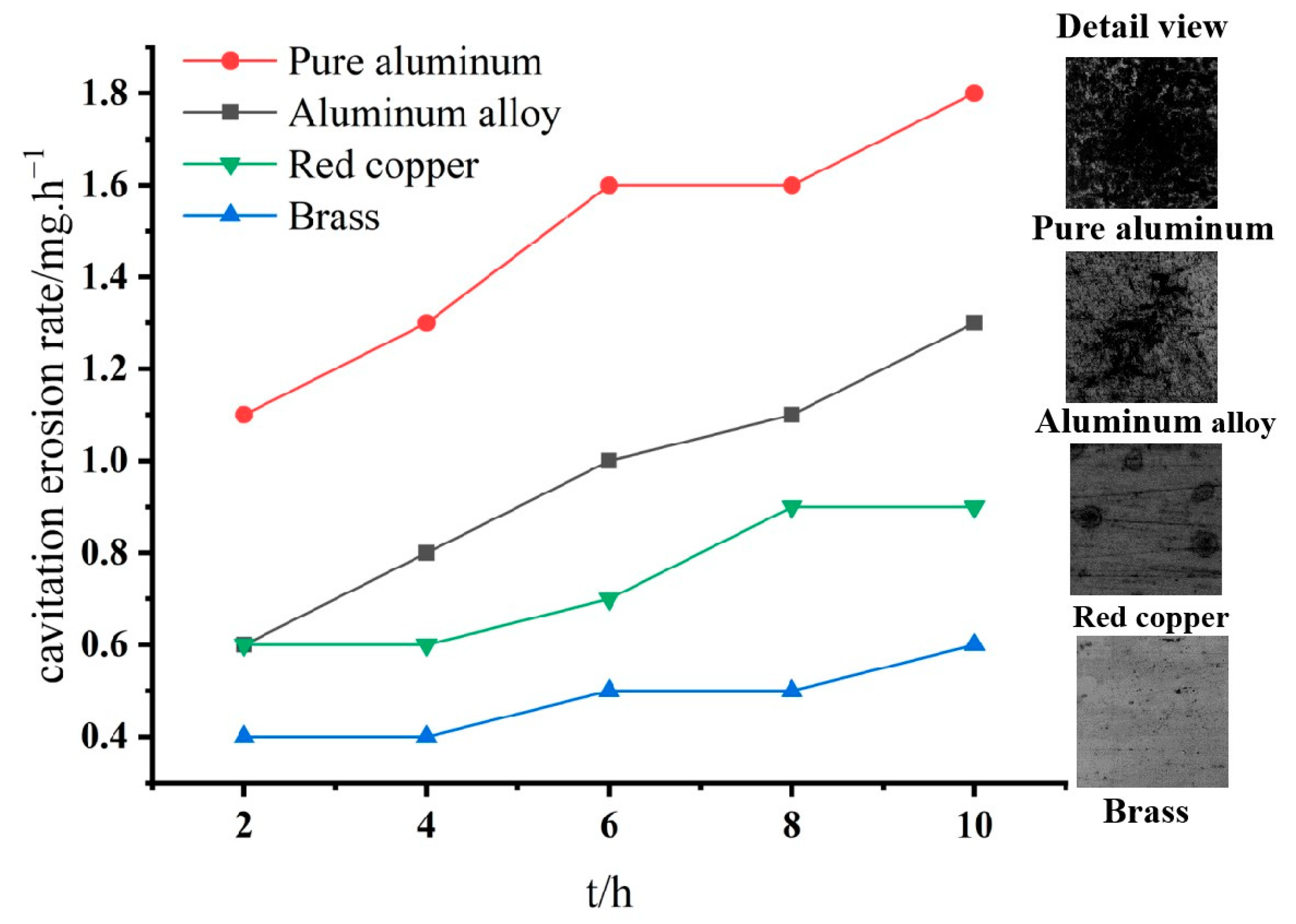

3.1. Cavitation Erosion Behavior on Different Metallic Metals

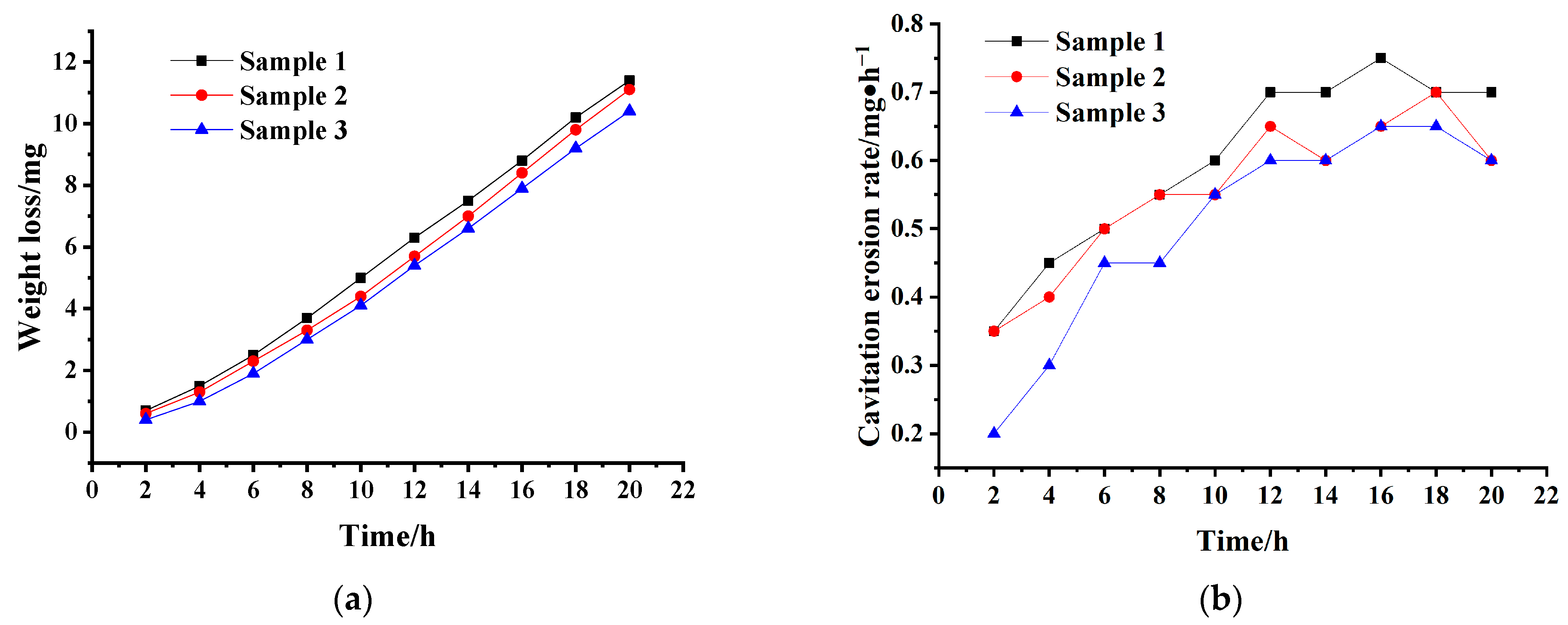

3.2. Cavitation Erosion Behavior of Brass at Different Position

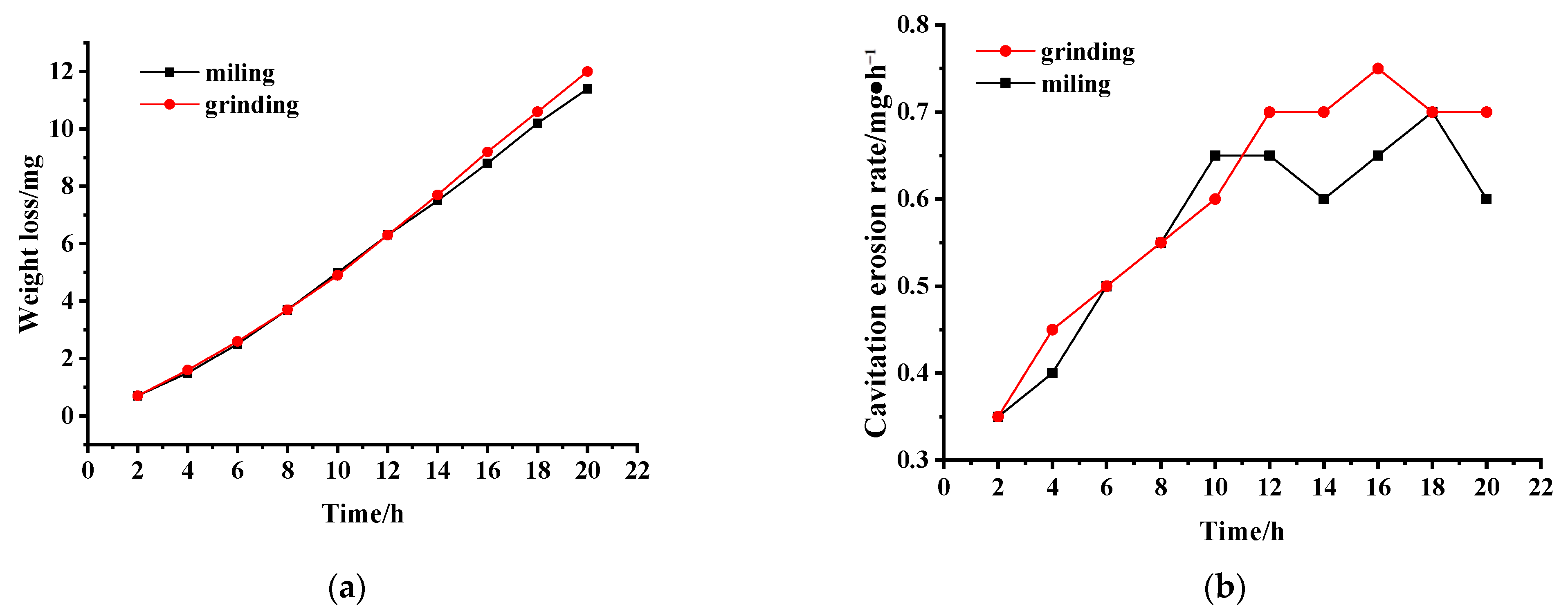

3.3. Influence of Surface Roughness on Cavitation Erosion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, M.R.; Zhu, H.R.; Liu, C.L.; Guo, T.; Zhang, L.; Li, N. Numerical analysis and design optimization on full coverage film-cooling for turbine guided vane. Eng. Appl. Comp. Fluid Mech. 2022, 16, 904–936. [Google Scholar] [CrossRef]

- Xu, B.; Cheng, M. Motion control of multi-actuator hydraulic systems for mobile machineries: Recent advancements and future trends. Front. Mech. Eng. 2018, 13, 151–166. [Google Scholar] [CrossRef]

- Chahine, G.L.; Franc, J.P.; Karimi, A. Advanced Experimental and Numerical Techniques for Cavitation Erosion Prediction; Fluid Mechanics and Its Applications; Springer: Dordrecht, The Netherlands, 2014; Volume 106. [Google Scholar] [CrossRef]

- Hammitt, F.G. Temperature effects on single bubble collapse and induced impulsive pressure. J. Fluids Eng.-Trans. ASME 1988, 110, 344. [Google Scholar] [CrossRef]

- Ni, W.W.; Cass, M.; Bartholme, D. The Jet Fuel Hydrodynamic Cavitation Bubble Size with Cavitation Power and Energy from Rayleigh-Plesset Equation. SAE Int. J. Aerosp. 2015, 8, 195–202. [Google Scholar] [CrossRef]

- Nigmatulin, R.I.; Aganin, A.A.; Il’gamov, M.A.; Toporkov, D.Y. Extreme Focusing of Energy during Shock Compression of the Vapor Bubble in Hydrocarbon Liquids. High Temp. 2019, 57, 228–235. [Google Scholar] [CrossRef]

- Turangan, C.K.; Ball, G.J.; Jamaluddin, A.R.; Leighton, T.G. Numerical studies of cavitation erosion on an elastic-plastic material caused by shock-induced bubble collapse. Proc. R. Soc. A Math. Phys. Eng. Sci. 2017, 473, 20170315. [Google Scholar] [CrossRef]

- Soyama, H.; Kumano, H. The fundamental threshold level—A new parameter for predicting cavitation erosion resistance. J. Test. Eval. 2002, 30, 421–431. [Google Scholar]

- Dockar, D.; Gibelli, L.; Borg, M.K. Shock-induced collapse of surface nanobubbles. Soft Matter 2021, 17, 6884–6898. [Google Scholar] [CrossRef] [PubMed]

- Dular, M.; Bachert, B.; Stoffel, B.; Širok, B. Relationship between cavitation structures and cavitation damage. Wear 2004, 257, 1176–1184. [Google Scholar] [CrossRef]

- Lv, Z.; Hou, R.; Zhang, Z.; Fan, Z. Effect of ultrasonic vibration on cavitation erosion of aluminum oxide in fluid jet machining. Int. J. Adv. Manuf. Technol. 2020, 111, 2911–2918. [Google Scholar] [CrossRef]

- Hutli, E.; Nedeljkovic, M.S.; Radovic, N.A.; Bonyár, A. The relation between the high speed submerged cavitating jet behaviour and the cavitation erosion process. Int. J. Multiph. Flow 2016, 83, 27–38. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Kang, Y.; Wang, X.; Ding, X.; Fang, Z. Effects of nozzle inner surface roughness on the cavitation erosion characteristics of high speed submerged jets. Exp. Therm. Fluid Sci. 2016, 74, 444–452. [Google Scholar] [CrossRef]

- Paolantonio, M.; Hanke, S. Damage mechanisms in cavitation erosion of nitrogen-containing austenitic steels in 3.5% NaCl solution. Wear 2021, 464–465, 203526. [Google Scholar] [CrossRef]

- Sarc, A.; Stepisnik-Perdih, T.; Petkovsek, M.; Dular, M. The issue of cavitation number value in studies of water treatment by hydrodynamic cavitation. Ultrason. Sonochem. 2017, 34, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhuang, S.; Liu, H.; Zhao, Z.; Dular, M.; Wang, J. Image post-processed approaches for cavitating flow in orifice plate. J. Mech. Sci. Technol. 2017, 31, 3305–3315. [Google Scholar] [CrossRef]

- Hattori, S.; Nakao, E. Cavitation erosion mechanisms and quantitative evaluation based on erosion particles. Wear 2001, 249, 839–845. [Google Scholar] [CrossRef]

- Nouri, J.M.; Vasilakos, I.; Yan, Y.Y.; Reyes-Aldasoro, C.C. Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly. Lubricants 2019, 7, 88. [Google Scholar] [CrossRef] [Green Version]

- Dular, M.; Khlifa, I.; Fuzier, S.; Maiga, M.A.; Coutier-Delgosha, O. Scale effect on unsteady cloud cavitation. Exp. Fluids 2012, 53, 1233–1250. [Google Scholar] [CrossRef]

- Qian, P.F.; Pu, C.W.; Liu, L.; Li, X.; Zhang, B.; Gu, Z.Y.; Meng, D.Y. Development of a new high-precision friction test platform and experimental study of friction characteristics for pneumatic cylinders. Meas. Sci. Technol. 2022, 33, 065001. [Google Scholar] [CrossRef]

| Material | H62 Brass | T2 Red Copper | 6061 Aluminum-Alloy | 1060 Industry Pure Aluminum |

|---|---|---|---|---|

| Yield strength (MPa) | 120 | 70–90 | 103 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Liu, X.; Li, B.; Zhai, J.; Song, J. Cavitation Erosion Characteristics for Different Metal Surface and Influencing Factors in Water Flowing System. Appl. Sci. 2022, 12, 5840. https://doi.org/10.3390/app12125840

He J, Liu X, Li B, Zhai J, Song J. Cavitation Erosion Characteristics for Different Metal Surface and Influencing Factors in Water Flowing System. Applied Sciences. 2022; 12(12):5840. https://doi.org/10.3390/app12125840

Chicago/Turabian StyleHe, Jie, Xiumei Liu, Beibei Li, Jixing Zhai, and Jiaqing Song. 2022. "Cavitation Erosion Characteristics for Different Metal Surface and Influencing Factors in Water Flowing System" Applied Sciences 12, no. 12: 5840. https://doi.org/10.3390/app12125840

APA StyleHe, J., Liu, X., Li, B., Zhai, J., & Song, J. (2022). Cavitation Erosion Characteristics for Different Metal Surface and Influencing Factors in Water Flowing System. Applied Sciences, 12(12), 5840. https://doi.org/10.3390/app12125840