Design Study of Steel Fibre Reinforced Concrete Shaft Lining for Swelling Ground in Toronto, Canada

Abstract

1. Introduction

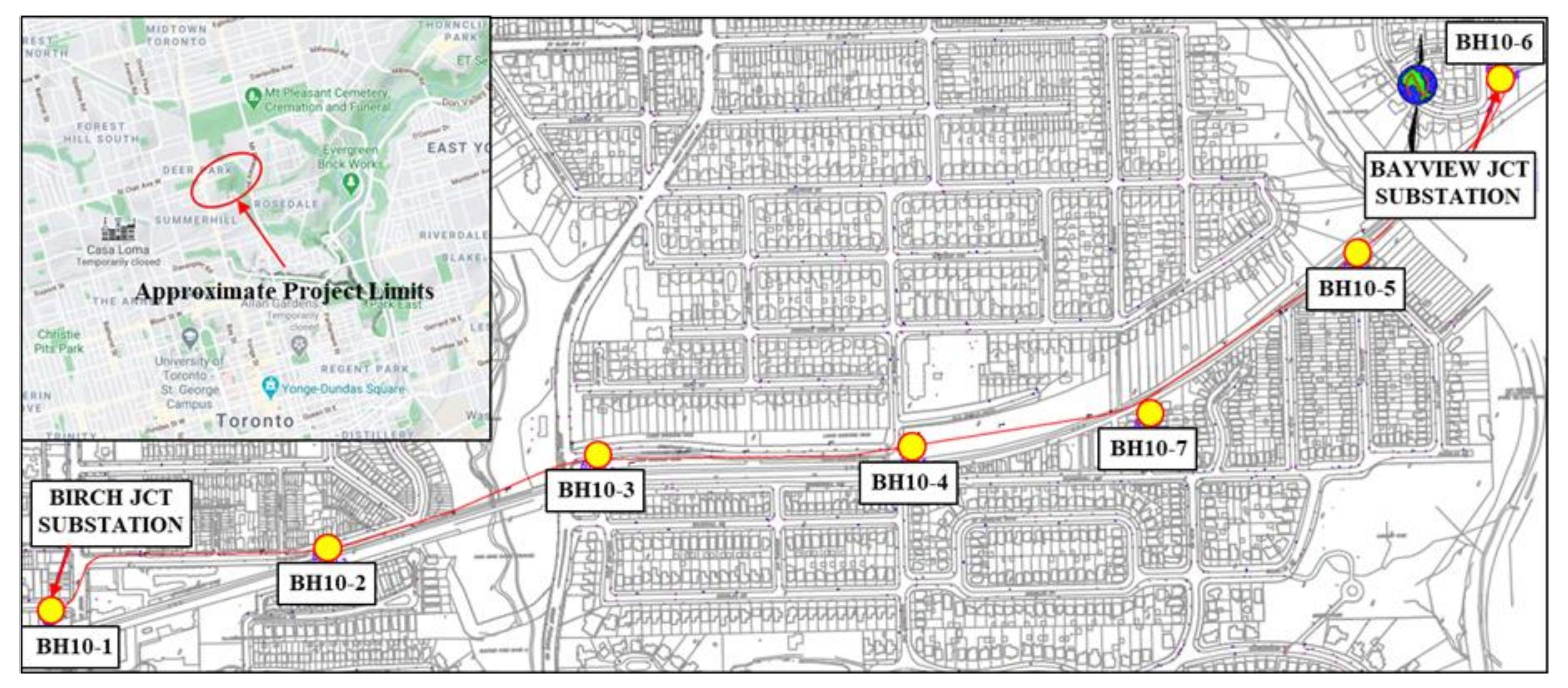

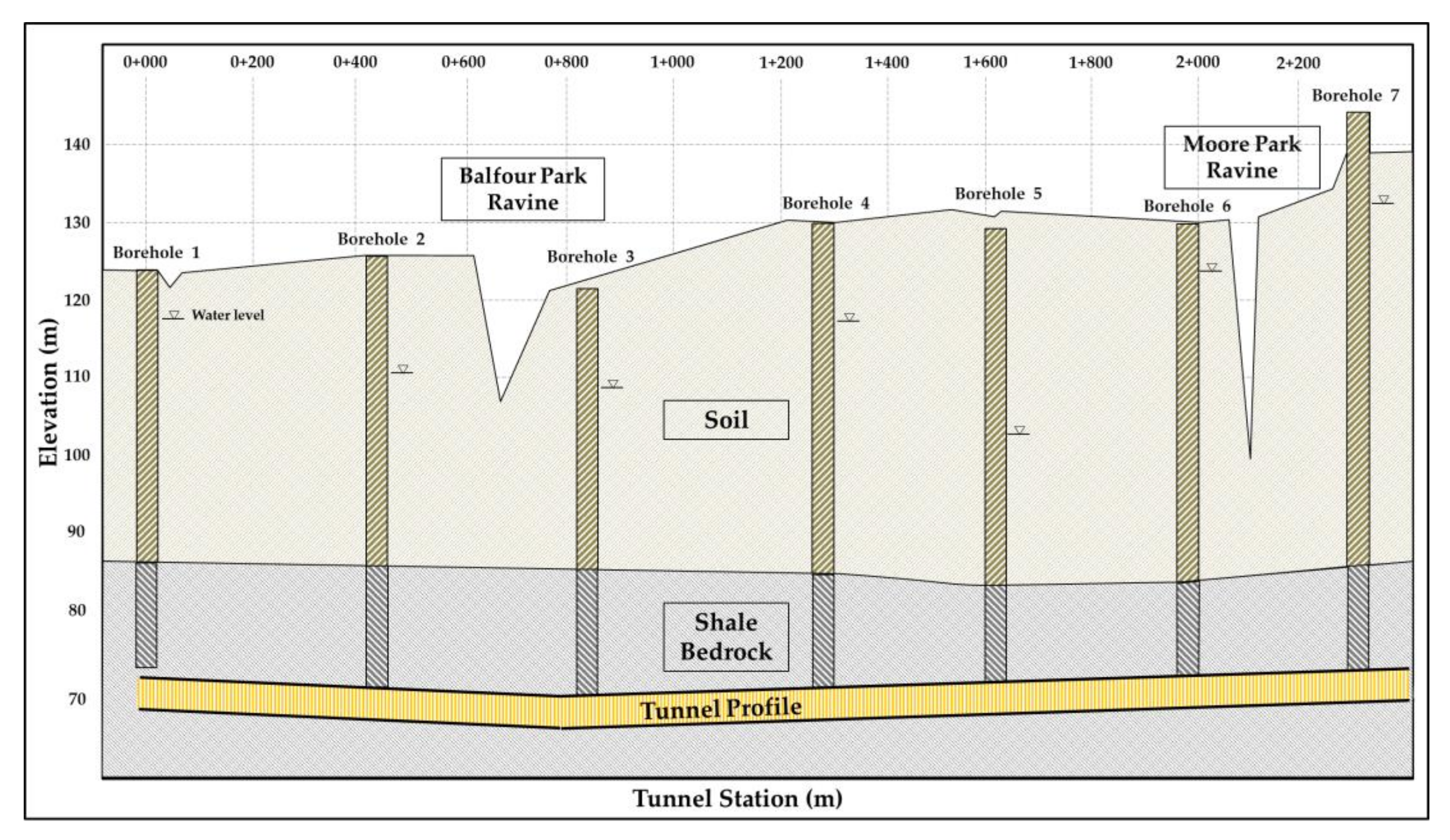

2. Project Description

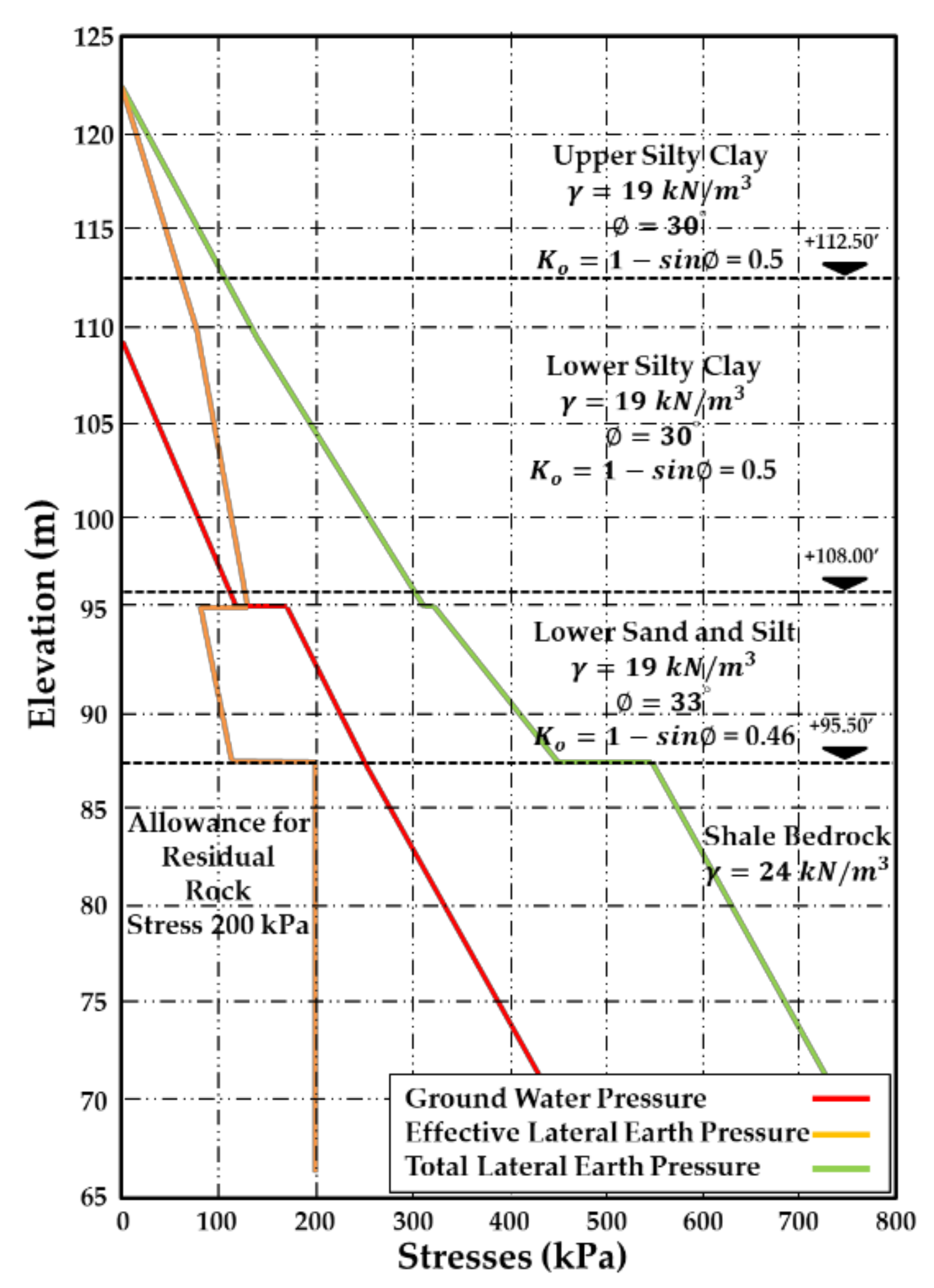

3. Key Design Issues

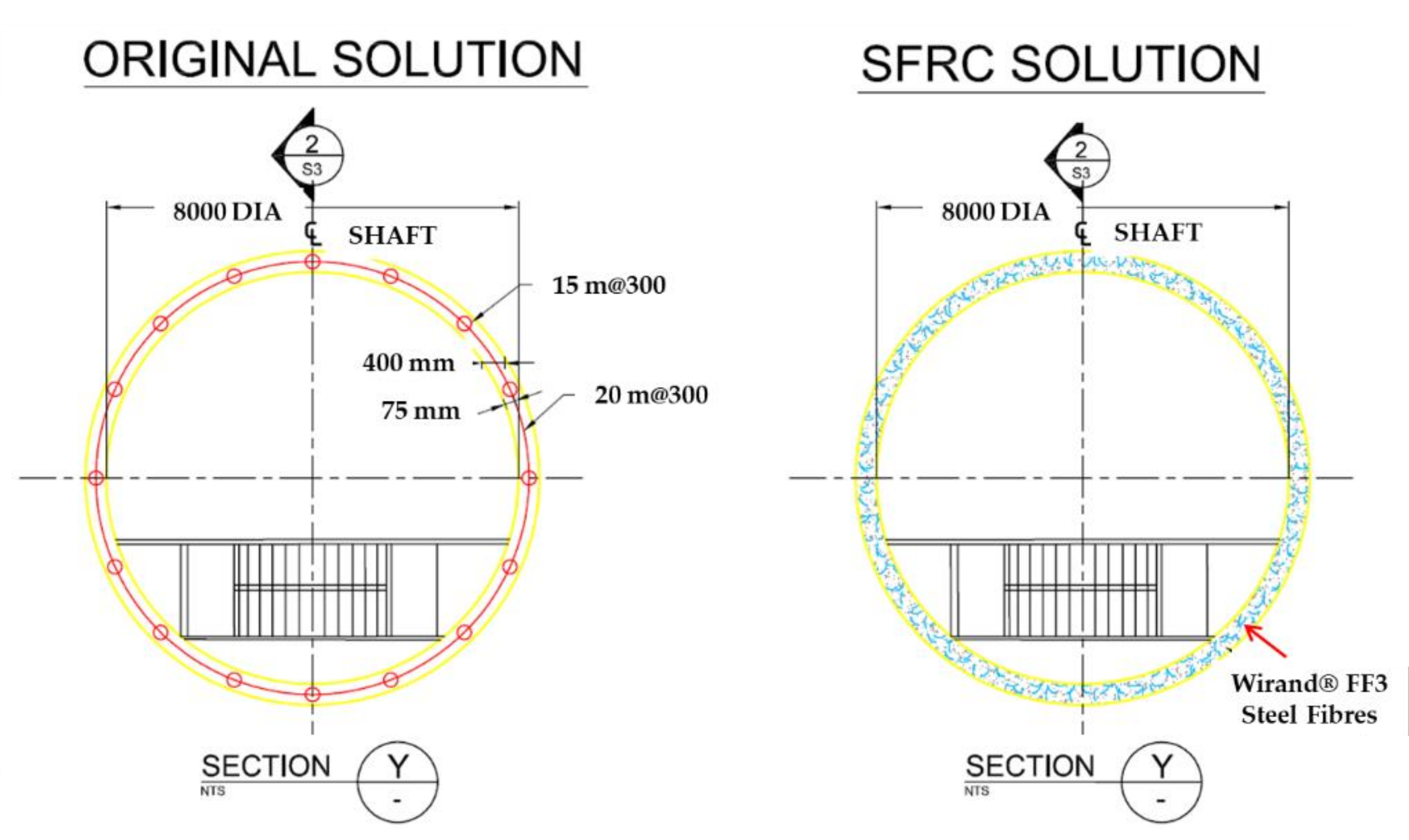

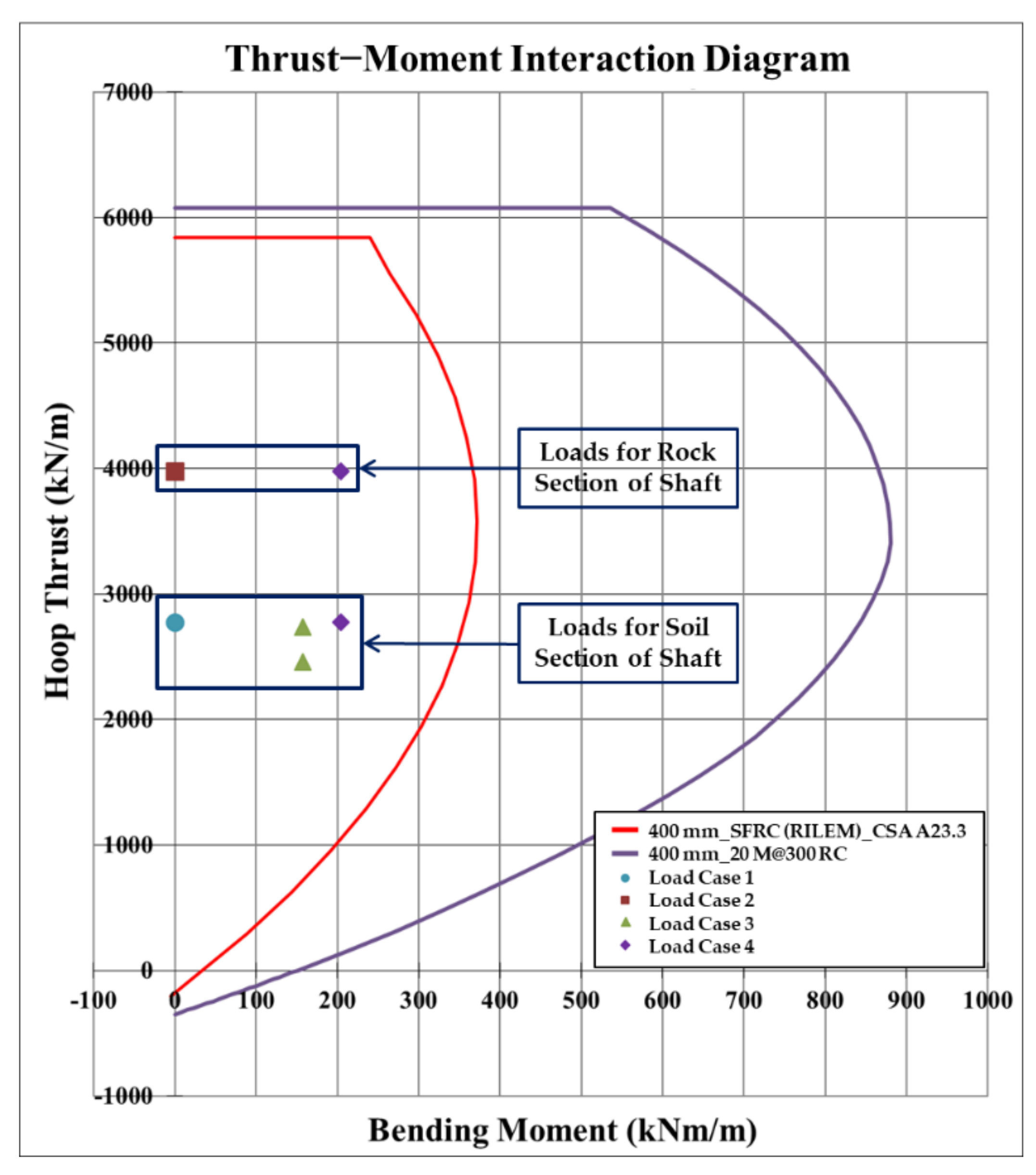

4. Structural Design of Lining

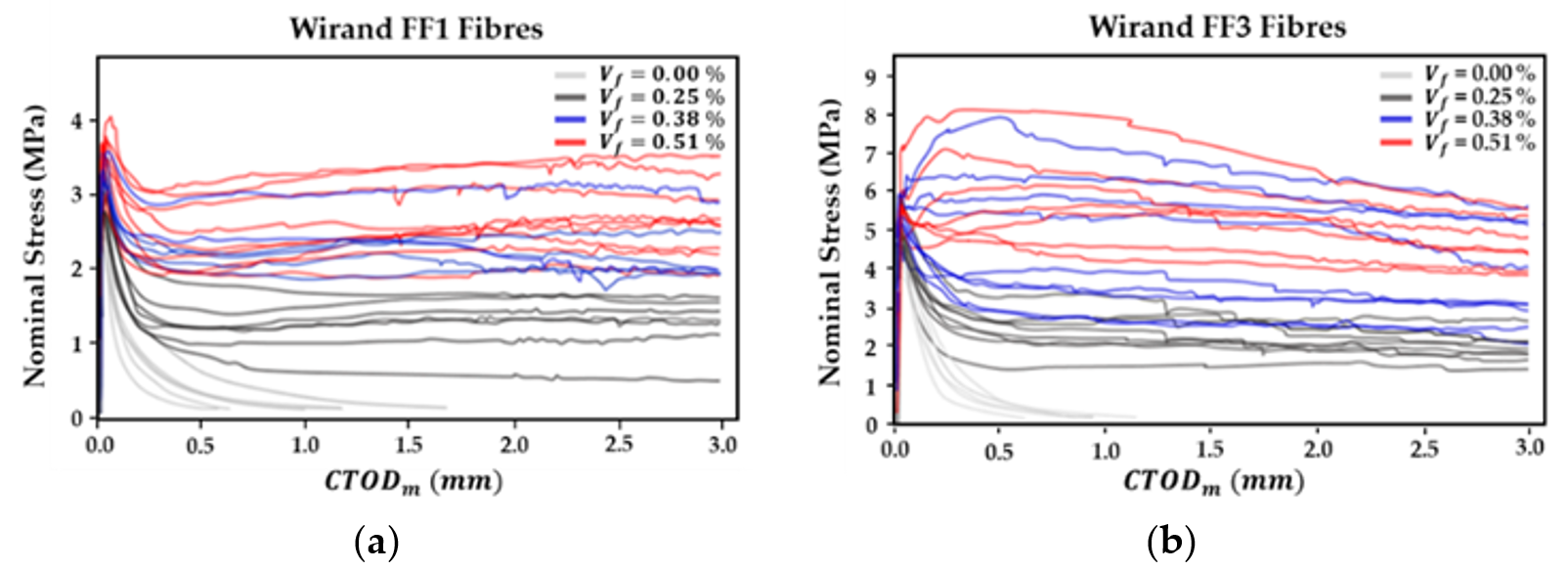

4.1. Theoretical Approaches for the Alternative Design Using SFRC

4.2. Design of Shaft Using SFRC

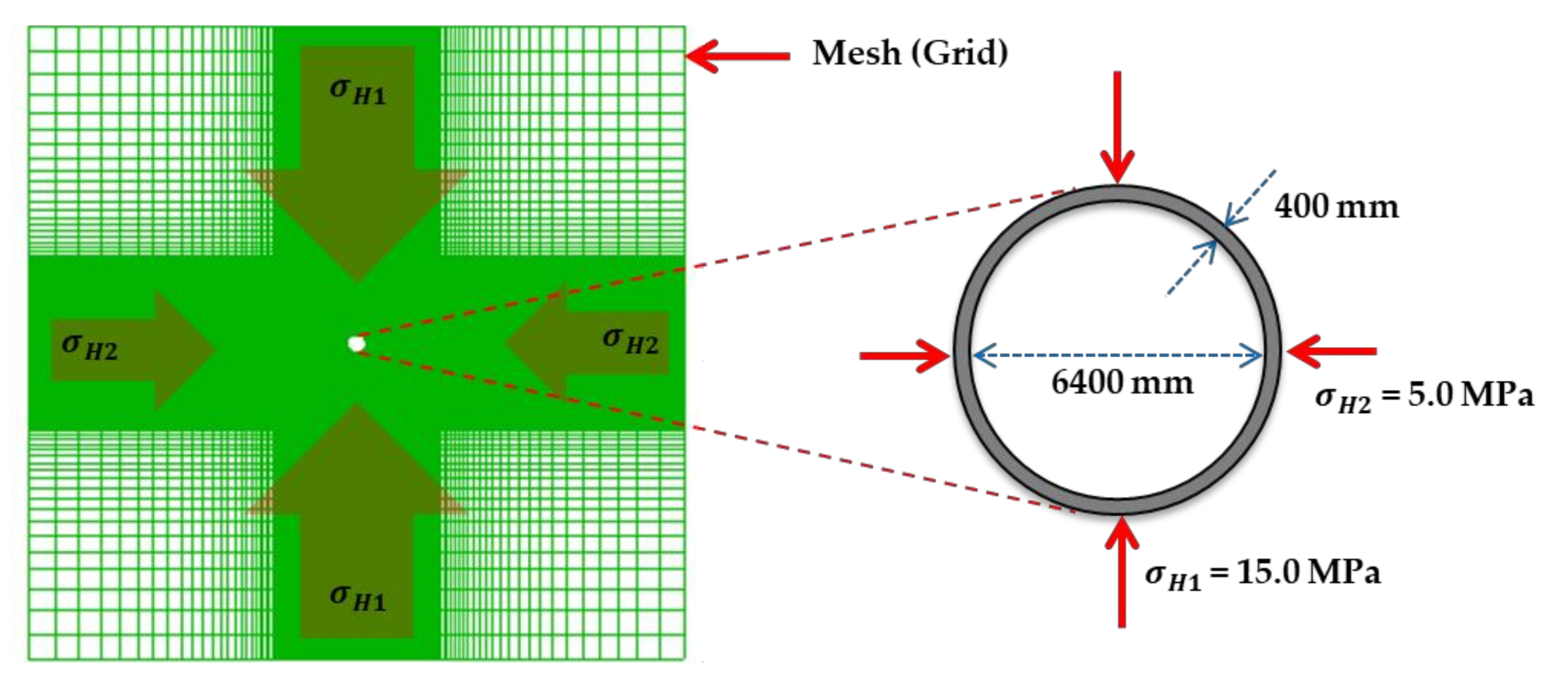

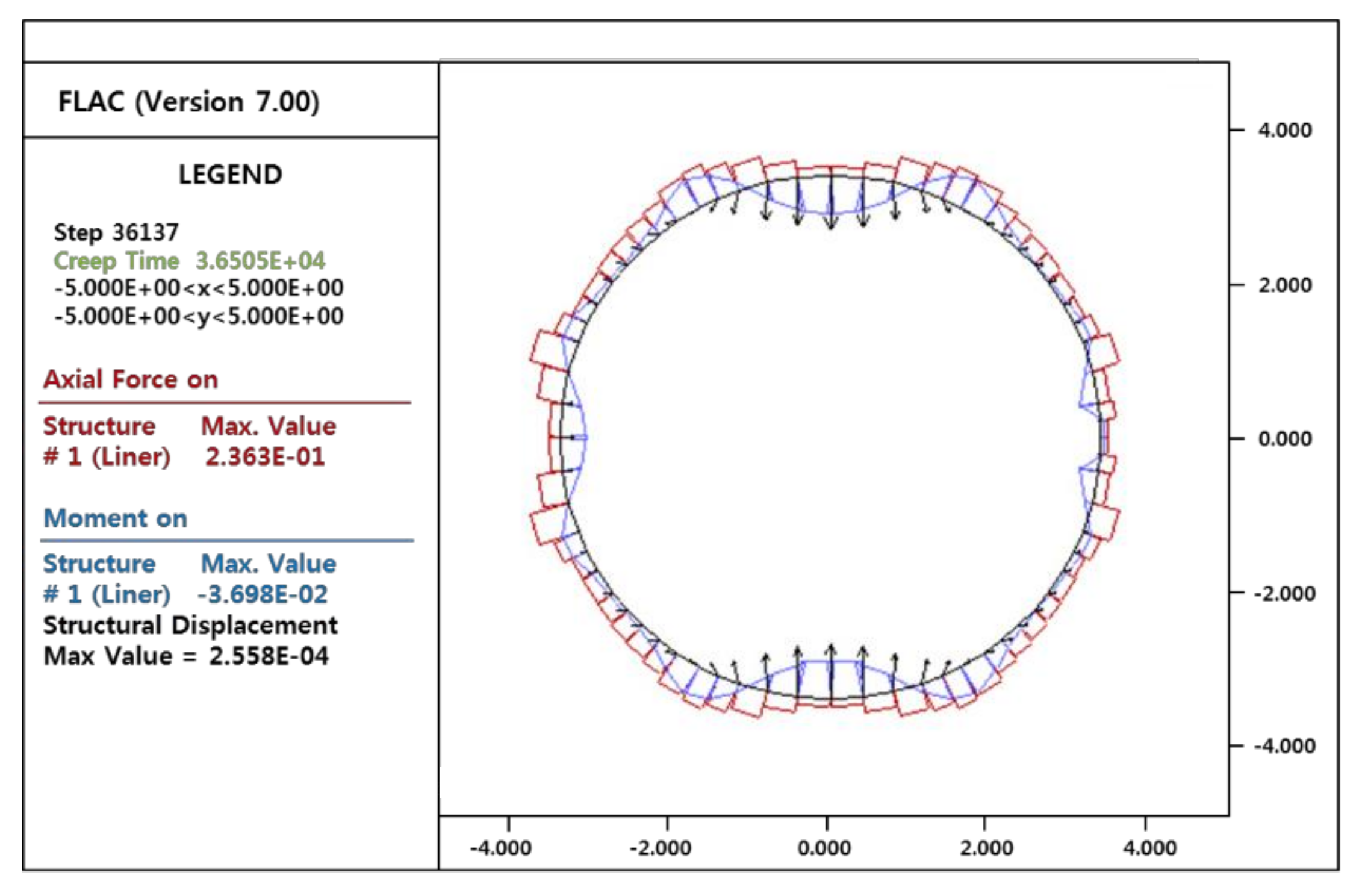

5. Numerical Analysis

5.1. Analysis Method and Input Data

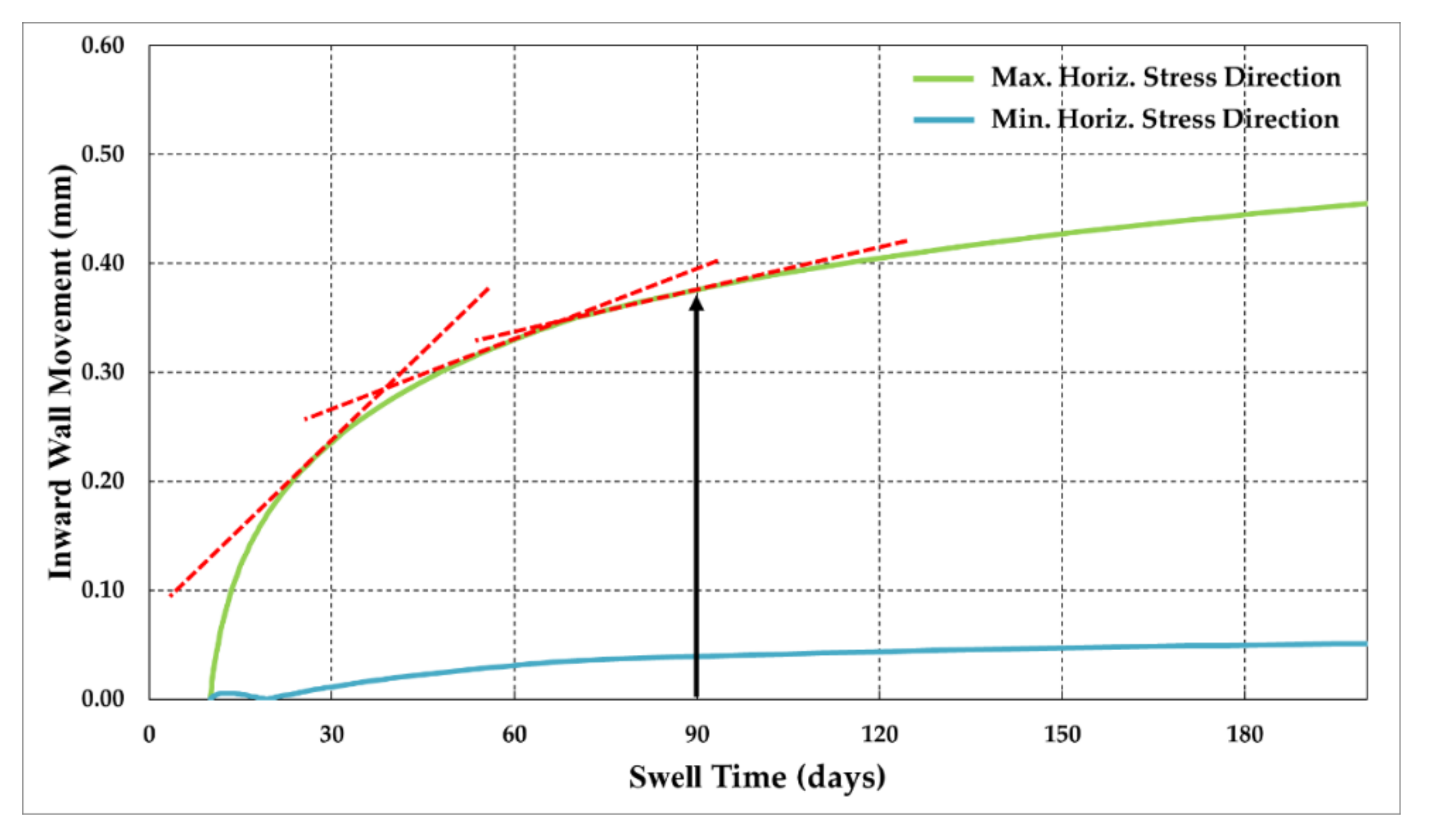

5.2. Results of Inward Wall Movement

5.3. Results of Mobilised Lining Forces

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shin, Y.W.; Moon, K.S.; Joo, K.W. A study on asymmetric load on circular shaft due to engineering characteristics of discontinuous rock masses. J. Korean Tunn. Undergr. Sp. Assoc. 2008, 10, 119–128. [Google Scholar]

- You, K.H.; Song, W.Y. A case study on a tunnel back analysis to minimize the uncertainty of ground properties based on artificial neural network. J. Korean Tunn. Undergr. Sp. Assoc. 2012, 14, 37–53. [Google Scholar] [CrossRef]

- Qin, H.; Xie, X.G.; Vrugt, J.A.; Zeng, K.; Hong, G. Underground structure defect detection and reconstruction using cross GPR and Bayesian wave form inversion. Autom. Constr. 2016, 68, 156–169. [Google Scholar] [CrossRef]

- Gazetas, G.; Gerolymos, N.; Anastasopoulos, I. Response of three Athens metro underground structures in the 1999 Parnitha earthquake. Soil. Dyn. Earthq. Eng. 2005, 25, 617–633. [Google Scholar] [CrossRef]

- Zhang, X.P.; Jiang, Y.J.; Sugimoto, S. Seismic damage assessment of mountain tunnel: A case study on the Tawarayama tunnel due to the 2016 Kumamoto Earthquake. Tunn. Undergr. Sp. Tech. 2018, 71, 138–148. [Google Scholar] [CrossRef]

- Zhang, X.P.; Jiang, Y.J.; Maegawa, K.H. Mountain tunnel under earthquake force: A review of possible causes of damages and restoration methods. J. Rock Mech. Geotech. Eng. 2020, 12, 414–426. [Google Scholar] [CrossRef]

- Shin, Y.W.; Moon, K.S.; Kang, H.T.; Lee, S.H. Investigation of earth pressure on vertical shaft by field monitoring. J. Korea Geo Environ. Soc. 2008, 9, 63–76. [Google Scholar]

- Kim, K.Y.; Lee, D.S.; Cho, J.Y.; Jeong, S.S.; Lee, S.J. The effect of arching pressure on a vertical circular shaft. Tunn. Undergr. Sp. Tech. 2013, 37, 10–21. [Google Scholar] [CrossRef]

- Park, S.C.; Moon, H.G. Stress-path and stress-mode analyses of a circular-shaped shaft excavated in various in-situ rock stress states. J. Korean Soc. Miner. Energy Resour. Eng. 2014, 51, 794–807. [Google Scholar] [CrossRef]

- Zhao, Z.; Jing, L.; Pei, Q.; Ma, H.W.; Wang, Z.H. An experimental study of the dynamic split tension properties of reinforced concrete. Strength Mater. 2016, 48, 63–68. [Google Scholar] [CrossRef]

- Simonsson, E. Complex shapes with textile reinforced concrete. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2017. [Google Scholar]

- ITA Working Group on Maintenance and Repair of Underground Structures. Report on the damaging effects of water on tunnels during their working life. Tunn. Undergr. Sp. Tech. 1991, 6, 11–76. [Google Scholar] [CrossRef]

- Garden, H.N.; Hollaway, L.C.; Thorne, A.M. The strengthening and deformation behaviour of reinforced concrete beams upgraded using prestressed composite plates. Mater Struct. 1998, 31, 247–258. [Google Scholar] [CrossRef]

- Chang, S.H.; Lee, G.P.; Choi, S.W.; Bae, G.J. State of the art of segment lining in shield tunnel and statistical analysis of its key design parameters. Tunn. Undergr. Space 2011, 21, 427–438. [Google Scholar]

- Song, J.L.; Li, Y.X.; Xu, W.; Lui, H.; Lu, Y. Inexpensive and non-fluorinated superhydrophobic concrete coating for anti-icing and anti-corrosion. J. Colloid Interface Sci. 2019, 541, 86–92. [Google Scholar] [CrossRef]

- Bowser, M.; Stephenson, J. Segmental construction in the cold: Bridging the grand river. Struct. Eng. Int. 2017, 27, 29–31. [Google Scholar] [CrossRef]

- Babaie, R.; Abolfazli, M.; Fahimifar, A. Mechanical properties of steel and polymer fiber reinforced concrete. J. Mech. Behav. Mater. 2019, 28, 119–134. [Google Scholar] [CrossRef]

- Zhang, L.J.; Zhao, J.; Fan, C.Y.; Wang, Z. Effect of surface shape and content of steel fiber on mechanical properties of concrete. Adv. Civ. Eng. 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Martinelli, E.; Pepe, M.; Franternali, F. Meso-scale formulation of a cracked-hinge model for hybrid fiber-reinforced cement composites. Fibers 2020, 8, 56. [Google Scholar] [CrossRef]

- Chu, S.H.; Li, L.G.; Kwan, A.K.H. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 1–9. [Google Scholar]

- Ghalehnovi, M.; Karimipour, A.; Brito, J.D.; Chaboki, H.R. Crack width and propagation in recycled coarse aggregate concrete beams reinforced with steel fibres. Appl. Sci. 2020, 10, 7587. [Google Scholar] [CrossRef]

- Son, D.H.; Bae, B.I.; Lee, M.S.; Lee, M.S.; Choi, C.S. Flexural strength of composite deck slab with macro synthetic fiber reinforced concrete. Appl. Sci. 2021, 11, 1662. [Google Scholar] [CrossRef]

- Wafa, F.F. Properties and application of fiber reinforced concrete. Eng. Sci. 1990, 2, 49–63. [Google Scholar] [CrossRef]

- Musmar, M. Tensile strength of steel fiber reinforced concrete. Contemp. Eng. Sci. 2013, 6, 225–237. [Google Scholar] [CrossRef]

- Herrmann, H.; Pastorelli, E.; Kallonen, A.; Suuronen, J.P. Methods for fibre orientation analysis of X-ray tomography images of steel fibre reinforced concrete (SFRC). J. Mater. Sci. 2016, 51, 3772–3783. [Google Scholar] [CrossRef]

- Choi, W.C.; Jung, K.Y.; Jang, S.J.; Yun, H.D. The influence of steel fiber tensile strength and aspect ratio on the fracture properties of high-strength concrete. Materials 2019, 12, 2105. [Google Scholar] [CrossRef]

- Concrete Society Working Group. Guidance for the design of steel-fibre-reinforced concrete. Concr. Soc. 2007, 63, 1–109. [Google Scholar]

- Chu, S.H.; Kwan, A.K.H. A new method for pull out test of reinforcing bars in plain and fibre reinforced concrete. Eng. Struct. 2018, 164, 82–91. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, J.H. Three-dimensional modelling of steel fiber reinforced concrete material under intense dynamic loading. Constr. Build. Mater. 2013, 44, 118–132. [Google Scholar] [CrossRef]

- Ou, Y.C.; Tsai, M.S.; Liu, K.Y.; Chang, K.C. Compressive behavior of steel-fiber-reinforced concrete with a high reinforcing index. J. Mater. Civ. Eng. 2012, 24, 207–215. [Google Scholar] [CrossRef]

- Liao, W.C.; Perceka, W.; Liu, E.J. Compressive stress-strain relationship of high strength steel fiber reinforced concrete. J. Adv. Concr. Technol. 2015, 13, 379–392. [Google Scholar] [CrossRef]

- Paul, S.C.; Zijl, G.P.A.G.; Savija, B. Effect of fibers on durability of concrete: A practical review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef]

- Yang, K.H.; O, S.J. Effect of volume fraction and length of fiber on the mechanical properties of fiber reinforced concrete. J. Korea Inst. Build. Constr. 2008, 8, 43–48. [Google Scholar] [CrossRef]

- Mangat, P.S.; Gurusamy, K. Long-term properties of steel fibre reinforced marine concrete. Mater. Struct. 1987, 20, 273–282. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Vallini, P. Combining fiber-reinforced concrete with traditional reinforcement in tunnel linings. Eng. Struct. 2009, 31, 1600–1606. [Google Scholar] [CrossRef]

- Funete, A.; Pujadas, P.; Blanco, A.; Aguado, A. Experiences in Barcelona with the use of fibres in segmental linings. Tunn. Undergr. Sp. Tech. 2012, 27, 60–71. [Google Scholar]

- Tiberti, G.; Minelli, F.; Plizzari, G. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Compos. B Eng. 2014, 58, 199–207. [Google Scholar] [CrossRef]

- Meda, A.; Rinaldi, Z.; Spagnuolo, S.; Rivaz, B.D.; Giamundo, N. Hybrid precast tunnel segments in fibre reinforced concrete with glass fiber reinforced bars. Tunn. Undergr. Sp. Tech. 2019, 86, 100–112. [Google Scholar] [CrossRef]

- Cao, L.F.; Peaker, S.M.; Ahmad, S.; Sirati, A. Engineering characteristic of Georgian Bay Formation in Toronto. In Proceedings of the 67th Canadian Geotechnical Conference, Regina, SK, Canada, 30 September 2014. [Google Scholar]

- GEOTERRE. Geotechnical Baseline Report–Hydro One Midtown Toronto Tunnel Project; GEOTERRE: Brampton, ON, Canada, 2010. [Google Scholar]

- Koh, S.I. Mechanical characteristics of shield TBM segment reinforced with steel fiber and its application to tunnelling. Ph.D. Thesis, Dongguk University, Seoul, Korea, 2017. [Google Scholar]

- Yasmin, T.; Bitencourt, L.A.G., Jr.; Osvaldo, L.M. Design of SFRC members aided by a multiscale model: Part II–Predicting the behavior of RC-SFRC beams. Compos. Struct. 2020, 241, 1–13. [Google Scholar]

- RILEM. TC-162 TDF, Test and design methods for steel fibre reinforced concrete–Design of steel fibre reinforced concrete using the σ-ω method: Principles and applications. Mater. Struct. 2002, 35, 262–278. [Google Scholar]

- Lee, S.S. Numerical model for shaley rock masses displaying long-term time dependent deformation (TDD) behavior and its application to a pedestrian tunnel constructed under Lake Ontario. KSCE J. Civ. Eng. 2017, 21, 2919–2931. [Google Scholar] [CrossRef]

- GEOTERRE. Geotechnical Data Report–Hydro One Midtown Toronto Tunnel Project; GEOTERRE: Brampton, ON, Canada, 2010. [Google Scholar]

- U.S. Department of Transportation. Precast Concrete Segmental Liners for Large Diameter Road Tunnels-Literature Survey and Synthesis; U.S. Department of Transportation: Washington, DC, USA, 2020.

- Alshorafa, M.A. Modifications of conventional rigid and flexible methods for Mat foundation design. Master’s Thesis, Islamic University of Gaza, Gaza, Palestine, 2008. [Google Scholar]

- Yazici, S.; Inan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Jeon, J.K.; Jeon, C.K.; Kim, N.Y.; Kim, S.M.; Lee, J.E. A study on controlling of cracks occurred at crown of tunnel concrete lining using model test. J. Korean Tunn. Undergr. Sp. Assoc. 2006, 8, 227–235. [Google Scholar]

- Yang, K.H. Slump and mechanical properties of hybrid steel-PVA fiber reinforced concrete. J. Korea Concr. Inst. 2010, 22, 651–658. [Google Scholar] [CrossRef]

- Lee, G.P.; Bae, G.J.; Moon, D.Y.; Kang, T.S.; Chang, S.H. Evaluation of steel fiber reinforcement effect in segment lining by full scale bending test. J. Korean Tunn. Undergr. Sp. Assoc. 2013, 15, 215–223. [Google Scholar]

- Gilbert, R.I. Tension stiffening in lightly reinforced concrete slabs. J. Struct. Eng. 2007, 133, 899–903. [Google Scholar] [CrossRef]

- Lee, J.H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Duddeck, H.; Erdmann, J. Structural design models for tunnels in soft soil. Underground Space 1985, 9, 246–259. [Google Scholar]

- Christou, P.; Michael, A.; Neofytou, Z. Development of interaction diagrams for RC sections confined with CFRP composites. WIT Trans. Modelling Simul. 2011, 51, 385–396. [Google Scholar]

- Spagnoli, G.; Oreste, P.; Bianco, L.L. Estimation of shaft radial displacement beyond the excavation bottom before installation of permanent lining in nondilatant weak rocks with a novel formulation. Int. J. Geomech. 2017, 17, 1–9. [Google Scholar] [CrossRef]

- Showkati, A.; Salari-rad, H.; Aghchai, M.H. Predicting long-term stability of tunnels considering rock mass weathering and deterioration of primary support. Tunn. Undergr. Sp. Tech. 2021, 107, 1–15. [Google Scholar] [CrossRef]

- Kwon, S.Y.; Yoo, M.T. A study on the dynamic behavior of a vertical tunnel shaft embedded in liquefiable ground during earthquakes. Appl. Sci. 2021, 11, 1560. [Google Scholar] [CrossRef]

- Lo, K.Y.; Wai, R.S.C. Time-dependent deformation of shaley rocks in southern Ontario. Can. Geotech. J. 1978, 15, 537–547. [Google Scholar] [CrossRef]

- Lo, K.Y. Design of tunnel lining in rock for long term time effects. Can. Geotech. J. 1981, 18, 24–39. [Google Scholar] [CrossRef]

- Hawlader, B.C.; Lee, Y.N.; Lo, K.Y. Three-dimensional stress effects on time-dependent swelling behavior of shaly rock. Can. Geotech. J. 2003, 40, 501–511. [Google Scholar] [CrossRef]

- Hawlader, B.C.; Lo, K.Y.; Moore, I.D. Analysis of tunnels in shaley rock considering three-dimensional stress effects on swelling. Can. Geotech. J. 2005, 42, 1–12. [Google Scholar] [CrossRef]

- Lo, K.Y.; Micic, S. Research Report GEOT-10-05-Evaluation of Swelling Properties of Shales for the Design of Underground Structures; Western Geotechnical Research: Brampton, ON, Canada, 2009. [Google Scholar]

| Parameters | Type of Steel Fibre | ||

|---|---|---|---|

| FF1 | FF3 | ||

| Nominal dimensions | Diameter () | 1.00 | 0.75 |

| Length () | 50 | 50 | |

| Aspect ratio (length/diameter) () | 50 | 67 | |

| Mechanical properties | Tensile strength of the wire (MPa) | >1100 | >1100 |

| Ultimate strain () | <4 | <4 | |

| Properties | RC | SFRC |

|---|---|---|

| Steel Bar (20 mm@300) | FF3 | |

| Base of the cross-section () | 1000 | 1000 |

| Thickness of cross-section () | 400 | 400 |

| Tensile strength of reinforcement bar () | 414 | - |

| Area of reinforcement bar () | 1047.20 | - |

| Depth of flexural reinforcement bar position () | 325 | - |

| Ductility of SFRC (%) | - | 102 |

| Concrete first crack strength for 35 MPa-grade ( | - | 4.70 |

| Equivalent resistance of SFRC by flexural test ASTM C1609 () | - | 4.79 |

| Moment resistance for cross-section (MNmm) | 126.8 | 127.7 |

| Properties | RC | SFRC |

|---|---|---|

| Reinforcement Bar (20 mm@300) | FF3 | |

| Cross-section width () | 1000 | 1000 |

| Thickness of cross-section () | 400 | 400 |

| Tensile strength of reinforcement bar () | 414 | - |

| Area of reinforcement bar () | 1047.20 | - |

| Reduction factor (-) | 0.90 | - |

| Reduction factor for tensile strength by CNR-204 | - | 0.45 |

| Reduction factor for members in tension | - | 1.30 |

| Concrete first crack strength () | - | 4.70 |

| Equivalent resistance by flexural test ASTM C1609 (%) | - | 102 |

| Equivalent resistance by flexural test ASTM C1609 () | - | 4.79 |

| Cross-section tensile force (kN) | 390.2 | 663.8 |

| Full Bond | Tangential Slip | |

|---|---|---|

| Maximum bending moment | ||

| Average hoop thrust | ||

| Variable hoop thrust | ||

| Constant radial displacement | ||

| Maximum radial displacement | ||

| Parameters | Values | Sources | |

|---|---|---|---|

| Unit weight of rock () | 24 | Nearby project data & calculation | |

| Deformation modulus of rock () | 6800 | ||

| Rock mass tensile strength () | 0.2 | ||

| Rock mass cohesion () | 2.0 | ||

| Rock mass friction angle (°) | 40 | ||

| Vertical stress () | 1.4 | ||

| Density () | 2500 | 35 -grade concrete | |

| Elastic modulus (MPa) | 34,077 | ||

| Poisson’s ratio (-) | 0.2 | ||

| Max. horizontal stress () | 15.0 | Geotechnical baseline report | |

| Min. horizontal stress () | 5.0 | ||

| Pseudo Poisson’s ratio | 0.6 | Lab result & calculation | |

| Swelling potential (%) | Vertical | 0.9 | |

| Horizontal () | 0.22 | ||

| Horizontal () | 0.22 | ||

| Critical stress (MPa) | Vertical | 1.3 | |

| Horizontal () | 1.8 | ||

| Horizontal () | 1.8 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.S.; Lee, S.S. Design Study of Steel Fibre Reinforced Concrete Shaft Lining for Swelling Ground in Toronto, Canada. Appl. Sci. 2021, 11, 3490. https://doi.org/10.3390/app11083490

Kim MS, Lee SS. Design Study of Steel Fibre Reinforced Concrete Shaft Lining for Swelling Ground in Toronto, Canada. Applied Sciences. 2021; 11(8):3490. https://doi.org/10.3390/app11083490

Chicago/Turabian StyleKim, Min Seong, and Sean Seungwon Lee. 2021. "Design Study of Steel Fibre Reinforced Concrete Shaft Lining for Swelling Ground in Toronto, Canada" Applied Sciences 11, no. 8: 3490. https://doi.org/10.3390/app11083490

APA StyleKim, M. S., & Lee, S. S. (2021). Design Study of Steel Fibre Reinforced Concrete Shaft Lining for Swelling Ground in Toronto, Canada. Applied Sciences, 11(8), 3490. https://doi.org/10.3390/app11083490