Early Warning of the Construction Safety Risk of a Subway Station Based on the LSSVM Optimized by QPSO

Abstract

:1. Introduction

2. Related Work

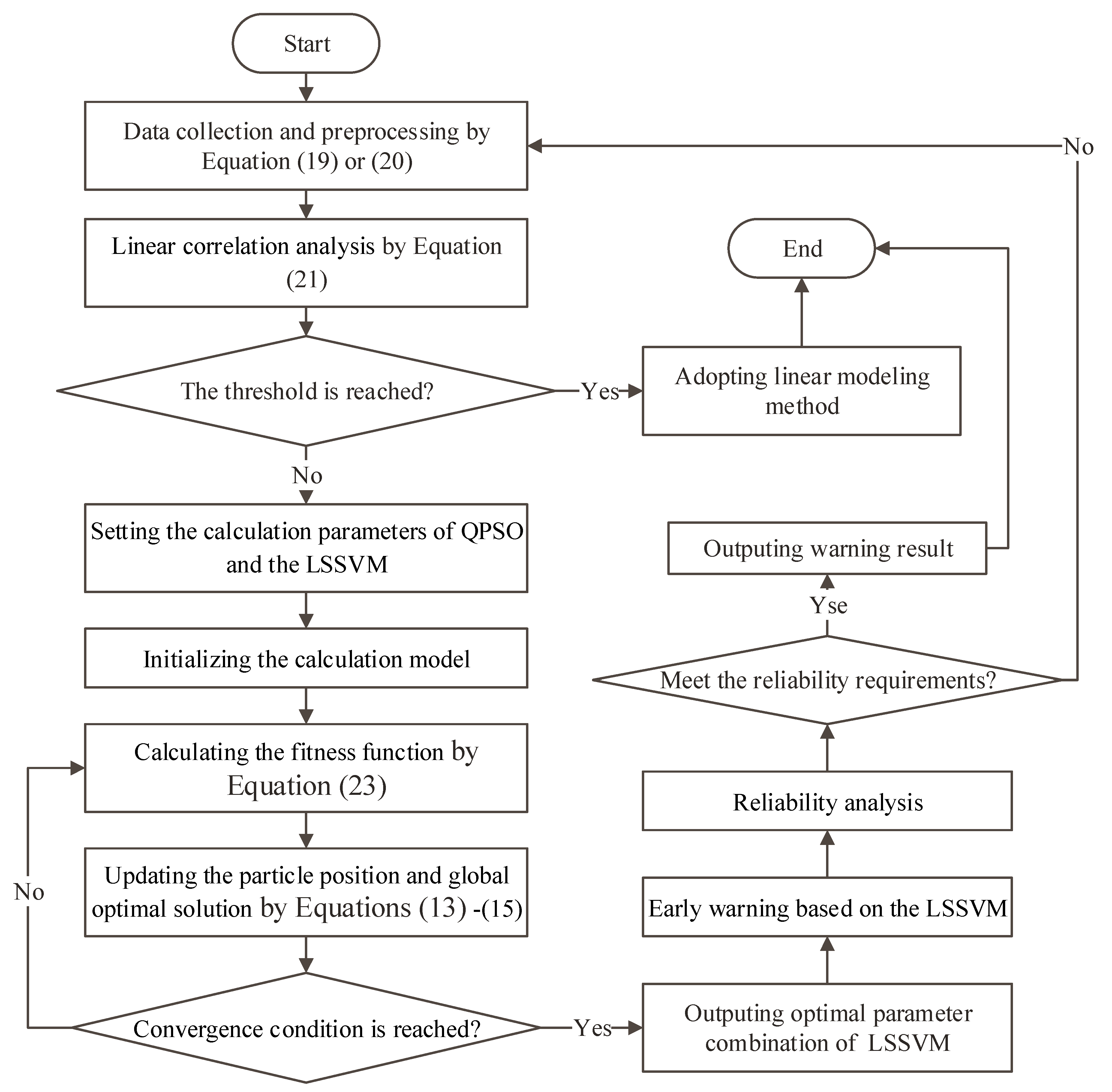

3. Early Warning Index System

3.1. Risk Identification Based on Accident Causation Theory

3.2. Early Warning Index System

3.3. Acquisition Methods of the Index Data

3.4. Classification of Early Warning Levels

4. The Early Warning Model

4.1. Introduction to QPSO

4.2. Introduction to the LSSVM

4.3. The Proposed Prediction Model

- (1)

- Setting the calculation parameters of QPSO and the LSSVM.

- (2)

- Initializing the calculation model

- (3)

- Calculating the fitness function

- (4)

- Updating the particle position and global optimal solution according to the fitness function.

- (5)

- Judging whether the convergence condition is reached.

5. Case Analysis

5.1. Project Overview and Data Acquisition

5.2. Data Preprocessing and Correlation Analysis

5.3. Early Warning of Construction Safety Risks

- (1)

- Set the parameters of algorithms

- (2)

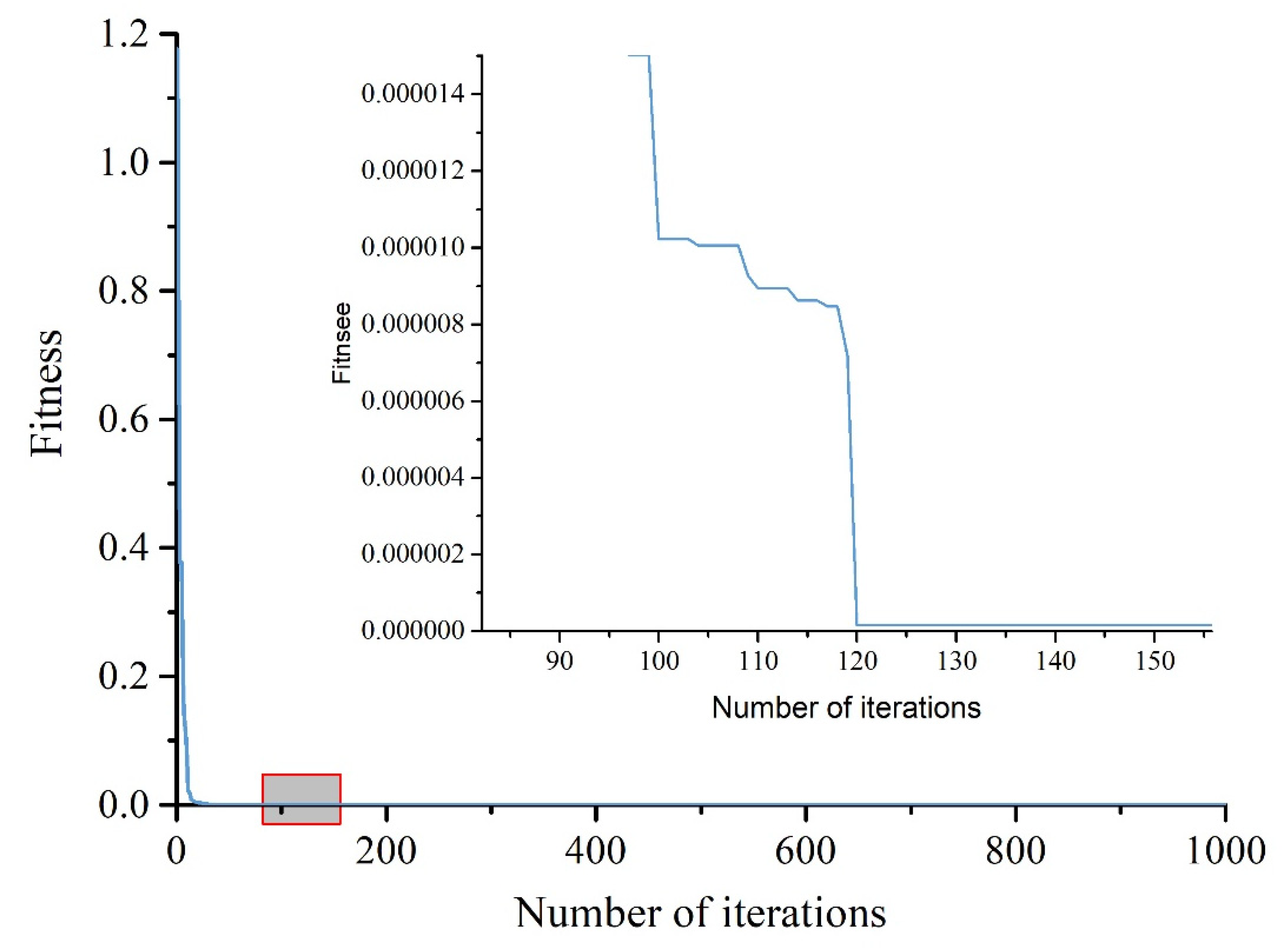

- Find the optimal parameter combination of the LSSVM based on QPSO

- (3)

- Construction of the early warning model based on the LSSVM

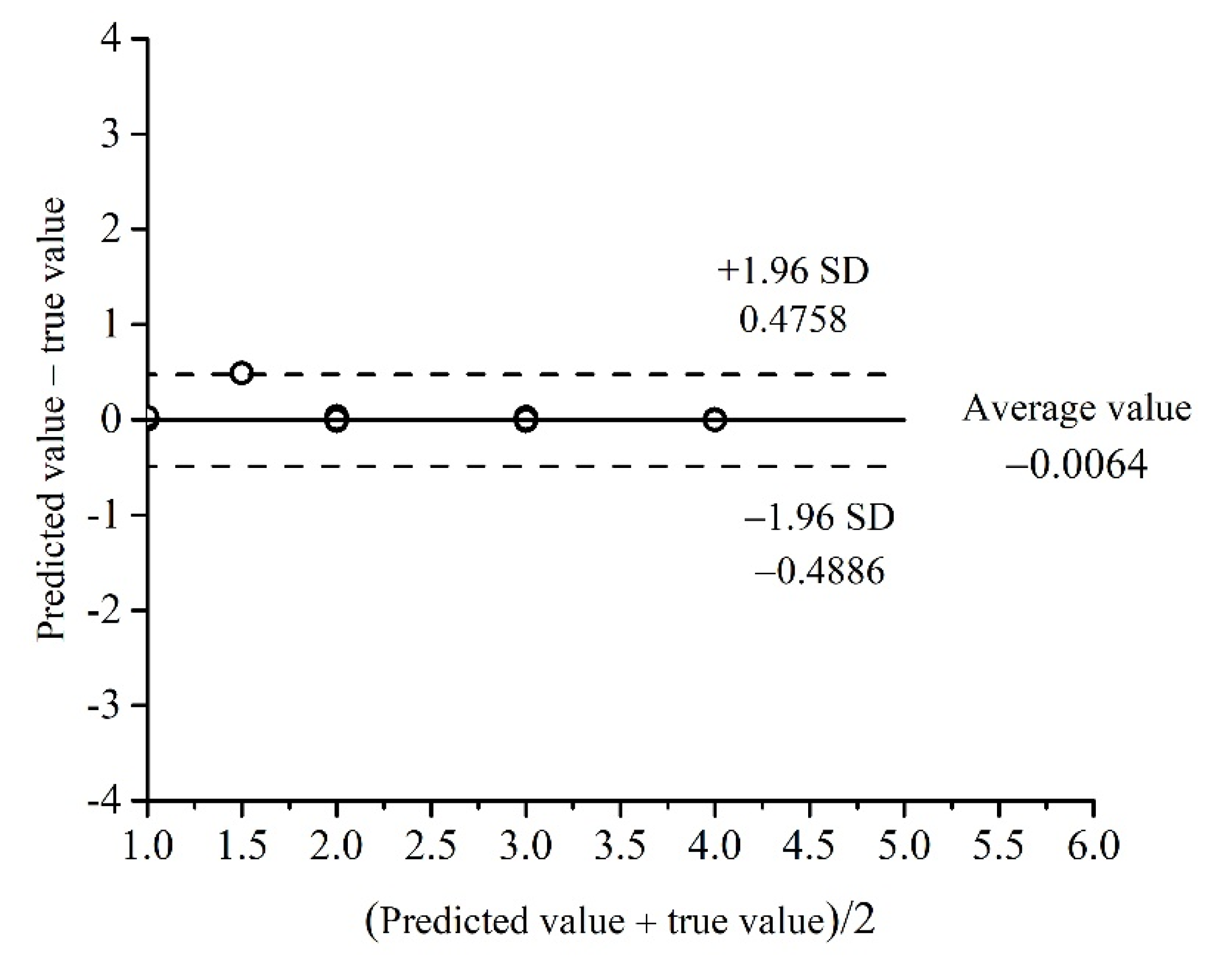

5.4. Reliability Analysis of Early Warning Results

6. Discussion

6.1. Computational Performance of Different Optimization Algorithms

6.2. Computational Performance of Different Prediction Methods

6.3. The Influence of the Different Ratios of Training Sets and Test Sets

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haddad, E.A.; Hewings, G.J.D.; Porsse, A.A.; Van Leeuwen, E.S.; Vieira, R.S. The underground economy: Tracking the higher-order economic impacts of the Sao Paulo Subway System. Transp. Res. Part A Policy Pract. 2015, 73, 18–30. [Google Scholar] [CrossRef]

- Zhou, Z.; Irizarry, J.; Li, Q. Using network theory to explore the complexity of subway construction accident network (SCAN) for promoting safety management. Saf. Sci. 2014, 64, 127–136. [Google Scholar] [CrossRef]

- Merz, B.; Kuhlicke, C.; Kunz, M.; Pittore, M.; Babeyko, A.; Bresch, D.N.; Domeisen, D.I.V.; Feser, F.; Koszalka, I.; Kreibich, H.; et al. Impact Forecasting to Support Emergency Management of Natural Hazards. Rev. Geophys. 2020, 58, e2020RG000704. [Google Scholar] [CrossRef]

- Liu, L.; Wu, H.; Wang, J.; Yang, T. Research on the evaluation of the resilience of subway station projects to waterlogging disasters based on the projection pursuit model. Math. Biosci. Eng. 2020, 17, 7302–7331. [Google Scholar] [CrossRef]

- Sjekavica Klepop, M.; Radujkovic, M. Early Warning System in Managing Water Infrastructre Projects. J. Civ. Eng. Manag. 2019, 25, 531–550. [Google Scholar] [CrossRef] [Green Version]

- Qiu, H.; Yu, X.; Dong, J. Risk Factor Prediction Model of Oil and Gas Construction Project Based on Combination Mathematical Model. Ekoloji 2019, 28, 4033–4043. [Google Scholar]

- Senthil, J.; Muthukannan, M. Predication of construction risk management in modified historical simulation statistical methods. Ecol. Inform. 2021, 66, 101439. [Google Scholar] [CrossRef]

- Yadav, A.K.; Chandel, S.S. Identification of relevant input variables for prediction of 1-minute time step photovoltaic module power using Artificial Neural Network and Multiple Linear Regression Models. Renew. Sustain. Energy Rev. 2017, 77, 955–969. [Google Scholar] [CrossRef]

- Shen, T.; Nagai, Y.; Gao, C. Design of building construction safety prediction model based on optimized BP neural network algorithm. Soft Comput. 2020, 24, 7839–7850. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Ali, Z.H.; Salih, S.Q.; Al-Ansari, N. Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model. Sustainability 2020, 12, 1514. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Xie, M.; Bian, J.; Li, H.; Song, L. A Hybrid PSO-SVM Model Based on Safety Risk Prediction for the Design Process in Metro Station Construction. Int. J. Environ. Res. Public Health 2020, 17, 1714. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yusuf, F.; Olayiwola, T.; Afagwu, C. Application of Artificial Intelligence-based predictive methods in Ionic liquid studies: A review. Fluid Phase Equilibria 2021, 531, 112898. [Google Scholar] [CrossRef]

- Huang, J.; Liang, Y.; Bian, H.; Wang, X. Using Cluster Analysis and Least Square Support Vector Machine to Predicting Power Demand for the Next-Day. IEEE Access 2019, 7, 82681–82692. [Google Scholar] [CrossRef]

- Zeng, F.; Nait Amar, M.; Mohammed, A.S.; Motahari, M.R.; Hasanipanah, M. Improving the performance of LSSVM model in predicting the safety factor for circular failure slope through optimization algorithms. Eng. Comput. 2021. [Google Scholar] [CrossRef]

- Cui, G.; Xiong, S.; Zhou, C.; Liu, Z. Research on HC-LSSVM Model for Soft Soil Settlement Prediction Based on Homotopy Continuation Method. Appl. Sci. 2021, 11, 10666. [Google Scholar] [CrossRef]

- Zhu, X.; Ma, S.-q.; Xu, Q.; Liu, W.-d. A WD-GA-LSSVM model for rainfall-triggered landslide displacement prediction. J. Mt. Sci. 2018, 15, 156–166. [Google Scholar] [CrossRef]

- Noori, A.M.; Mikaeil, R.; Mokhtarian, M.; Haghshenas, S.S.; Foroughi, M. Feasibility of Intelligent Models for Prediction of Utilization Factor of TBM. Geotech. Geol. Eng. 2020, 38, 3125–3143. [Google Scholar] [CrossRef]

- Sun, J.; Wu, X.; Palade, V.; Fang, W.; Lai, C.-H.; Xu, W. Convergence analysis and improvements of quantum-behaved particle swarm optimization. Inf. Sci. 2012, 193, 81–103. [Google Scholar] [CrossRef]

- Alajmi, M.S.; Almeshal, A.M. Prediction and Optimization of Surface Roughness in a Turning Process Using the ANFIS-QPSO Method. Materials 2020, 13, 2986. [Google Scholar] [CrossRef]

- Yang, L.; Fu, Y.; Wang, Z.; Zhen, X.; Yang, Z.; Fan, X. An Optimized Level Set Method Based on QPSO and Fuzzy Clustering. IEICE Trans. Inf. Syst. 2019, E102D, 1065–1072. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Fang, W.; Wang, D.; Xu, W. Solving the economic dispatch problem with a modified quantum-behaved particle swarm optimization method. Energy Convers. Manag. 2009, 50, 2967–2975. [Google Scholar] [CrossRef]

- Singh, J.; Verma, A.K.; Banka, H.; Singh, T.N.; Maheshwar, S. A study of soft computing models for prediction of longitudinal wave velocity. Arab. J. Geosci. 2016, 9, 224. [Google Scholar] [CrossRef]

- Hyungju, K.; Stein, H.; Bouwer, U.I. Assessment of accident theories for major accidents focusing on the MV SEWOL disaster: Similarities, differences, and discussion for a combined approach. Saf. Sci. 2016, 82, 410–420. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.; Liang, W. An Accident Causation Analysis and Taxonomy (ACAT) model of complex industrial system from both system safety and control theory perspectives. Saf. Sci. 2017, 92, 94–103. [Google Scholar] [CrossRef]

- Zhang, S.; Sunindijo, R.Y.; Loosemore, M.; Wang, S.; Gu, Y.; Li, H. Identifying critical factors influencing the safety of Chinese subway construction projects. Eng. Constr. Archit. Manag. 2021, 28, 1863–1886. [Google Scholar] [CrossRef]

- Yue, Y.; Xiahou, X.; Li, Q. Critical Factors of Promoting Design for Safety in China’s Subway Engineering Industry. Int. J. Environ. Res. Public Health 2020, 17, 3373. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J. Assessment of Waterlogging Risk in the Deep Foundation Pit Projects Based on Projection Pursuit Model. Adv. Civ. Eng. 2020, 2020, 2569531. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H. Integrated assessment of ecological risk for multi-hazards in Guangdong province in southeastern China. Geomat. Nat. Hazards Risk 2019, 10, 2069–2093. [Google Scholar] [CrossRef]

- Xia, C.; Nie, G.; Li, H.; Fan, X.; Yang, R. Study on the seismic lethal level of buildings and seismic disaster risk in Guangzhou, China. Geomat. Nat. Hazards Risk 2022, 13, 800–829. [Google Scholar] [CrossRef]

- Zhou, M.; Kuang, Y.; Ruan, Z.; Xie, M. Geospatial modeling of the tropical cyclone risk in the Guangdong Province, China. Geomat. Nat. Hazards Risk 2021, 12, 2931–2955. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J. A Method for Prediction of Waterlogging Economic Losses in a Subway Station Project. Mathematics 2021, 9, 1421. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, T. Prediction of subgrade elastic moduli in different seasons based on BP neural network technology. Road Mater. Pavement Des. 2018, 19, 271–288. [Google Scholar] [CrossRef]

- Ahmadi, H.; Ahmadi, H.; Baghban, A. Modeling vaporization enthalpy of pure hydrocarbons and petroleum fractions using LSSVM approach. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 569–576. [Google Scholar] [CrossRef]

- Bujang, M.A.; Omar, E.D.; Baharum, N.A. A Review on Sample Size Determination for Cronbach’s Alpha Test: A Simple Guide for Researchers. Malays. J. Med. Sci. 2018, 25, 85–99. [Google Scholar] [CrossRef]

- Salemi, A.; Mikaeil, R.; Haghshenas, S.S. Integration of Finite Difference Method and Genetic Algorithm to Seismic analysis of Circular Shallow Tunnels (Case Study: Tabriz Urban Railway Tunnels). KSCE J. Civ. Eng. 2018, 22, 1978–1990. [Google Scholar] [CrossRef]

- Mikaeil, R.; Haghshenas, S.S.; Sedaghati, Z. Geotechnical risk evaluation of tunneling projects using optimization techniques (case study: The second part of Emamzade Hashem tunnel). Nat. Hazards 2019, 97, 1099–1113. [Google Scholar] [CrossRef]

- Huang, G.; Huang, G.-B.; Song, S.; You, K. Trends in extreme learning machines: A review. Neural Netw. 2015, 61, 32–48. [Google Scholar] [CrossRef]

- Verma, A.K.; Sirvaiya, A. Comparative analysis of intelligent models for prediction of Langmuir constants for CO2 adsorption of Gondwana coals in India. Geomech. Geophys. Geo-Energy Geo-Resour. 2016, 2, 97–109. [Google Scholar] [CrossRef] [Green Version]

| No. | Position | Length of Work Years | Title | Number of Subway Projects Involved |

|---|---|---|---|---|

| (1) | Contractor | 16 | Senior engineer | 47 |

| (2) | Contractor | 21 | Senior engineer | 38 |

| (3) | Contractor | 28 | Senior engineer | 27 |

| (4) | Contractor | 25 | Senior engineer | 30 |

| (5) | Contractor | 10 | Senior engineer | 35 |

| (6) | Design | 35 | Senior engineer | 147 |

| (7) | Design | 38 | Senior engineer | 205 |

| (8) | Government | 12 | Senior engineer | 7 |

| (9) | Government | 5 | Intermediate engineer | 5 |

| (10) | Academy | 35 | Professor | 16 |

| Primary Index | Secondary Index | Unit |

|---|---|---|

| : Man | : Rate of operation violation | % |

| : Rate of technical failure | % | |

| : Emergency handling | - | |

| : Rate of monitoring error | % | |

| : Proportion of old workers | % | |

| : Machine | : Rate of mechanical quality failure | % |

| : Rate of mechanical installation failure | % | |

| : Rate of mechanical maintenance failure | % | |

| : Material | : Qualified rate of concrete | % |

| : Qualified rate of steel | % | |

| : Rate of material supply | % | |

| : Rate of material stacking error | % | |

| : Environment | : Maximum deformation of foundation pit | mm |

| : 24-h maximum rainfall | mm | |

| : Poor geological conditions | - | |

| : Poor geomorphic conditions | - | |

| : Extreme weather conditions | - | |

| : Management | : Efficiency of communication | - |

| : Team cohesion | - | |

| : Rate of personnel change | % | |

| : Rationality of organization | - |

| Indexes | I | II | III | IV | V |

|---|---|---|---|---|---|

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (%) | |||||

| (mm) | |||||

| (mm) | |||||

| Rarely | A few | Acceptable | Many | Too many | |

| Rarely | A few | Acceptable | Many | Too many | |

| Rarely | A few | Acceptable | Many | Too many | |

| Very efficient | Efficient | Acceptable | Inefficient | Very inefficient | |

| Very good | Good | Acceptable | Bad | Very bad | |

| Very reasonable | Reasonable | Acceptable | Unreasonable | Completely unreasonable |

| Station | Maximum Excavation Depth | Regional Characteristics | Contractor | Adverse Conditions |

|---|---|---|---|---|

| Huilong Boulevard Station | 21.26 m | Urban region under construction | CCTEB | Abandoned pipe gallery, high slope |

| Science Park Station | 18.65 m | Urban region under construction | CCTEB | Abandoned pipe gallery |

| Science Park East Station | 19.75 m | Urban region under construction | CCTEB | Fish pond, gas pipeline, high-voltage electric tower |

| Science Park South Station | 25.18 m | Urban region under construction | CCTEB | Rivers, high gas |

| Wan’an Station | 21.45 m | Urban region under construction | CCTEB | Multiple ponds, high gas |

| Lushan Boulevard Station | 28.84 m | Established urban region | CCTEB | Under a bridge, high gas. |

| Shenyang Road Station | 19.45 m | Established urban region | CSCRIE | Many ponds and rivers, high-voltage lines, high gas. |

| Dakoujing Station | 18.46 m | Established urban region | CSCRIE | Many projects under construction, high gas |

| Miaoyan Station | 26.47 m | Established urban region | CCTEB | High gas |

| Tianfu CBD North Station | 28.80 m | Urban region under construction | CSCRIE | High voltage tower |

| Tianfu CBD East Station | 22.50 m | Urban region under construction | CSCRIE | Large bridge |

| Guobin Boulevard station | 24.37 m | Urban region under construction | CSCRIE | Utility tunnel, underpass tunnel, viaduct |

| Lujiao Village Station | 19.57 m | Urban region under construction | CSCRIE | Ponds, chemical tanks, high-voltage wire towers, projects under construction |

| Diaoyuzui East Station | 18.50 m | Suburban region | CCTEB | Ponds |

| Diaoyuzui Station | 19.85 m | Suburban region | CCTEB | Flood channel, high slope, landscape bridge |

| Huilong Road Station | 20.75 m | Suburban region | CCTEB | Low terrain, rivers, existing subway line |

| Huilonglu West station | 22.46 m | Suburban region | CCTEB | Ponds, slopes, rivers |

| No. | 1 | 2 | 3 | 4 | 5 | 257 | 258 | 259 | 260 | 261 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Risk Level | II | III | I | II | II | IV | II | II | I | III | |

| 1.47 | 3.45 | 0.12 | 2.62 | 0.88 | 4.01 | 1.34 | 5.76 | 4.90 | 2.62 | ||

| 5.89 | 5.9 | 8.04 | 2.52 | 4.11 | 2.77 | 6.08 | 7.93 | 7.26 | 2.44 | ||

| 5 | 4 | 0 | 1 | 5 | 13 | 9 | 1 | 7 | 3 | ||

| 5.46 | 2.47 | 3.19 | 9.94 | 4.61 | 10.07 | 6.65 | 2.96 | 5.41 | 9.86 | ||

| 10.90 | 21.81 | 13.73 | 18.50 | 6.82 | 10.92 | 7.46 | 20.35 | 10.14 | 5.37 | ||

| 3.18 | 3.76 | 4.50 | 3.69 | 2.67 | 1.71 | 4.80 | 4.49 | 4.10 | 3.36 | ||

| 0.21 | 1.62 | 0.06 | 0.87 | 1.64 | 1.07 | 1.86 | 0.29 | 1.29 | 2.00 | ||

| 0.29 | 5.54 | 6.54 | 2.97 | 3.74 | 5.12 | 3.26 | 5.33 | 5.98 | 5.65 | ||

| 98.77 | 99.15 | 99.55 | 99.68 | 99.64 | 98.77 | 99.66 | 98.92 | 98.44 | 98.94 | ||

| 99.58 | 98.5 | 98.18 | 99.51 | 98.67 | 99.97 | 99.21 | 98.98 | 99.71 | 98.70 | ||

| 99.67 | 97.10 | 97.98 | 97.77 | 95.19 | 95.91 | 98.23 | 95.99 | 97.10 | 96.69 | ||

| 2.45 | 3.58 | 2.93 | 2.77 | 0.49 | 1.29 | 1.26 | 3.24 | 0.84 | 2.10 | ||

| 28.20 | 21.03 | 24.14 | 7.90 | 21.41 | 33.33 | 6.98 | 13.01 | 30.57 | 6.90 | ||

| 167 | 0 | 0 | 5 | 55 | 0 | 0 | 15 | 120 | 10 | ||

| 34.5 | 35 | 37.5 | 44 | 33.5 | 38 | 47.5 | 35 | 46 | 49 | ||

| 65 | 71 | 74.5 | 13 | 36 | 52 | 51.5 | 57 | 85 | 73.5 | ||

| 30 | 32.5 | 36 | 10 | 22.5 | 27 | 24.5 | 28 | 29.5 | 19 | ||

| 10 | 14.5 | 19 | 13.5 | 13 | 18 | 10.5 | 20 | 12.5 | 15.5 | ||

| 11 | 19.5 | 180 | 16 | 19.5 | 17 | 17.5 | 18 | 13 | 16 | ||

| 13.58 | 12.57 | 13.98 | 14.69 | 18.69 | 15.19 | 15.89 | 11.99 | 13.43 | 18.51 | ||

| 24 | 24.5 | 27 | 26.5 | 17 | 16.5 | 26 | 14.5 | 11 | 12.5 |

| Secondary index | |||||||

| Pearson correlation coefficient | −0.4871 | −0.7124 | 0.5767 | −0.7521 | 0.1574 | 0.8017 | −0.2578 |

| Secondary index | |||||||

| Pearson correlation coefficient | −0.7533 | 0.4297 | 0.8746 | 0.3325 | −0.1247 | 0.7197 | −0.5427 |

| Secondary index | |||||||

| Pearson correlation coefficient | 0.3475 | 0.2458 | −0.3462 | 0.746 | 0.3024 | −0.7003 | −0.2467 |

| Iterations | Fitness of the k − 1 Iteration | Fitness of the k Iteration | Accuracy | Continue? |

|---|---|---|---|---|

| 118 | 0.0000084643 | 0.0000084643 | 0 < 0.0000001 | Yes |

| 119 | 0.0000084643 | 0.0000071867 | 0.0000012776 > 0.0000001 | Yes |

| 120 | 0.0000071867 | 0.0000001597 | 0.0000070270 > 0.0000001 | Yes |

| 1000 | 0.0000001597 | 0.0000001597 | 0 < 0.0000001 | No |

| Test Set | Actual Risk | The Predicted Results | Test Set | Actual Risk | The Predicted Results |

|---|---|---|---|---|---|

| 1 | II | II (2.003) | 141 | III | III (2.985) |

| 11 | II | II (1.986) | 151 | I | II (1.975) |

| 21 | III | III (3.014) | 161 | II | II (2.037) |

| 31 | I | I (0.997) | 171 | III | III (3.004) |

| 41 | IV | IV (4.006) | 181 | IV | IV (3.995) |

| 51 | II | II (2.013) | 191 | II | II (2.007) |

| 61 | I | I (1.012) | 201 | III | III (3.014) |

| 71 | II | II (2.004) | 211 | I | I (1.005) |

| 81 | III | III (2.987) | 221 | II | II (2.003) |

| 91 | I | I (1.001) | 231 | III | III (3.014) |

| 101 | III | III (3.027) | 241 | I | I (1.027) |

| 111 | II | II (2.001) | 251 | II | II (2.002) |

| 121 | I | I (1.000) | 261 | III | III (2.999) |

| 131 | II | II (1.998) | - | - | - |

| Optimization Algorithm | Average Number of Misjudgments | Average Prediction Error | Average Calculation Time | Average Iteration Times at Convergence |

|---|---|---|---|---|

| TE | 4.14 | 24.35% | - | - |

| GA | 1.01 | 5.94% | 1574.24 | 574.14 |

| PSO | 1.27 | 7.47% | 654.04 | 377.08 |

| GSA | 1.05 | 6.18% | 317.17 | 229.07 |

| WOA | 1.24 | 7.29% | 357.81 | 197.43 |

| QPSO | 0.75 | 4.41% | 203.38 | 134.71 |

| Early Warning Model | QPSO-BP | QPSO-ELM | QPSO-LSSVM |

|---|---|---|---|

| Average number of misjudgments | 3.28 | 1.74 | 0.75 |

| Average prediction error | 19.29% | 10.24% | 4.41% |

| Average calculation time | 687.52 | 374.24 | 203.38 |

| Average iteration times at convergence | 439.34 | 233.01 | 134.71 |

| Ratio of Training Set and Test Set | Average Number of Misjudgments | Average Prediction Error | Bland–Altman Analysis |

|---|---|---|---|

| 247:14 94.64%:5.36% | 0.23 | 1.64% | Pass |

| 234:17 89.66%:10.34% | 0.75 | 4.41% | Pass |

| 208:53 79.69%:20.31% | 2.26 | 4.26% | Pass |

| 182:79 69.73%:30.27% | 7.54 | 9.54% | Fail |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wang, J.; Wu, H.; Wu, M.; Guo, J.; Wang, S. Early Warning of the Construction Safety Risk of a Subway Station Based on the LSSVM Optimized by QPSO. Appl. Sci. 2022, 12, 5712. https://doi.org/10.3390/app12115712

Zhang L, Wang J, Wu H, Wu M, Guo J, Wang S. Early Warning of the Construction Safety Risk of a Subway Station Based on the LSSVM Optimized by QPSO. Applied Sciences. 2022; 12(11):5712. https://doi.org/10.3390/app12115712

Chicago/Turabian StyleZhang, Leian, Junwu Wang, Han Wu, Mengwei Wu, Jingyi Guo, and Shengmin Wang. 2022. "Early Warning of the Construction Safety Risk of a Subway Station Based on the LSSVM Optimized by QPSO" Applied Sciences 12, no. 11: 5712. https://doi.org/10.3390/app12115712

APA StyleZhang, L., Wang, J., Wu, H., Wu, M., Guo, J., & Wang, S. (2022). Early Warning of the Construction Safety Risk of a Subway Station Based on the LSSVM Optimized by QPSO. Applied Sciences, 12(11), 5712. https://doi.org/10.3390/app12115712