Evaluation of Changes in Structure of Modified Cement Composite Using Fractal Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Testing of Samples

2.3. Calculation of Multifractal Parameters

- -

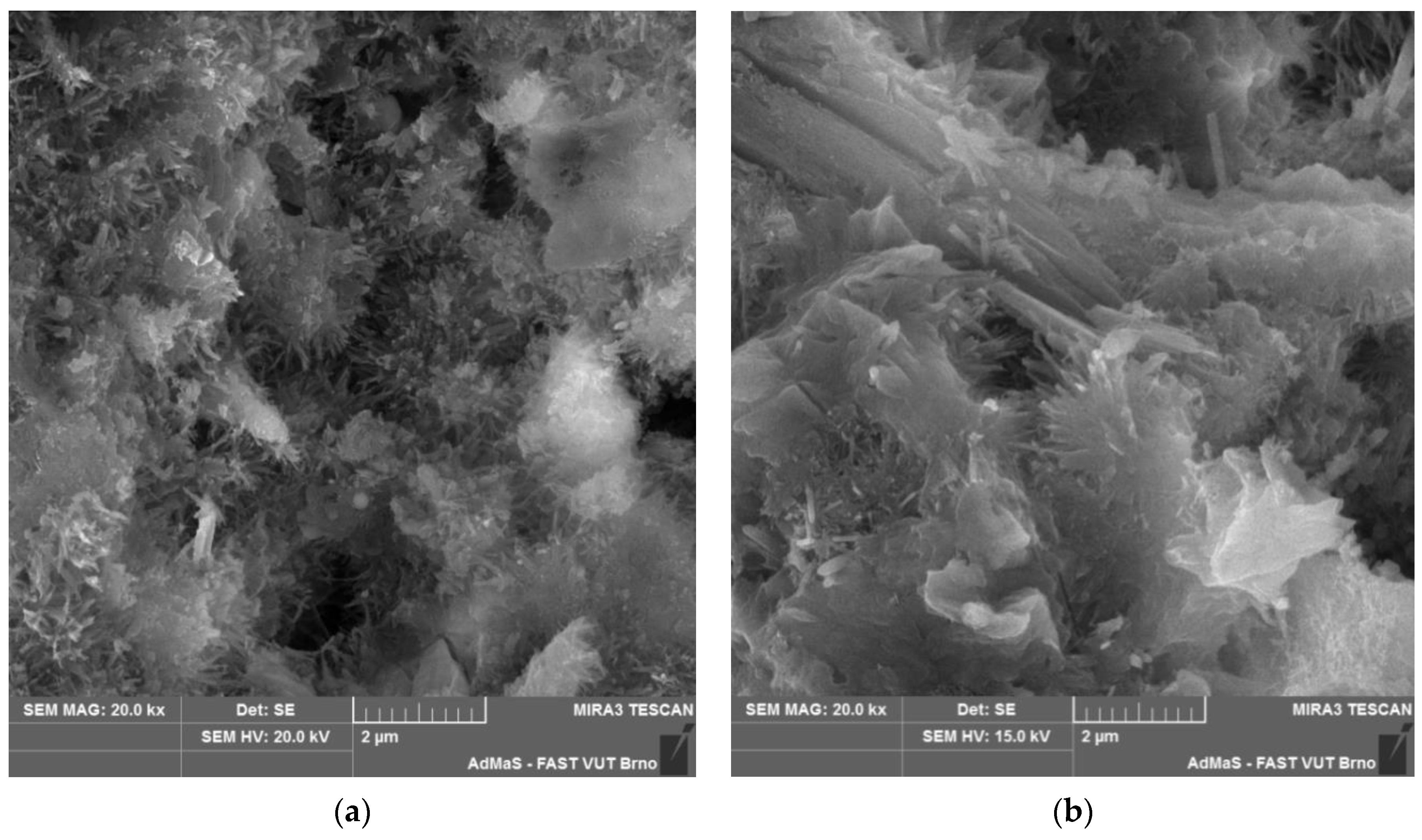

- Obtaining the digital image of the concrete surface under study using an electron microscope according to the scheme in Figure 1;

- -

- Selecting the sections of scanner images of the microstructure of concrete samples;

- -

- Calculating the multifractal characteristics for the scanning area;

- -

- Studying the obtained multifractal characteristics.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, G.M.; Nam, I.W.; Yang, B.; Yoon, H.N.; Lee, H.K.; Park, S. Carbon nanotube (CNT) incorporated cementitious composites for functional construction materials: The state of the art. Compos. Struct. 2019, 227, 111244. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Zeng, L.; Li, R.; Tian, H.; Fu, X.; Zhong, W.H. A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. J. Mater. Sci. 2019, 54, 1036–1076. [Google Scholar]

- Lee, G.C.; Kim, Y.; Seo, S.Y.; Yun, H.D.; Hong, S. Sulfuric Acid Resistance of CNT-Cementitious Composites. Appl. Sci. 2021, 11, 2226. [Google Scholar] [CrossRef]

- Szeląg, M. Mechano-physical properties and microstructure of carbon nanotube reinforced cement paste after thermal load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef]

- Huang, T.; Li, J.L.; Yang, J.H.; Zhang, N.; Wang, Y.; Zhou, Z.W. Carbon nanotubes induced microstructure and property changes of polycarbonate/poly (butylene terephthalate) blend. Compos. Part B Eng. 2018, 133, 177–184. [Google Scholar] [CrossRef]

- Tragazikis, I.K.; Kordatou, T.Z.; Exarchos, D.A.; Dalla, P.T.; Matikas, T.E. Monitoring the Hydration Process in Carbon Nanotube Reinforced Cement-Based Composites Using Nonlinear Elastic Waves. Appl. Sci. 2021, 11, 1720. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, H.; He, X.; Zhao, R.; Yang, J.; Su, Y. Nano particles prepared from hardened cement paste by wet grinding and its utilization as an accelerator in Portland cement. J. Clean. Prod. 2020, 283, 124632. [Google Scholar] [CrossRef]

- Foldyna, J.; Foldyna, V.; Zeleňák, M. Dispersion of carbon nanotubes for application in cement composites. Procedia Eng. 2016, 149, 94–99. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Multifunctional and smart carbon nanotube reinforced cement-based materials. In Nanotechnology in Civil Infrastructure; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–47. [Google Scholar]

- Smirnova, O.M. Technology of Increase of Nanoscale Pores Volume in Protective Cement Matrix. Int. J. Civ. Eng. Technol. 2018, 9, 1991–2000. [Google Scholar]

- Fedorova, G.D.; Alexandrov, G.N.; Yakovlev, G.I.; Polyanskikh, I.S.; Pudov, I.A. Fine Grain Portland Cement Concrete with Complex Nanodisperse Admixture for Structure Rehabilitating. Adv. Mater. Res. 2015, 1122, 105–110. [Google Scholar] [CrossRef]

- Pukharenko, Y.; Staroverov, V.; Ryzhov, D. Nanomodified concrete mixes for form-free moulding. Mater. Today Proc. 2019, 19, 2189–2192. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Wang, J.; Liu, M.; Wang, Y.; Zhou, Z.; Xu, D.; Du, P.; Cheng, X. Synergistic effects of nano-silica and fly ash on properties of cement-based composites. Constr. Build. Mater. 2020, 262, 120737. [Google Scholar] [CrossRef]

- Niu, L.; Xu, J.; Yang, W.; Ma, J.; Zhao, J.; Kang, C.; Su, J. Study on the Synergetic Fire-Retardant Effect of Nano-Sb2O3 in PBT Matrix. Materials 2018, 11, 1060. [Google Scholar] [CrossRef] [PubMed]

- Pundienė, I.; Pranckevičienė, J.; Kligys, M.; Kizinievič, O. The synergetic interaction of chemical admixtures on the properties of eco-friendly lightweight concrete from industrial technogenic waste. Constr. Build. Mater. 2020, 256, 119461. [Google Scholar] [CrossRef]

- Li, D.; Chen, B.; Chen, X.; Fu, B.; Wei, H.; Xiang, X. Synergetic effect of superabsorbent polymer (SAP) and crystalline admixture (CA) on mortar macro-crack healing. Constr. Build. Mater. 2020, 247, 118521. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Liang, H.; Jiang, J.; Yang, Y.; He, Z. Synergistic enhancement of mechanical property of the high replacement low-calcium ultrafine fly ash blended cement paste by multiple chemical activators. J. Build. Eng. 2020, 32, 101520. [Google Scholar] [CrossRef]

- Mikhailov, A.V.; Garmaev, O.Z.; Fedorov, A.S. The relationship between fractal properties and active porosity of peat compositions. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2020; Volume 836, pp. 58–62. [Google Scholar]

- Vasilenko, T.; Islamov, A.; Kirillov, A.; Doroshkevich, A.; Doroshkevich, N. Investigation of Tectonically Disturbed Zones of Coal Seams of the Kuznetsk Coal Basin Using SANS. J. Surf. Investig. X-ray Synchrotron Neutron Technol. 2020, 14, S235–S241. [Google Scholar]

- Yang, J.; She, W.; Zuo, W.; Zhang, Q. Rational application of nano-SiO2 in cement paste incorporated with silane: Counterbalancing and synergistic effects. Cem. Concr. Compos. 2021, 118, 103959. [Google Scholar] [CrossRef]

- Wang, H.; Hou, P.; Li, Q.; Adu-Amankwah, S.; Chen, H.; Xie, N.; Zhao, P.; Huang, Y.; Wang, S.; Cheng, X. Synergistic effects of supplementary cementitious materials in limestone and calcined clay-replaced slag cement. Constr. Build. Mater. 2021, 282, 122648. [Google Scholar] [CrossRef]

- Güler, Ö.; Cacim, N.N.; Evin, E.; Yahia, I.S. The synergistic effect of CNTs-polymeric surfactant on the properties of concrete nanocomposites: Comparative study. J. Compos. Mater. 2020, 55. [Google Scholar] [CrossRef]

- Ghadikolaee, M.R.; Korayem, A.H.; Sharif, A.; Liu, Y.M. The halloysite nanotube effects on workability, mechanical properties, permeability and microstructure of cementitious mortar. Constr. Build. Mater. 2020, 267, 120873. [Google Scholar] [CrossRef]

- Da, Y.; He, T.; Shi, C.; Wang, M.; Feng, Y. Studies on the formation and hydration of tricalcium silicate doped with CaF2 and TiO2. Constr. Build. Mater. 2021, 266, 121128. [Google Scholar] [CrossRef]

- He, T.; Yang, R.; Guo, X.; Xu, R.; Da, Y.; Fan, X. Effects of liquid accelerators on carbonation properties of C3A and C3S hydration products. Adv. Cem. Res. 2020. [Google Scholar] [CrossRef]

- Pashkevich, M.A.; Bech, J.; Matveeva, V.A.; Alekseenko, A.V. Biogeochemical assessment of soils and plants in industrial, residential and recreational areas of Saint Petersburg. J. Min. Inst. 2020, 241, 125–130. [Google Scholar] [CrossRef]

- Ochkurov, V.I.; Vilenskii, M.Y. Comparative evaluation of the saving of binder with fine ground slag. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 666, p. 012026. [Google Scholar]

- Klyuev, S.V.; Klyuev, A.V.; Vatin, N.I. Fiber concrete for the construction industry. Mag. Civ. Eng. 2018, 84, 41–47. [Google Scholar]

- Flores-Vivian, I.; Pradoto, R.G.; Moini, M.; Kozhukhova, M.; Potapov, V.; Sobolev, K. The effect of SiO2 nanoparticles derived from hydrothermal solutions on the performance of Portland cement based materials. Front. Struct. Civ. Eng. 2017, 11, 436–445. [Google Scholar] [CrossRef]

- Habbaba, A.; Zouaoui, N.; Plank, J. Synergistic and Antagonistic Effect of SO4 2-on Dispersing Power of Polycarboxylate. ACI Mater. J. 2013, 110, 641–645. [Google Scholar]

- Sobolev, K.; Flores-Vivian, I.; Pradoto, R.G.; Kozhukhova, M.; Potapov, V. The effect of natural SiO2 nanoparticles on the performance of Portland cement based materials. Spec. Publ. 2018, 326, 14.1–14.10. [Google Scholar]

- Silva, B.; Pinto, A.P.F.; Gomes, A.; Candeias, A. Effect of Air-entraining and Water-repellent Admixtures and of Their Dosage on the Performance of Lime Mortars. Int. J. Archit. Herit. 2020, 1–15. [Google Scholar] [CrossRef]

- Tan, H.; Li, M.; He, X.; Su, Y.; Yang, J.; Zhao, H. Effect of wet grinded lithium slag on compressive strength and hydration of sulphoaluminate cement system. Constr. Build. Mater. 2021, 267, 120465. [Google Scholar] [CrossRef]

- Wang, J.; Ma, B.; Tan, H.; Du, C.; Chu, Z.; Luo, Z.; Wang, P. Hydration and mechanical properties of cement-marble powder system incorporating triisopropanolamine. Constr. Build. Mater. 2021, 266, 121068. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Garcia-Lodeiro, I.; Maltseva, O.; Palomo, A. Hydration mechanisms of hybrid cements as a function of the way of addition of chemicals. J. Am. Ceram. Soc. 2019, 102, 427–436. [Google Scholar] [CrossRef]

- Krivenko, P.; Gelevera, O.; Kovalchuk, O.; Bumanis, G.; Korjakins, A. Alkali-aggregate reaction in alkali-activated cement concretes. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 660, p. 012002. [Google Scholar]

- Maeva, I.S. Modification of Anhydrite Compositions by Ultra- and Nanodisperse Additives. Ph.D. Thesis, Abstract of the Dissertation for the Degree of Candidate of Technical Sciences, Kazan State University of Architecture and Construction, Kazan, Russia, 2010; 20p. [Google Scholar]

- Liu, H.; Sun, S.; Wang, L.; Zhang, Y.; Wang, J.; Luo, G.; Han, L. Microscopic Mechanism of the Macroscopic Mechanical Properties of Cement Modified Subgrade Silty Soil Subjected to Freeze-Thaw Cycles. Appl. Sci. 2020, 10, 2182. [Google Scholar] [CrossRef]

- Kalina, L.; Bílek, V.; Novotný, R.; Mončeková, M.; Másilko, J.; Koplík, J. Effect of Na3PO4 on the Hydration Process of Alkali-Activated Blast Furnace Slag. Materials 2016, 9, 395. [Google Scholar] [CrossRef] [PubMed]

- Karapetian, K.; Dzhevaga, N. Modern technologies of complex processing of phosphates. ARPN J. Eng. Appl. Sci. 2017, 12, 4588–4594. [Google Scholar]

- Kazanskaya, L.; Privalov, N.; Privalova, S. Fine ground granulated blast furnace slag for saving quantity of binder. E3S Web Conf. 2019, 110, 01055–01059. [Google Scholar] [CrossRef]

- Gorlanov, E.S.; Bazhin, V.Y.; Vlasov, A.A. Electrochemical borating of titanium-containing carbographite materials. Russ. Metall. 2017, 2017, 489–493. [Google Scholar] [CrossRef]

- ElDeeb, A.B.; Brichkin, V.N.; Kurtenkov, R.V.; Bormotov, I.S. Extraction of alumina from kaolin by a combination of pyro-and hydro-metallurgical processes. Appl. Clay Sci. 2019, 172, 146–154. [Google Scholar] [CrossRef]

- Gao, F.; Tian, W.; Wang, Z.; Wang, F. Effect of diameter of multi-walled carbon nanotubes on mechanical properties and microstructure of the cement-based materials. Constr. Build. Mater. 2020, 260, 120452. [Google Scholar] [CrossRef]

- Ivanova, V.S.; Vstovsky, G.V. Mesomechanics of fractal structures in nonlinear conditions. Phys. Mesomech. 1999, 2, 19–25. [Google Scholar]

- Lu, Z.; Sha, A.; Wang, W. Permeability evaluation of clay-quartz mixtures based on low-field NMR and fractal analysis. Appl. Sci. 2020, 10, 1585. [Google Scholar] [CrossRef]

- Gao, Y.; Jiang, J.; De Schutter, G.; Ye, G.; Sun, W. Fractal and multifractal analysis on pore structure in cement paste. Constr. Build. Mater. 2014, 69, 253–261. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.; He, X.; Su, Y.; Tan, H.; Chen, W.; Wang, X.; Strnadel, B. Segmented fractal pore structure covering nano-and micro-ranges in cementing composites produced with GGBS. Constr. Build. Mater. 2019, 225, 1170–1182. [Google Scholar] [CrossRef]

- Li, J.; Wang, F.; Yi, F.; Ma, J.; Lin, Z. Fractal analysis of the fracture evolution of freeze-thaw damage to asphalt concrete. Materials 2019, 12, 2288. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Niu, D.; Fu, Q.; Luo, D. Fractal characteristics of pore structure of hybrid Basalt–Polypropylene fibre-reinforced concrete. Cem. Concr. Compos. 2020, 109, 103555. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.; Zheng, J.; Wang, J.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Sun, M.; Zou, C.; Xin, D. Pore structure evolution mechanism of cement mortar containing diatomite subjected to freeze-thaw cycles by multifractal analysis. Cem. Concr. Compos. 2020, 114, 103731. [Google Scholar] [CrossRef]

- Khlyupin, A.N.; Dinariev, O.Y. Fractal analysis of the three-dimensional microstructure of porous materials. Zh.T.F. 2015, 85, 17–22. [Google Scholar]

- Evelson, L.I.; Nikolaenko, A.N.; Rivonenko, Y.A. Some practical aspects of fractal modeling of the structure of nanocomposite material. Constr. Mater. 2015, 11, 25–27. [Google Scholar]

- Yakovlev, G.; Cern, V.; Polyanskikh, I.; Gordina, A.; Pudov, I.; Gumenyuk, A.; Smirnova, O. The Effect of Complex Modification on the Impedance of Cement Matrices. Materials 2021, 14, 557. [Google Scholar] [CrossRef] [PubMed]

- Stepanov, V.A.; Belykh, V.V. Program for Comparative Fractal Analysis of Raster Images. Federal Service on Intellectual Property. Patent No. 2016615852, 1 June 2016. [Google Scholar]

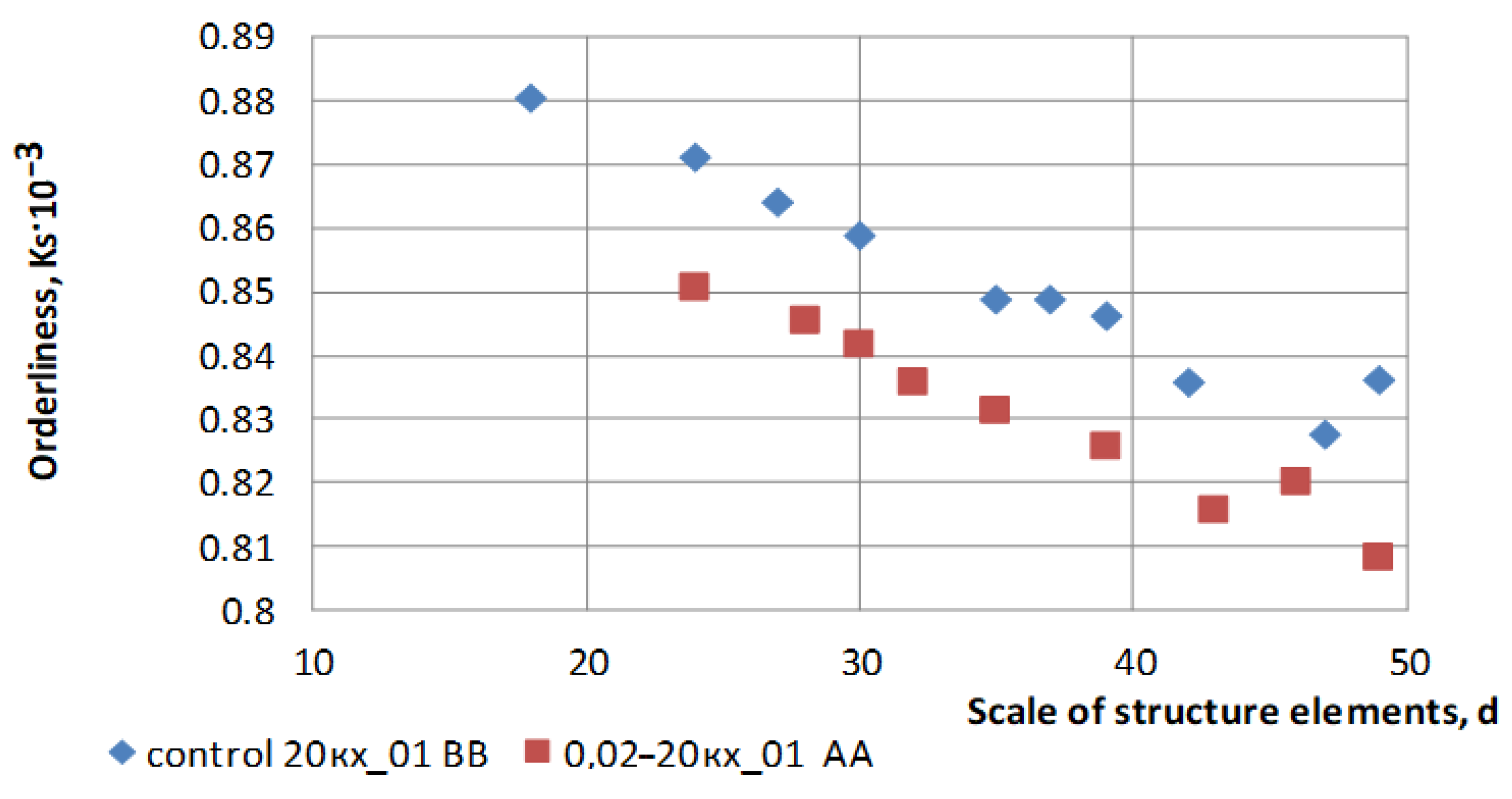

| Microstructure | AA | AB | BA | BB |

|---|---|---|---|---|

| Status Function | Deterministic | Deterministic | Deterministic | Deterministic |

| H | 13.07 | 10.22 | 10.3 | 10.33 |

| Hmax | 18.92 | 14.8 | 14.91 | 14.95 |

| H* | 10.43 | 8.49 | 10.22 | 8.52 |

| S = H*/Hmax | 0.55 | 0.57 | 0.69 | 0.57 |

| ∆H = Hmax − H* | 8.49 | 6.31 | 4.69 | 6.43 |

| R = 1 − S | 0.45 | 0.43 | 0.31 | 0.43 |

| Transmitted information Hold/H* | 0.42 | 0.3 | 0.5 | 0.3 |

| New information Hnew/H* | 0.58 | 0.7 | 0.5 | 0.7 |

| H − H* | 2.64 | 1.73 | 0.08 | 1.81 |

| D1equil | 0.89209 | 0.87534 | 0.8753 | 0.8805 |

| D1non-equil | 0.83098 | 0.83175 | 0.83473 | 0.83609 |

| K = exp(H) | 4.7 × 105 | 2.7 × 104 | 2.94 × 104 | 3.1 × 104 |

| K* = exp(H*) | 3.4 × 104 | 0.5 × 104 | 2.7 × 104 | 0.5 × 104 |

| Microstructure | AA | AB | BA | BB |

|---|---|---|---|---|

| Status Function | Stochastic | Deterministic | Deterministic | Deterministic |

| H | 6.89 | 9.53 | 8.537 | 10.11 |

| Hmax | 9.97 | 13.8 | 12.36 | 14.64 |

| H * | 10.73 | 8.72 | 4.11 | 7.74 |

| S = H*/Hmax | 1.08 | 0.63 | 0.33 | 0.53 |

| ∆H = Hmax − H* | −0.757 | 5.08 | 8.25 | 6.9 |

| R = 1 − S | −0.08 | 0.37 | 0.67 | 0.47 |

| Transmitted information Hold/H* | 0.39 | 0.1 | 0 | 0.21 |

| New Information Hnew/H* | 0.61 | 0.9 | 1.0 | 0.79 |

| H − H* | −3.34 | 0.83 | 4.43 | 2.37 |

| D1equil | 0.89085 | 0.907 | 0.8502 | 0.85076 |

| D1non-equil | 0.82523 | 0.8416 | 0.7976 | 0.80827 |

| K = exp(H) | 9.82 × 102 | 1.4 × 104 | 5.1 × 103 | 2.4 × 104 |

| K* = exp(H*) | 2.1 × 104 | 6.1 × 103 | 60 | 2.3 × 103 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yakovlev, G.; Polyanskikh, I.; Belykh, V.; Stepanov, V.; Smirnova, O. Evaluation of Changes in Structure of Modified Cement Composite Using Fractal Analysis. Appl. Sci. 2021, 11, 4139. https://doi.org/10.3390/app11094139

Yakovlev G, Polyanskikh I, Belykh V, Stepanov V, Smirnova O. Evaluation of Changes in Structure of Modified Cement Composite Using Fractal Analysis. Applied Sciences. 2021; 11(9):4139. https://doi.org/10.3390/app11094139

Chicago/Turabian StyleYakovlev, Grigory, Irina Polyanskikh, V. Belykh, Vladimir Stepanov, and Olga Smirnova. 2021. "Evaluation of Changes in Structure of Modified Cement Composite Using Fractal Analysis" Applied Sciences 11, no. 9: 4139. https://doi.org/10.3390/app11094139

APA StyleYakovlev, G., Polyanskikh, I., Belykh, V., Stepanov, V., & Smirnova, O. (2021). Evaluation of Changes in Structure of Modified Cement Composite Using Fractal Analysis. Applied Sciences, 11(9), 4139. https://doi.org/10.3390/app11094139