On-Site Full-Scale Load Test and Reliability Evaluation of Prefabricated Bridge Substructure for “Pile–Column Integration”

Abstract

:1. Introduction

2. Materials and Methods

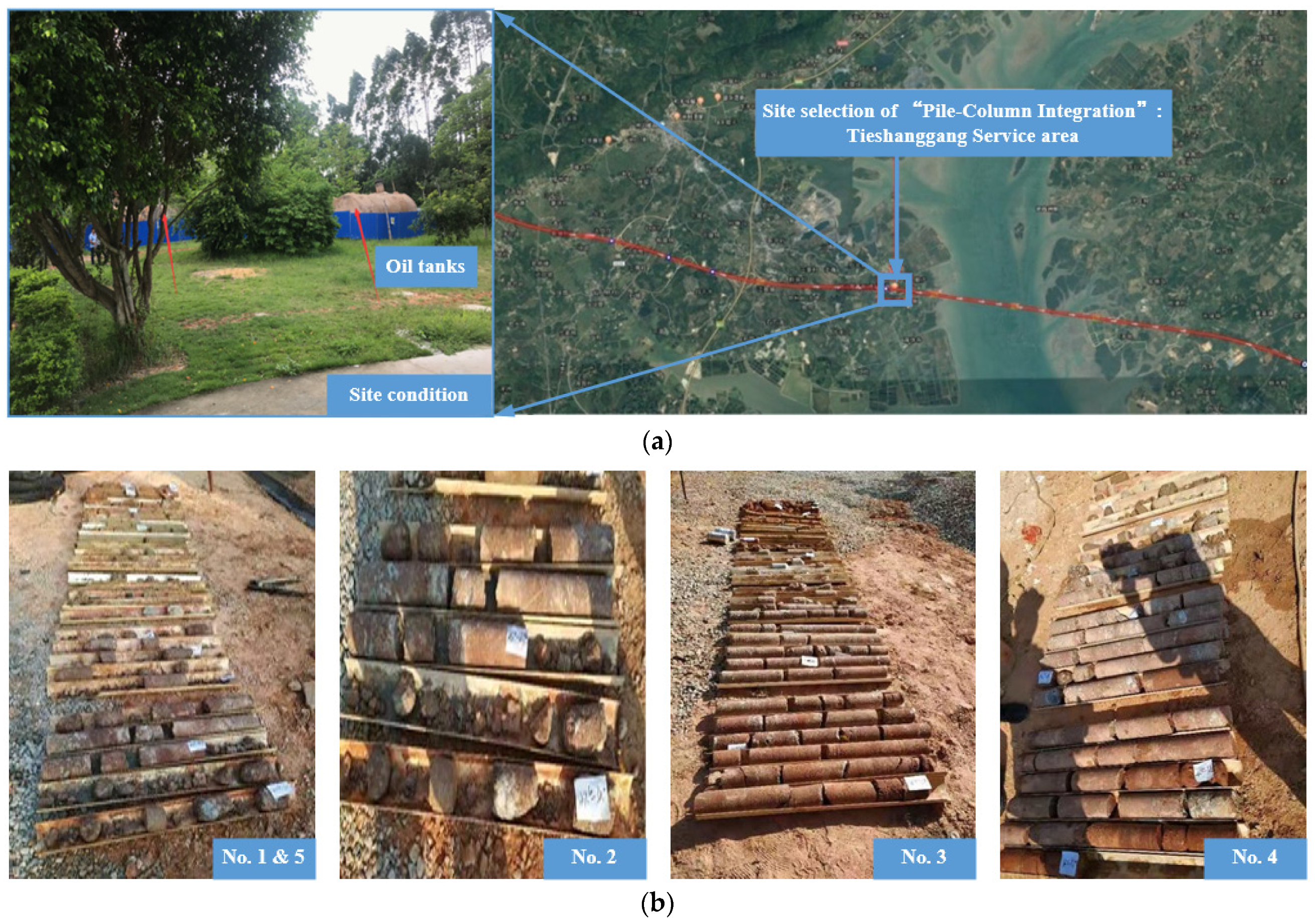

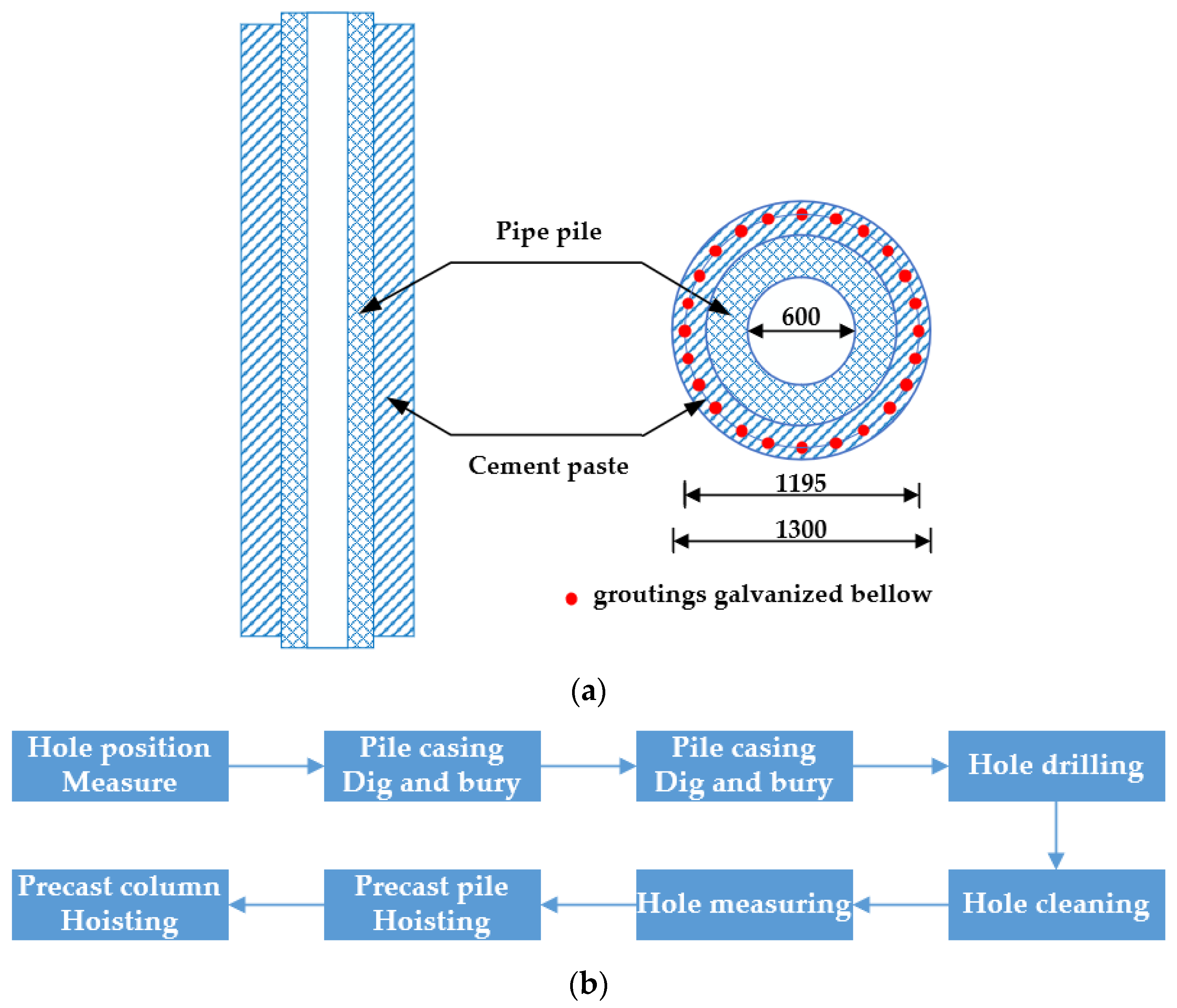

2.1. Description of Engineering Project and Geology Condition

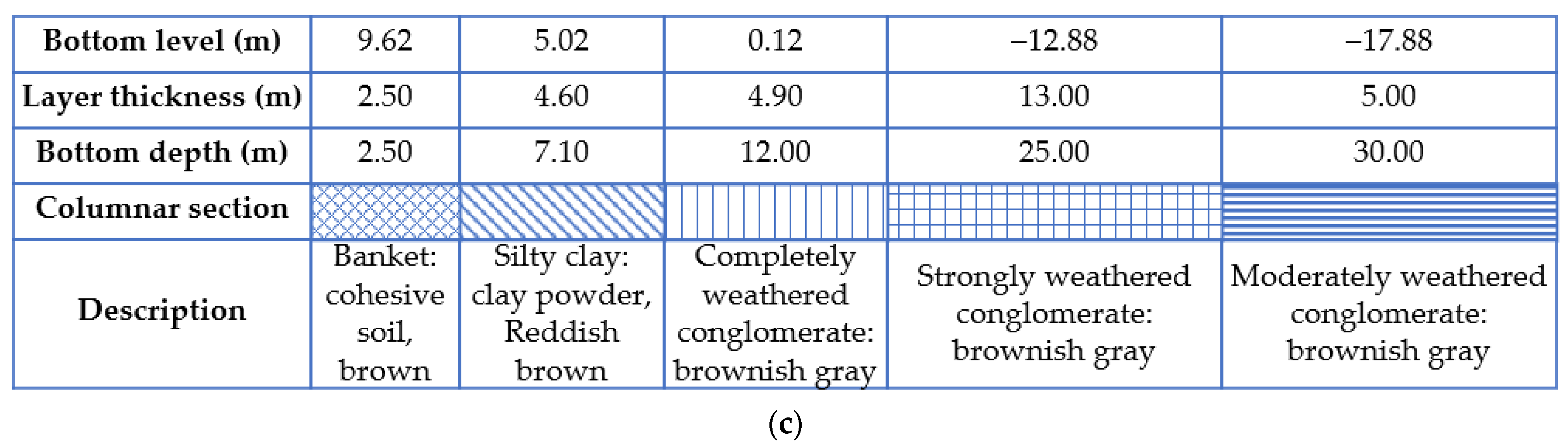

2.2. Raw Materials and Bridge Substructure

2.2.1. Main Materials and Properties

2.2.2. Model of Bridge Substructure

2.3. Experimental Methods

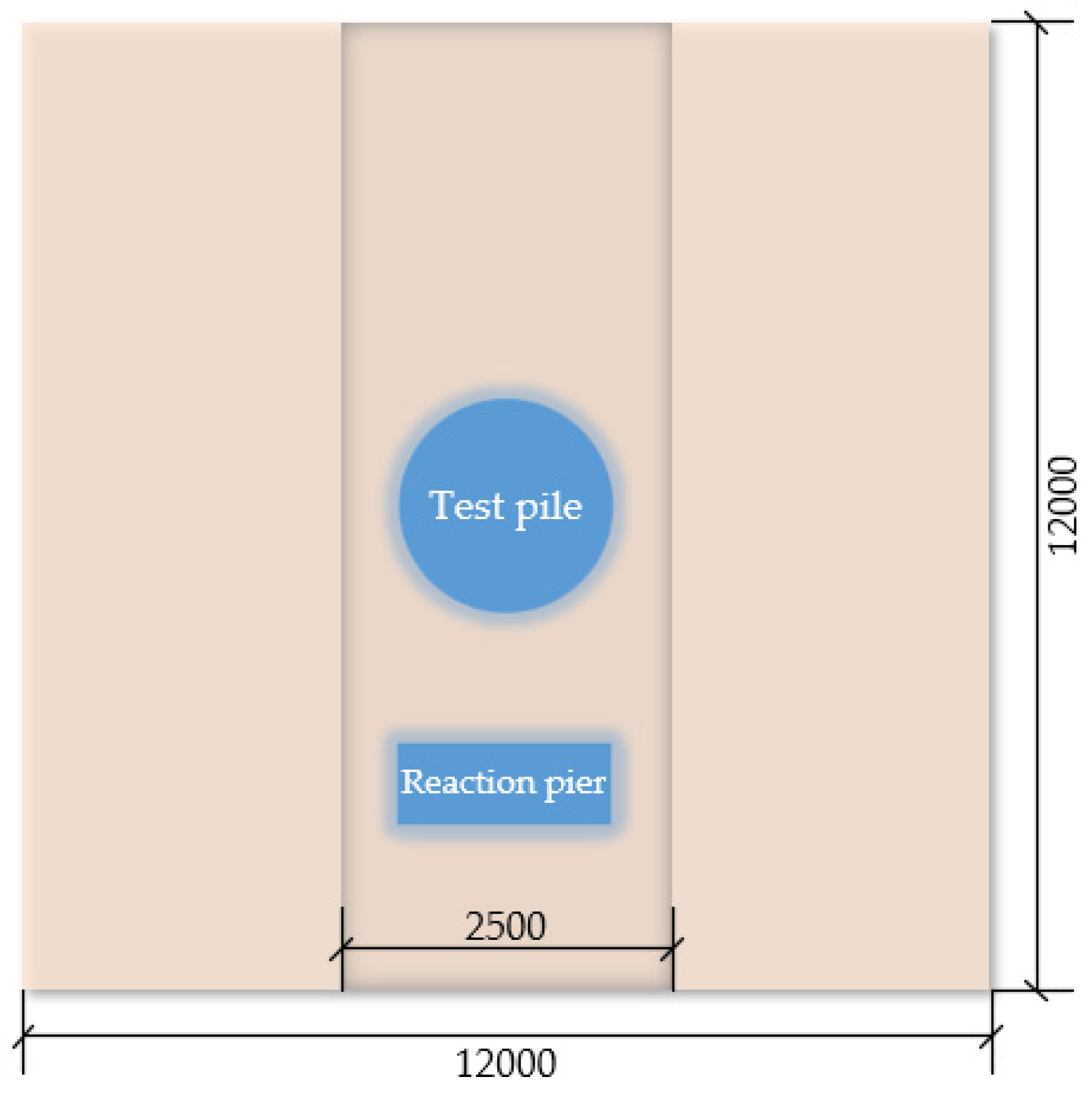

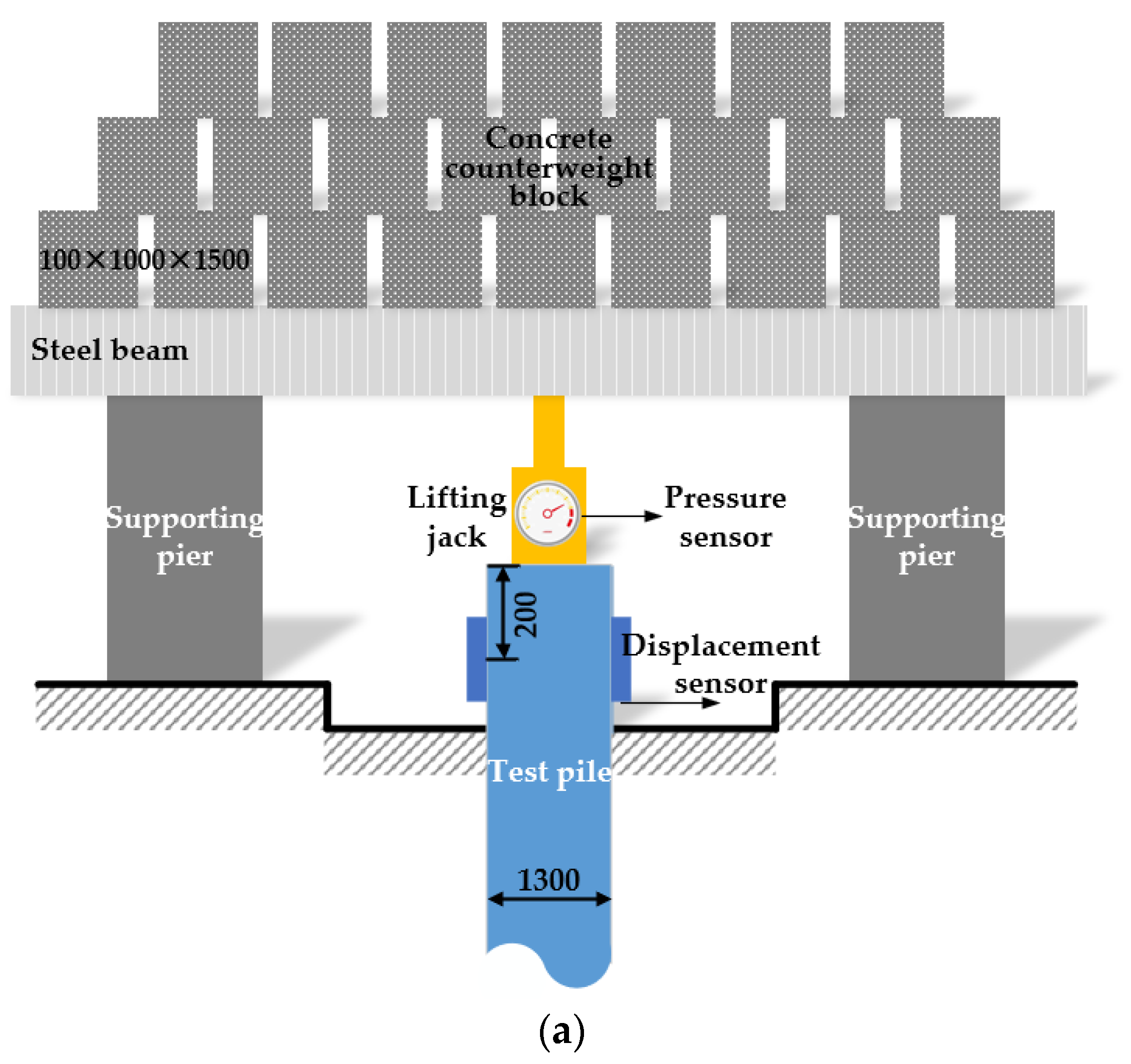

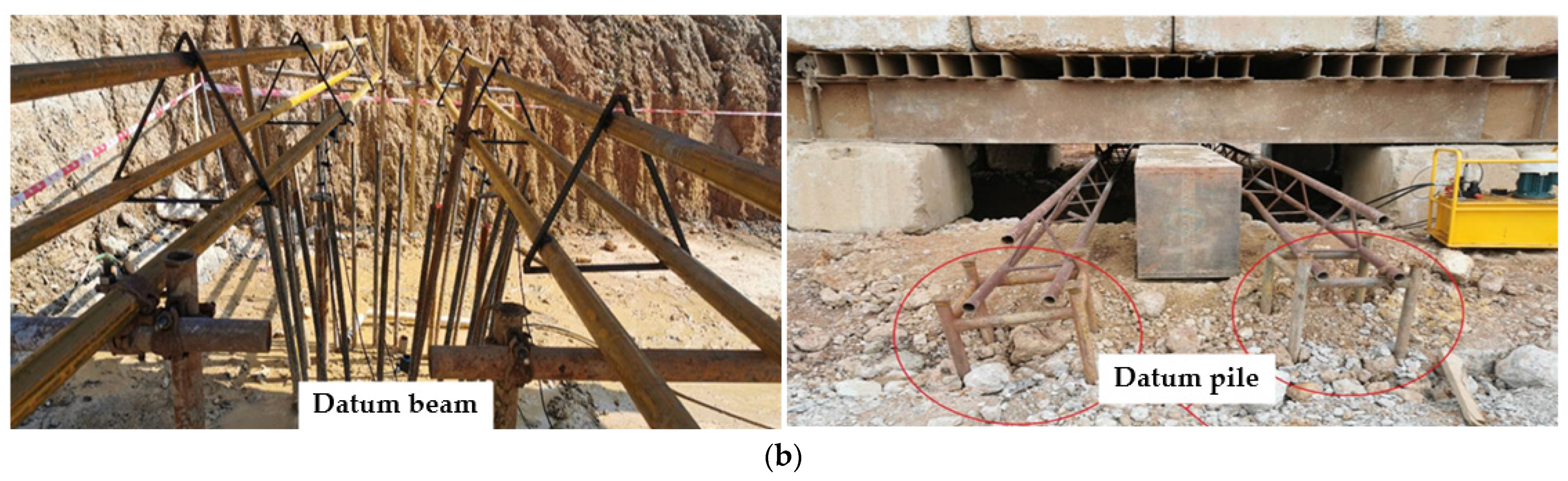

2.3.1. Vertical Compressive Static Load Test of Single Pile

- Preparation before vertical compressive static load test of single pile:

- Soil treatment around the pile

- Construction of ballast platform

- Sensor installation and system detection.

- 2.

- Test loading method and displacement observation

- Test loading method

- Displacement observation

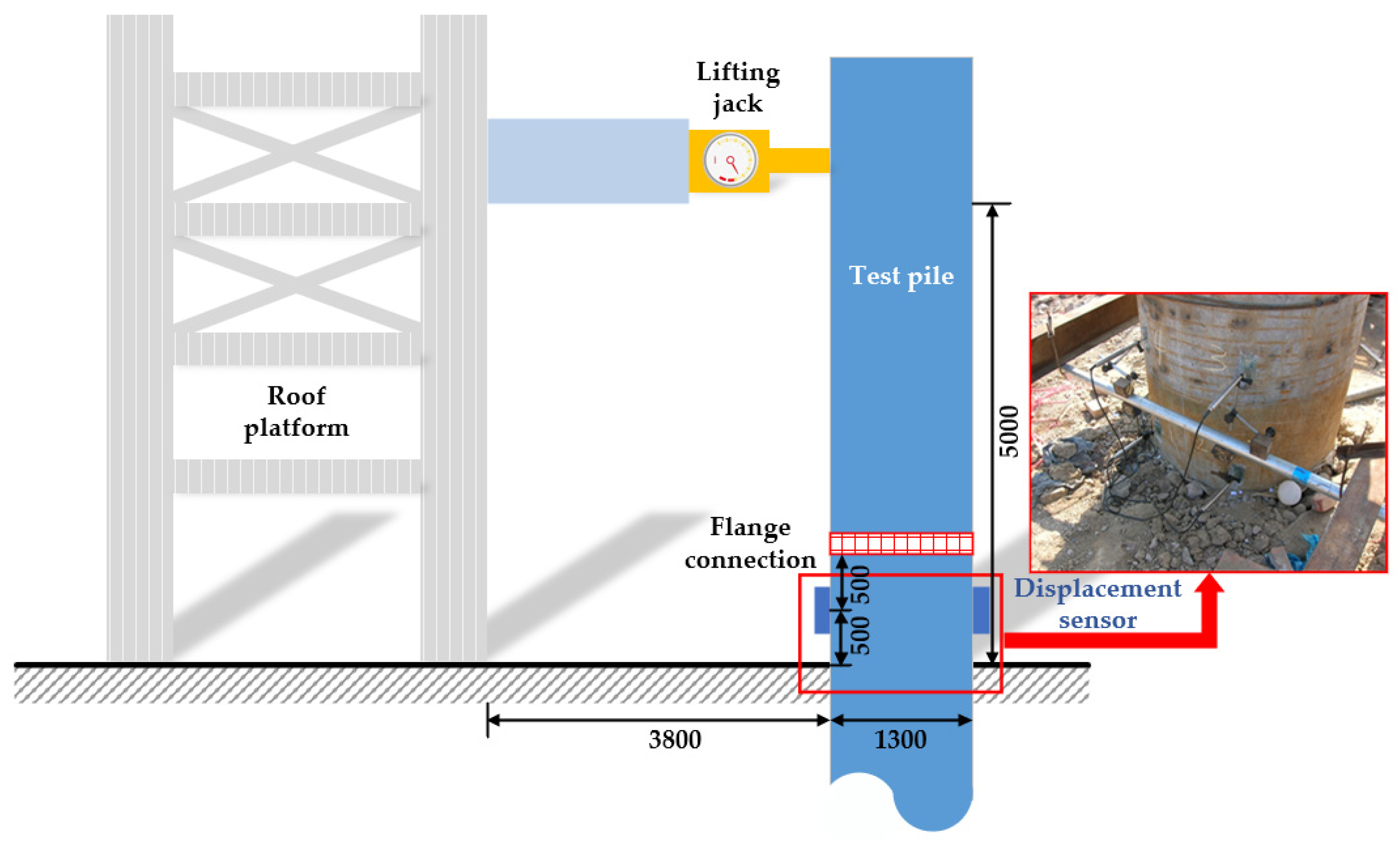

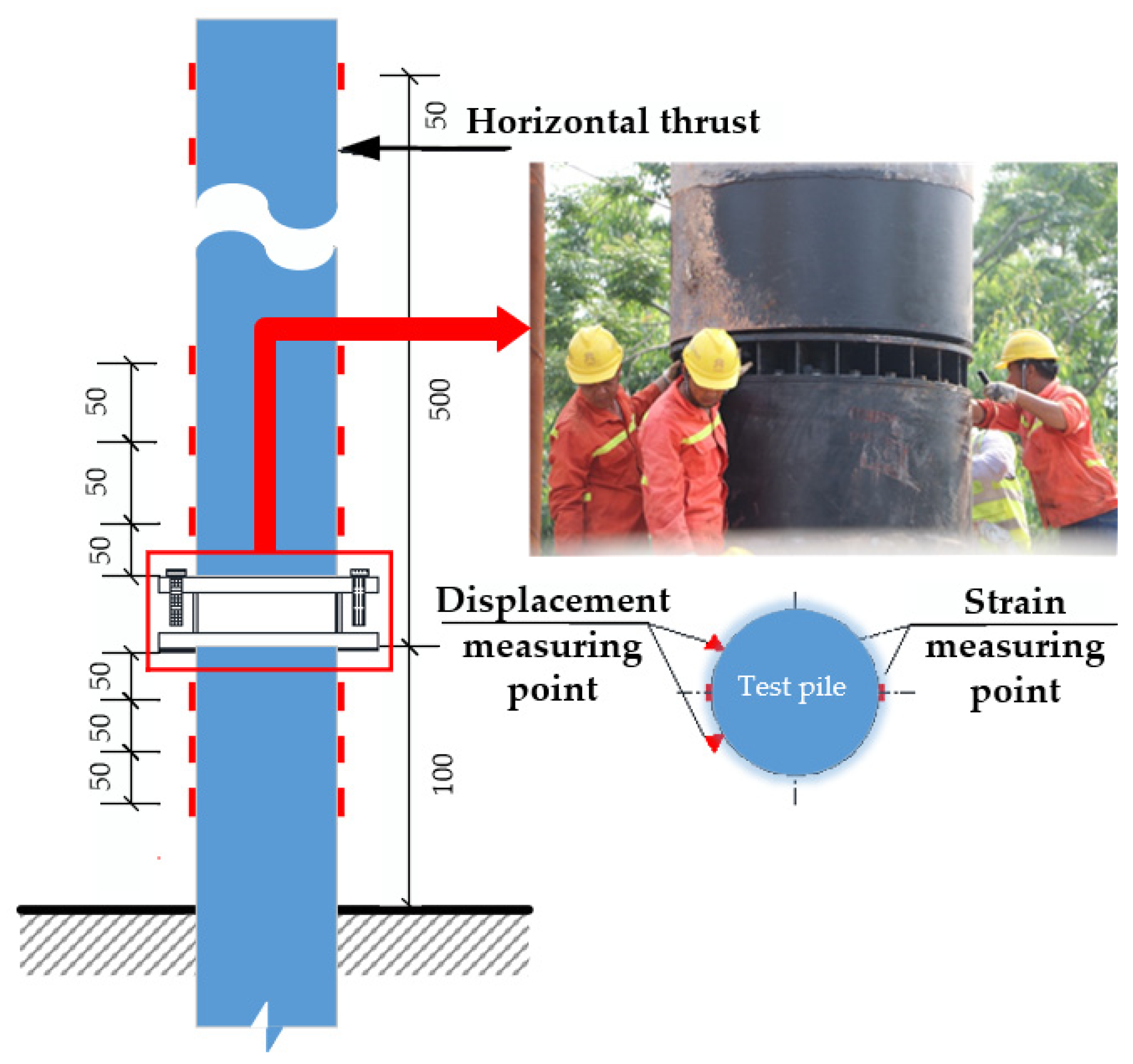

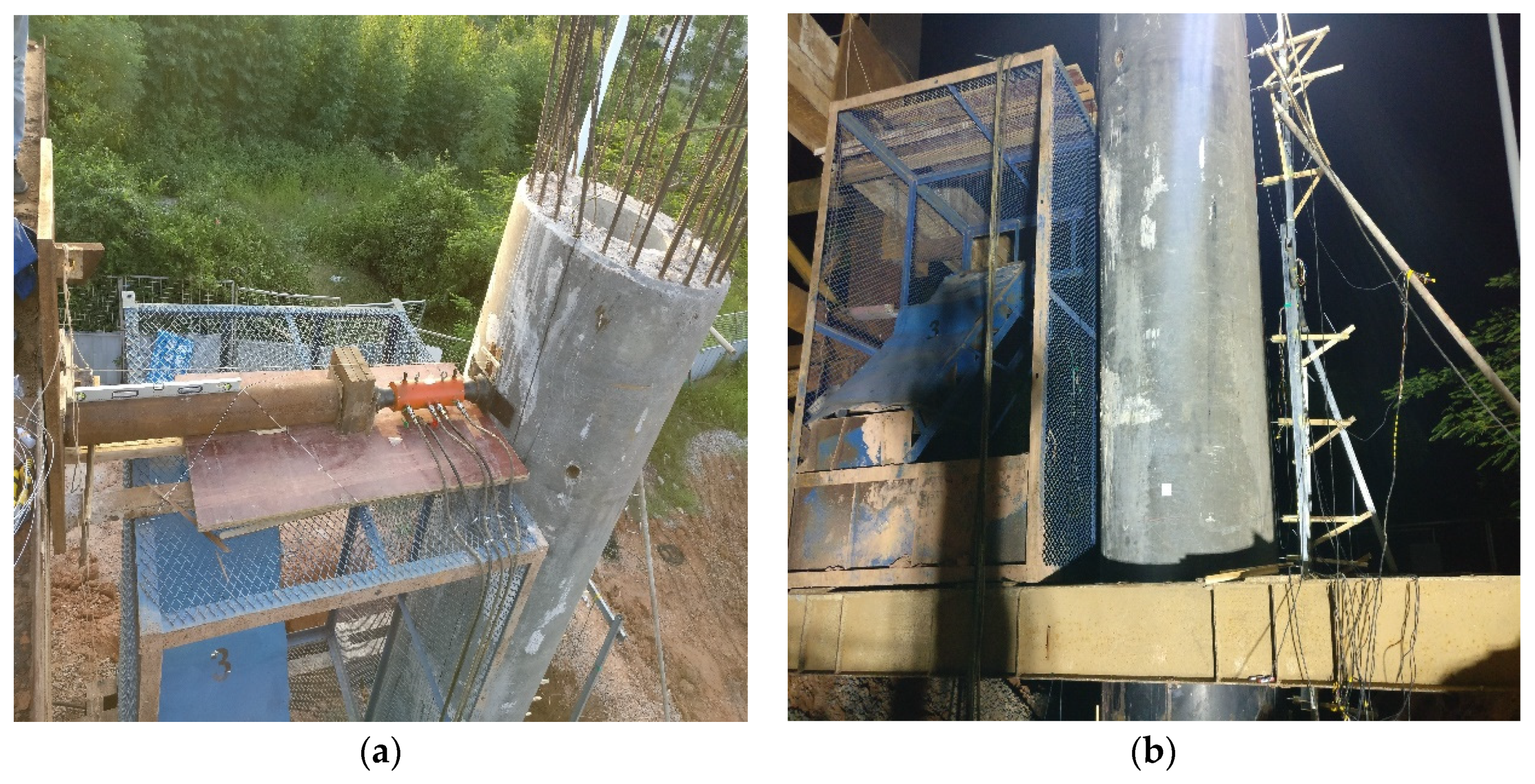

2.3.2. Horizontal Static Load Test of Single Pile

2.3.3. Reliability Test of Pile–Column Connection

3. Results and Discussion

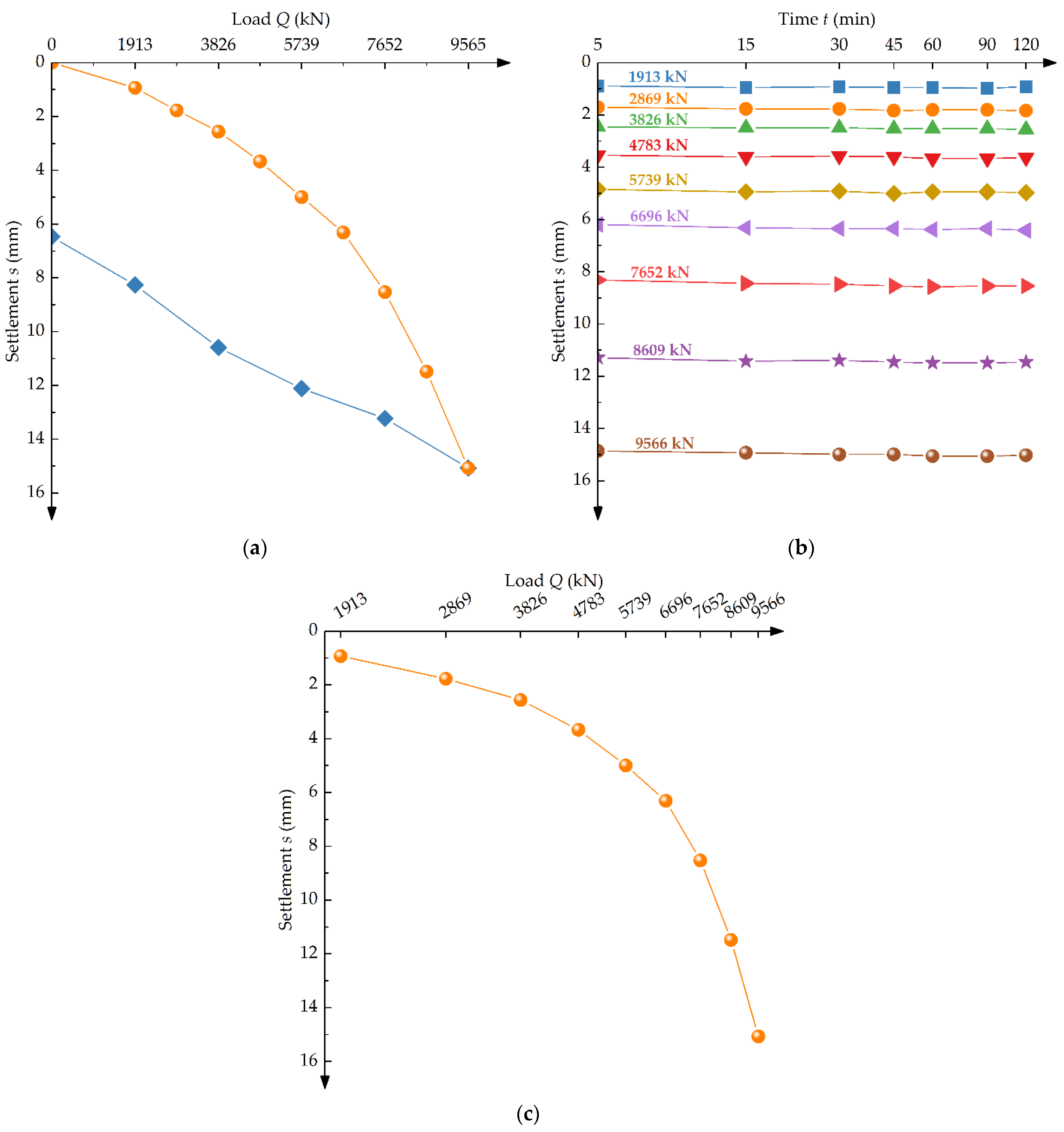

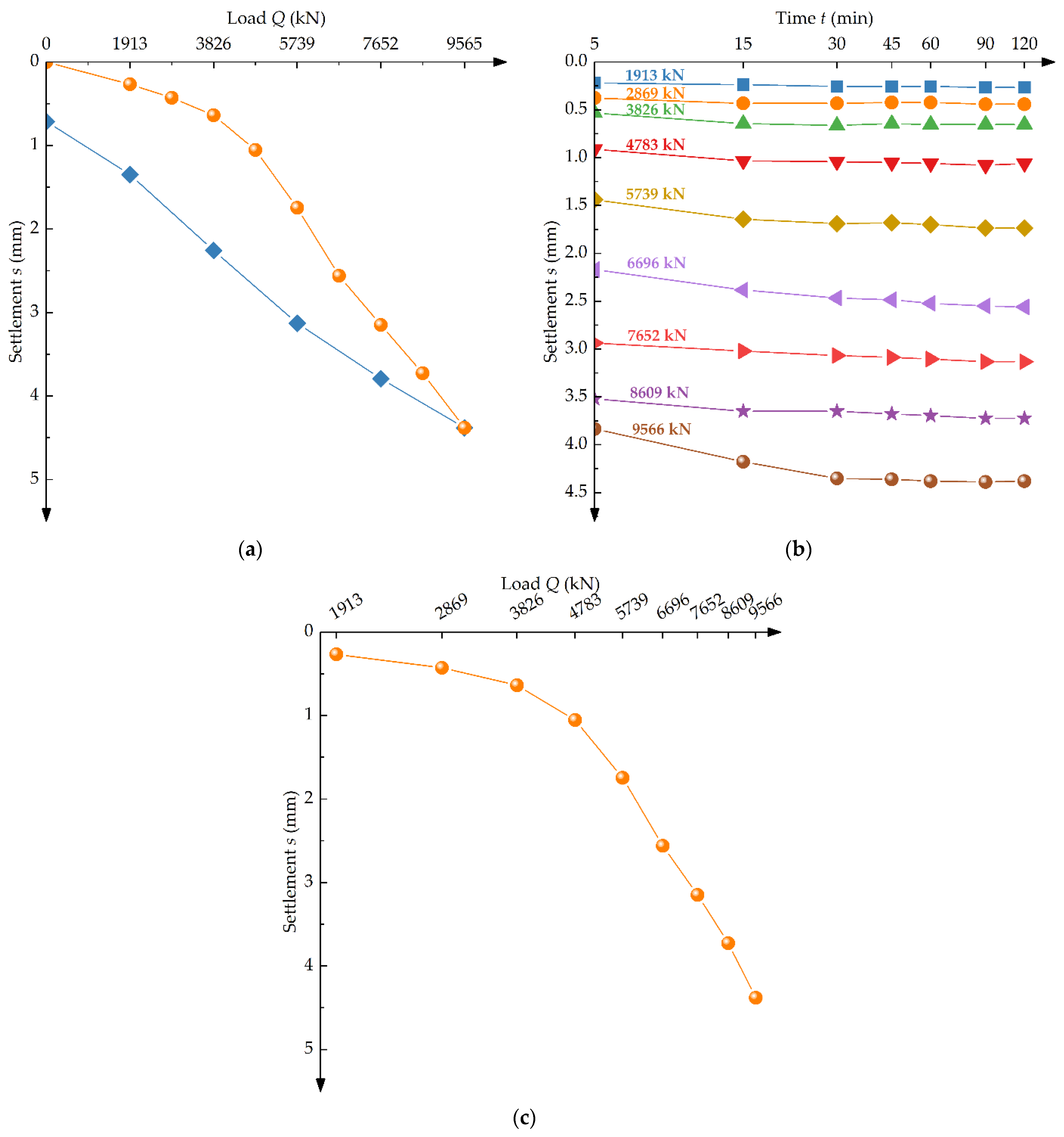

3.1. Analysis of Vertical Compressive Static Load Test of Single Pile

3.1.1. Load Classification of Vertical Compressive Static Load Test of Single Pile

3.1.2. Analysis and Judgment of Test Data

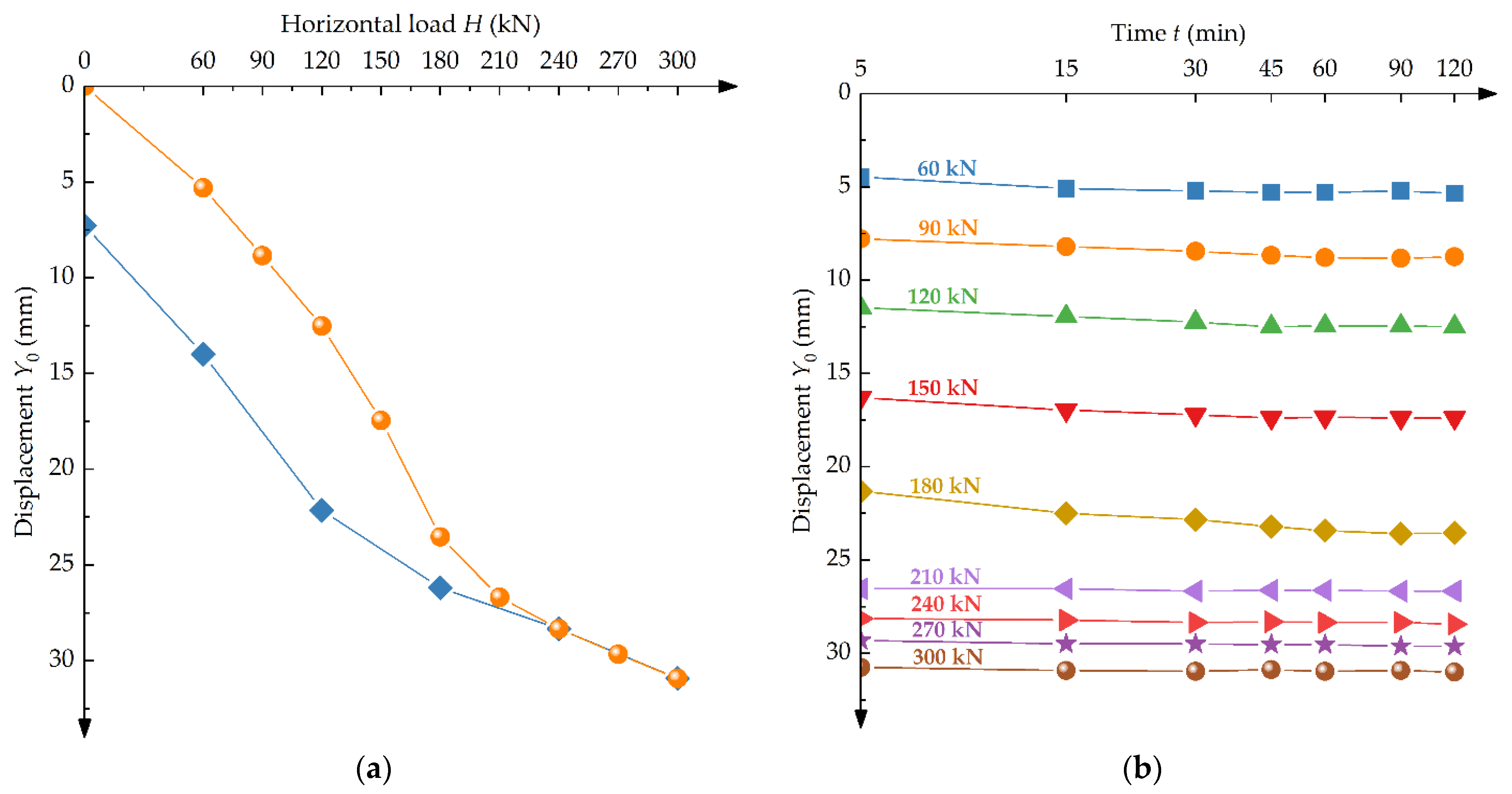

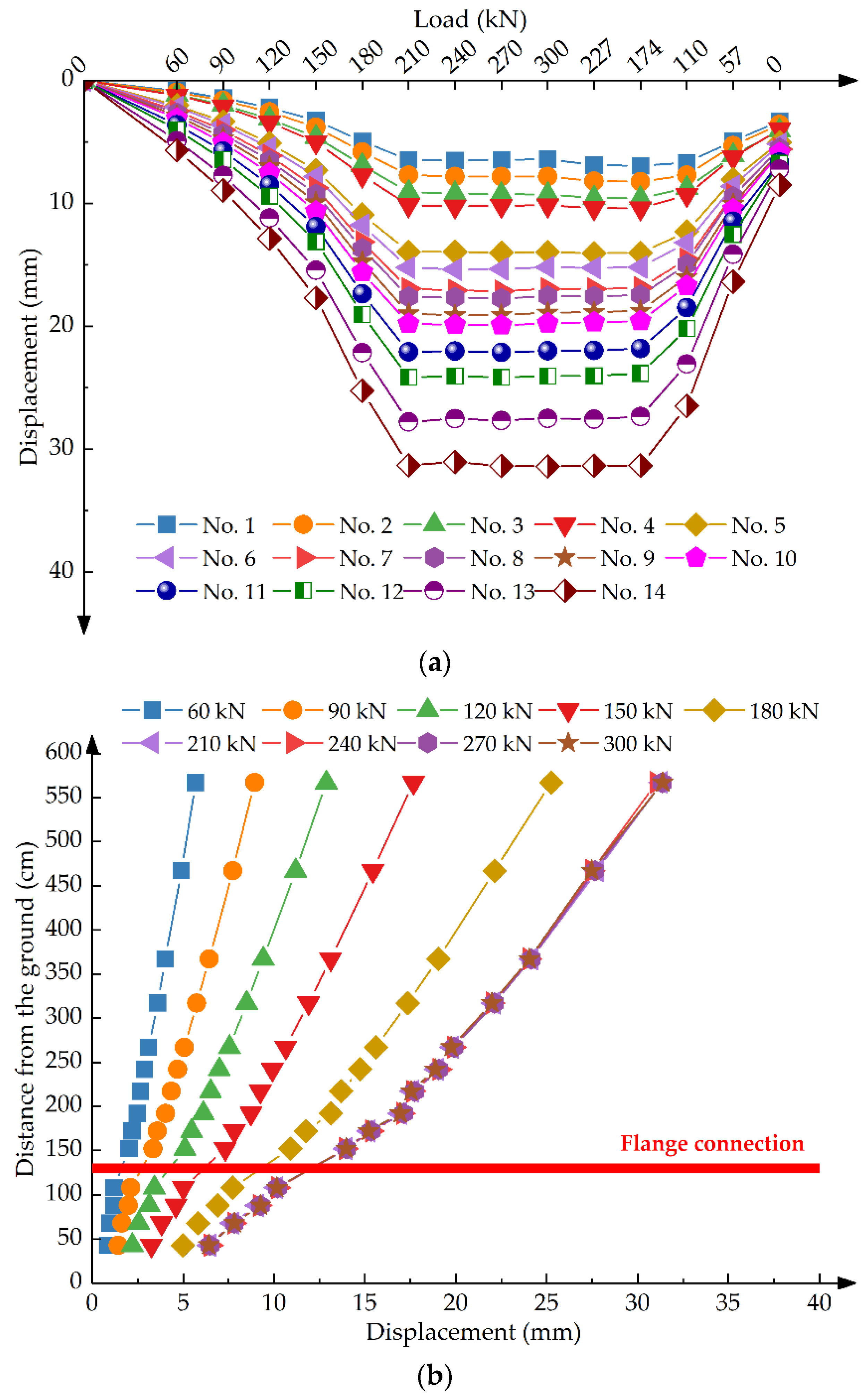

3.2. Analysis of Horizontal Static Load Test of Single Pile

3.2.1. Load Classification of Vertical Compressive Static Load Test of Single Pile

3.2.2. Analysis and Judgment of Test Data

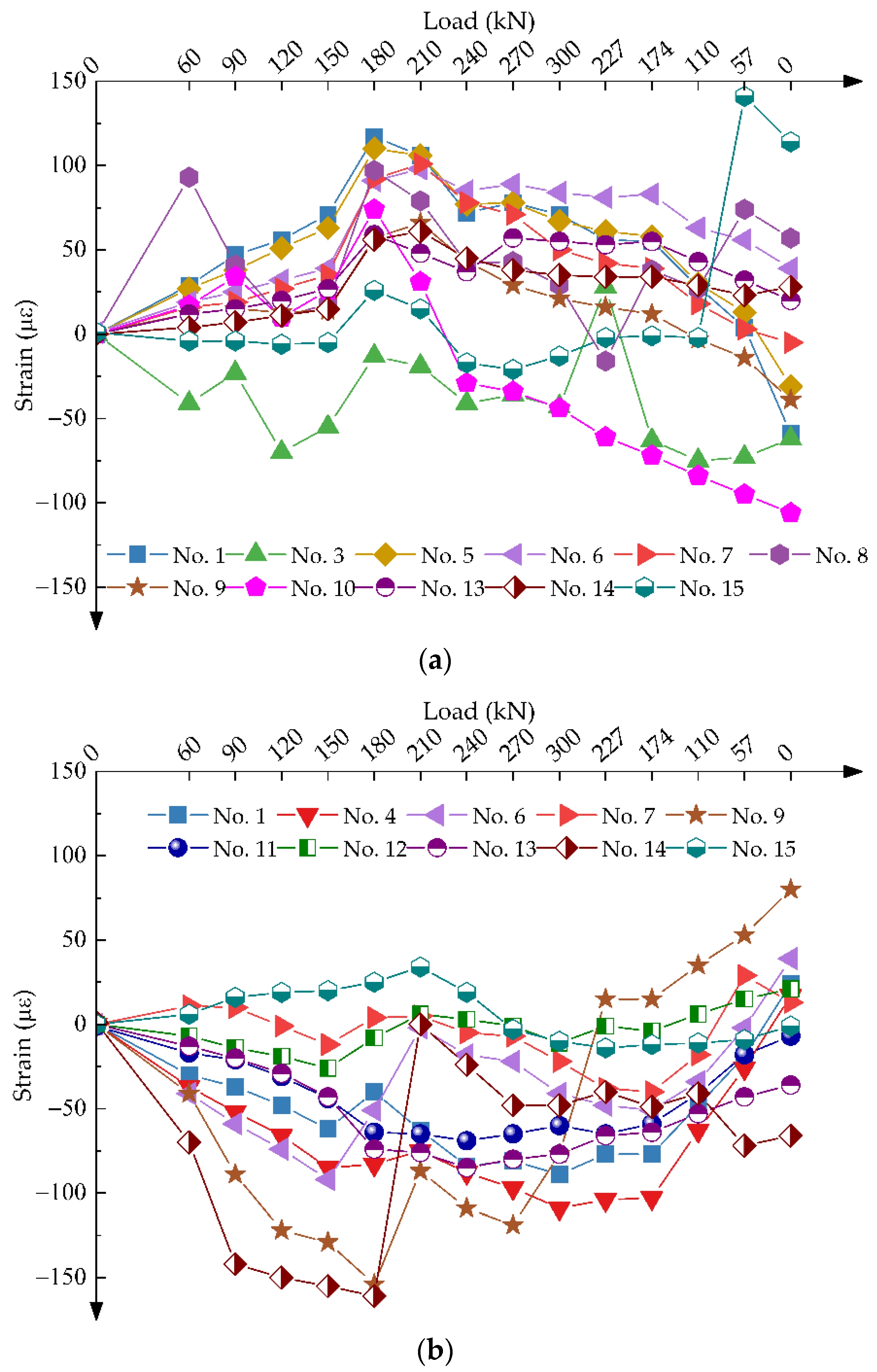

3.3. Analysis of Reliability Test of Pile–Column Connection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Serra, M.; Festa, G.; Vassallo, M.; Zollo, A.; Quattrone, A.; Ceravolo, R. Damage detection in elastic properties of masonry bridges using coda wave interferometry. Struct. Control Health Monit. 2017, 24, e1976. [Google Scholar] [CrossRef]

- Liu, H.B.; Wang, H.; Tan, G.J.; Wang, W.S.; Liu, Z.Y. Effect of temperature and spring-mass systems on modal properties of timoshenko concrete beam. Struct. Eng. Mech. 2018, 65, 389–400. [Google Scholar]

- Jiang, G.; Liang, Q.; Wang, H.; Ju, Y.; Wang, H.; Wang, X.; Wang, L.; Wang, W. Study on Evaluation Theory of Bridge Damage State and Methodology on Early Warning of Danger. Adv. Mater. Sci. Eng. 2022, 2022, 6636959. [Google Scholar] [CrossRef]

- Yi, T.; Wang, H.; Xie, J.; Wang, W. Flexural Strength and Acoustic Damage Characteristics of Steel Bar Reactive Powder Concrete. Appl. Sci. 2021, 11, 7017. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Wang, H.; Ning, Y.; Huang, K.; Wang, W. Performance Evaluation of a Long-Span Cable-Stayed Bridge Using Non-Destructive Field Loading Tests. Appl. Sci. 2022, 12, 2367. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Zhuo, X.; Huang, K.; Wang, X.; Wang, W. Study on the Precise Displacement Controlling Method for a Suspended Deck in the Hanger Replacement Process of an Arch Bridge. Appl. Sci. 2021, 11, 9607. [Google Scholar] [CrossRef]

- Saleem, M.A.; Zafar, M.N.; Saleem, M.M.; Xia, J. Recent developments in the prefabricated bridge deck systems. Case Stud. Constr. Mater. 2021, 15, e00750. [Google Scholar] [CrossRef]

- Xia, L.; Hu, Z.; Shah, Y.I. Longitudinal load distribution of a weakly connected prefabricated bridge abutment. Arch. Appl. Mech. 2021, 91, 4121–4140. [Google Scholar] [CrossRef]

- Shim, C.-S.; Dang, S.N.; Park, S. Three-Dimensional Information Delivery for Design and Construction of Prefabricated Bridge Piers. Struct. Eng. Int. 2018, 28, 6–12. [Google Scholar] [CrossRef]

- Ryu, H.-K.; Kim, Y.-J.; Chang, S.-P. Crack control of a continuous composite two-girder bridge with prefabricated slabs under static and fatigue loads. Eng. Struct. 2007, 29, 851–864. [Google Scholar] [CrossRef]

- Haider, M.A.; Batikha, M.; Elhag, T. Precast versus cast in-situ concrete in the construction of post-tensioned box-girder bridges: Span effect. Struct. Concr. 2020, 21, 56–64. [Google Scholar] [CrossRef]

- Moyo, P.; Sibanda, B.; Beushausen, H. Modelling and integrity assessment of shear connectors in precast cast-in-situ concrete bridges. Struct. Eng. Mech. 2012, 42, 55–72. [Google Scholar] [CrossRef]

- Kuryłowicz-Cudowska, A. Determination of Thermophysical Parameters Involved in The Numerical Model to Predict the Temperature Field of Cast-In-Place Concrete Bridge Deck. Materials 2019, 12, 3089. [Google Scholar] [CrossRef] [Green Version]

- Jensen, T.W.; Poulsen, P.N.; Hoang, L.C. Limit analysis of reinforced concrete slabs with construction joints. Eng. Struct. 2020, 205, 110062. [Google Scholar] [CrossRef]

- Fasching, S.; Huber, T.; Rath, M.; Kollegger, J. Semi-precast segmental bridges: Development of a new construction method using thin-walled prefabricated concrete elements. Struct. Concr. 2021, 22, 1561–1573. [Google Scholar] [CrossRef]

- Suffner, A.; Schulze, T. Green bridges from prefabricated arch-segments. Bautechnik 2016, 93, 98–101. [Google Scholar] [CrossRef]

- Chandara, K.; Chang-Su, S.; Sung-Jun, P. Seismic performance of prefabricated bridge columns with combination of continuous mild reinforcements and partially unbonded tendons. Smart Struct. Syst. 2016, 17, 541–557. [Google Scholar]

- Billington, S.L.; Barnes, R.W.; Breen, J.E. A Precast Segmental Substructure System for Standard Bridges. PCI J. 1999, 44, 56–73. [Google Scholar] [CrossRef]

- Zhuo, W.; Tong, T.; Liu, Z. Analytical Pushover Method and Hysteretic Modeling of Precast Segmental Bridge Piers with High-Strength Bars Based on Cyclic Loading Test. J. Struct. Eng. 2019, 145, 04019050. [Google Scholar] [CrossRef]

- ElGawady, M.A.; Dawood, H.M. Analysis of segmental piers consisted of concrete filled FRP tubes. Eng. Struct. 2012, 38, 142–152. [Google Scholar] [CrossRef]

- Peeters, B.; Couvreur, G.; Razinkov, O.; Kündig, C.; Van Der Auweraer, H.; De Roeck, G. Continuous monitoring of the Øresund Bridge: System and data analysis. Struct. Infrastruct. Eng. 2009, 5, 395–405. [Google Scholar] [CrossRef]

- Park, J.; Choi, J.; Jang, Y.; Park, S.-K.; Hong, S. An Experimental and Analytical Study on the Deflection Behavior of Precast Concrete Beams with Joints. Appl. Sci. 2017, 7, 1198. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the Promotion of Prefabricated Construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef] [Green Version]

- Wu, Q.H.; Qiu, Z.Z.; Niu, Z. Study on the Factory Prefabrication Technology of Large-Span Bridges Pier. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 501, pp. 1413–1417. [Google Scholar] [CrossRef]

- Li, F.; Shen, Y. Full-scale test of the hydration heat and the curing method of the wet joints of a precast segmental pier of a bridge. Eur. J. Environ. Civ. Eng. 2017, 21, 348–370. [Google Scholar] [CrossRef]

- Chen, R.; Tan, Y.; Zhang, B.; Shen, W.; Liu, G.; Wang, Z. Installation of Integral Prefabricated Bridge Abutment and Pier with Flexible Water Stop Curtain. J. Constr. Eng. Manag. 2018, 144, 04018087. [Google Scholar] [CrossRef]

- Wu, D.; Xiong, W.; Guo, J. Establishment and Repetition Survey of Primary GNSS Control Network of Hong Kong–Zhuhai–Macao Bridge. J. Surv. Eng. 2022, 148, 05021006. [Google Scholar] [CrossRef]

- Fan, J.-J.; Feng, D.-C.; Wu, G.; Hou, S.; Lu, Y. Experimental study of prefabricated RC column-foundation assemblies with two different connection methods and using large-diameter reinforcing bars. Eng. Struct. 2020, 205, 110075. [Google Scholar] [CrossRef]

- Billington, S.L.; Yoon, J.K. Cyclic Response of Unbonded Posttensioned Precast Columns with Ductile Fiber-Reinforced Concrete. J. Bridge Eng. 2004, 9, 353–363. [Google Scholar] [CrossRef]

- Marriott, D.; Pampanin, S.; Palermo, A. Quasi-static and pseudo-dynamic testing of unbonded post-tensioned rocking bridge piers with external replaceable dissipaters. Earthq. Eng. Struct. Dyn. 2009, 38, 331–354. [Google Scholar] [CrossRef]

- Roh, H.; Reinhorn, A.M. Hysteretic behavior of precast segmental bridge piers with superelastic shape memory alloy bars. Eng. Struct. 2010, 32, 3394–3403. [Google Scholar] [CrossRef]

- Kim, D.H.; Moon, D.Y.; Kim, M.K.; Zi, G.; Roh, H. Experimental test and seismic performance of partial precast concrete segmental bridge column with cast-in-place base. Eng. Struct. 2015, 100, 178–188. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Ge, J.P.; Wei, H.Y. Seismic performance of prestressed concrete bridge column of east sea bridge. J. Tongji Univ. 2008, 32, 1462–1466. [Google Scholar]

- Ma, J.; Han, S.; Gao, X.; Li, D.; Guo, Y.; Liu, Q. Dynamic Lateral Response of the Partially-Embedded Single Piles in Layered Soil. Appl. Sci. 2022, 12, 1504. [Google Scholar] [CrossRef]

- Garala, T.K.; Madabhushi, G.S.P. Role of Pile Spacing on Dynamic Behavior of Pile Groups in Layered Soils. J. Geotech. Geoenviron. Eng. 2021, 147, 04021005. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Yang, K.; Xie, S.; Wei, G.; Li, R.; Wang, W. Full-Scale Prefabrication and Non-Destructive Quality Monitoring of Novel Bridge Substructure for “Pile-Column Integration”. Buildings 2022, 12, 715. [Google Scholar] [CrossRef]

| Parameters | Elastic Modulus (MPa) | Bulk Density (kN/m3) | Axial Compression Strength Design fcd (MPa) | Axial Tension Strength Design ftd (MPa) | Poisson’s Ratio | Linear Expansion Coefficient (°C) |

|---|---|---|---|---|---|---|

| C70 | 3.75 × 104 | 26 | 30.5 | 2.10 | 0.2 | 1.0×10−5 |

| C50 | 3.45 × 104 | 26 | 22.4 | 1.83 | 0.2 | 1.0×10−5 |

| C40 | 3.25 × 104 | 26 | 18.4 | 1.65 | 0.2 | 1.0×10−5 |

| C30 | 3.00 × 104 | 26 | 13.8 | 1.39 | 0.2 | 1.0×10−5 |

| Parameters | Elastic Modulus Es (MPa) | Tensile Design Strength fsd (MPa) | Standard Strength fsk (MPa) |

|---|---|---|---|

| HPB300 | 2.1 × 105 | 195 | 300 |

| HPB400 | 2.0 × 105 | 280 | 400 |

| Parameters | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 |

| Load (kN) | 1913.2 | 2869.8 | 3826.4 | 4783.0 | 5739.6 | 6696.2 | 7652.8 |

| Pressure (MPa) | 7.982 | 11.870 | 15.758 | 19.646 | 23.534 | 27.421 | 31.309 |

| Parameters | Level 9 | Level 10 | Level 8 | Level 6 | Level 4 | Level 2 | Unload to 0 |

| Load (kN) | 8609.4 | 9566.0 | 7652.8 | 5739.6 | 3826.4 | 1913.2 | 0 |

| Pressure (MPa) | 35.197 | 39.085 | 31.309 | 23.534 | 15.758 | 7.982 | 0 |

| No. | Pile Diameter (mm) | Pile Length (m) | Maximum Settlement (mm) | Maximum Rebound (mm) | Rebound Rate (%) | Ultimate Bearing Capacity (kN) |

|---|---|---|---|---|---|---|

| 3 | 1300 | 24 | 15.01 | 8.53 | 56.8 | 9566 |

| 4 | 1300 | 24 | 4.27 | 3.66 | 83.8 | 9566 |

| Parameters | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 |

| Load (kN) | 60 | 90 | 120 | 150 | 180 | 210 | 240 |

| Pressure (MPa) | 0.450 | 0.572 | 0.694 | 0.816 | 0.938 | 1.060 | 1.182 |

| Parameters | Level 9 | Level 10 | Level 8 | Level 6 | Level 4 | Level 2 | Unload to 0 |

| Load (kN) | 270 | 300 | 240 | 180 | 120 | 60 | 0 |

| Pressure (MPa) | 1.304 | 1.426 | 1.182 | 0.938 | 0.694 | 0.450 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wang, L.; Yang, K.; Xie, S.; Wei, G.; Li, R.; Wang, W. On-Site Full-Scale Load Test and Reliability Evaluation of Prefabricated Bridge Substructure for “Pile–Column Integration”. Appl. Sci. 2022, 12, 5520. https://doi.org/10.3390/app12115520

Wang H, Wang L, Yang K, Xie S, Wei G, Li R, Wang W. On-Site Full-Scale Load Test and Reliability Evaluation of Prefabricated Bridge Substructure for “Pile–Column Integration”. Applied Sciences. 2022; 12(11):5520. https://doi.org/10.3390/app12115520

Chicago/Turabian StyleWang, Hua, Longlin Wang, Kailv Yang, Shuzhi Xie, Gangrong Wei, Ruijiao Li, and Wensheng Wang. 2022. "On-Site Full-Scale Load Test and Reliability Evaluation of Prefabricated Bridge Substructure for “Pile–Column Integration”" Applied Sciences 12, no. 11: 5520. https://doi.org/10.3390/app12115520

APA StyleWang, H., Wang, L., Yang, K., Xie, S., Wei, G., Li, R., & Wang, W. (2022). On-Site Full-Scale Load Test and Reliability Evaluation of Prefabricated Bridge Substructure for “Pile–Column Integration”. Applied Sciences, 12(11), 5520. https://doi.org/10.3390/app12115520