Production Scheduling Methodology, Taking into Account the Influence of the Selection of Production Resources

Abstract

1. Introduction

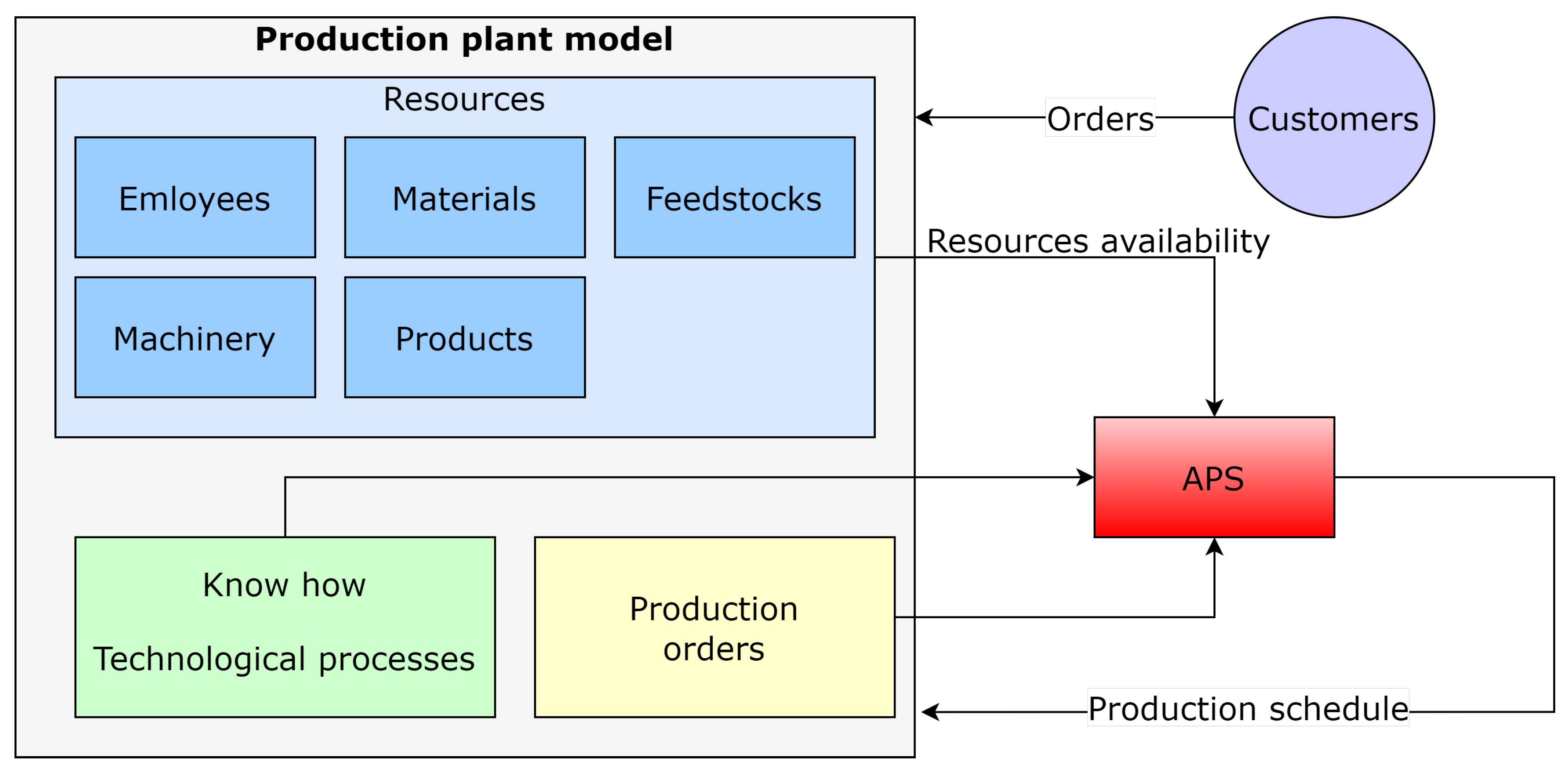

2. New Production Scheduling Methodology

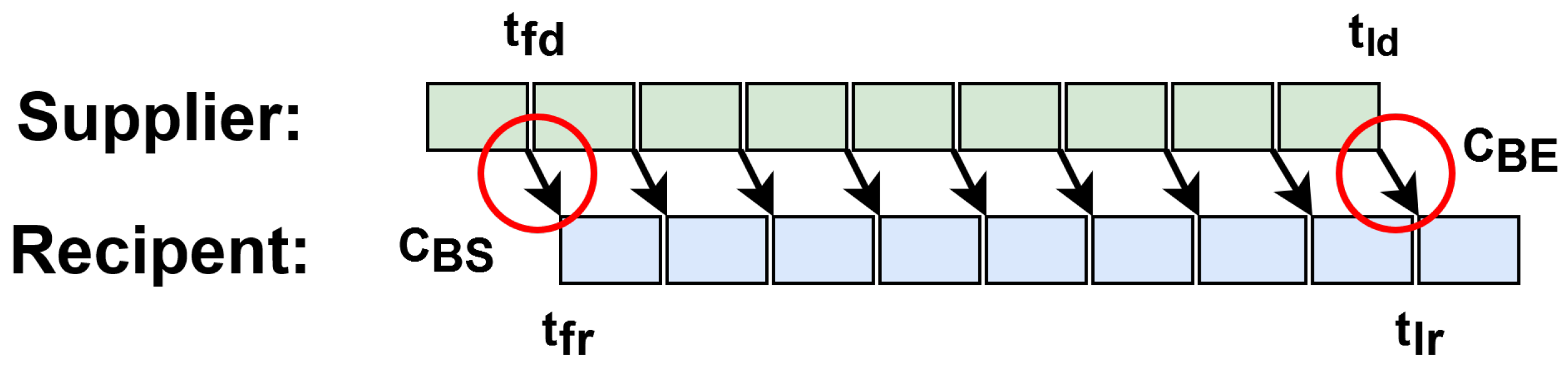

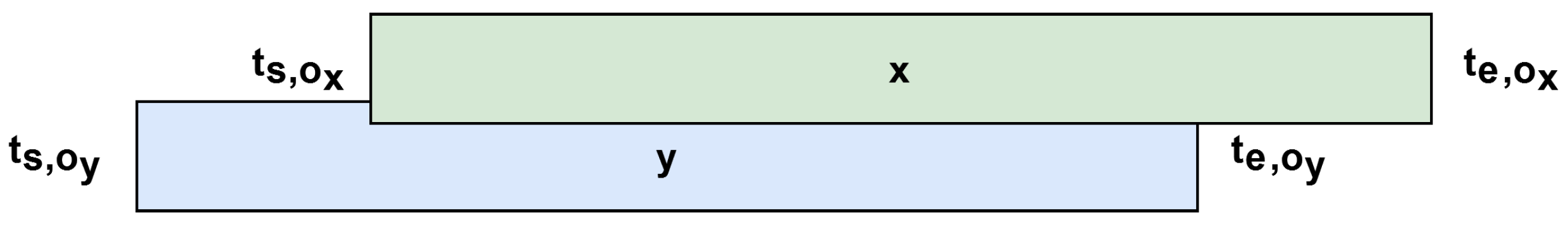

2.1. Feasibility Constraint

2.2. Criterion of Maximum Completion Time

2.3. Criterion of the Cost of the Production Process

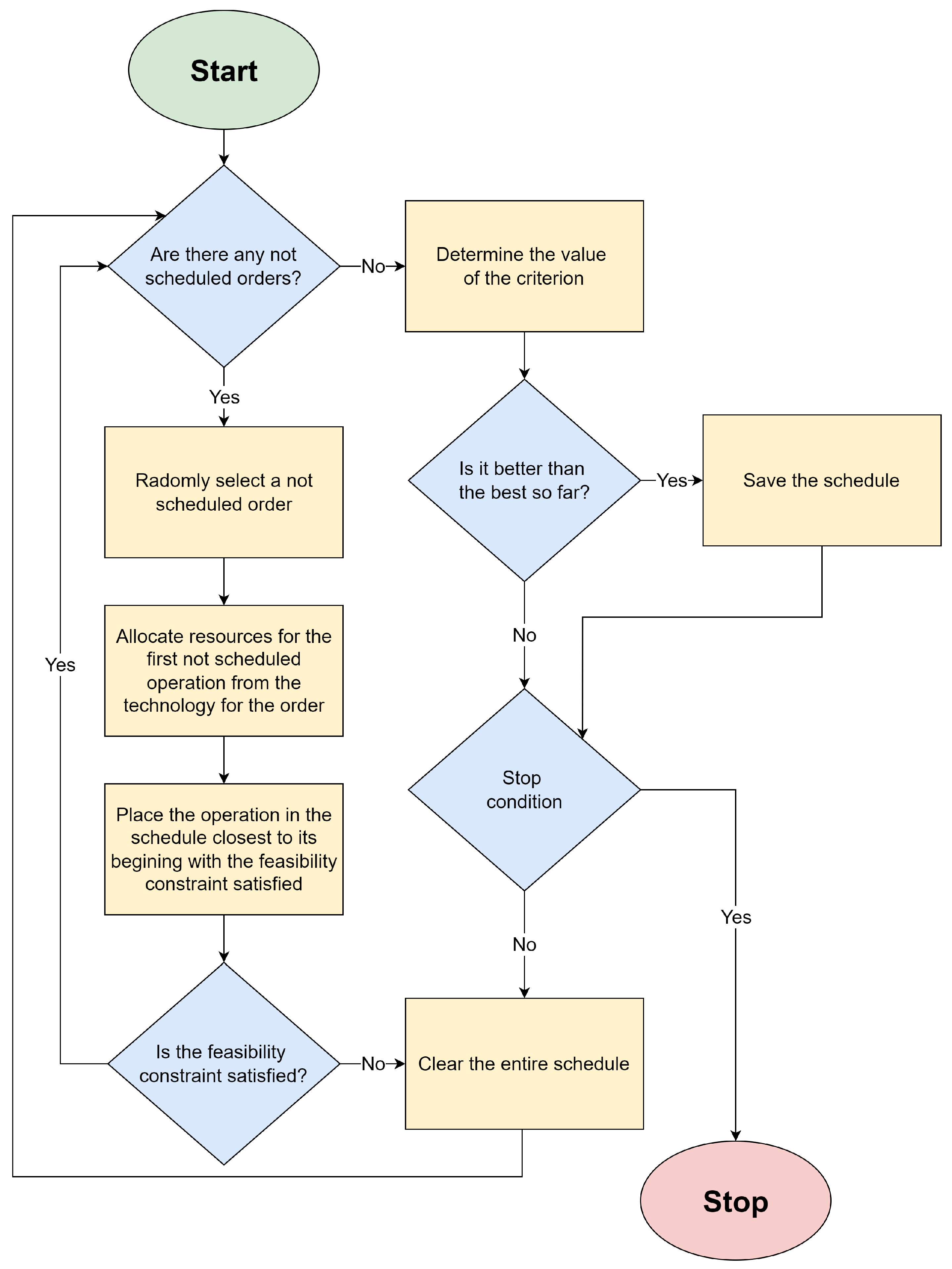

2.4. Optimization Algorithm

3. Research Methodology

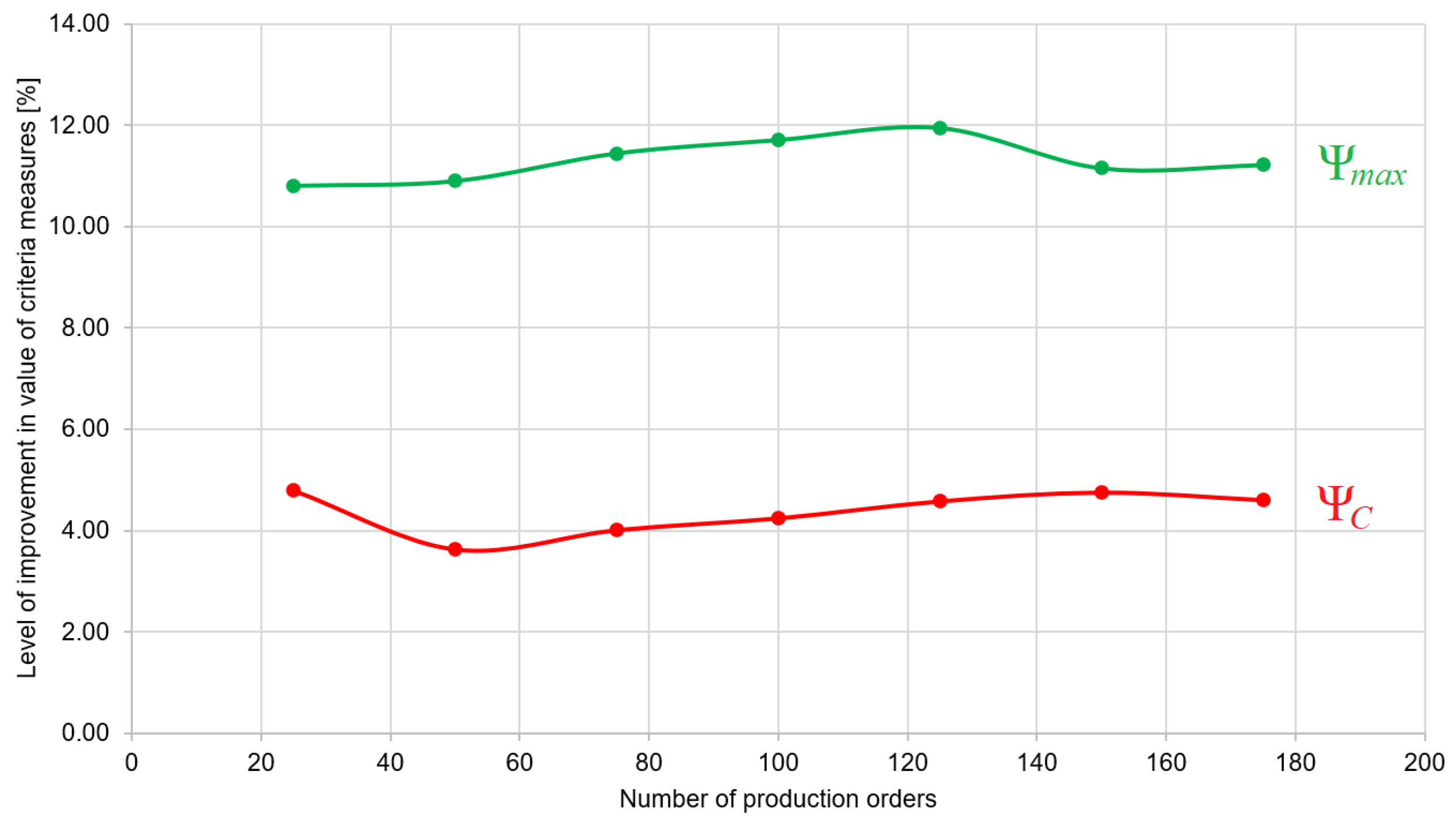

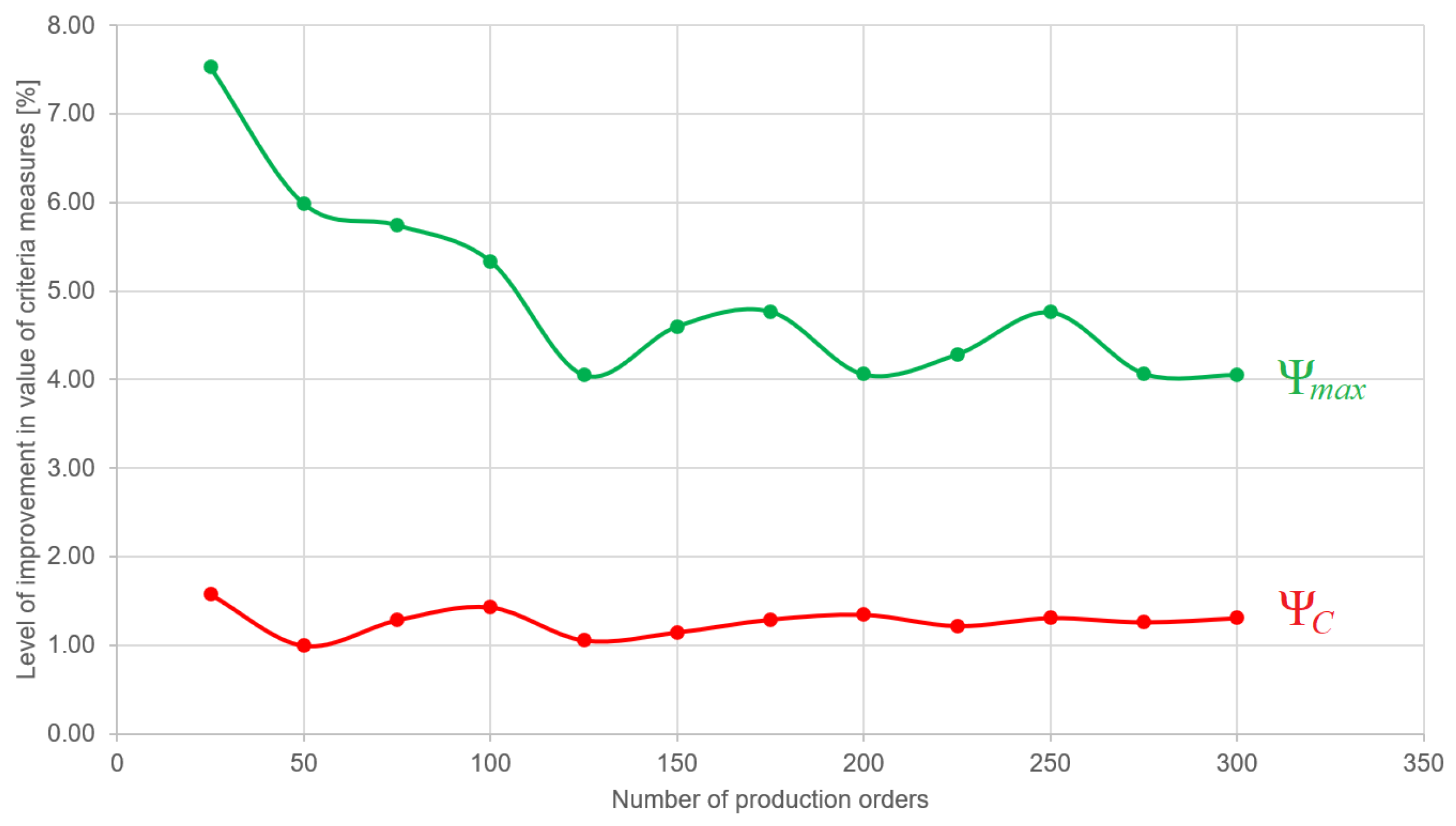

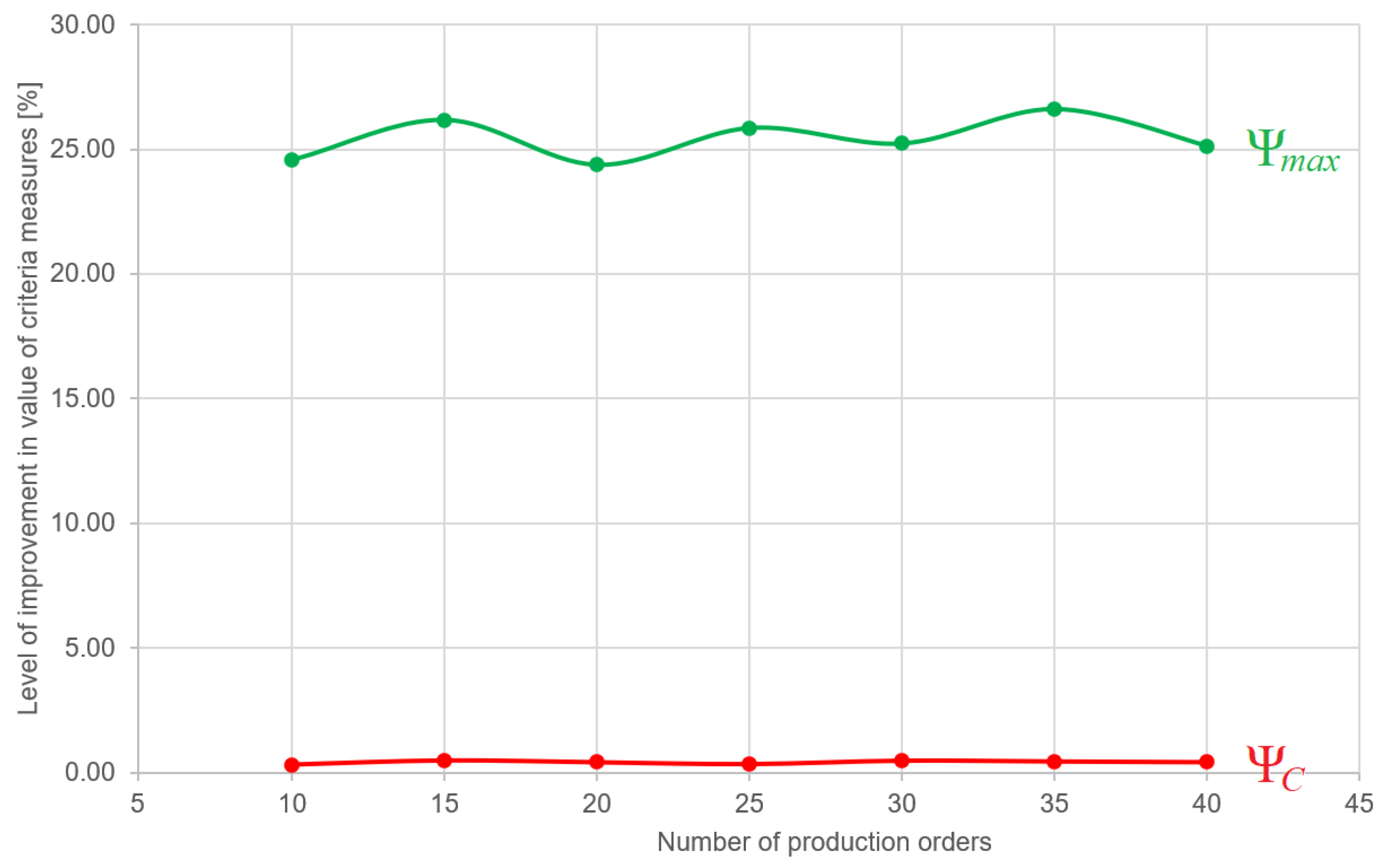

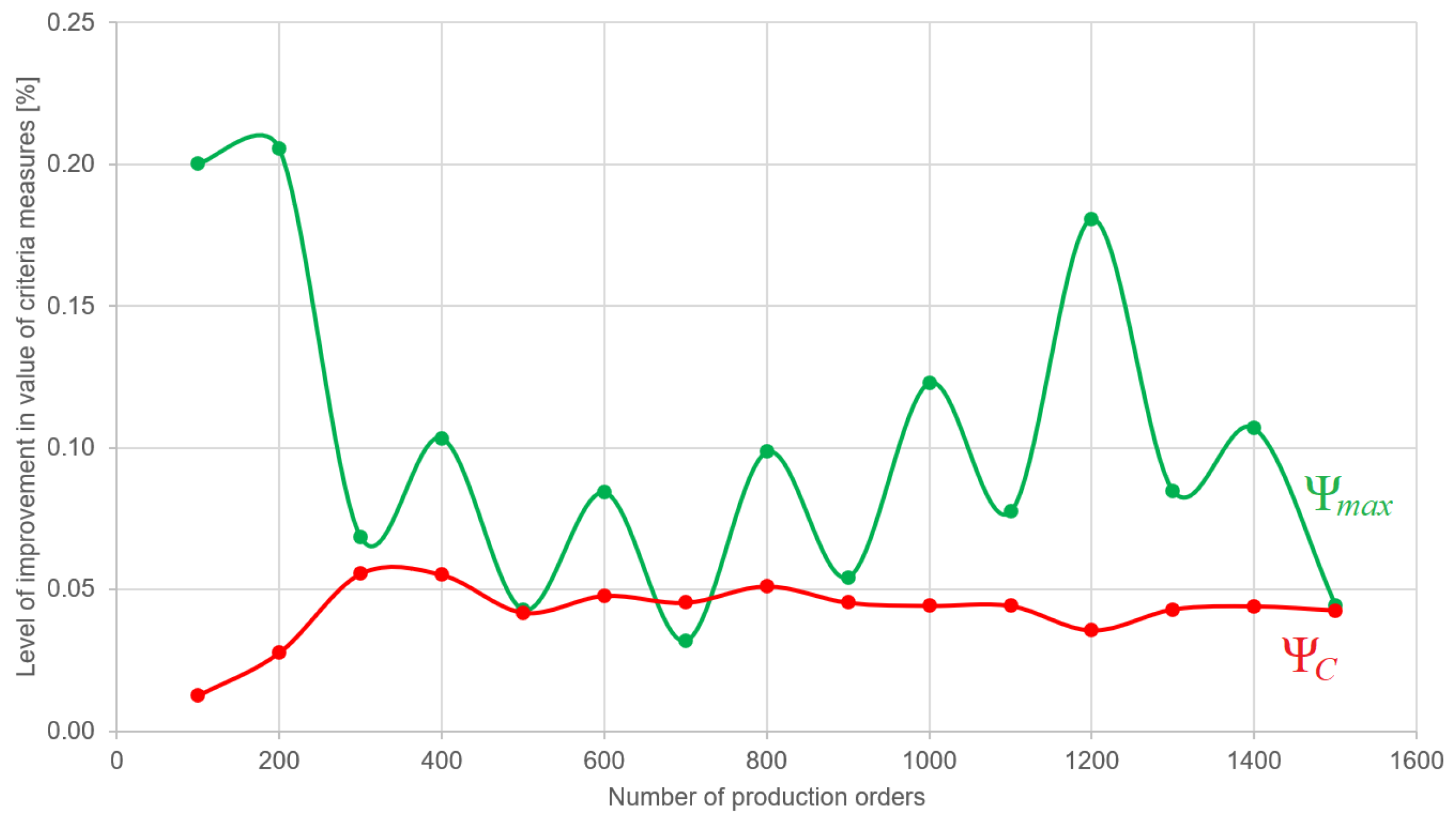

4. Experiments, Results, and Discussion

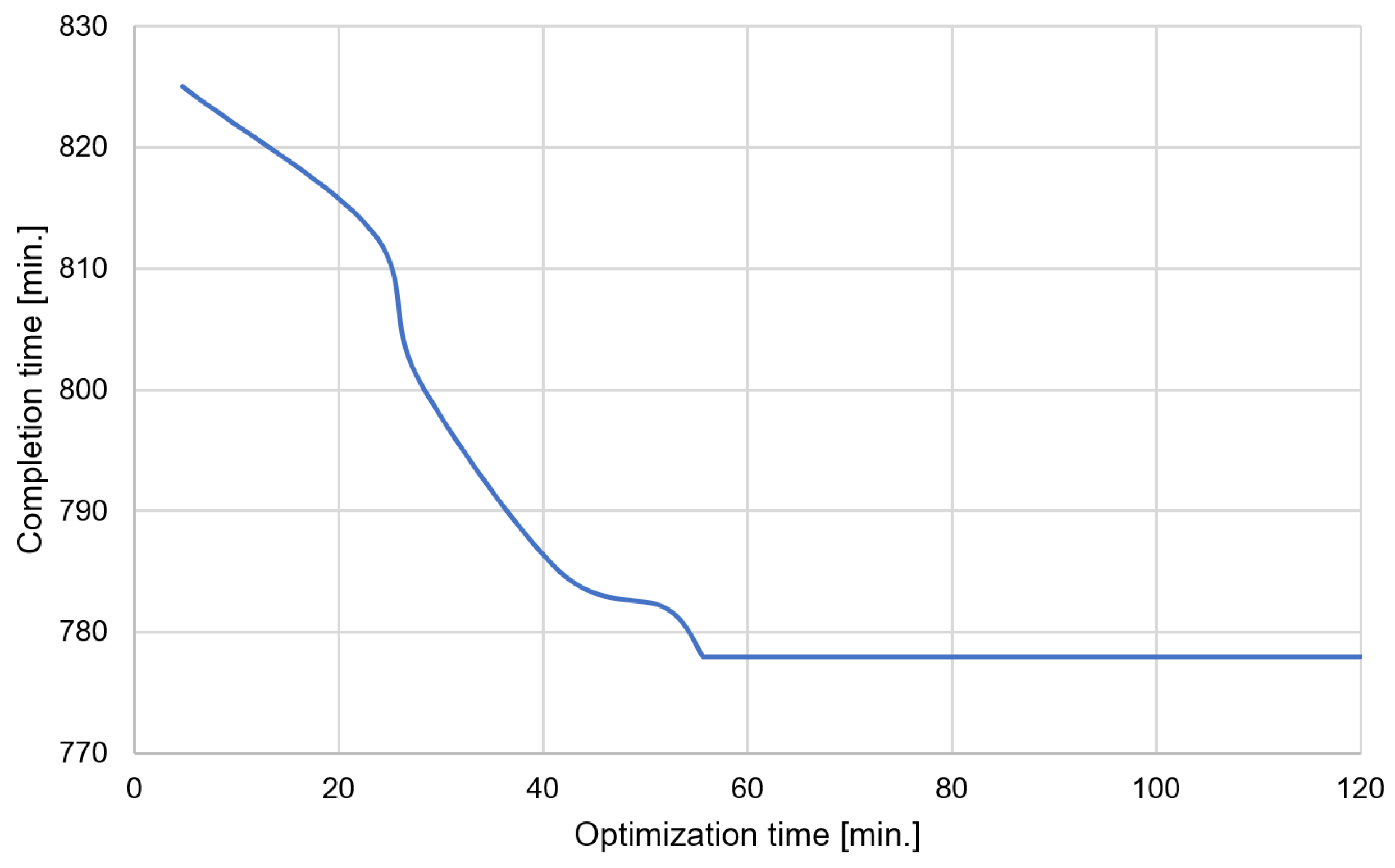

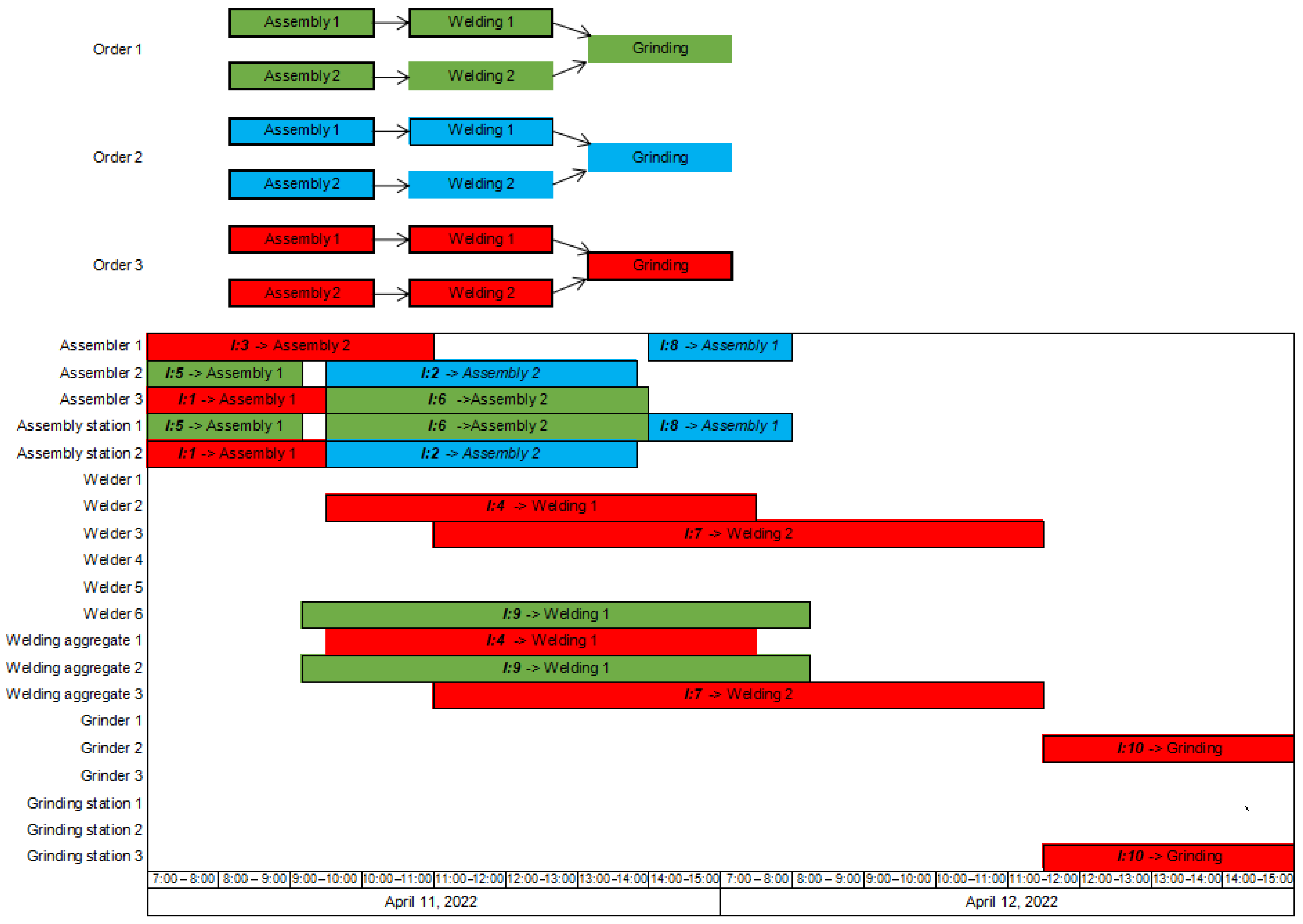

4.1. Production of the Scraper Conveyor Chute

4.2. Production of the Closing Flap

4.3. Production of the RG Switchgear

4.4. Production of the Self-Adhesive PVC Film

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gansterer, M. Aggregate Planning and Forecasting in Make-to-order Production Systems. Int. J. Prod. Econ. 2015, 170, 521–528. [Google Scholar] [CrossRef]

- Burdett, R.L.; Corry, P.; Eustace, C.; Smith, S. A flexible job shop scheduling approach with operators for coal export terminals—A mature approach. Comput. Oper. Res. 2020, 115, 104834. [Google Scholar] [CrossRef]

- Liu, Q.; Li, X.; Gao, L.; Li, Y. A modified genetic algorithm with new encoding and decoding methods for integrated process planning and scheduling problem. IEEE Trans. Cybern. 2020, 51, 4429–4438. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Wang, L.; Zhao, F.; Fan, Y.; Tang, R.; Wen, Y. Optimization of Production Scheduling Using Self-Crossover Genetic Algorithm. In Proceedings of the 2019 International Conference on Wavelet Analysis and Pattern Recognition (ICWAPR), Kobe, Japan, 7–10 July 2019; pp. 1–7. [Google Scholar]

- Sadiq, S.S.; Abdulazeez, A.M.; Haron, H. Solving multi-objective master production schedule problem using memetic algorithm. Indones. J. Electr. Eng. Comput. Sci. 2020, 18, 938–945. [Google Scholar] [CrossRef]

- Bagchi, T.P.; Gupta, J.N.; Sriskandarajah, C. A review of TSP based approaches for flowshop scheduling. Eur. J. Oper. Res. 2006, 169, 816–854. [Google Scholar] [CrossRef]

- Bewoor, L.A.; Prakash, V.C.; Sapkal, S.U. Production scheduling optimization in foundry using hybrid Particle Swarm Optimization algorithm. Procedia Manuf. 2018, 22, 57–64. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, C. A hybrid multi-objective gray wolf optimization algorithm for a fuzzy blocking flow shop scheduling problem. Adv. Mech. Eng. 2018, 10, 1687814018765535. [Google Scholar] [CrossRef]

- Tomazella, C.P.; Nagano, M.S. A comprehensive review of Branch-and-Bound algorithms: Guidelines and directions for further research on the flowshop scheduling problem. Expert Syst. Appl. 2018, 158, 113556. [Google Scholar] [CrossRef]

- Neufeld, J.S.; Gupta, J.N.; Buscher, U. A comprehensive review of flowshop group scheduling literature. Comput. Oper. Res. 2016, 70, 56–74. [Google Scholar] [CrossRef]

- Cheng, T.E.; Gupta, J.N.; Wang, G. A review of flowshop scheduling research with setup times. Prod. Oper. Manag. 2000, 9, 262–282. [Google Scholar] [CrossRef]

- Cheng, T.C.E.; Wu, C.C.; Chen, J.C.; Wu, W.H.; Cheng, S.R. Two-machine flowshop scheduling with a truncated learning function to minimize the makespan. Int. J. Prod. Econ. 2013, 141, 79–86. [Google Scholar] [CrossRef]

- Najari, F.; Mohammadi, M.; Nadi, H. A genetic algorithm for scheduling jobs and maintenance activities in a permutation flow shop with learning and aging effects. Int. J. Ind. Syst. Eng. 2016, 24, 32–43. [Google Scholar] [CrossRef]

- Wang, J.B.; Wang, M.Z. Minimizing makespan in three-machine flow shops with deteriorating jobs. Comput. Oper. Res. 2013, 40, 547–557. [Google Scholar] [CrossRef]

- Burdett, R.; Kozan, E. Resource aggregation issues and effects in mixed model assembly. In Proceedings of the 5th Operations Research Conference of Australian Society for Operations Research Queensland Branch on Operations Research into the 21st Century; Australian Society for Operations Research Queensland Branch: Brisbane, QLD, Australia, 2003; pp. 35–53. [Google Scholar]

- Burdett, R.L.; Kozan, E. Evolutionary algorithms for resource constrained non-serial mixed flow shops. Int. J. Comput. Intell. Appl. 2005, 3, 411–435. [Google Scholar] [CrossRef]

- Jansen, K.; Mastrolilli, M.; Solis-Oba, R. Approximation schemes for job shop scheduling problems with controllable processing times. Eur. J. Oper. Res. 2005, 167, 297–319. [Google Scholar] [CrossRef]

- Burdett, R.L.; Corry, P.; Eustace, C.; Smith, S. Scheduling pre-emptible tasks with flexible resourcing options and auxiliary resource requirements. Comput. Ind. Eng. 2021, 151, 106939. [Google Scholar] [CrossRef]

- Kreipl, S.; Dickersbach, J.T. Scheduling coordination problems in supply chain planning. Ann. Oper. Res. 2008, 161, 103–123. [Google Scholar] [CrossRef]

- Meyr, H. Simultaneous lotsizing and scheduling by combining local search with dual reoptimization. Eur. J. Oper. Res. 2000, 120, 311–326. [Google Scholar] [CrossRef]

- Karimi, B.; Fatemi Ghomi, S.M.T.; Wilson, J.M. The capacitated lot sizing problem: A review of models and algorithms. OMEGA 2003, 31, 365–378. [Google Scholar] [CrossRef]

- Chan, H.K.; Chung, S.H.; Lim, M.K. Recent research trend of economics lot scheduling problems. J. Manuf. Technol. Manag. 2013, 24, 465–482. [Google Scholar] [CrossRef]

- Ferreira, D.; Clark, A.R.; Almada-Lobo, B.; Morabito, R. Single stage formulations for synchronised two-stage lot sizing and scheduling in soft drink production. Int. J. Prod. Econ. 2012, 136, 255–265. [Google Scholar] [CrossRef]

- Guimaraes, L.; Klabjan, D.; Almada-Lobo, B. Pricing, relaxing and fixing under lot sizing and scheduling. Eur. J. Oper. Res. 2013, 230, 399–411. [Google Scholar] [CrossRef]

- Clark, A.R.; Almada-Lobo, B.; Almeder, C. Lot sizing and scheduling- industrial extensions and research opportunities, special issue on lot sizing and scheduling. Int. J. Prod. Res. 2011, 49, 2457–2461. [Google Scholar] [CrossRef]

- Toso, A.V.; Morabito, R.; Clark, A.R. Lot sizing and sequencing optimization and an animal feed plant. Comput. Ind. Eng. 2009, 57, 813–821. [Google Scholar] [CrossRef]

- Pechmann, A.; Schöler, I. Optimizing energy costs by intelligent production scheduling. In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C., Eds.; Springer: Berlin, Germany, 2011; pp. 293–298. [Google Scholar]

- Aghelinejad, M.; Ouazene, Y.; Yalaoui, A. Production scheduling optimisation with machine state and time-dependent energy costs. Int. J. Prod. Res. 2018, 56, 5558–5575. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres-Meré, J.; García-Sánchez, A.; Ortega-Mier, M. Optimizing the production scheduling of a single machine to minimize total energy consumption costs. J. Clean. Prod. 2014, 67, 197–207. [Google Scholar] [CrossRef]

- Burdett, R.L.; Kozan, E. Techniques to effectively buffer schedules in the face of uncertainties. Comput. Ind. Eng. 2015, 87, 16–29. [Google Scholar] [CrossRef][Green Version]

- Lambrechts, O.; Demeulemeester, E.L.; Herroelen, W.S. Proactive and reactive strategies for resource-constrained project scheduling with uncertain resource availabilities. J. Sched. 2008, 11, 121–136. [Google Scholar] [CrossRef]

- Červeňanská, Z.; Važan, P.; Juhás, M.; Juhásová, B. Multi-criteria optimization in operations scheduling applying selected priority rules. Appl. Sci. 2021, 11, 2783. [Google Scholar] [CrossRef]

- Gajdzik, B.; Grabowska, S.; Saniuk, S. A theoretical framework for industry 4.0 and its implementation with selected practical schedules. Energies 2021, 14, 940. [Google Scholar] [CrossRef]

- Husár, J.; Dupláková, D. Material flow planning for bearing production in digital factory. In Key Engineering Materials; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2016; Volume 669, pp. 541–550. [Google Scholar]

- Burdett, R.L.; Kozan, E. The assignment of individual renewable resources in scheduling. Asia-Pac. J. Oper. Res. 2004, 21, 355–377. [Google Scholar] [CrossRef]

- Stadtler, H.; Kilger, C. Supply Chain Management and Advanced Planning–Concepts, Models, Software and Case Studies, 3rd ed.; Springer: Berlin, Germany, 2005. [Google Scholar]

- Blackstone, J.H. APICS Dictionary, 13th ed.; APICS: Chicago, IL, USA, 2010. [Google Scholar]

- Asta, S.; Karapetyan, D.; Kheiri, A.; Özcan, E.; Parkes, A.J. Combining Monte-Carlo and hyper-heuristic methods for the multi-mode resource-constrained multi-project scheduling problem. Inf. Sci. 2016, 373, 476–498. [Google Scholar] [CrossRef]

- Lubosch, M.; Kunath, M.; Winkler, H. Industrial scheduling with Monte Carlo tree search and machine learning. Procedia CIRP 2018, 72, 1283–1287. [Google Scholar] [CrossRef]

- Papavasileiou, V.; Koulouris, A.; Siletti, C.; Petrides, D. Optimize manufacturing of pharmaceutical products with process simulation and production scheduling tools. Chem. Eng. Res. Des. 2007, 85, 1086–1097. [Google Scholar] [CrossRef]

- Kordos, M.; Boryczko, J.; Blachnik, M.; Golak, S. Optimization of warehouse operations with genetic algorithms. Appl. Sci. 2020, 10, 4817. [Google Scholar] [CrossRef]

- Zhou, T.; Tang, D.; Zhu, H.; Wang, L. Reinforcement Learning With Composite Rewards for Production Scheduling in a Smart Factory. IEEE Access 2021, 9, 752–766. [Google Scholar] [CrossRef]

- Ojstersek, R.; Brezocnik, M.; Buchmeister, B. Multi-objective optimization of production scheduling with evolutionary computation: A review. Int. J. Ind. Eng. Comput. 2020, 11, 359–376. [Google Scholar] [CrossRef]

- Dehghanimohammadabadi, M.; Keyser, T.K. Intelligent simulation: Integration of SIMIO and MATLAB to deploy decision support systems to simulation environment. Simul. Model. Pract. Theory 2017, 71, 45–60. [Google Scholar] [CrossRef]

- Ciepliński, P.; Golak, S. Methodology of research on an influence of technological conditions on the quality of a production schedule. In Nowoczesne Technologie–Strategie, Rozwiązania i Perspektywy Rozwoju. T. 1; Bujalska, B., Maciąg, K., Eds.; TYGIEL: Lublin, Poland, 2021; pp. 244–256. [Google Scholar]

| Operation | Processing Times | Resources | ||

|---|---|---|---|---|

| Min | Max | Employees (Person) | Tools (pcs) | |

| Assembly 1 | 120.0 | 150.0 | 3 assembers | 2 assembly stations |

| Welding 1 | 360.0 | 425.0 | 6 welders | 3 welding aggregates |

| Assembly 2 | 240.0 | 270.0 | 3 assembers | 2 assembly stations |

| Welding 2 | 510.0 | 606.3 | 6 welders | 3 welding aggregates |

| Grinding | 180.0 | 210.0 | 3 grinders | 3 grinding stations |

| Sum | 1410.0 | 1661.3 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciepliński, P.; Golak, S.; Blachnik, M.; Gawryś, K.; Kachel, A. Production Scheduling Methodology, Taking into Account the Influence of the Selection of Production Resources. Appl. Sci. 2022, 12, 5367. https://doi.org/10.3390/app12115367

Ciepliński P, Golak S, Blachnik M, Gawryś K, Kachel A. Production Scheduling Methodology, Taking into Account the Influence of the Selection of Production Resources. Applied Sciences. 2022; 12(11):5367. https://doi.org/10.3390/app12115367

Chicago/Turabian StyleCiepliński, Piotr, Sławomir Golak, Marcin Blachnik, Katarzyna Gawryś, and Adam Kachel. 2022. "Production Scheduling Methodology, Taking into Account the Influence of the Selection of Production Resources" Applied Sciences 12, no. 11: 5367. https://doi.org/10.3390/app12115367

APA StyleCiepliński, P., Golak, S., Blachnik, M., Gawryś, K., & Kachel, A. (2022). Production Scheduling Methodology, Taking into Account the Influence of the Selection of Production Resources. Applied Sciences, 12(11), 5367. https://doi.org/10.3390/app12115367