Preliminary Study of New Sustainable, Alkali-Activated Cements Using the Residual Fraction of the Glass Cullet Recycling as Precursor

Abstract

Featured Application

Abstract

1. Introduction

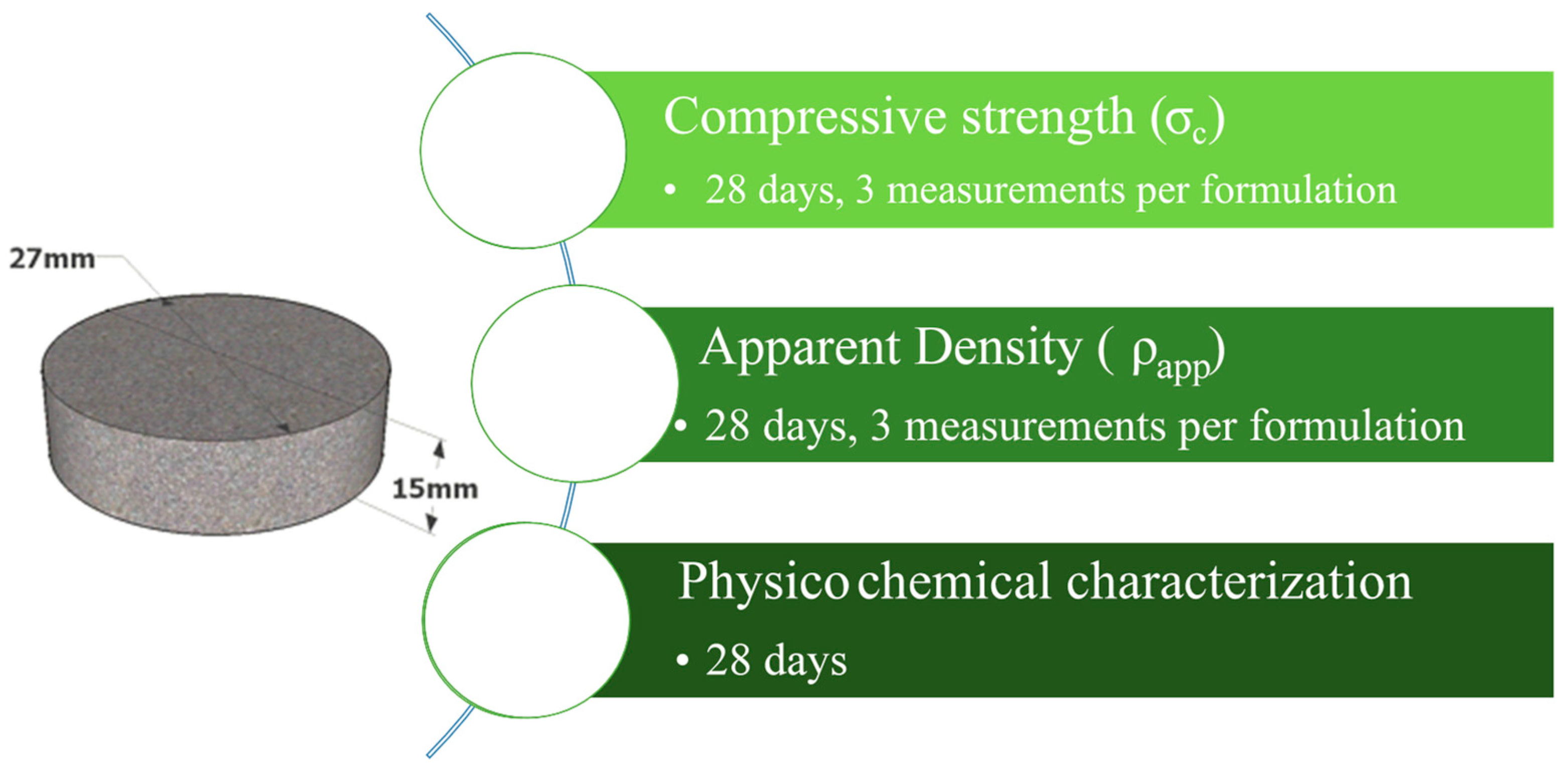

2. Materials and Methods

3. Results

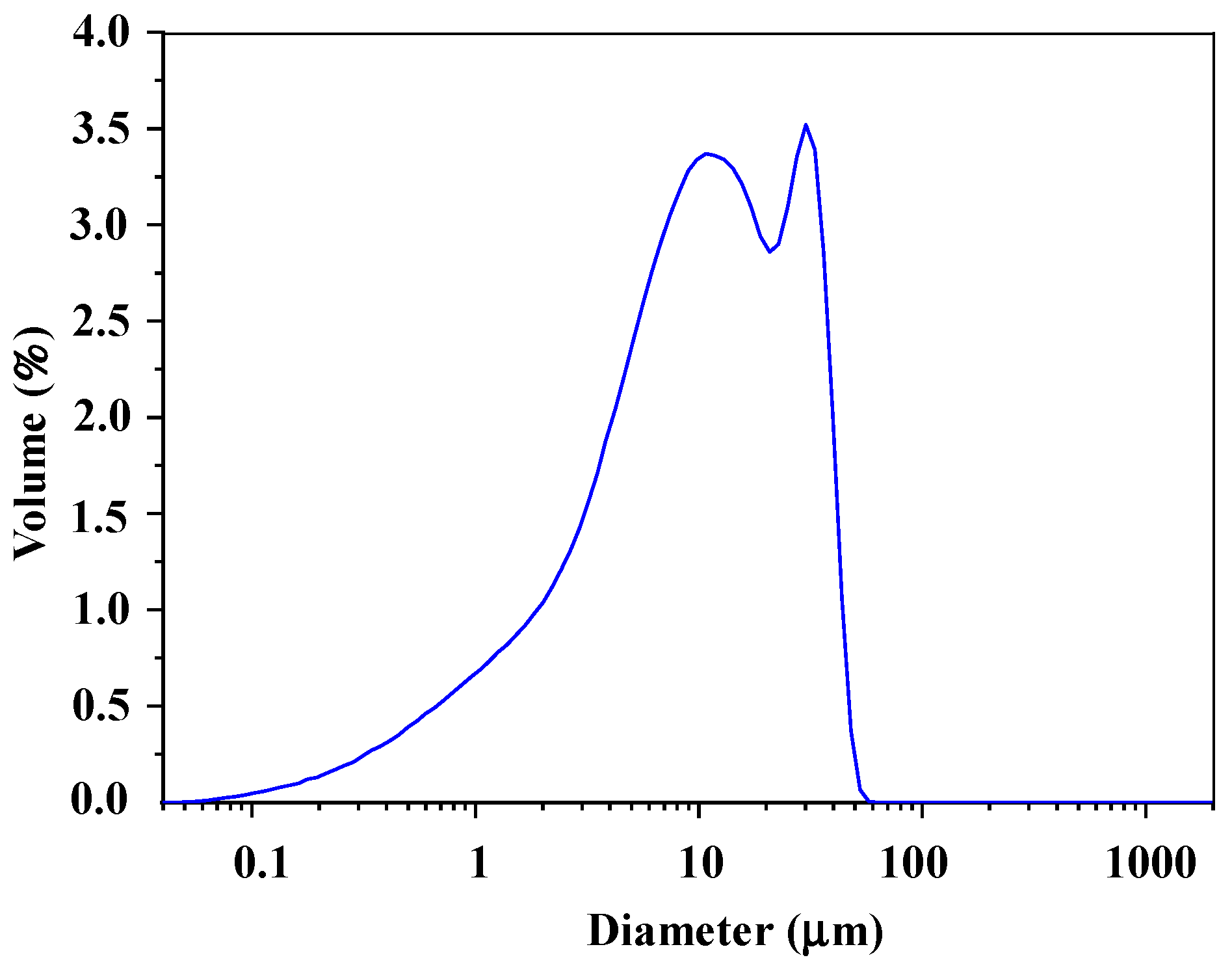

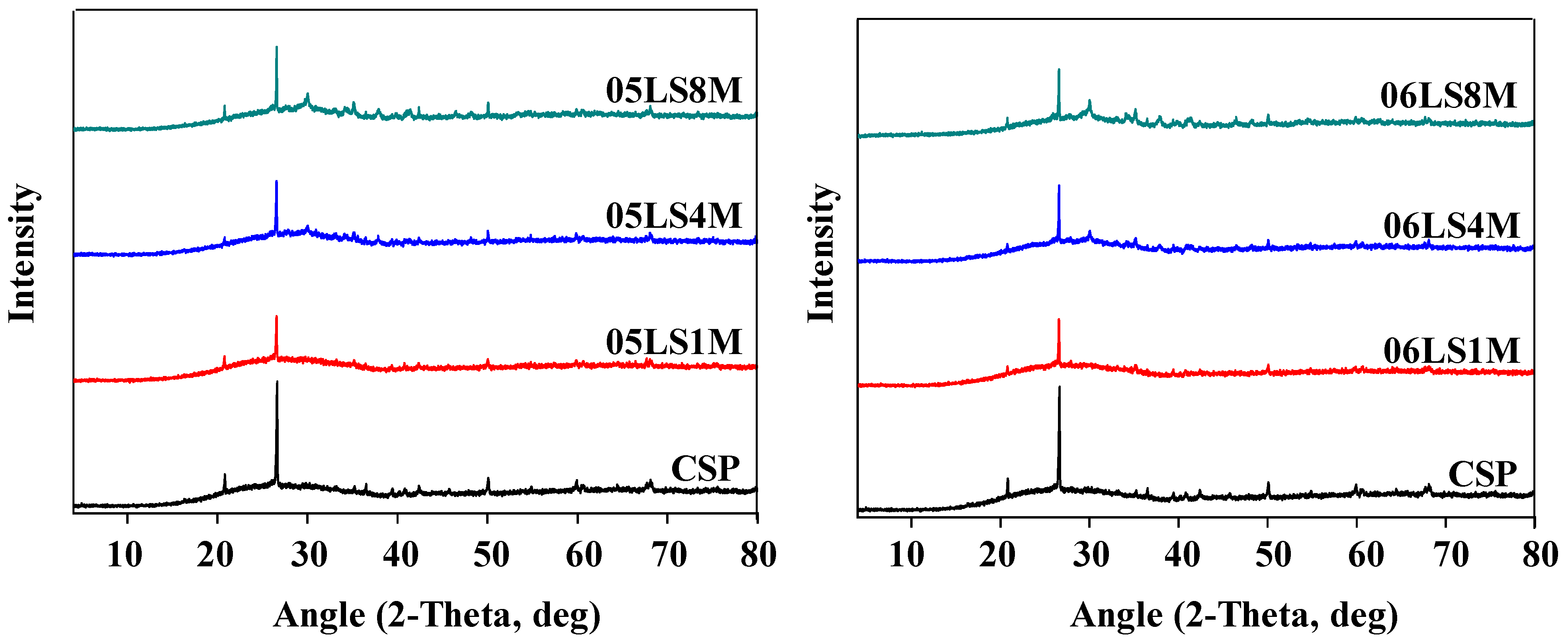

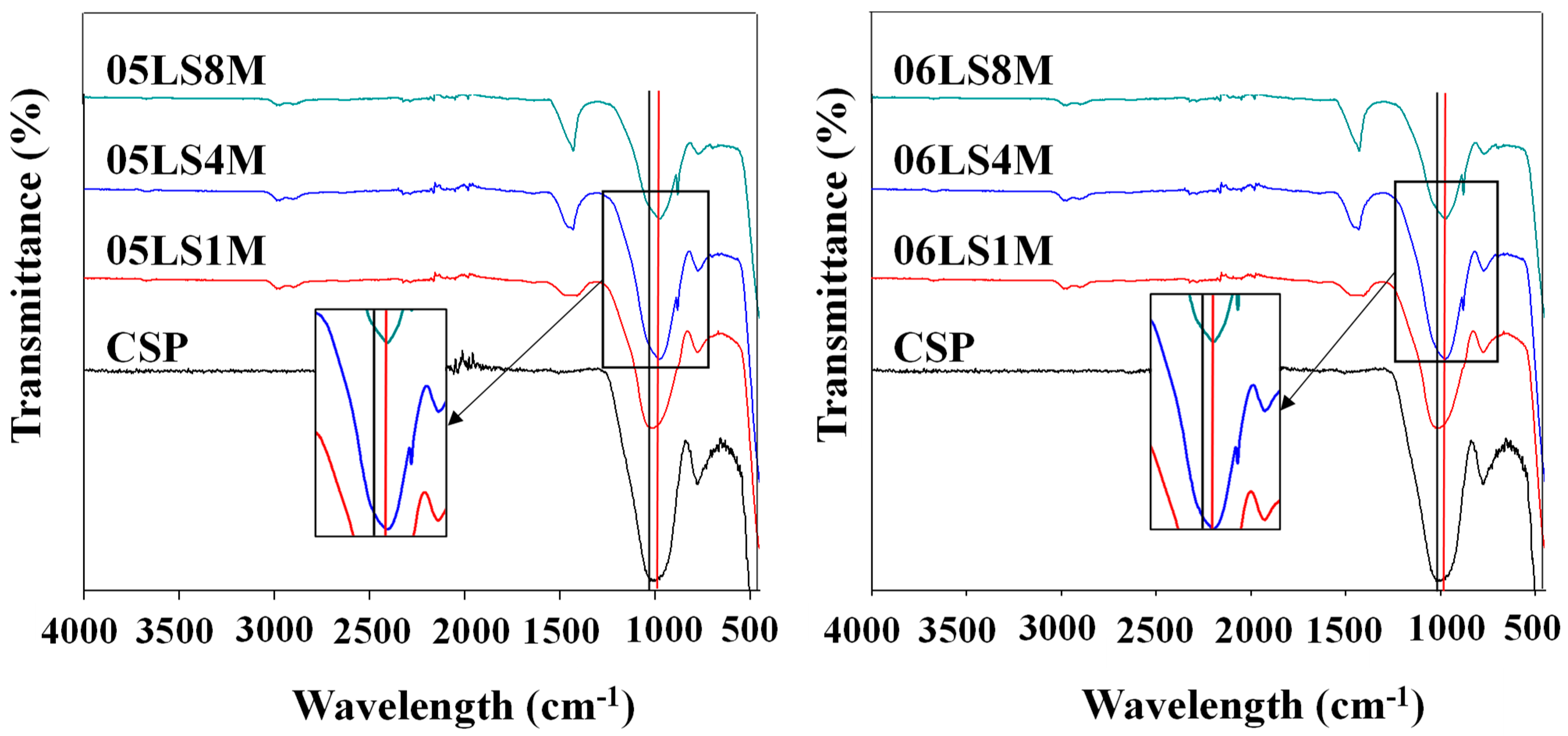

3.1. CSP Characterization

3.2. AAC Characterization

3.2.1. AAC Physico-Chemical Characterization

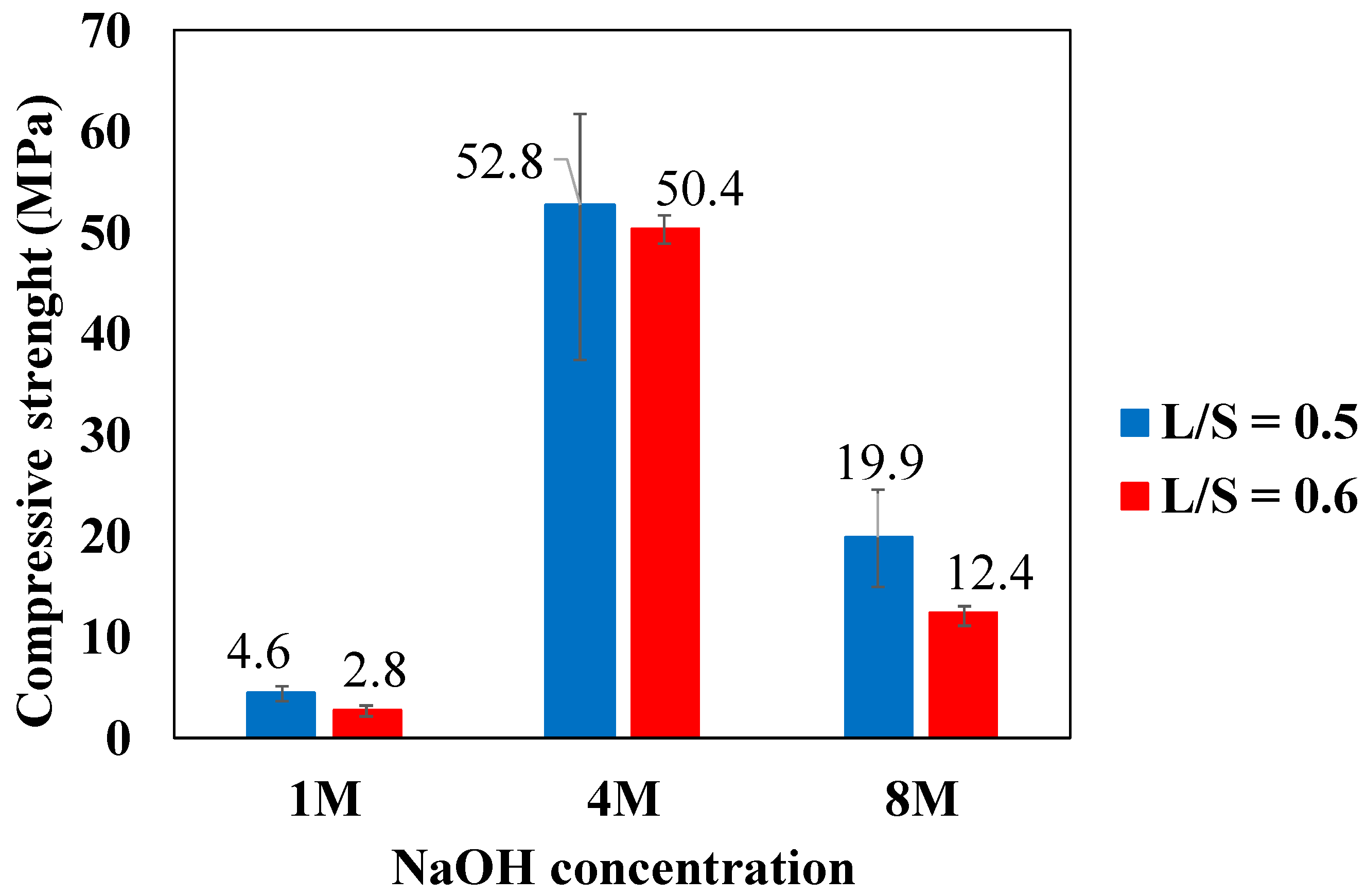

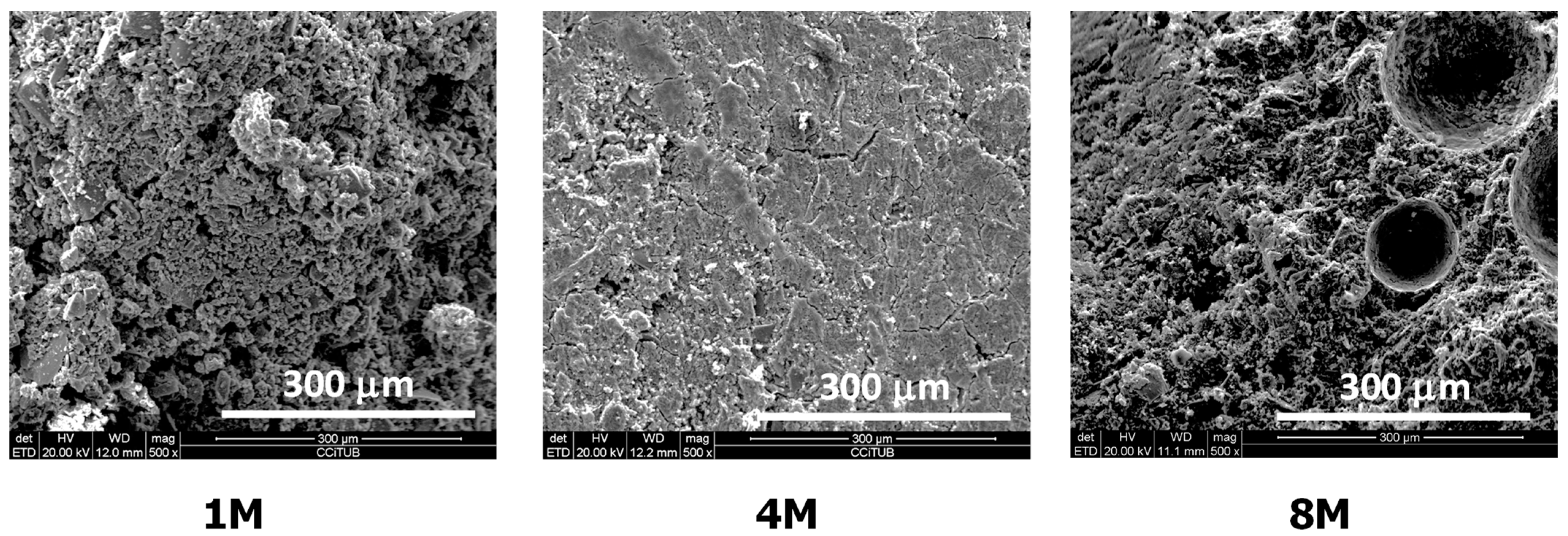

3.2.2. AAC Physical and Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. An EU Action Plan for the Circular Economy. 2015. Available online: https://ec.europa.eu/environment/strategy/circular-economy-action-plan_en (accessed on 14 April 2021).

- Giro-Paloma, J.; Maldonado-Alameda, A.; Formosa, J.; Barbieri, L.; Chimenos, J.M.; Lancellotti, I. Geopolymers based on the valorization of Municipal Solid Waste Incineration residues. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012125. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Lacasta, A.M.; Giro-Paloma, J.; Chimenos, J.M.; Haurie, L.; Formosa, J. Magnesium phosphate cements formulated with low grade magnesium oxide incorporating phase change materials for thermal energy storage. Constr. Build. Mater. 2017, 155. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Lancellotti, I.; Cannio, M.; Bollino, F.; Catauro, M.; Barbieri, L.; Leonelli, C. Geopolymers: An option for the valorization of incinerator bottom ash derived “end of waste”. Ceram. Int. 2015, 41, 2116–2123. [Google Scholar] [CrossRef]

- Morales, M.; Formosa, J.; Xuriguera, E.; Niubó, M.; Segarra, M.; Chimenos, J.M. Elastic modulus of a chemically bonded phosphate ceramic formulated with low-grade magnesium oxide determined by Nanoindentation. Ceram. Int. 2015, 41. [Google Scholar] [CrossRef]

- European Commission. Directive of the European Parliament and of the Council—Amending Directive 94/62/EC on Packaging and Packaging Waste. 2015. Available online: https://www.eea.europa.eu/policy-documents/directive-eu-2018-852-of (accessed on 14 April 2021).

- Eurostat, Recycling Rates for Glass Packaging Waste. 2018; Available online: https://ec.europa.eu/eurostat/databrowser/product/view/ENV_WASPACR (accessed on 2 February 2018).

- The European Container Glass Federation: Glass Packaging Closed Loop Recycling Up to 74% in the EU. 2016. Available online: https://feve.org/glass-packaging-closed-loop-recycling-74-eu/ (accessed on 14 April 2021).

- Beerkens, R.; Kers, G.; Van Santen, E.; TNO Glass Group. Recycling of Post-Consumer Glass: Energy Savings, CO2 Emissions Reduction, Effects on Glass Quality and Glass Melting. Available online: https://repository.tno.nl/islandora/object/uuid%3Ae2aab36a-2fa0-4cff-b085-f34d992aed79 (accessed on 14 April 2021).

- Agència de Residus de Catalunya. Balanç de les Dades Estadístiques de Residus Municipals de L’any 2016; Agència de Residus de Catalunya: Barcelona, Spain, 2017. [Google Scholar]

- Marını, P.; Bellopede, R.; Zanottı, G.; Ramon, V. Waste of the secondary glass waste (glass waste 3): New solutions for a sustainable industrial recovery. In Proceedings of the 15th International Conference on Environmental Science and Technology, Rhodes, Greece, 31 August–2 September 2017. [Google Scholar]

- Beerkens, R.; Van Santen, E. Recycling in container glass production present problems in European glass industry. In Proceedings of the 66th Conference on Glass Problems: Collection of Papers Presented at the 66th Conference on Glass Problems, The University of Illinois at Urbana-Champaign, Champaign, IL, USA, 24–26 October 2005; John Wiley & Sons: Hoboken, NJ, USA, 2004; pp. 181–202. [Google Scholar]

- Dutch Waste Management Association. Closing the Glass Recycling Loop; Dutch Waste Management Association: Hertogenbosch, The Netherlands, 2015; pp. 1–5. [Google Scholar]

- Mogensen GmbH &, Co. KG Glass Recycling. 2008. Available online: https://koasltd.com/ckfinder/userfiles/images/PDF/Glass_Recycling_2008.pdf (accessed on 14 April 2021).

- European Commission. Directive of the European Parliament and of the Council—Amending Directive 2008/98/EC on Waste. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015PC0595 (accessed on 14 April 2021).

- Lou, X.F.; Nair, J. The impact of landfilling and composting on greenhouse gas emissions—A review. Bioresour. Technol. 2009, 100, 3792–3798. [Google Scholar] [CrossRef] [PubMed]

- Kasassi, A.; Rakimbei, P.; Karagiannidis, A.; Zabaniotou, A.; Tsiouvaras, K.; Nastis, A.; Tzafeiropoulou, K. Soil contamination by heavy metals: Measurements from a closed unlined landfill. Bioresour. Technol. 2008, 99, 8578–8584. [Google Scholar] [CrossRef] [PubMed]

- Assmuth, T.W.; Strandberg, T. Ground water contamination at Finnish landfills. Water. Air. Soil Pollut. 1993, 69, 179–199. [Google Scholar] [CrossRef]

- Marijan, A.; Mikac, N.; Cosovic, B.; Prohic, E.; Soukup, V. The impact of contamination from a municipal solid waste landfill (Zagreb, Croatia) on underlying soil. Water Sci. Technol. 1998, 37, 203–210. [Google Scholar]

- Huete-Hernández, S.; Maldonado-Alameda, A.; Giro-Paloma, J.; Chimenos, J.M.; Formosa, J. Fabrication of sustainable magnesium phosphate cement micromortar using design of experiments statistical modelling: Valorization of ceramic-stone-porcelain containing waste as filler. Ceram. Int. 2020. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Alonso, S.; Palomo, A. Calorimetric study of alkaline activation of calcium hydroxide-metakaolin solid mixtures. Cem. Concr. Res. 2001, 31, 25–30. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, X.; Zhao, A.; Struble, L.J.; Yang, E.H. Synthesis of high strength binders from alkali activation of glass materials from municipal solid waste incineration bottom ash. J. Clean. Prod. 2019, 212, 261–269. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Compressive strength and microstructure analysis of geopolymer paste using waste glass powder and fly ash. J. Clean. Prod. 2016, 172, 2892–2898. [Google Scholar] [CrossRef]

- Xiao, R.; Ma, Y.; Jiang, X.; Zhang, M.; Zhang, Y.; Wang, Y.; Huang, B.; He, Q. Strength, microstructure, efflorescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J. Clean. Prod. 2020, 252, 119610. [Google Scholar] [CrossRef]

- Part, W.K.; Ramli, M.; Cheah, C.B. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial byproducts. Handb. Low Carbon Concr. 2016, 77, 263–334. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and valorisation of wastes through use in producing alkali-activated cement materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass as a precursor in alkaline activation: Chemical process and hydration products. Constr. Build. Mater. 2017, 139, 342–354. [Google Scholar] [CrossRef]

- Lu, J.X.; Poon, C.S. Use of waste glass in alkali activated cement mortar. Constr. Build. Mater. 2018, 160, 399–407. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of inorganic polymer (geopolymer) mortars made of glass cullet. J. Mater. Sci. 2012, 47, 2782–2797. [Google Scholar] [CrossRef]

- Cheng, J.; Xiao, Z.; Yang, K.; Wu, H. Viscosity, fragility and structure of Na2O-CaO-Al2O3-SiO2 glasses of increasing Al/Si ratio. Ceram. Int. 2013, 39, 4055–4062. [Google Scholar] [CrossRef]

- Norton, M.G.; Carter, C.B. Ceramic Materials Science and Engineering; Springer: New York, NY, USA, 2007. [Google Scholar]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A.; Macphe, D.E. Effect of calcium additions on N–A–S–H cementitious gels. J. Am. Ceram. Soc. 2010, 1934–1940. [Google Scholar] [CrossRef]

- Onisei, S.; Pontikes, Y.; Van Gerven, T.; Angelopoulos, G.N.; Velea, T.; Predica, V.; Moldovan, P. Synthesis of inorganic polymers using fly ash and primary lead slag. J. Hazard. Mater. 2012, 205–206, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Criado, M.; Aperador, W.; Sobrados, I. Microstructural and mechanical properties of alkali activated Colombian raw materials. Materials 2016, 9, 158. [Google Scholar] [CrossRef]

| Reference | CSP (g) | NaOH Solution (g) | L/S (wt %) | ||

|---|---|---|---|---|---|

| 1 M | 4 M | 8 M | |||

| 05LS1M | 16 | 8.0 | 0.5 | ||

| 05LS4M | 16 | 8.0 | 0.5 | ||

| 05LS8M | 16 | 8.0 | 0.5 | ||

| 06LS1M | 16 | 9.6 | 0.6 | ||

| 06LS4M | 16 | 9.6 | 0.6 | ||

| 06LS8M | 16 | 9.6 | 0.6 | ||

| Compounds | CSP (wt %) |

|---|---|

| SiO2 | 70.78 |

| Na2O | 11.15 |

| CaO | 9.37 |

| Al2O3 | 4.81 |

| MgO | 1.61 |

| K2O | 0.94 |

| Fe2O3 | 0.57 |

| TiO2 | 0.13 |

| P2O5 | 0.04 |

| MnO | 0.02 |

| LOI | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giro-Paloma, J.; Maldonado-Alameda, A.; Alfocea-Roig, A.; Mañosa, J.; Chimenos, J.M.; Formosa, J. Preliminary Study of New Sustainable, Alkali-Activated Cements Using the Residual Fraction of the Glass Cullet Recycling as Precursor. Appl. Sci. 2021, 11, 3528. https://doi.org/10.3390/app11083528

Giro-Paloma J, Maldonado-Alameda A, Alfocea-Roig A, Mañosa J, Chimenos JM, Formosa J. Preliminary Study of New Sustainable, Alkali-Activated Cements Using the Residual Fraction of the Glass Cullet Recycling as Precursor. Applied Sciences. 2021; 11(8):3528. https://doi.org/10.3390/app11083528

Chicago/Turabian StyleGiro-Paloma, Jessica, Alex Maldonado-Alameda, Anna Alfocea-Roig, Jofre Mañosa, Josep Maria Chimenos, and Joan Formosa. 2021. "Preliminary Study of New Sustainable, Alkali-Activated Cements Using the Residual Fraction of the Glass Cullet Recycling as Precursor" Applied Sciences 11, no. 8: 3528. https://doi.org/10.3390/app11083528

APA StyleGiro-Paloma, J., Maldonado-Alameda, A., Alfocea-Roig, A., Mañosa, J., Chimenos, J. M., & Formosa, J. (2021). Preliminary Study of New Sustainable, Alkali-Activated Cements Using the Residual Fraction of the Glass Cullet Recycling as Precursor. Applied Sciences, 11(8), 3528. https://doi.org/10.3390/app11083528