Analysis on Flow and Temperature Field of High-Power Magnetorheological Fluid Transmission Device

Abstract

:1. Introduction

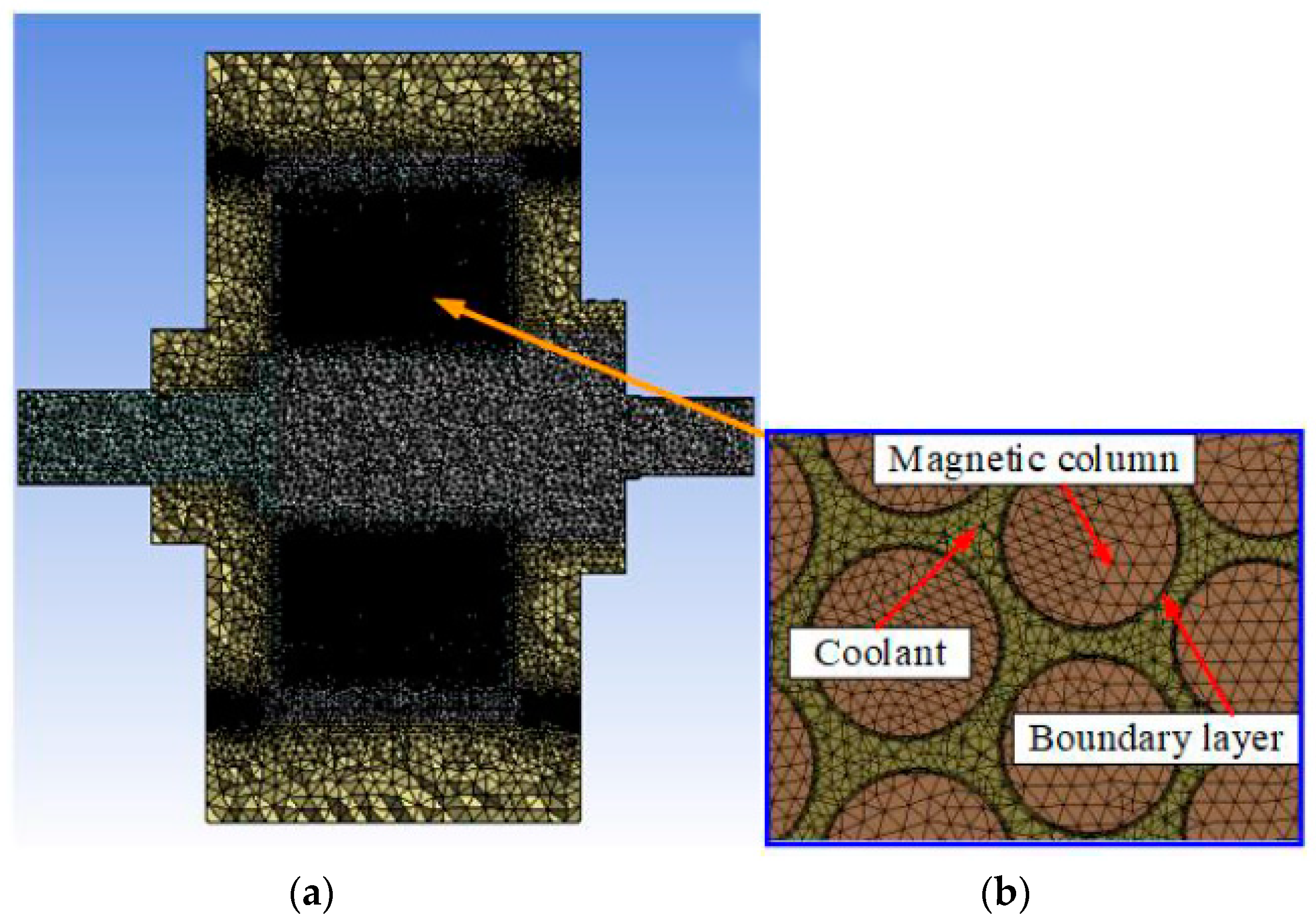

2. Design of MR Fluid Transmission Model

3. Meshing

3.1. Meshing Parameters Setting

3.2. Local Mesh Refinement

3.3. Meshing Results

4. Factors Affecting Distribution of Coolant Flow Field

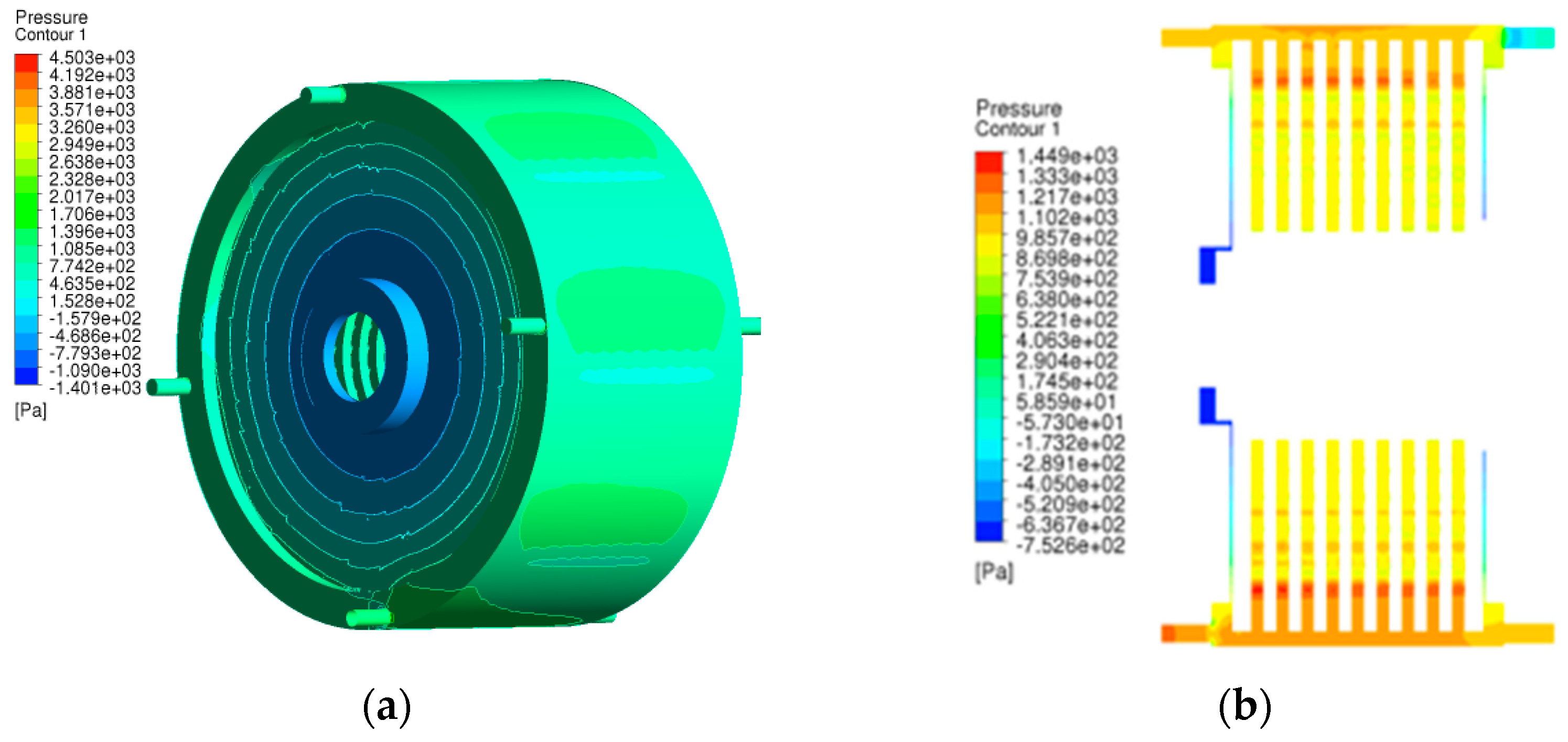

4.1. Global Distribution of Coolant Pressure Field

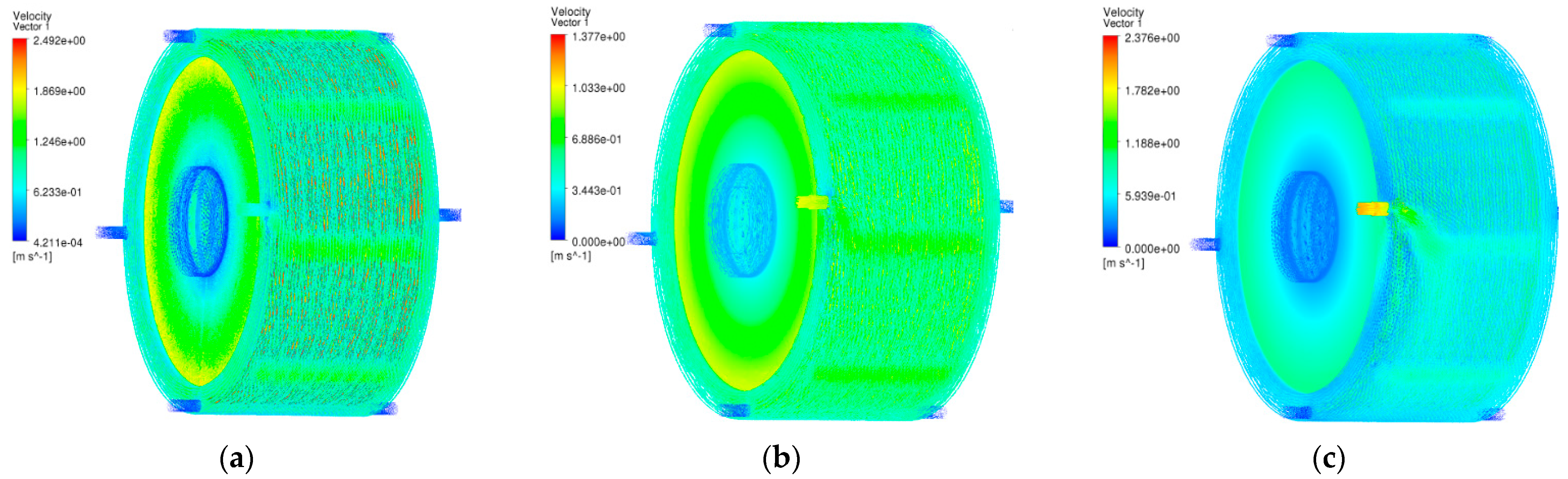

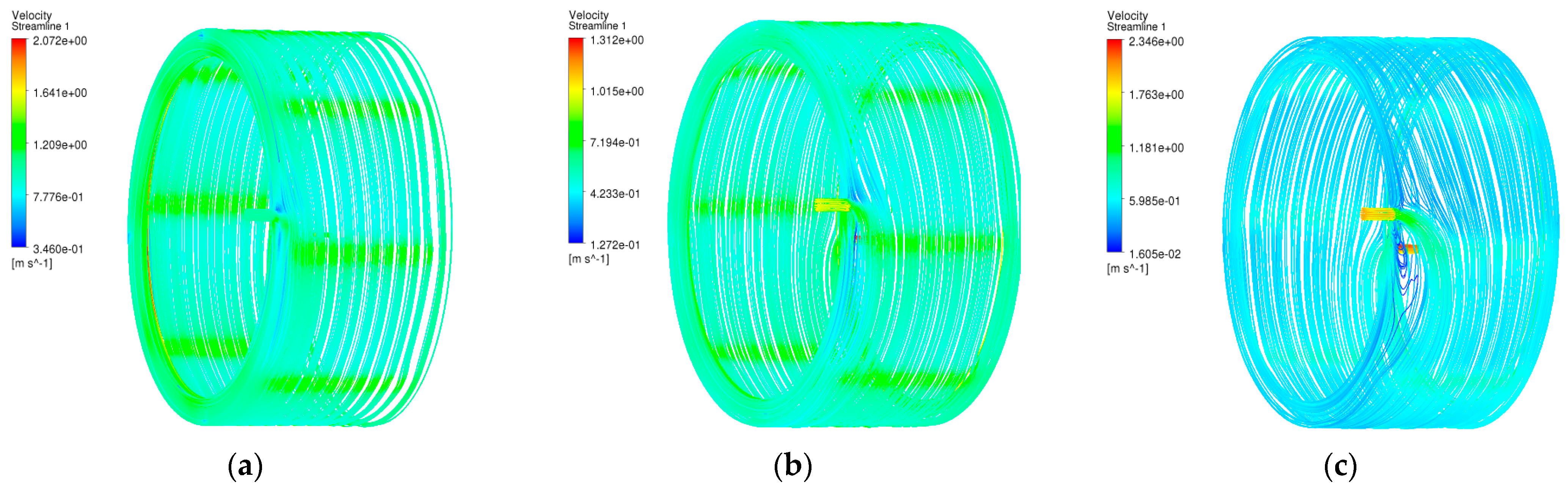

4.2. Factors Affecting Distribution of Coolant Flow Field

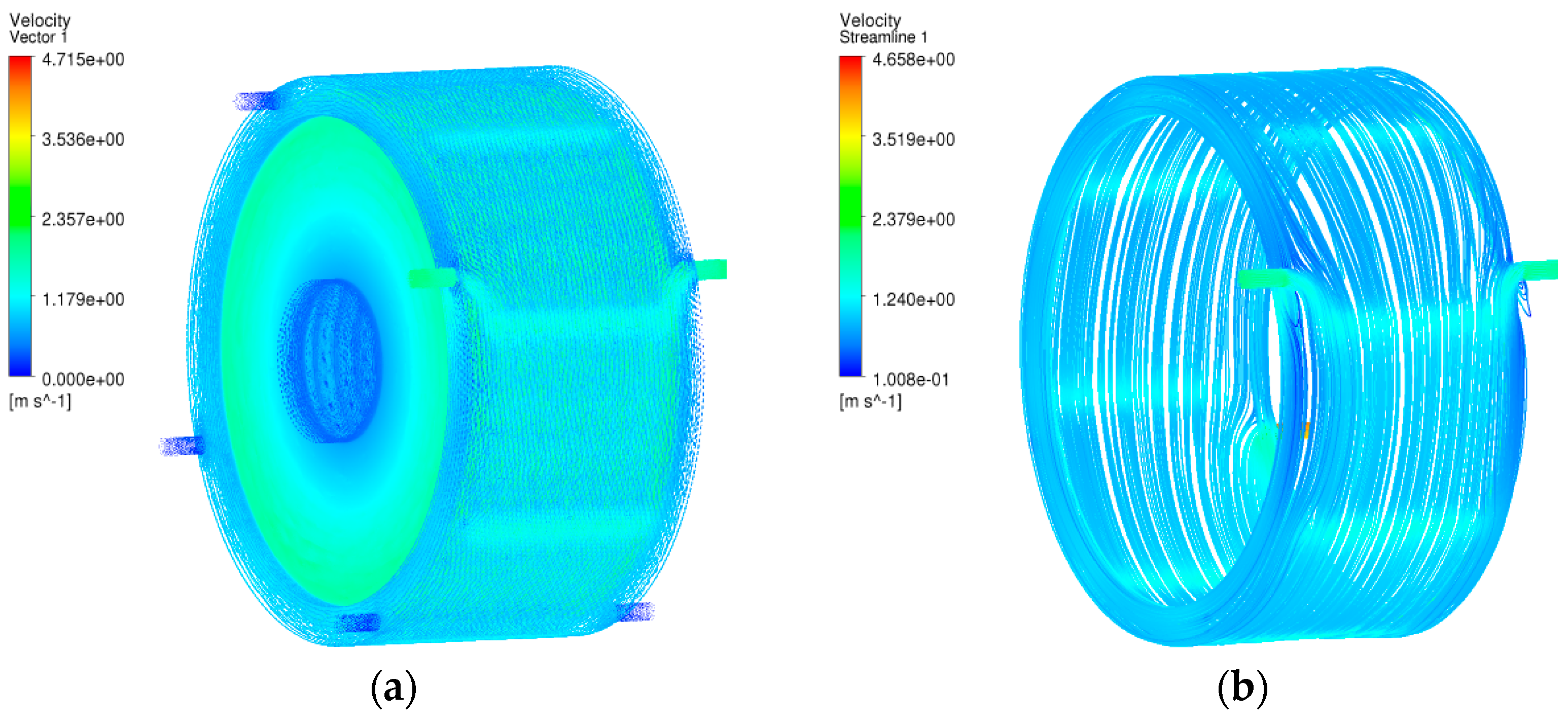

4.2.1. Rotating Speed and Inlet Velocity

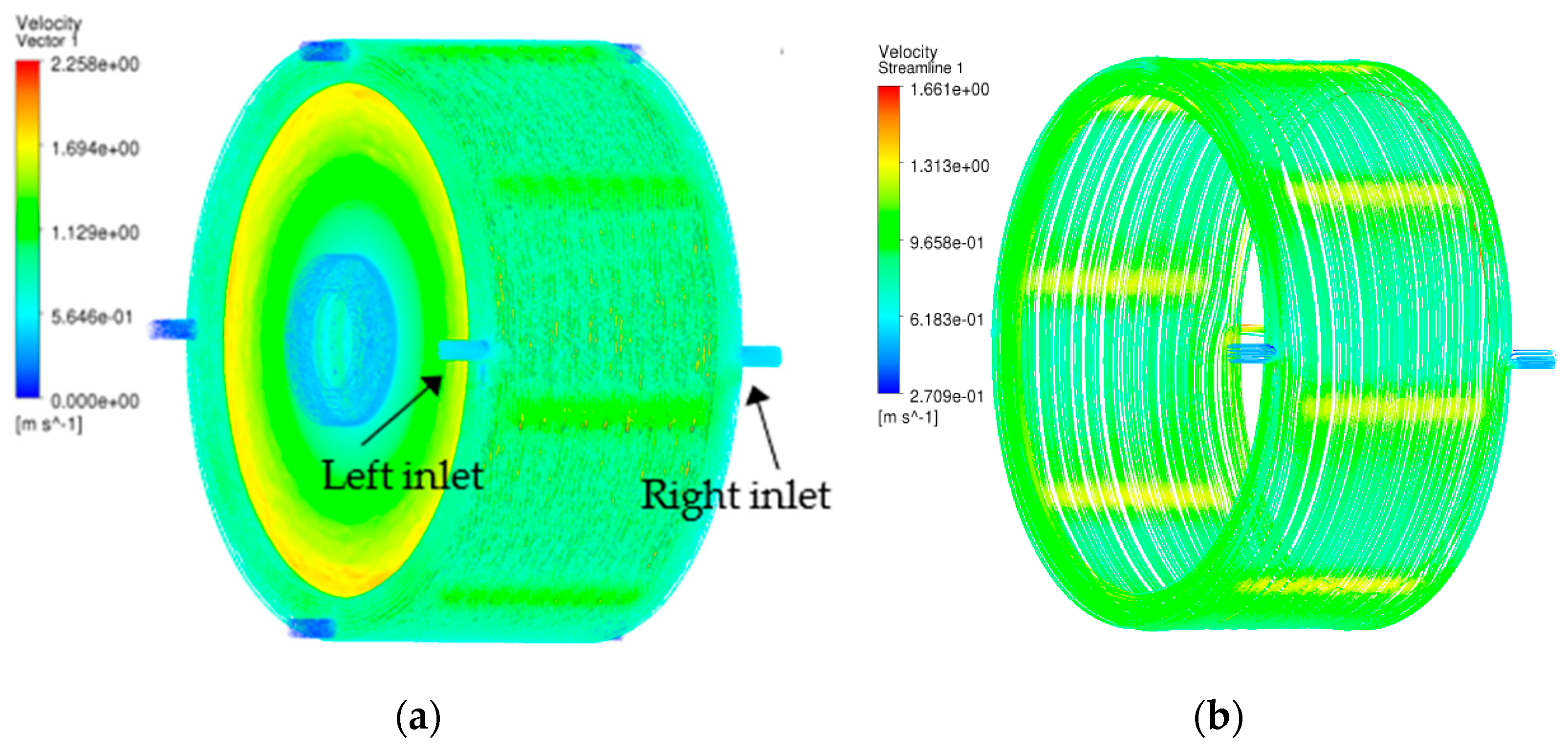

4.2.2. Inlet Position

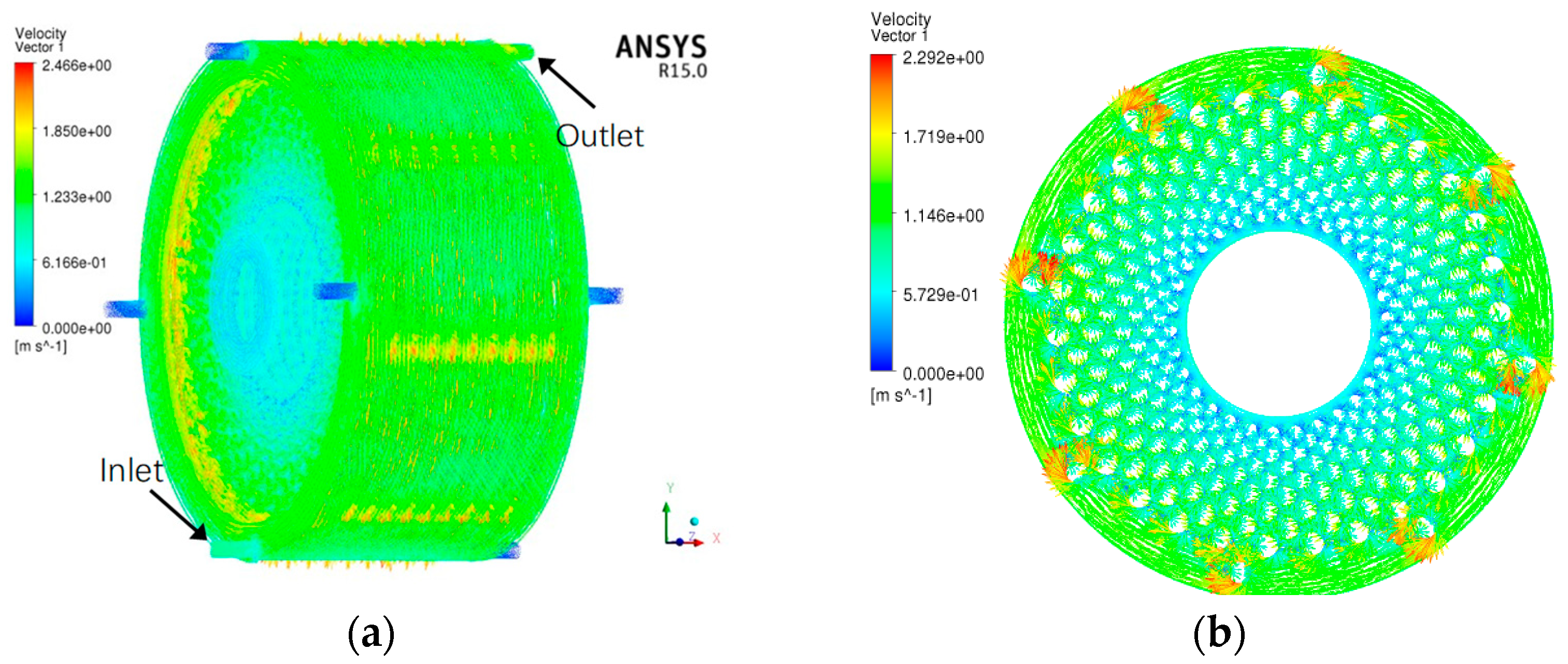

4.2.3. Diameter of Magnetic Columns

4.2.4. Number of Magnetic Columns

5. Temperature Field Analysis of MR Transmission Device

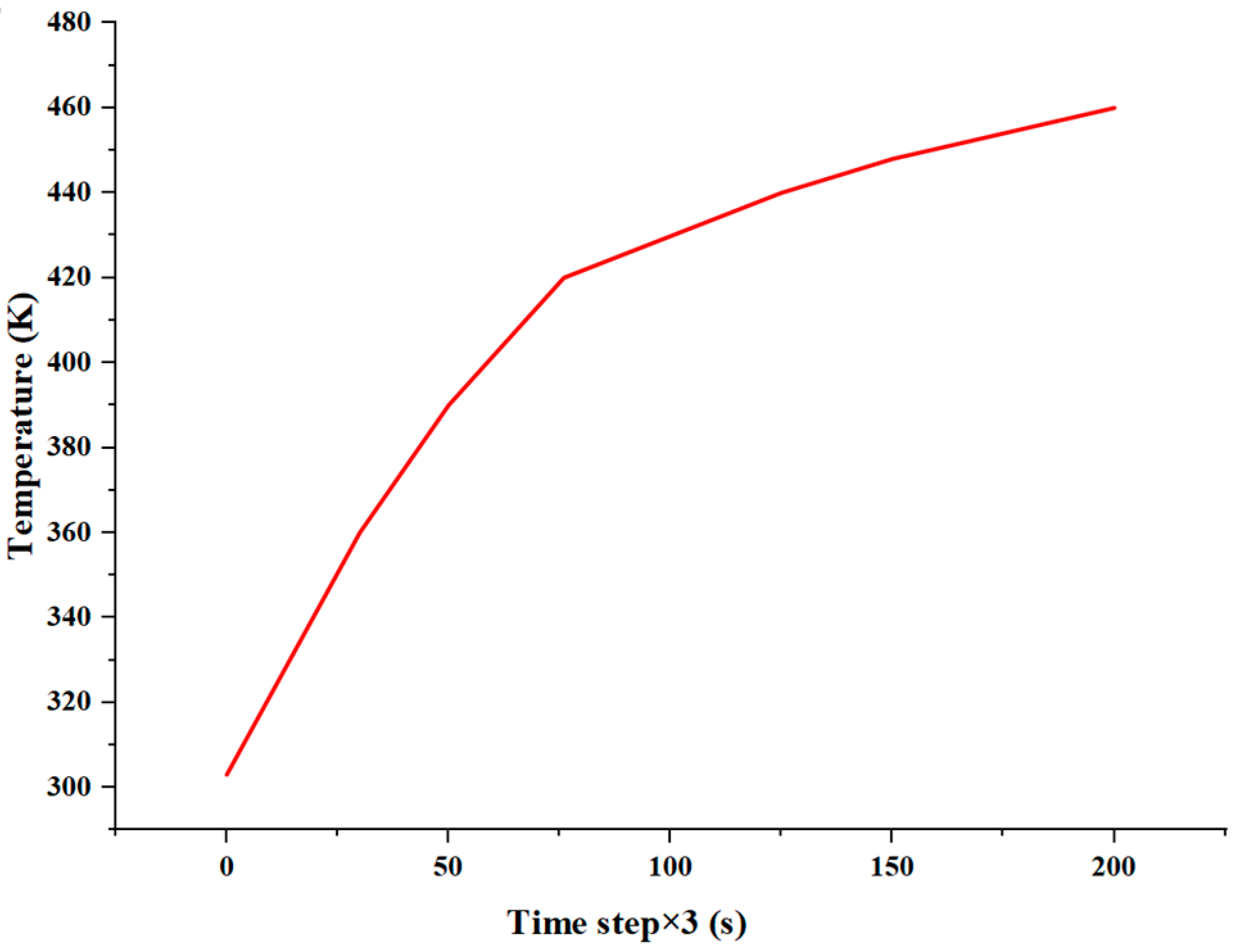

5.1. Analysis of Transient Temperature Field

5.2. Analysis of Temperature Field in Ultimate Slip Power

6. Experiments and Discussions

6.1. Experimental System

6.2. No-Load Characteristics

6.3. Rotating Speed Characteristics

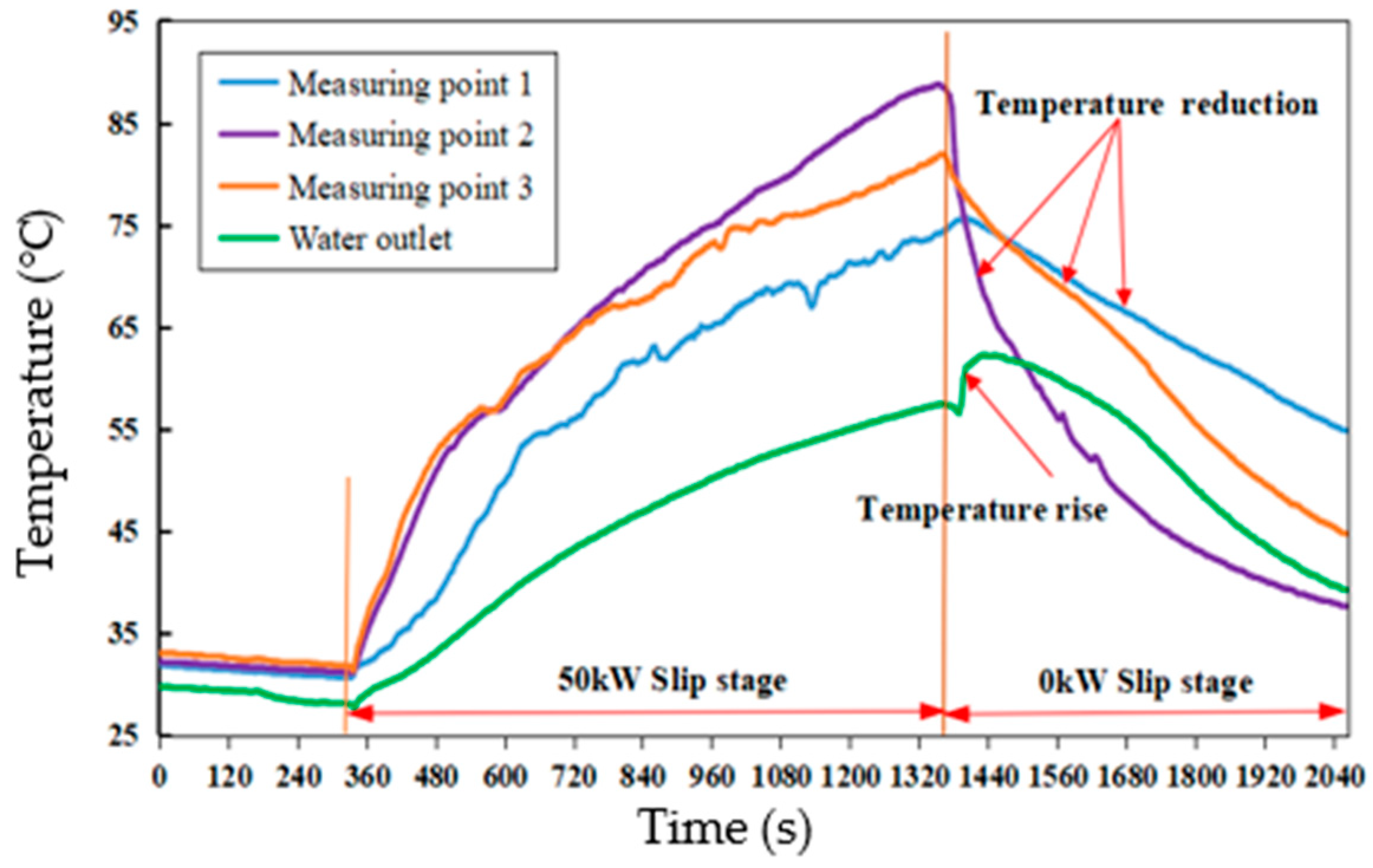

6.4. Influence of Slip Power and Rotating Speed on Heat Dissipation

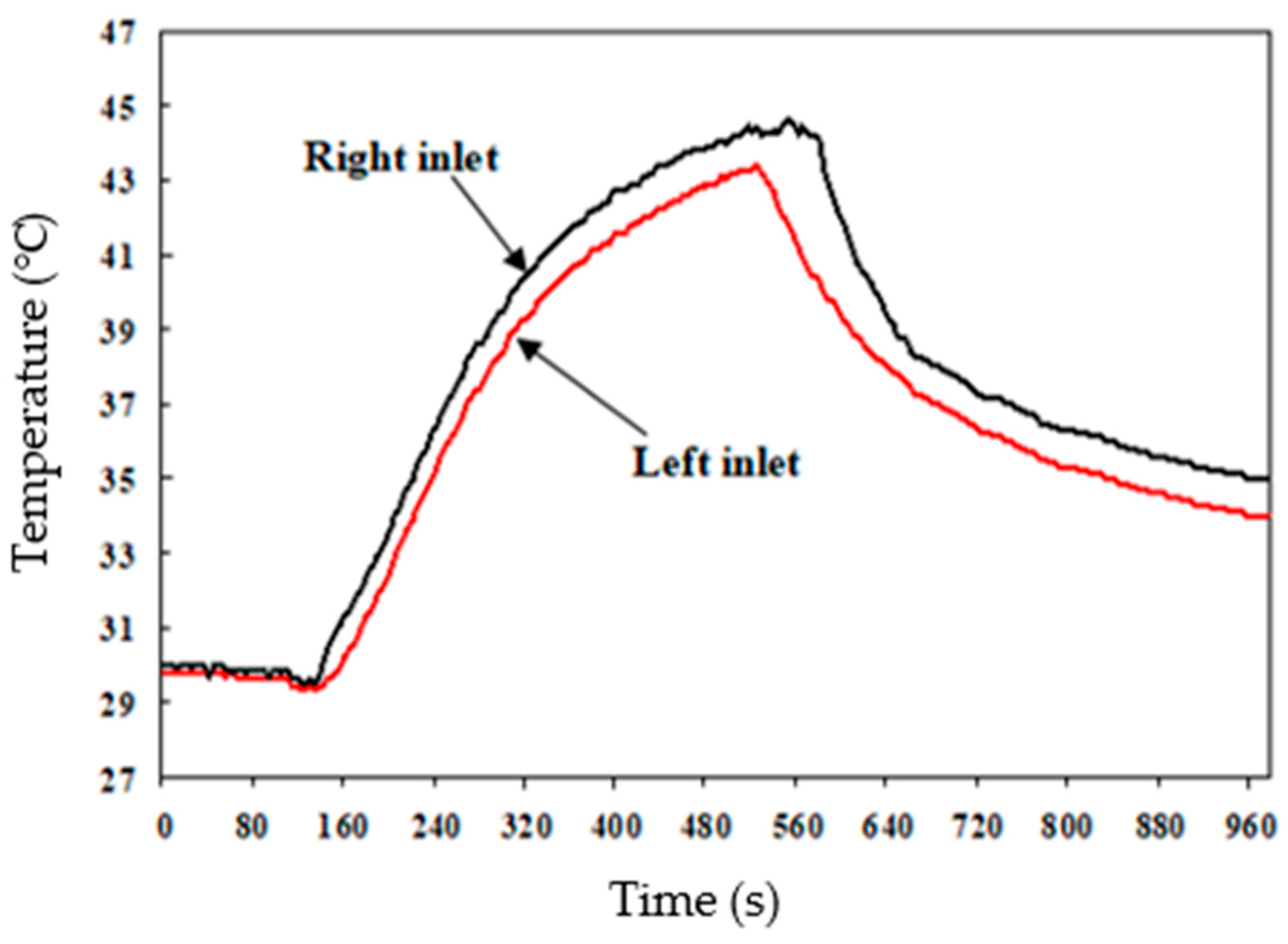

6.5. Influence of Inlet Position

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, X.F.; Huang, C.H.; Tian, Z.Z. Development of a novel magnetorheological fluids transmission device for high-power applications. Smart Mater. Struct. 2019, 28, 05502. [Google Scholar] [CrossRef]

- Liu, X.H.; Wang, L.F.; Lu, H. A study of the effect of nanometer Fe3O4 addition on the properties of silicone oil-based magnetorheological fluids. Mater. Manuf. Process. 2015, 30, 204–209. [Google Scholar] [CrossRef]

- Rabbani, Y.; Ashtiani, M.; Hashemabadi, S.H. An experimental study on the effects of temperature and magnetic field strength on the magnetorheological fluid stability and MR effect. Soft Matter. 2015, 11, 4453–4460. [Google Scholar] [CrossRef] [PubMed]

- Widodo, P.J.; Budiana, E.P.; Ubaidillah, U.; Imaduddin, F. Magnetically-Induced Pressure Generation in Magnetorheological Fluids under the Influence of Magnetic Fields. Appl. Sci. 2021, 11, 9807. [Google Scholar] [CrossRef]

- Chen, W.J.; Huang, J.; Yan, Y. Research on the Transmission Performance of a High-Temperature Magnetorheological Fluid and Shape Memory Alloy Composite. Appl. Sci. 2022, 12, 3228. [Google Scholar] [CrossRef]

- Cheng, H.; Lim, T.; Kim, S. Sound insulation effect of magnetorheological fluid as a function of magnetic field strength and direction. Mater. Res. Lett. 2022, 10, 310–317. [Google Scholar] [CrossRef]

- Zhao, D.; Zhao, J.B.; Zhao, Z.H. Design and experimental study of the porous foam metal magnetorheological fluid damper based on built-in multi-pole magnetic core. J. Intell. Mater. Syst. Struct. 2022, 31, 687–703. [Google Scholar] [CrossRef]

- Liu, X.M.; Shi, Y.; Xu, J. Parameters tuning approach for proportion integration differentiation controller of magnetorheological fluids brake based on improved fruit fly optimization algorithm. Symmetry 2017, 9, 109. [Google Scholar] [CrossRef] [Green Version]

- Hato, M.J.; Choi, H.J.; Sim, H.H. Magnetic carbonyl iron suspension with organoclay additive and its magnetorheological properties. Colloids. Surf. A 2011, 377, 103–109. [Google Scholar] [CrossRef]

- Arief, I.; Mukhopadhyay, P.K. Magnetorheology in CoNi nanoplatelet-based MRFs: Effect of platelet orientation and oscillatory shear. J. Magn. Magn. Mater. 2019, 479, 326–331. [Google Scholar] [CrossRef]

- Luong, Q.V.; Jo, B.H.; Hwang, J.H.; Jang, D.S. A Supervised Neural Network Control for Magnetorheological Damper in an Aircraft Landing Gear. Appl. Sci. 2022, 12, 400. [Google Scholar] [CrossRef]

- Zhu, X.C.; Jing, X.; Cheng, L. Magnetorheological fluid dampers: A review on structure design and analysis. J. Intell. Mater. Syst. Struct. 2012, 28, 839–873. [Google Scholar] [CrossRef]

- Li, H.P.; Jonkkari, I.; Sarlin, E. Temperature effects and temperature-dependent constitutive model of magnetorheological fluids. Rheol. Acta. 2021, 60, 719–728. [Google Scholar] [CrossRef]

- Tian, Z.Z.; Chen, F.; Wu, X.F. A novel preparation process for magnetorheological fluid with high sedimentation stability. Mater. Manuf. Process. 2016, 31, 2030–2036. [Google Scholar]

- Rizzo, R. An innovative multi-gap clutch based on magneto-rheological fluids and electrodynamic effects: Magnetic design and experimental characterization. Smart Mater. Struct. 2017, 26, 015007. [Google Scholar] [CrossRef] [Green Version]

- Acharya, S.; Saini, T.; Kumar, H. Determination of optimal magnetorheological fluid particle loading and size for shear mode monotube damper. J. Braz. Soc. Mech. Sci. 2019, 41, 392. [Google Scholar] [CrossRef]

- Lu, C.D.; Wu, M.F.; Wen, D.H. Experimental study on magnetorheological (MR) jet polishing of mould free surface. Key Eng. Mater. 2012, 500, 287–290. [Google Scholar]

- Nguyen, Q.H.; Choi, S.B. Optimal design of an automotive magnetorheological brake considering geometric dimensions and zero-field friction heat. Smart Mater. Struct. 2010, 19, 115024. [Google Scholar] [CrossRef]

- Li, G.; Ruan, Z.Y.; Gu, R.H. Fuzzy Sliding Mode Control of Vehicle Magnetorheological Semi-Active Air Suspension. Appl. Sci. 2021, 11, 10925. [Google Scholar] [CrossRef]

- Weiss, K.D.; Duclos, T.G. Controllable fluids: The temperature dependence of post-yield properties. Int. J. Mod. Phys. 1994, 8, 3015–3032. [Google Scholar] [CrossRef]

- Gordaninejad, F.; Breese, D.G. Heating of magnetorheological fluid dampers. J. Intell. Mater. Syst. Struct. 1999, 10, 634–645. [Google Scholar] [CrossRef]

- Wiehe, A.; Kieburg, C.; Mass, J. Temperature induced effects on the durability of MR fluids. J. Phys. Conf. Ser. 2013, 412, 012017. [Google Scholar] [CrossRef]

- Wang, D.M.; Hou, Y.F. Design and experimental evaluation of a multidisk magnetorheological fluid actuator. J. Intell. Mater. Syst. Struct. 2013, 24, 640–650. [Google Scholar] [CrossRef]

- Chen, F.; Tian, Z.Z.; Wang, J. Influence of temperature on the performance of magnetorheological fluid. J. Funct. Mate. 2014, 45, 015707. [Google Scholar]

- Francesco, B.; Paola, F. Temperature Effect on the Torque Characteristic of a Magnetorheological Clutch. Mech. Sci. Mater. Struct. 2015, 22, 150–158. [Google Scholar]

- Tian, Z.Z.; Wu, X.F.; Xiao, X.M. Influence of Temperature on Torque Transmission Stability of Magnetorheological Fluid. J. Magn. 2018, 23, 529–535. [Google Scholar] [CrossRef]

- Yang, J.; Chen, S.; Huang, J. Micro-analysis of slip differential heat of magnetorheological fluids based on micromechanics and microstructures. Mater. Res. Express 2019, 6, 065708. [Google Scholar] [CrossRef]

- Ashok, K.K.; Hemantha, K.; Arun, M. Influence of temperature on magnetorheological fluid properties and damping performance. Smart Mater. Struct. 2022, 31, 055018. [Google Scholar]

- Wang, D.M.; Zi, B.; Zheng, Y.S. An investigation of thermal characteristics of a liquid-cooled magnetorheological fluid-based clutch. Smart Mater. Struct. 2015, 24, 055020. [Google Scholar] [CrossRef]

- Huang, H.; Chen, S.; Chen, K. Novel magnetorheological brake with self-protection and water cooling for elevators. J. Mech. Sci. Technol. 2018, 32, 1955–1964. [Google Scholar] [CrossRef]

- Du, C.B.; Zeng, F.N.; Liu, B. A novel magnetorheological fluid damper with a heat insulation function. Smart Mater. Struct. 2021, 30, 075001. [Google Scholar] [CrossRef]

| Type | Parameter | Setting |

|---|---|---|

| Fluid domain | Material | Water (1 atm) |

| Heat Transfer | Thermal Energy | |

| Turbulence | k-ε model | |

| Wall Type | Smooth Wall (No Slip) | |

| Solid domain | Material | Steel |

| Domain Motion | Rotating | |

| Heat Transfer | Thermal Energy | |

| Wall Type | Wall | |

| Heat Transfer Coefficient | 10 W/(m2·K) | |

| Outside Temperature | 300 K | |

| Rotating solid domain | Material | Steel |

| Domain Motion | Rotating | |

| Heat Transfer | Thermal Energy |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Guo, Y.; Tian, Z.; Xie, F.; Ji, J.; Li, H. Analysis on Flow and Temperature Field of High-Power Magnetorheological Fluid Transmission Device. Appl. Sci. 2022, 12, 5044. https://doi.org/10.3390/app12105044

Wu X, Guo Y, Tian Z, Xie F, Ji J, Li H. Analysis on Flow and Temperature Field of High-Power Magnetorheological Fluid Transmission Device. Applied Sciences. 2022; 12(10):5044. https://doi.org/10.3390/app12105044

Chicago/Turabian StyleWu, Xiangfan, Yangyang Guo, Zuzhi Tian, Fangwei Xie, Jinjie Ji, and Haopeng Li. 2022. "Analysis on Flow and Temperature Field of High-Power Magnetorheological Fluid Transmission Device" Applied Sciences 12, no. 10: 5044. https://doi.org/10.3390/app12105044

APA StyleWu, X., Guo, Y., Tian, Z., Xie, F., Ji, J., & Li, H. (2022). Analysis on Flow and Temperature Field of High-Power Magnetorheological Fluid Transmission Device. Applied Sciences, 12(10), 5044. https://doi.org/10.3390/app12105044