Phase Formation and the Electrical Properties of YSZ/rGO Composite Ceramics Sintered Using Silicon Carbide Powder Bed

Abstract

:1. Introduction

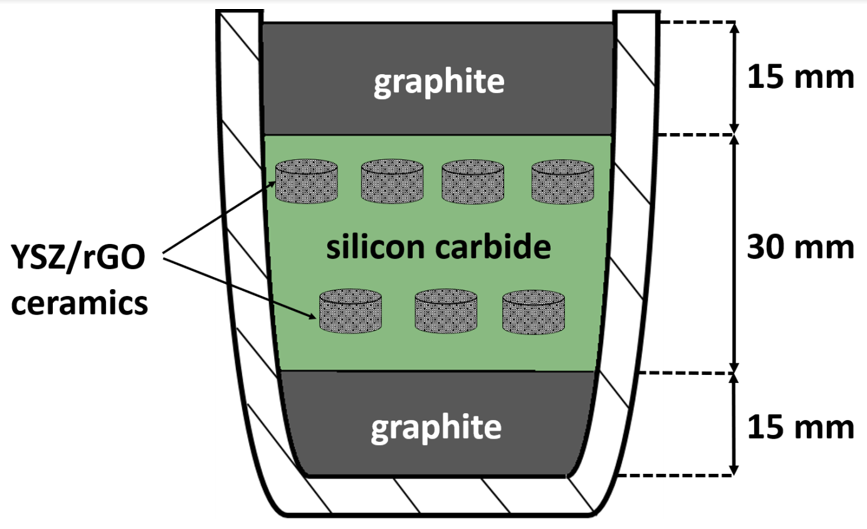

2. Materials and Methods

2.1. YSZ-rGO Composite Manufacturing

2.2. Characterization of the Obtained YSZ-rGO Ceramics

2.3. Electrochemical Study

3. Results

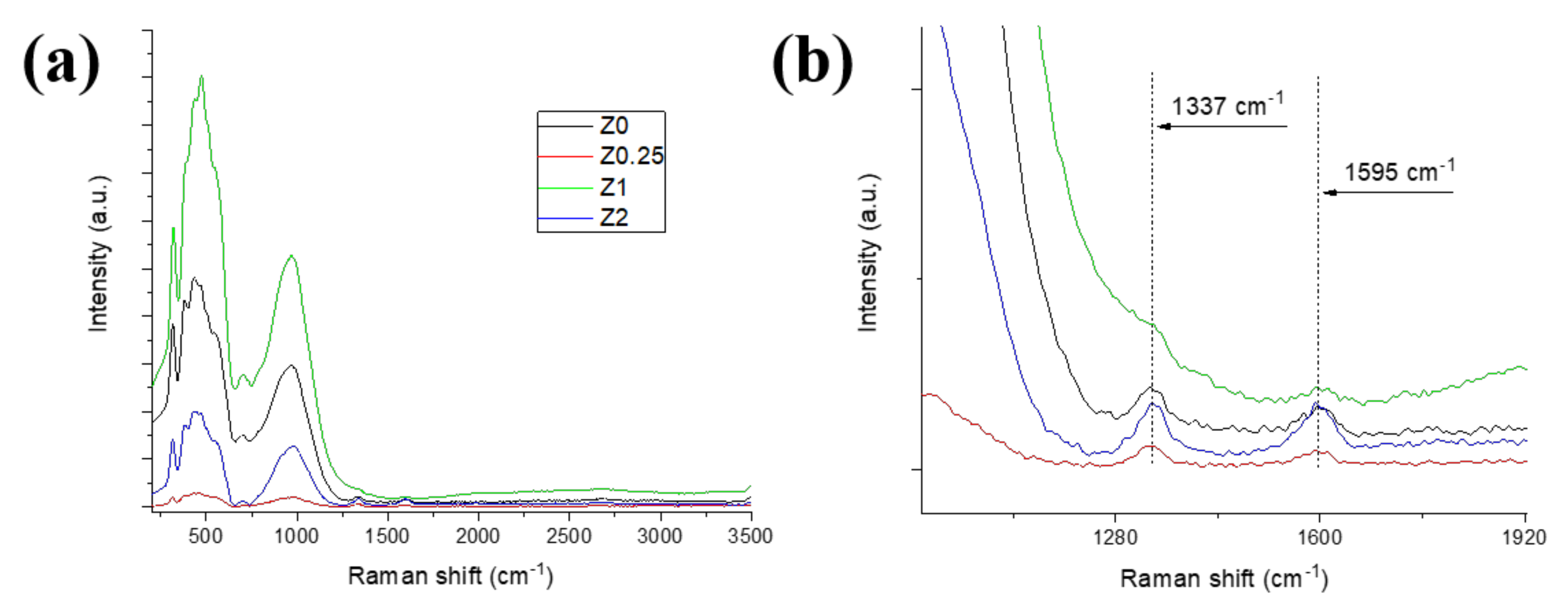

3.1. Phase Composition

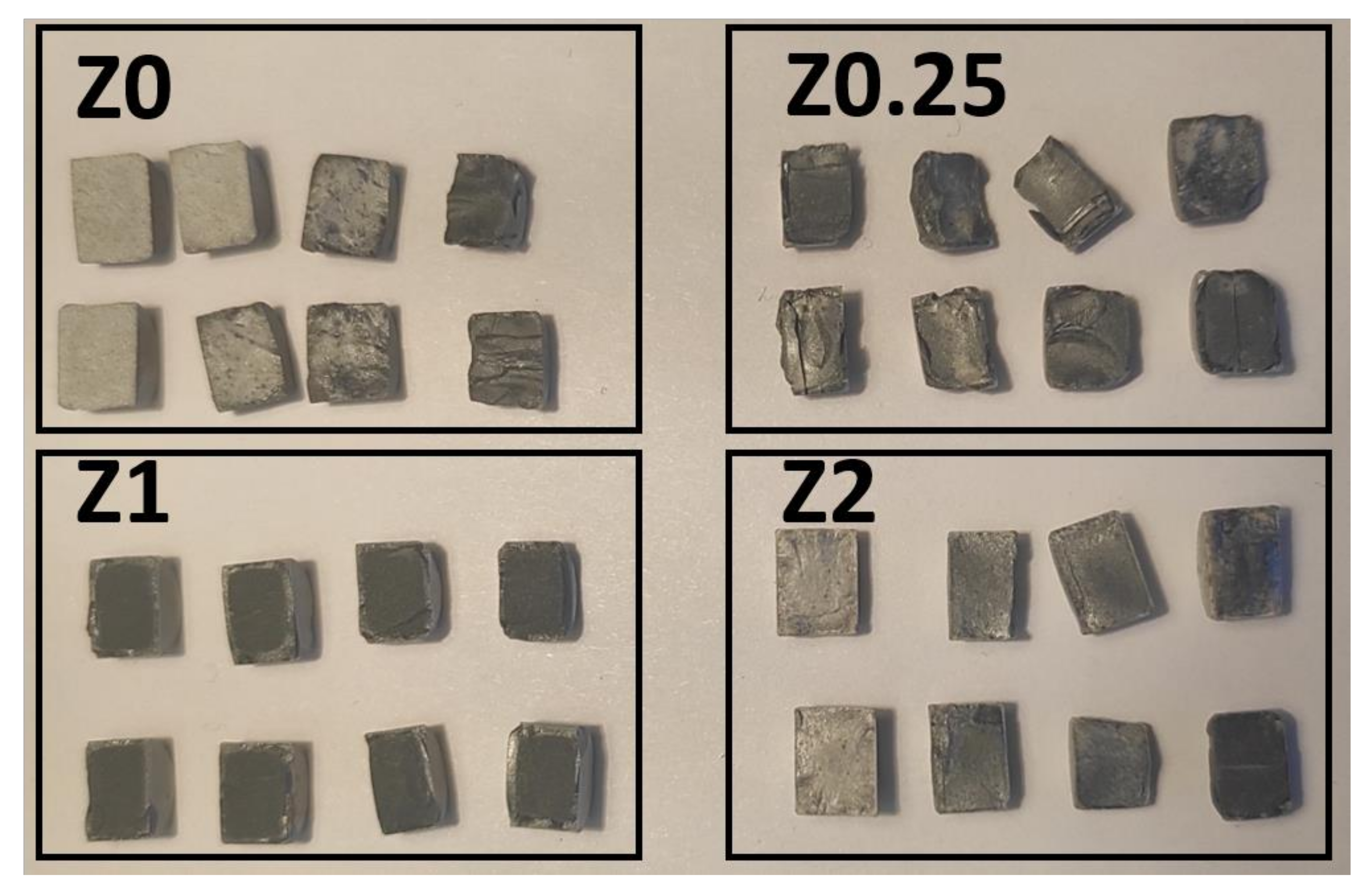

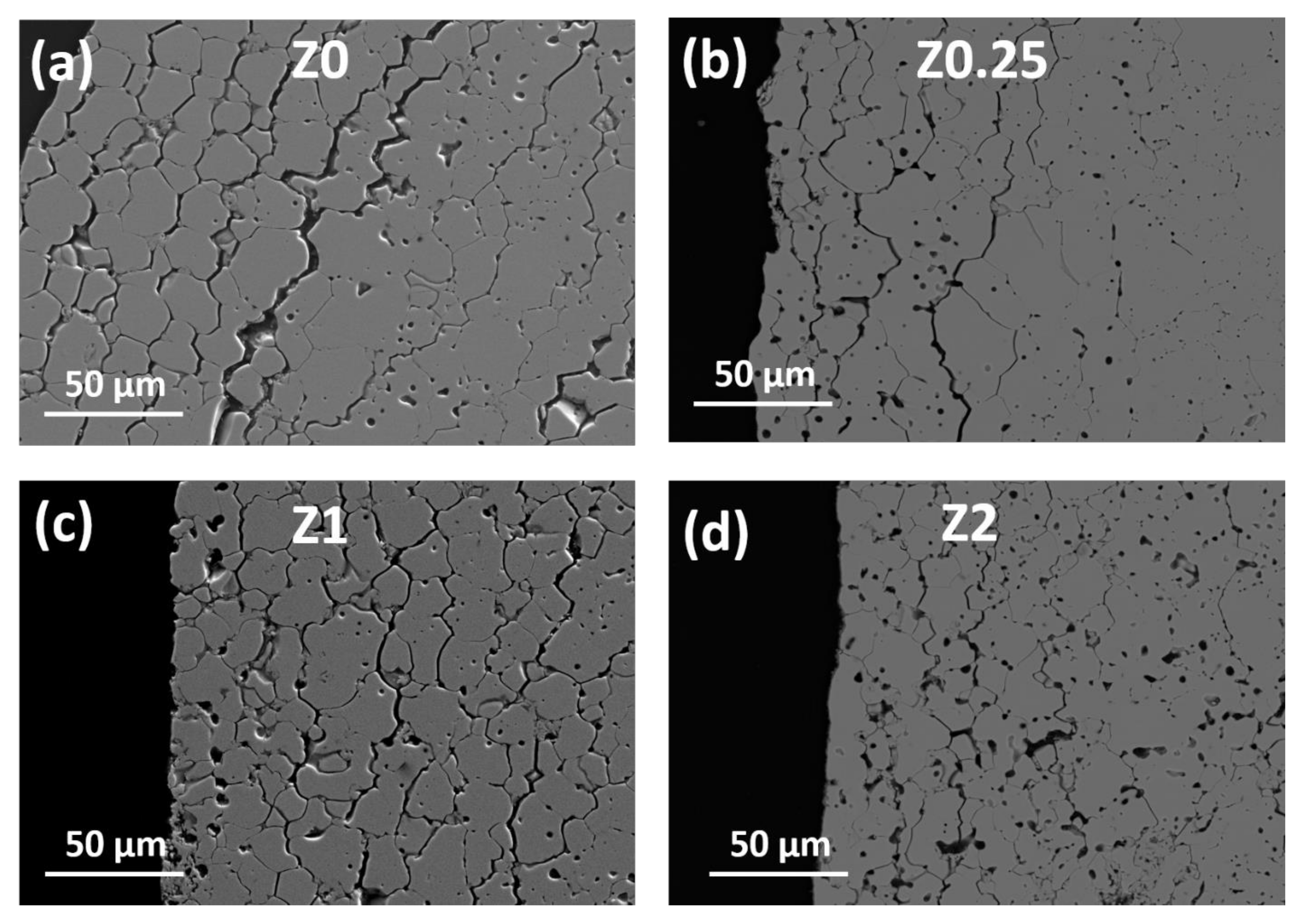

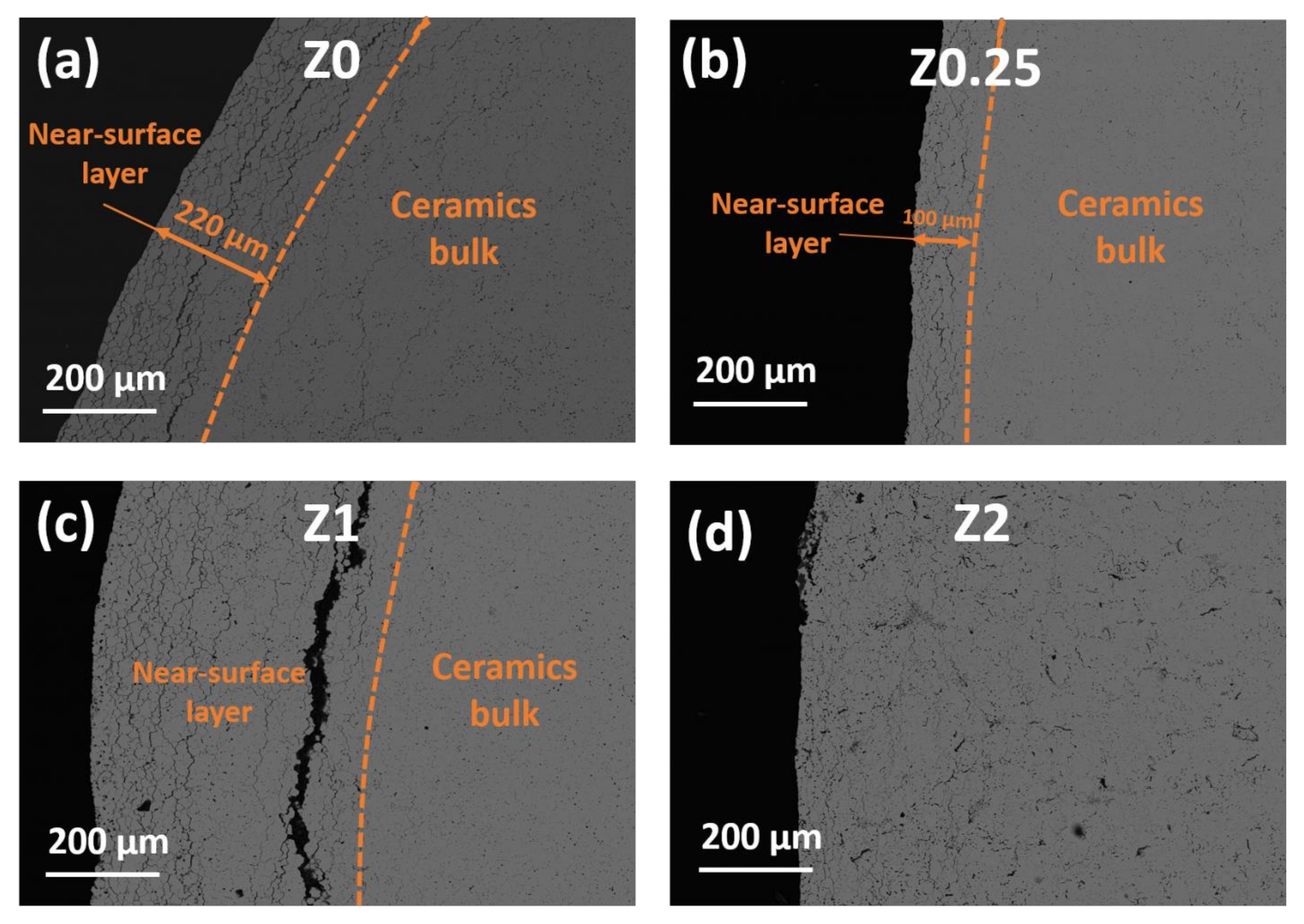

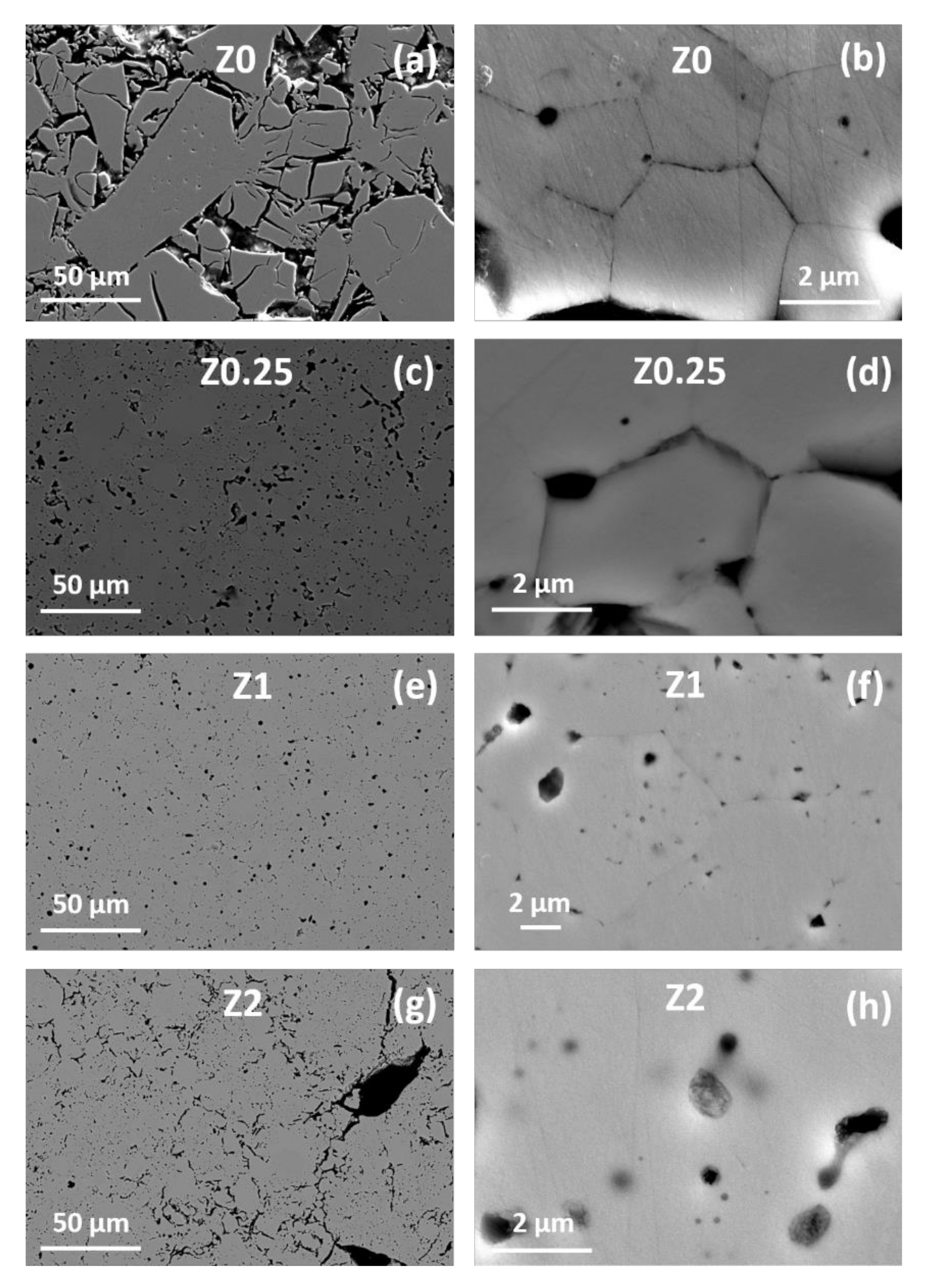

3.2. Microstructure and Density of Sintered Ceramics

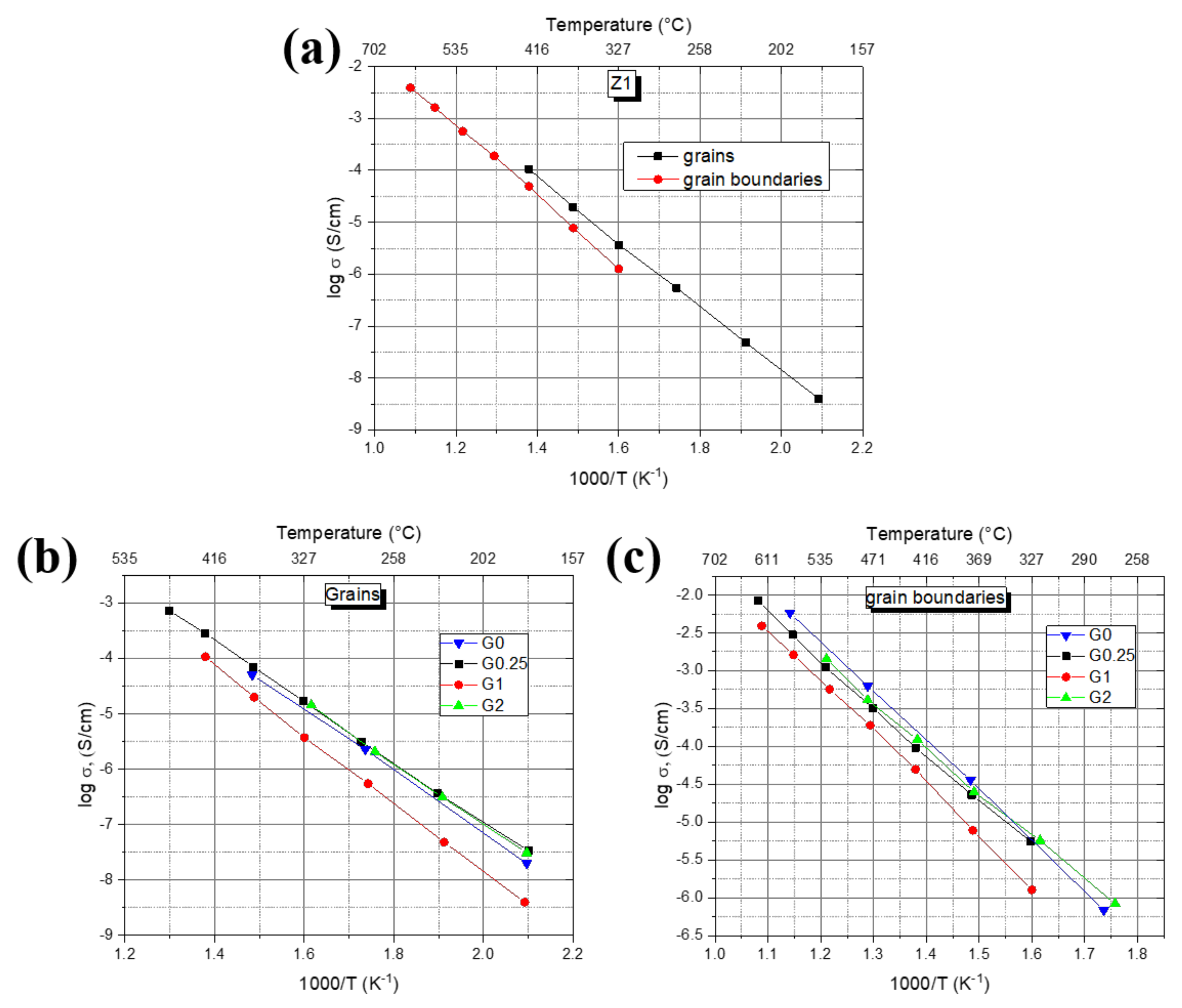

3.3. Electrochemical Study of Composites

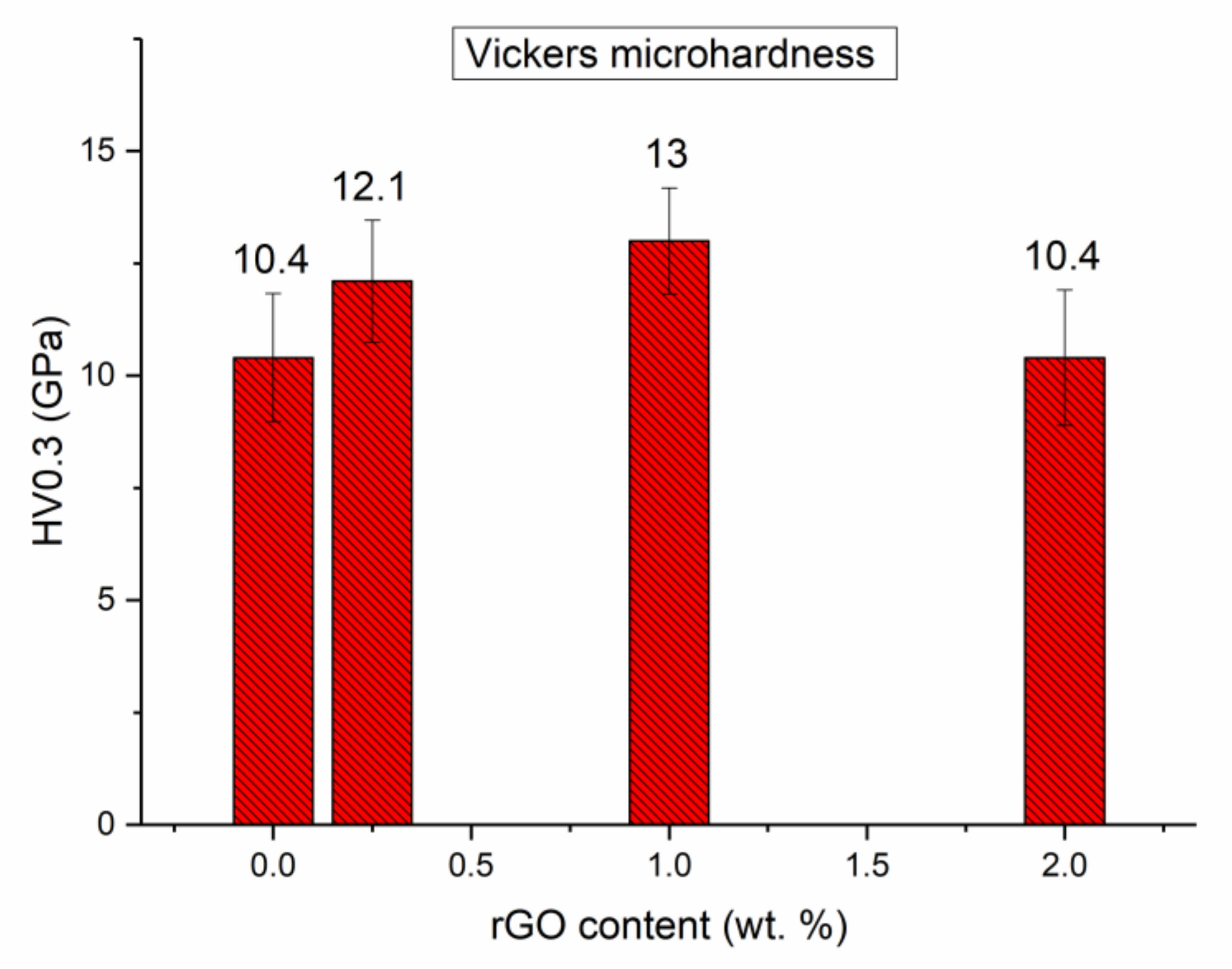

3.4. Microhardness of Sintered Ceramics

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, W.; Zhang, Y.; Cheng, L.; Wu, H.; Zheng, L.; Zhao, D. The applications of carbon nanotubes and graphene in advanced rechargeable lithium batteries. J. Mater. Chem. A 2016, 4, 8932–8951. [Google Scholar] [CrossRef]

- Kim, H.; Park, K.Y.; Hong, J.; Kang, K. All-graphene-battery: Bridging the gap between supercapacitors and lithium ion batteries. Sci. Rep. 2014, 4, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Park, C.W.; Lee, J.-H.; Seo, J.K.; Jo, W.Y.; Whang, D.; Hwang, S.M.; Kim, Y.-J. Graphene collage on Ni-rich layered oxide cathodes for advanced lithium-ion batteries. Nat. Commun. 2021, 12, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Cheng, D.; Zhu, H.; Du, J.; Li, K.; Zang, H.Y.; Tan, H.; Wang, Y.; Xing, W.; Li, Y. A bismuth oxide/graphene oxide nanocomposite membrane showing super proton conductivity and low methanol permeability. Chem. Sci. 2019, 10, 556–563. [Google Scholar] [CrossRef] [Green Version]

- Mahmoudi, M.; Farhadian, M.; Raeissi, K.; Labbaf, S.; Karimzadeh, F.; Golozar, M.A.; Barnoush, A. The role of graphene oxide interlayer on corrosion barrier and bioactive properties of electrophoretically deposited ZrO2–10 at. % SiO2 composite coating on 316 L stainless steel. Mater. Sci. Eng. C 2020, 117, 111342. [Google Scholar] [CrossRef] [PubMed]

- Armugam, A.; Hosakoppa, S.N.; Holavanahalli Doraiswamy, S. Enhanced corrosion resistance of atmospheric plasma-sprayed zirconia–GNP composite by graphene oxide nanoplatelet encapsulation. Appl. Phys. A Mater. Sci. Process. 2020, 126, 1–12. [Google Scholar] [CrossRef]

- Miranzo, P.; Belmonte, M.; Osendi, M.I. From bulk to cellular structures: A review on ceramic/graphene filler composites. J. Eur. Ceram. Soc. 2017, 37, 3649–3672. [Google Scholar] [CrossRef] [Green Version]

- Glukharev, A.; Glumov, O.; Temnikova, M.; Saffarshamshirgar, A.; Kurapova, O.; Hussainova, I.; Konakov, V. YSZ-rGO composite ceramics by spark plasma sintering: The relation between thermal evolution of conductivity, microstructure and phase stability. Electrochim. Acta 2020, 367, 137533. [Google Scholar] [CrossRef]

- Kurapova, O.Y.; Glukharev, A.G.; Glumov, O.V.; Kurapov, M.Y.; Boltynjuk, E.V.; Konakov, V.G. Structure and electrical properties of YSZ-rGO composites and YSZ ceramics, obtained from composite powder. Electrochim. Acta 2019, 320, 134573. [Google Scholar] [CrossRef]

- Marinha, D.; Belmonte, M. Mixed-ionic and electronic conduction and stability of YSZ-graphene composites. J. Eur. Ceram. Soc. 2019, 39, 389–395. [Google Scholar] [CrossRef]

- Cano-Crespo, R.; Rivero-Antúnez, P.; Gómez-García, D.; Moreno, R.; Domínguez-Rodríguez, A. The Possible Detriment of Oxygen in Creep of Alumina and Zirconia Ceramic Composites Reinforced with Graphene. Materials 2021, 14, 984. [Google Scholar] [CrossRef]

- Rodríguez-Rojas, F.; Cano-Crespo, R.; Borrero-López, O.; Domínguez-Rodríguez, A.; Ortiz, A.L. Effect of 1-D and 2-D carbon-based nano-reinforcements on the dry sliding-wear behaviour of 3Y-TZP ceramics. J. Eur. Ceram. Soc. 2021, 41, 3595–3602. [Google Scholar] [CrossRef]

- Porwal, H.; Grasso, S.; Reece, M.J. Review of graphene–ceramic matrix composites. Adv. Appl. Ceram. 2014, 112, 443–454. [Google Scholar] [CrossRef]

- Xiao, W.; Ni, N.; Fan, X.; Zhao, X.; Liu, Y.; Xiao, P. Ambient flash sintering of reduced graphene oxide/zirconia composites: Role of reduced graphene oxide. J. Mater. Sci. Technol. 2021, 60, 70–76. [Google Scholar] [CrossRef]

- Becker, M.Z.E.; Shomrat, N.; Tsur, Y. Recent Advances in Mechanism Research and Methods for Electric-Field-Assisted Sintering of Ceramics. Adv. Mater. 2018, 30, 1706369. [Google Scholar] [CrossRef]

- Hu, C.; Li, F.; Qu, D.; Wang, Q.; Xie, R.; Zhang, H.; Peng, S.; Bao, Y.; Zhou, Y. Developments in hot pressing (HP) and hot isostatic pressing (HIP) of ceramic matrix composites. In Advances in Ceramic Matrix Composites, 2nd ed.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2014; pp. 177–202. ISBN 9780081021675. [Google Scholar] [CrossRef]

- Glukharev, A.G.; Konakov, V.G. Synthesis and properties of zirconia-graphene composite ceramics: A brief review. Rev. Adv. Mater. Sci. 2018, 56, 124–138. [Google Scholar] [CrossRef]

- Hussainova, I.; Drozdova, M.; Pérez-Coll, D.; Rubio-Marcos, F.; Jasiuk, I.; Soares, J.A.N.T.; Rodríguez, M.A. Electroconductive composite of zirconia and hybrid graphene/alumina nanofibers. J. Eur. Ceram. Soc. 2017, 37, 3713–3719. [Google Scholar] [CrossRef]

- Giachello, A.; Martinengo, P.C.; Tommasini, G.; Popper, P. Sintering of silicon nitride in a powder bed. J. Mater. Sci. 1979, 14, 2825–2830. [Google Scholar] [CrossRef]

- Šajgalík, P.; Haviar, M. Pressureless sintering of Si3N4 with Y2O3 and Al2O3 additives-compatibility of powder beds. Ceram. Int. 1992, 18, 279–283. [Google Scholar] [CrossRef]

- Winn, E.J.; Clegg, W.J. Role of the powder bed in the densification of silicon carbide sintered with yttria and alumina additives. J. Am. Ceram. Soc. 1999, 82, 3466–3470. [Google Scholar] [CrossRef]

- Inada, R.; Kimura, K.; Kusakabe, K.; Tojo, T.; Sakurai, Y. Synthesis and lithium-ion conductivity for perovskite-type Li 3/8Sr7/16Ta3/4Zr1/4O3 solid electrolyte by powder-bed sintering. Solid State Ionics 2014, 261, 95–99. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Jakhar, R.; Yap, J.E.; Joshi, R. Microwave reduction of graphene oxide. Carbon N. Y. 2020, 170, 277–293. [Google Scholar] [CrossRef]

- Jorgensen, P.J.; Wadsworth, M.E.; Cutler, I.B. Oxidation of Silicon Carbide. J. Am. Ceram. Soc. 1959, 42, 613–616. [Google Scholar] [CrossRef]

- PDF-2 (Powder Diffraction File) Database; International Centre for Diffraction Data: Newtown Square, PA, USA, 2021.

- Chase, M.W. Constants of Inorganic Substances. A Handbook; Revised and Augmented Edition; Lidin, R.A., Andreeva, L.L., Molochko, V.A., Eds.; Begell House, Inc.: New York, NY, USA, 1996; 444p, ISBN 1-56700-014-X. [Google Scholar] [CrossRef]

- Johra, F.T.; Lee, J.W.; Jung, W.G. Facile and safe graphene preparation on solution based platform. J. Ind. Eng. Chem. 2014, 20, 2883–2887. [Google Scholar] [CrossRef]

- Stichert, W.; Schüth, F. Influence of Crystallite Size on the Properties of Zirconia. Chem. Mater. 1998, 10, 2020–2026. [Google Scholar] [CrossRef]

- Kurapova, O.Y.; Glumov, O.V.; Lomakin, I.V.; Golubev, S.N.; Pivovarov, M.M.; Krivolapova, J.V.; Konakov, V.G. Microstructure, conductivity and mechanical properties of calcia stabilized zirconia ceramics obtained from nanosized precursor and reduced graphene oxide doped precursor powders. Ceram. Int. 2018, 44, 15464–15471. [Google Scholar] [CrossRef]

- Kontoyannis, C.G.; Orkoula, M. Quantitative determination of the cubic, tetragonal and monoclinic phases in partially stabilized zirconias by Raman spectroscopy. J. Mater. Sci. 1994, 29, 5316–5320. [Google Scholar] [CrossRef]

- Ward, Y.; Young, R.J.; Shatwell, R.A. Microstructural study of silicon carbide fibres through the use of Raman microscopy. J. Mater. Sci. 2001, 36, 55–66. [Google Scholar] [CrossRef]

- Jamnik, J. Impedance spectroscopy of mixed conductors with semi-blocking boundaries. Solid State Ionics 2003, 157, 19–28. [Google Scholar] [CrossRef]

- Bauerle, J.E. Study of solid electrolyte polarization by a complex admittance method. Solid State Commun. 1969, 30, 2657–2670. [Google Scholar] [CrossRef]

- Ahamer, C.; Opitz, A.K.; Rupp, G.M.; Fleig, J. Revisiting the Temperature Dependent Ionic Conductivity of Yttria Stabilized Zirconia (YSZ). J. Electrochem. Soc. 2017, 164, F790–F803. [Google Scholar] [CrossRef]

- Ghazanfari, A.; Li, W.; Leu, M.C.; Watts, J.L.; Hilmas, G.E. Additive manufacturing and mechanical characterization of high density fully stabilized zirconia. Ceram. Int. 2017, 43, 6082–6088. [Google Scholar] [CrossRef] [Green Version]

- Shin, J.H.; Hong, S.H. Fabrication and properties of reduced graphene oxide reinforced yttria-stabilized zirconia composite ceramics. J. Eur. Ceram. Soc. 2014, 34, 1297–1302. [Google Scholar] [CrossRef]

- Sasaki, Y.; Nishina, Y.; Sato, M.; Okamura, K. Raman study of SiC fibres made from polycarbosilane. J. Mater. Sci. 1987, 22, 443–448. [Google Scholar] [CrossRef]

- Richter, H.; Wang, Z.P.; Ley, L. The one phonon Raman spectrum in microcrystalline silicon. Solid State Commun. 1981, 39, 625–629. [Google Scholar] [CrossRef]

- Palchaev, D.K.; Murlieva, Z.K.; Palchaeva, K.S. Thermal expansion of silicon carbide materials. J. Eng. Phys. Thermophys. 1994, 66, 660–662. [Google Scholar] [CrossRef]

- Hayashi, H.; Saitou, T.; Maruyama, N.; Inaba, H.; Kawamura, K.; Mori, M. Thermal expansion coefficient of yttria stabilized zirconia for various yttria contents. Solid State Ionics 2005, 176, 613–619. [Google Scholar] [CrossRef]

- Barin, I. Thermochemical Data of Pure Substances, 3rd ed.; Wiley: Weinheim, Germany, 1995; Volume 1, ISBN 3527287450. [Google Scholar]

| Sample | Brutto-Composition | Sintering Conditions |

|---|---|---|

| Z0 | 91ZrO2-8Y2O3 (8YSZ, mol.%) | 1550 °C; 3 h; 3-layer graphite/SiC/graphite powder bed |

| Z0.25 | YSZ + 0.25 wt.% rGO | |

| Z1 | YSZ + 1 wt.% rGO | |

| Z2 | YSZ + 2 wt.% rGO |

| Sample | Z0 | Z0.25 | Z1 | Z2 |

|---|---|---|---|---|

| K, % | 98 | 94 | 93 | 94 |

| dcryst, nm | 115 | 112 | 114 | 118 |

| Relative density, % | 94.5 ± 1.3 | 96.3 ± 1.3 | 97.1 ± 0.4 | 95.6 ± 0.7 |

| Sample | Activation Energy of Conductivity Ea, eV | |

|---|---|---|

| Grain Component | Grain Boundary Component | |

| Z0 | 1.10 | 1.31 |

| Z0.25 | 1.06 | 1.21 |

| Z1 | 1.23 | 1.35 |

| Z2 | 1.10 | 1.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glukharev, A.; Glumov, O.; Smirnov, I.; Boltynjuk, E.; Kurapova, O.; Konakov, V. Phase Formation and the Electrical Properties of YSZ/rGO Composite Ceramics Sintered Using Silicon Carbide Powder Bed. Appl. Sci. 2022, 12, 190. https://doi.org/10.3390/app12010190

Glukharev A, Glumov O, Smirnov I, Boltynjuk E, Kurapova O, Konakov V. Phase Formation and the Electrical Properties of YSZ/rGO Composite Ceramics Sintered Using Silicon Carbide Powder Bed. Applied Sciences. 2022; 12(1):190. https://doi.org/10.3390/app12010190

Chicago/Turabian StyleGlukharev, Artem, Oleg Glumov, Ivan Smirnov, Evgeniy Boltynjuk, Olga Kurapova, and Vladimir Konakov. 2022. "Phase Formation and the Electrical Properties of YSZ/rGO Composite Ceramics Sintered Using Silicon Carbide Powder Bed" Applied Sciences 12, no. 1: 190. https://doi.org/10.3390/app12010190

APA StyleGlukharev, A., Glumov, O., Smirnov, I., Boltynjuk, E., Kurapova, O., & Konakov, V. (2022). Phase Formation and the Electrical Properties of YSZ/rGO Composite Ceramics Sintered Using Silicon Carbide Powder Bed. Applied Sciences, 12(1), 190. https://doi.org/10.3390/app12010190