Evaluation of a Wet Acid Scrubber and Dry Filter Abatement Technologies in Pig Barns by Dynamic Olfactometry

Abstract

1. Introduction

2. Materials and Methods

2.1. Animal Housing and Conditions

2.2. Abatement Technologies

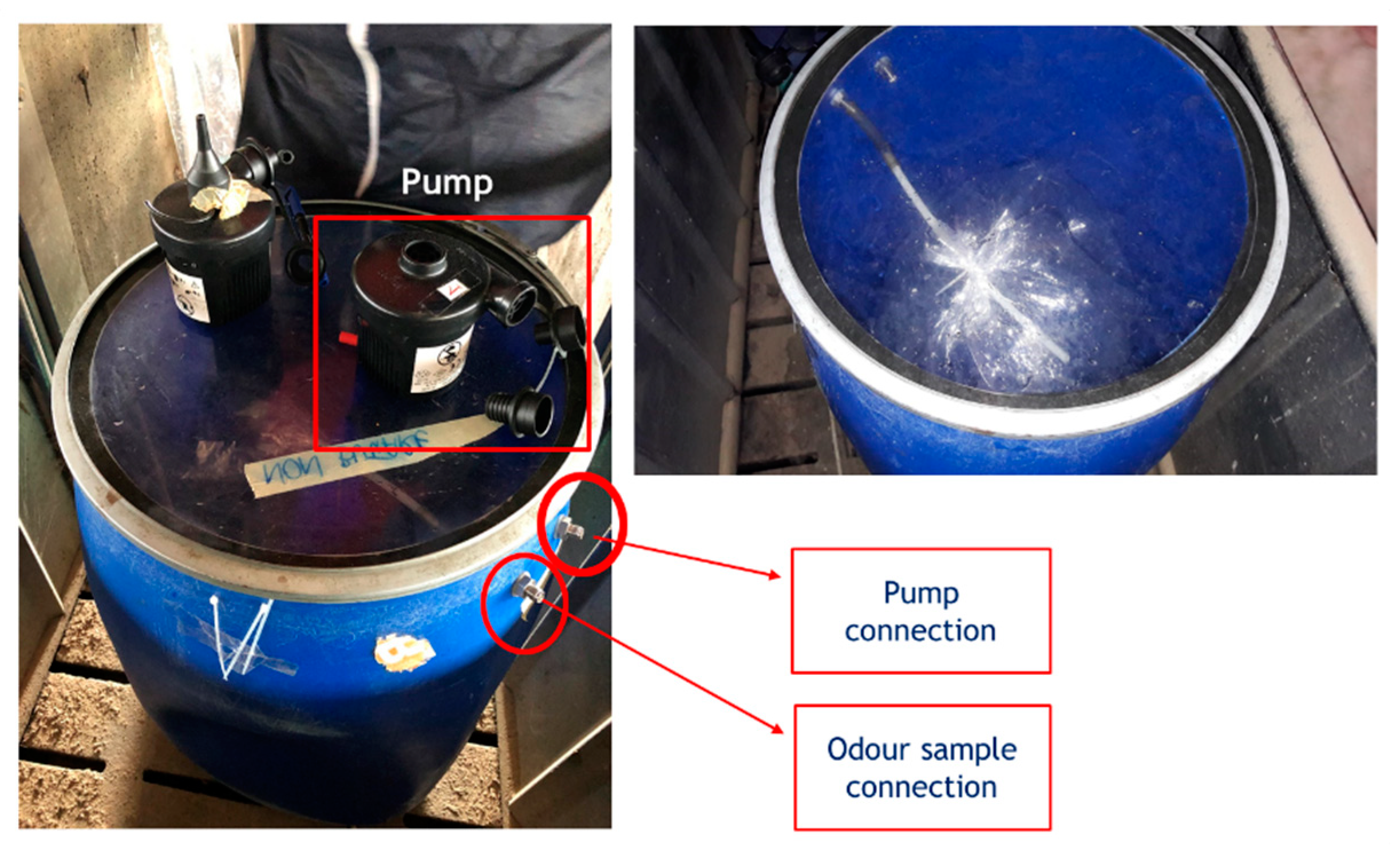

2.3. Odor Sampling and Dynamic Olfactometry Analysis

- Sampling on farm in WAS and CR;

- Dynamic olfactometry analysis;

- Sampling on farm DF and CR;

- Dynamic olfactometry analysis.

3. Results and Discussion

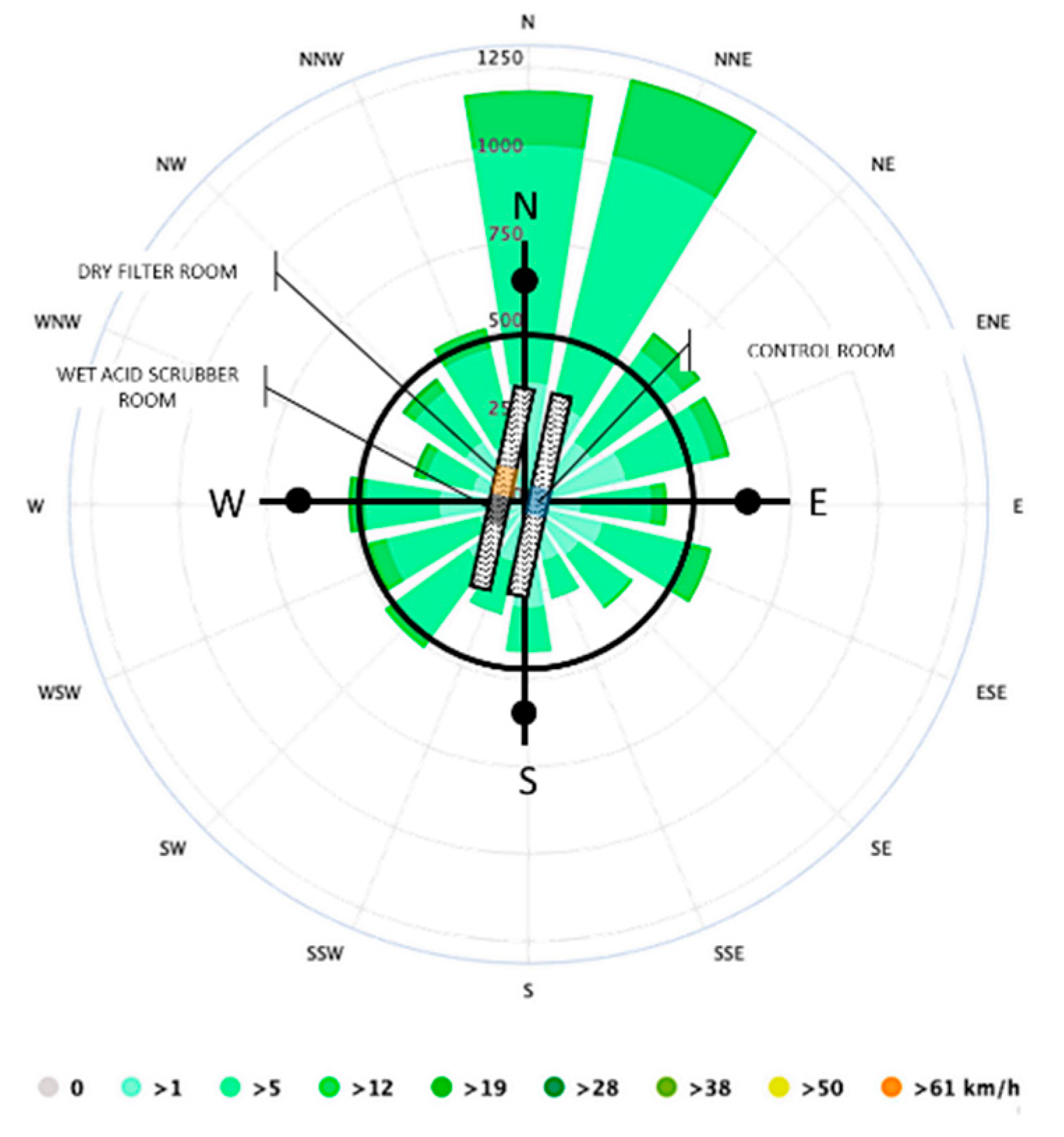

3.1. Environmental Parameters

3.2. Olfactometric Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hayes, J.E.; Stevenson, R.J.; Stuetz, R.M. The impact of malodour on communities: A review of assessment techniques. Sci. Total Environ. 2014, 500, 395–407. [Google Scholar] [CrossRef] [PubMed]

- Dunlop, M.W.; Blackall, P.J.; Stuetz, R.M. Odour emissions from poultry litter–A review litter properties, odour formation and odorant emissions from porous materials. J. Environ. Manag. 2016, 177, 306–319. [Google Scholar] [CrossRef]

- Trabue, S.; Scoggin, K.; Tyndall, J.; Sauer, T.; Hernandez-Ramirez, G.; Pfeiffer, R.; Hatfield, J. Odorous compounds sources and transport from a swine deep-pit finishing operation: A case study. J. Environ. Manag. 2019, 233, 12–23. [Google Scholar] [CrossRef] [PubMed]

- Invernizzi, M.; Capelli, L.; Sironi, S. Proposal of odor nuisance index as urban planning tool. Chem. Senses 2017, 42, 105–110. [Google Scholar] [CrossRef] [PubMed]

- Hooiveld, M.; van Dijk, C.E.; van der Sman-de Beer, F.; Smit, L.A.M.; Vogelaar, M.; Wouters, I.M.; Heederik, D.J.; Yzermans, C.J. Odour annoyance in the neighbourhood of livestock farming—Perceived health and health care seeking behaviour. Ann. Agric. Environ. Med. 2015, 22, 55–61. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Blanes-Vidal, V.; Suh, H.; Nadimi, E.S.; Løfstrøm, P.; Ellermann, T.; Andersen, H.V.; Schwartz, J. Residential exposure to outdoor air pollution from livestock operations and perceived annoyance among citizens. Environ. Int. 2012, 40, 44–50. [Google Scholar] [CrossRef]

- Martel, M.C.; Lemay, S.P.; Predicala, B.Z.; Girard, M.; Belzile, M.; Feddes, J.; Hogue, R.; Godbout, S. Detailed study of odor from pig buildings to improve understanding of biotrickling filter performance. Trans. ASABE 2017, 60, 2151–2162. [Google Scholar] [CrossRef]

- Nie, E.; Zheng, G.; Ma, C. Characterization of odorous pollution and health risk assessment of volatile organic compound emissions in swine facilities. Atmos. Environ. 2020, 223, 117233. [Google Scholar] [CrossRef]

- Chen, L.; Hoff, S.J. Mitigating odors from agricultural facilities: A review of literature concerning biofilters. Appl. Eng. Agric. 2009, 25, 751–766. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A.; Kalus, K.; Andersen, D.S.; Opalinski, S. Pilot-scale testing of non-activated biochar for swine manure treatment and mitigation of ammonia, hydrogen sulfide, odorous volatile organic compounds (VOCs), and greenhouse gas emissions. Sustainability 2017, 9, 929. [Google Scholar] [CrossRef]

- Huang, H.; Miller, G.Y.; Ellis, M.; Funk, T.; Hollis, G.; Zhang, Y.; Heber, A.J. Odor management and swine finishing building characteristics: Costs and effectiveness. In Proceedings of the Air Pollution from Agricultural Operations-III, Raleigh, NC, USA, 12–15 October 2003; American Society of Agricultural and Biological Engineers: San Jose, MI, USA, 2003; p. 323. [Google Scholar]

- Nimmermark, S. Odour influence on well-being and health with specific focus on animal production emissions. Ann. Agric. Environ. Med. 2004, 11, 163–173. [Google Scholar]

- Santonja, G.G.; Georgitzikis, K.; Scalet, B.M.; Montobbio, P.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs; EUR 28674 EN; Publications Office of the European Union: Seville, Spain, 2017. [Google Scholar] [CrossRef]

- Guo, H.; Jacobson, L.D.; Schmidt, D.R.; Nicolai, R.E.; Janni, K.A. Comparison of Five Models for Setback Distance Determination. In Proceedings of the 2001 ASAE Annual Meeting, Sacramento, CA, USA, 28 July–1 August 2001; American Society of Agricultural and Biological Engineers: San Jose, MI, USA, 1998; p. 1. [Google Scholar]

- Piringer, M.; Knauder, W.; Petz, E.; Schauberger, G. Factors influencing separation distances against odour annoyance calculated by Gaussian and Lagrangian dispersion models. Atmos. Environ. 2016, 140, 69–83. [Google Scholar] [CrossRef]

- Leek, A.B.G.; Hayes, E.T.; Curran, T.P.; Callan, J.J.; Beattie, V.E.; Dodd, V.A.; O’Doherty, J. V The influence of manure composition on emissions of odour and ammonia from finishing pigs fed different concentrations of dietary crude protein. Bioresour. Technol. 2007, 98, 3431–3439. [Google Scholar] [CrossRef]

- Létourneau, V.; Duchaine, C.; Belzile, M.; Girard, M.; Lemay, S.P.; Godbout, S. Bench-Scale Pig Buildings: Validation of a Model for Studying Airborne Contaminants of Concern for Human and Animal Health. Trans. ASABE 2020, 63, 541–548. [Google Scholar] [CrossRef]

- Yi, Q.; Janke, D.; Thormann, L.; Zhang, G.; Amon, B.; Hempel, S.; Nosek, Š.; Hartung, E.; Amon, T. Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution. Appl. Sci. 2020, 10, 4931. [Google Scholar] [CrossRef]

- Guarino, M.; Fabbri, C.; Brambilla, M.; Valli, L.; Navarotto, P. Evaluation of simplified covering systems to reduce gaseous emissions from livestock manure storage. Trans. ASABE 2006, 49, 737–747. [Google Scholar] [CrossRef]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural anaerobic digestion plants: What LCA studies pointed out and what can be done to make them more environmentally sustainable. Appl. Energy 2016, 179, 669–686. [Google Scholar] [CrossRef]

- Fangueiro, D.; Ribeiro, H.; Vasconcelos, E.; Coutinho, J.; Cabral, F. Treatment by acidification followed by solid–liquid separation affects slurry and slurry fractions composition and their potential of N mineralization. Bioresour. Technol. 2009, 100, 4914–4917. [Google Scholar] [CrossRef]

- Van der Heyden, C.; Demeyer, P.; Volcke, E.I.P. Mitigating emissions from pig and poultry housing facilities through air scrubbers and biofilters: State-of-the-art and perspectives. Biosyst. Eng. 2015, 134, 74–93. [Google Scholar] [CrossRef]

- Bibbiani, C.; Russo, C. Odour emission from intensive livestock production system: Approaches for emission abatement and evaluation of their effectiveness. Large Anim. Rev. 2012, 18, 135–138. [Google Scholar]

- Melse, R.W.; Mol, G. Odour and ammonia removal from pig house exhaust air using a biotrickling filter. Water Sci. Technol. 2004, 50, 275–282. [Google Scholar] [CrossRef] [PubMed]

- Melse, R.W.; Ogink, N.W.M. Air scrubbing techniques for ammonia and odor reduction at livestock operations: Review of on-farm research in the Netherlands. Trans. ASAE 2005, 48, 2303–2313. [Google Scholar] [CrossRef]

- Conti, C.; Guarino, M.; Bacenetti, J. Measurements techniques and models to assess odor annoyance: A review. Environ. Int. 2020, 134, 105261. [Google Scholar] [CrossRef]

- Brinkmann, T.; Both, R.; Scalet, B.M.; Roudier, S.; Sancho, L.D. JRC Reference Report on Monitoring of Emissions to Air and Water from IED Installations; EUR 29261 EN; Publications Office of the European Union: Seville, Spain, 2018; p. 155. [Google Scholar]

- CEN—Committee for European Normalization. EN 13725:2004 Air Quality—Determination of Odour Concentration by Dynamic Olfactometry; CEN: Brussels, Belgium, 2004. [Google Scholar]

- Bax, C.; Sironi, S.; Capelli, L. How can odors be measured? An overview of methods and their applications. Atmosphere 2020, 11, 92. [Google Scholar] [CrossRef]

- Hansen, M.; Jonassen, K.; Feilberg, A. Evaluation of abatement technologies for pig houses by dynamic olfactometry and on-site mass spectrometry. Chem. Eng. Trans. 2014, 40, 253–258. [Google Scholar]

- Sironi, S.; Capelli, L.; Céntola, P.; Del Rosso, R.; Pierucci, S. Odour impact assessment by means of dynamic olfactometry, dispersion modelling and social participation. Atmos. Environ. 2010, 44, 354–360. [Google Scholar] [CrossRef]

- Zhao, Y.; Aarnink, A.J.A.; De Jong, M.C.M.; Ogink, N.W.M.; Koerkamp, P.W.G.G. Effectiveness of multi-stage scrubbers in reducing emissions of air pollutants from pig houses. Trans. ASABE 2011, 54, 285–293. [Google Scholar] [CrossRef]

- Jamaludin, Z.; Rollings-Scattergood, S.; Lutes, K.; Vaneeckhaute, C. Evaluation of sustainable scrubbing agents for ammonia recovery from anaerobic digestate. Bioresour. Technol. 2018, 270, 596–602. [Google Scholar] [CrossRef]

- Hove, N.C.Y.; Demeyer, P.; Van der Heyden, C.; Van Weyenberg, S.; Van Langenhove, H. Improving the repeatability of dynamic olfactometry according to EN 13725: A case study for pig odour. Biosyst. Eng. 2017, 161, 70–79. [Google Scholar] [CrossRef]

- Gralapp, A.K.; Powers, W.J.; Bundy, D.S. Comparison of olfactometry, gas chromatography, and electronic nose technology for measurement of indoor air from swine facilities. Trans. ASAE 2001, 44, 1283. [Google Scholar] [CrossRef]

- Dumont, E.; Hamon, L.; Lagadec, S.; Landrain, P.; Landrain, B.; Andres, Y. NH3 biofiltration of piggery air. J. Environ. Manag. 2014, 140, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-C.; Han, M.-F.; Jia, T.-P.; Hu, X.-R.; Zhu, H.-Q.; Tong, Z.; Lin, Y.-T.; Wang, C.; Liu, D.-Z.; Peng, Y.-Z. Emissions, measurement, and control of odor in livestock farms: A review. Sci. Total Environ. 2021, 776, 145735. [Google Scholar] [CrossRef] [PubMed]

- De Vries, J.W.; Melse, R.W. Comparing environmental impact of air scrubbers for ammonia abatement at pig houses: A life cycle assessment. Biosyst. Eng. 2017, 161, 53–61. [Google Scholar] [CrossRef]

| Trial | Date | Description of Activities |

|---|---|---|

| 1 | 7 September | Sampling on farm in WAS and CR |

| 8 September | Dynamic olfactometry analysis | |

| 9 September | Sampling on farm DF and CR | |

| 10 September | Dynamic olfactometry analysis | |

| 2 | 15 September | Sampling on farm in WAS and CR |

| 16 September | Dynamic olfactometry analysis | |

| 17 September | Sampling on farm DF and CR | |

| 17 September afternoon | Dynamic olfactometry analysis | |

| 3 | 17 September | Sampling on farm in WAS and CR |

| 18 September | Dynamic olfactometry analysis | |

| 21 September | Sampling on farm DF and CR | |

| 22 September | Dynamic olfactometry analysis | |

| 4 | 29 October | Sampling on farm in WAS and CR |

| 30 October | Dynamic olfactometry analysis | |

| 2 November | Sampling on farm DF and CR | |

| 2 November afternoon | Dynamic olfactometry analysis | |

| 5 | 24 November | Sampling on farm WAS, DF and CR |

| 24 November afternoon | Dynamic olfactometry analysis | |

| 25 November | Dynamic olfactometry analysis |

| Sampling Date | T, °C | RH, % | Wind Speed, m/s | Wind Direction |

|---|---|---|---|---|

| 7 September | 22 | 84 | 1.78 | SSW |

| 9 September | 23 | 80 | 1.43 | E |

| 15 September | 24 | 72 | 1.61 | E |

| 17 September | 24 | 70 | 1.26 | S |

| 21 September | 19 | 96 | 1.55 | SSE |

| 29 October | 11 | 95 | 1.12 | WSW |

| 2 November | 11 | 100 | 0.70 | S |

| 24 November | 4 | 89 | 1.21 | WSW |

| Sampling Date | T, °C | RH, % | Windows |

|---|---|---|---|

| 7 September | 20.1 | 81.1 | Open 70% |

| 9 September | 20.6 | 77.2 | Open 90% |

| 15 September | 21.2 | 73.0 | Open 80% |

| 17 September | 21.1 | 72.8 | Open 60% |

| 21 September | 18.7 | 84.6 | Open 80% |

| 29 October | 17.2 | 84.1 | Open 10% |

| 2 November | 19.3 | 81.0 | Open 5% |

| 24 November | 10.7 | 83.2 | Open 50% |

| Session | Wet Acid Scrubber | Dry Filter | Control |

|---|---|---|---|

| 1 (7–10 September 2020) | 1102 ± 175 | 2285 ± 446 | 3260 ±1168 |

| 2 (15–17 September 2020) | 2617 ± 562 | 11,220 ± 1490 | 10,131 ± 1572 |

| 3 (17–22 September 2020) | 8287 ± 2064 | 10,001 ± 567 | 10,131 ± 1572 |

| 4 (29 October–2 November 2020) | 34,123 ± 4317 | 38,339 ± 10,078 | 34,112 ± 3860 |

| 5 (24–25 November 2020) | 104,329 ± 9112 | 163,478 ± 36,340 | 57,911 ± 23,101 |

| Session | WAS vs. DF | WAS vs. CR | DF vs. CR |

|---|---|---|---|

| 1 | −52% | −66% | −30% |

| 2 | −77% | −74% | +11% |

| 3 | −17% | −18% | −1% |

| 4 | −11% | 0% | +12% |

| 5 | −36% | +80%1 | +182% 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conti, C.; Tullo, E.; Bacenetti, J.; Guarino, M. Evaluation of a Wet Acid Scrubber and Dry Filter Abatement Technologies in Pig Barns by Dynamic Olfactometry. Appl. Sci. 2021, 11, 3219. https://doi.org/10.3390/app11073219

Conti C, Tullo E, Bacenetti J, Guarino M. Evaluation of a Wet Acid Scrubber and Dry Filter Abatement Technologies in Pig Barns by Dynamic Olfactometry. Applied Sciences. 2021; 11(7):3219. https://doi.org/10.3390/app11073219

Chicago/Turabian StyleConti, Cecilia, Emanuela Tullo, Jacopo Bacenetti, and Marcella Guarino. 2021. "Evaluation of a Wet Acid Scrubber and Dry Filter Abatement Technologies in Pig Barns by Dynamic Olfactometry" Applied Sciences 11, no. 7: 3219. https://doi.org/10.3390/app11073219

APA StyleConti, C., Tullo, E., Bacenetti, J., & Guarino, M. (2021). Evaluation of a Wet Acid Scrubber and Dry Filter Abatement Technologies in Pig Barns by Dynamic Olfactometry. Applied Sciences, 11(7), 3219. https://doi.org/10.3390/app11073219