An Improved Vector Control Strategy for Switched Reluctance Motor Drive Based on the Two-Degree-of-Freedom Internal Model Control

Abstract

:1. Introduction

- (1)

- A novel 2DOF IMC controller is reported in this paper based on the SRM model in the rotating reference frame, which considers the coupling relationship between different axes. The proposed controller can provide good control performance by using only two adjustment parameters, and the good performance of the set-point tracking and disturbance rejection of the controller can be guaranteed simultaneously.

- (2)

- Secondly, an adaptive disturbance observer (ADO) is introduced to eliminate the time-variable disturbance. Furthermore, a stability analysis is carried out according to the Lyapunov theory, and a guideline in selecting the ADO gains is given.

- (3)

- Finally, the experimental results demonstrate that the proposed control system can provide good tracking and disturbance rejection performance. On this basis, the torque ripple can be effectively suppressed by such good current control performance.

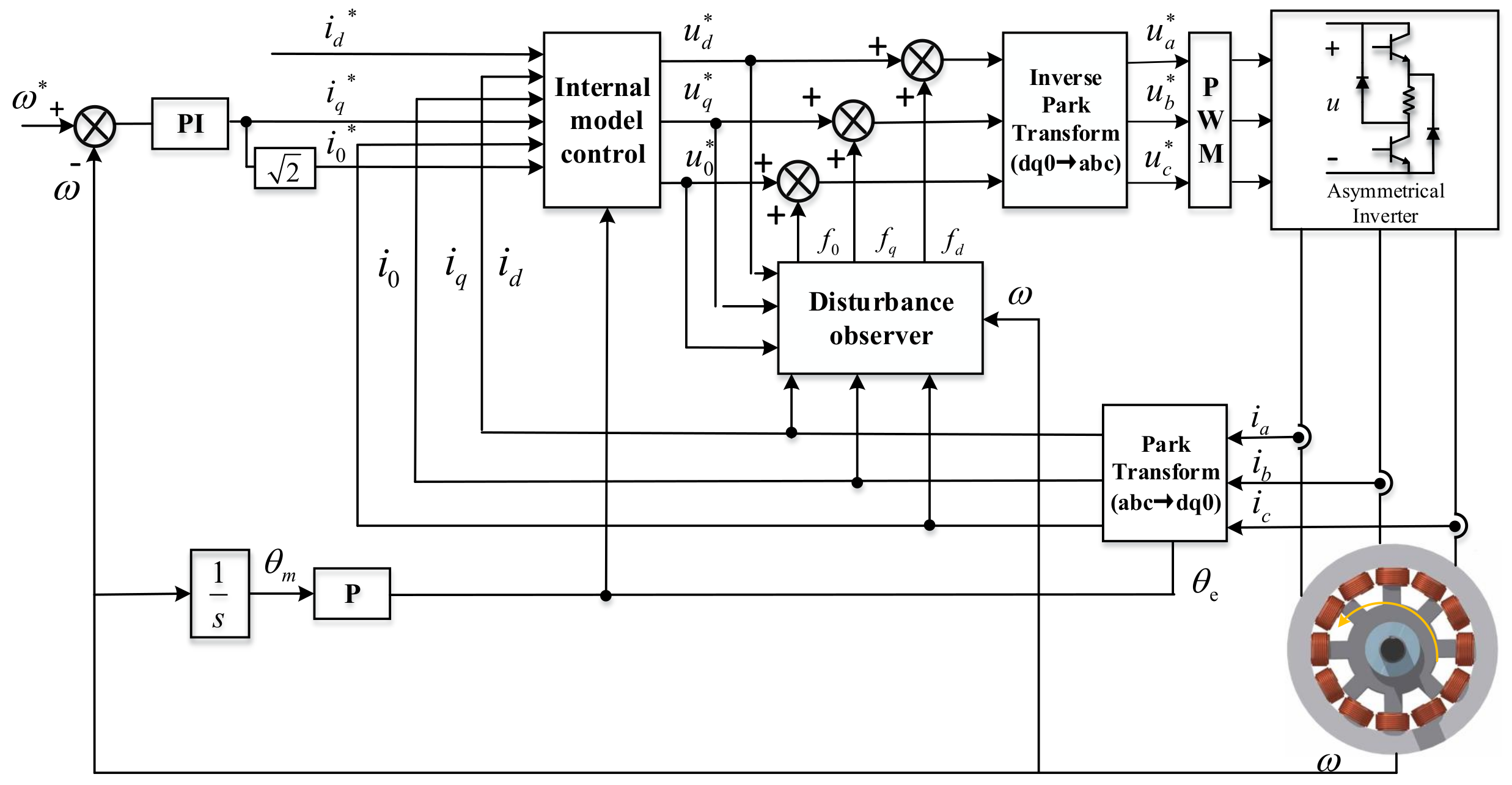

2. 2DOF IMC for SRM

2.1. Mathematical Model of the SRM

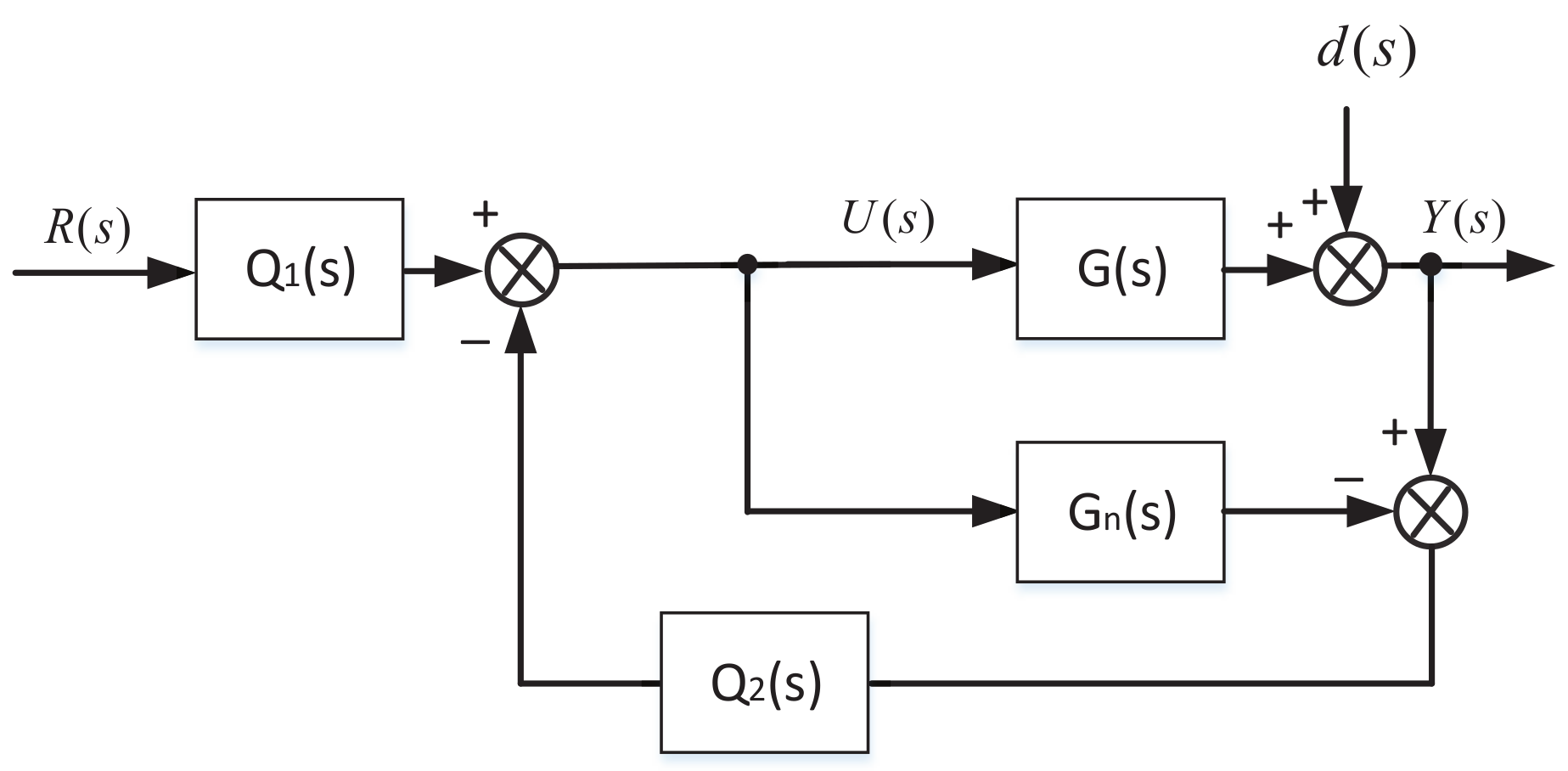

2.2. Design of the 2DOF IMC Current Regulator

2.3. Stability Analysis and Parameter Tuning

3. 2DOF IMC Strategy for SRMs Based on ADO

3.1. Design of the ADO

3.2. Stability Analysis and Parameter Tuning for the ADO

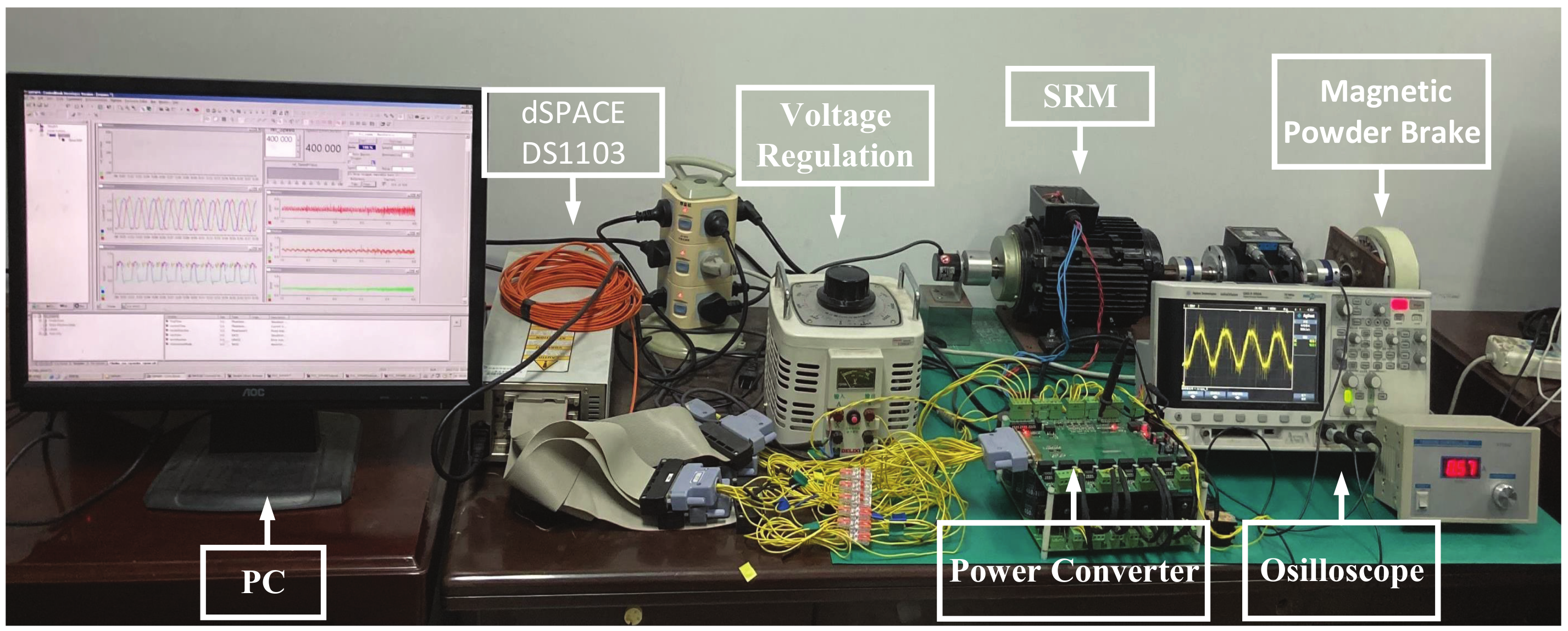

4. Experimental Verification

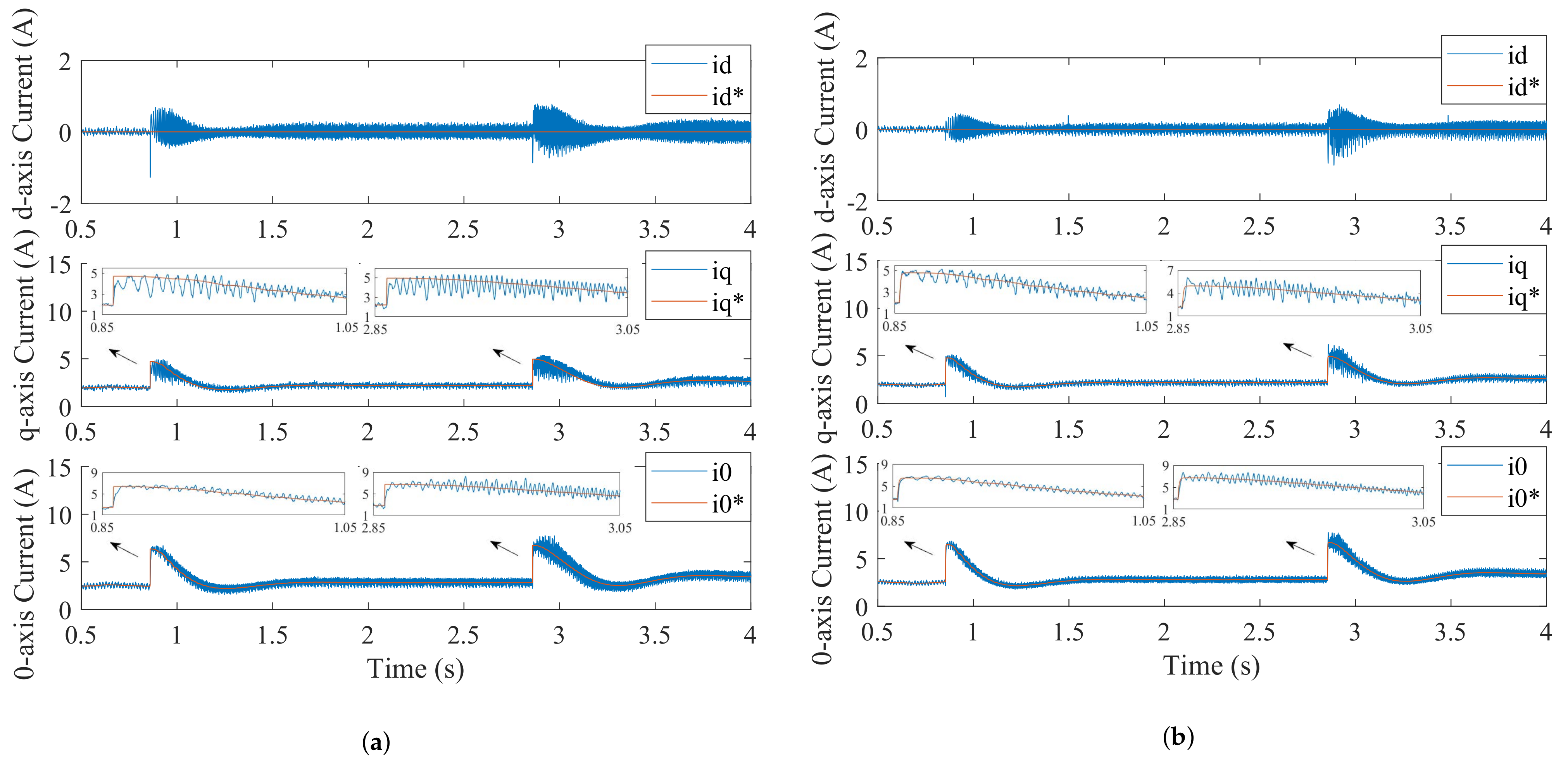

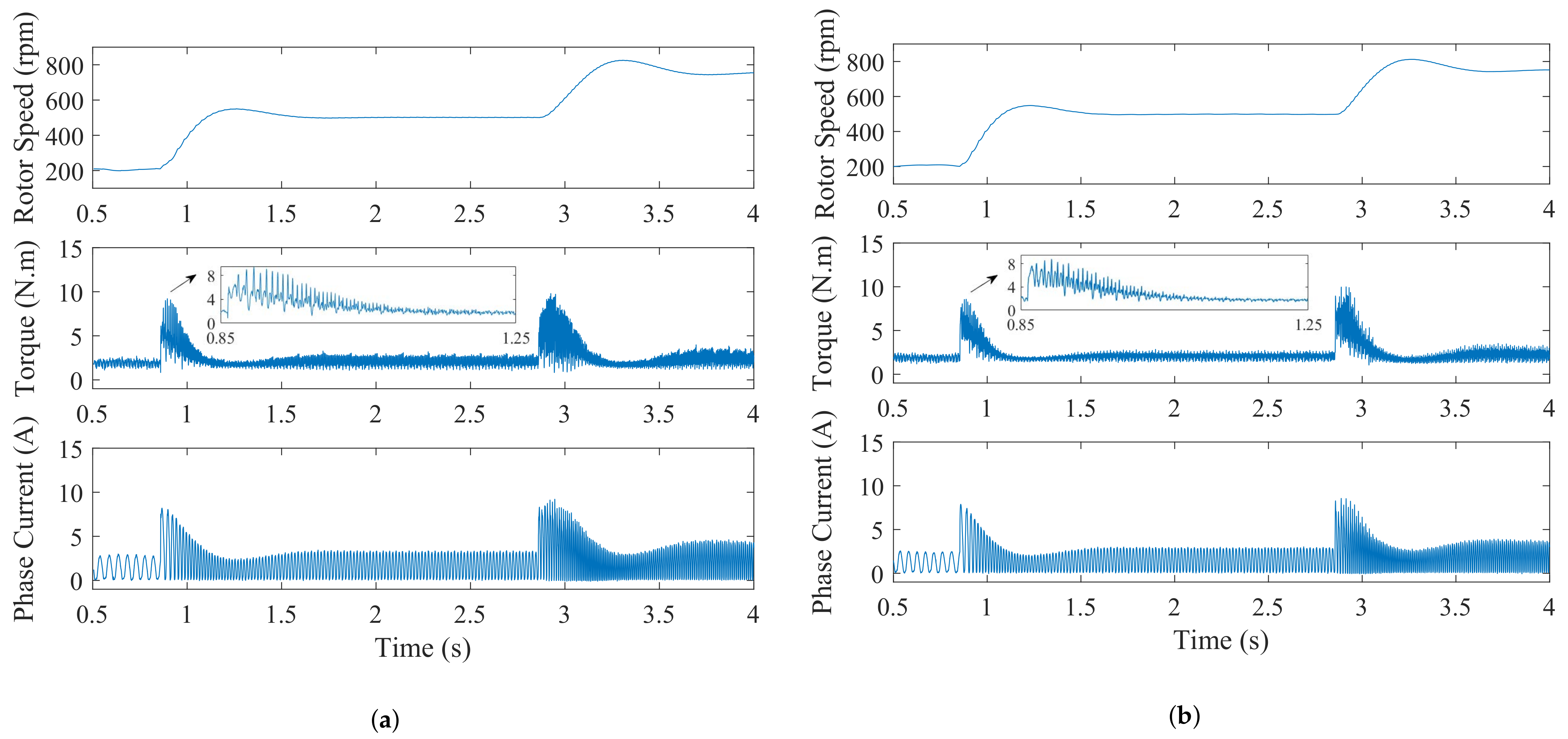

4.1. Experimental Results with Rotor Speed Change

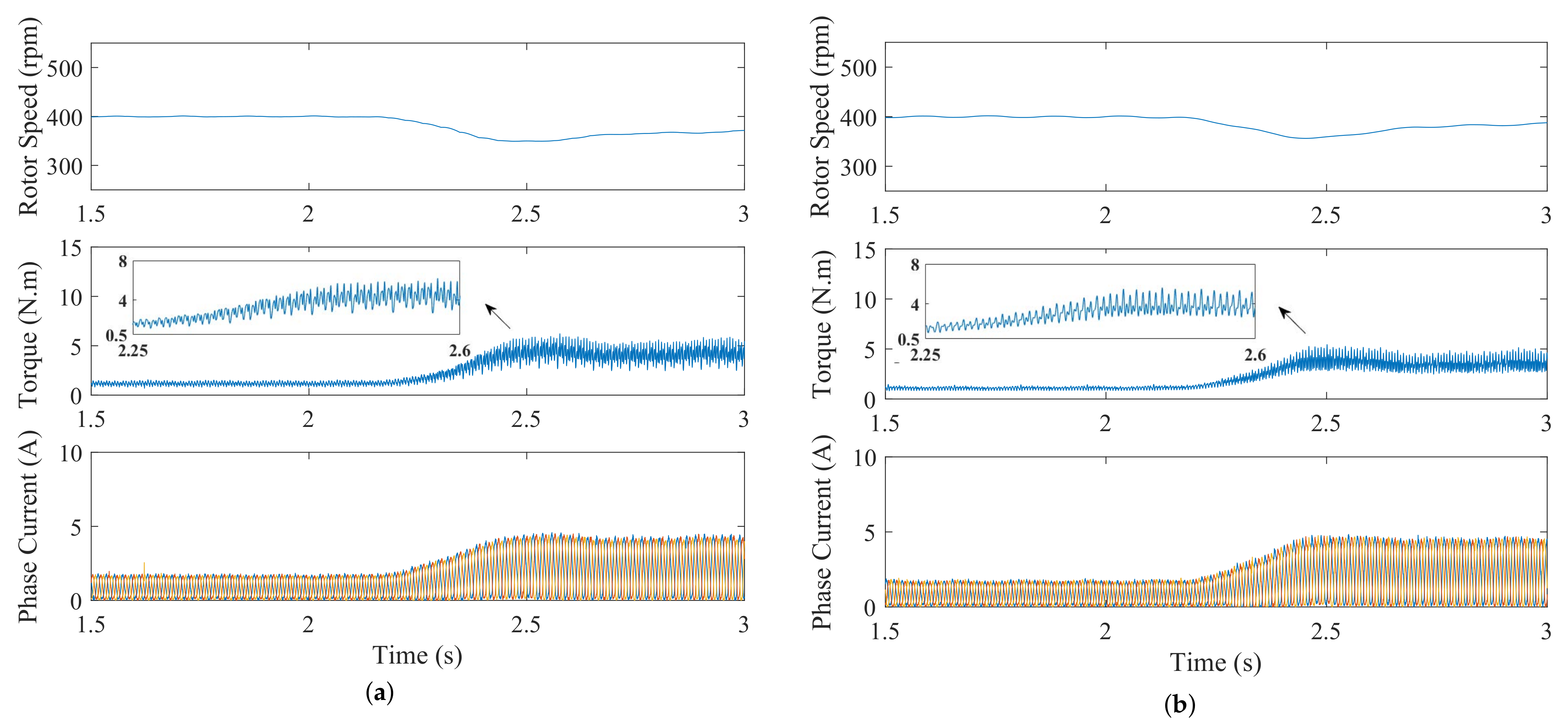

4.2. The Experimental Result with Load Torque Change

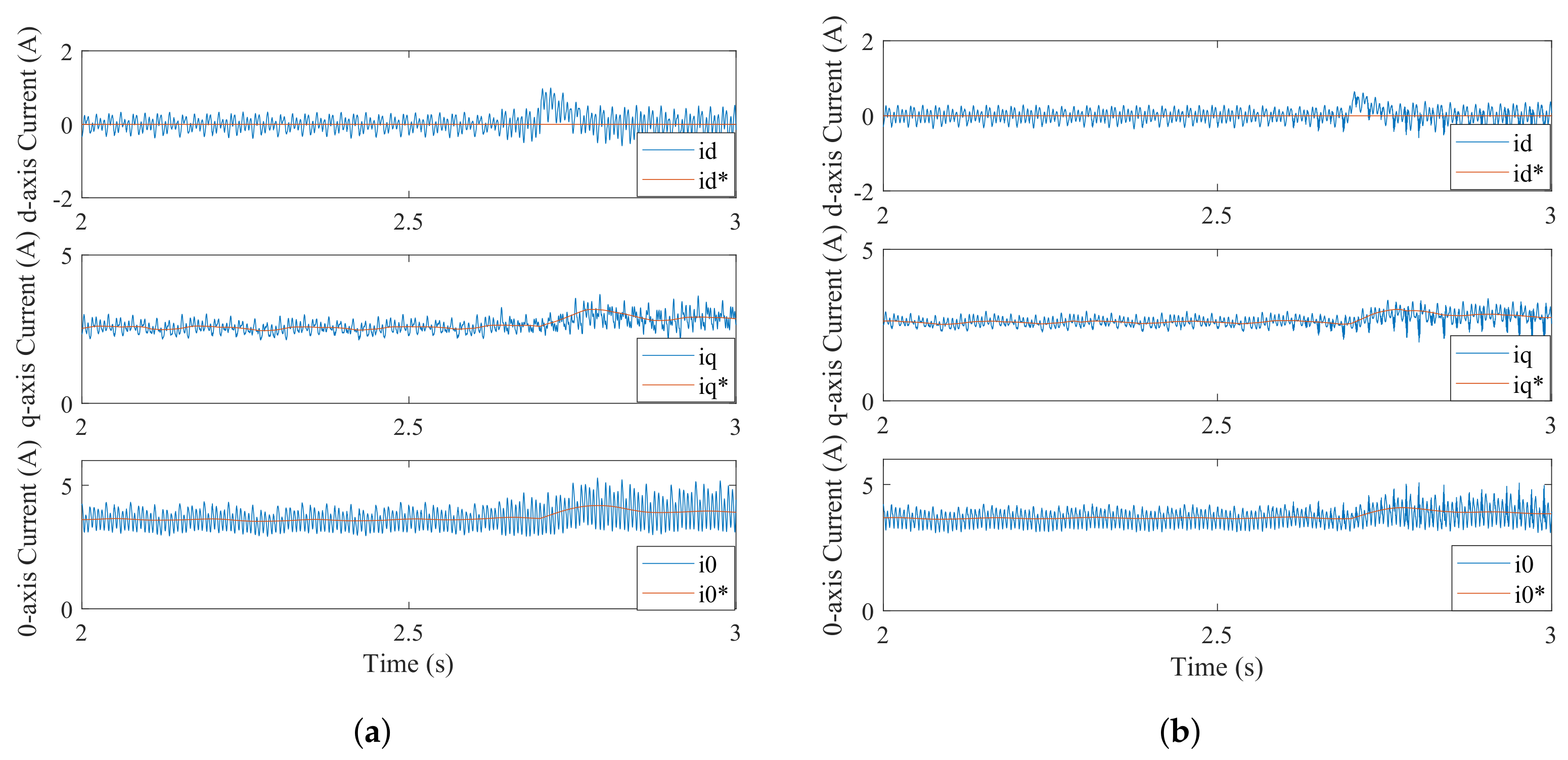

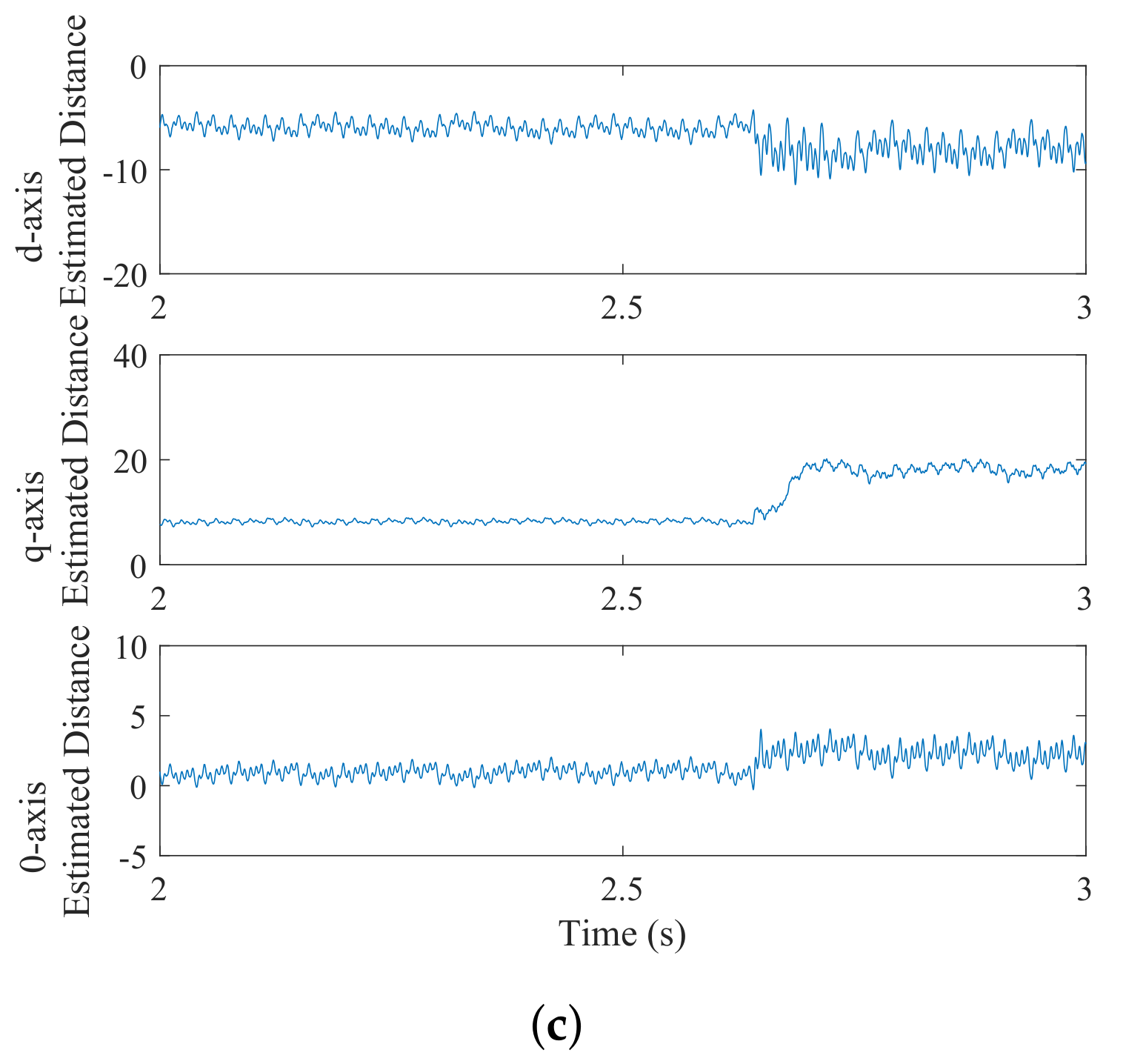

4.3. Experimental Results with Parameter Variation

5. Conclusions

- (1)

- The 2DOF IMC ADO can effectively reduce the current tracking errors and quickly converge to stable conditions when the system is affected by different disturbances.

- (2)

- With the improvement in the control precision for the current controller, the proposed 2DOF IMC ADO scheme also delivers good performance in torque ripple suppression.

- (3)

- The regulation performance of the 2DOF IMC ADO controller can be guaranteed even with inaccurate model parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lawrenson, P. Switched-reluctance motor drives. IEEE Rev. 1983, 29, 144–147. [Google Scholar] [CrossRef]

- Chen, H.; Liu, C.; Chen, Z. Simulation and implementation of wind turbine based on switched reluctance motor drive. In Proceedings of the 2012 3rd IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Aalborg, Denmark, 25–28 June 2012. [Google Scholar]

- Valdivia, V.; Todd, R.; Bryan, F.J.; Barrado, A. Behavioral modeling of a switched reluctance generator for aircraft power systems. IEEE Trans. Ind. Electron. 2014, 61, 2690–2699. [Google Scholar] [CrossRef]

- Liu, J.; Wang, G.; Sun, L.; Liu, D.; Fan, Y. A Novel Method to Obtain the Flux-Linkage Characteristics of Switched Reluctance Motors. IEEE Trans. Magn. 2021, 57, 8205011. [Google Scholar] [CrossRef]

- Valenciagarcia, D.F.; Tarvirdilu-Asl, R.; Garcia, C.; Rodriguez, J.; Emadi, A. A review of predictive control techniques for switched reluctance machine drives. Part I: Fundamentals and current control. IEEE Trans. Energy Convers. 2020, 36, 1313–1322. [Google Scholar]

- Ye, J.; Bilgin, B.; Emadi, A. An offline torque sharing function for torque ripple reduction in switched reluctance motor drives. IEEE Trans. Energy Convers. 2015, 30, 726–735. [Google Scholar] [CrossRef]

- Xia, Z.; Bilgin, B.; Nalakath, S.; Emadi, A. A new torque sharing function method for switched reluctance machines with lower current tracking error. IEEE Trans. Ind. Electron. 2020, 68, 10612–10622. [Google Scholar] [CrossRef]

- Sun, X.; Diao, K.; Yang, Z.; Lei, G.; Zhu, J. Direct torque control based on a fast modeling method for a segmented-rotor switched reluctance motor in hev application. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 232–241. [Google Scholar] [CrossRef]

- Ning, Y.; Xin, C.; Deng, Z.Q. Direct torque control for switched reluctance motor to obtain high torque-ampere ratio. IEEE Trans. Ind. Electron. 2018, 66, 5144–5152. [Google Scholar]

- Wang, S.; Hu, Z.; Cui, X. Research on novel direct instantaneous torque control strategy for switched reluctance motor. IEEE Access 2020, 66910–66916. [Google Scholar] [CrossRef]

- Sun, X.; Feng, L.; Diao, K.; Yang, Z. An Improved Direct Instantaneous Torque Control Based on Adaptive Terminal Sliding Mode for a Segmented-Rotor SRM. IEEE Trans. Ind. Electron. 2020, 68, 10569–10579. [Google Scholar] [CrossRef]

- Li, X.; Shamsi, P. Model Predictive Current Control of Switched Reluctance Motors With Inductance Auto-Calibration. IEEE Trans. Ind. Electron. 2016, 3934–3941. [Google Scholar] [CrossRef]

- Mademlis, C.; Kioskeridis, I. Gain-Scheduling Regulator for High-Performance Position Control of Switched Reluctance Motor Drives. IEEE Trans. Ind. Electron. 2010, 57, 2922–2931. [Google Scholar] [CrossRef]

- Nakao, N.; Akatsu, K. Vector control specialized for switched reluctance motor drives. IEEJ Trans. Ind. Appl. 2015, 194, 24–36. [Google Scholar]

- Kuai, S.; Zhang, H.; Xi, X.; Li, K. Unipolar sinusoidal excited switched reluctance motor control based on voltage space vector. IET Electr. Power Appl. 2019, 13, 670–675. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Lee, B.; Xu, L. Integrated field and armature current control strategy for variable flux reluctance machine using open winding. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 31 March–2 April 2015. [Google Scholar]

- Nakao, N.; Kan, A. Vector control for switched reluctance motor drives using an improved current controller. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 1379–1386. [Google Scholar]

- Saxena, S.; Hote, Y. Advances in Internal Model Control Technique: A Review and Future Prospects. IETE Tech. Rev. 2012, 29, 461–472. [Google Scholar] [CrossRef]

- Li, P.; Zhu, G.; Zhang, M. Linear active disturbance rejection control for servo motor systems with input delay via internal model control rules. IEEE Trans. Ind. Electron. 2021, 68, 1077–1086. [Google Scholar] [CrossRef]

- Sun, X.; Long, C.; Jiang, H.; Yang, Z.; Chen, J.; Zhang, W. High-performance control for a bearingless permanent-magnet synchronous motor using neural network inverse scheme plus internal model controllers. IEEE Trans. Ind. Electron. 2016, 63, 3479–3488. [Google Scholar] [CrossRef]

- Liu, G.; Chen, L.; Zhao, W.; Jiang, Y.; Qu, L. Internal model control of permanent magnet synchronous motor using support vector machine generalized inverse. IEEE Trans. Ind. Inform. 2013, 9, 890–898. [Google Scholar] [CrossRef]

- Sun, X.; Zhou, S.; Long, C.; Yang, Z. Internal model control for a bearingless permanent magnet synchronous motor based on inverse system method. IEEE Trans. Energy Convers. 2016, 31, 1539–1548. [Google Scholar] [CrossRef]

- Zhu, Q.; Yin, Z.; Zhang, Y.; Niu, J.; Li, Y.; Zhong, Y. Research on two-degree-of-freedom internal model control strategy for induction motor based on immune algorithm. IEEE Trans. Ind. Electron. 2015, 63, 1981–1992. [Google Scholar] [CrossRef]

- Yin, Z.; Bai, C.; Du, N.; Du, C.; Liu, J. Research on internal model control of induction motors based on luenberger disturbance observer. IEEE Trans. Power Electron. 2021, 36, 8155–8170. [Google Scholar] [CrossRef]

- Wu, S.; Li, Z.; Zhang, R. An improved 2-degree-of-freedom internal model proportional–integral–derivative controller design for stable time-delay processes. Meas. Control. 2020, 53, 841–849. [Google Scholar] [CrossRef] [Green Version]

- Juwari; Chin, S.Y.; Samad, N.; Aziz, B. Two-degree-of-freedom internal model control for parallel cascade scheme. In Proceedings of the 2008 International Symposium on Information Technology, Kuala Lumpur, Malaysia, 26–28 August 2008. [Google Scholar]

- Xu, H.; Zhang, Q. Comparison of convergence of the modified and relaxed hybrid steepest-descent methods for variational inequalities under different conditions. In Proceedings of the Third International Joint Conference on Computational Science Optimization, Huangshan, China, 28–31 May 2010. [Google Scholar]

| Parameters | Value |

|---|---|

| Phase | 3 |

| Stator/rotor poles | 12/8 |

| Rated power | 1.5 kW |

| Rated torque | 9.5 N · m |

| Speed range | 100–1500 r/min |

| Maximum flux linkage | 0.986 Wb |

| Stator resistance | 0.9 |

| Rated voltage | 220 V |

| Method | Speed (rpm) | Load Torque (N · m) | |

|---|---|---|---|

| Reference [14] | 200 | 2 | 52.2% |

| 500 | 2 | 65.1% | |

| 750 | 2 | 100.8% | |

| 2DOF IMC ADO | 200 | 2 | 47.3% |

| 500 | 2 | 54.75 % | |

| 750 | 2 | 94.1 % |

| Method | Speed (rpm) | Load Torque (N · m) | |

|---|---|---|---|

| Reference [14] | 400 | 1 | 65.01% |

| 400 | 4 | 85.73% | |

| IMC ADO | 400 | 1 | 56.49% |

| 400 | 4 | 67.73% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Wang, G.; Liu, J.; Fan, Y.; Mu, D. An Improved Vector Control Strategy for Switched Reluctance Motor Drive Based on the Two-Degree-of-Freedom Internal Model Control. Appl. Sci. 2022, 12, 5407. https://doi.org/10.3390/app12115407

Liu D, Wang G, Liu J, Fan Y, Mu D. An Improved Vector Control Strategy for Switched Reluctance Motor Drive Based on the Two-Degree-of-Freedom Internal Model Control. Applied Sciences. 2022; 12(11):5407. https://doi.org/10.3390/app12115407

Chicago/Turabian StyleLiu, Di, Guofeng Wang, Jian Liu, Yunsheng Fan, and Dongdong Mu. 2022. "An Improved Vector Control Strategy for Switched Reluctance Motor Drive Based on the Two-Degree-of-Freedom Internal Model Control" Applied Sciences 12, no. 11: 5407. https://doi.org/10.3390/app12115407

APA StyleLiu, D., Wang, G., Liu, J., Fan, Y., & Mu, D. (2022). An Improved Vector Control Strategy for Switched Reluctance Motor Drive Based on the Two-Degree-of-Freedom Internal Model Control. Applied Sciences, 12(11), 5407. https://doi.org/10.3390/app12115407