1. Introduction

The upper limb is an essential organ for any person due to its ability to complete a lot of actions with a higher level of dexterity. This is how, by using their upper limbs, people can achieve tasks such as grasping, holding, picking, and lifting more efficiently than other living creatures can. According to the World Health Organization report on disability [

1], about “15% of the global population—over a billion people—lives with some form of disability, of whom 2–4% experience significant difficulties in functioning”.

According to Kim et al. [

2], cited by [

3], “the ratio of upper-extremity to lower-extremity amputations is 1:2.2” and the “persons with upper-extremity amputations suffer from frustration and difficulty during the rehabilitation process. The main factors causing loss of the upper limbs are accidents followed by general diseases and injuries, and also in some cases for diseases and tumours, the amputation is a way of stopping the spread of the disease to the rest of the body [

3]”.

Many of these people “suffer from frustration and difficulty during the rehabilitation process and experience paresthesia due to the loss of delicate movement by the hands, complicated tactile senses of the upper extremities, and proprioceptive sensory functions [

3]” and all of these people require assistive technologies such as prostheses, wheelchairs, etc.

Considering the crucial functions of hands, the life of people who are missing hands is complicated, and, for this reason, it is very difficult to adapt to situations in which something that used to be done naturally is now done within limits imposed by this disability. Upper limb prostheses (ULP) are generally classified into two categories based on their functionality: passive prostheses and active prostheses [

4], cited by [

5]. A good solution for artificial hands is myoelectric prostheses, which are currently being developed. With these types of prostheses, the myoelectric signals of muscle contractions are ultimately transformed into functions desired by the users through the use of surface electrodes [

3]. It is a ‘myoelectric control system’ for controlling the myoelectric prosthesis [

6], cited by [

3]. However, the design, the control structure, and the manufacturing process are difficult, and moreover, the cost is a very important element to consider in all of these phases [

3,

5]. An adaptable hand with flexibility, dexterity, and load carrying capacity analogous to the human hand seems to be the ideal objective for prosthetic application [

7].

Prosthetics research has contributed to the development of very complicated hand prostheses but their structures, with programmable control systems, are not always user-friendly. This makes them very difficult in operation, and the people at whom they are aimed do not use them in the usual way [

7,

8,

9,

10].

Thus, it is necessary to develop intelligent prostheses that can be easily adapted to the requirements of each individual they are intended for. For the development of such products, researchers must consider the following basic systems: mechanical, actuators and motors, sensors, and command and control [

10].

According to [

11], for designing a hand prosthesis, the project team needs to understand the mechanics of mechanisms such as gears, levers, and points of mechanical advantage, and electromechanical design such as switches, DC motors, and electronics. Mechatronics is the new word used to describe this “marriage” of mechanical and electronic engineering. However, for applying the concepts of mechatronics in bioengineering, it is necessary to take into account the principles of how the human body functions.

Electromyography (EMG) [

12] is used to evaluate and record the electrical activity produced by the muscles of human body. Recently, it has been used in the rehabilitation of patients with amputations in the form of robotic prostheses, it is a tool used to evaluate and classify the different movements of body, so that the robotic mechanism can effectively imitate the motions of human limbs. In [

13], mathematical algorithms tested in prototypes of intracortical neuromotor prostheses have been developed. These closed-loop algorithms [

13] offer visual access (neurally derived cursor trajectories), and mechanical access (as in the stimulation of muscles via implanted electrodes) to any number of output devices.

The upper limb prostheses should be customized, complex, high-performance, and able to ensure a good life for the person wearing it. There are many hand prostheses available on this special “market”, but efficient prostheses are expensive and are not affordable for all of the people who might need them.

This paper presents aspects of the concept and design of a customized prosthesis for the upper limb. The software and hardware tandem concept of this mechatronic system enables complex motion (in the horizontal and vertical planes) with accurate trajectory and different set rules (gripping pressure, object temperature, acceleration toward the object). The command and control system is embedded, and the data received from the sensors are processed by a micro-controller for managing the control of the micro-motors. The customized prosthesis is intended to be light and user-friendly, is estimated to have medium manufacturing costs (a few thousand Euros), and would be reliable, with little maintenance required.

2. Materials and Methods

One of the first steps in the conceptualization of the customized upper limb prosthesis is that of the kinematic analysis of its finger mechanism. In order to perform this, some basic aspects of the mechanism theory have been considered as follows [

14,

15,

16,

17,

18,

19,

20,

21,

22]:

Link—is a rigid body.

Joint—is a permanent contact between two links.

Planar motion—is the motion “in which all points belonging to a link move in a plane known as the plane of motion, while simultaneously the link is free to rotate about an axis perpendicular to the plane of motion”.

Degree of freedom of a rigid body—is the number of independent movements it has.

Kinematic constraints are “constraints between rigid bodies that result in the decrease of the degrees of freedom of the rigid body system”.

An Assur group is a set of kinematic chains developed by Leonid Assur whose degree of freedom is zero. A complex structure can be constructed by extending the Assur kinematic chain. The complex linkage mechanism can be regarded as originating from some Assur kinematic chains

Kinematic analysis is the motion analysis aimed at determining the positions, speed, and acceleration distributions of each element, previously knowing their constructive characteristics and the relative movement of the active link elements.

A dyad is an Assur group made of two parts, three joints, and two outputs (

Figure 1a,b).

A triad is an Assur group made of four parts, six joints, and three outputs (

Figure 1c).

For the mechanism of the designed prosthesis, the kinematic analysis was done by the matrix–vector method [

23,

24], which is simple, intuitive, and fits for open spatial contours. For its index finger mechanism, the kinematic scheme is shown in

Figure 2. The final Hartenberg–Denavit trihedral,

T1,

T2, ...,

Ti+1, is associated with the fingertips. The trihedral versos are

,

.

The main steps of the calculus required for the kinematic analysis of the index finger mechanism are presented next. The simplified structure of the mechanism is a serial open kinematic chain made of dyads. The base trihedral,

,

,

, overlaps the orthogonal reference trihedral Oxyz with the

,

,

versors. The position vector of the

T1 customized point,

, is given by relation (1):

where:

- -

represents the distance between normal versors, and (axial displacement), with a positive sign along the axis;

- -

is the distance between the and axes, positive sign;

- -

is the angle between the and versors, positive sign along axis;

- -

is the angle between the and versors (crossing angle), positive sign along axis.

In order to simplify the transformation matrix elements’ notation, the symbols are:

, , and .

Coordinates transformation of a point, from

trihedral to

trihedral, is:

where:

is the transformation matrix.

Consequently, there are evidenced the relations that follows:

and

where

represent the component elements of the transformation matrix,

Based on all the above, the projections of the position vector,

, on the Oxyz trihedral are:

or, written as a matrix, it turns into:

where:

and

For the designed index finger mechanism (see

Figure 2), there are some customized values that equal zero, as follows:

- -

the axial displacements: ; ;

- -

the distances between axes versors: ; ; .

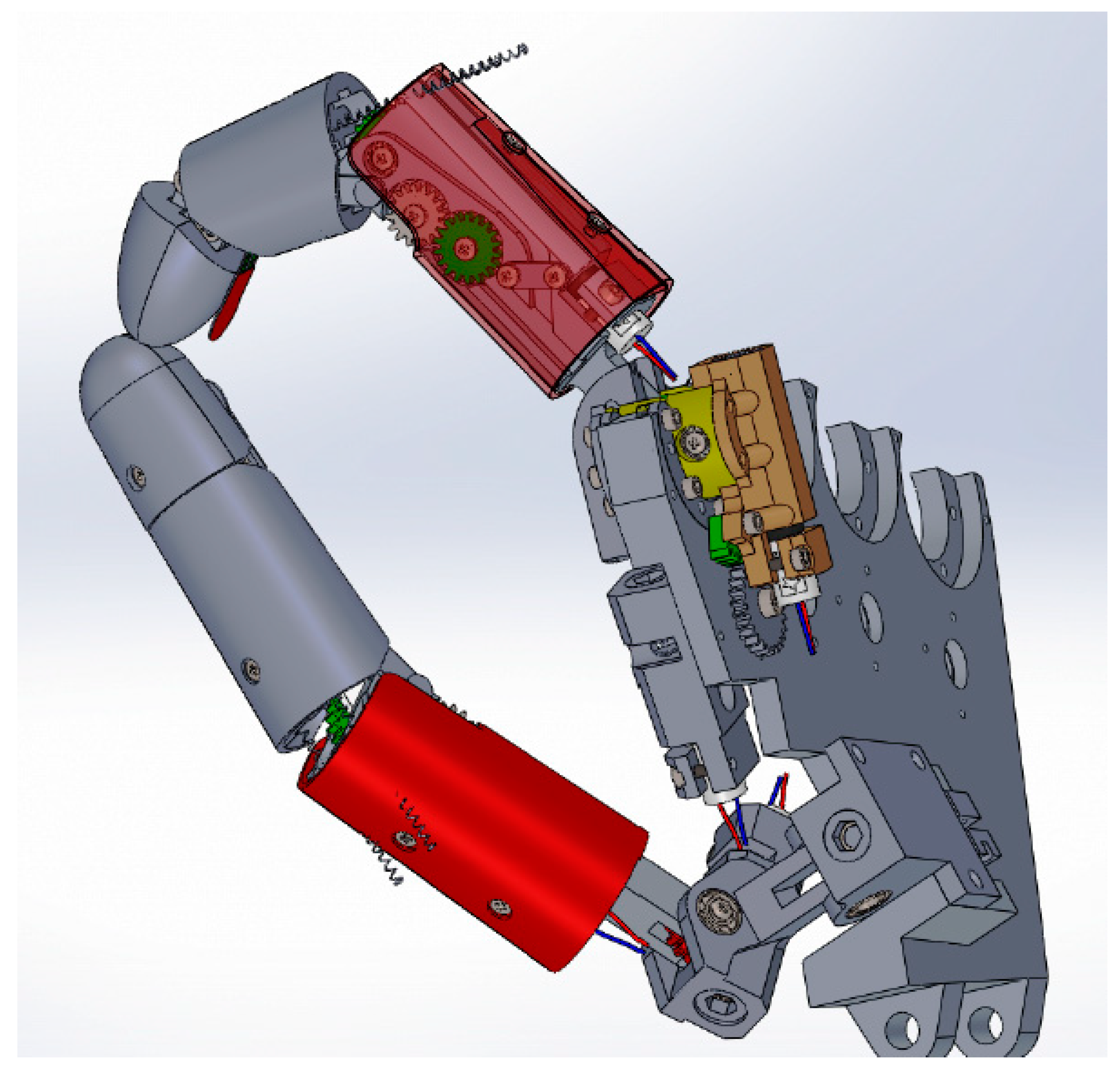

Results of the kinematic analysis are further presented in

Section 3. The mechatronic system for the upper limb has been designed so that it enables finger and forearm motion like that of a real limb as much as possible. Each finger is driven by three micromotors, and its mechanism allows for complex motion, in both the horizontal and vertical planes. The hand and forearm are to be driven by two motors each (and, if required, by assigned gearboxes), and their motion will be possible in two planes (horizontal and vertical).

From the point of view of the system’s appearance and its components’ dimensions, it has been envisaged to look similar to a real hand. The reverse engineering technique has been used to scan a real hand and to obtain its surface dimensions. The technique used was laser scanning, the specific equipment was a MetraSCAN 3D scanner, and the scanning process did not last more than 3 min. Still, if any slight movement of the real hand occurs while scanning, the acquired data (point cloud) generate a contour surface with errors. This is why the process had to be repeated few times till a correct and complete surface had been generated.

The scanning process was performed using a 0.1 mm mesh resolution at a measurement rate of 800,000 measurements/s. The finished scanned body was achieved by aligning 3 scans, with each scan containing overlapping areas. The resulting body can be seen in

Figure 3b,c.

After each scan, the concerned body and also the table body on which the hand is resting (see

Figure 3a) were cleaned by different surplus meshes by using the proprietary software (VXmodel) and different types of commands and functions within the software. The images taken while scanning are presented in

Figure 3.

Once the surface of the real upper limb was obtained (by combining and aligning 3 different scans of the same hand), further processing to determine the hand and fingers’ dimensions was performed. Information about the dimensions and contour characteristics (shape and size) of the hand were obtained by using reverse engineering software (Geomagic DesignX and Solidworks) and plane generation, as can be seen in

Figure 4. For this process, we used 43 planes from the tips of the fingers to the back of the hand.. The planes were generated using the offset function, and the distance between two consecutive planes was set to 10 mm.

If the interest on dimensions referred to the horizontal plane, the scanning process, using the proprietary software (VXmodel), generated a triangle mesh in real time through the alignment or registration method. This process can be seen in

Figure 5a. After this is done, the dimensions and dimension parameters were obtained by using reverse engineering software (Geomagic DesignX) and specific tools, such as in

Figure 5b. Then, a sketch was generated and parametrized, as in

Figure 5c.

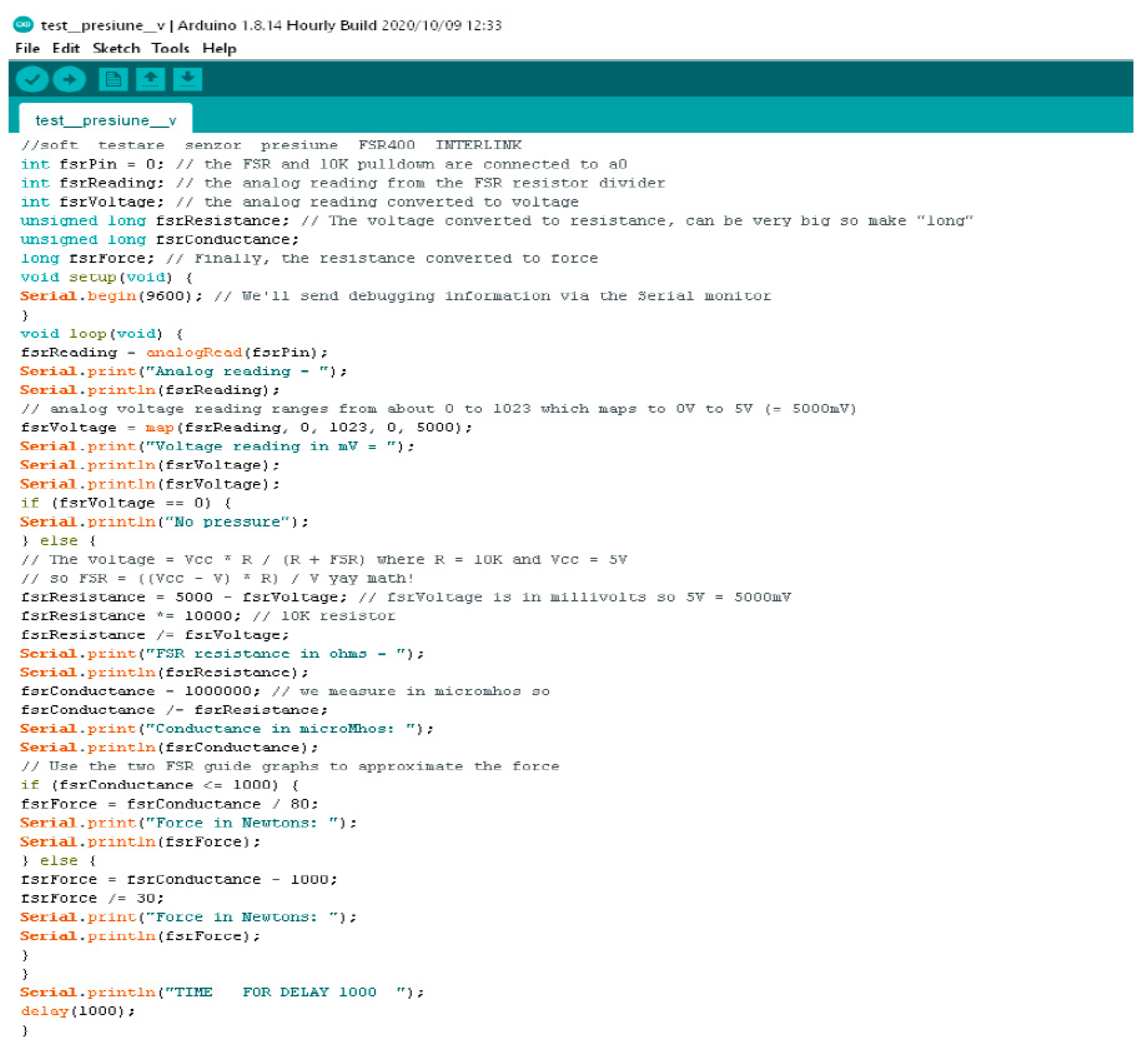

The command and control system for the upper limb prosthesis is embedded and designed for customized applied mechatronics application.

Available applications of this prothesis are in the social–medical fields for people with upper limb amputations (hand, forearm or, arm) who would be closer to “normal” everyday life. Another application would be in the field of CBRNE (Chemical, Biological, Radiological, Nuclear, and Explosives) security, for taking samples and/or the manipulation of harmful products in dangerous environments (radiations, chemicals). Still, this presented research is focused on applications for improving the quality of life of people with upper limb disabilities via prosthesis.

This designed system uses data acquisition and control, the data being received from sensors (pressure, tilt, temperature, etc.) and further processed by a micro-controller to manage the micro-motors’ control. Depending on the missing part of the human body, the system’s design and structure varies from the point of view of the sensors’ type, number, and position; micro-motors; micro-controllers; electric circuit pattern, etc.

The algorithm scheme of the upper limb prosthesis is shown in

Figure 6. The novelty of this concept is that, for each of the five fingers, there are three micro-motors to generate motions (not servomotors, as with most of the available myoelectric prostheses), so that the combination of software and hardware (including the mechatronic system) is specific to this prosthesis. The fingers’ control is accurate and complex due to the complexity of motions (in the horizontal and vertical planes).

Basically, the main components of the system are:

- -

sensors—for peripheral control (pressure sensors for the gripping force of an object, temperature sensors for estimating the temperature of the object to be gripped, and tilt sensors for the inclination angle of the fingers’ phalanges);

- -

drivers for the micro-motors;

- -

micro-motors (for the fingers’ motion) and motors (for the hand and forearm motion) with an assigned demultiplication gearbox, if required;

- -

microcontroller—a microcomputer with digital and analogic inputs and a GPIO (General-Purpose Input/Output) port.

The whole system is conceived as an open hardware platform with high versatility. A sound or vibration warning system could be added if visually impaired people would need the prosthesis.

The main aspects of how the customized prosthesis is designed to work are presented in

Figure 7. The first step is that of checking the battery status. If it is necessary, then the battery should be plugged in via the USB port. This port also enables writing to the flash memory, operational maintenance, adjustment/repairs the system, and updating and improving the prosthesis’ system.

The temperature sensor is an infrared active digital sensor with an I2C communication protocol, and is aimed at determining the temperature of the object going to be gripped. The gyroscope–accelerometer sensors are aimed at determining the angular position of the prosthesis and its motion acceleration. The pressure and tilt sensors are resistive, and for higher conversion accuracy they are connected to an ADC (Analog-to-Digital Converter) by an instrumentation amplifier. If there is not enough digital inputs, then different ADC components will be used (in the case of multi-channel EMG).

The EMG sensor (MyoWare) is aimed at initiating the motion. It could be multi-channel EMG for higher sensitivity.

Micro-motor drivers get commands from the controller via a GPIO interface. The feedback loop is aimed at controlling the energy consumption by measures on each of the micro-motors. The software–hardware tandem ensures motion control by experimenting with the conditions for the correct gripping of objects that are going to be set. By utilizing software limits, p = psoft, Acc = Accsoft, °C < XTemp, α < αsoft, the system continues with the motion or stops it.

In

Appendix A, the customized scheme for the EMG sensor (

Figure A1) and the customized schemes for the resistive sensors (pressure, tilt) and for the gyroscope sensor (

Figure A2) are presented.

4. Discussion

The research results presented in this paper are focused on the concept and design of a prosthesis for the upper limb.

Customization of this prosthesis is an important issue. Due to the reverse engineering technique, size, dimensions, and other geometric characteristics of a real upper limb would be achievable with this prosthesis. The 3D scan of the upper limb was performed for one of the authors of this paper. The reverse engineering technique enabled determining the value for any dimension, both in the transversal and horizontal planes. The design of this prosthesis would match, as much as possible, these dimensions, which are the ones of the scanned upper limb. This poses a real challenge for the concept and design of the mechanical components, as there is limited available space when considering the reverse engineered contour characteristics.

The finger mechanism was studied from the point of view of kinematic and kinetostatic analyses. The matrix–vector method, aided by Matlab software, was used to determine the joint and fingertip trajectories. Simulation results for the finger mechanism evidenced correct motions.

The command and control system is embedded and designed for customized applied mechatronics applications. The novelty of this concept is that for each of the five fingers, there are three micro-motors to generate motion (and not servomotors, as in most available myoelectric prostheses). The combination of software and hardware (the mechatronic system included) is specific to this prosthesis. It enables the accurate trajectory of the fingertips and different set rules (gripping pressure, object temperature, acceleration toward the object). The ROM of each joint will be defined once all the tests are completed, and the validation of the results will be performed.

Preliminary testing of the sensors and micro-motors on a small platform, Arduino, was performed for the prototype (two fingers, 2-FPRINT). The conclusion from testing the resistive sensors pointed out the need for the careful selection of the base material, specifically the one for the fingers’ surface. The upper limb prosthesis (whole product) will have its PCB, or micro-computer; will be versatile; and will be of small dimensions.

The concept of this upper limb prosthesis is aimed at becoming a high-versatility hardware platform. Optionally, for example, a system for sound or vibration warning could be integrated if a visually impaired person was to need the prosthesis.

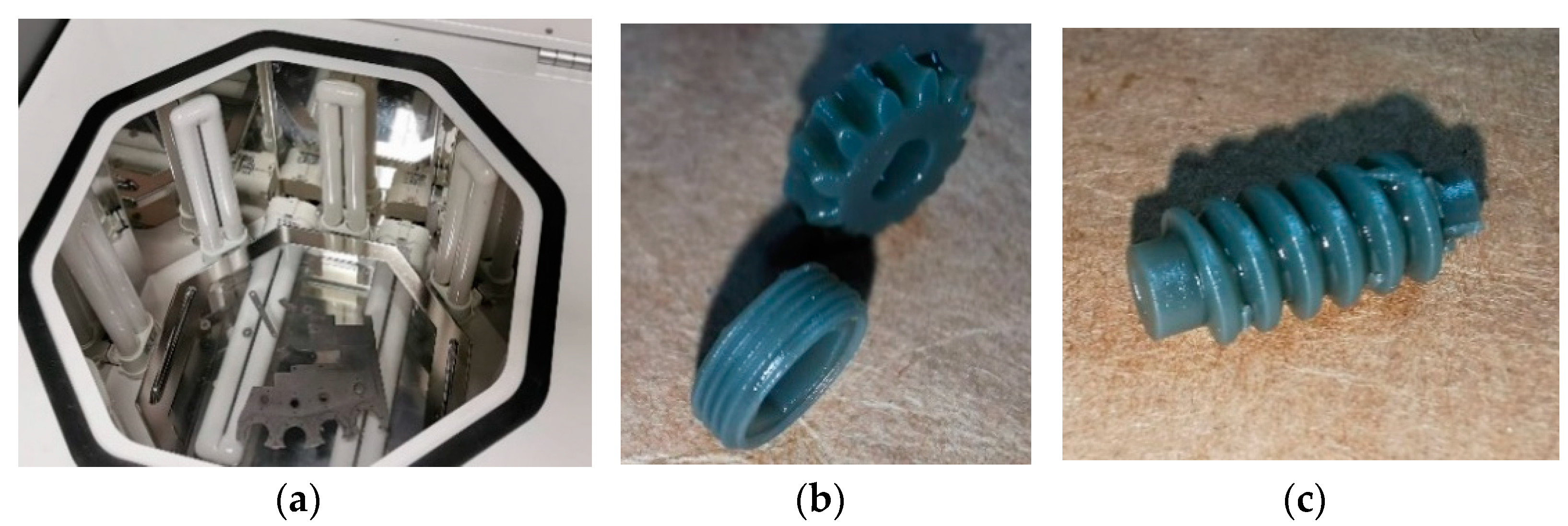

Prototyping the mechanical components has been a challenge because of the high accuracy needed for the geometric precision of parts. Several techniques of rapid prototyping have been considered, out of which the DLP (Digital Light Processing) proved to be the right one.

As, for the moment, only obtaining the prototype is intended, there is no ethical approval asked from any authorities. Later in time, after the prototype manufacturing is completed and all tests are correct, validation and, perhaps, IRB approval would be required.

5. Conclusions

This paper presents aspects of the concept and design of a customized prosthesis for the upper limb. The software and hardware tandem concept of this mechatronic system enables complex motion (in the horizontal and vertical planes) with accurate trajectory and different set rules (gripping pressure, object temperature, acceleration toward the object).

The concept of this upper limb prosthesis is different from the many existing prostheses existing on the market. The fingers’ motion is initiated by EMG sensor signal, and the mechanical components are driven by micro-motors, three for each finger (and not by servo-motors, as with most myoelectric prostheses). The rapid prototyping of mechanical components has been considered instead of classical manufacturing techniques (CNC machining by turning, milling, drilling, etc). There were several 3D printing techniques applied of those available and estimated to fulfil the requirements of parts (high geometric precision and accurate finish). It was only DLP (digital light processing) that enabled the manufacturing of mechanical parts with the conditions prescribed in the design.

The customization of the prosthesis’ aspect and dimensions, close to those of a person’s real limb, is due to the reverse engineering technique. Further development of this research will aim for the careful selection of materials and manufacturing of the all the mechanical components for the upper limb prosthesis, assembling them into a whole prototype (including micro-motors, controllers, sensors, etc.), and the complete testing and validation of results.

The upper limb prosthesis prototype will be in accordance with the body features of the person wearing it, will be lightweight, be easy to maintain, and its cost will be a few thousand Euros.