Abstract

The use of granule activated carbon (GAC) and rubber particles as the bio-fouling reducer in a membrane bioreactor (MBR) was evaluated in this study. The addition of GAC tends to temporarily reduce Transmembrane Pressure (TMP). Then, after the initial reduction, TMP gradually increased back up to 0.7 bar, indicating significant fouling on the membrane. Low TMP values were observed after adding 0.5% (V/V) rubber particles to the same MBR. The organic compound and nitrogen removal efficiencies of the MBR under intermittent aeration were over 94% and 93.3%, respectively. The results showed that Dysgonomonas, Acidobacteria, and Pantoea sp. contributed to the nitrification process while Lactobacillus, Erythrobacter, Phytobacter, and Mycobacterium contributed to the denitrification process.

1. Introduction

Membrane bioreactors (MBRs) are among the most promising domestic wastewater treatment technologies due to their high efficiency [1,2,3]. However, several challenges impede the wide application of MBRs such as low nitrogen removal efficiency and a tendency for membrane fouling. To achieve high nitrogen removal through the MBR process, it is essential to provide contrasting conditions in two separate reactors that hold either nitrifying or denitrifying bacteria. Effluent from aerobic units containing nitrites and nitrates should be recycled in the anoxic unit to achieve denitrification. However, these additional processes increase the operational complexity and cost [4].

The use of a single reactor under time division operation is one of the approaches for nitrification-denitrification applied in MBR. Intermittent aeration in a single-reactor MBR has been reported as an attractive way to create an anoxic environment; this approach results in greater operating flexibility, process simplicity, and lower energy consumption. However, its wide application is limited by membrane fouling. Although intermittent aeration is beneficial for nitrogen removal in MBRs, it may aggravate membrane fouling due to the decreased shear force acting on the membrane surface during non-aeration periods [5]. Membrane fouling leads to increased operation and maintenance costs, thus gradually decreasing MBR treatment capacity, as well as shortened membrane lifetime. Several studies have shown that the addition of a bio-fouling reducer is an effective strategy to reduce the fouling propensity in the MBR process. The direct addition of adsorbents or granule activated carbon into submerged MBRs could enhance organic removal efficiency without the need for a membrane chemical cleaning step and therefore reduced operating time. For instance, it has been reported that the addition of the use of zeolite as bio-fouling reducer has been reported to stabilize the operation process of the membrane bioreactor, and also reduces membrane fouling [6,7,8,9,10]. In addition, the use of bio-fouling reducers could be a key mechanism in increasing MBRs retention time. However, this approach has not yet been tested on single-reactor MBRs with intermittent aeration; this is crucial especially during the important non-aerated period. In addition to bio-fouling reducers, quorum quenching has also been reported as a promising solution to the fouling problem, but it has not been tested widely enough to be considered for practical application in MBRs [11].

The objective of this study is to evaluate the performance of an intermittently aerated single membrane reactor with and without the addition of a bio-fouling reducer. Chemical oxygen demand (COD), nitrogen removal efficiency, and fouling reduction were monitored in all our tests. In addition, the effects of important influencing factors, such as the aerobic/anoxic time ratio, on system performance were also investigated. The PCR-amplified v3 region of 16s rDNA was analyzed using denaturing gradient gel electrophoresis (DGGE) to evaluate the microbial diversity involved in intermittently aerated MBRs.

2. Experimental Method

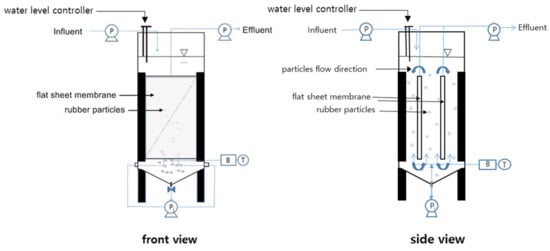

For this study, a 20 L laboratory-scale MBR system (Figure 1) was used and operated at room temperature (approximately 25 ℃). Initially, a polypropylene flat sheet membrane module (Pure-Envitech, Korea) with a pore size of 0.4 μm and an area of 0.07 m2 was immersed in the MBR. This provided a flux of 20 L/m2/h. Air was then introduced 10 cm below the membrane module through a diffuser with an air rate set at 2 L/min, corresponding to an air to water ratio (defined as the air rate divided by the liquid rate through the membrane) of about 500 [12]. Either granule activated carbon (GAC) or rubber particles roughly 2 mm in diameter were added as fouling reducers to the reactor, and they were circulated by aeration or by an internal circulation pump below the reactor during non-aeration periods. The effluent pump of the reactor was operated in an alternating fashion with a filtration time of 8 min followed by 2 min of idle time.

Figure 1.

Configuration of MBR system. P: pump, Pi: pump for internal circulation, B: blower for air supply, T: timer.

The MBRs were seeded with activated sludge from the Ujeongbu wastewater treatment plant, Korea. The hydraulic retention time of the reactor was set to 18 h. The mixed liquor suspended solids (MLSS) concentration of the sludge was maintained in the range of 3200–3400 mg/L. The aeration/non-aeration periods of the reactor for nitrogen removal were set to either 20 min/40 min, 30 min/30 min, 20 min/40 min, or 10 min/50 min. A glucose-based synthetic feed with a COD concentration of 220 mg/L was prepared by adding nutrients and other ingredients to tap water. Table 1 lists the compositions of the compounds in the synthetic wastewater.

Table 1.

Compositions of the compounds in the synthetic wastewater.

The levels of MLSS, COD, total suspended solids (TSS), total nitrogen (TN), NH4+-N, NO2−-N, and NO3−-N were measured following the Standard Method [13]. The dissolved oxygen content and pH levels, respectively, were measured using a YSI 52 dissolved oxygen meter (YSI, Inc., Yellow Springs, OH, USA) and an Accumet Ap62 pH meter (Fisher Scientific Co., Pittsburgh, PA, USA).

The rubber particles that were used as fouling reducers were produced from waste tires, and they were added to decrease the TMP in the MBR. The GAC and rubber particles were first dried and shifted with sieves No. 10 and 20 to achieve a fraction between 2.00 and 0.85 mm. The obtained particles were then washed and dried before being used in the experiment. The GAC and rubber particles had bulk densities of 0.45 and 0.85 g/cm3, respectively.

To analyze the complexity of the microbial community in the MBR, the DNA of the microorganism was extracted from the samples. The eluted DNA from the microorganisms in the samples was reamplified by PCR with forward primer 341f and reverse primer 518r [14]. The quality of the DNA sample was analyzed by DGGE. The sequencing analyses of the bands on the gradient gel and their closest reference microorganisms in the GenBank database were found using the BLAST program [15].

Analysis of the experimental results was done using the average values obtained from repeated experiments.

3. Results & Discussion

3.1. Performance of the MBR with Intermittent Aeration

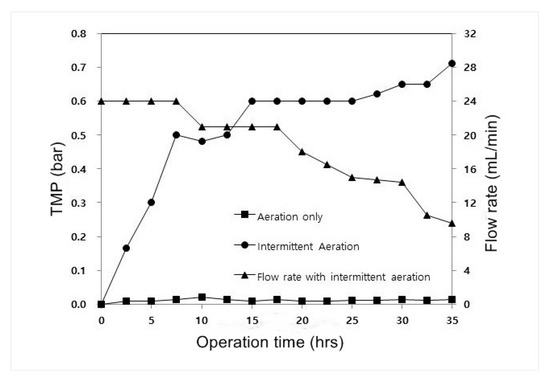

Figure 2 shows the changes in the TMP of the MBR over time with intermittent aeration (30 min air on/30 min air off) at a constant flux of 20 L/m2/h. For comparison, TMP was also monitored under continuous aeration mode. During the experiments, the MBR with intermittent aeration produced higher TMPs than the MBR with continuous aeration. The TMP for the MBR with intermittent aeration promptly rose to around 0.7 bar after the operation started, which resulted in a reduced flux (flow rate of the effluent) of less than 10 mL/min. On the other hand, the flux of the MBR with continuous aeration was constant during the experiment with no changes to the TMP. The changes of TMP in the MBR with intermittent aeration led to significant fouling on the membrane. These results indicate that including a non-aeration period during MBR operation leads to a crucial obstacle for the widespread application of intermittently aerated single membrane reactors. Earlier studies [16,17] reported that extracellular polymeric substances (EPS) and soluble microbial products (SMP) are two important factors that affect the membrane fouling propensity. The fouling problems observed in this experiment were possibly due to EPS and SMP.

Figure 2.

Trans-membrane pressure (TMP) profiles and flow rates of effluent under continuous aeration or intermittent aeration in MBRs.

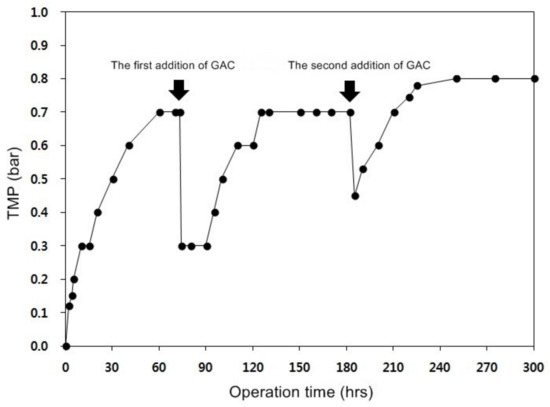

Several studies [7,9,18] have shown that the addition of a bio-fouling reducer can reduce the fouling problem in MBRs. Activated carbon is one of the most effective bio-fouling reducers, and it can both improve flux and remove organic submerged anaerobic material by the MBR. Figure 3 shows the changes in the TMP of the intermittently aerated single membrane reactor over time at a constant flux in the experiment after the addition of 0.5% (V/V) granule activated carbon (GAC). The increase in TMP took place gradually up to 0.7 bar during the experiment, indicating significant fouling on the membrane. At 70 h after the first addition of GAC, the TMP had dramatically decreased to 0.3 bar. However, the MBR could not even sustain this TMP for 20 h, then the TMP gradually increased with time back up to 0.7 bar. At 180 h, a second addition of GAC was made, and the TMP decreased back to 0.45 bar. After the second addition of GAC, the TMP increased back to 0.8 bar over time. These results indicate that the addition of GAC as a fouling reducer can reduce TMP for a short time. However, after initial improvement, the TMP in the MBR gradually increases back to previous levels. It could also be noted that the granules of activated carbon were breaking down to activated carbon powder by the end of the experiment, resulting in less friction between the activated carbon and EPS or SMP on the surface of the membrane. This result differs from previous results showing that the addition of activated carbon could reduce TMP in submerged MBRs [19].

Figure 3.

Transmembrane pressure (TMP) profiles of an intermittently aerated single membrane reactor with the addition of 0.5% (V/V) GAC.

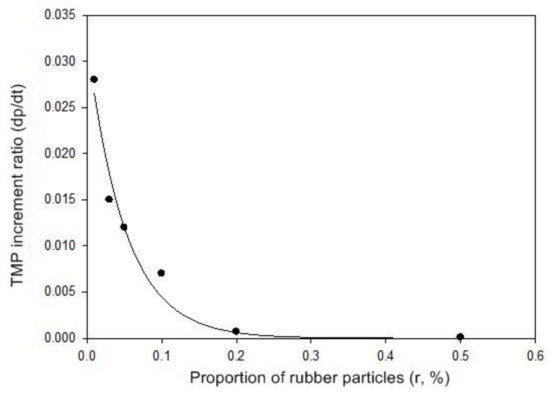

To reduce TMP in intermittently aerated single membrane reactors, rubber particles produced from waste tires were added to the MBR instead of activated carbon. Figure 4 illustrates the fouling behavior of TMP under a constant flux of 20 L/m2/h in the experiments with the addition of 0.01 to 0.5% (V/V) rubber particles to the MBR. The TMP slope (dP/dt) was measured by examining the initial pressure drop rate with time over the first 25 h. Membrane fouling after the addition of rubber particles reduced substantially compared to that without the addition of rubber particles. The addition of over 0.2% rubber particles substantially enhanced the reduction in the TMP of the MBR. In contrast to GAC, the rubber particles did not break down with internal circulation during the non-aeration periods. This allowed the rubber particles to work as a scouring agent causing additional shear forces near the membrane surface, thus helping remove deposits from the membrane.

Figure 4.

TMP increment ratio (dP/dt) versus waste rubber particle addition to MBR. Regression was conducted using the exponential equation [dP/dt = dp0/dt· EXP (-k·r)]. The pressure drop coefficient, k, was 19.76, while r represents the proportion of rubber particles (%, V/V) in the reactor. The R-square and p-value of the regression line were 0.97 and 0.0005, respectively.

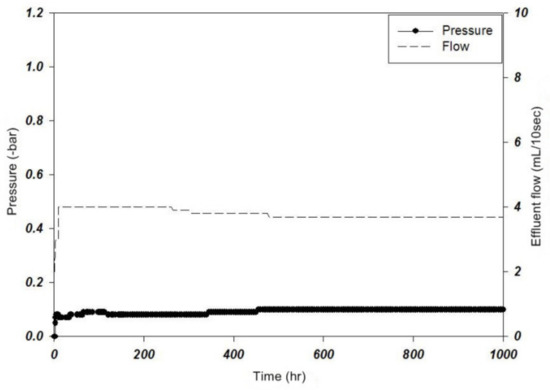

Figure 5 shows changes in TMP over time with 0.5% (V/V) rubber particles. Based on a flux of 20 L/m2/h, the TMP stabilized at around 0.1 bar, indicating less membrane fouling with rubber particles. These results indicate the possibility of operating the MBR for some time at constant flux. The result suggests that using rubber particles as a scouring agent is effective in reducing internal fouling. In contrast to our study, Hu and Stuckey concluded that a larger surface area of powdered activated carbon (PAC), compared to that of GAC, improves operating flux and critical flux in MBRs [20]. In this experiment, the addition of GAC did not lead to satisfactory results in maintaining the desired TMP, due to the breakage of GAC into PAC during internal circulation. However, the addition of rubber fouling reducing agents greatly enhanced the effective operating period and helped maintain the membrane’s permeability.

Figure 5.

TMP profile and flux of MBR with intermittent aeration (20 min aeration and 40 min non-aeration).

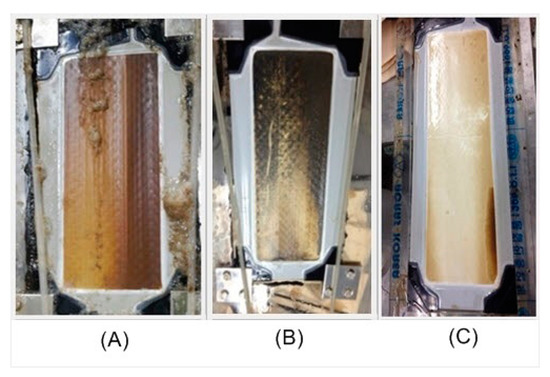

The results indicate that EPS, SMP, and colloids are the main contributors to increasing the TMP in MBRs, and this conclusion is supported by visual examinations of the membrane. After using an MBR for over 40 days without backwash, the membrane was extracted and observed. As shown in Figure 6, when no fouling reducer was used, a significant amount of deposit was found on the surface of the membrane. However, the existence of these kinds of deposits was slightly reduced when using GAC, and minimal deposits were detected when using rubber particles (the membrane had a white appearance).

Figure 6.

Images of membranes after the experimental period. (A) Without fouling reducer, (B) with 0.5% (V/V) GAC, and (C) with 0.5% (V/V) rubber particles.

Although membrane surface damages were not visually observed for over 40 days as shown in Figure 6, friction due to long-term use of the fouling reducer may damage the surface of the membrane. Considering the importance of a stable fouling reducer, it is recommended that follow-up research should be conducted.

3.2. Nutrient Removal by a Reactor with Intermittent Aeration

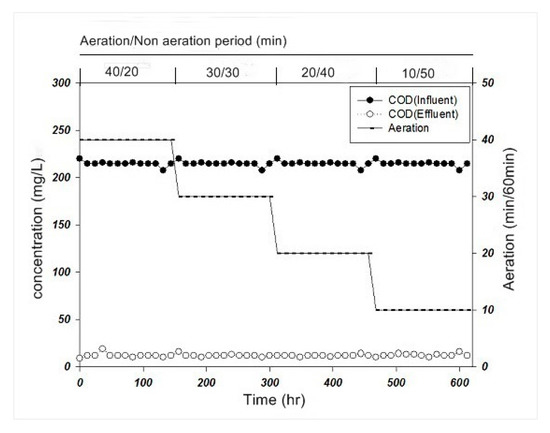

3.2.1. Organic Substance Removal

Figure 7 shows the variation in COD concentration and the removal efficiencies of an intermittently aerated MBR with the addition of 0.5% rubber particles. The initial COD concentrations were maintained at an average level of 215 mg COD/L while using aeration/non-aeration periods of 40 min/20 min, 30 min/30 min, 20 min/40 min, or 10 min/50 min in the MBR. The effluent COD concentration was less than 12.5 mg/L (with over 94% COD removal efficiency). The bioreactor performed well in organic carbon removal. These results indicate that changes in aerobic duration have virtually no effect on COD removal.

Figure 7.

COD concentration in MBR with intermittent aeration.

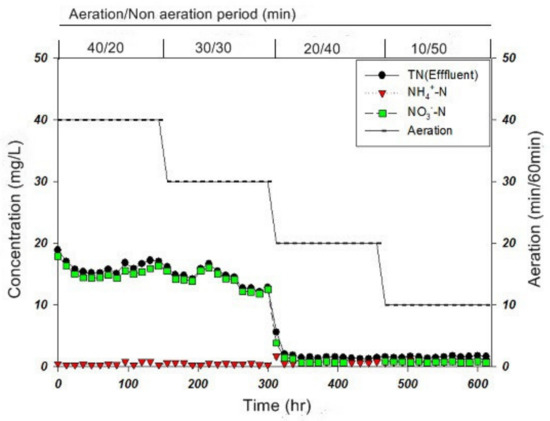

3.2.2. Nitrogen Removal

Figure 8 illustrates the variations in the T-N concentration of the MBR with intermittent aeration in the presence of 0.5% rubber particles. According to the figure, NH4+ was completely oxidized to NO3− over the experimental period, whereas the T-N removal efficiency varied according to the aeration/non-aeration period. With aeration/non-aeration periods of 40 min/20 min or 30 min/30 min, ammonia was oxidized to nitrate; however, denitrification was not satisfactorily accomplished. With aeration/non-aeration periods of 20 min/40 min or 10 min/50 min, the average effluent T-N concentration was 3.2 or 1.6 mg/L, respectively. The T-N removal efficiencies with aeration/non-aeration periods of 40 min/20 min, 30 min/30 min, 20 min/40 min, and 10 min/50 min were 36.8, 43.1, 87.0, and 93.3%, respectively. This indicates that increasing the non-aeration period of the intermittent aeration period effectively improved the T-N removal. At the same time, changes in anoxic duration did not have a notable effect on ammonia oxidation to nitrate. It can be concluded that the intermittent aeration time is important for achieving T-N removal, and the aeration/non-aeration period of 10 min/50 min is the most suitable for simultaneous COD and T-N removal with an influent COD/T-N ratio of 2.7.

Figure 8.

T-N concentration in MBR with intermittent aeration.

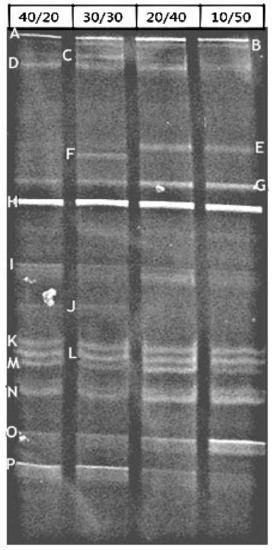

3.2.3. PCR-DGGE Analysis of the Microflora in the MBR with Intermittent Aeration

Different samples of bacterial populations were analyzed and compared using PCR-DGGE analysis targeting eubacterial 16S rDNA. Figure 9 shows the PCR-DGGE profiles of each sample showing various band patterns. The relative diversity of the microbial community and the degree of abundance of each microbial group is closely associated with the number of bands and the band intensity in the gel, respectively [21]. It was found that several dominant populations were severely inhibited using short non-aeration periods. In addition, the microbial population differed according to the intermittent aeration period. Regardless of the intermittent aeration period, bands A, B, D, H, I, K, L, and M were present in the sludge; among these bands, A and H were bright, while the intensities of B, D, and I were not clear, indicating low microbial activity. Further, bands C, F, J, and P were detected using longer aeration periods, whereas bands E, G, N, and O appeared when using longer non-aeration periods. These results suggest that the microbial diversities differ substantially according to the intermittent aeration period in the reactor.

Figure 9.

Denaturing gradient gel electrophoresis (DGGE) profiles of PCR-amplified 16S rDNA extracted from the sludge. The values of 40/20, 30/30, 20/40, and 10/50 figures on the top of the graph represent the aeration/non-aeration periods during intermittent aeration. Alphabetic bands were excised, purified, and re-amplified to determine their sequences. The gradient concentration of the denaturant used was 40–60%.

Depending on the sequences of gel bands, the accession numbers of closely related 16s rDNA were classified using the NCBI BLAST program. The affiliations and the similarity of the gel bands based on their sequences are listed in Table 2. Three major bacterial taxa were identified; four sequences were related to phylum proteobacteria, four were related to bacteria, four were related to Firmicute, and four were related to the phylum Acidobacteria. The growth of Dysgonomonasmossii, uncultured Acidobacteria bacterium, Pantoea sp., and the bacterium enrichment culture were stimulated with relatively long aeration periods in an intermittently aerated reactor. However, Lactobacillus harbinensis, Erythrobacterlitoralis, Phytobacterdiazotrophicus, and Mycobacterium sp., as represented by bands E, G, N, and O in Figure 9, respectively, were dominant when longer non-aeration periods were used.

Table 2.

Affiliation and similarity of DGGE bands based on 16S rDNA sequences.

Among these, the contributions of Dysgonomonas, Acidobacteria, and Pantoea sp. to the nitrification process have already been reported in previous studies [22,23,24]. Lactobacillus, Erythrobacter, and Mycobacterium are known to be microflora associated with the denitrification process used in wastewater treatment plants [25,26,27]. However, the contribution of Phytobacter to the denitrification process has yet to be reported. Further studies based on independent incubation should be conducted to confirm the contributions of each species to nitrification or denitrification.

4. Conclusions

The research presented here focused on the simultaneous organic compound and nitrogen removal, as well as the fouling behavior, of single-chamber MBRs with intermittent aeration. Several conclusions were drawn: First, the fouling rate is higher when employing intermittent aeration in MBRs, compared to constant aeration. The addition of GAC tended to reduce TMP initially. However, these results were not maintained as the flux was reduced over a long time. Lower TMP values were achieved under intermittent aeration with the addition of rubber particles in the MBR. Second, MBR coupling with rubber particles from waste tires extended the effective filtration duration to 40 days without using any physical cleaning techniques. However, the addition of GAC did not result in the MBR maintaining the desired TMP due to the GAC breaking down into PAC with internal circulation. Third, simultaneous organic compound and nitrogen removal can be achieved by MBRs under intermittent aeration. With an aeration/non-aeration period of 10 min/50 min, the organic compound and T-N removal efficiencies were over 94% and 93.3%, respectively. Lastly, from the analysis of the DGGE profiles, three major bacterial taxa were identified, with four sequences related to the phylum proteobacteria, four affiliated with bacteria, four affiliated with Firmicute, and four affiliated with phylum Acidobacteria. Dysgonomonas, Acidobacteria, and Pantoea sp. contributed to the nitrification process, while Lactobacillus, Erythrobacter, Phytobacter, and Mycobacterium contributed to the denitrification process.

Author Contributions

Conceptualization, T.-J.L.; methodology, M.-S.C. and Y.H.; validation, T.-J.L. and Y.H.; formal analysis, M.-S.C.; investigation, T.-J.L. and Y.H.; resources, T.-J.L.; data curation, M.-S.C.; writing—original draft preparation, M.-S.C.; writing—review and editing, T.-J.L. and Y.H.; visualization, M.-S.C.; supervision, T.-J.L.; project administration, T.-J.L.; funding acquisition, T.-J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2020R1A6A1A0304274211).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mao, X.; Myavagh, P.H.; Lotfikatouli, S.; Hsiao, B.S.; Walker, H.W. Membrane bioreactors for nitrogen removal from wastewater: A review. J. Environ. Eng. 2020, 146, 3120002. [Google Scholar] [CrossRef]

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane bioreactors—A review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects. J. Membr. Sci. 2017, 527, 207–227. [Google Scholar] [CrossRef]

- Goswami, L.; Kumar, R.V.; Borah, S.N.; Manikandan, N.A.; Pakshirajan, K.; Pugazhenthi, G. Membrane bioreactor and integrated membrane bioreactor systems for micropollutant removal from wastewater: A review. J. Water Process Eng. 2018, 26, 314–328. [Google Scholar] [CrossRef]

- Baeza, J.A.; Gabriel, D.; Lafuente, J. Effect of internal recycle on the nitrogen removal efficiency of an anaerobic/anoxic/oxic (A2/O) wastewater treatment plant (WWTP). Process Biochem. 2004, 39, 1615–1624. [Google Scholar] [CrossRef]

- Zhang, Q.; Singh, S.; Stuckey, D.C. Fouling reduction using adsorbents/flocculants in a submerged anaerobic membrane bioreactor. Bioresour. Technol. 2017, 239, 226–235. [Google Scholar] [CrossRef]

- Sohn, W.; Guo, W.; Ngo, H.H.; Deng, L.; Cheng, D.; Zhang, X. A review on membrane fouling control in anaerobic membrane bioreactors by adding performance enhancers. J. Water. Process Eng. 2021, 40, 101867. [Google Scholar] [CrossRef]

- Iorhemen, O.T.; Hamza, R.A.; Tay, J.H. Membrane fouling control in membrane bioreactors (MBRs) using granular materials. Bioresour. Technol. 2017, 240, 9–24. [Google Scholar] [CrossRef]

- Hazrati, H.; Jahanbakhshi, N.; Rostamizadeh, M. Fouling reduction in the membrane bioreactor using synthesized zeolite nano-adsorbents. J. Membr. Sci. 2018, 555, 455–462. [Google Scholar] [CrossRef]

- Akram, A.; Stuckey, D.C. Flux and performance improvement in a submerged anaerobic membrane bioreactor (SAMBR) using powdered activated carbon (PAC). Process Biochem. 2008, 43, 93–102. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, Y.; Wang, X.C.; Ngo, H.H.; Sun, Q.; Li, S.; Tang, J.; Yu, Z. Effects of powdered activated carbon addition on filtration performance and dynamic membrane layer properties in a hybrid DMBR process. Chem. Eng. J. 2017, 327, 39–50. [Google Scholar] [CrossRef]

- Liu, J.; Eng, C.Y.; Ho, J.S.; Chong, T.H.; Wang, L.; Zhang, P.; Zhou, Y. Quorum quenching in anaerobic membrane bioreactor for fouling control. Water Res. 2019, 156, 159–167. [Google Scholar] [CrossRef]

- Fallah, N.; Bonakdarpour, B.; Nasernejad, B.; AlaviMoghadam, M.R. Long-term operation of submerged membrane bioreactor (MBR) for the treatment of synthetic wastewater containing styrene as volatile organic compound (VOC): Effect of hydraulic retention time (HRT). J. Hazard. Mater. 2010, 178, 718–724. [Google Scholar] [CrossRef]

- American Public Health Association (APHA); American Water Works Association (AWWA); Water Pollution Control Federation (WEF). Standard Methods for the Examination of Water and Wastewater, 18th ed.; APHA: Washington, DC, USA, 1992. [Google Scholar]

- Han, R.; Yuan, Y.; Cao, Q.; Li, Q.; Chen, L.; Zhu, D.; Liu, D. PCR–DGGE Analysis on Microbial Community Structure of Rural Household Biogas Digesters in Qinghai Plateau. Curr. Microbiol. 2018, 75, 541–549. [Google Scholar] [CrossRef]

- García, D.; Alcántara, C.; Blanco, S.; Pérez, R.; Bolado, S.; Muñoz, R. Enhanced carbon, nitrogen and phosphorus removal from domestic wastewater in a novel anoxic-aerobic photobioreactor coupled with biogas upgrading. Chem. Eng. J. 2017, 313, 424–434. [Google Scholar] [CrossRef]

- Shuang, L.; Cui, L.; Lianfa, S. Soluble Microbial Products in Membrane Bioreactor Operation: Behaviors, Characteristics, and Fouling Potential. Water Res. 2007, 41, 95–101. [Google Scholar] [CrossRef]

- Teng, J.; Wu, M.; Chen, J.; Lin, H.; He, Y. Different fouling propensities of loosely and tightly bound extracellular polymeric substances (EPSs) and the related fouling mechanisms in a membrane bioreactor. Chemosphere 2020, 255, 126953. [Google Scholar] [CrossRef]

- Gkotsis, P.; Peleka, E.; Zouboulis, A. The Use of Natural Minerals in a Pilot-Scale MBR for Membrane Fouling Mitigation. Separations 2020, 7, 24. [Google Scholar] [CrossRef]

- Wu, B.; Zamani, F.; Lim, W.; Liao, D.; Wang, Y.; Liu, Y.; Chew, J.W.; Fane, A.G. Effect of mechanical scouring by granular activated carbon (GAC) on membrane fouling mitigation. Desalination 2017, 403, 80–87. [Google Scholar] [CrossRef]

- Hu, A.Y.; Stuckey, D.C. Activated Carbon Addition to a Submerged Anaerobic Membrane Bioreactor: Effect on Performance, Transmembrane Pressure, and Flux. J. Environ. Eng. 2007, 133, 73–80. [Google Scholar] [CrossRef]

- Zajic, J.E.; Kosaric, N.; Brosseau, J.D. Microbial production hydrogen. Adv. Biochem. Eng. 2006, 9, 57–109. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.B.; Huang, Z.; Xiao, X.; Tang, M.; Li, B.; Zhang, X. Removal of nitric oxide from biomass combustion by thermophilic nitrification-aerobic denitrification combined with catalysis in membrane biofilm reactor. Biomass Bioenergy 2019, 126, 34–40. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, Y.; Wu, J.; Wang, J. Nitrogen removal in recirculating aquaculture water with high dissolved oxygen conditions using the simultaneous partial nitrification, anammox and denitrification system. Bioresour. Technol. 2020, 305, 123037. [Google Scholar] [CrossRef] [PubMed]

- Vanparys, B.; Kim, H.; Lebbe, L.; Vos, P.D. Pedobactercaeni sp. nov., a novel species isolated from a nitrifying inoculum. Int. J. Syst. Evol. Microbial. 2005, 55, 1315–1318. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, G.; Zhou, A.; Yue, X.; Duan, Y.; Kong, X.; Zhang, X. Effect of nitrate on indole degradation characteristics and methanogenesis under mixed denitrification and methanogenesis culture. Biochem. Eng. J. 2019, 145, 33–41. [Google Scholar] [CrossRef]

- Sun, F.L.; Fan, L.L.; Wang, Y.S.; Huang, L.Y. Metagenomic analysis of the inhibitory effect of chromium on microbial communities and removal efficiency in A2O sludge. J. Hazard. Mater. 2019, 368, 523–529. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Guo, F.; Liu, Z.; Liu, Y.; Liu, H. Enhancing the electricity generation and nitrate removal of microbial fuel cells with a novel denitrifying exoelectrogenic strain EB-1. Front. Microbiol. 2018, 9, 2633. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).