A Set of Novel Procedures for Carbon Fiber Reinforcement on Complex Curved Surfaces Using Multi Axis Additive Manufacturing

Abstract

:1. Introduction

1.1. Prior Work

1.2. Our Method

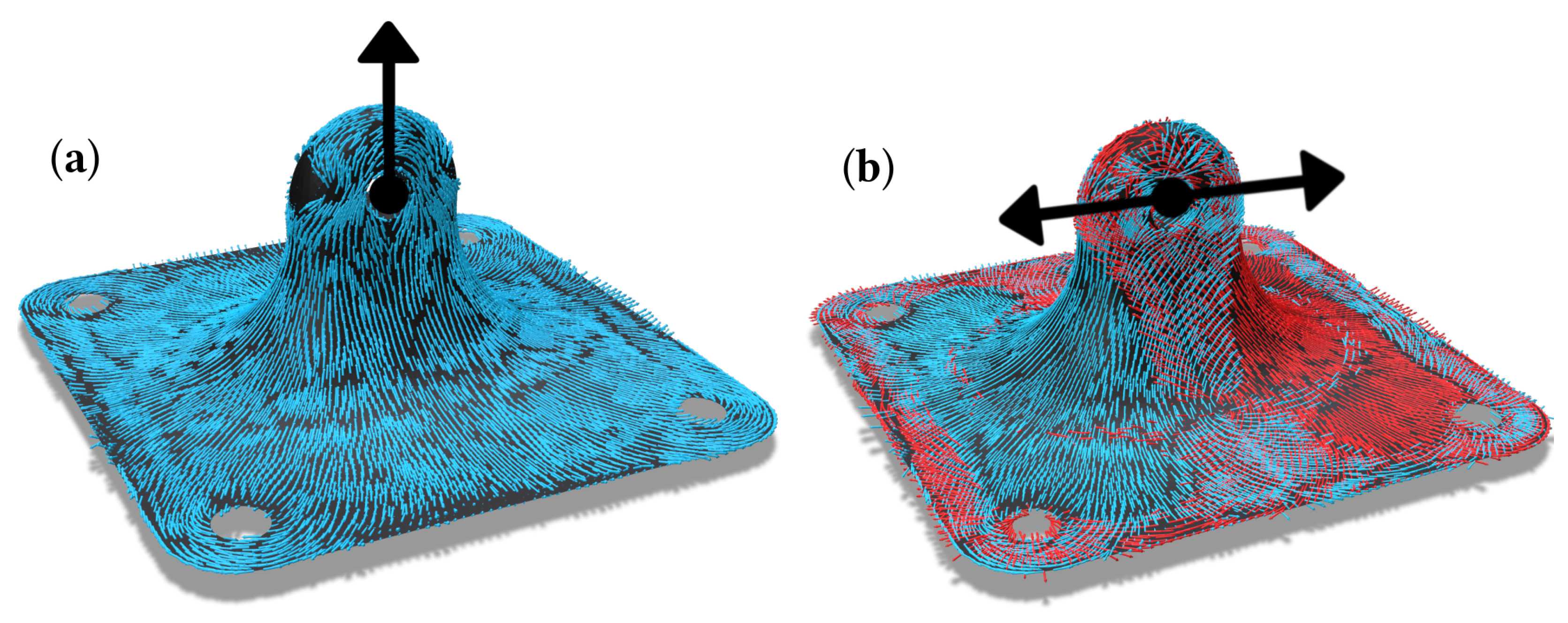

- The proposed procedure starts by analyzing the part to be manufactured in an external finite element method (FEM) software to extract the major principle stress vectors. An exemplary result can be found in Figure 1a.

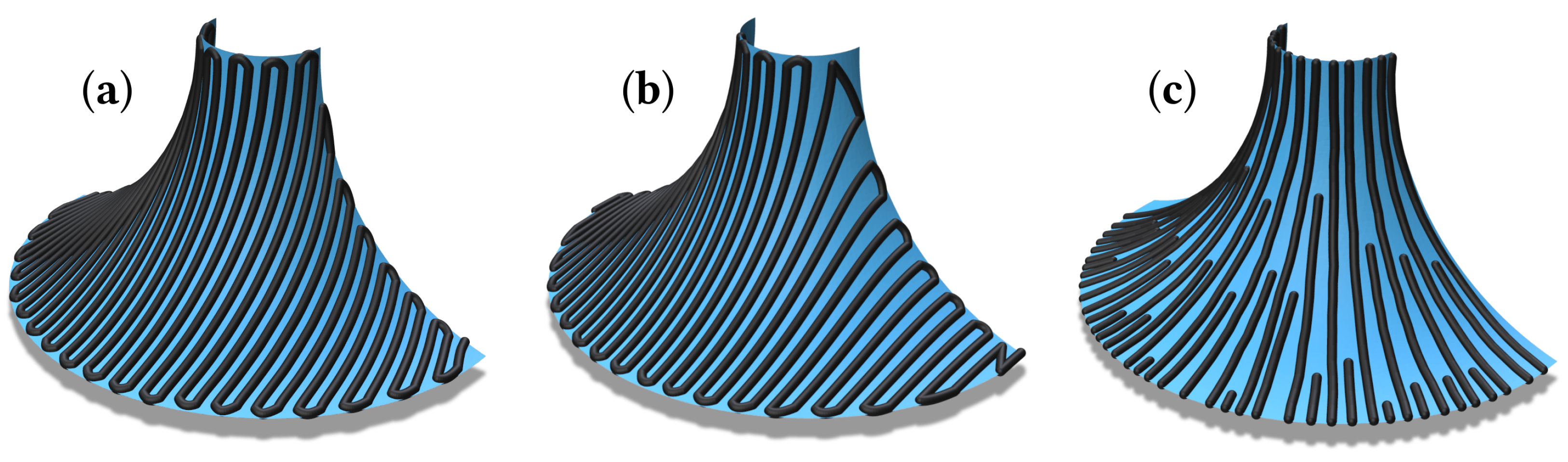

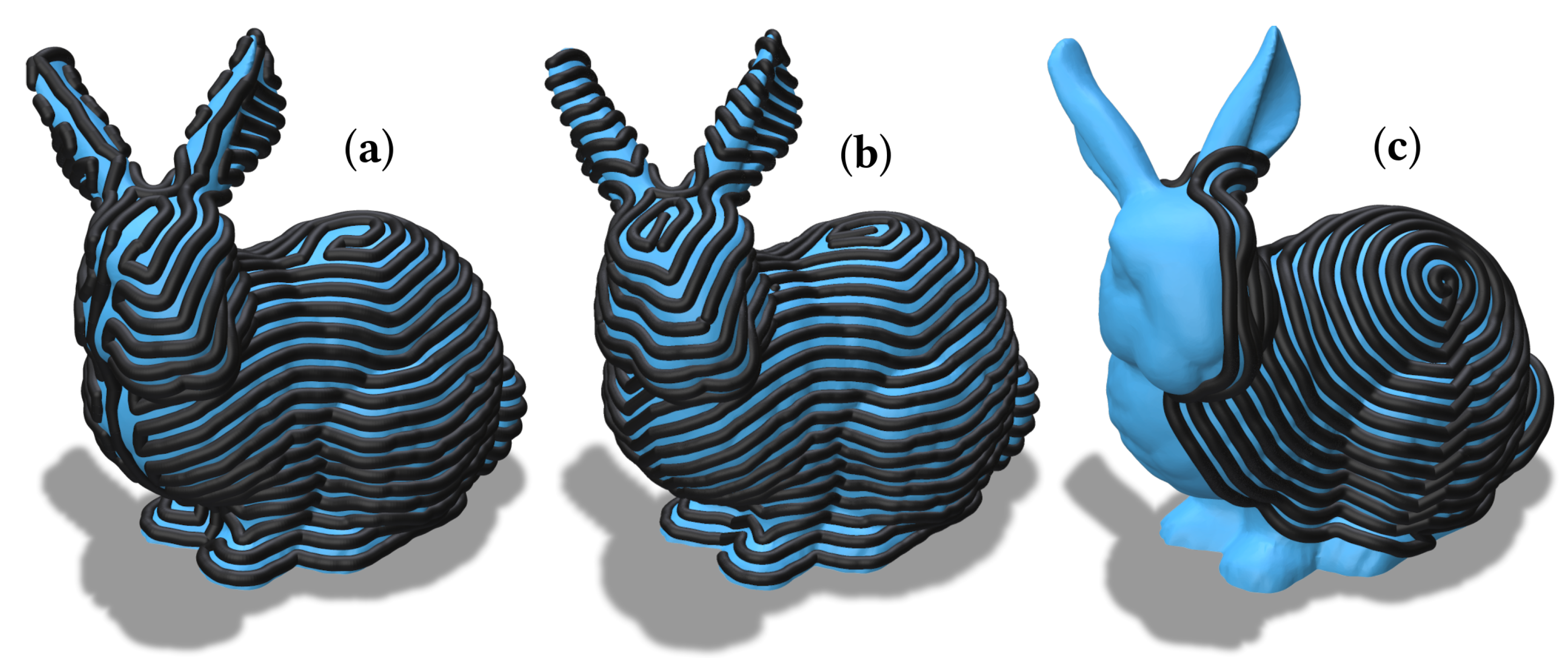

- The resulting information enables the partitioning of the surface to be reinforced into subsurfaces with the goal of achieving a high compliance of local fiber direction and directions of major principle stress. Figure 1b illustrates such a partitioning. This is similar to the zoning approach, used in the layup process.

- The subsurfaces are triangulated with high precision to ensure minimal computation error.

- For every subsurface a suitable algorithm is chosen. This is performed with the intent of maximizing the measured values of the evaluation criteria and relies on knowledge of the procedures.

- The chosen algorithm is executed for every surface resulting in paths that include possible travel motions, an example of which can be seen in Figure 1c.

- Post-processing of the paths yields a Gcode to be executed on the multi-axis printer.

2. Methods and Evaluation Criteria

2.1. Evaluation Criteria

2.1.1. Continuity

2.1.2. Curvature

2.1.3. Fiber Area Fraction

2.1.4. Load Adequacy

3. Algorithms

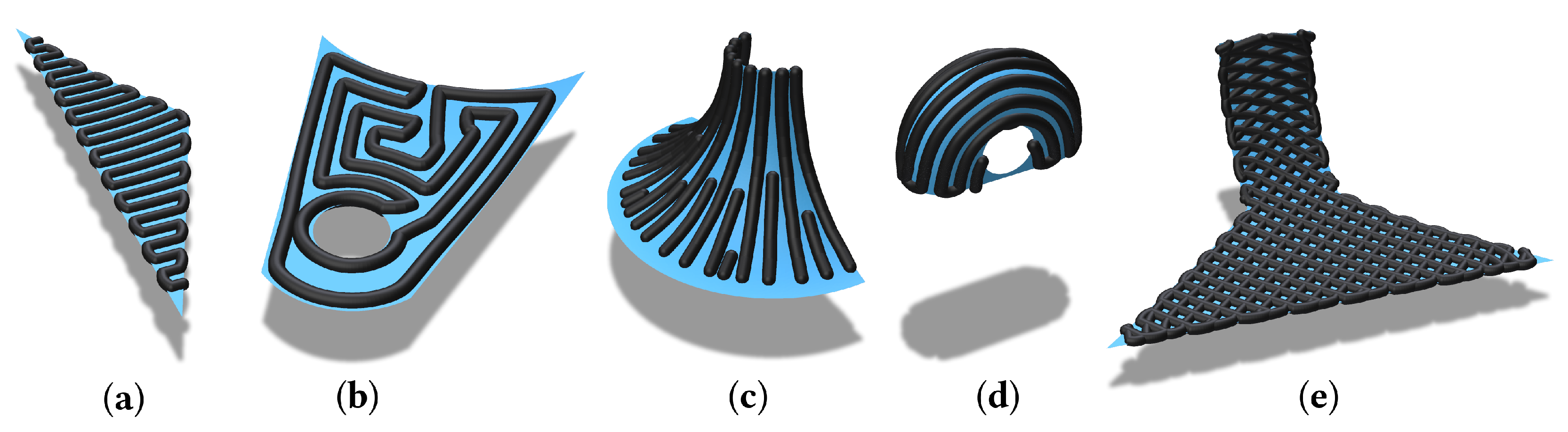

- Direction parallel:

- Fixed intrinsic angle (FInA);

- Fixed extrinsic angle (FExA);

- Seeded ortho-isogeodesics (Ortheo).

- Contour parallel:

- Geodesic first in spiral out (Geo-FISO);

- Geodesic contour parallel spirals (Geo-Contour);

- Geodesic spiral around seed-point (Geo-Spiral).

3.1. Direction Parallel Algorithms

3.1.1. Fixed Intrinsic Angle (FInA)

3.1.2. Fixed Extrinsic Angle (FExA)

3.1.3. Seeded Ortho-Isogeodesics (Ortheo)

3.2. Contour Parallel Algorithms

3.2.1. Geodesic First in Spiral Out (Geo-FISO)

3.2.2. Geodesic Contour Parallel Spirals (Geo-Contour)

3.2.3. Geodesic Spiral around Seed-Point (Geo-Spiral)

4. Evaluation

4.1. Evaluation Criteria

4.1.1. Continuity

4.1.2. Curvature

4.1.3. Fiber Area Fraction

4.1.4. Load Adequacy

4.2. Results

4.2.1. Direction Parallel Algorithms

4.2.2. Contour Parallel Algorithms

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| CFRP | Carbon fiber reinforced polymers |

| FDM | Fused deposition modeling |

| Prepreg | Pre-impregnated |

| FEM | Finite element methods |

| FEA | Finite element analysis |

| FInA | Fixed intrinsic angle |

| FExA | Fixed extrinsic angle |

| Ortheo | Seeded ortho-isogeodesics |

| Geo-FISO | Geodesic first in spiral out |

| Geo-Contour | Geodesic contour parallel spirals |

| Geo-Spiral | Geodesic spiral around seed-point |

References

- Sanei, S.H.R.; Popescu, D. 3D-Printed Carbon Fiber Reinforced Polymer Composites: A Systematic Review. J. Compos. Sci. 2020, 4, 98. [Google Scholar] [CrossRef]

- Pandelidi, C.; Bateman, S.; Piegert, S.; Hoehner, R.; Kelbassa, I.; Brandt, M. The technology of continuous fibre-reinforced polymers: A review on extrusion additive manufacturing methods. Int. J. Adv. Manuf. Technol. 2021, 113, 3057–3077. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication-A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Becker, C.; Oberlercher, H.; Heim, R.B.; Wuzella, G.; Faller, L.M.; Riemelmoser, F.O.; Nicolay, P.; Druesne, F. Experimental Quantification of the Variability of Mechanical Properties in 3D Printed Continuous Fiber Composites. Appl. Sci. 2021, 11, 1315. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, T.; Jiang, Q.; He, L.; Bismarck, A.; Hu, Q. Recent progress of 3D printed continuous fiber reinforced polymer composites based on fused deposition modeling: A review. J. Mater. Sci. 2021, 56, 12999–13022. [Google Scholar] [CrossRef]

- Huang, H.; Liu, W.; Liu, Z. An additive manufacturing-based approach for carbon fiber reinforced polymer recycling. CIRP Ann. 2020, 69, 33–36. [Google Scholar] [CrossRef]

- Saccani, A.; Fiorini, M.; Manzi, S. Recycling of Wastes Deriving from the Production of Epoxy-Carbon Fiber Composites in the Production of Polymer Composites. Appl. Sci. 2022, 12, 4287. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, W.; Ding, X. Multi-axis additive manufacturing process for continuous fibre reinforced composite parts. Procedia CIRP 2019, 85, 114–120. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Wulle, F.; Coupek, D.; Schäffner, F.; Verl, A.; Oberhofer, F.; Maier, T. Workpiece and Machine Design in Additive Manufacturing for Multi-Axis Fused Deposition Modeling. Procedia CIRP 2017, 60, 229–234. [Google Scholar] [CrossRef]

- Kallai, Z.; Dammann, M.; Schueppstuhl, T. Operation and experimental evaluation of a 12-axis robot-based setup used for 3D-printing. In Proceedings of the ISR 2020, 52th International Symposium on Robotics, Online. 9–10 December 2020; pp. 1–9. [Google Scholar]

- Such, M.; Ward, C.; Potter, K. Aligned Discontinuous Fibre Composites: A Short History. J. Multifunct. Compos. 2014, 2, 155–168. [Google Scholar] [CrossRef]

- Chen, X.; Fang, G.; Liao, W.H.; Wang, C.C. Field-Based Toolpath Generation for 3D Printing Continuous Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2022, 49, 102470. [Google Scholar] [CrossRef]

- Li, Y.; Xu, K.; Liu, X.; Yang, M.; Gao, J.; Maropoulos, P. Stress-oriented 3D printing path optimization based on image processing algorithms for reinforced load-bearing parts. CIRP Ann. 2021, 70, 195–198. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Y.; Aburaia, M.; Lackner, M. 3D Printing of Objects with Continuous Spatial Paths by a Multi-Axis Robotic FFF Platform. Appl. Sci. 2021, 11, 4825. [Google Scholar] [CrossRef]

- Li, Y.; He, D.; Wang, X.; Tang, K. Geodesic Distance Field-based Curved Layer Volume Decomposition for Multi-Axis Support-free Printing. arXiv 2020, arXiv:2003.05938. [Google Scholar]

- Schueler, K.; Miller, J.; Hale, R. Approximate Geometric Methods in Application to the Modeling of Fiber Placed Composite Structures. J. Comput. Inf. Sci. Eng. 2004, 4, 251–256. [Google Scholar] [CrossRef]

- Han, Z.; Qiangqiang, F.; Fan, Y.; Yunzhong, F.; Hongya, F. A Path Planning Algorithm of Closed Surface for Fiber Placement. In Proceedings of the 1st International Conference on Mechanical Engineering and Material Science, Prague, Czech Republic, 28–30 December 2012; Atlantis Press: Paris, France, 2012. [Google Scholar] [CrossRef] [Green Version]

- Hély, C.; Birglen, L.; Xie, W.F. Feasibility study of robotic fibre placement on intersecting multi-axial revolution surfaces. Robot. Comput.-Integr. Manuf. 2017, 48, 73–79. [Google Scholar] [CrossRef]

- Xiao, H.; Han, W.; Tang, W.; Duan, Y. An Efficient and Adaptable Path Planning Algorithm for Automated Fiber Placement Based on Meshing and Multi Guidelines. Materials 2020, 13, 4209. [Google Scholar] [CrossRef]

- Rousseau, G.; Wehbe, R.; Halbritter, J.; Harik, R. Automated Fiber Placement Path Planning: A state-of-the-art review. Comput.-Aided Des. Appl. 2018, 16, 172–203. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Link, G.; Wang, T.; Ramopoulos, V.; Neumaier, D.; Hofele, J.; Walter, M.; Jelonnek, J. Path-designed 3D printing for topological optimized continuous carbon fibre reinforced composite structures. Compos. Part Eng. 2020, 182, 107612. [Google Scholar] [CrossRef]

- Wang, T.; Li, N.; Link, G.; Jelonnek, J.; Fleischer, J.; Dittus, J.; Kupzik, D. Load-dependent path planning method for 3D printing of continuous fiber reinforced plastics. Compos. Part Appl. Sci. Manuf. 2021, 140, 106181. [Google Scholar] [CrossRef]

- Kim, J.; Kang, B.S. Enhancing Structural Performance of Short Fiber Reinforced Objects through Customized Tool-Path. Appl. Sci. 2020, 10, 8168. [Google Scholar] [CrossRef]

- Bere, P.; Neamtu, C.; Udroiu, R. Novel Method for the Manufacture of Complex CFRP Parts Using FDM-based Molds. Polymers 2020, 12, 2220. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, C.B.; Kaszynski, A. PyVista: 3D plotting and mesh analysis through a streamlined interface for the Visualization Toolkit (VTK). J. Open Source Softw. 2019, 4, 1450. [Google Scholar] [CrossRef]

- Schroeder, W.; Martin, K.; Lorensen, B. The Visualization Toolkit—An Object-Oriented Approach to 3D Graphics, 4th ed.; Kitware, Inc.: New York, NY, USA, 2006. [Google Scholar]

- The Qt Company Ltd. Qt 5.15. Available online: https://doc.qt.io/qt-5.15/ (accessed on 2 May 2022).

- Riverbank Computing Limited. PyQt5 Reference Guide. 2021. Available online: https://www.riverbankcomputing.com/static/Docs/PyQt5/ (accessed on 2 May 2022).

- Harris, C.R.; Millman, K.J.; van der Walt, S.J.; Gommers, R.; Virtanen, P.; Cournapeau, D.; Wieser, E.; Taylor, J.; Berg, S.; Smith, N.J.; et al. Array programming with NumPy. Nature 2020, 585, 357–362. [Google Scholar] [CrossRef]

- Sharp, N. potpourri3d. 2022. Available online: https://github.com/nmwsharp/potpourri3d (accessed on 2 May 2022).

- Hagberg, A.A.; Schult, D.A.; Swart, P.J. Exploring network structure, dynamics, and function using NetworkX. In Proceedings of the 7th Python in Science Conference (SciPy2008), Pasadena, CA, USA, 19–24 August 2008; pp. 11–15. [Google Scholar]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [Green Version]

- Dawson-Haggerty, M. Trimesh. 2022. Available online: https://github.com/mikedh/trimesh (accessed on 2 May 2022).

- Matsuzaki, R.; Nakamura, T.; Sugiyama, K.; Ueda, M.; Todoroki, A.; Hirano, Y.; Yamagata, Y. Effects of Set Curvature and Fiber Bundle Size on the Printed Radius of Curvature by a Continuous Carbon Fiber Composite 3D Printer. Addit. Manuf. 2018, 24, 93–102. [Google Scholar] [CrossRef]

- Crane, K.; Weischedel, C.; Wardetzky, M. The Heat Method for Distance Computation. Commun. ACM 2017, 60, 90–99. [Google Scholar] [CrossRef]

- Harnisch, M.; Kipping, J.; Schueppstuhl, T. Evaluation of path planning strategies in automated honeycomb potting. In Proceedings of the ISR 2020, 52th International Symposium on Robotics, Online. 9–10 December 2020; pp. 1–7. [Google Scholar]

| Parameters | Results | |||||

|---|---|---|---|---|---|---|

| Surface () | Algorithm | Load Case | Mean Curv. (1%) | Fiber Area Fraction | Load Adequacy | Discontinuities |

| A | Geo-Contour | X + Y | 26.35° | 0.87 | 0.78 | 0 |

| A | FExA | X + Y | 29.7° | 0.9 | 0.82 | 0 |

| B | Geo-FISO | X + Y | 28.2° | 0.85 | 0.66 | 0 |

| B | FExA | X + Y | 39.25° | 0.92 | 0.93 | 6 |

| C | Ortheo = D | Y | 4.2° | 0.84 | 0.98 | 39 |

| C | FInA | Y | 61.55° | 0.93 | 0.85 | 0 |

| D | Geo-Spiral | Y | 43.02° | 0.33 | 0.43 | 0 |

| D | FInA | Y | 50° | 0.91 | 0.72 | 4 |

| E | FInA + FInA | X | 58.5° | 0.92 | 0.84 | 1 |

| E | Geo-Contour | X | 51.6° | 0.9 | 0.83 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kipping, J.; Kállai, Z.; Schüppstuhl, T. A Set of Novel Procedures for Carbon Fiber Reinforcement on Complex Curved Surfaces Using Multi Axis Additive Manufacturing. Appl. Sci. 2022, 12, 5819. https://doi.org/10.3390/app12125819

Kipping J, Kállai Z, Schüppstuhl T. A Set of Novel Procedures for Carbon Fiber Reinforcement on Complex Curved Surfaces Using Multi Axis Additive Manufacturing. Applied Sciences. 2022; 12(12):5819. https://doi.org/10.3390/app12125819

Chicago/Turabian StyleKipping, Johann, Zsolt Kállai, and Thorsten Schüppstuhl. 2022. "A Set of Novel Procedures for Carbon Fiber Reinforcement on Complex Curved Surfaces Using Multi Axis Additive Manufacturing" Applied Sciences 12, no. 12: 5819. https://doi.org/10.3390/app12125819

APA StyleKipping, J., Kállai, Z., & Schüppstuhl, T. (2022). A Set of Novel Procedures for Carbon Fiber Reinforcement on Complex Curved Surfaces Using Multi Axis Additive Manufacturing. Applied Sciences, 12(12), 5819. https://doi.org/10.3390/app12125819