Short-Time/-Angle Spectral Analysis for Vibration Monitoring of Bearing Failures under Variable Speed

Abstract

1. Introduction

2. Methods

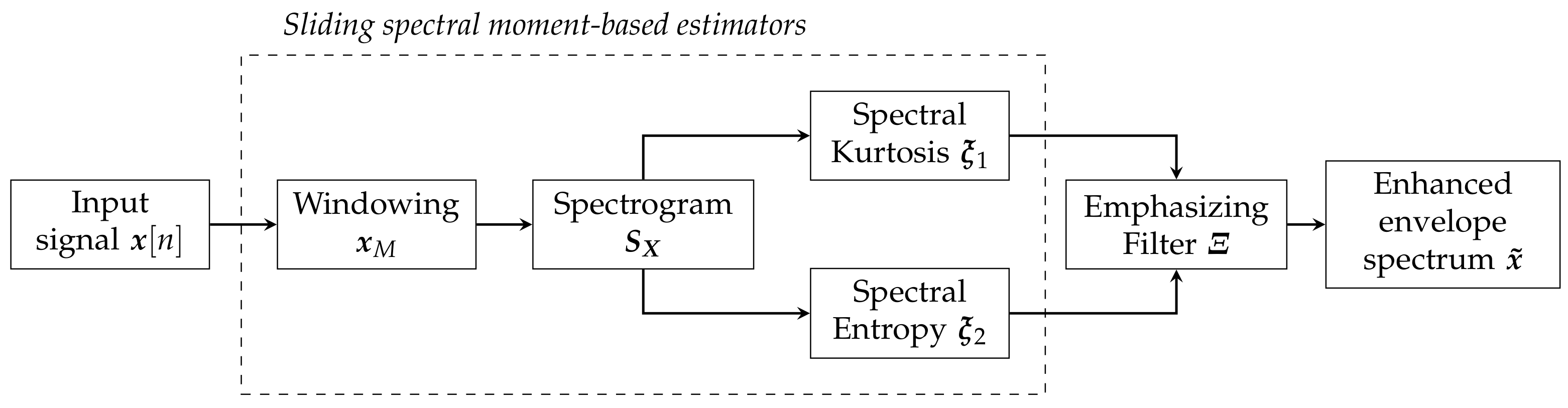

2.1. Estimation of Squared Envelope Spectrum

2.2. Spectral Filter Emphasizing Impulsive Components

- –

- Spectral kurtosis (SK): provided there is a cyclostationary process, the highlighting filter (noted as ) is modeled through kurtosis, having elements defined by the following absolute value moment [27]:where stands for the empirical moment of the n-th order, averaging representation over l domain.

- –

- Spectral entropy (SE): an entropy-based filter (noted as ) is proposed that is modeled as follows:where is the VQ entropy proposed in [28].

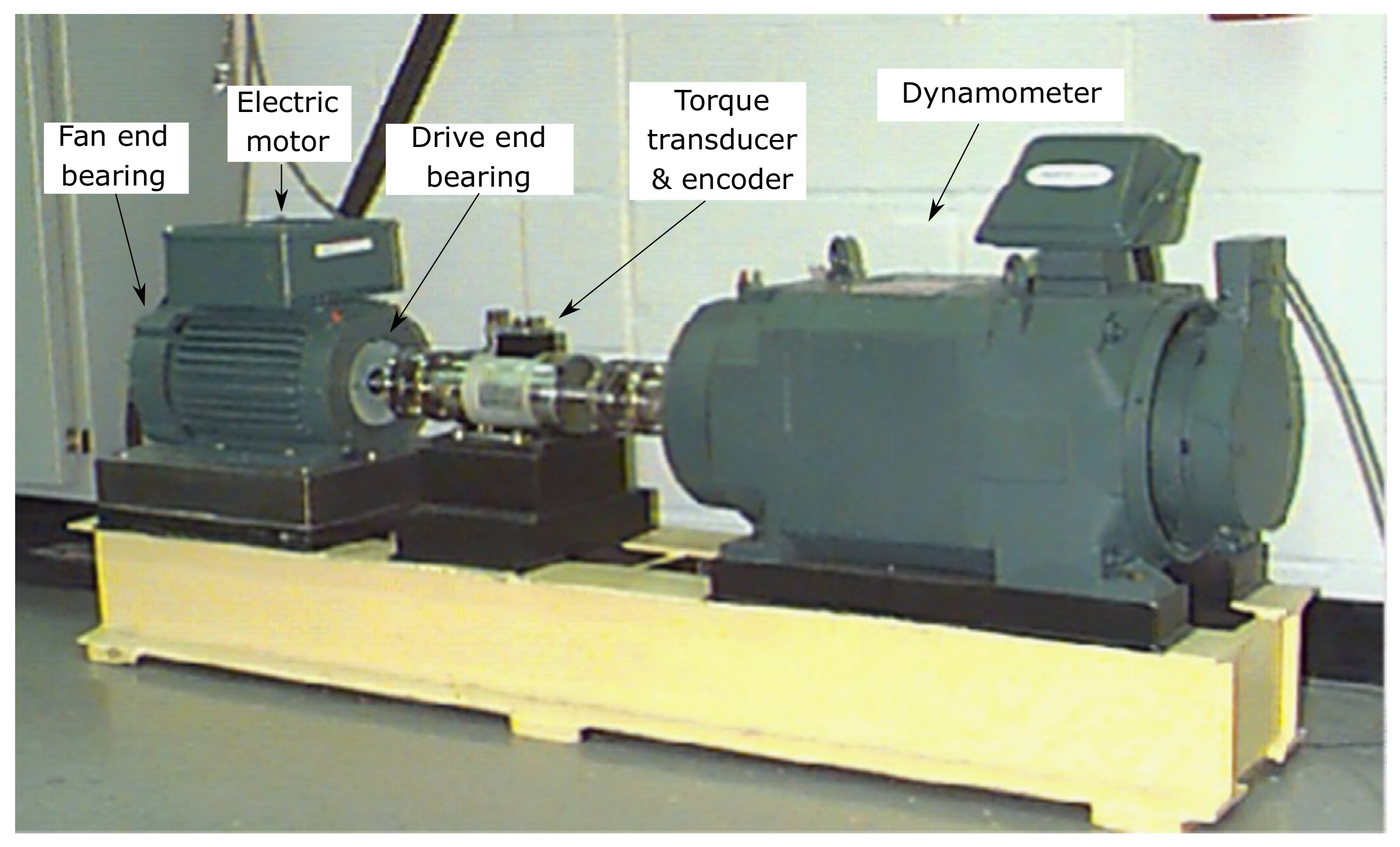

3. Experiment Setup

Simulation Framework of Rolling-Element Bearing Faults

4. Results and Discussion

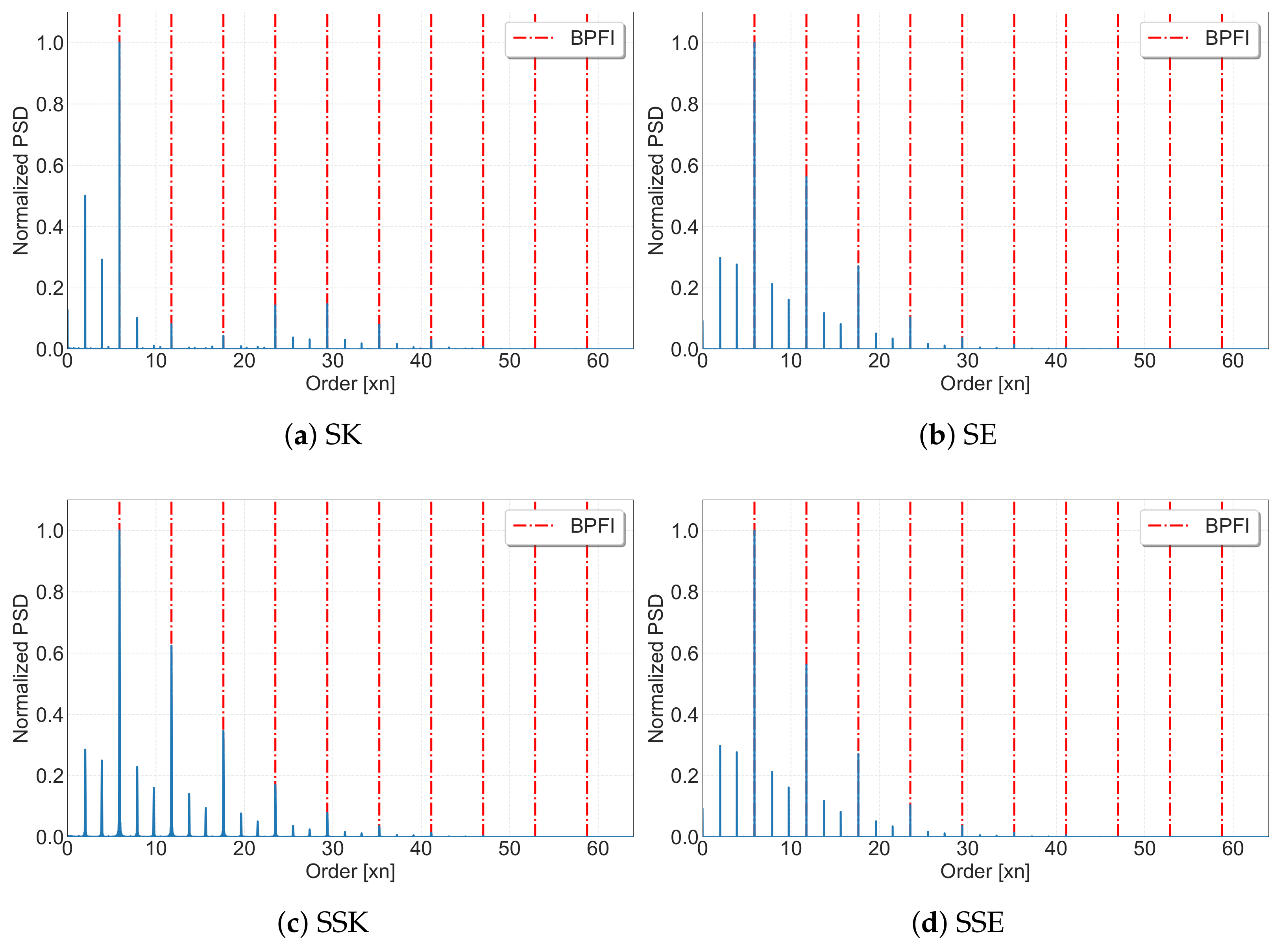

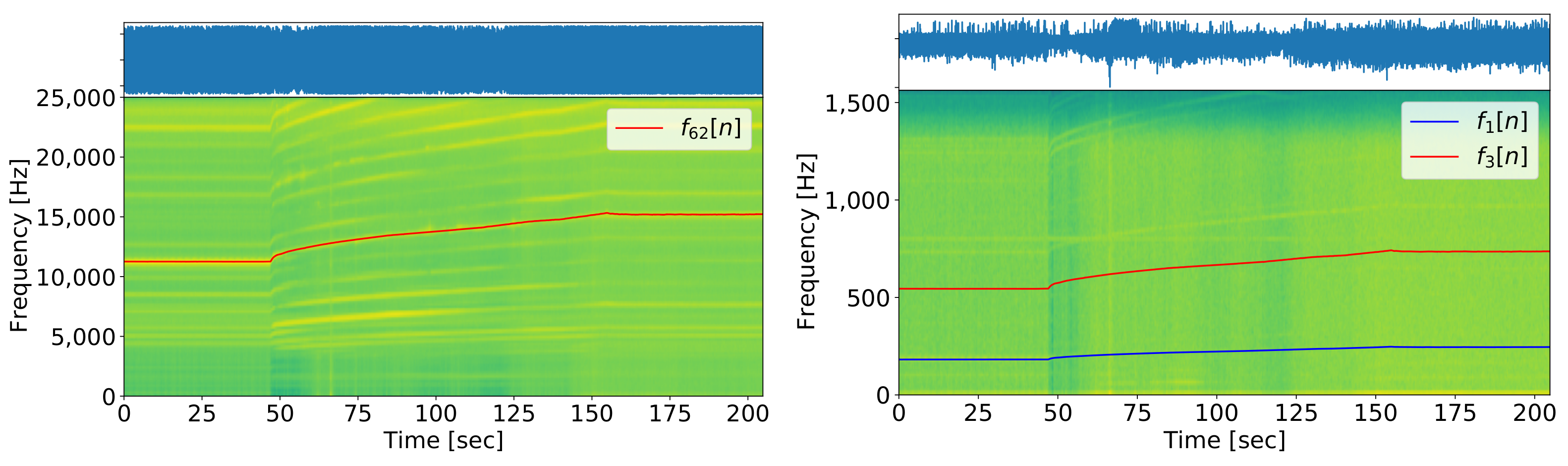

4.1. Experiment Results by SAFRAN

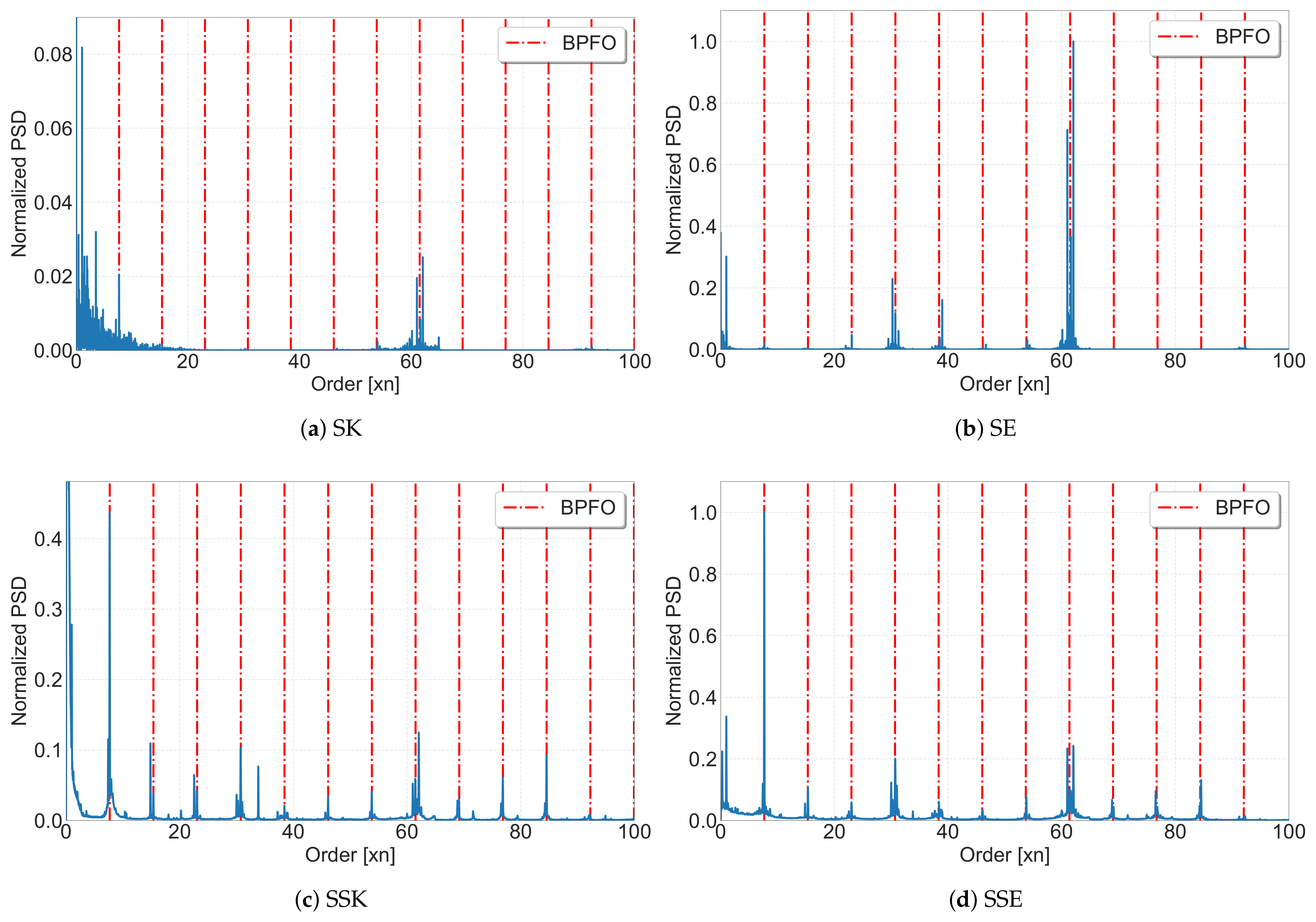

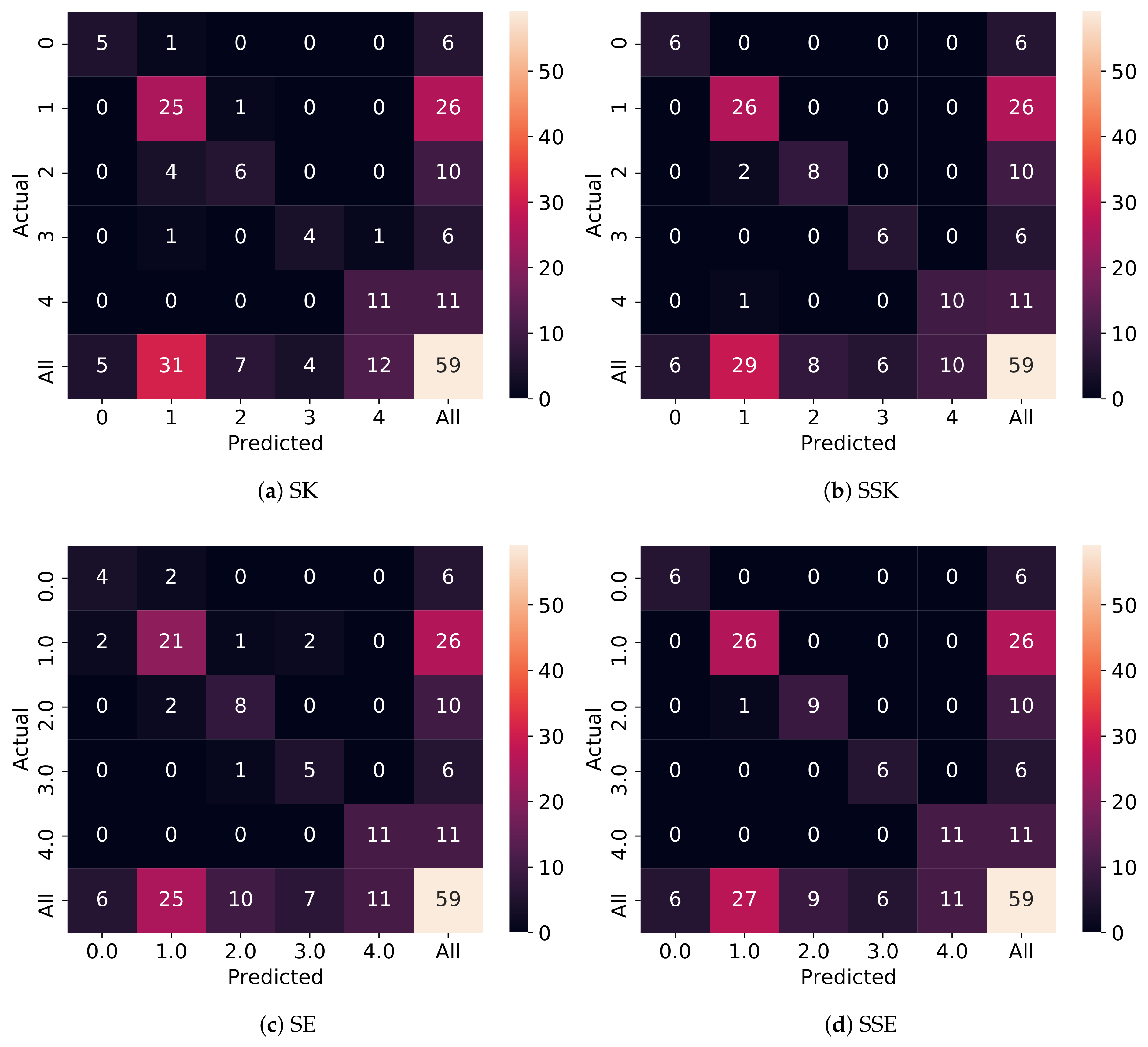

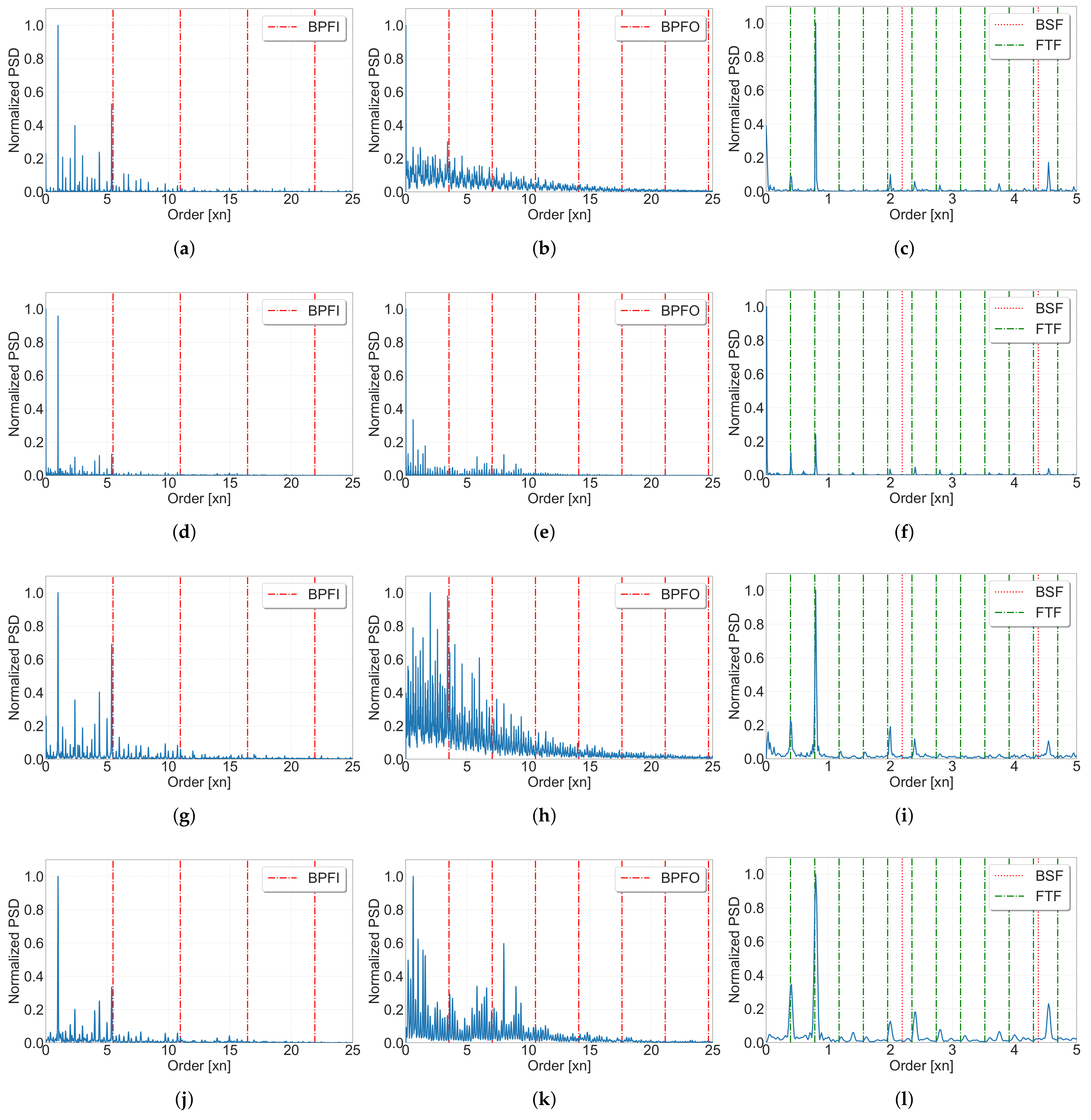

4.2. Experiment Results from CWRU

- Discrete or random separation (DRS) to remove deterministic (discrete frequency) components.

- Spectral kurtosis to determine the most impulsive band, followed by bandpass filtering.

- Envelope analysis (squared envelope spectrum) of a bandpass-filtered signal.

4.3. Experiment Results from UNC

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nithin, S.; Hemanth, K.; Shamanth, V. A review on combustion and vibration condition monitoring of IC engine. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Koukoura, S.; Carroll, J.; McDonald, A. On the use of AI based vibration condition monitoring of wind turbine gearboxes. J. Phys. Conf. Ser. 2019, 1222, 12045. [Google Scholar] [CrossRef]

- Strömbergsson, D.; Marklund, P.; Berglund, K.; Larsson, P.E. Bearing monitoring in the wind turbine drivetrain: A comparative study of the FFT and wavelet transforms. Wind. Energy 2020, 23, 1381–1393. [Google Scholar] [CrossRef]

- John, S.K.; Mishra, R.; Hari, K.; Ramesha, H.; Ram, K.K. Investigation of Bearing Failure in a Turbo Shaft Engine. J. Fail. Anal. Prev. 2020, 20, 34–39. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Delprete, C.; Brusa, E.; Rosso, C.; Bruzzone, F. Bearing Health Monitoring Based on the Orthogonal Empirical Mode Decomposition. Shock Vib. 2020, 2020, 8761278. [Google Scholar] [CrossRef]

- Goyal, D.; Mongia, C.; Sehgal, S. Applications of Digital Signal Processing in Monitoring Machining Processes and Rotary Components: A Review. IEEE Sensors J. 2021, 21, 8780–8804. [Google Scholar] [CrossRef]

- He, M.; He, D. A new hybrid deep signal processing approach for bearing fault diagnosis using vibration signals. Neurocomputing 2020, 396, 542–555. [Google Scholar] [CrossRef]

- Tao, H.; Wang, P.; Chen, Y.; Stojanovic, V.; Yang, H. An unsupervised fault diagnosis method for rolling bearing using STFT and generative neural networks. J. Frankl. Inst. 2020, 357, 7286–7307. [Google Scholar] [CrossRef]

- Hou, B.; Wang, D.; Wang, Y.; Yan, T.; Peng, Z.; Tsui, K.L. Adaptive Weighted Signal Preprocessing Technique for Machine Health Monitoring. IEEE Trans. Instrum. Meas. 2020, 70, 1–11. [Google Scholar] [CrossRef]

- Hu, Y.; Li, Q. An adjustable envelope based EMD method for rolling bearing fault diagnosis. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1043, 32017. [Google Scholar] [CrossRef]

- Attoui, I.; Oudjani, B.; Boutasseta, N.; Fergani, N.; Bouakkaz, M.S.; Bouraiou, A. Novel predictive features using a wrapper model for rolling bearing fault diagnosis based on vibration signal analysis. Int. J. Adv. Manuf. Technol. 2020, 106, 3409–3435. [Google Scholar] [CrossRef]

- Wang, H.; Du, W. Feature extraction of latent fault components of rolling bearing based on self-learned sparse atomics and frequency band entropy. J. Vib. Control. 2020, 27. [Google Scholar] [CrossRef]

- Peeters, C.; Antoni, J.; Helsen, J. Blind filters based on envelope spectrum sparsity indicators for bearing and gear vibration-based condition monitoring. Mech. Syst. Signal Process. 2020, 138, 106556. [Google Scholar] [CrossRef]

- Jia, X.; Zhao, M.; Di, Y.; Li, P.; Lee, J. Sparse filtering with the generalized lp/lq norm and its applications to the condition monitoring of rotating machinery. Mech. Syst. Signal Process. 2018, 102, 198–213. [Google Scholar] [CrossRef]

- He, L.; Yi, C.; Wang, D.; Wang, F.; Lin, J.H. Optimized minimum generalized Lp/Lq deconvolution for recovering repetitive impacts from a vibration mixture. Measurement 2021, 168, 108329. [Google Scholar] [CrossRef]

- Chen, W.; Li, J.; Wang, Q.; Han, K. Fault feature extraction and diagnosis of rolling bearings based on wavelet thresholding denoising with CEEMDAN energy entropy and PSO-LSSVM. Measurement 2021, 172, 108901. [Google Scholar] [CrossRef]

- Yang, C.; Jia, M. Hierarchical multiscale permutation entropy-based feature extraction and fuzzy support tensor machine with pinball loss for bearing fault identification. Mech. Syst. Signal Process. 2021, 149, 107182. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, L.; Cai, Y. Rolling bearing fault diagnosis using generalized refined composite multiscale sample entropy and optimized support vector machine. Measurement 2020, 156, 107574. [Google Scholar] [CrossRef]

- Minhas, A.S.; Kankar, P.; Kumar, N.; Singh, S. Bearing fault detection and recognition methodology based on weighted multiscale entropy approach. Mech. Syst. Signal Process. 2021, 147, 107073. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.; Zhou, Y.; Kumar, R.; Xiang, J. Variational mode decomposition based symmetric single valued neutrosophic cross entropy measure for the identification of bearing defects in a centrifugal pump. Appl. Acoust. 2020, 165, 107294. [Google Scholar] [CrossRef]

- Huo, Z.; Zhang, Y.; Jombo, G.; Shu, L. Adaptive multiscale weighted permutation entropy for rolling bearing fault diagnosis. IEEE Access 2020, 8, 87529–87540. [Google Scholar] [CrossRef]

- Song, J.; Shi, Z.; Wang, L.; Wang, H. Random error analysis of MEMS gyroscope based on an improved DAVAR algorithm. Micromachines 2018, 9, 373. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, B.; Gu, J.; Chen, Y.; Gao, Z.; Ma, X.; Kendrick, K.M.; Woo, W.L. Wearable long-term social sensing for mental wellbeing. IEEE Sensors J. 2018, 19, 8532–8542. [Google Scholar] [CrossRef]

- Shukla, S.; Singh, S.K.; Mitra, D. An efficient heart sound segmentation approach using kurtosis and zero frequency filter features. Biomed. Signal Process. Control. 2020, 57, 101762. [Google Scholar] [CrossRef]

- Serrano Calle, S. Measuring Uncertainties in Energy Companies Caused by Governmental Regulation: The Role of Information Theory. USAEE Work. Pap. 2012, 12, 148. [Google Scholar] [CrossRef]

- Antoni, J. Cyclic spectral analysis in practice. Mech. Syst. Signal Process. 2007, 21, 597–630. [Google Scholar] [CrossRef]

- Velasquez-Martinez, L.; Caicedo-Acosta, J.; Castellanos-Dominguez, G. Entropy-Based Estimation of Event-Related De/Synchronization in Motor Imagery Using Vector-Quantized Patterns. Entropy 2020, 22, 703. [Google Scholar] [CrossRef] [PubMed]

- Antoni, J. The spectral kurtosis: A useful tool for characterising non-stationary signals. Mech. Syst. Signal Process. 2006, 20, 282–307. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J.; Chobsaard, S. The relationship between spectral correlation and envelope analysis in the diagnostics of bearing faults and other cyclostationary machine signals. Mech. Syst. Signal Process. 2001, 15, 945–962. [Google Scholar] [CrossRef]

- Antoni, J.; Griffaton, J.; André, H.; Avendaño-Valencia, L.D.; Bonnardot, F.; Cardona-Morales, O.; Castellanos-Dominguez, G.; Daga, A.P.; Leclère, Q.; Vicuña, C.M.; et al. Feedback on the Surveillance 8 challenge: Vibration-based diagnosis of a Safran aircraft engine. Mech. Syst. Signal Process. 2017, 97, 112–144. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64, 100–131. [Google Scholar] [CrossRef]

- Marins, M.A.; Ribeiro, F.M.; Netto, S.L.; da Silva, E.A. Improved similarity-based modeling for the classification of rotating-machine failures. J. Frankl. Inst. 2018, 355, 1913–1930. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Si, S.; Huang, S. Entropy based fault classification using the Case Western Reserve University data: A benchmark study. IEEE Trans. Reliab. 2019, 69, 754–767. [Google Scholar] [CrossRef]

- Sun, S.; Przystupa, K.; Wei, M.; Yu, H.; Ye, Z.; Kochan, O. Fast bearing fault diagnosis of rolling element using Lévy Moth-Flame optimization algorithm and Naive Bayes. Eksploat. Niezawodn. Maint. Reliab. 2020, 22, 730–740. [Google Scholar] [CrossRef]

- Sierra-Alonso, E.F.; Antoni, J.; Castellanos-Dominguez, G. Cyclo-non-stationary analysis for bearing fault identification based on instantaneous angular speed estimation. In Proceedings of the Surveillance, Vishno and AVE Conferences, Lyon, France, 8–10 July 2019. [Google Scholar]

| Parameter | Simulation | SAFRAN | CWRU | UNC |

|---|---|---|---|---|

| 256 | 256 | 256 | 256 | |

| M | 2048 | 4096 | 8192 | 32,768 |

| Samples per revolution | 128 | 256 | 400.67 | 1024 |

| Failure | Model |

|---|---|

| Ball-pass frequency inner race (BPFI) | |

| Ball-pass frequency outer race (BPFO) | |

| Fundamental train frequency (FTF) | |

| Ball spin frequency (BSF) |

| L1 (L5) | L4 (L5) | L5 (L5) | |

|---|---|---|---|

| Speed | 1.34 | 0.984 | 1 |

| FTF | 0.55 | 0.40 | 0.43 |

| BSF | 3.46 | 2.44 | 3.56 |

| BPFI | 7.95 | 5.87 | 10.24 |

| BPFO | 5.45 | 3.97 | 7.76 |

| Rig Position | Model Number | Fault Frequencies (IAS Multiple) | |||

|---|---|---|---|---|---|

| BPFI | BPFO | FTF | BSF | ||

| Drive end | SKF 6205-2RS JEM | 5.415 | 3.585 | 0.3983 | 2.357 |

| Fan end | SKF 6203-2RS JEM | 4.947 | 3.053 | 0.3816 | 1.994 |

| Diagnosis | Diagnosis | Explanation |

|---|---|---|

| Category | Success | |

| Y1 | Yes | Data clearly diagnosable and show classical characteristics for a given bearing fault in both t-f domains |

| Y2 | Yes | Data clearly diagnosable with nonclassical characteristics in either or both t-f domains |

| P1 | Partial | Data probably diagnosable; e.g., envelope spectrum shows discrete components at expected fault frequencies, but not dominant in the spectrum |

| P2 | Partial | Data potentially diagnosable; e.g., envelope spectrum shows smeared components that appear to coincide with expected fault frequencies |

| N1 | No | Data not diagnosable for specified bearing fault, but with other identifiable problems (e.g., looseness) |

| N2 | No | Data not diagnosable and virtually indistinguishable from noise, excepting possibly shaft harmonics in the envelope spectrum |

| Fault Type | |||||

|---|---|---|---|---|---|

| IR | Ball | OR Centered | OR Orthogonal | OR Opposite | |

| Drive end bearing faults 12 kHz data | 3001 = N2/-/-, 3002 = N2/-/-, 3003 = N2/-/-, 3004 = N2/-/-, 3001 = P2/-/-, 3002 = P2/-/-, 3003 = P2/-/-, 3004 = P2/-/-, 3001 = P2/-/-, 3002 = P2/-/-, 3003 = P2/-/-, 3004 = P2/-/- | 118 = N2/N2/N2, 119 = N2/N2/N2, 120DE = P1, 120BA = N2, 121BA = P2, 187FE = N2, 224DE = N1, 224BA = P2, 225DE = P2, 225FE = N2, 118 = P2/N2/N1, 119 = P1/N2/N1, 120DE = P2, 120BA = P2, 121BA = N2, 187FE = N1, 224DE = P2, 224BA = P2, 225DE = P2, 225FE = N1, 118 = P2/N2/N1, 119 = P2/N2/N1, 120DE = P1, 120BA = P2, 121BA = N2, 187FE = N1, 224DE = P1, 224BA = N1, 225DE = P1, 225FE = N1 | 197FE = N2, 197BA = P2, 198FE = N2, 198BA = N1, 199FE = N2, 200 = N2/N2/P2, 197FE = N1, 197BA = Y2, 198FE = P2, 198BA = P2, 199FE = N1, 200 = P1/N1/P2, 197FE = N2, 197BA = P1, 198FE = N2, 198BA = P2, 199FE = N2, 200 = P2/N1/P2 | — | — |

| Drive end bearing faults 48 kHz data | 174 = N1/N1, 174 = N2/N2, 174 = N2/N2 | 122 = N2/N2, 123 = N2/N2, 124 = P2/N2, 125 = P2/N1, 192 = N1/N1, 228DE = N2, 229DE = N2, 122 = P1/N2, 123 = P2/N2, 124 = P2/N1, 125 = P1/N1, 192 = P2/N1, 228DE = N2, 229DE = N2, 122 = P2/N1, 123 = P2/N2, 124 = P2/N1, 125 = P2/N1, 192 = P2/N1, 228DE = N2, 229DE = N2 | 202FE = N2, 204FE = N2, 202FE = N2, 204FE = P2, 202FE = N2, 204FE = P2 | — | — |

| Fan end bearing faults 12 kHz data | — | 282FE = N2, 285FE = N2, 290DE = N2, 290FE = N2, 292FE = N2, 293DE = N2, 282FE = N2, 285FE = P2, 290DE = P2, 290FE = N2, 292FE = P2, 293DE = P2, 282FE = N2, 285FE = P2, 290DE = P2, 290FE = N2, 292FE = P2, 293DE = P2 | — | 298BA = N2, 298BA = N2, 298BA = N2 | 302 = N2/N2/N2, 305FE = N2, 306 = N2/N2/N2, 307 = N1/N1/N2, 302 = N2/N2/N2, 305FE = N1, 306 = N1/N1/N2, 307 = N1/P2/N2, 302 = N2/N2/N2, 305FE = N1, 306 = N1/N1/N2, 307 = N1/P2/N2 |

| [33] | [34] | [35] | SK | SSK | SE | SSE | |

|---|---|---|---|---|---|---|---|

| Without removing engine influence | - | - | - | √ | √ | √ | √ |

| Visual inspection | - | - | - | √ | √ | √ | |

| Accuracy | 98.95 | 99.83 | 90.46 | 87.64 ± 2.26 | 90.24 ± 2.31 | 87.27 ± 2.95 | 94.53 ± 2.26 |

| label | 0 | 1 | 2 | |

| Failure | IR | OR | Ball | |

| records | 13 | 14 | 11 | |

| SK | SSK | SE | SSE | |

| Accuracy | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sierra-Alonso, E.F.; Caicedo-Acosta, J.; Orozco Gutiérrez, Á.Á.; Quintero, H.F.; Castellanos-Dominguez, G. Short-Time/-Angle Spectral Analysis for Vibration Monitoring of Bearing Failures under Variable Speed. Appl. Sci. 2021, 11, 3369. https://doi.org/10.3390/app11083369

Sierra-Alonso EF, Caicedo-Acosta J, Orozco Gutiérrez ÁÁ, Quintero HF, Castellanos-Dominguez G. Short-Time/-Angle Spectral Analysis for Vibration Monitoring of Bearing Failures under Variable Speed. Applied Sciences. 2021; 11(8):3369. https://doi.org/10.3390/app11083369

Chicago/Turabian StyleSierra-Alonso, Edgar F., Julian Caicedo-Acosta, Álvaro Ángel Orozco Gutiérrez, Héctor F. Quintero, and German Castellanos-Dominguez. 2021. "Short-Time/-Angle Spectral Analysis for Vibration Monitoring of Bearing Failures under Variable Speed" Applied Sciences 11, no. 8: 3369. https://doi.org/10.3390/app11083369

APA StyleSierra-Alonso, E. F., Caicedo-Acosta, J., Orozco Gutiérrez, Á. Á., Quintero, H. F., & Castellanos-Dominguez, G. (2021). Short-Time/-Angle Spectral Analysis for Vibration Monitoring of Bearing Failures under Variable Speed. Applied Sciences, 11(8), 3369. https://doi.org/10.3390/app11083369