Abstract

Extensive numerical and analytical studies exist that focus on the scours around bridge piers with different cross-sections. However, studies addressing the scour around bridge piles are rather limited and not conclusive. Therefore, the most efficient cross-section reducing the local scour around a pile group is experimentally examined herein. Accordingly, comparative scouring of three different shapes, namely, circular, rectangular and lenticular, is investigated by installing a cohesion-less bedding material around scaled bridge piles immersed in clear water. It is also shown that the available pier scour predictive models grossly underestimate the depth of pile scour holes. For example, the pier predictive models underestimate the pile scours hole by more than 50% in the case of square and circular cross-sections. It also transpires from the experimental investigation that the scour hole depth around the square shape pile is significant, around the circular pile is moderate and around the lenticular pile is minimal.

1. Introduction

Local scour around a bridge pier is one of the most critical challenges that can jeopardize the stability of the bridges [1,2,3]. The scour results in altering the riverbed level, thereby causing a major structural problem for bridge piers. Local scour is amplified during extreme weather events such as floods and hurricanes, causing currents and vortices past bridge piers. Scouring is even more pronounced in the typically grouped pile foundation because of the boundary separation on the upstream side and vortex shedding on the downstream side of the grouped foundation [4,5,6].

It comes as no surprise that the study of local scour depth at bridge piers has received considerable attention and the literature devoted to this subject is vast. Various forms of equations have been proposed that describe mathematically the relationship between the scour hole and various influencing parameters. Unlike individual pier, scouring in the pile groups appears not to have been examined extensively, mainly because the group effect seems similar to that of the individual pier. Nevertheless, this expectation may not be realized because of Hannah’s study [7] on scouring in binary piles.

The first systematic study of two piles have been made by Hannah [7] in which the effect of pile spacing was discussed keeping pile diameter constant. Hannah [7] introduced a dimensionless parameter S/D, which is the ratio between the face to face spacing of piles in a group and individual pile diameter D. This study shows that when the piles are spaced at face-to-face distance equal to pile diameter, i.e., S/D = 1, the depth of scour at the front pile equals the scour due to an equivalent individual pile with the width twice that of a pile in the group. With increasing pile spacing, the effect of the reinforcing factor can be seen in the first pile. The reinforcing factor effect reaches its maximum in S/D = 2.5 and exists up to S/D = 11. A similar investigation has been reported by Beheshti and Ataie-Ashtiani [8] in which both the pile diameters and spacing were considered variables.

Beheshti and Ataie-Ashtiani [8] examined the effects of pile spacing on the maximum depth of scour at bridge piles. The results showed that by increasing the spacing between the piles, the amount of scouring reduces. This study was extended to find the effect of different S/D ratios on the scour depth [9]. They showed that if the ratio S/D > 11, then the scouring depth at the front pile is equal to the value of an individual pile. In addition, investigating the ratios S/D = 0.5, 1, 2, 4 and 6, they concluded that the scour depth reduces when the pile spacing increases. To be specific, for S/D = 0.25, the maximum depth of scour was found to be 50% more than a single pile. In a continuation of this study, Beg [10] reported the effect of pile spacing on the scour depth. It was found that for the ratio S/D = 1, scour depth is 1.95 times greater than that of an individual pile. Contrary to Beheshti et al. [8] investigation, Movahedi et al. [11] reached different conclusions from a similar study.

Movahedi et al. [11], from a study of piles at ratios S/D = 0, 0.5 and 1, observed that the adjacent pile scour holes interfere with each other and form a big hole at the location of upstream piles. However, at these S/D ratios, when the minimum spacing increases either to 2D or 4D, scour holes and scour ridges around the piles do not interfere. This study also showed that by increasing the spacing between the piles, scour depth decreases, such as for the ratio S/D = 6, the scour depth approaches that of a single pile.

The review of the literature highlighted above has focussed primarily on circular piles. Attempts have also been made to find the most efficient pile cross-sectional dimensions that can effectively reduce the scour depth. For example, the scour parameters of the cylindrical pile group have been considered by Sanei et.al. [12], investigating the effect of cylindrical pile diameter on the scour hole depth and volume. Their study showed that a 90% increase in the pile diameter results in about a 70% increase in the scour depth and an 85% decrease in the scour hole volume. Many other researchers [13,14,15,16,17,18,19,20] have worked on the size and spacing of the piles.

To find an efficient pile that can reduce the scour due to the erosive action of flowing water, Elnikhely [21] employed perforated piles having holes with different orientations. The author has reported an 80% reduction in scouring when the hole orientation is 45° and a 47% reduction in scouring when the hole is oriented at 90°. However, the presence of holes in piles can lead to loss of strength and possible structural failure. Apart from this, soil improvement measures can be applied around bridge piers to prevent the possibility of excessive souring. For example, corrugated aprons [22] can be used to counter the formation of deep scour holes.

All these experimental investigations on piles identify variables of interest that set up the basis for empirical and numerical approaches for estimating the depth of scour holes [23,24]. Ferraro et al. [25] offered an empirical method for predicting the scour depth based on the pile cap. However, it is essential to use caution in using the empirical relations of piers and pile caps for piles, because they can lead to ambiguous results.

A review of the literature shows that various shapes of bridge piers and pile caps are studied extensively with a sense of purpose to minimize local scour [26,27,28,29,30,31,32,33,34,35,36,37,38]. However, the effect of pile shapes in a group has not been studied in great detail. Gautam et al. [39] have carried out experimental investigations concerning scour around a complex pier with a lenticular or elliptical pile cap. It is shown that the elliptical pile cap can effectively reduce the scour. (However, field observation has revealed that most of the time the filing of the earth is up to piles and pile cap shape does not play any role).

It is clear from the review of the above literature that there are few studies examining scour around bridge piles. Thus, it is the purpose to provide a bridge to this subject and to investigate the effect of different shapes of piles on the degree of scouring. The study extends the pile geometry to three different shapes of pile groups and examines these piles experimentally under constant conditions. It is found that the scouring around the lenticular piles is least as compared to the square and circular piles. Moreover, the frontal piles experience the maximum scouring as compared to the end piles. Finally, the experimental scouring values are further compared with the commonly used pier empirical models, which suggests amending these empirical formulas for predicting the scour-hole depth.

2. Research Significance

Local scour (Appendix C) around bridge piers is an important research topic in coastal and ocean engineering. Although considerable amounts of experimental investigations and empirical models are available examining the bridge pier scour, studies investigating scour around piles of various cross-sections are still lacking to a large extent. The present study aims to provide new insight into the scouring around a group of piles of different shapes, i.e circular, rectangular and lenticular. Because no empirical predictive models have been proposed for assessing the scour depth around piles. However, the comparison of pier empirical results versus the experimental results of piles proved the inadequacy of the pier models. The current study also suggests that lenticular cross-section piles are the most efficient pile shape as compared to circular and rectangular shapes.

3. Methodology

3.1. Flume

The experimental study is carried out using the flume shown in Figure 1. This flume is 15.85 m long, 0.30 m wide and 0.45 m deep. The flume assembly comprises a centrifugal pump with three water tanks having a single inflow control valve, main flume, weir and outflow control valve. This pump moves the water from the recirculation tank and also supplies water to the flume. Subsequently, this flow discharges into a sump tank after passing through the test section. A valve installed at the downstream end of the flume controls the flow depth, while a valve at the upstream end regulates the flow rate.

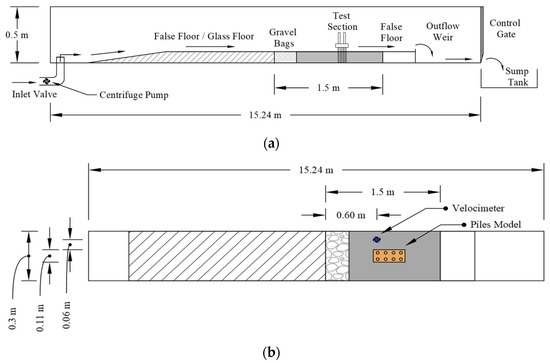

Figure 1.

(a) The schematic side view drawing of the flume used in the present study. (b) The schematic plan view drawing of the flume used in the present study.

The quantities measured are the scour depth and flow velocity. Scour depth is measured by a point gauge and the flow velocity is measured by a velocimeter. The point gauge is placed at the aluminum railing and installed at the top of the flume. The point gauge can slide smoothly along as well as across the flume. Moreover, the velocimeter measures the velocity with a precision propeller calibrated before the commencement of the experiment. The velocimeter is placed in the flume at a distance shown in Figure 1b, in such a way that it will not disturb the approaching velocity of the water. A rectangular weir is also installed at the end of the test section for two reasons. First, to measure the flow rate in the flume and second, to trap the sediments in the flowing water. The sediments are regularly removed to avoid choking the pump responsible for controlling the water discharge.

Some necessary modifications are made to the flume to improve its performance. A 1.52 m long test section is prepared at a distance of 1.52 m from the upstream starting point, as shown in Figure 1. The test section had glass sheets installed at the upstream and the downstream side, thereby avoiding any turbulence at the section entrance. This glass bed is used as a datum for measuring velocity and water depth.

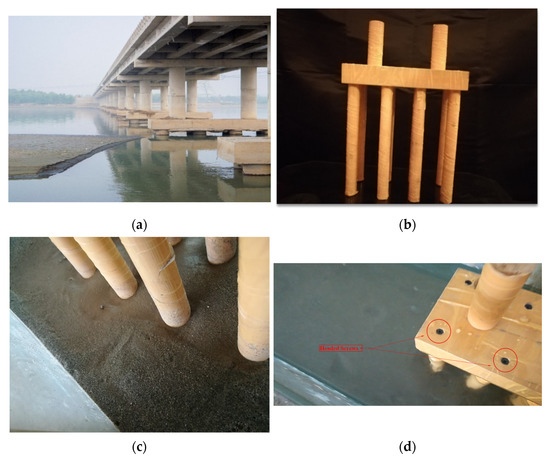

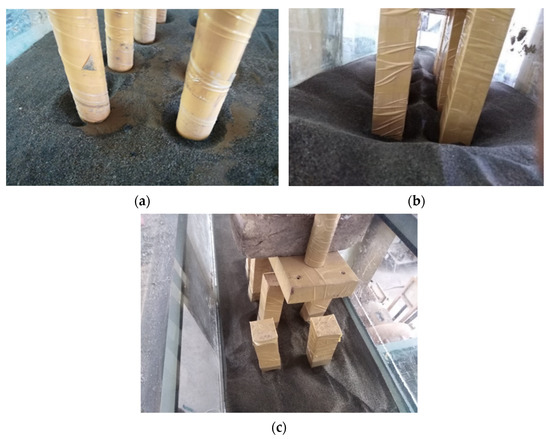

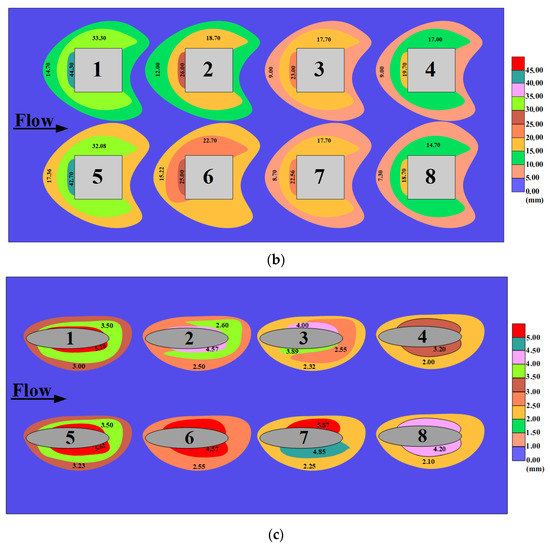

The test section is overlain by a leveled and compacted fine sand before the test pile is installed, Figure 2. This section tended to erode during the water flow over the glass bed, consequently affecting the local scour depth around the test pile. Therefore, to avoid local erosion and ensure a smooth flow, a few gravel bags are stacked at the entrance of the glass bed. Similarly, 0.61 m long wooden plank is positioned near the downstream end of this section, preventing sediment transport and stabilizing the test section. In order to avoid any dislocation of the piles from their mean position, the piles are attached to the pile cap with the help of screws, as shown in Figure 2d. Moreover, a moderate load is placed over the pile cap to ensure an undisturbed position of piles during water flow, Figure 2e. Figure 2b,c,e,f show the model, its fitting in the testing flume and its subjection to the steady water currents, respectively.

Figure 2.

(a) Existing Pakhtoon Gari Bridge. (b) Model prepared for laboratory test. (c) Model fitted in flume test section. (d) Fixing of piles with pile cap. (e) Front view of the test section. (f) Square piles subjected to water current. (g) Electronic velocity meter.

3.2. Sieve Analysis

Sediment size is a key parameter that affects both the scour depth and the scour hole dimensions. Although the most commonly used sediment size affecting the characteristics of local scour is the d50 median grain size diameter, the adopted similitude analysis could not scale down the sediment size to this diameter. Therefore, an effort was made to select smaller diameter sediment that had a negligible influence on the scouring. In this context, there have been few attempts to assess the interaction of sediment size and attributes of local scour. Ettema et al. [40] have reported that the fine uniform particle of non-cohesive sand has an insignificant influence on scour depth. Subsequently, Melville and Chiew [41] have drawn the same conclusion during their experimental investigations concerning the influence of fine sediments on scouring action.

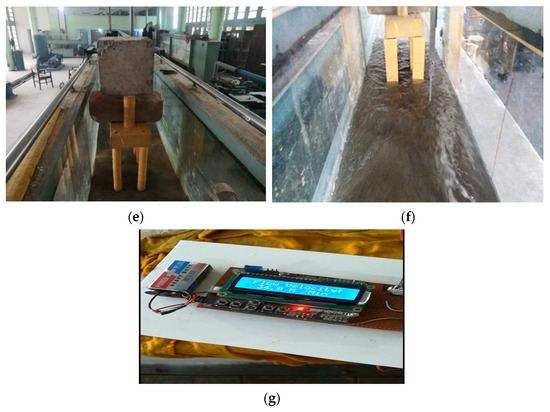

Consequently, a sieving operation is performed herein for determining the sediment size so that the selected median diameter does not influence the local scour. In this respect, to begin, two samples of bed material were collected and dried in an oven for 24 h; following this, the gradation curves were drawn separately; and finally, 0.419 mm of the median diameter of non-cohesive sand was chosen to characterize the desired grading of the sediment for filling the test section of the flume. The results of the sieve analysis are shown in Table 1 and Figure 3.

Table 1.

Sieve analysis of fine aggregate.

Figure 3.

Sieve analysis.

3.3. Bridge Pier Piles Models Selection

The experimental model is the scaled archetype of Pakhtoon Gari bridge (Figure 2a) situated across the river Kabul (34.021 N, 71.832 S Google Earth). This bridge is a multiple-span bridge composed of prestressed concrete I beam and a concrete deck supported on concrete stub abutments. The total span length between the bridge’s abutments is 420 m with 14 equal spans of 30 m center to center between the piers. The bridge is supported by a piled foundation with 104 piles in the piers and 20 piles in the abutments. The pier piles are arranged in a group of 8, laid out in a rectangular grid pattern of 2 × 4 piles. The individual pile is 750 mm in diameter, where the embedment is 28 m in piers and 18 m in abutments.

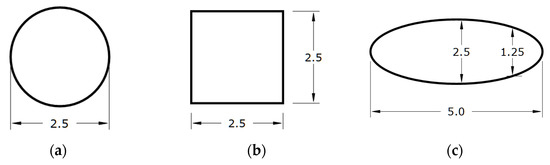

Because of the important effect of pile geometry on scour depth, an experimental investigation has been carried out using three different pile cross-sections: circular, square and lenticular. An experimental pile group model is prepared to employ a reasonable geometric scaling factor derived after several mathematical trials. To study the scour characteristic of this model, a scaled ratio of 1:30 is selected based on the limitations due to the flume size, water pump capacity and environmental constraints. Considering the ratio of prototype length () to model length (), the geometric scale factor () is

Given the system involving open channel flow, it is necessary to consider the Froude number. Thus

where defines the velocity of the flow, represents the flow depth and acceleration due to gravity.

In order to remain consistent, the Froude number of the experimental model and its prototype structure is taken the same:

Since,

Moreover, the discharge in the testing flume can be calculated as:

where the width of the prototype and model are and , respectively. Incorporating these values in Equation (10), the resultant discharge of the prototype.

Now, it turns out, when using Equation (12), that the model flow rate gives geometric similarity to the actual flow rate of 1061 m3 s−1, based on the average peak flood flow in the last fifty years in the Kabul river. Similarly, using the scale factor of 1:30, the model dimensions are determined, as shown in Table 2, Figure 4 and Figure 5.

Table 2.

Scale down values of different members of bridge pier piles.

Figure 4.

Systematic diagram of model (all dimensions are in cm): (a) plan; (b) elevation.

Figure 5.

Dimension of different piles (all dimensions are in cm): (a) circular; (b) square; (c) lenticular.

4. Results and Discussion

As discussed previously, 30 experiments are conducted to investigate the effect of different pile shapes on scour hole depth, Figure 6, Figure 7 and Figure 8. Of the 30 experiments, 10 included the circular piles, 10 involved the square piles and the remaining 10 lenticular piles. The average scour depth, corresponding to the pile shape, is found by adding the reading of the respective 10 experiments and dividing by 10. It is important to note that each experiment is run for 24 h to obtain the maximum possible scouring. The scour holes are measured in four positions A, B, C and D around each pile, as shown in Figure 7. The results obtained from these experiments are presented and analyzed in Figure 8 and Appendix A. It reveals that the scour hole around the square piles is maximum. The main reason for the largest scour hole is the maximal flow obstruction, leading to progressive horseshoe formation.

Figure 6.

(a) Scour hole around the circular pile; (b) scour hole around the square piles; (c) dislocation of the pile cap due to excess loss of soil.

Figure 7.

Point of measurement around: (a) circular; (b) lenticular; (c) square piles.

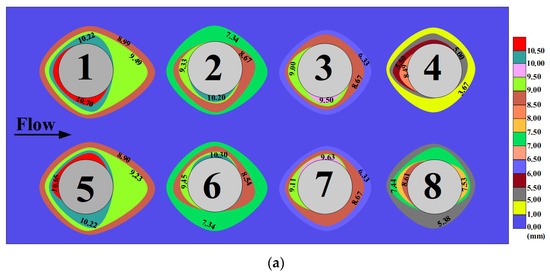

Figure 8.

Scour depths contours for pile group: (a) circular; (b) square; (c) lenticular.

Contrarily, the lenticular shape has shown minimal scour depth at the leading frontal edge of piles. This reduced scouring is due to its sharp nose, which provides minimal obstruction to water flow. However, the lenticular pile side camber line experienced more scouring than the piles leading front and trailing tail. A detailed special comparison of the scouring of piles is discussed below.

4.1. Scouring at Different Positions of Piles

Figure 8 shows that the piles facing the water current first experienced maximum scouring compared to the preceding group of piles. It can be seen that the frontal area of upstream piles 1 and 5 experiences the maximum local scour of 10.7 mm and 10.65 mm. As regards the square piles, the same trend is observed in circular piles, with the scouring of 44.3 mm and 42.7 mm at the upstream piles 1 and 5. Notably, scouring at the downstream piles is less than at the upstream pile. The reason lies in the fact that as the water flows through different piles, the flow velocity decreases, thereby leading to a less intense horseshoe vortex. Moreover, the scouring material from the front scour holes is deposited in the rare scour holes, decreasing the scour depth at the rare piles. This phenomenon can be seen in Figure 6c, where the rear two downstream piles remain in their original position while the rest of the six piles displace. The main reasons are the excessive soil erosion in the upstream piles and the interaction of the scour holes.

4.2. Scouring around Each Pile

The post-experimental scouring holes for the 2 × 4 pile group are shown in Figure 6. Figure 8 illustrates measured scour depths at a different location, marked as A, B, C and D around each pile, shown in Figure 7. It follows that the scouring at location A of piles 1 and 5 is maximum in the case of circular and square piles, while the scouring decrease as the flow approaches the rare piles. Contrarily, the lenticular piles have the least scouring at position A, i.e., 3.20 mm and 3.25 mm compared to other positions, as a rounded nose produces the least disturbance in the streamlines and causes the incoming flow to separate smoothly. Apart from A, position D of the lenticular piles (Pile No 1–4) and position B of piles (Pile No 5–8) experience more scouring, ranging from 5.62 mm to 3.20 mm. This is due to the compressed horseshoe vortex effects and increased flow velocity due to the contraction of the flow area. However, the overall scouring of the lenticular piles at different positions is much less as compared to the circular and square piles. Therefore, lenticular piles are very efficient in scouring.

4.3. Scour Prediction Equations

Various models used for predicting the scour depth around piers, along with their applicability range and limitation, are listed in Appendix B. These models are commonly adopted for piles, even though the scouring behavior around piles is different from that around piers. Based on simplicity and their use of influencing factors consistent with scouring around piles, the empirical equations proposed by Neill, C. R. [23] and Hanco [24] are compared with the experimental results. The empirical models are stated as.

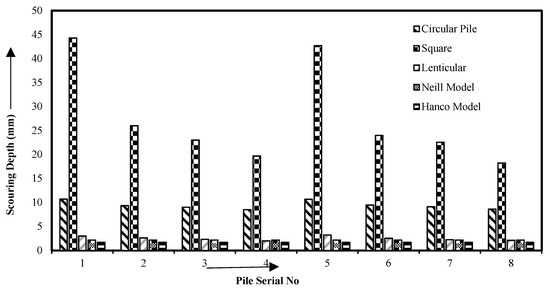

where represents the scouring depth. defines the diameter of breath or diameter of the piles, is the sediment diameter and represents the depth of the approach flow. A comparison of the experimental and the estimated scour holes is given in Table 3 and Figure 9. Accordingly, those pile positions have been selected that experience the maximum scouring, i.e., position A in the square and circular piles and position B in the lenticular piles. It is anticipated that these empirical equations cannot estimate the scour hole around the circular and square piles. However, the empirical estimation is nearly equal to the experimental results obtained from the lenticular piles.

Table 3.

Comparison of Scouring Depth at different Position (based on maximum sscour) with Neil and Hanco Model.

Figure 9.

Comparison scouring depth at Position A with Neill and Hanco Model.

5. Conclusions

This study experimentally investigates the scour around pile groups of various cross-sections, namely rectangular, square and lenticular. A focus is placed on comprehending the scouring process around a rectangular array of eight pile-cap. The depth of a local scour around piles is predicted using empirical models based on piers exposed to steady water currents. The following conclusions can be drawn from this experimental study:

- The scour at a pile group is more extreme relative to that around a single pile, mainly due to the increase in the flow velocity of closely spaced piles resulting in a compressed horseshoe vortex.

- The very first pile at the upstream side of the pile group experiences the maximum scour. This is mainly due to the weakening of the downflow at the pile upstream and the weakening of the horseshoe vortex, which results in a reduced scour around rare piles.

- The influence of geometry of piles has a particularly large effect on the scouring. The effect of scouring is more pronounced in the square piles, followed by the circular piles and minimal in the lenticular piles.

- The existing engineering practice of employing pier scour empirical models is not accurate enough in predicting the scour depth of piles. For example, the current study suggests that the popular Neill and Hanco models underestimate the scour depth by more than 50%.

- Given the inconsistencies between the pier scour predicting models and the experimental scour around the piles, new empirical models based only on piles scouring are needed. Furthermore, the preceding conclusions are valid for the pile groups that are aligned to the flow. For a skewed pile group, the variables influencing the local scour depth are different, thus requiring additional research.

Author Contributions

M.T.: Conceptualization, Methodology, Investigation, Software, Formal Analysis. Writing—original draft, Validation, Experimental Proceudure. A.K.: Resources, Writing—review and editing, Supervision. M.K.: Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

The research work is self funded.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The experimental work is carried out in the hydraulic laboratory of UET Peshawar (Pakistan). Special thanks are extended to Hamna (Local Government, Govt. of Khyber Pakhtunkhwa), for providing Electronic Velocity meter to carry out laboratory experimental test work with high accuracy. I also thank Fazal Farooq (NESPAK-Peshawar) for his guidance, supervision in the selection of the bridge. His assistance and discussions for the selection of Pakhtun Gari Bridge which was suffering from a unique type of bridge piles scouring are highly acknowledged.

Conflicts of Interest

The authors whose names are listed certify that they have NO affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript.

Appendix A

Table A1.

Scouring depth at position A.

Table A1.

Scouring depth at position A.

| Pile No | Discharge (L s−1) | Pier Size (mm) | Flow Depth (mm) | Flow Velocity (mm s−1) | Sediment Size (d50) (mm) | Mean Scour Depth (mm) | ||

|---|---|---|---|---|---|---|---|---|

| Circular | Square | Lenticular | ||||||

| 1 | 4.25 | 25 | 65 | 222 | 0.41 | 10.70 | 44.30 | 3.00 |

| 2 | 4.25 | 25 | 65 | 222 | 0.41 | 9.33 | 26.00 | 2.62 |

| 3 | 4.25 | 25 | 65 | 222 | 0.41 | 9.00 | 23.00 | 2.32 |

| 4 | 4.25 | 25 | 65 | 222 | 0.41 | 8.50 | 19.70 | 2.00 |

| 5 | 4.25 | 25 | 65 | 222 | 0.41 | 10.65 | 42.70 | 3.23 |

| 6 | 4.25 | 25 | 65 | 222 | 0.41 | 9.45 | 24.00 | 2.55 |

| 7 | 4.25 | 25 | 65 | 222 | 0.41 | 9.11 | 22.56 | 2.25 |

| 8 | 4.25 | 25 | 65 | 222 | 0.41 | 8.61 | 18.23 | 2.12 |

Table A2.

Scouring depth at position B.

Table A2.

Scouring depth at position B.

| Pile No | Discharge (L s−1) | Pier Size (mm) | Flow Depth (mm) | Flow Velocity (mm s−1) | Sediment Size (d50) (mm) | Mean Scour Depth (mm) | ||

|---|---|---|---|---|---|---|---|---|

| Circular | Square | Lenticular | ||||||

| 1 | 4.25 | 25 | 65 | 222 | 0.41 | 10.22 | 33.30 | 5.23 |

| 2 | 4.25 | 25 | 65 | 222 | 0.41 | 7.34 | 18.70 | 4.67 |

| 3 | 4.25 | 25 | 65 | 222 | 0.41 | 6.35 | 17.70 | 4.00 |

| 4 | 4.25 | 25 | 65 | 222 | 0.41 | 5.39 | 14.70 | 3.46 |

| 5 | 4.25 | 25 | 65 | 222 | 0.41 | 11.00 | 34.00 | 7.00 |

| 6 | 4.25 | 25 | 65 | 222 | 0.41 | 10.30 | 22.70 | 6.37 |

| 7 | 4.25 | 25 | 65 | 222 | 0.41 | 9.63 | 19.30 | 5.89 |

| 8 | 4.25 | 25 | 65 | 222 | 0.41 | 7.44 | 18.06 | 4.09 |

Table A3.

Scouring depth at position C.

Table A3.

Scouring depth at position C.

| Pile No | Discharge (L s−1) | Pier Size (mm) | Flow Depth (mm) | Flow Velocity (mm/s) | Sediment Size (d50) (mm) | Mean Scour Depth (mm) | ||

|---|---|---|---|---|---|---|---|---|

| Circular | Square | Lenticular | ||||||

| 1 | 4.25 | 25 | 65 | 222 | 0.41 | 9.33 | 14.70 | 3.50 |

| 2 | 4.25 | 25 | 65 | 222 | 0.41 | 8.67 | 12.00 | 2.82 |

| 3 | 4.25 | 25 | 65 | 222 | 0.41 | 6.33 | 11.00 | 2.55 |

| 4 | 4.25 | 25 | 65 | 222 | 0.41 | 4.67 | 9.00 | 2.00 |

| 5 | 4.25 | 25 | 65 | 222 | 0.41 | 9.23 | 17.36 | 3.45 |

| 6 | 4.25 | 25 | 65 | 222 | 0.41 | 8.54 | 15.22 | 2.75 |

| 7 | 4.25 | 25 | 65 | 222 | 0.41 | 8.13 | 8.70 | 2.47 |

| 8 | 4.25 | 25 | 65 | 222 | 0.41 | 7.53 | 7.30 | 2.10 |

Table A4.

Scouring depth at position D.

Table A4.

Scouring depth at position D.

| Pile No | Discharge (L s−1) | Pier Size (mm) | Flow Depth (mm) | Flow Velocity (mm/s) | Sediment Size (d50) (mm) | Mean Scour Depth (mm) | ||

|---|---|---|---|---|---|---|---|---|

| Circular | Square | Lenticular | ||||||

| 1 | 4.25 | 25 | 65 | 222 | 0.41 | 11.05 | 33.78 | 5.20 |

| 2 | 4.25 | 25 | 65 | 222 | 0.41 | 10.20 | 20.70 | 4.57 |

| 3 | 4.25 | 25 | 65 | 222 | 0.41 | 9.50 | 18.30 | 3.89 |

| 4 | 4.25 | 25 | 65 | 222 | 0.41 | 7.22 | 17.06 | 3.20 |

| 5 | 4.25 | 25 | 65 | 222 | 0.41 | 10.2 | 32.8 | 5.68 |

| 6 | 4.25 | 25 | 65 | 222 | 0.41 | 7.33 | 18.7 | 5.12 |

| 7 | 4.25 | 25 | 65 | 222 | 0.41 | 6.33 | 17.7 | 4.85 |

| 8 | 4.25 | 25 | 65 | 222 | 0.41 | 5.38 | 14.7 | 4.20 |

Appendix B

Table A5.

Models for finding the scour depth.

Table A5.

Models for finding the scour depth.

| Authors | Empirical Formulas |

|---|---|

| Laursen & Toch (1956) | |

| Chitale (1962) | |

| Breusers (1965) | |

| Blench (1969) | |

| Shen et al. (1969) | |

| Hancu (1971) | |

| Coleman (1971) | |

| Breusers et al. (1977) | from Neill’s formulation (1973) |

| Jain & Fisher (1979) | from Neill’s formulation (1973) |

| Jain (1981) | from Neill’s formulation (1973) |

| Froelich (1988) | |

| Froelich Design | |

| Kothyari, Garde & Ranga (1992) | |

| Mississippi (Wilson 1995) | |

| Simplified Chinese Gao et al. (1993) | |

| Melville & Sutherland (1988) | |

| Melville (1997) | for a bridge pier |

| Melville & Coleman (2000) | total time to reach equilibrium profile |

| Melville & Kandasamy (1998) | |

| Sheppard & Miller (2006) | from Neill’s formulation (1973) |

| Sheppard et. al., (2014) | for cylindrical piers for rectangular piers |

| FDOT (Arneson et. al., 2012) | |

| HEC-18 or CSU equations | for clear-water scouring |

| Richardson et al. (1993) | |

| Richardson & Davis (1995) | Dimensionless excess velocity intensity |

| Mueller (1996) | |

| Critical velocity (Neill 1973) | using Shields parameter |

| Mueller & Wagner (2005) | |

| Molinas (2004) | |

| Molinas (2004) | |

| Ali & Karim (2002) | |

| Guo (2012) | Densiometric particle Froude number |

| Neill (1973) |

Appendix C. Discussion: Scour around Bridge Piles

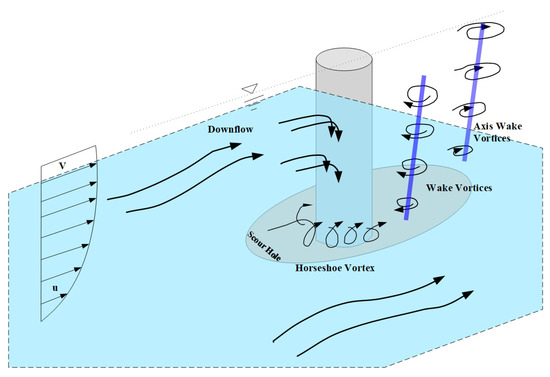

The threat of local scour around bridge piles has been known for many years. Local scouring is a complex phenomenon resulting from a complicated flow pattern as shown in Figure A1 [42]. The primary cause of scouring is the downflow emanating from the presence of the pier’s upstream face, which also results in pressure differential. Consequently, the layer of fluid near the pier splits forming a helical flow at the pier base and a horseshoe vortex system ensues. There can also be a splitting of flow at the sides of a pier in the form of counter-rotating vortices called wake vortices [9,42,43,44]. Thus, a pier scour is also affected by wake vortices where a rotating column of fluid can lift the sediment from the bed and create a scour hole downstream of the pier.

In practice, bridge foundations are designed to withstand the effects of scouring without failing for the worst conditions resulting from floods equal to the 100-year flood or a smaller flood if it causes scour depths deeper than the 100-year flood. These foundations are also checked for the accidental situation of a 500-year super flood [45].

Because of its prevalence as a cause of bridge failure, scour is highly prioritized by the modern bridge code of practices. Several national and provincial bridge design codes (including the American Association of State Highway and Transportation Officials (AASHTO) [46], Load and Resistance Factor Design (LRFD) [47], Load and Resistance Factor Design (LRFD), Ontario Highway Bridge Design Code (OHBDC) [48] and Canadian Highway Bridge Design Code (CHBDC) [49], include provisions for the hydraulic design. Specific provisions for the design of bridge piles to scouring invite the designers to use code-specified “approved methods.” These methods refer to the empirical equations, which have been derived using experimental and field data over the past half-century. These equations are used to calculate the depth under which foundations are placed to avoid failure due to scour. However, these widely used equations tend to over-predict this depth (referred to as equilibrium scour depth).

Figure A1.

Flow mechanics around piles subjected to water current.

References

- Johnson, P.A.; Dock, D.A. Probabilistic Bridge Scour Estimates. J. Hydraul. Eng. 1998, 124, 750–754. [Google Scholar] [CrossRef]

- Bridge Inspection and Maintenance Manual. Transit New Zealand. 2001; pp. 1–162. Available online: https://www.nzta.govt.nz/assets/resources/bridge-inspection-maintenance-manual/docs/title-pages-and-contents.pdf (accessed on 2 April 2022).

- Melville, B.W.; Coleman, S.E. Bridge Scour; Water Resources Publications: Littleton, CO, USA, 1973. [Google Scholar]

- Hjorth, P. Studies on the Nature of Local Scour; Lund Publications: Lund, Sweden, 1975. [Google Scholar]

- Melville, B.W. Local Scour at Bridge Sites. Ph.D. Thesis, University of Auckland, School of Engineering, Auckland, New Zealand, 1975. [Google Scholar]

- Dargahi, B. Controlling Mechanism of Local Scouring. J. Hydraul. Eng. 1992, 118, 504–505. [Google Scholar] [CrossRef]

- Hannah, C.R. Scour at Pile Groups. Ph.D. Thesis, University of Canterbury, Department of Civil Engineering, Christchurch, New Zealand, 1978. [Google Scholar]

- Beheshti, A.; Ataei-Ashtiani, B. Scour in the Clear Water around the Pile Groups. In Proceedings of the First National Congress of Civil Engineering, Tehran, Iran, 29 May 2004. [Google Scholar]

- Ataie-Ashtiani, B.; Beheshti, A.A. Experimental Investigation of Clear-Water Local Scour at Pile Groups. J. Hydraul. Eng. 2006, 132, 1100–1104. [Google Scholar] [CrossRef] [Green Version]

- Beg, M. Characteristics of Developing Scour Holes around Two Piers Placed in Transverse Arrangement. In Proceedings of the International Conference on Scour and Erosion (ICSE-5), San Francisco, CA, USA, 7–10 November 2010; pp. 76–85. [Google Scholar] [CrossRef]

- Movahedi, N.; Dehghani, A.; Arabi, M.; Zahiri, A. The Pile Spacing Effect Distance between the Pile Groups on the Time Development of Scour in Pile Groups Perpendicular to the Flow Direction. In Proceedings of the 11th Conference of Hydraulic, Urmia, Iran, 6 November 2012. [Google Scholar]

- Sanei, M.; Mohammadnezhad, A.A. Evaluation the Effect of the Diameter of the Cylindrical Pile on the Amount of Scour. Q. Build. Enhanc. Rehabil. Ind. 2010. [Google Scholar]

- Amini, A.; Melville, B.W.; Ali, T.M.; Ghazali, A.H. Clear-Water Local Scour around Pile Groups in Shallow-Water Flow. J. Hydraul. Eng. 2012, 138, 177–185. [Google Scholar] [CrossRef]

- Gaudio, R.; Tafarojnoruz, A.; Calomino, F. Combined Flow-Altering Countermeasures against Bridge Pier Scour. J. Hydraul. Res. 2012, 50, 35–43. [Google Scholar] [CrossRef]

- Tafarojnoruz, A.; Gaudio, R.; Calomino, F. Bridge Pier Scour Mitigation under Steady and Unsteady Flow Conditions. Acta Geophys. 2012, 60, 1076–1097. [Google Scholar] [CrossRef]

- Amini, A.; Melville, B.W.; Ali, T.M. Local Scour at Piled Bridge Piers Including an Examination of the Superposition Method. Can. J. Civ. Eng. 2014, 41, 461–471. [Google Scholar] [CrossRef]

- Amini, A.; Mohammad, T.A. Local Scour Prediction around Piers with Complex Geometry. Mar. Georesources Geotechnol. 2017, 35, 857–864. [Google Scholar] [CrossRef]

- Diab, R.; Link, O.; Zanke, U. Geometry of Developing and Equilibrium Scour Holes at Bridge Piers in Gravel. Can. J. Civ. Eng. 2010, 37, 544–552. [Google Scholar] [CrossRef]

- Das, S.; Das, R.; Mazumdar, A. Variation in Clear Water Scour Geometry at Piers of Different Effective Widths. Turkish J. Eng. Environ. Sci. 2014, 37, 97–111. [Google Scholar] [CrossRef]

- Azhari, A.; Taghipoor, R.; Alizadeh, M. Local Scour around Bridge Piers Group: Effect of Channel Arc Angle and Piles Spacing. In Proceedings of the 11th Conference of Hydraulic Iran, Urmia, Iran, 6 November 2012. [Google Scholar]

- Elnikhely, E.A. Minimizing Scour around Bridge Pile Using Holes. Ain Shams Eng. J. 2017, 8, 499–506. [Google Scholar] [CrossRef] [Green Version]

- Ali, H.M.; El Gendy, M.M.; Mirdan, A.M.H.; Ali, A.A.M.; Abdelhaleem, F.S.F. Minimizing Downstream Scour Due to Submerged Hydraulic Jump Using Corrugated Aprons. Ain Shams Eng. J. 2014, 5, 1059–1069. [Google Scholar] [CrossRef] [Green Version]

- Neill, C.R. Guide To Bridge Hydraulics; University of Toronto Press: Toronto, ON, Canada, 1973. [Google Scholar]

- Breusers, H.N.C.; Nicollet, G.; Shen, H.W. Local Scour Around Cylindrical Piers. J. Hydraul. Res. 1977, 15, 211–252. [Google Scholar] [CrossRef]

- Ferraro, D.; Tafarojnoruz, A.; Gaudio, R.; Cardoso, A.H. Effects of Pile Cap Thickness on the Maximum Scour Depth at a Complex Pier. J. Hydraul. Eng. 2013, 139, 482–491. [Google Scholar] [CrossRef]

- Melville, B.W.; Raudkivi, A.J. Effects of Foundation Geometry on Bridge Pier Scour. J. Hydraul. Eng. 1996, 122, 203–209. [Google Scholar] [CrossRef]

- Jalal, H.K.; Hassan, W.H. Effect of Bridge Pier Shape on Depth of Scour. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012001. [Google Scholar] [CrossRef]

- Al-Shukur, A.-H.K.; Hadi Obeid, Z. Experimental Study of Bridge Pier Shape To Minimize Local Scour. Int. J. Civ. Eng. Technol. 2016, 7, 162–171. [Google Scholar]

- Aly, A.M.; Dougherty, E. Bridge Pier Geometry Effects on Local Scour Potential: A Comparative Study. Ocean Eng. 2021, 234. [Google Scholar] [CrossRef]

- Fael, C.; Lança, R.; Cardoso, A. Effect of Pier Shape and Pier Alignment on the Equilibrium Scour Depth at Single Piers. Int. J. Sediment Res. 2016, 31, 244–250. [Google Scholar] [CrossRef]

- Moussa, A.M.A. Evaluation of Local Scour around Bridge Piers for Various Geometrical Shapes Using Mathematical Models. Ain Shams Eng. J. 2018, 9, 2571–2580. [Google Scholar] [CrossRef]

- Vijayasree, B.A.; Eldho, T.I.; Mazumder, B.S.; Ahmad, N. Influence of Bridge Pier Shape on Flow Field and Scour Geometry. Int. J. River Basin Manag. 2019, 17, 109–129. [Google Scholar] [CrossRef]

- Roy, C. Effect of Bridge Pier Geometry on Local Scouring. Int. J. Earth Sci. Eng. 2017, 10, 374–377. [Google Scholar] [CrossRef]

- Panici, D.; de Almeida, G.A.M. Influence of Pier Geometry and Debris Characteristics on Wood Debris Accumulations at Bridge Piers. J. Hydraul. Eng. 2020, 146, 04020041. [Google Scholar] [CrossRef]

- Eghbali, P.; Dehghani, A.; Arvanaghi, H.; Menazadeh, M. The Effect of Geometric Parameters and Foundation Depth on Scour Pattern around Bridge Pier. J. Civ. Eng. Urban. 2013, 3, 156–163. [Google Scholar]

- Ghodsi, H.; Najafzadeh, M.; Khanjani, M.J.; Beheshti, A. Effects of Different Geometric Parameters of Complex Bridge Piers on Maximum Scour Depth: Experimental Study. J. Waterw. Port Coast. Ocean Eng. 2021, 147, 04021021. [Google Scholar] [CrossRef]

- Khan, M.; Tufail, M.; Ajmal, M.; Haq, Z.U.; Kim, T.W. Experimental Analysis of the Scour Pattern Modeling of Scour Depth Around Bridge Piers. Arab. J. Sci. Eng. 2017, 42, 4111–4130. [Google Scholar] [CrossRef]

- Dahe, P.; Kharode, S. Evaluation of Scour Depth around Bridge Piers with Various Geometrical Shapes. Evaluation 2015, 2, 41–48. [Google Scholar]

- Gautam, P.; Eldho, T.I.; Behera, M.R. Experimental Study of Scour around a Complex Pier with Elliptical Pile-Cap. In Proceedings of the 8th International Conference on Scour and Erosion, ICSE 2016, Oxford, UK, 12–15 September 2016; pp. 759–765. [Google Scholar] [CrossRef] [Green Version]

- Ettema, R.; Kirkil, G.; Muste, M. Similitude of Large-Scale Turbulence in Experiments on Local Scour at Cylinders. J. Hydraul. Eng. 2006, 132, 33–40. [Google Scholar] [CrossRef]

- Melville, B.W.; Chiew, Y.-M. Time Scale for Local Scour at Bridge Piers. J. Hydraul. Eng. 1999, 125, 59–65. [Google Scholar] [CrossRef]

- Ghodsian, M.; Vaghefi, M. Experimental Study on Scour and Flow Field in a Scour Hole around a T-Shape Spur Dike in a 90° Bend. Int. J. Sediment Res. 2009, 24, 145–158. [Google Scholar] [CrossRef]

- Heidarpour, M.; Afzalimehr, H.; Izadinia, E. Reduction of Local Scour around Bridge Pier Groups Using Collars. Int. J. Sediment Res. 2010, 25, 411–422. [Google Scholar] [CrossRef]

- Akib, S.; Jahangirzadeh, A.; Wei, L.H.; Moniruzzaman, S.; Rahman, S. Experimental Study on the Skewed Integral Bridge by Using Crushed Concrete Geobags as Scour Protection. In Proceedings of the 6th International Conference on Scour and Erosion, ICSE6, Paris, French, 27–31 August 2012; pp. 197–203. [Google Scholar]

- Richardson, E.; Davis, S. Evaluating Scour at Bridges, 4th ed.; U.S. Department of Transportation; Federal Highway Administration: Washington, DC, USA, 2001; FHWA NHI 01-001.2001. [Google Scholar]

- AASHTO M145-91; Classif Soils Soil-Aggregate Mix Highw Constr Purp 9. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2008.

- Galambos, T.V. Load and Resistance Factor Design. Eng. J. 1981, 18, 74–82. [Google Scholar] [CrossRef]

- Division THE. Ontario Highway Bridge Design Code; Highway Engineering Division: Toronto, ON, Canada, 1983. [Google Scholar]

- Canadian Standards Association (CSA). Canadian Highway Bridge Design Code; Csa S6-19 833; Canadian Standards Association (CSA): Toronto, ON, Canada, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).