Elastic Modulus Prediction Model of Foamed Concrete Based on the Walsh Formula

Abstract

:1. Introduction

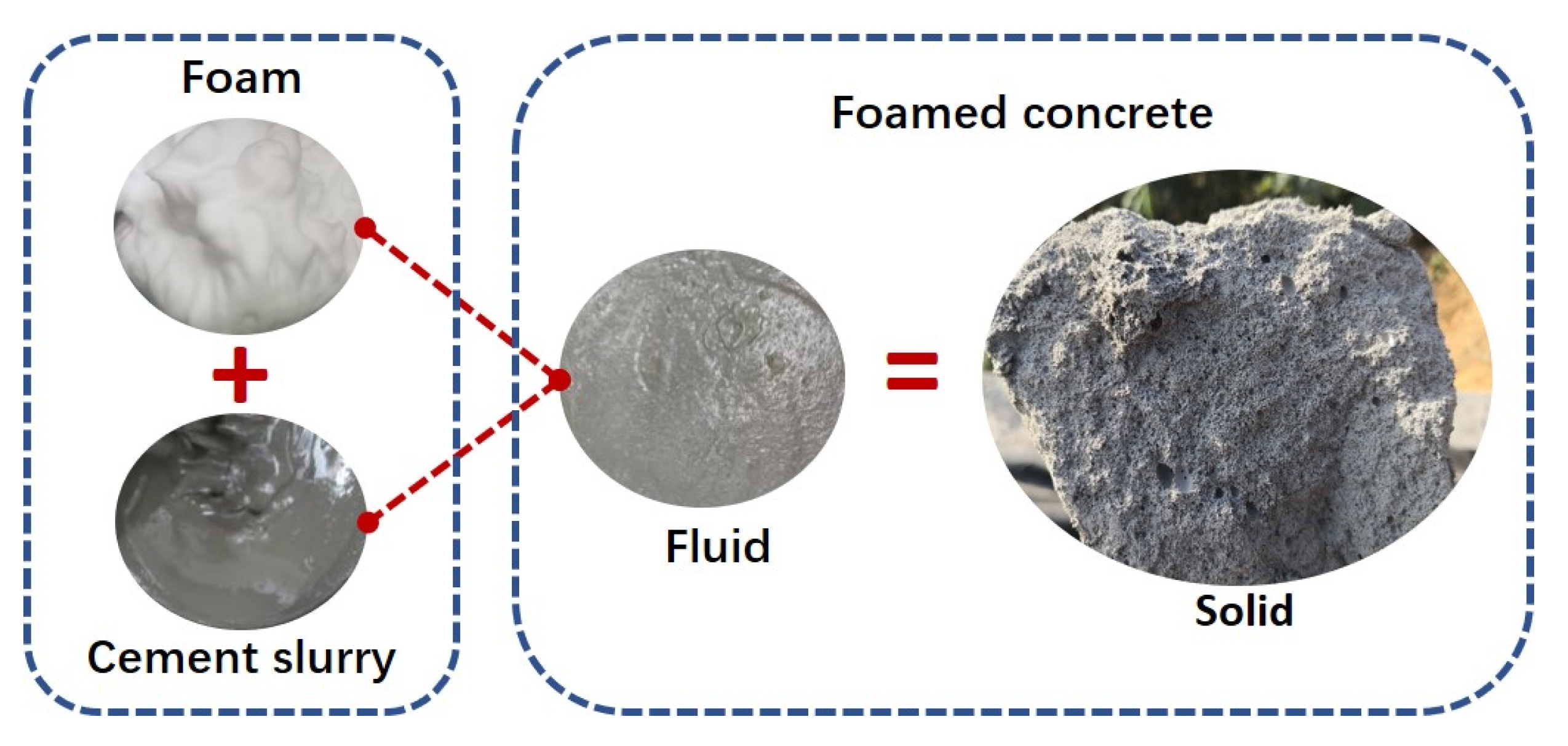

2. Micromechanical Analysis of Foamed Concrete Elements

2.1. Walsh Formula

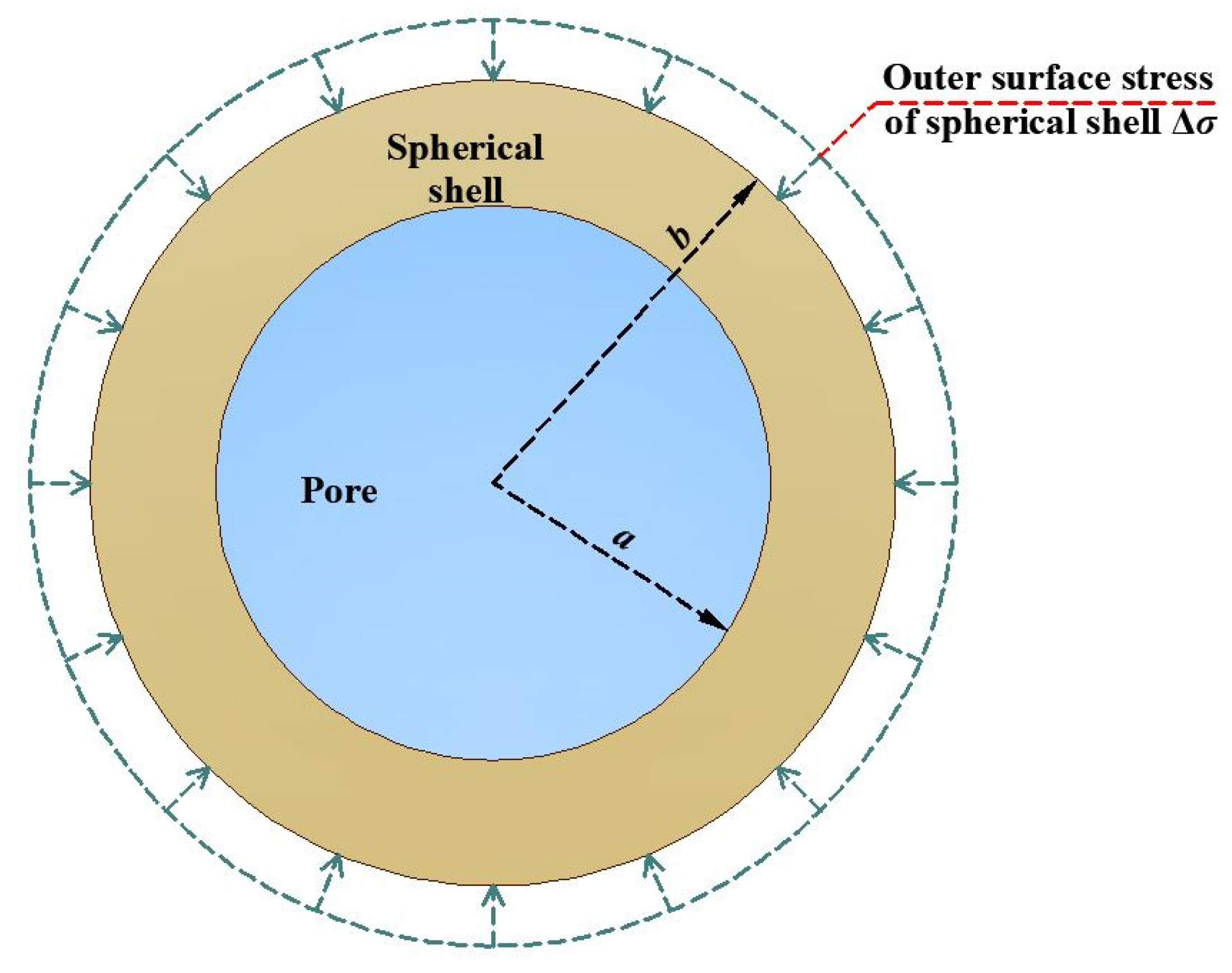

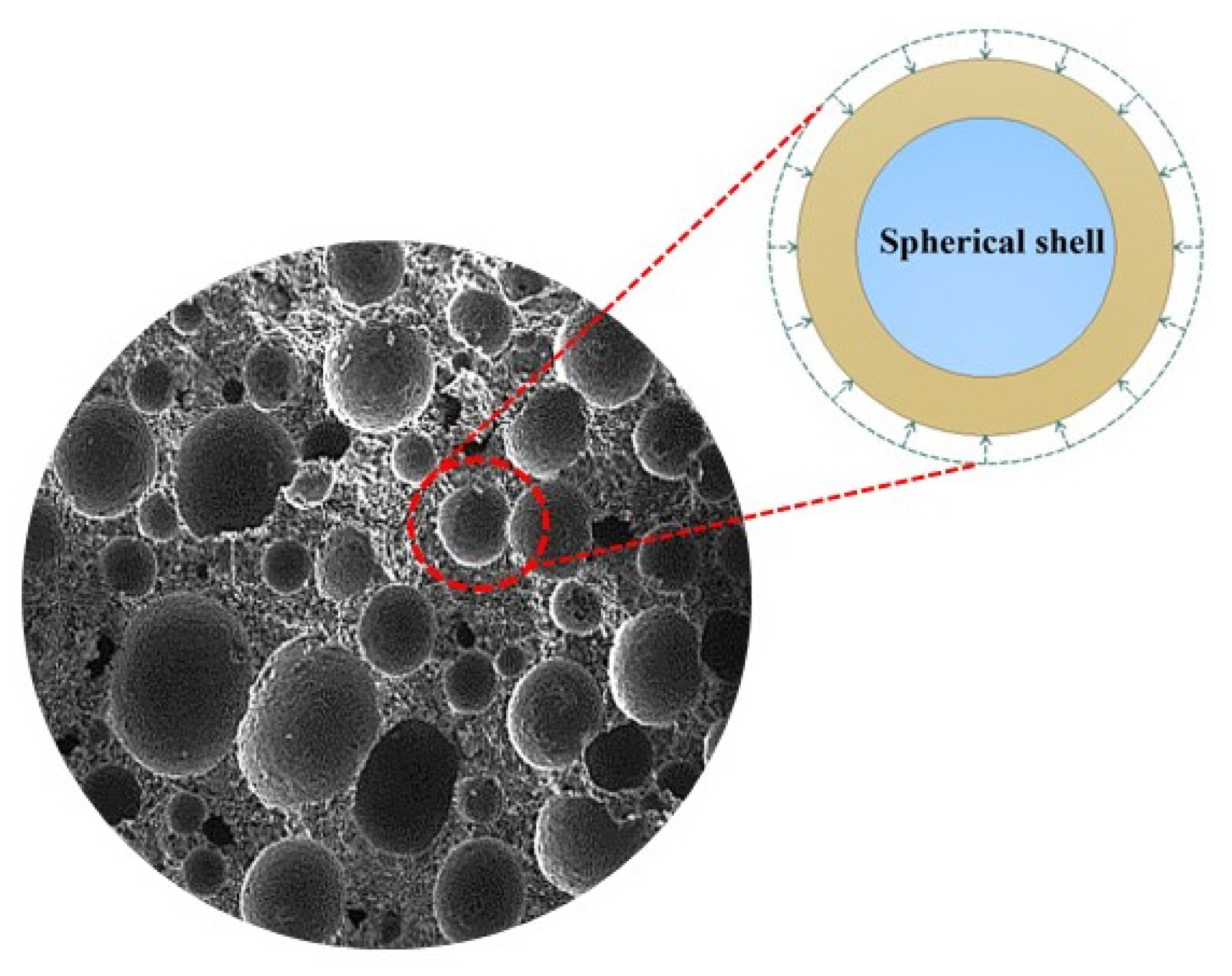

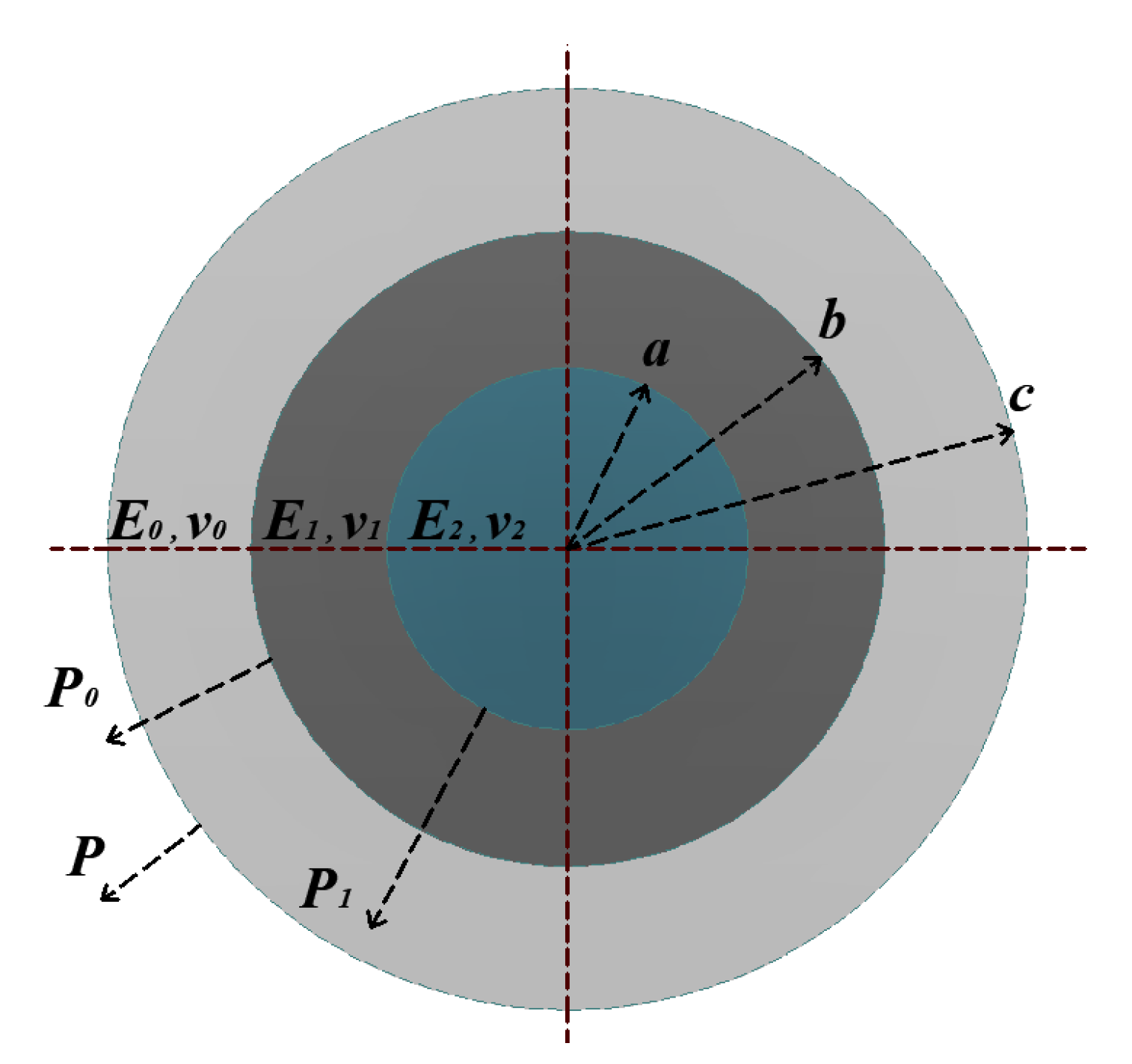

2.2. Spherical Pore Assumption

2.3. Spherical Shell Elastic Modulus of Foamed Concrete

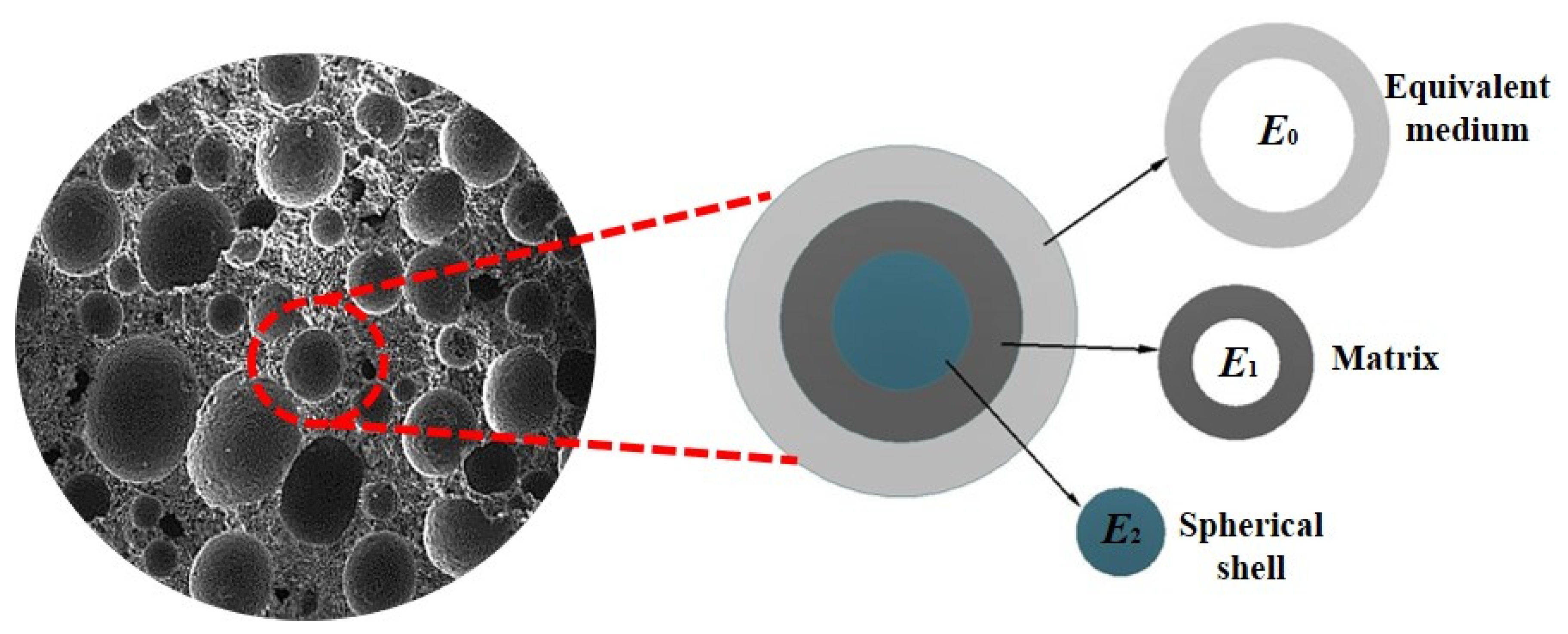

3. Two-Layer Embedded Model Analysis of Foamed Concrete

3.1. Two-Layer Embedded Model

3.2. Prediction Model for the Elastic Modulus of Foamed Concrete

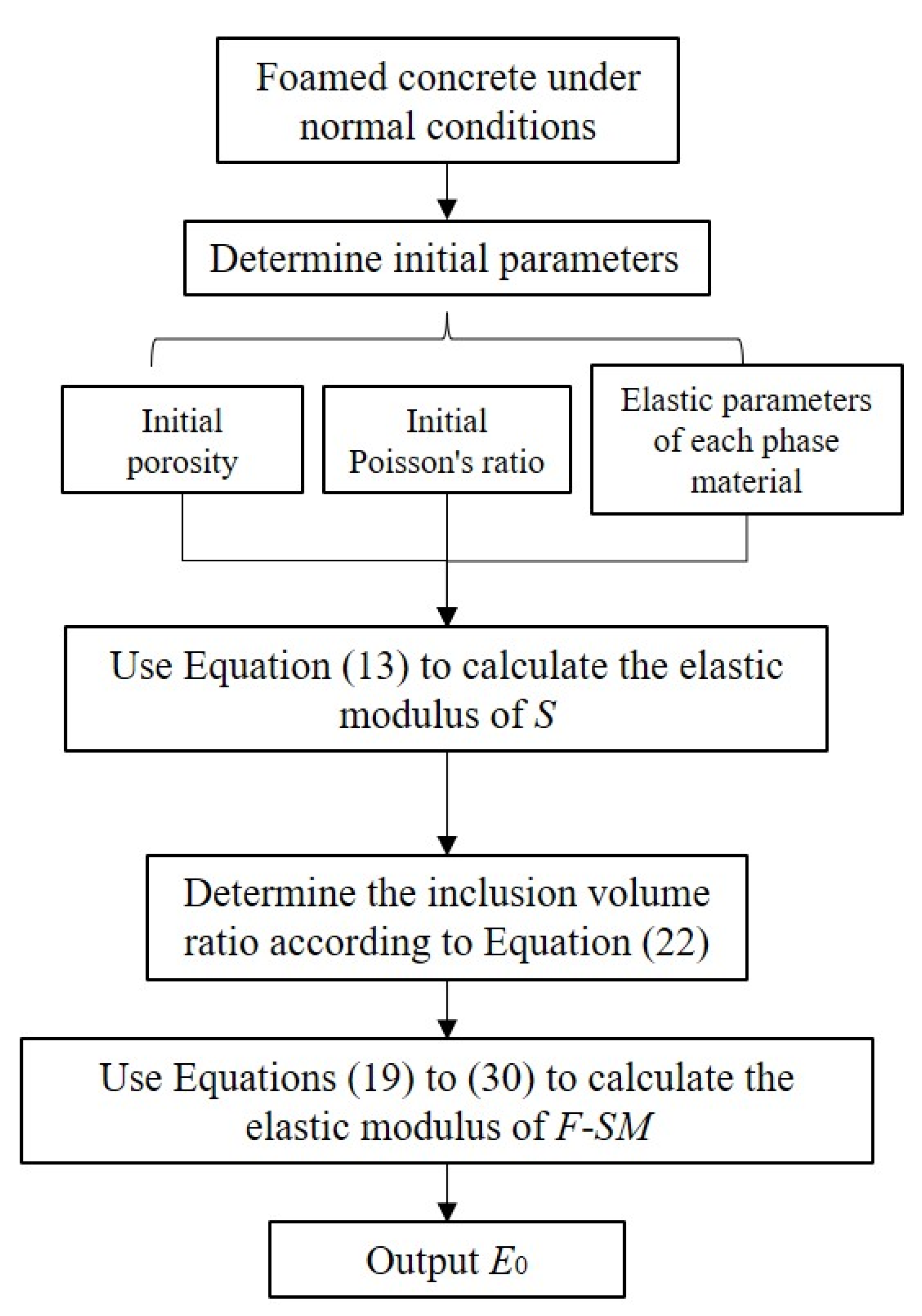

3.3. Calculation Process for the Elastic Modulus of Foamed Concrete

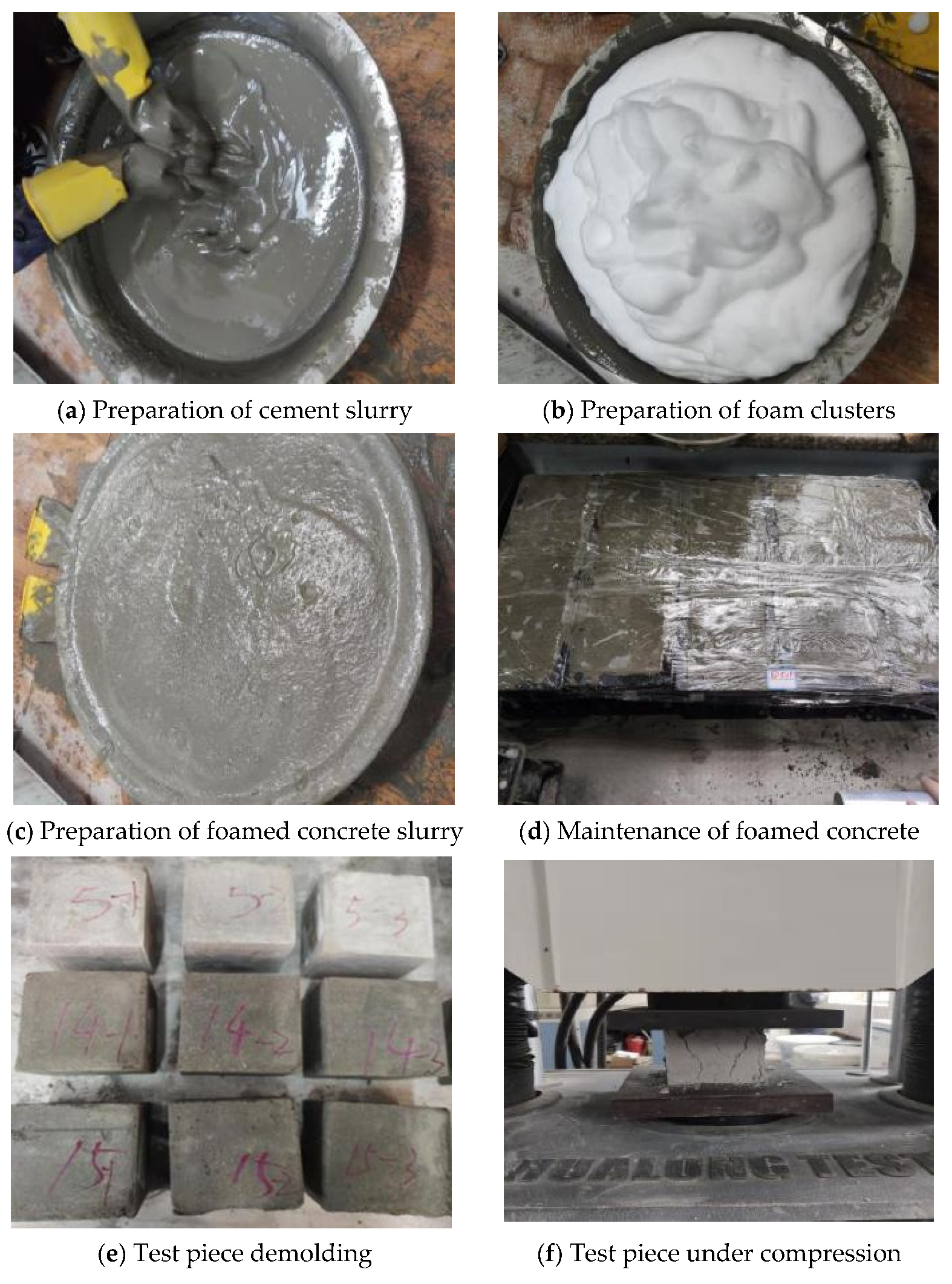

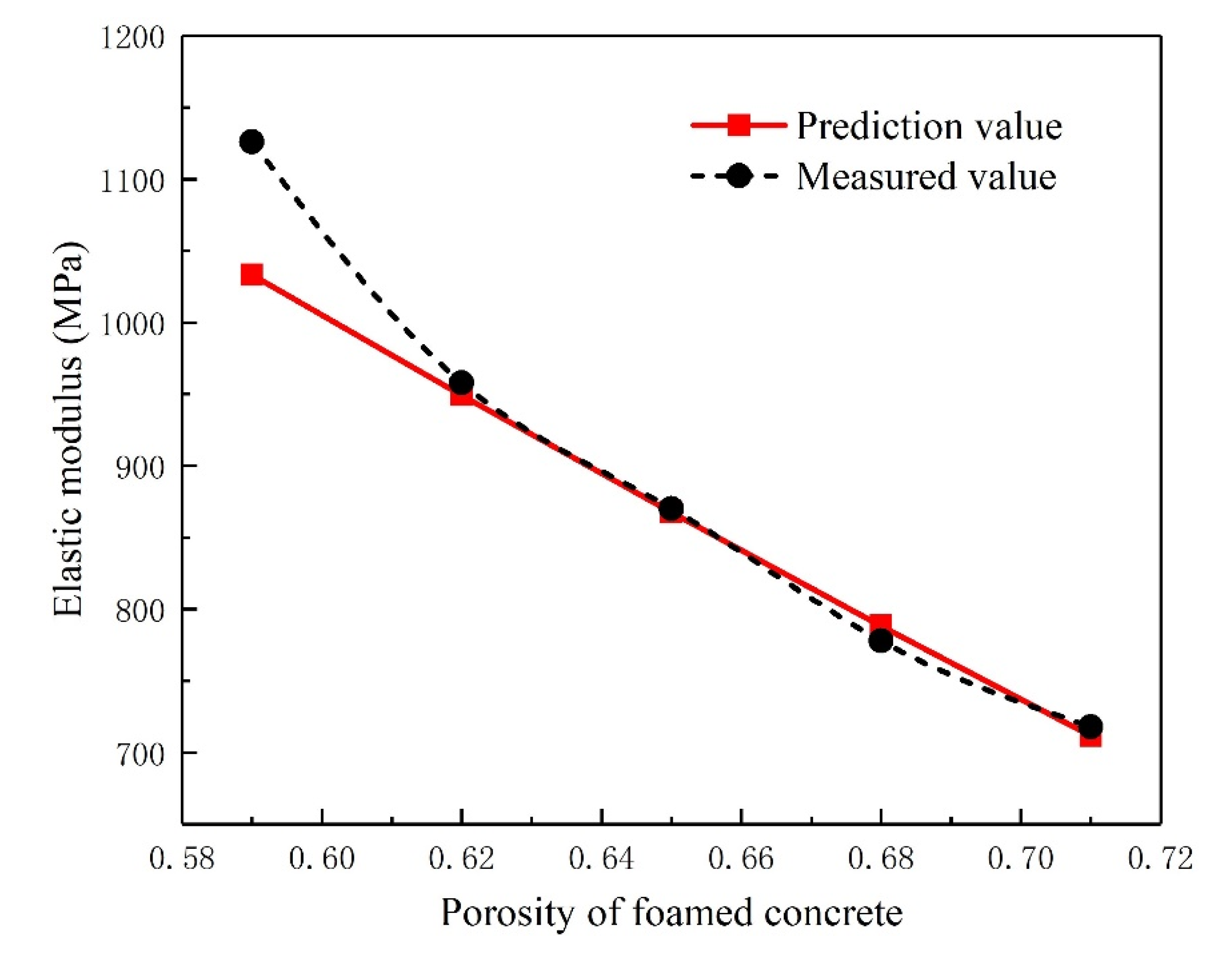

4. Model Validation

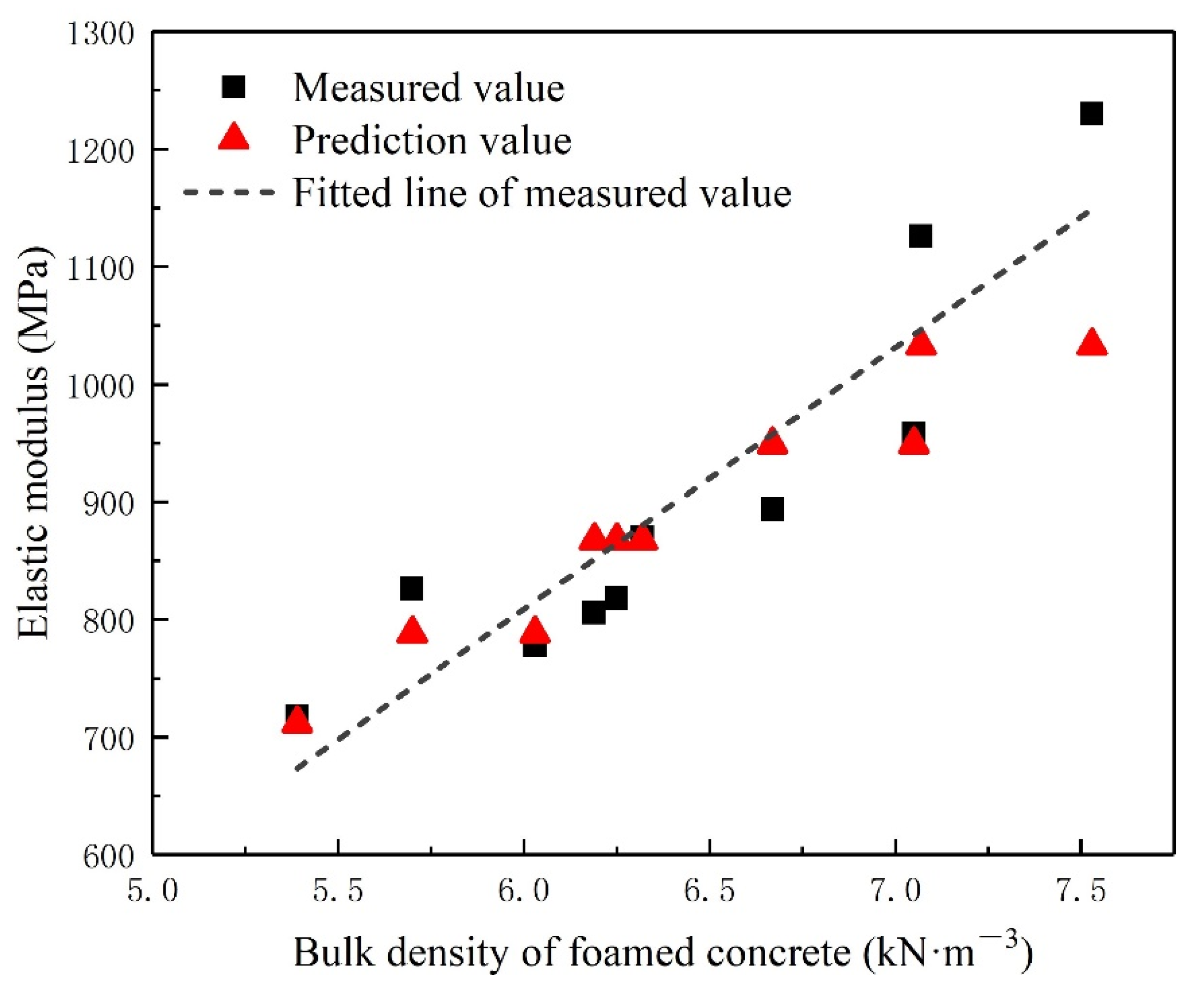

4.1. Comparison with Test Results

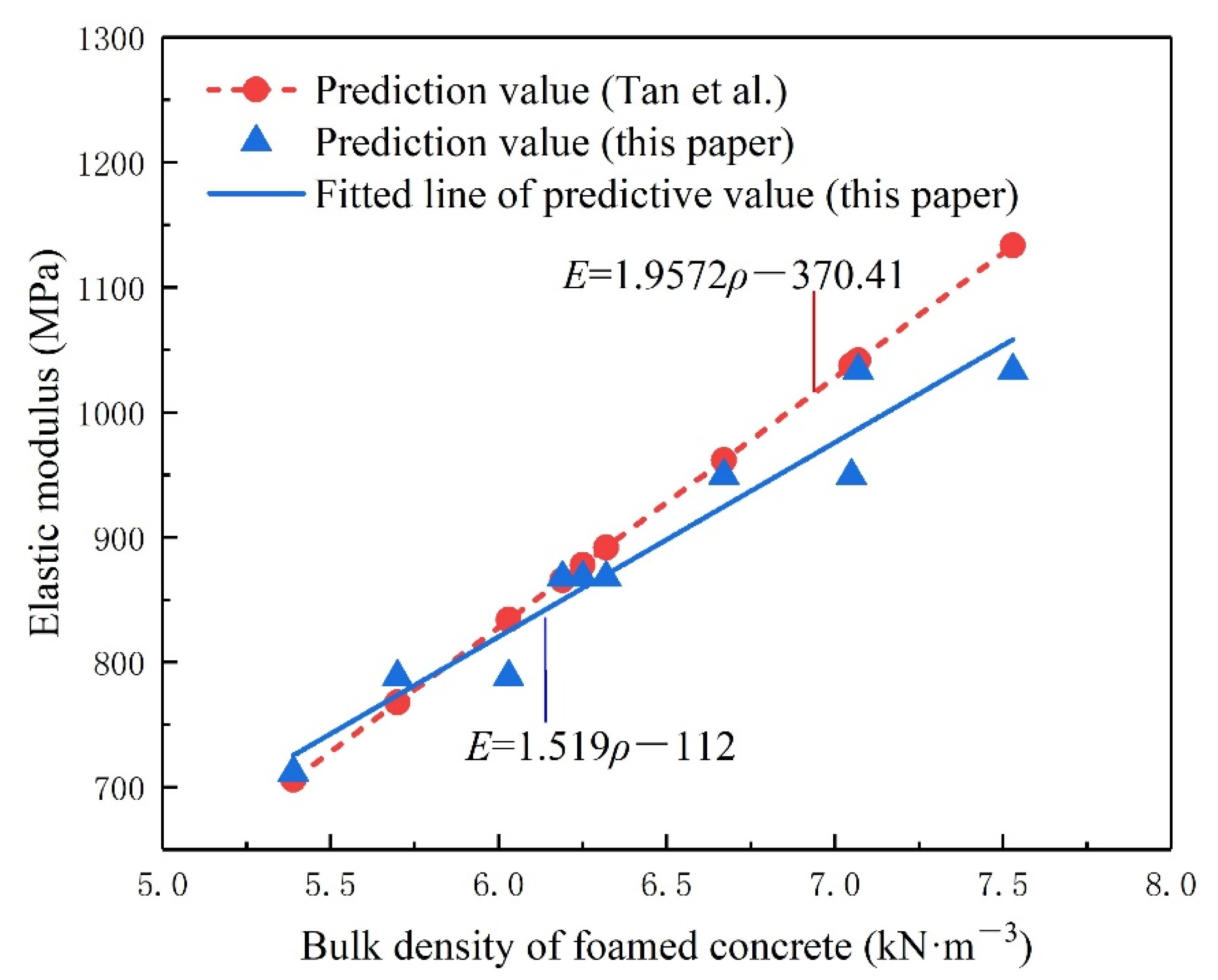

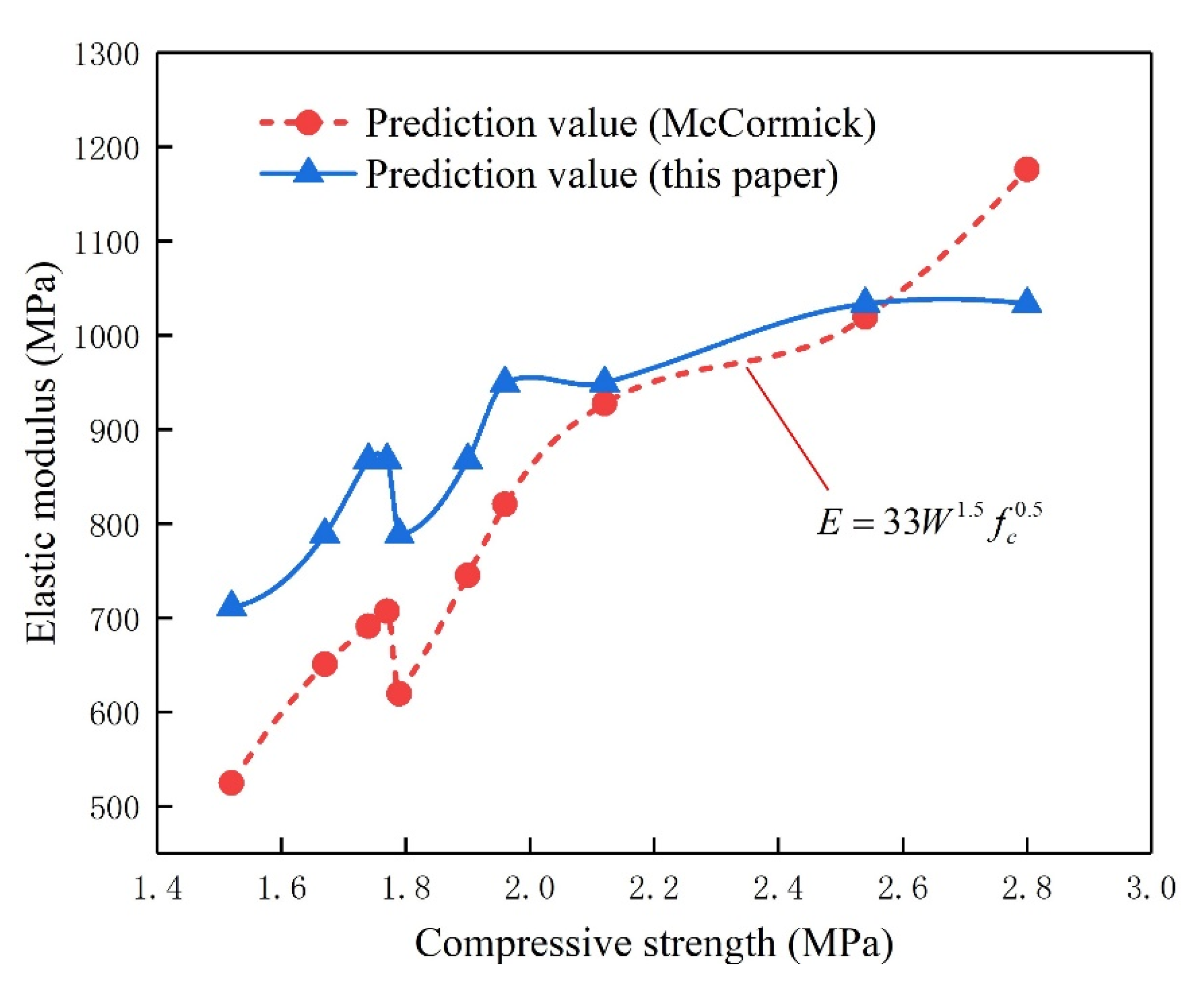

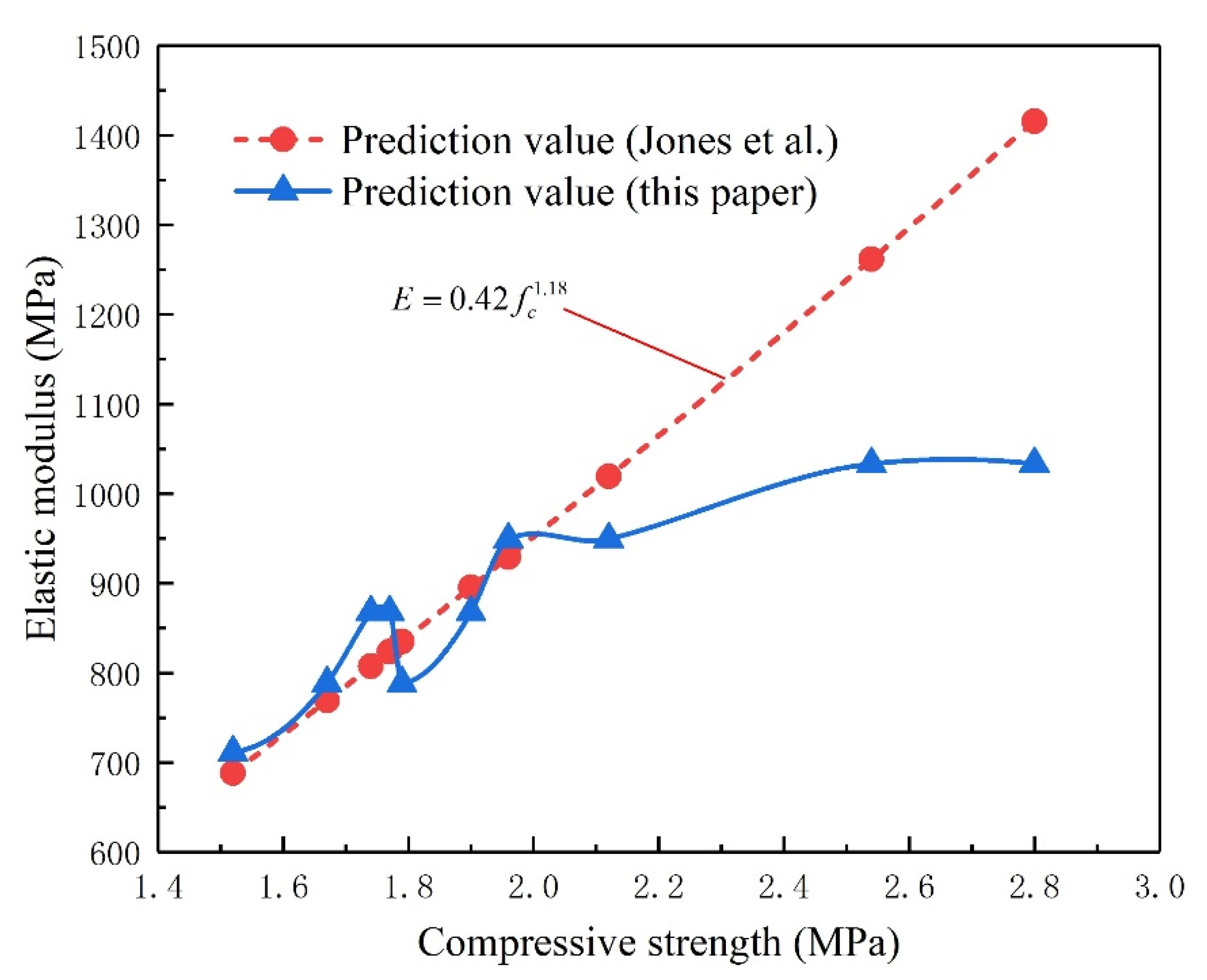

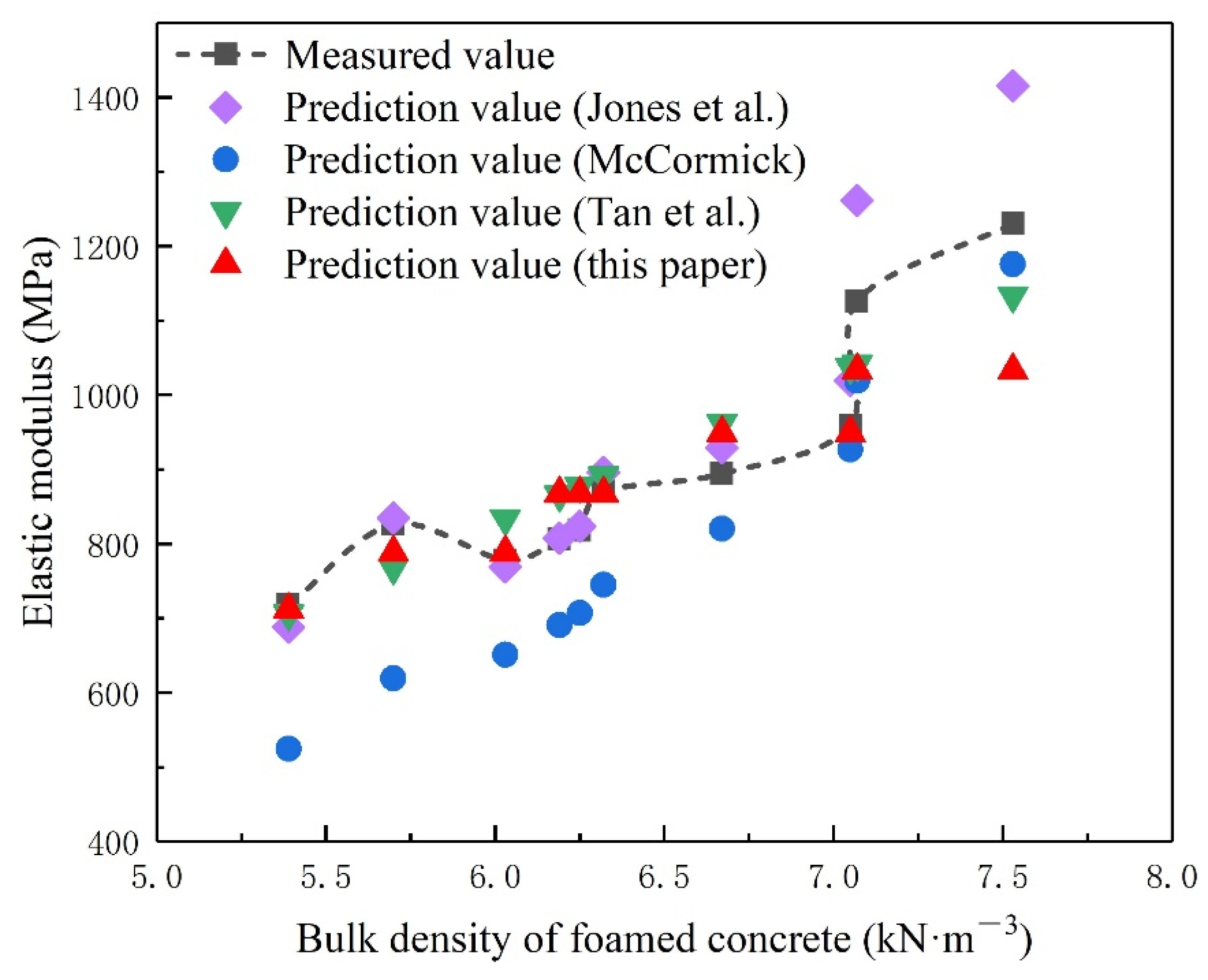

4.2. Comparison with Existing Research

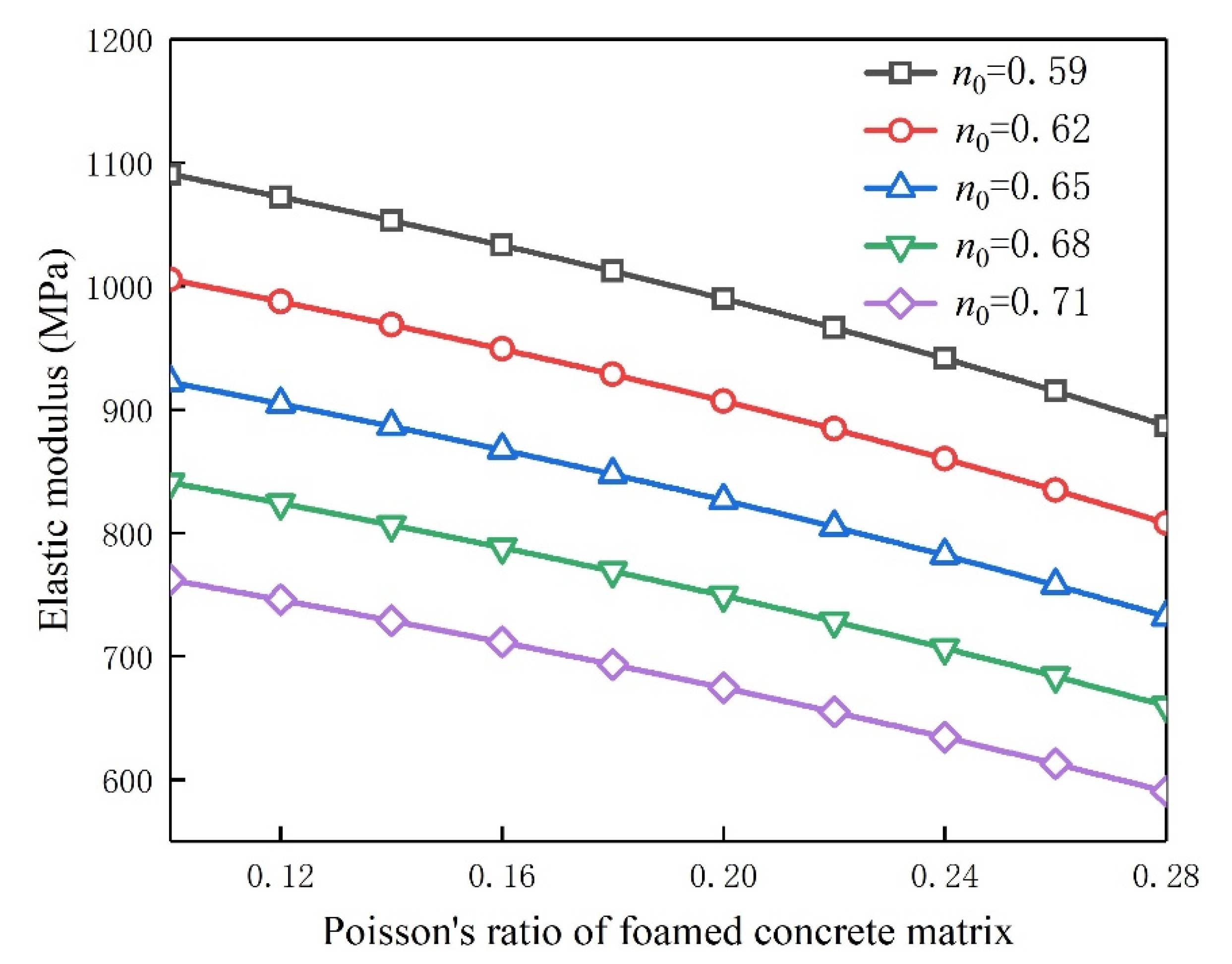

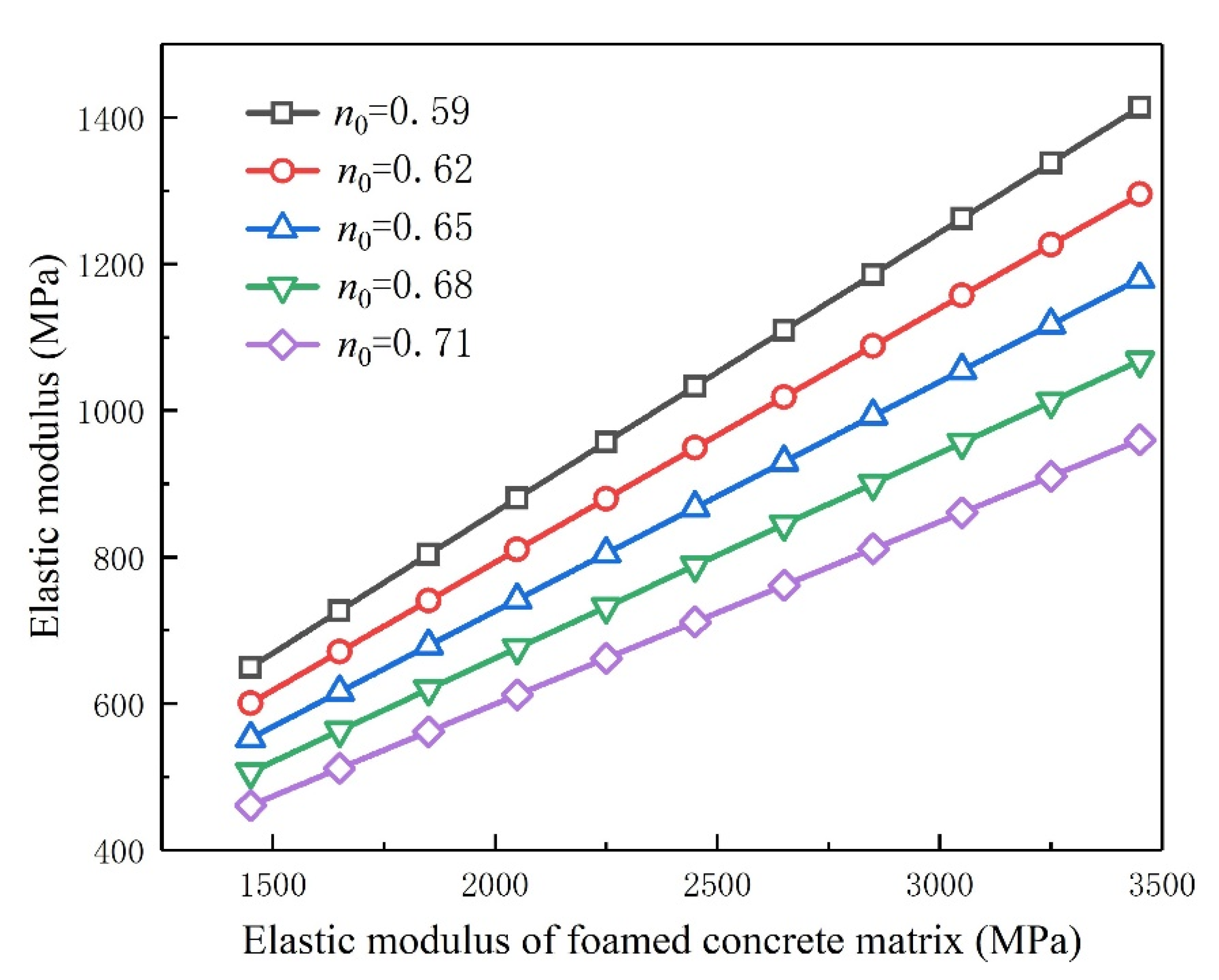

5. Parameter Sensitivity Analysis

5.1. Porosity of Foamed Concrete

5.2. Poisson’s Ratio of Foamed Concrete Matrix

5.3. Elastic Modulus of Foamed Concrete Matrix

6. Conclusions

- (1)

- According to the internal structure characteristics of foamed concrete, the calculation formula is established for elastic modulus of spherical shell by introducing the Walsh formula and spherical pore hypothesis. Moreover, the elastic modulus prediction model of foamed concrete is constructed based on the two-layer embedded model in inclusion theory.

- (2)

- The uniaxial compression test of foamed concrete is carried out, and the proposed model is compared with the test data and the existing theoretical models. The verification results show that the elastic modulus values calculated using the proposed model are consistent with the experimental data. The values are also in good agreement with the distribution law of the calculation results calculated by using other theoretical models.

- (3)

- The effects of porosity, Poisson’s ratio of matrix, and elastic modulus of matrix on the elastic modulus of foamed concrete are analyzed by the proposed model. The results show that the elastic modulus of foamed concrete decreases with the increase in porosity and matrix Poisson’s ratio, and increases with the increase in matrix elastic modulus.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Main symbols and notations used in the paper | |

| Symbol | Description |

| a | inner diameter of spherical shell |

| b | outer diameter of spherical shell |

| c | outer diameter of equivalent medium |

| E | elastic modulus |

| E0 | elastic modulus of equivalent medium |

| E1 | elastic modulus of the matrix |

| E2 | elastic modulus of the spherical shell element |

| f | volume percentage of inclusions |

| fc | compressive strength of foamed concrete |

| n | porosity |

| n0 | initial porosity of foamed concrete |

| P | radial effective stress at the outer diameter of the equivalent medium |

| P0 | radial effective stress at the outer diameter of spherical shell |

| P1 | radial effective stress at the inner radius of spherical shell |

| ua | radial displacement of the spherical shell |

| u0b | displacement of equivalent medium at boundary r = b |

| u0c | displacement of equivalent medium at boundary r = c |

| u1a | displacement of matrix at boundary r = a |

| u1b | displacement of matrix at boundary r = b |

| u2a | displacement of spherical shell at boundary r = a |

| V | volume of the porous medium |

| Vc | pore volume |

| W | wet bulk density of foamed concrete |

| δ | volume compliance of the overall unit |

| δs | volume compliance of the matrix |

| ΔVc | change in pore volume |

| Δa | change of inner diameter of spherical shell |

| Δσ | the action of volume stress |

| ρ | density of foamed concrete |

| ρs | density of the matrix |

| υ | Poisson’s ratio |

| υ0 | Poisson’s ratio of foamed concrete |

| υ1 | Poisson’s ratio of the matrix |

| υ2 | Poisson’s ratio of the spherical shell |

References

- Othuman, M.A.; Wang, Y.C. Elevated-temperature thermal properties of lightweight foamed concrete. Constr. Build. Mater. 2011, 25, 705–716. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 233–239. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of high fly ash content on the compressive strength of foamed concrete. Cem. Concr. Res. 2001, 31, 105–112. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, J.J.; Gong, C.J. Automatic detection method of tunnel lining multi-defects via an enhanced You Only Look Once network. Comput.-Aided Civil Infrastruct. Eng. 2022, 37, 762–780. [Google Scholar] [CrossRef]

- Huang, J.J.; Su, Q.; Zhao, W.H.; Li, T.; Zhang, X.X. Experimental study on use of lightweight foam concrete as subgrade bed filler of ballastless track. Constr. Build. Mater. 2017, 149, 911–920. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, T.H.; Kang, G.C. Performance evaluation of road embankment constructed using lightweight soils on an unimproved soft soil layer. Eng. Geol. 2013, 160, 34–43. [Google Scholar] [CrossRef]

- Chen, Z.P.; Wang, J.B.; Liu, J.F.; Zhao, W.H. Experimental study on dynamic engineering characteristics of foam lightweight soil. Highway 2019, 64, 77–80. (In Chinese) [Google Scholar]

- Jiang, C.; Wu, Y.F.; Jiang, J.F. Effect of aggregate size onstress-strain behavior of concrete confined by fiber composites. Compos. Struct. 2017, 168, 851–862. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. The Use of Additives to Enhance Properties of Pre-Formed Foamed Concrete. Int. J. Eng. Technol. 2015, 7, 286–293. [Google Scholar] [CrossRef] [Green Version]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On void structure and strength of foamed concrete made without/with additives. Constr. Build. Mater. 2015, 85, 157–164. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Liu, C.; Luo, J.; Li, Q.; Gao, S.; Su, D.; Zhang, J.; Chen, S. Calcination of green highbelite sulphoaluminate cement (GHSC) and performance optimizations of GHSC-based foamed concrete. Mater. Des. 2019, 182, 107986. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Ranjani, G.I.S.; Ramamurthy, K. Behaviour of foam concrete under sulphate environments. Cem. Concr. Compos. 2012, 34, 825–834. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. 3D-printable lightweight foamed concrete and comparison with classical foamed concrete in terms of fresh state properties and mechanical strength. Constr. Build. Mater. 2020, 254, 119271. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Compressive and flexural strength of fiber-reinforced foamed concrete: Effect of fiber content, curing conditions and dry density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Panesar, D.K. Cellular concrete properties and the effect of synthetic and protein foaming agents. Constr. Build. Mater. 2013, 44, 575–584. [Google Scholar] [CrossRef]

- She, W.; Du, Y.; Zhao, G.; Feng, P.; Zhang, Y.; Cao, X. Influence of coarse fly ash on the performance of foam concrete and its application in high-speed railway roadbeds. Constr. Build. Mater. 2018, 170, 153–166. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, D.; Liang, Y.; Qu, K.; Lu, K.; Chen, S.; Kong, M. Study on engineering properties of foam concrete containing waste seashell. Constr. Build. Mater. 2020, 260, 119896. [Google Scholar] [CrossRef]

- Ben Youssef, M.; Lavergne, F.; Sab, K.; Miled, K.; Neji, J. Upscaling the elastic stiffness of foam concrete as a three-phase composite material. Cem. Concr. Res. 2018, 110, 13–23. [Google Scholar] [CrossRef] [Green Version]

- Jones, M.R.; McCarthy, A. Preliminary views on the potential of foamed concrete as a structural material. Mag. Constr. Res. 2005, 57, 21–32. [Google Scholar] [CrossRef]

- Ge, Z.; Guan, H.Q.; Sun, R.J.; Zhang, H.Z.; Wang, W.L.; Qi, H. Use of green calcium sulphoaluminate cement to prepare foamed concrete for road embankment: A feasibility study. Constr. Build. Mater. 2020, 237, 117791. [Google Scholar] [CrossRef]

- Tan, X.J.; Chen, W.Z.; Yang, D.S.; Liu, H.Y.; Chan, A.H.C. Experimental and theoretical studies on effect of height-to-diameter ratios on failure forms and mechanical characteristics of foamed concrete. J. Mater. Civ. Eng. 2019, 31, 04018341. [Google Scholar] [CrossRef]

- Mydin, M.A.O.; Wang, Y.C. Mechanical properties of foamed concrete exposed to high temperatures. Constr. Build. Mater. 2012, 26, 638–654. [Google Scholar] [CrossRef]

- Li, L.; Purkiss, J. Stress-strain constitutive equations of concrete material at elevated temperatures. Fire Saf. J. 2005, 40, 669–686. [Google Scholar] [CrossRef]

- Shi, X.N.; Huang, J.J.; Su, Q. Experimental and numerical analyses of lightweight foamed concrete as filler for widening embankment. Constr. Build. Mater. 2020, 250, 118897. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Suddeepong, A.; Chinkulkijniwat, A.; Liu, M.D. Strength and compressibility of lightweight cemented clays. Appl. Clay. Sci. 2012, 69, 11–21. [Google Scholar] [CrossRef] [Green Version]

- Cong, M.; Bing, C. Properties of a foamed concrete with soil as filler. Constr. Build. Mater. 2015, 76, 61–69. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- McCormick, F.C. Rational proportioning of preformed foam cellular concrete. ACI J. Proc. 1967, 64, 104–110. [Google Scholar]

- Saint-Jalmes, A.; Peugeot, M.L.; Ferraz, H.; Langevin, D. Differences between protein and surfactant foams: Microscopic properties, stability and coarsening. Colloids Surf. A Physicochem. Eng. Asp. 2005, 263, 219–225. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Walsh, J.B. The effect of cracks on the compressibility of rock. J. Geophys. Res. 1965, 70, 381–389. [Google Scholar] [CrossRef]

- Cao, W.G.; Li, P.; Xu, X.; He, M. An analytical method of ground foundation settlement influenced by modulus change and thre e-dimensional stress. J. Hunan Univ. (Nat. Sci.) 2018, 45, 142–148. (In Chinese) [Google Scholar]

- Yang, H.; Zhou, Z.; Wang, X.C.; Zhang, Q.F. Elastic modulus calculation model of a soil-rock mixture at normal or freezing temperature based on micromechanics approach. Adv. Mater. Sci. Eng. 2015, 2015, 576080. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Yang, H.; Xing, K.; Gao, W.Y. Prediction models of the shear modulus of normal or frozen soil-rock mixtures. Geomech. Eng. 2018, 15, 783–791. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Z.Z.; Yang, H.; Gao, W.Y.; Zhang, C.C. Freeze-thaw damage mechanism of elastic modulus of soil-rock mixtures at different confining pressures. J. Cent. South Univ. 2020, 27, 554–565. [Google Scholar] [CrossRef]

- Li, G.; Li, Y.; Metcalf, J.B.; Pang, S.S. Elastic modulus prediction of asphalt concrete. J. Mater. Civ. Eng. 1999, 11, 236–241. [Google Scholar] [CrossRef]

- Christensen, R.M.; Lo, K.H. Solutions for effective shear properties in three phase sphere and cylinder models. J. Mech. Phys. Solids 1979, 27, 315–330. [Google Scholar] [CrossRef]

- Tan, X.J.; Chen, W.Z.; Liu, H.Y.; Chan, A.H.C. Stress-Strain Characteristics of Foamed Concrete Subjected to Large Deformation under Uniaxial and Triaxial Compressive Loading. J. Mater. Civ. Eng. 2018, 30, 04018095. [Google Scholar] [CrossRef]

| Test Group Number | Water–Solid Ratio | Bubble Rate | Wet Severity/kN·m−3 | 28-Day Unconfined Compressive Strength/MPa | Elastic Modulus/MPa |

|---|---|---|---|---|---|

| 1 | 1:1.8 | 0.71 | 5.39 | 1.52 | 718 |

| 2 | 1:1.8 | 0.68 | 5.70 | 1.79 | 826 |

| 3 | 1:1.8 | 0.68 | 6.03 | 1.67 | 778 |

| 4 | 1:1.8 | 0.65 | 6.19 | 1.74 | 806 |

| 5 | 1:1.8 | 0.65 | 6.25 | 1.77 | 818 |

| 6 | 1:1.8 | 0.65 | 6.32 | 1.90 | 870 |

| 7 | 1:1.8 | 0.62 | 6.67 | 1.96 | 894 |

| 8 | 1:1.8 | 0.62 | 7.05 | 2.12 | 958 |

| 9 | 1:1.8 | 0.59 | 7.07 | 2.54 | 1126 |

| 10 | 1:1.8 | 0.59 | 7.53 | 2.80 | 1230 |

| Matrix Material Parameters | v1 | E1/MPa | μ1/MPa | ρs/kg·m−3 |

|---|---|---|---|---|

| value | 0.16 | 2450 | 1060 | 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Hu, J.; Li, F.; Zhang, J.; Lei, M. Elastic Modulus Prediction Model of Foamed Concrete Based on the Walsh Formula. Appl. Sci. 2022, 12, 5142. https://doi.org/10.3390/app12105142

Zhou Z, Hu J, Li F, Zhang J, Lei M. Elastic Modulus Prediction Model of Foamed Concrete Based on the Walsh Formula. Applied Sciences. 2022; 12(10):5142. https://doi.org/10.3390/app12105142

Chicago/Turabian StyleZhou, Zhong, Jiangfeng Hu, Fan Li, Junjie Zhang, and Mingfeng Lei. 2022. "Elastic Modulus Prediction Model of Foamed Concrete Based on the Walsh Formula" Applied Sciences 12, no. 10: 5142. https://doi.org/10.3390/app12105142

APA StyleZhou, Z., Hu, J., Li, F., Zhang, J., & Lei, M. (2022). Elastic Modulus Prediction Model of Foamed Concrete Based on the Walsh Formula. Applied Sciences, 12(10), 5142. https://doi.org/10.3390/app12105142