Abstract

This study proposes a fuzzy logic controller for adjusting the electrical conductivity (EC) and pH of the nutrient solution in a hydroponic system. The proposed control system detects the EC and pH of the solution through sensors and adjusts the working time of the solution pump through the fuzzy controller. Specifically, the EC and pH of the nutrient solution are maintained at specific values. A Raspberry Pi3 development board is used in the proposed control system to realize and solve the problem of adjusting the EC and pH of the solution. In the fuzzy controller, the inputs are EC and pH sensors, and the output is the operating time of the pump. Experimental results indicate that the proposed control system can effectively reduce the measurement burden and complex calculations of producers by adjusting nutrient solutions.

1. Introduction

Hydroponics technology is used throughout the world. Numerous methods and techniques have been developed. However, most hydroponic nutrient solutions are prepared in a traditional manner, with their electrical conductivity (EC) and pH manually measured by producers, often daily. Adjustments are calculated to meet the needs of the plants. This is a time-consuming and labor-intensive task, and a computational error can result in plant death.

The conditions to be controlled to promote plant growth include ambient temperature, light, water temperature, water oxygen concentration, humidity, water level, EC, pH, and nitrate level [1,2,3,4,5]. These conditions have been closely studied, and manufacturers exhibit equipment designed to address them at international exhibitions. However, the key to stable hydroponic growth remains the balance of the nutrient solution. The solution is formulated with the fertilizer required by the crop for optimal growth until harvest [6]. Nutrients must be controlled correctly and effectively.

The composition of the nutrient solution is responsible for half of the success of the solution. Crucial to the suitability of a nutrient solution are its pH and EC [7]. Adjustments to pH levels are frequently required, because pH affects photosynthesis. CO2 is readily dissolved in water, and this lowers its pH [8]. The pH of a nutrient solution affects plant growth, health, and yield [9]. EC is an indicator of the concentration of a nutrient solution (and can also be said to be an indicator of the salt concentration of a solution). The EC value represents the conductivity of ions per volume of solution. Ions can carry positive or negative charges; as EC increases, resistance decreases. Therefore, a higher EC indicates a higher ion concentration in the solution. High EC cases can result in plant death. The pH and EC of a nutrient solution may be reduced due to environmental factors such as high temperature causing water evaporation or the absorption of nutrients by plants. The rise and fall of pH and EC may exceed the range that the plant can withstand. Therefore, the pH and EC of a nutrient solution must be controlled to create an environment suitable for plant growth [10]. Measuring them daily for adjustment is a time-consuming and labor-intensive task for producers [11,12].

In recent years, many researchers [13,14,15,16,17,18] have confirmed that the fuzzy logic controller is effectively implemented in the hydroponic cultivation system. Ibrahim et al. [13] designed a fuzzy logic control system for nutrient solution to maintain the EC of nutrient solution using Arduino. Model of tomato cultivation based on certain reference was simulated with scale 1:1440 for cultivation time. Yolanda et al. [14] implemented a fuzzy logic to control the EC and pH condition of the nutrient film technique (NFT)-based hydroponic system in internet of things (IoT) system environment. By implementing this method, the required to complete the process and achieve the desired value does not exceed the limit tolerance given is ±15 min. The controller based on fuzzy logic [15] was designed and implemented for pH regulation using a PLC as a processing element. The final error was established, on average, at pH = 0.035 units. A Sugeno type fuzzy controller [16] was designed to control a hydroponic germination chamber with the input from experts in Plant Biology from the InBioMis. The results obtained show that the fuzzy controller is able to control the environment inside the chamber to improve crop production. The fuzzy logic control module [17] was utilized for finding optimal working level and operational duration to the actuators with analyzing the current and optimized data of the water and humidity levels in the experimental environment. The fuzzy logic [18] was implemented in the controlled system for decision-making purposes. The efficient and precise smart-controlled system helps in plant growth, which can be observed and measured though plant height, length, and various other parameters.

The purpose of this study was to design a hydroponic system that uses fuzzy logic control. The system can detect the EC and pH of a nutrient solution through sensors at any time. Fuzzy control is employed to control the action of the nutrient solution pump; thus, the EC and pH are automatically raised or lowered to encourage plant growth. This can reduce the long duration spent by producers in measuring these quantities and avoid the need for complex chemical calculations to adjust nutrient solutions. The system can reduce the time burden of producers and provide superior accuracy and control.

2. Nutrition Solution Regulation System

2.1. System Architecture

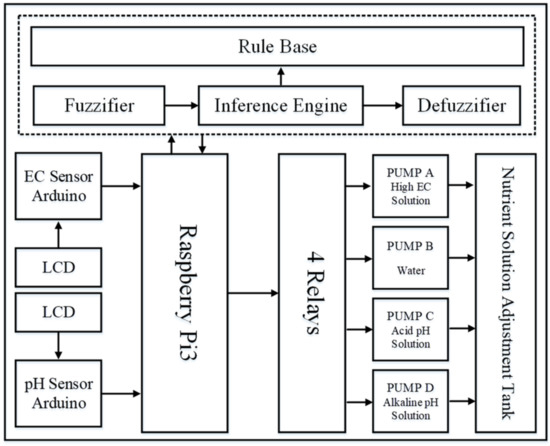

Figure 1 shows a flowchart of the system architecture. The proposed fuzzy controller including fuzzyify, inference engine, rule base, and defuzzifier in this study is embedded in the Raspberry Pi3. The two inputs of the Raspberry Pi3 hardware are EC sensing value and pH sensing value, and its output is four relays to adjust high EC solution, water, acid solution, and alkaline solution. Finally, the system pumps the adjusted mixture fluid into the nutrient solution adjustment tank.

Figure 1.

System architecture.

2.2. Design of Hydroponic Fuzzy Controller

Fuzzy control technology has been widely used in agriculture, such as district irrigation intelligent system [19], electro-hydraulic suspension system [20], and autonomous navigation of wolfberry picking robot [21]. In this study, we also adopted fuzzy control technology for automating electrical conductivity and pH in hydroponic cultivation.

The Raspberry Pi3 development board, Arduino Uno development board, EC and pH sensors, handheld EC and pH sensors, pumps, relays, and other hardware used in this study are described in this section. The following describes the output pins corresponding to the development software and the bcm2835 library used by the Raspberry Pi3 as well as the fuzzy control rules and fuzzy membership functions.

Fuzzy control program: The program was written directly using the Geany development environment of the Raspberry Pi3. This fuzzy control program is written in C language. Therefore, it must be compiled with g++ for the output of general-purpose input/output (GPIO) pins. The bcm2835 library must be downloaded for pin settings; Python pins must not be used.

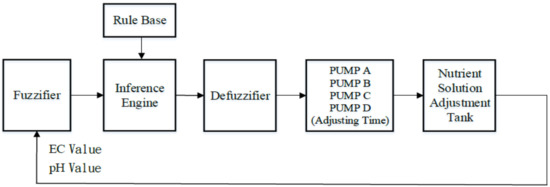

Hydroponic fuzzy controller design flow: Figure 2 presents a schematic of a hydroponic system with its basic operation and the flow of the pumps, the sensors, and the four conditioning fluids. The design process and steps are as follows.

Figure 2.

Hydroponic fuzzy controller architecture.

Step 1: Through the hydroponic system diagram in Figure 2, the system’s input and output relationships are confirmed. (1) Input: EC sensor and pH sensor. (2) Outputs: Pump A (high EC solution), Pump B (water), Pump C (acid solution), and Pump D (alkaline solution). Figure 2 illustrates the structure of the hydroponic fuzzy controller.

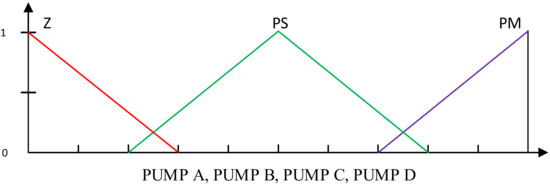

Step 2: The fuzzy set of inputs and outputs is defined. The conditions of control are described in vague language. EC fuzzy set: EC = {NM, NS, Z, PS, PM}. pH fuzzy set: pH = {NM, NS, Z, PS, PM}. Four pump (A–D) fuzzy sets: pump(A, B, C, D) = {Z, PS, PM}, where NM is negative medium, NS is negative small, Z is zero, PS is positive small, and PM is positive medium.

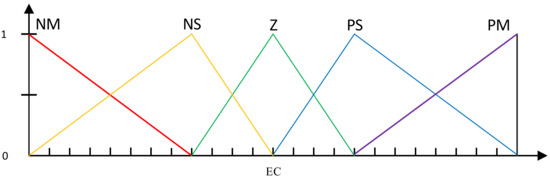

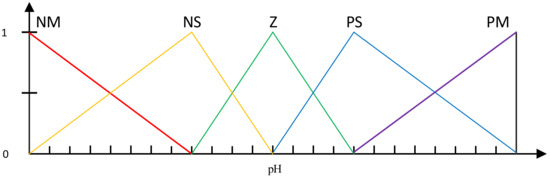

Step 3: The membership functions of the hydroponic fuzzy controller are designed. The purpose of fuzzification is to obtain the degree of membership of the input variables. The membership function for each input variable and output variable is designed. The errors obtained are divided into large, appropriate, and small errors. Therefore, a fuzzy membership function must be established. A fuzzy membership function is established for pH (acidity and alkalinity), EC (high, medium, or low) and the pump. All designed fuzzy membership functions must pass numerous tests, as depicted in Figure 3, Figure 4 and Figure 5. In this study, triangular membership functions, in spite of them being different from what we elicit from the experts, have been successfully used. Furthermore, triangular membership functions provide the exact reconstruction of the appropriate global characteristic of the signal.

Figure 3.

Electrical conductivity (EC) membership function.

Figure 4.

pH membership function.

Figure 5.

Pump membership function.

Step 4: The fuzzy rule base of the hydroponic fuzzy controller is designed. Table 1 contains the fuzzy rule base established in this study. The definitions of steps 2 to 5 must be followed. The membership functions and fuzzy rules establish fuzzy rule bases.

Table 1.

Hydroponics fuzzy rule base.

Step 5: A defuzzification process is used to convert fuzzy sets into crisp values. In the process of defuzzification, the center of area method is employed. The formula is used to calculate the explicit value in seconds; is the adjustment (s) output of the pump; is the membership value; and is the corresponding number of seconds of the membership value of the pump, as shown in Equation (1).

3. Experimental Environment

3.1. Experimental Control

The experimental control includes manual adjustment control and automatic system adjustment control. The manual adjustment control proves that the system can be adjusted to the required EC and pH. The system automatically adjusts the control to verify that it fulfils the designed function. The experimental environment of the experiment was indoors, and the ambient temperature was approximately 24 to 25 °C. The water came from the school setting. The measurement results are presented in Table 2. For the control conditions, the conditions that the hardware and system could withstand had to be considered. The required EC and pH for the growth of various plants are different, and Table 3 shows the required EC and pH for Lettuce, Strawberry, and Broccoli. In this study, the designed system will demonstrate the regulation process of the EC and pH for the three different plants. Four basic adjustment solutions were used, namely a high EC nutrient solution, water, and acidic and alkaline solutions. The high EC nutrient solution increased the EC value (when the EC value drops). Water was used to reduce the EC value. Acidic and alkaline solutions were used to adjust the pH (Table 4). The parameter settings were established through experimentation (described in Section 3.2) and through consideration of the hardware limitations.

Table 2.

Basic water quality conditions.

Table 3.

The required EC and pH for different plants.

Table 4.

Parameter setting of hydroponic nutrient solution.

Four experimental tests were conducted. The first included preparation tests, testing of the pump output, and preparation of the initial nutrient solution. In Experiment 1, manual adjustment of the initial nutrient solution was performed. The upper and lower regulatory controls were based on the EC and pH values required by the three plants. Experiment 2 was automatic system adjustment control of the initial nutrient solution to match the EC and pH of the three plants. Experiment 3 involved actual planting of plants. In this experiment, lettuce was cultivated, and the growth of the plants was observed.

3.2. Modulation of the Initial Nutrient Solution

The initial nutrient solution was prepared for subsequent experimental control. Four 3-L jars individually marked “high EC”, “water”, “acid”, and “alkali” were prepared. The purpose of the labeling was to prevent mistakes and to facilitate observation of the operation of the system. Water was necessary to modulate the values of the parameters listed in Table 4. Handheld sensors were used to measure and record EC and pH values. The first jar was filled with 1 L of water, and hydroponics balanced fertilizer was added until the EC reached 4.5. The pH was recorded. The initial components of the used fertilizer includes nitrogen (N), potassium (K), calcium (Ca), magnesium (Mg), phosphorus (P), and sulphur (S), and smaller amounts of the micronutrients: chlorine (Cl), iron (Fe), boron (B), manganese (Mn), zinc (Zn), copper (Cu), nickel (Ni), and molybdenum (Mo). The second jar was filled with 1 L of water, and nothing was added. The third jar was filled with 1 L of water, and nitrous acid was added until the pH was 4.0. The EC value was recorded. The fourth jar was filled with 1 L of water, and potassium hydroxide was added until the pH was 9.0. The EC value was again recorded. Next, 250 mL of each of the solutions was collected and mixed for use as an initial nutritional solution. A handheld sensor was used to measure and record the EC and pH (Table 5).

Table 5.

Results of initial nutrient solution mixing.

4. Experiments and Results

4.1. Nutrient Solution Rise and Fall Test

In this experiment, manual tests to simulate the rise and fall of the EC and pH values of nutrient solution were conducted. As described earlier, plants require suitable EC and pH levels. However, these values increase or decrease due to environmental factors. Therefore, artificial manual adjustment tests must be performed for these two main parameters. A high EC nutrient solution, water, an acid, and an alkali were used for the initial nutrient solution. The nutrient solution had an initial EC of 1.5 and a pH of 6.43. Fertilizer was added until the EC reached 4.5, with the pH level recorded. Water was added until the EC fell to 0.8 (Table 6). A comparable procedure was followed for pH (Table 7) using acidic and alkaline solutions. This control system is designed to avoid the frequent operation of the relay to cause that the adjustment liquid cannot be neutralized. Therefore, the adjustment frequency is set on the controller to be once every 60 s, i.e., the time interval between every two successive measurements is set to 60 s (Table 6 and Table 7).

Table 6.

Simulated EC rise and reduction experiments.

Table 7.

Simulated pH rise and reduction experiments.

4.2. Control Results Using the Fuzzy Control Method

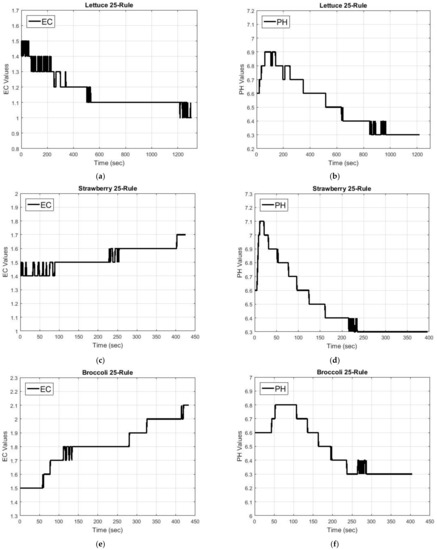

This experiment used 25 fuzzy rules for the regulation of EC and pH for growing lettuce, strawberry, and broccoli. In Figure 6, the results indicate that the control of the adjustments met the set requirements.

Figure 6.

Results of the control of lettuce, strawberry, and broccoli by using 25 fuzzy rules. (a) Lettuce-EC; (b) Lettuce-PH; (c) Strawberry-EC; (d) Strawberry-PH; (e) Broccoli-EC; (f) Broccoli-PH.

4.3. Hydroponic Cultivation Experiment

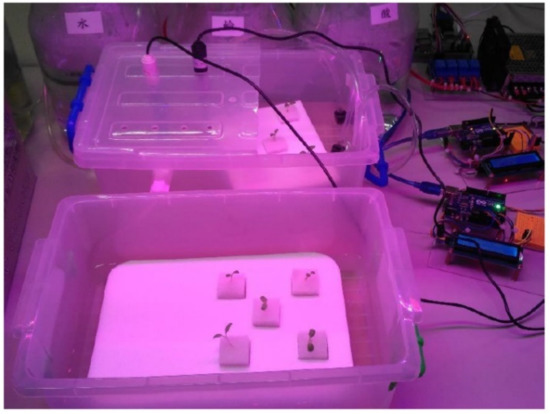

Lettuce was selected for planting experiments, and the 25 rules were employed to control EC and pH levels. First, germination of the seeds was performed. When the seedlings had grown to a length of approximately 2 cm, they were transplanted to a controlled or uncontrolled system and observed.

4.3.1. Controlled Plants

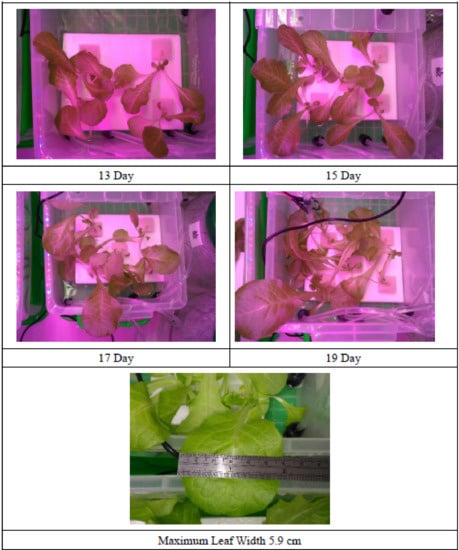

The controlled system is depicted in Figure 7. A plant-specific light source with red and blue (R: 660 ± 30 nm and B: 430 ± 30 nm) ratios was installed above the plants for photosynthesis. The plant’s growth is detailed in Figure 8 and Table 8. The maximum leaf width of the controlled plants was 5.9 cm.

Figure 7.

Planted in the system.

Figure 8.

Results of initial nutrient solution mixing.

Table 8.

Controlled plant growth and systematic observation.

4.3.2. Uncontrolled Plants

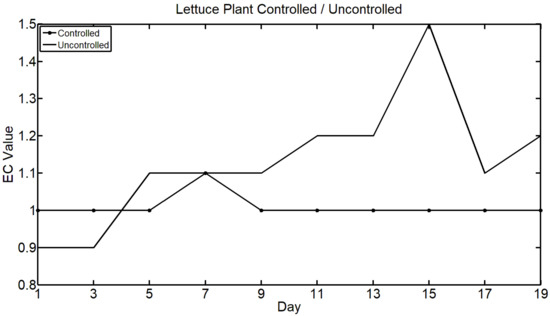

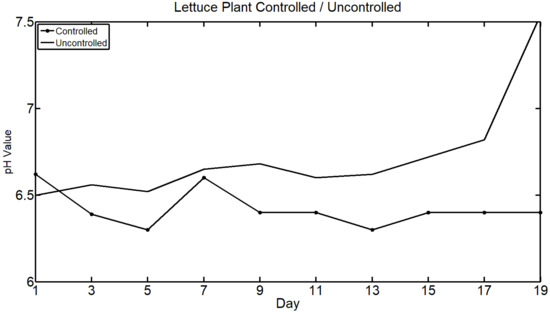

Seedlings were also transplanted into an uncontrolled system for comparison. The differences between the two groups are presented in Table 9. The maximum leaf width of the controlled plants was 5.9 cm. Because there was no more water, nutrient solution was added on the 15th day. Figure 9 and Figure 10 present comparisons of the controlled and uncontrolled EC and pH values. The results for the controlled system were more favorable.

Table 9.

Uncontrolled plant growth and observation system.

Figure 9.

Comparison of lettuce EC values over 19 days.

Figure 10.

Comparison of lettuce pH values over 19 days.

5. Discussion

This study proposes a fuzzy logic controller for adjusting the EC and pH of the nutrient solution in a hydroponic system. Furthermore, a Raspberry Pi3 development board was used in the proposed control system to realize and solve the problem of adjusting the EC and pH of the solution. The advantages of this study are summarized as follows. First, this study designed a fuzzy logic controller in hydroponic cultivation system. The inputs of the controller are the EC and pH of the nutrient solution to infer the appropriate EC and pH by the design fuzzy logic controller. Second, the designed fuzzy controller is embedded in the Raspberry Pi3 hardware. The inputs of the hardware are connected to the EC sensor and the pH sensor. The output is connected to four relays to pump high EC, water, acid solution, and alkali solution to compound a suitable nutrient solution for plants. Third, it can be shown that the designed fuzzy controller can successfully compound a suitable EC and pH for plants and can grow larger leaf plants in the experimental results.

6. Conclusions

In this study, a hydroponic system was designed to control EC and pH values by using a fuzzy logic controller. To enable plants to flourish, the EC and pH levels of the nutrient solution must be maintained at specific values. The proposed system can detect the EC and pH of nutrient solution in a storage tank through sensors at any time and thus reduce the measurement burden on producers and the complex calculations required to adjust the solution. The proposed system can provide producers with effective control and reduce labor requirements.

In future work, we will consider the size and diversity of plants. Plants have different EC and pH requirements at different growth stages. In addition, we will use image technology to determine the plant scale and diversity in future work. Thus, after the addition of image recognition, the system can be expanded, and two or more plant types can be grown.

Author Contributions

Conceptualization, C.-H.C. and C.-J.L.; Methodology, C.-H.C. and C.-J.L.; Software, S.-Y.J. and C.-H.C.; Data Curation, C.-H.C. and C.-J.L.; Writing—Original Draft Preparation, C.-H.C., S.-Y.J. and C.-J.L.; Writing—Review & Editing, C.-H.C., S.-Y.J. and C.-J.L.; Supervision, C.-H.C. and C.-J.L.; Funding Acquisition, C.-J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Technology of the Republic of China, grant number MOST 110-2218-E-005-016.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

The authors would like to thank the funding support of the Ministry of Science and Technology of the Republic of China.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nilton, N.C.; Diene, M.B.; Karla, G.; Leonardo, R.H.; Marinaldo, F.Z. Cooling and concentration of nutrient solution in hydroponic lettuce crop. Hortic. Bras. 2013, 31, 287–292. [Google Scholar]

- Padma, N.C.; Nyoman, K.W.I.; Komang, A.A.A.I.; Agus, H. Hommons: Hydroponic management and monitoring system for an IOT based NFT farm using web technology. In Proceedings of the 2017 5th International Conference on Cyber and IT Service Management (CITSM), Bali, Indonesia, 8–10 August 2017; pp. 1–6. [Google Scholar]

- Robert, G.A.; Schmidt, L.S. Nutrient analysis of selected commercial organic fertilizers for greenhouse lettuce production. In Greenhouse Use of Organic Fertilizers and Composts, Floriculture Research Report; University of Kentucky: Lexington, KY, USA, 2019; pp. 1–4. [Google Scholar]

- Ahmad, N.H.; Robiah, A.; Norliza, M. WSN application in LED plant factory using continuous lighting (CL) method. In Proceedings of the 2015 IEEE Conference on Open Systems (ICOS), Melaka, Malaysia, 24–26 August 2015; pp. 56–61. [Google Scholar]

- Chanya, P.; Pantita, S.; Wannisa, S.; Thanwadee, S. DIY sensor-based automatic control mobile application for hydroponics. In Proceedings of the 2016 Fifth ICT International Student Project Conference (ICT-ISPC), Nakhon Pathom, Thailand, 27–28 May 2016; pp. 57–60. [Google Scholar]

- Dian, P.; Andik, Y. Implementasi fuzzy logic controller untuk mengatur pH nutrisi pada sistem hidroponik nutrient film technique (NFT). J. Nas. Tek. Elektro 2016, 5, 278–289. [Google Scholar]

- Saaid, M.F.; Sanuddin, A.; Ali, M.; Yassin, M.S.A.I.M. Automated pH controller system for hydroponic cultivation. In Proceedings of the 2015 IEEE Symposium on Computer Applications & Industrial Electronics (ISCAIE), Kedah, Malaysia, 12–14 April 2015; pp. 186–190. [Google Scholar]

- Nakaoka, S.; Yamada, A. A system for measuring the photosynthetic activity of water plants based on carbon dioxide absorption. In Proceedings of the 2012 International Symposium on Micro-NanoMechatronics and Human Science (MHS), Aichi, Japan, 4–7 November 2012; pp. 29–31. [Google Scholar]

- Saparamadu, J.S.; Wijesekera, R.D.; Gunawardhana, H.D.; Weerakkody, W.A.P. A low cost nutrient formulation with a buffer for simplified hydroponics systems. J. Hortic. For. 2010, 2, 99–103. [Google Scholar]

- Ju, Y.; Arifur, L.R.; Hossain, A.; Hyung, S.K.; Man, J.K. Characterizing nutrient uptake kinetics for efficient crop production during solanum lycopersicum var. cerasiforme alef. growth in a closed indoor hydroponic system. PLoS ONE 2017, 12, e0177041. [Google Scholar]

- Neil, M.; Tanya, M. Symptoms of Common Nutrient Deficiencies in Hydroponic Lettuce.e-GRO. 1 December 2021. Available online: https://urbanagnews.com/blog/news/symptoms-of-common-nutrient-deficiencies-in-hydroponic-lettuce-by-neil-mattson-and-tanya-merrill (accessed on 27 December 2021).

- El-Kazzaz, K.A.; El-Kazzaz, A.A. Soilless agriculture a new and advanced method for agriculture development: An introduction. Agric. Res. Technol. Open Access J. 2017, 3, 1–10. [Google Scholar]

- Ibrahim, R.; Solahudin, M.; Widodo, S. Control system for nutrient solution of nutrient film technique using fuzzy logic. Telkomnika Indones. J. Electr. Eng. 2015, 13, 1281–1288. [Google Scholar] [CrossRef]

- Yolanda, D.; Hindersah, H.; Hadiatna, F.; Triawan, M.A. Implementation of real-time fuzzy logic control for NFT-based hydroponic system on internet of things environment. In Proceedings of the 2016 IEEE 6th International Conference on System Engineering and Technology, Bandung, Indonesia, 3–4 October 2016; pp. 153–159. [Google Scholar]

- Velazquez-Gonzalez, R.; Gomez-Lemus, T.; Rodriguez, J. A pH process control embedded on a PLC using fuzzy logic. In Proceedings of the 2017 XIII International Engineering Congress, Santiago de Queretaro, Mexico, 15–19 May 2017; pp. 1–6. [Google Scholar]

- Marinelli, M.; Acosta, N.; Toloza, J.; Kornuta, C. Fuzzy control of a germination chamber. J. Comput. Sci. Technol. 2017, 17, 74–78. [Google Scholar]

- Khudoyberdiev, A.; Ahmad, S.; Ullah, I.; Kim, D. An optimization scheme based on fuzzy logic control for efficient energy consumption in hydroponics environment. Energies 2020, 13, 289. [Google Scholar] [CrossRef] [Green Version]

- Biswas, S.; Deka, B.; Dash, S.; Rout, K. IoT-based fuzzy logic-controlled novel and multilingual mobile application for hydroponic farming. In AI, Edge and IoT-Based Smart Agriculture; Academic Press: Cambridge, MA, USA, 2022; pp. 31–42. [Google Scholar]

- Benyezza, H.; Bouhedda, M.; Rebouh, S. Zoning irrigation smart system based on fuzzy control technology and IoT for water and energy saving. J. Clean. Prod. 2021, 302, 127001. [Google Scholar] [CrossRef]

- Xu, J.; Li, R.; Li, Y.; Zhang, Y.; Sun, H.; Ding, X.; Ma, Y. Research on variable-universe fuzzy control technology of an electro-hydraulic hitch system. Processes 2021, 9, 1920. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, W.; Qureshi, W.S.; Gao, C.; Zhang, C.; Li, W. Autonomous navigation for a wolfberry picking robot using visual cues and fuzzy control. Inf. Process. Agric. 2021, 8, 15–26. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).