Abstract

Cross-domain knowledge can stimulate radical concept generation (RCG), but there is a lack of guidance to utilize the cross-domain knowledge for RCG. This paper proposes an effective process of RCG in four steps: (1) Identifying radical technology opportunities based on analysis of the dynamic relationship between demand and technical performances; (2) Applying laws and lines of the technological system evolution to determine the search direction of cross-domain knowledge in a qualitative perspective; (3) Taking the minimum complementary distance measure for appropriate cross-domain knowledge in a quantitative perspective; (4) Forming radical concepts using the cross-domain knowledge as inspirations. The method reduces risks and costs caused by uncertainty in RCG and has potential to fertilize research on radical innovation and knowledge-based innovation. A radical concept of gas generator demonstrates the effectiveness of the proposed method.

1. Introduction

The modern world is facing multiple rapid changes and problems resulting from them. Radical innovation (RI) is an effective way to cope with changes and solve problems with revolutionary technology [1]. Radical innovation provides entirely new function, unprecedented performance benefits, substantial cost reductions, and new marketing opportunities for the development and commercialization of products/services offered [2,3]. For examples, 5G technologies accelerate the transformation and upgrading of traditional manufacturing [4] and health care industries [5]. Artificial intelligence brings new opportunities for autonomous driving and smart medical care [6,7]. Therefore, many firms are willing to engage in radical innovation activities, hoping to establish technological advantages and gain more market share. However, only a small number of innovation projects have truly reached the level of radical innovation, and the majority of innovations are still incremental innovations [8,9].

In new product development, design concepts decide as much as about 80% of the work and cost for the whole development [10]. A successful radical innovation project begins with a reasonable radical concept or idea that provides a unique solution for innovation and has enormous business value. Further research shows that the radicalness of RI usually depends on uniqueness of new technologies which comes from the result of cross-domain knowledge application to solve a difficult problem [11,12,13]. Cross-domain knowledge refers to knowledge that comes from domains other than the domain in which the problem needs to be solved [14,15]. Research in radical innovation management has demonstrated that cross-domain knowledge has an important inspiring effect on the RCG [16,17]. Cheng [18] and Pichlak [19] realize that open innovation, e.g., alliance network and partnerships, enables firms to acquire more cross-domain knowledge from the outside and stimulates the RCG. Further research suggests that the better the absorptive capacity, the more favorable it is for firms to acquire cross-domain knowledge for RCG [20,21,22]. Researchers above mainly focus on how to improve firm’s access to external knowledge to generate radical ideas.

However, the development and application of cross-domain knowledge for RCG is a complex multi-standard decision-making process [23,24]. Not all knowledge from outside can help engineers to generate radical ideas and concepts. How do we accurately search the cross-domain knowledge suitable for the development of radical ideas? How do we develop radical concept based on the cross-domain knowledge? Therefore, approaches to grasp key techniques precisely to search, screen and utilize the cross-domain knowledge for RCG have to be further studied [25]. A systematic process management method of cross-domain knowledge for RCG is still lacking.

The aim of this paper is to establish a process management method of cross-domain knowledge development for RCG. Building on the strategy literature and research of related theories, the predictive function of the law of the technological evolution and the advantage of minimum complement distance measurement are suggested to connect with radical innovations to address the above problem. Radical technology opportunities are identified based on the analysis of the dynamic relationship between customer needs and technical performance. Laws and lines of technological system evolution are used to determine the search direction of cross-domain knowledge in a qualitative perspective and select cross-domain knowledge in the minimum complementary distance in a quantitative perspective. Finally, radical ideas and concepts are established with cross-domain knowledge as inspirations. The precise process reduces uncertainty in cross-domain knowledge search and increases the efficiency and success of RCG.

Remaining parts of the paper are organized as follows. Section 2 introduces related research on RI and main tools used in the research including laws of the technological system evolution and minimum complementary distance. Section 3 proposes a process management method of cross-domain knowledge development to support radical creativity and concept generation including the identification of radical technology opportunities, establishment of cross-domain knowledge search direction, selection of cross-domain knowledge sources, and radical concept generation. In Section 4, the proposed method is demonstrated with a radical concept of the airbag gas generator. Section 5 discusses the conclusion and further work.

2. Related Research

2.1. Definition and Features of Radical Innovations

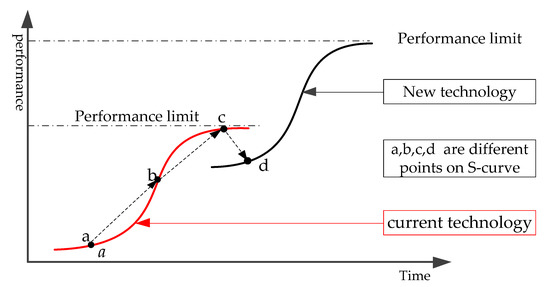

According to the degree of technological change and impact on the market, innovations are traditionally divided into incremental innovation and radical innovation (RI) [26,27]. Incremental innovation is continuous and small changes on the original technological trajectory (S-curve) [28,29] which is the continuous exploration and improvement of the original technological potential. As shown in Figure 1, incremental innovation occurs from point a to b or from point b to c on the same S-curve. Most companies, especially those large and established ones, prefer to engage in incremental innovation because of its low risk. RI is to replace the old technological trajectory with a new one, which can greatly improve the product performance or significantly reduce the cost of the product [30,31]. RI occurs in the replacement phase of S-curve from point c to d as shown in Figure 1. When the performance of current technology has developed to the limit, engineers or designers need to find a new technology to replace the current one [32,33]. The discontinuity of the S-curve is the most obvious technical manifestation of RI [34].

Figure 1.

Parallel and serial technological competition preceding RI.

RI is characterized by divergence and nonlinearity, showing a leap-type and discontinuous development [35]. The radical performance of RI means that a new product or technology is significantly different from the current product or technology in one of the following aspects: (a) the new product offers an entirely new set of performance features, (b) five-times or greater improvement in known performance features, (c) a significant (30% or great) reduction in cost [36,37]. These performances provide operational opportunities to implement RI.

Features of RI related to the technological trajectory and radical performance are the new technical principles inspired by cross-domain knowledge. However, how to accurately and effectively find cross-domain knowledge suitable for the development of radical idea is still a problem. The technological trajectory discontinuity of RI makes it difficult for engineers to predict the next-generation technology and obtain cross-domain knowledge for RCG. And RI has high requirements on firms’ knowledge reserves [38], strategic positioning [39], absorptive capacity [21,22] and other aspects. It is difficult for firms to find appropriate cross-domain knowledge to form radical concepts and ideas with low cost and risk, especially small and medium-sized ones [40]. Therefore, it is essential to have an operable process for RCG to improve the success rate of RIs.

2.2. Technological Forecasting in TRIZ

One of the most striking features of RI is the transformation of the technology trajectory [41]. When the technical performance reaches its limit or is difficult to improve due to other factors, engineers need to find new technologies to replace the current one, but it is usually difficult to identify the next-generation technology to overcome the performance limits. As a knowledge-based systematic method, TRIZ (Theory of innovation problem solving) defines nine laws of technological system evolution: (a) law of increasing degree of ideality, (b) law of non-uniform evolution of sub-systems, (c) law of transition to a higher-lever system, (d) law of increasing flexibility of system, (e) law of transition from macro-to micro-level, (f) law of shortening of energy flow path, (g) law of harmonization, (h) law of completeness, (i) law of increasing controllability [42,43].

Each law shows a general direction for products or next-generation technologies. The predicting power of each law is greatly enhanced by several associated lines that specify successive stages of evolution along a certain direction [44]. Based on laws and lines of the evolution, engineers can actively identify strategic directions of the technology evolution with analysis of the past and current system evolution. Much research has been conducted on utilizing laws and lines of the evolution as stimuli for next-generation technology. Zhang et al. [45] applied the laws into the conceptual design of new stereo garage. Ping et al. [46] proposed a comprehensive process for product RI based on the analysis of product technology system and law of technology evolution. Cascini et al. [47] proposed an approach for technological forecasting of satisfying the need of manufacturing industries to support decision-making processes in planning corporate strategies for R&D.

Laws of the technological evolution provide an effective way to predict future technologies. However, they can only make analysis in a qualitative perspective, without providing an appropriate choice in a quantitative perspective. Given high risk of RI from the technology uncertainty, it is difficult to use laws of the evolution to search for appropriate cross-domain knowledge for RCG. An innovative development process with the quantitative analysis is required to identify appropriate cross-domain knowledge accurately.

2.3. Technological Distance Measure

The radical performance of RI is usually the result of introduction of other domain knowledge or technology to solve difficult problems; however, it does not mean that cross-domain knowledge must come from far away [48,49]. Because even though the learning and recombination of external knowledge will bring engineers and designers more creative inspiration and opportunities, firms may not have the necessary absorptive capacity for learning and mastering to take place [50]. The relationship between technological distance and innovative performance is an inverted U-shaped [51,52] and has been corroborated by many empirical studies [48,53]. Intuitively, if the technological distance between two firms is too close together, the high similar knowledge bases will not lead to the generation of novelty value. On the contrary, if the technological distance is too far away from each other, it is difficult for firms to absorb and utilize the cross-domain knowledge to achieve radical ideals [54,55]. Therefore, a moderate level of technological distance is desirable for firms to use cross-domain knowledge for RCG effectively.

The measure of technological distance was pioneered by Jaffe to describe the effect of knowledge spillover [56,57]. The Euclidean Distance and Cosine Angle are two common measures along with the introduction of patent vector [56,58], and both take all the patent classes into the calculation according to their own calculation rules [49]. However, Bar and Leiponen [59] argued that collaboration, technology transfer, knowledge spillover, or R&D competition between a target firm with some empty patent classes and other firms should depend on patent classes in which the target firm has some patent holdings, rather than the other firm allocation of patents in classes that are empty for the target firm. This is particularly important because small innovative firms are often concentrated in a few classes and not likely to have very broad patent layout, whereas technology giants may own dozens of patent classes. Obviously, technological distance is an objective existence and should not be affected by the size of the firm. In order to eliminate the influence of this asymmetry in technological distance measure, Bar and Leiponen [59] developed a new measure, named minimum complement distance, as an alternative measure of technological distance. When using this method, the share of invention overlap will be subtracted from the whole universe of firm’s inventions. The remaining part has a share of non-overlapping inventions, which are interpreted as the technological distance. In the research of innovation collaborations, Stein et al. [49] showed that the use of the minimum complement distance seems to be reasonable due to the intuitive property of the independence of irrelated patent classes in cross-industry collaboration settings.

Cross-domain knowledge for RCG comes from firms of different sizes firms, either a small enterprise or a technology giant. Technological distance measure can quantitatively identify cross-industry partners and contribute to valuable partnering decisions. Considering that effective quantitative methods are necessary to identify cross-domain knowledge for RCG, we try to integrate the minimum complement distance into the process of the selection systematically to improve the effectiveness of RCG. Simultaneously, we also hope the potential of the measure is fully explored.

2.4. Summary of Review

From the review works above, scholars and engineers have realized the important role of cross-domain knowledge for RCG, but how to accurately and effectively find cross-domain knowledge suitable for the development of radical idea is still a problem. By collecting the feedback from industrial experts, details of the problem are described as follows. (1) The technological trajectory discontinuity of RI makes it difficult for engineers to determine the next-generation technology and obtain cross-domain knowledge. (2) Considering the inverted u-shaped relationship between technological distance and innovation performance, the selection of cross-domain knowledge for RCG is not quantitatively analyzed. According to the review and analysis above, the predictive function of the law of the technological evolution and the advantage of minimum complement distance measurement are suggested to connect with radical innovations to address the above problem. Therefore, this research proposes the integration of laws of the technological evolution and minimum complement distance for effective using of cross-domain knowledge as inspirations to support RCG.

3. Proposed Method

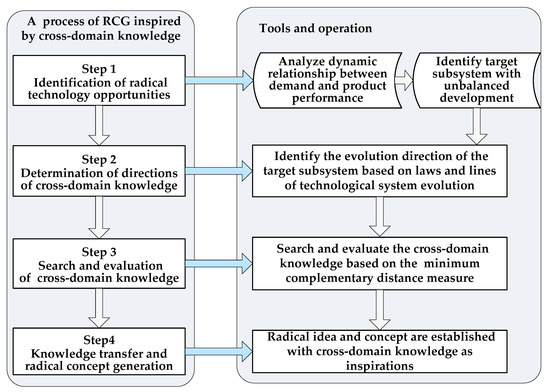

Based on features of the radical innovation and process of radical product development, we propose a process management method of cross-domain knowledge development to support RCG. The overall flow of the approach includes the following four steps as shown in Figure 2.

Figure 2.

Steps of the proposed approach.

- Identification of radical technology opportunities. The technical performance development of system is out of sync with the growth of user demand. This inconsistency provides radical technology opportunities.

- Determination of direction of cross-domain knowledge. The past state and current state of the technical system (subsystem) are analyzed, and then the future technological state can be determined with advantage of the laws and lines of technological evolution, thereby determining the search direction of knowledge.

- Search and evaluation of cross-domain knowledge. The measure of minimum complementary distance is introduced to evaluate appropriate firms and cross-domain knowledge.

- Knowledge transfer and radical concept generation. These principles or structures included in cross-domain knowledge are used to generate radical ideas and concepts.

3.1. Identification of Radical Technology Opportunities

Many companies advocate RI, but they are not clear about the formation process of radical technology opportunities. Many innovative ideas are proposed without considering features of the radical innovation and the process of radical product development. Because of the lack of sufficient pre-condition constraints and clear goal guidance, most of the innovative ideas do not conform to firms’ radical strategic goals and laws of the technology development.

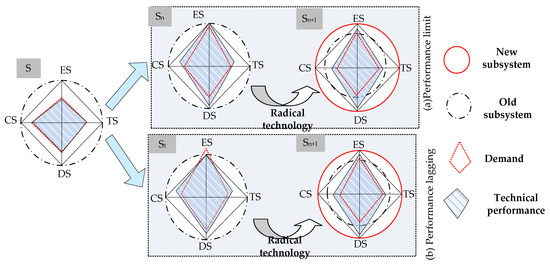

A complete technical system includes four subsystems: control subsystem (CS), driving subsystem (DS), transmission subsystem (TS) and execution subsystem (ES) [60]. In the development of technical systems, the speed of technical performance improvement and the growth of user requirements are not always synchronized; the technical performance development of some subsystems evolves ahead of the development of user requirements, while some are just the opposite. The unbalanced development of subsystems provides opportunities for RI. According to Ehrnberg’s analysis of the discontinuity of the technological trajectory, the formation of radical technology opportunities can be divided into two situations: performance limit situation and performance lagging situation, as shown in Figure 3 [33]. In order to facilitate the analysis of these two situations, taking ES as an example, four key stages are defined. These items are shown in Table 1. Details are as follows.

Figure 3.

Analysis of radical technology opportunities.

Table 1.

List of Items for Technological Attributes.

Performance limit situation: In the initial state S of the technical system, the performance of all subsystems meets customer needs. Driven by market pull and technology push, technical system goes from state S to state Sn through incremental development. In the state Sn, ES has developed to the performance limit, but CS-DS-TS have not reached the performance limit. The technical performance of all the subsystems in the state Sn is still able to meet the customer needs, or even in a state of performance ahead of the demands. However, in order to meet the rapid growth of user needs, establish technical advantages, create exciting needs of users, and form technical barriers to other firms and other factors, it is necessary for firms to carry out a new technology to replace the old one in ES. In other words, it is an opportunity for firms to develop radical technology. Through the application of new technologies, ES moves from state Sn to a new state Sn+1, the technical performance of ES will be greatly improved, as shown in Figure 3a.

Performance lagging situation: In the technical system from state S to state St, the improvement of technical performance of CS-DS-TS is always faster than the growth of customer needs. In the state St, the technical performance of CS-DS-TS is still able to meet the customer needs, or even in a state of performance ahead of the demands. However, in the state St, the technical performance of ES has seriously lagged behind the customer needs because it is difficult to improve the performance of ES from state S to state St due to other additional conditions such as environmental protection and patent rights for a long time. If companies continue to improve the performance of ES, they need to spend huge investment and time. At this time, a new technology should be applied to ES to eliminate the current restrictions, and ES can go from St to a new state Sn+1 without considering these constraints. As shown in Figure 3b, the technical performance of ES can be rapidly improved in the later stage.

3.2. Determination of Directions of Cross-Domain Knowledge

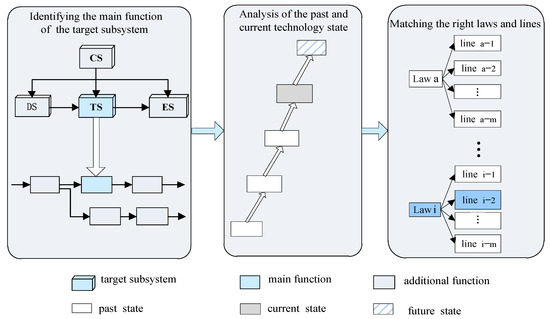

Through the analysis of radical technology opportunities above, we can identify the target subsystem that needs radical technology to improve the performance. In order to accurately find cross-domain knowledge for RCG, we need to determine the search direction of cross-domain knowledge first. In this part, a comprehensive process to identify the search direction of cross-domain knowledge under the guidance of laws and lines of evolution is produced. In the process, the technological trajectory and radical performance of RI are considered. The overall flow of the approach includes the following four steps as shown in Figure 4.

Figure 4.

Determination of directions of cross-domain knowledge.

- Identifying the main function of the target subsystem. According to the importance of functions to customers, functions can be divided into two categories: main functions and additional functions [61]. RI requires changing the way the main functions of the target subsystem implemented. The determination of the main function of the target subsystem should be considered from three aspects: (1) The main function expresses the necessary and basic needs of customers. (2) The main function corresponds to a primary product purpose. (3) The product properties will change overall after the main function is changed. Under the guidance of this description, the products of the target firm or external firms of the same type are collected to analyze the structure, components and parts of the target subsystem, and abstract the main function, principle or technical characteristics of the target subsystem [62].

- Analysis of the past and current technology state. As the name suggests, this step is essentially about analysis of the technology evolution of the target subsystem. The development of any technical system usually follows an S-shaped curve, reflecting the dynamics of the system benefit-to-cost ratio [63]. By searching for relevant patents, literature and market research, relevant technologies for the realization of the main function of the target subsystem. Arrange these techniques in evolutionary order to determine the past and current technical status of the main function of the target subsystem. The key step allows for positioning the technology or product on its S-curve, thereby helping to define radical technology strategies [64].

- Matching the right laws and lines. Based on the analysis of the past and current technology state, possible laws and lines that conform to the trend of evolution are selected for likely directions of the future state. According to the different focus on the target subsystem, engineers are allowed to choose different laws and lines to develop different strategies to achieve radical technology. Under the guidance of the laws and lines, engineers can discover future state including next-generation technologies of the target subsystem. The search direction of cross-domain knowledge can be clarified by analyzing the next-generation technology. Radical ideas and concept proposed based on the next-generation technology will be consistent with the evolution of technology to reduce the uncertainty of technology development of RI.

3.3. Search and Evaluation of the Cross-Domain Knowledge

The patent database contains more than 90% of the world technical information, providing a wealth of resource for the acquisition of cross-domain knowledge [65,66]. At the same time, the number of patents distributed in different patent classes reflects the technological focus and advantages of firms [67]. More importantly, the patent activity can characterize the knowledge base in most industries that actively pursue R&D and engage in cross-industry research to explore new technologies [68,69]. Therefore, we use a patent database as a knowledge storage pool to capture cross-domain knowledge for RCG. The details are as follows:

- Identifying related patents and firms. In order to accurately search for cross-domain knowledge, it is necessary to establish and combine keywords or technical language to describe the main function of the target subsystem based on the next-generation technology. With the description and constraints of the keywords and technical language, firms with patents related to the next-generation technology are captured in the patent database. We define them as related patents and related firms. It is important to note that these related firms should belong to different industries from the target firm in the retrieval process. For example, if a traditional car firm (target firm) wants to develop an electric vehicle, it had better look for firms related to battery technology development rather than automobile firms.

- Technological position description. Representation of technological status of a firm is based on the technological space described by patents and International Patent Classification (IPC) codes [70]. According to the IPC codes, patents are divided into eight categories (A, B, C, D, E, F, G, H) in 120 subcategories [71]. Each firm occupies its unique position based on its technological knowledge characterized by its patent classification and patent portfolio. The technological position of a firm can be represented by a vector P as follows:where P is the technical position of the firm, k is the classification number of the patent, Pk is the ratio of the number of patents under classification k to the total patents of the firm, n is the total number of patent classifications of the firm.

- Measuring technological distance. According to the minimal complementary distance measure [59], the technological distance between firm I and firm J can be decided as follows.where M is the technological distance between firms I and firm J, PI is the technical position of the firm I, PJ is the technical position of the firm J. M∈ [0,1], and when M = 0 the technological distance between the two firms is the closest.

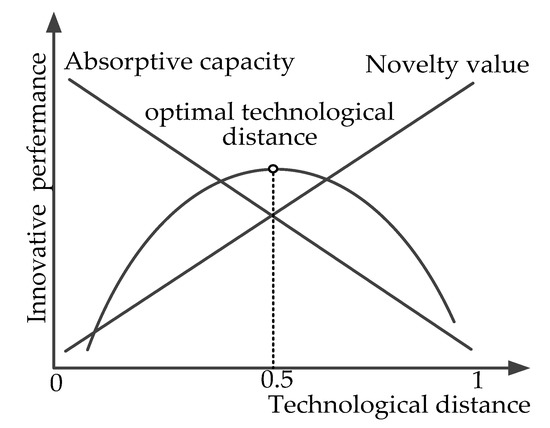

- Appropriate cross-domain knowledge. Technological distance affects both knowledge acquisition and innovation performance, but there are two opposing mechanisms at work, as described in the first paragraph of 2.3 [72]. That is why the relationship between technological distance and innovation performance is an inverted U-shaped curve, as illustrated in Figure 5.

Figure 5. Inverted U-shaped and the optimal technological distance.

Figure 5. Inverted U-shaped and the optimal technological distance.

Obviously, ideal firms that provide appropriate cross-domain knowledge should be those close to the optimal technological distance 0.5 under ideal conditions. In fact the optimal distance is not unique and constant, because the desire for innovation (Novelty Value) and employee learning ability (Absorptive Capacity) of the firms is not absolutely reciprocal. Wuyts et al. [53] tested the relation between cognitive distance and innovation performance of firms engaged in technology-based alliances and pointed out that the optimal cognitive distance at the mean value of technological capital is 38.4 on a scale between zero and hundred. Gao [73] suggested that the technological distance between target firm and its partners should be around 0.4, which is conducive to the flow of knowledge between firms and the emergence of radical technologies.

The related firms are ranked according to the results of the technical distance, and those whose distance are close to the optimal technological distance are called ideal firms. The related patents of these ideal firms provide the appropriate cross-domain knowledge to support the development of future state of the target subsystem. Therefore, radical concept and ideas can be generated by utilizing the technology in these ideal firms to realize the main functions of the target subsystem. Next, we will describe and illustrate RCG based on the cross-domain knowledge from the related patents.

3.4. Knowledge Transfer and Radical Concept Generation

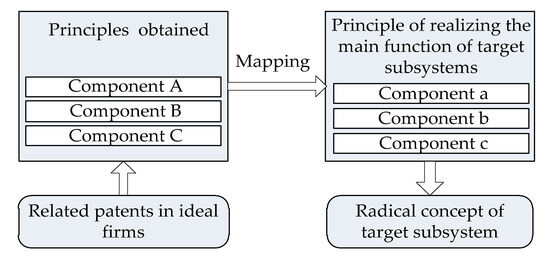

The technical system design is to provide specific functions [74]. Similar functions can be achieved with different structures and principles. The analogy process is the transfer of structures or principles with similar functions from one system to another new system to achieve the desired function of the new system [75]. Guided by analogy, we can build radical concepts of the target subsystem with cross-domain knowledge gained from the above process. The process is shown in Figure 6, and details are as follows:

Figure 6.

Knowledge transfer and concept generation.

- Analysis and acquisition of technical principles. To take advantage of this cross-domain knowledge for RCG, the text and pictures of related patents in ideal firms are analyzed first. By analyzing the technical information contained in these patents, engineers can obtain the technical principle and structure from the related patents first [76]. These principles may be some chemical effects or a complex mechanical structure. The functions achieved by these principles or structures are the same or similar to those of the target subsystem.

- Technical principle mapping. According to the results of the function-oriented search above, these technical principles obtained can realize the function of the target subsystem. Inspired by these principles and structures, engineers can find a new principle to realize target subsystem function. For example, the technical principles and structure (component A, B, C) in the related patents can be transferred to generate a new structure (component a, b, c) of the target subsystem through the mapping process. The implementation of an analogy mechanism is introduced as shown in Figure 6.

- Radical concept generation. Finally, inspired by new principle solution, engineers can develop radical concepts of the target subsystem combined with personal design experience.

4. Cases Study

EAST JOY LONG (ESL) is an industrial partner of our research center in the ‘Innovative Method Promotion and Application’ research project. This firm is the only domestic one who masters the core technology of airbag systems and provides products and services to many companies, such as SAIC MOTOR and IKCO. This section discusses the radical concept design of a new airbag gas generation device to verify the proposed approach.

4.1. Problem Statement and Opportunity Identification

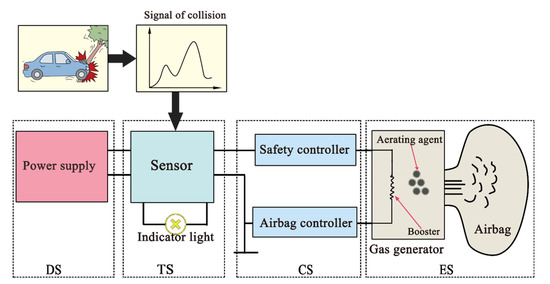

Airbag systems provide a passive protection for drivers and passengers. When the car collides, the sensor senses the intensity of the collision and transmits the signal to the controller. The controller receives the signal from the sensor and judges the severity of the impact. If the airbag needs to be opened, the controller immediately sends an ignition signal to the gas generator so that the gas generator can inflate the airbag in a very short time. The composition of the airbag system and the operation process between the subsystems are shown in Figure 7.

Figure 7.

The airbag system.

The power (DS) supply provides the driving force for the airbag system, the sensor (TS) is responsible for compiling and transmitting signal, the safety controller and airbag controller (CS) recognize the signal from the sensor and determine whether to activate the air bag, the gas generator and air bag (ES) form a protection system.

ESL’s investigation and analysis of many traffic accidents show that drivers can be re-injury because of the airbag system in some accidents. When collisions are enough, the gas generator relies on the chemical reaction of gunpowder to produce gas, accompanied by high temperature (Peak value of about 2000 °C) and high pressure (Close to 400 Kpa). The result is that the air pocket pops up at a speed of more than 200 km per hour to protect passengers. However, the speed is so fast that when the driver or passenger is very close to the airbag, it will cause re-injury to them—especially for drivers with short legs, because drivers with short legs need to operate brakes and other equipment closely. At the same time, a large amount of hot gas produced by the chemical reaction is discharged from the airbag vent hole, which may cause skin burns. Therefore, ESL hopes to develop a new gas generator (execution subsystem, ES) to eliminate the above problems.

4.2. Analysis and Selection of Problem Solving Direction

The main function of the generator is to quickly generate gas and fill the air pocket. The first-generation gas generator (past state) realizes airbag inflation by releasing compressed gas stored, with less gas production and slow inflation speed. The second-generation (current state) uses the high temperature and high pressure after gunpowder combustion to inflate the air bag, but the hot flame can burn the airbag, and the combustion products can have toxic side effects on the human body.

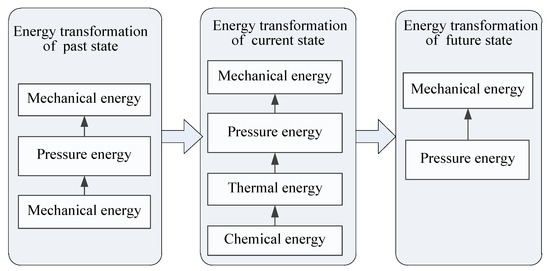

Based on the analysis in Section 4.1, engineers believe that the release of airbags should become more controllable, with as few harmful effects as possible, and the energy transmission should be more efficient. The current and past energy transmission paths of the gas generator subsystem are shown in Figure 8.

Figure 8.

Analysis of the evolutionary direction of engine subsystem.

The past energy transmission path of gas generator is as follows: the compressed gas is stored in a container by external mechanical energy. When a collision occurs, the compressed gas (Pressure energy) is released to inflate the airbag (Mechanical energy). The current energy transmission path of ESL products is as follows: the chemical reaction (Chemical energy) produces gas and heat (Thermal energy), gas expansion produces pressure (Pressure energy), and pressure is converted into mechanical energy. In order to reduce harmful effects and shorten the path of energy transfer, engineers choose f (law of shortening of energy flow path) as a guide for generating ideas. Inspired by reducing the number of stages of energy transfer and improving energy controllability, a next-generation technology is determined from pressure energy to mechanical energy in order to avoid uncontrollable chemical energy and thermal energy, as shown in Figure 8.

4.3. Acquisition of Cross-Domain Knowledge

This part describes the search and evaluation of the cross-domain knowledge to support the development of radical concept of gas generator. We use Patsnap [77], a patent database including 140 million+ patents, as a knowledge storage pool to capture cross-domain knowledge with the minimum complement distance measure to filter and evaluate appropriate cross-domain knowledge.

- Related patents and firms. The function related to the target problem is “increase the gas to create enough pressure”. We further standardize it into “increase gas pressure” based on sets of terminologies stored in PatSnap. In the process of generating gas through gunpowder or similar chemical reactions, high temperatures are almost inevitable. Therefore, the new gas generator concept should not continue to use chemical reactions. The patent activity characterizes the technological focus and R&D capabilities of most industries that are actively engaged in R&D and cross-industry research to explore new technologies. Therefore, we choose firms with a large number of related patents in the last ten years (from 2011 to 2020). These related firms belong to firms outside the airbag industry. In the end, a total of twelve related firms are selected as listed in Table 2, denoted as No.1–No.12.

Table 2. List of related firms.

Table 2. List of related firms.

The 12 related firms belong to different fields from ESL and have a large number of patents related to the generation of gas pressure. The cross-domain knowledge contained in these related patents will support the generation of radical concept of gas generator.

- 2.

- Data collection and technology space description. A total sample of 234,512 patents assigned to eight patent classifications (A/B/C/D/E/F/G/H) derived from 12 related firms forms the basis of the following analyses. The detailed description is given in Table 3.

Table 3. Patents of ESL and 12 related firms under the 1st-level classification.

Table 3. Patents of ESL and 12 related firms under the 1st-level classification.

The firm with the largest number of patents is No.2 (88,841), and the least is No.7 (37). No.2 is a super-large state-owned firm, while No.7 is a biotechnology firm established in 2016. No.2, No.3 and No.6 have patents distributed in all eight patent classifications, while No.1, No.7 and No.9 only in few patent classifications. The number of patents under different IPC categories reflects the technological focus and technological position of different firm. The patent distribution in each classification of all related firms is shown in Table 4.

Table 4.

Patents distribution of ESL and 12 related firms under the 1st-level classification.

- 3.

- Technological distance measurement. According to the minimum complementary distance measure, the distance between ESL and 12 firms is shown in Figure 9.

Figure 9. Technological distance between ESL and 12 related firms.

Figure 9. Technological distance between ESL and 12 related firms.

Among them, the distance between No.12 and ESL (M = 0.149) is the closest. No.12 is a firm that studies the rocket launch technology and has applied for many patents related to the combustion and expansion of liquefied gases (i.e., 2H2 + O2 = H2O). The combustion of liquefied gas is still a chemical reaction, and the working principle of the ‘rocket’ is similar to the current gas generator, which cannot help to generate radical innovative solutions. However, there is a large technological gap between No.9 and ESL (M = 0.949), which shows that it is difficult to develop technology suitable for gas generators relying on related technology in textile machinery. The distance of No.1 (M = 0.504) and No.10 (M = 0.419) is close to the optimal technological distance. To obtain appropriate cross-domain knowledge, we further analyze related patents in No.1 and No.10.

- 4.

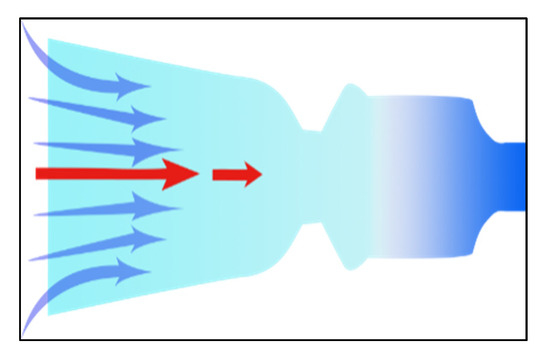

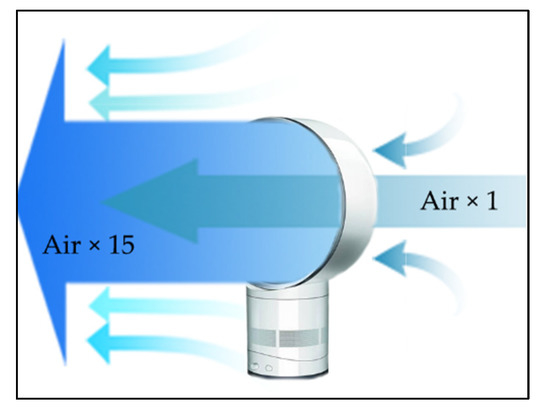

- Analysis of related patents. Analyze the main technology and principles used in related patents of the firms No.1 and No.10. No.1 is an internal combustion engine manufacturing firm that uses the “Conda Effect” to improve the design of the combustion chamber to increase the intake efficiency of the internal combustion engine. The red arrow shows a small amount of compressed air, and the blue arrows are the ambient air that is being sucked, as shown in Figure 10. No.10 also utilizes the “Conda Effect” to develop air-multiplier product such as bladeless fan, as shown in Figure 11. The high-speed airflow flows in from the base of the bladeless fan, and then it flows out from the narrow gap reserved by the top ring structure. The low pressure created by the high-speed airflow will drive a large amount of surrounding air through the ring, making people feel cooler.

Figure 10. A structure that delivers air to reaction chamber.

Figure 10. A structure that delivers air to reaction chamber. Figure 11. A bladeless fan.

Figure 11. A bladeless fan.

The “Conda Effect” means that when the ejected fluid in the pipe moves rapidly, the pressure between the fluid and the surface of the pipe decreases rapidly. At this time, the static fluid around the inlet of the pipe will also quickly enter the pipe, thereby increasing the flow of fluid through the pipe. Therefore, a higher pressure can be obtained at the outlet of the pipe. Therefore, the principle and structure of the “Conda Effect” can be used to develop a new structure that generates high pressure gas.

4.4. Radical Concept Generation Based on Conda Effect

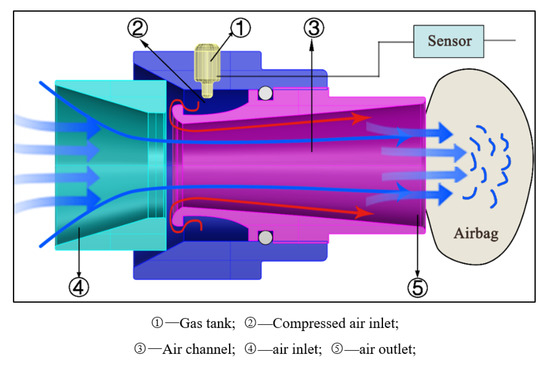

Based on the principle and structure of the “Conda Effect”, we propose a radical concept of a new gas generator. The structure is shown in Figure 12.

Figure 12.

Radical concept design of an aspirated gas generator.

When the car is hit, the sensor of the airbag sends out a signal to the gas tank that stores the compressed gas. The compressed air stored is quickly released. The gas passes through the reserved narrow compressed air inlet, forming a high-speed airflow and flowing along the pipe wall. The red lines with arrows in the Figure 12 represent the direction of the high-speed airflow. The high-speed airflow forms a low-pressure area quickly, which further drives a large amount of external gas into the pipeline through the air inlet. The blue lines with arrows represent the direction of the external gas. Finally, a large amount of gas is ejected from the air outlet into the airbag, causing the airbag to expand rapidly. The amount of compressed gas in the air storage tank is determined through simulation experiments so that the gas that finally enters the airbag can generate enough pressure to protect the safety of the driver and passenger.

4.5. Evaluation of the Radical Concept

The radical concept has following advantages over the currently design of ESL:

- A physical prototype is formed instead of the chemical reaction to generate enough pressure to inflate the airbag. The production of a large amount of gas is only the physical movement, and it does not produce high temperatures such as chemical reactions. Therefore, it will not have a burning effect on the airbag and driver, and there will be no toxic side effects to the human body due to combustion products.

- Comparing with existing solutions, the inflating process of airbag can be adjusted to make the inflating process relatively gentle under the premise of meeting the demand. We can simulate and continuously optimize the shape of the nozzle, air velocity and cross-sectional shape of the channel using the Computer Aided Engineering method based on the conceptual model to obtain the ideal structure.

- Comparing with the hybrid type, the conceptual scheme has a simpler structure, easier technology implementation, and lower production cost. A prototype shows that the concept scheme is feasible. The adoption of new principles greatly improves the performance with a great technical development potential.

5. Discussions and Conclusions

This paper mainly contributes a process management method of the cross-domain knowledge development for RCG. Although previous research has demonstrated that cross-domain knowledge has an important inspiring effect on the RCG, these studies are limited to how to improve firm’s access to external knowledge; managers and engineers do not know how to accurately search, screen and utilize the cross-domain knowledge for the generation of radical concept. The method presented in this paper is among the first to describe how to leverage cross-domain knowledge to generate radical concepts, to the best of our knowledge. The proposed method helps firms to effectively use cross-domain knowledge to generate radical concept, reduce uncertainty and risk in the process of RCG, and improve success of the RI finally.

The main implications from the theoretical research and empirical findings of this paper are discussed from both theoretical and managerial aspects.

5.1. Theoretical Implications

The development and application of cross-domain knowledge for RCG is a complex multi-standard decision-making process. Identification of radical innovation opportunities is a prerequisite for related innovative design activities. Previous studies did not have a clear understanding of the formation process for RI opportunities, believing that the RI generation is an accidental event. Technology push and demand pull are the main drivers of innovation opportunities, but the speed of technical performance improvement and the growth of user requirements are not always synchronized. Based on the analysis of the dynamic relationship between customer needs and technical performances in different subsystems, this paper reveals the formation mechanism of radical opportunities. Case studies of airbags show that the analysis is effective in identifying opportunities for RI. Engineers can use this approach to quickly and accurately identify radical innovation opportunities.

Research in radical innovation management has demonstrated that cross-domain knowledge has an important inspiring effect on the RCG. However, previous studies were limited to how to improve firm’s access to cross-domain knowledge; managers and engineers do not know how to accurately search, screen and utilize the cross-domain knowledge for the generation of radical concept. Based on the predictive function of the law of the technological evolution and the advantage of minimum complement distance measurement, this paper establishes an effective method for obtaining cross-domain knowledge to support RCG. The successful radical concept of gas generators in the case responds to the effectiveness of the method. The method allows managers and engineers to select and utilize cross-domain knowledge for RCG.

It is commonly used in previous studies to obtain radical ideas by establishing evaluation criteria for radical ideas through case summary and screening radical ideas from a large number of ideas with this criterion. The “screening method” is a kind of post-analysis, which has a limited guidance for improving effectiveness of the radical concept development and cause a lot of cost during the idea generation stage. The method proposed in this paper considers constraints at an early stage before the ideas are established and helps firms to effectively use cross-domain knowledge to generate radical concept, reduce uncertainty and risk in the process of RCG, and improve success of the RI finally. As shown in the case of airbags, this study does respond to the existing problem about how to development and application of cross-domain knowledge for RCG.

5.2. Managerial Implication

Identifying RI through the evaluation of many innovative ideas belongs to the post-analysis. The construction and verification of many innovative ideas involve the development of product prototypes, which requires not only the high cost but also a long cycle. Considering the important role of cross-domain knowledge for radical ideas, this paper establishes a management method of the cross-domain knowledge development process to reduce uncertainty and high investment in the development of radical ideas through a series of operations. By establishing constraint conditions, this method advances the evaluation operation after the creation of previous ideas to the construction stage of radical ideas, and carries out precise knowledge management, which is helpful for innovation managers to improve the resource utilization and process management of radical concept ideas development. At the same time, this method has a strong operability for industrial firms to implement the development of breakthrough technology, and it is also instructive to other types of innovation.

Radical innovation is usually considered as the preserve of large firms, because the development of radical technology requires knowledge accumulation and a lot of investment. At the same time, the uncertainty of radical technology development leads to high risk and a series of problems such as the ambiguity of early market and the complexity of management. The method proposed in this paper can effectively utilize the rich cross-domain knowledge and technology in the patent database to improve the development of concept design in RI, reduce the difficulty and risk of technology development, and encourage small and medium-sized firms for RI. This will attract more firms to participate in RI activities, emerge more radical technologies, reshape the existing market environment, and even accelerate the development of the entire industry.

5.3. Suggestions for Further Research

As in other studies, this research also has limitations. RI activities are a dynamic and complex process. The method established in this article for RCG is based on a limited number of literature and actual research. Some of the key steps in the process, such as the selection of the evolution direction of subsystems, calculation and comparison of technological distance, depend on the quantity and quality of collected samples. In the future, the number of samples and quality of the samples will be improved, and more analysis will be conducted. Future research also includes the software development to assist industrial implementation of the proposed method.

Author Contributions

Conceptualization, methodology, investigation, data curation, writing—original draft, preparation, visualization, J.Z.; supervision, writing—review and editing, funding acquisition, R.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51675159, the Central Government Guides Local Science and Technology Projects of China, grant number 18241837G.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available in [Patsnap] at [https://analytics.zhihuiya.com] (accessed on 12 March 2022).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- O’Connor, G.C.; Ayers, A.D. Building a radical innovation competency. Res. Technol. Manag. 2005, 48, 23–31. [Google Scholar] [CrossRef]

- McDermott, C.M.; O’ Connor, G.C. Managing radical innovation: An Overview of Emergent Strategy Issues. J. Prod. Innov. Manag. 2002, 19, 424–438. [Google Scholar] [CrossRef]

- Slater, S.F.; Mohr, J.J.; Sengupta, S. Radical product innovation capability: Literature Review, Synthesis, and Illustrative Research Propositions. J. Prod. Innov. Manag. 2014, 31, 552–566. [Google Scholar] [CrossRef]

- Zhao, Z.; Lin, P.; Shen, L.; Zhang, M.; Huang, G.Q. IoT edge computing-enabled collaborative tracking system for manufacturing resources in industrial park. Adv. Eng. Inform. 2014, 43, 101044. [Google Scholar] [CrossRef]

- Li, E.; Wang, W. 5G will drive the development of health care. Chin. Med. J. 2019, 132, 2895–2896. [Google Scholar] [CrossRef]

- Hengstler, M.; Enkel, E.; Duelli, S. Applied artificial intelligence and trust—The case of autonomous vehicles and medical assistance devices. Technol. Forecast. Soc. Change 2016, 105, 105–120. [Google Scholar] [CrossRef]

- Ng, K.; Chen, C.H.; Lee, C. A systematic literature review on intelligent automation: Aligning Concepts from Theory, Practice, and Future Perspectives. Adv. Eng. Inform. 2016, 47, 101246. [Google Scholar] [CrossRef]

- Herrmann, T.; Binz, H.; Roth, D. Necessary extension of conventional idea processes by means of a method for the identification of radical product ideas. In Proceedings of the 21st International Conference on Engineering Design, Vancouver, BC, Canada, 21–25 August 2017. [Google Scholar]

- Kasmire, J.; Korhonen, J.M.; Nikolic, I. How radical is a radical innovation? An outline for a computational approach. Energy Procedia 2012, 20, 346–353. [Google Scholar] [CrossRef]

- Tiwari, V.; Jain, P.K.; Tandon, P. Product design concept evaluation using rough sets and VIKOR method. Adv. Eng. Inform. 2016, 30, 16–25. [Google Scholar] [CrossRef]

- Forés, B.; Camisón, C. Does incremental and radical innovation performance depend on different types of knowledge accumulation capabilities and organizational size? J. Bus. Res. 2016, 69, 831–848. [Google Scholar] [CrossRef]

- Coccia, M. Sources of technological innovation: Radical and incremental innovation problem-driven to support competitive advantage of firms. Technol. Anal. Strateg. Manag. 2017, 29, 1048–1061. [Google Scholar] [CrossRef]

- Albors-Garrigos, J.; Hervas-Oliver, J.L. Disruptive Innovation in Traditional Clusters: The Case of the Kerajet Ceramic Tile Cluster in Spain. Appl. Sci. 2019, 9, 5513. [Google Scholar] [CrossRef]

- Pershina, R.; Soppe, B.; Thune, T.M. Bridging analog and digital expertise: Cross-Domain Collaboration and Boundary-Spanning Tools in the Creation of Digital Innovation. Res. Policy 2019, 48, 103819. [Google Scholar] [CrossRef]

- Gassmann, O.; Zeschky, M.; Wolff, T. Crossing the industry-line: Breakthrough Innovation Through Cross-Industry Alliances with ‘Non-Suppliers’. Long Range Plan. 2010, 43, 639–654. [Google Scholar] [CrossRef]

- Tojeiro-Rivero, D.; Moreno, R.; Badillo, E.R. Radical Innovations: The Role of Knowledge Acquisition from Abroad. Rev. Ind. Organ. 2018, 55, 173–207. [Google Scholar] [CrossRef]

- Datta, A.; Jessup, L.M. Looking beyond the focal industry and existing technologies for radical innovations. Technovation 2013, 33, 355–367. [Google Scholar] [CrossRef]

- Cheng, C.; Yang, J.; Sheu, C. Effects of open innovation and knowledge-based dynamic capabilities on radical innovation: An Empirical Study. J. Eng. Technol. Manag. 2016, 41, 79–91. [Google Scholar] [CrossRef]

- Pichlak, M.; Szromek, A.R. Eco-Innovation, Sustainability and Business Model Innovation by Open Innovation Dynamics. J. Open Innov. Technol. Mark. Complex. 2021, 7, 149. [Google Scholar] [CrossRef]

- Chang, Y.; Chang, H.; Chi, H. How do established firms improve radical innovation performance? The organizational capabilities view. Technovation 2012, 32, 441–451. [Google Scholar] [CrossRef]

- Scaringella, L.; Burtschell, F. The challenges of radical innovation in Iran: Knowledge transfer and absorptive capacity highlights—Evidence from a joint venture in the construction sector. Technol. Forecast. Soc. Change 2015, 122, 151–169. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, X.; Zhou, K.Z. External learning, market dynamics, and radical innovation: Evidence from China’s high-tech firms. J. Bus. Res. 2012, 65, 1226–1233. [Google Scholar] [CrossRef]

- Liu, W.; Tan, R.H.; Cao, G.Z. A proposed radicality evaluation method for design ideas at conceptual design stage. Comput. Ind. Eng. 2019, 132, 141–152. [Google Scholar] [CrossRef]

- Frishammar, J.; Dahlskog, E.; Krumlinde, C. The front end of radical innovation: A Case Study of Idea and Concept Development at Prime Group. Creat. Innov. Manag. 2016, 25, 179–198. [Google Scholar] [CrossRef]

- Luisa Flor, M.; Cooper, S.Y.; Oltra, M.J. External knowledge search, absorptive capacity and radical innovation in high-technology firms. Eur. Manag. J. 2016, 36, 183–194. [Google Scholar] [CrossRef]

- Hommels, A.; Peters, P.; Bijker, W.E. Techno therapy or nurtured niches? Technology studies and the evaluation of radical innovations. Res. Policy 2017, 36, 1088–1099. [Google Scholar] [CrossRef]

- Danneels, E. Product innovativeness from the firm’s perspective: Its Dimensions and their Relation with Project Selection and Performance. J. Prod. Innov. Manag. 2010, 18, 357–373. [Google Scholar] [CrossRef]

- Christensen, C.M. Exploring the limits of the technology S-curve. Part I: Component Technologies. Prod. Oper. Manag. 1992, 1, 334–357. [Google Scholar] [CrossRef]

- Asthana, P. Jumping the technology S-CURVE. IEEE Spectrum 1995, 32, 49–54. [Google Scholar] [CrossRef]

- Slayton, R.G.; Spinardi, G. Radical innovation in scaling up: Boeing’s dreamliner and the challenge of socio-technical transitions. Technovation 2016, 47, 47–58. [Google Scholar] [CrossRef]

- Cooper, R.G. Perspective: The stage gate, idea to launch process—Update, what’s new, NexGen systems. J. Prod. Innov. Manag. 2019, 25, 213–232. [Google Scholar] [CrossRef]

- Sandberg, B.; Aarikka-Stenroos, L. What makes it so difficult? a systematic review on barriers to radical innovation. Ind. Mark. Manag. 2014, 43, 1293–1305. [Google Scholar] [CrossRef]

- Ehrnberg, E. On the definition and measurement of technological discontinuities. Technovation 1995, 15, 437–452. [Google Scholar] [CrossRef]

- Hasegawa, H.; Kozano, Y.; Goto, K. S-curves analysis focusing on WOM for technological system evolution. Procedia Eng. 2015, 131, 1094–1104. [Google Scholar] [CrossRef][Green Version]

- Sr, A. Procedure to sustain competitive advantage in an era of changing dominant design. Procedia CIRP. 2019, 81, 838–843. [Google Scholar]

- Leifer, R.; McDermott, C.M.; O’Connor, G. Radical innovation: How Mature Companies Can Outsmart Upstarts, 1st ed.; Harvard Business School Press: Boston, MA, USA, 2000; pp. 110–152. [Google Scholar]

- Leifer, R.; O’Connor, G.C.; Rice, M. Implementing radical innovation in mature firms: The Role of Hubs. Acad. Manag. Exec. 2001, 15, 102–113. [Google Scholar] [CrossRef]

- Tiberius, V.; Schwarzer, H.; Roig-Dobón, S. Radical innovations: Between Established Knowledge and Future Research Opportunities. J. Innov. Knowl. 2020, 6, 145–153. [Google Scholar] [CrossRef]

- Penker, M.; Khoh, S.B. Cultivating Growth and Radical Innovation Success in the Fourth Industrial Revolution with Big Data Analytics. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018. [Google Scholar]

- O’Connor, G.C.; Demartino, R. Organizing for radical innovation: An Exploratory Study of the Structural Aspects of RI Management Systems in Large Established Firms. J. Prod. Innov. Manag. 2020, 23, 475–497. [Google Scholar] [CrossRef]

- Sood, A.; Tellis, G.J. Technological evolution and radical innovation. J. Mark. 2005, 69, 152–168. [Google Scholar] [CrossRef]

- Sheu, D.D.; Lee, H.K. A proposed process for systematic innovation. Int. J. Prod. Res. 2011, 49, 847–868. [Google Scholar] [CrossRef]

- Hart, M.A. Innovation on Demand: New Product Development Using TRIZ by Victor R. Fey and Eugene I. Rivin. J. Prod. Innov. Manag. 2010, 24, 635–636. [Google Scholar] [CrossRef]

- Fey, V.; Rivin, E.I. Innovation on Demand: Guiding Technology Evolution; Cambridge University Press: Cambridge, UK, 2005; pp. 112–166. [Google Scholar]

- Zhang, M.; Cong, D.; Qin, H. Laws of Technological System Evolution Applied in the Conceptual Design of New Stereo Garage. Adv. Mater. Res. 2011, 308, 894–898. [Google Scholar] [CrossRef]

- Ping, E.; Tan, R.; Zhang, J. Research on generation ideas process for product radical innovation based on technology evolution theory. In Proceedings of the 2014 IEEE International Conference on Management of Innovation and Technology, Singapore, 23–25 September 2014. [Google Scholar]

- Cascini, G.; Becattini, N.; Kaikov, I. FORMAT–Building an Original Methodology for Technology Forecasting through Researchers Exchanges between Industry and Academia. Procedia Eng. 2015, 131, 1084–1093. [Google Scholar] [CrossRef][Green Version]

- Wang, F.; Jiang, Z.; Li, X. Cognitive factors of the transfer of empirical engineering knowledge: A Behavioral and fNIRS Study. Adv. Eng. Inform. 2021, 47, 101207. [Google Scholar] [CrossRef]

- Stein, N.V.; Sick, N.; Leker, J. How to measure technological distance in collaborations—The case of electric mobility. Technol. Forecast. Soc. Change 2005, 97, 154–167. [Google Scholar] [CrossRef]

- Wulung, R.; Takahashi, K.; Morikawa, K. A model for selecting appropriate technology for incubator-university collaboration by considering the technology transfer mechanism. Int. J. Prod. Res. 2018, 56, 2309–2321. [Google Scholar] [CrossRef]

- Nooteboom, B.; Van Haverbeke, W.; Duysters, G.V. Optimal cognitive distance and absorptive capacity. Res. Policy 2007, 36, 1016–1034. [Google Scholar] [CrossRef]

- Gilsing, V.; Nooteboom, B.; Vanhaverbeke, W. Network embeddedness and the exploration of novel technologies: Technological Distance, between Nesscentrality and Density. Res. Policy 2008, 37, 1717–1731. [Google Scholar] [CrossRef]

- Wuyts, S.; Colombo, M.G.; Dutta, S. Empirical tests of optimal cognitive distance. J. Econ. Behav. Organ. 2005, 58, 277–302. [Google Scholar] [CrossRef]

- Cowan, R.; Jonard, N.; Zimmermann, J.B. Bilateral collaboration and the emergence of innovation networks. Manag. Sci. 2007, 53, 1051–1067. [Google Scholar] [CrossRef]

- Sick, N.; Simon, H. Technological distance measures: New Perspectives on Nearby and Far Away. Scientometrics 2016, 107, 1299–1320. [Google Scholar]

- Jaffe, A. Technological opportunity and spillovers of R&D: Evidence from Firms’ Patents, Profits, and Market Value. Am. Econ. Rev. 1986, 76, 985–1001. [Google Scholar]

- Jaffe, A. Characterizing the ‘technological position’ of firms, with application to quantifying technological opportunity and research spillovers. Res. Policy 1989, 18, 87–97. [Google Scholar] [CrossRef]

- Angue, K.; Ayerbe, C.; Mitkova, L. A method using two dimensions of the patent classification for measuring the technological proximity: An Application in Identifying a Potential R&D Partner in Biotechnology. J. Technol. Transf. 2014, 39, 716–747. [Google Scholar]

- Bar, T.; Leiponen, A. A measure of technological distance. Econ. Lett. 2012, 116, 457–459. [Google Scholar] [CrossRef]

- Altshuler, G.S. The Innovation Algorithm: TRIZ Systematic Innovation and Technical Creativity; Technical Innovation Center, Inc.: Worcester, MA, USA, 1999. [Google Scholar]

- Guo, J.; Peng, Q.; Zhang, L. Estimation of product success potential using product value. Int. J. Prod. Res. 2020, 59, 5609–45625. [Google Scholar] [CrossRef]

- Cao, G.; Tan, R. The Principle and Application of Functional Design; Higher Education Press: Beijing, China, 2016; pp. 12–45. [Google Scholar]

- Clausing, D.; Fey, V. Front Matter. In Effective Innovation: The Development of Winning Technologies; ASME Press: New York, NY, USA, 2004; pp. 38–45. [Google Scholar]

- Li, T. Applying TRIZ and AHP to develop innovative design for automated assembly systems. Int. J. Adv. Manuf. Technol. 2010, 46, 301–313. [Google Scholar] [CrossRef]

- Song, K.; Kim, K.S.; Lee, S. Discovering new technology opportunities based on patents: Text-Mining and F-Term Analysis. Technovation 2017, 60, 1–14. [Google Scholar] [CrossRef]

- Geum, Y.; Kim, M. How to identify promising chances for technological innovation: Keygraph-Based Patent Analysis. Adv. Eng. Inform. 2020, 46, 101155. [Google Scholar] [CrossRef]

- Kay, L.; Youtie, J.; Shapira, P. Signs of things to come? What patent submissions by small and medium-sized enterprises say about corporate strategies in emerging technologies. Technol. Forecast. Soc. Change 2014, 85, 17–25. [Google Scholar] [CrossRef]

- Lee, C.; Kang, B.; Shin, J. Novelty-focused patent mapping for technology opportunity analysis. Technol. Forecast. Soc. Change 2014, 90, 355–365. [Google Scholar] [CrossRef]

- Aharonson, B.S.; Schilling, M.A. Mapping the technological landscape: Measuring Technology Distance, Technological Footprints, and Technology Evolution. Res. Policy 2016, 4, 81–96. [Google Scholar] [CrossRef]

- Benner, M.; Waldfogel, J. Close to you? bias and precision in patent-based measures of technological proximity. Res. Policy 2008, 37, 1556–1567. [Google Scholar] [CrossRef]

- World Intellectual Property Organization (International Patent Classification Official Publication). Available online: https://www.wipo.int/portal/en/index.html (accessed on 20 August 2021).

- Subramanian, A.M.; Bo, W.; Kah-Hin, C. The role of knowledge base homogeneity in learning from strategic alliances. Res. Policy 2018, 47, 158–168. [Google Scholar] [CrossRef]

- Gao, T. International R&D Alliances, Technology Distance and Radical Innovation of Enterprises, Contemporary. Econ. Mana 2020, 42, 21–26. [Google Scholar]

- Hirtz, J.; Stone, R.B.; Mcadams, D.A. A functional basis for engineering design: Reconciling and Evolving Previous Efforts. Res. Eng. Des. 2002, 13, 65–82. [Google Scholar] [CrossRef]

- Jia, L.; Peng, Q.; Tan, R. Analogical stimuli retrieval approach based on R-SBF ontology model. J. Eng. Des. 2019, 30, 599–624. [Google Scholar] [CrossRef]

- Gero, J.S.; Kannengiesser, U. The situated function-behaviour-structure framework. Des. Stud. 2004, 25, 373–391. [Google Scholar] [CrossRef]

- Patsnap. Available online: https://analytics.zhihuiya.com (accessed on 20 August 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).