1. Introduction

The safeguard of the built heritage is gaining an increasing interest in structural and seismic engineering [

1,

2]. The knowledge of the seismic response of the structures plays a fundamental role in the evaluation of the seismic vulnerability of existing structures [

3,

4,

5,

6] and in the prediction of the expected losses [

7,

8,

9]. The designer, to achieve a correct safety evaluation in terms of the capacity demand ratio, must resort to non−linear models and non−linear analyses [

10,

11,

12,

13], which, even though they are described in the codes, are very prone to being misinterpreted. The implementation of a non−linear model needs adequate experience and, first of all, an adequate knowledge of the condition of the building to be modelled in terms of geometry, loads, structural details, materials and degradation [

14,

15,

16,

17,

18]. In the perspective of a seismic classification of the built heritage, it is necessary to define a standardizable, unique and user−friendly methodology [

19,

20,

21,

22]; therefore, recently, a simplified assessment approach has been developed concerning steel moment resisting frames (MRFs) [

23] based on a trilinear model that needs only the elastic structural analysis and the rigid-plastic analysis and does not require any static or dynamic non−linear effort. Rigid plastic analysis has generally been used as an assessment tool against vertical and horizontal loads. The novelty point of the procedure is to use the rigid plastic and elastic analysis joined with a performance-based evaluation aimed at easily assessing the seismic performance of existing buildings, also ensuring a rapid mapping of the built heritage in terms of seismic vulnerability.

This assessment procedure is herein applied to some study cases to support their ease of application. It mainly consists of the definition of a trilinear capacity curve by some characteristic points that define three branches [

24,

25]. These points correspond to different limit states. It is important to mention that the code assessment approach does not provide the definition of specific performance points on the pushover curve, thus entrusting the designer to the definition of required target limits which are provided by codes in terms of member chord rotation.

The method has been set up by performing several parametric analyses, in terms of pushovers, on 420 frames, designed according to three different approaches, i.e., without any seismic detailing (O−MRFs), by Eurocode 8 (S−MRFs) and by the theory of plastic mechanism control (G−MRFs). It is usually observed that structures designed without any seismic provision exhibit a soft storey mechanism while the structures designed according to the modern approach of Eurocode 8 can achieve more robust performances even if the global mechanism can be assured only by the TPMC approach. The results belonging to the pushover analyses performed on the structures have been used to calibrate the assessment relationships, ensuring a wide application of the method. The comparison in terms of capacity and demand can be made according to two alternative approaches: the one proposed by Eurocode 8 [

26] and the one proposed by Nassar and Krawinkler [

27]. The former exploits the concept of ADRS spectrum while the latter has the benefit of being of more easily applicable because it does not single out between low and high periods of vibration. In the following, the main model equations are reported and described.

2. Fundamental Equations of the Trilinear Model

The simplified trilinear model needs only the elastic structural analysis and the rigid-plastic analysis [

28,

29,

30,

31] not requiring any static or dynamic non-linear analyses. Therefore, the user can quickly obtain the capacity curve through the intersection of three linear branches (

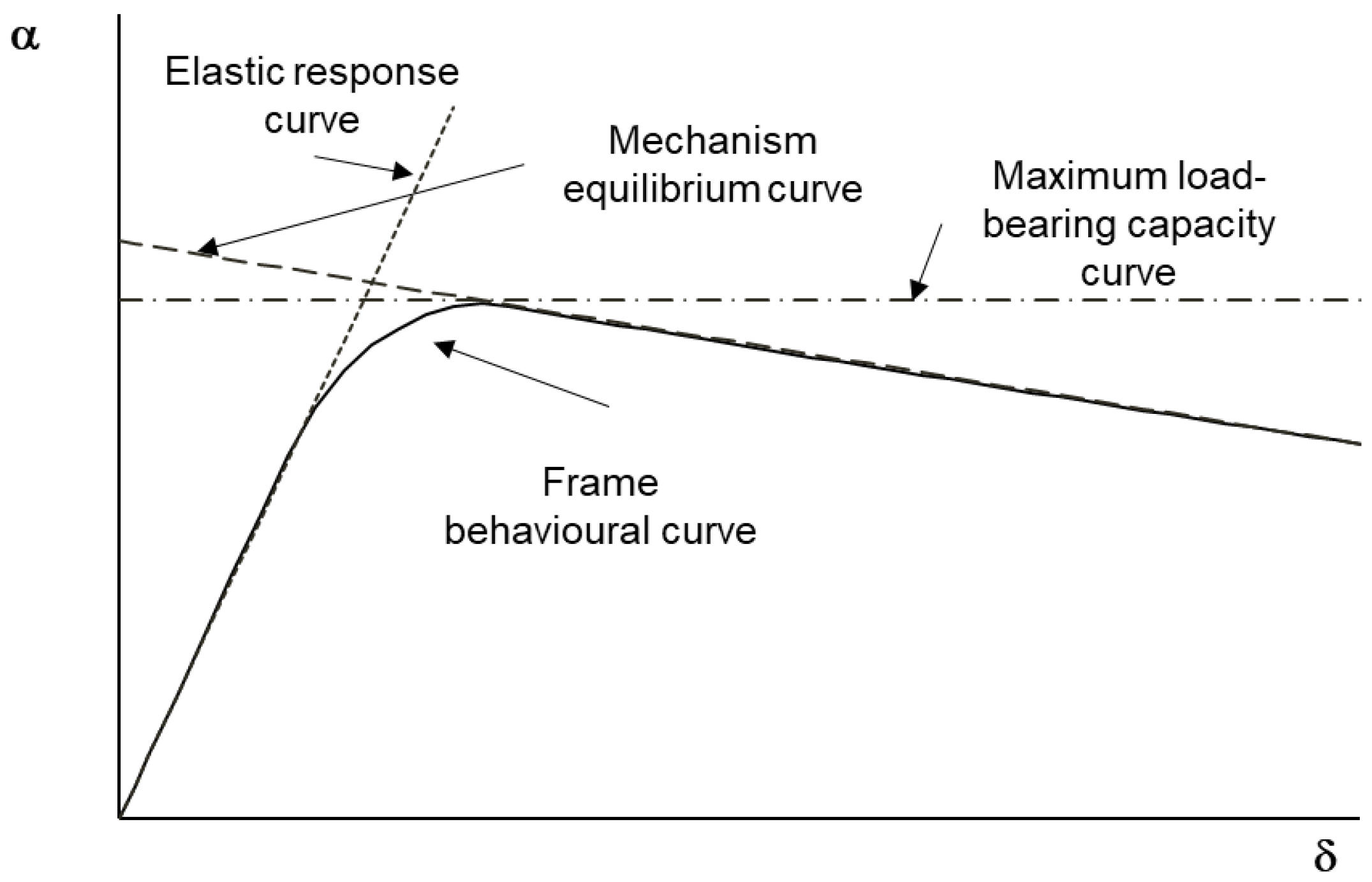

Figure 1), computed using simple relationships proposed in the following. Referring to the proposed model, the first branch of the curve can be approximated by the elastic response curve; the horizontal one is defined using the maximum load-bearing capacity given by the calibrated Merchant−Rankine formula, while, the softening branch is given by the collapse mechanism equilibrium curve of the structure, influenced by the second-order effects [

32,

33,

34,

35,

36]. The definition of the third branch is linked to the concept of the mechanism equilibrium curve. In particular, the equation of the third branch can be obtained by equating the virtual internal work of the dissipative zones with the virtual external work of the structure, accounting for second-order effects.

The equations of the three identified branches in the α−δ plane (horizontal force multiplier—top sway displacement) are reported below:

Maximum load-bearing capacity curve according to the modified Merchant−Rankine formulation [

23,

37,

38]

The use of Equation (3) is proposed by assuming for the coefficient Ψ with the following relation:

The mechanism equilibrium curve according to rigid-plastic analysis [

37]:

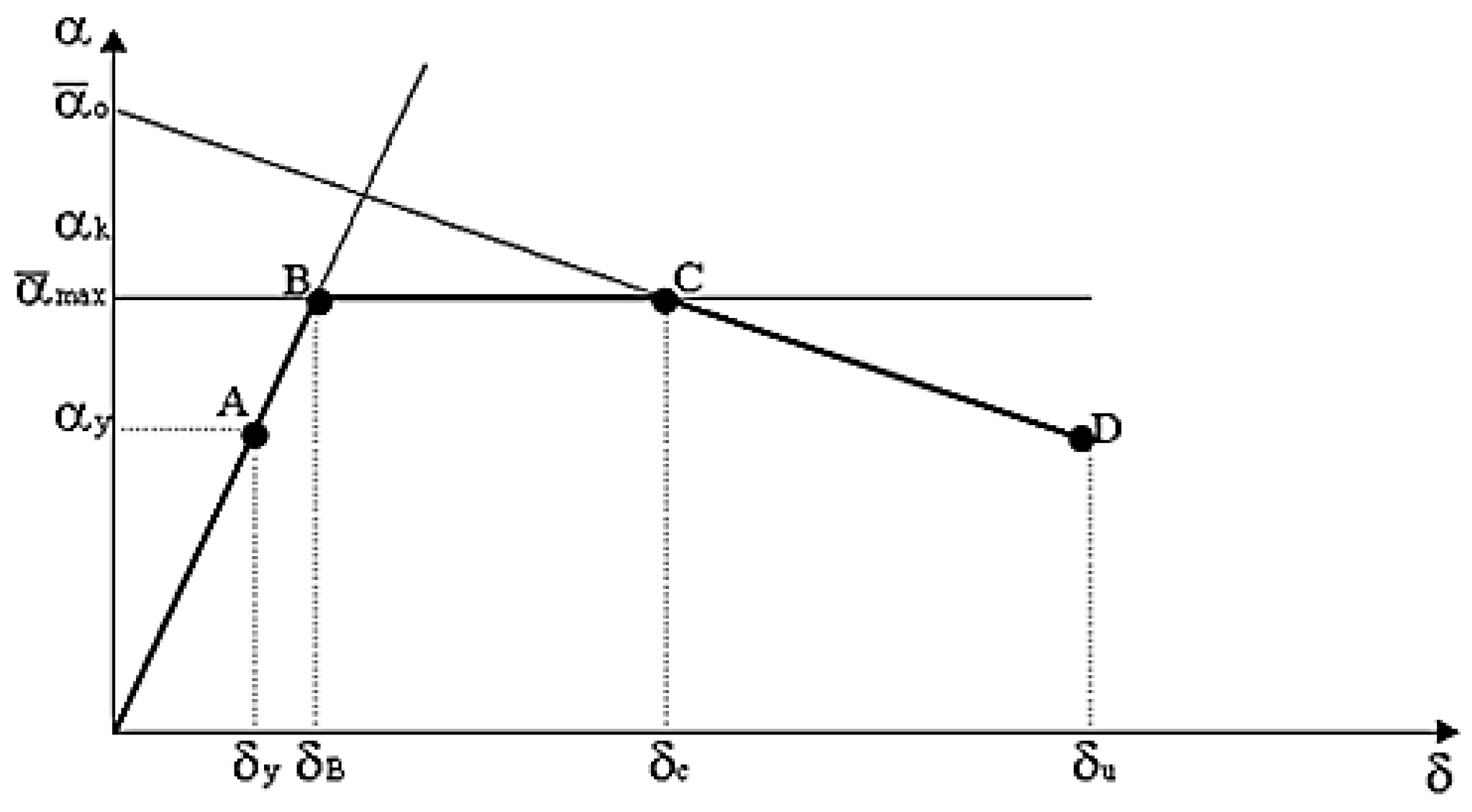

Characteristic performance points (points A, B, C, D of

Figure 2) have been identified on the trilinear model. The points are associated with specific limit states [

35], provided by codes, identifying a target performance level [

34,

39,

40,

41].

where

δA is the displacement corresponding to the minimum between the displacement in the service conditions and

δy is the displacement corresponding to the formation of the first plastic hinge.

where

αmax is the maximum multiplier defined according to the Equation (2).

This point derives from the intersection of the horizontal branch of equation α = αmαx with the softening branch, representative of the collapse mechanism equilibrium curve, of equation α = α0 − γS(δ − δy).

The chord rotation at yielding

ϑy is defined as a property of the member. For ductile elements and brittle elements involved into soft-storey mechanisms, are given by:

while for brittle elements involved in partial and global mechanisms:

For the evaluation of plastic rotations occurring in the critical members, an analytical formulation is proposed, based on a “shear−type” single−storey portal with different plastic moments at the top and base of the columns. The relationships for the evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism are reported as follows:

In particular, the coefficient with the apex refers to the element achieving the collapse (i.e., the critical element), with those without the apex to the element developing the first yielding.

The

Ψi coefficients to be used in Equations (13) and (14), are given by the following equations whose parameters are reported in

Table 1:

3. Assessment Procedure in Terms of Spectral Accelerations According to ADRS Spectrum

The capacity-demand assessment procedure can be expressed through the ADRS spectrum [

12,

26]. For each limit state, the spectrum

Sα −

SDe is defined by the means of the relationship

SDe(

T) =

Sα(

T)(

T/2π)

2. As regards the capacity, it is necessary to represent the characteristic points of the behavioral curve of the structure, in the ADRS plane. Of these points, it is necessary to know the abscissa, which is the displacement

.

It is necessary to distinguish between cases

T* >

TC and

T* <

TC. If

T* >

TC 41, the capacity in terms of spectral acceleration relative to the limit state considered can be obtained through the following relationship:

The demand is represented by the spectral acceleration provided by the code, for the specific limit state, in the case of the equivalent SDOF system with the equivalent period of vibration T*.

For the assessment procedure, the inequality Sαls ≥ Sα(T*) must be satisfied.

If

T* <

TC and

q > 1, according to the equality energy criterion, there is a different procedure to evaluate the capacity that leads to the anelastic spectrum whose parameters are listed below:

If

T* <

TC and

q ≤ 1, it results:

The checking is verified when the inequality Sαls ≥ Sα(T*) is satisfied.

4. Assessment Procedure in Terms of Spectral Accelerations According to Nassar and Krawinkler

In the framework of capacity-demand checking [

27,

37,

38,

39,

40,

41,

42,

43], an equivalent SDOF system replaces the MDOF actual system by means of the modal participation factor

Γ. Multiplying the multiplier

α with the design base shear, the capacity curve is reported in an

Fb—

dc plane. The capacity curve must be reduced through the modal participation factor and represented in an

F*—

d* plane. The demand is estimated through the period

T* and the equivalent mass

m* according to European codes. The capacity in terms of spectral acceleration for the points A, B, C, and D is given as follows:

where

and

.

where

and

.

The coefficient ϕ is a function of the ductility μ and the non-dimensional slope of the equilibrium curve γ.

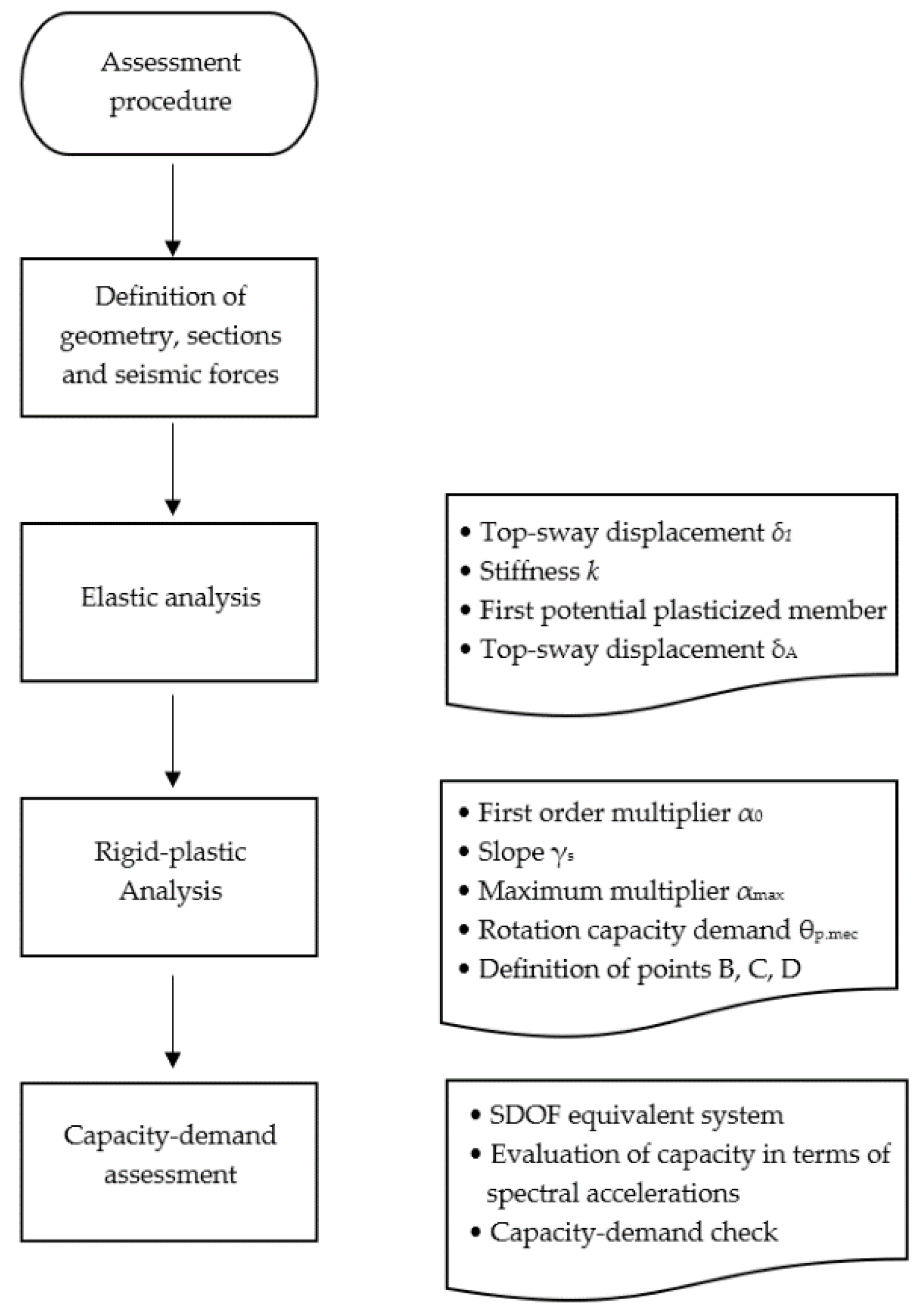

5. Numeric Example

The assessment procedure described above is applied to evaluate the capacity of a seven-storey and four-span steel moment resisting frame. The permanent loads

Gk are equal to 3.5 kN/m

2 while the live loads

Qk equal 3 kN/m

2. For the evaluation of gravitational loads on the beams, a frame tributary length of 6.00 m has been set. The steel used is S275. In

Figure 3a, a flowchart of the procedure is reported.

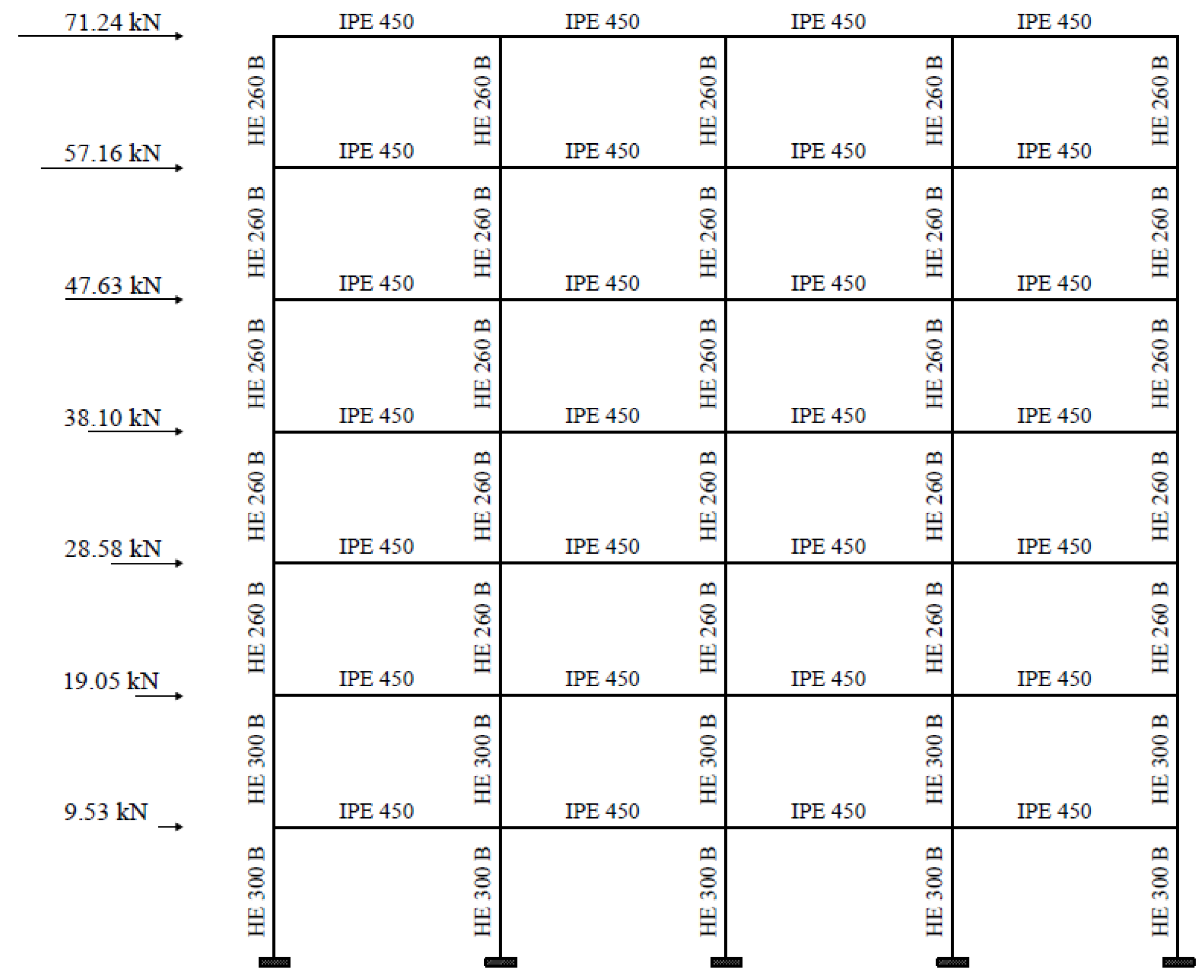

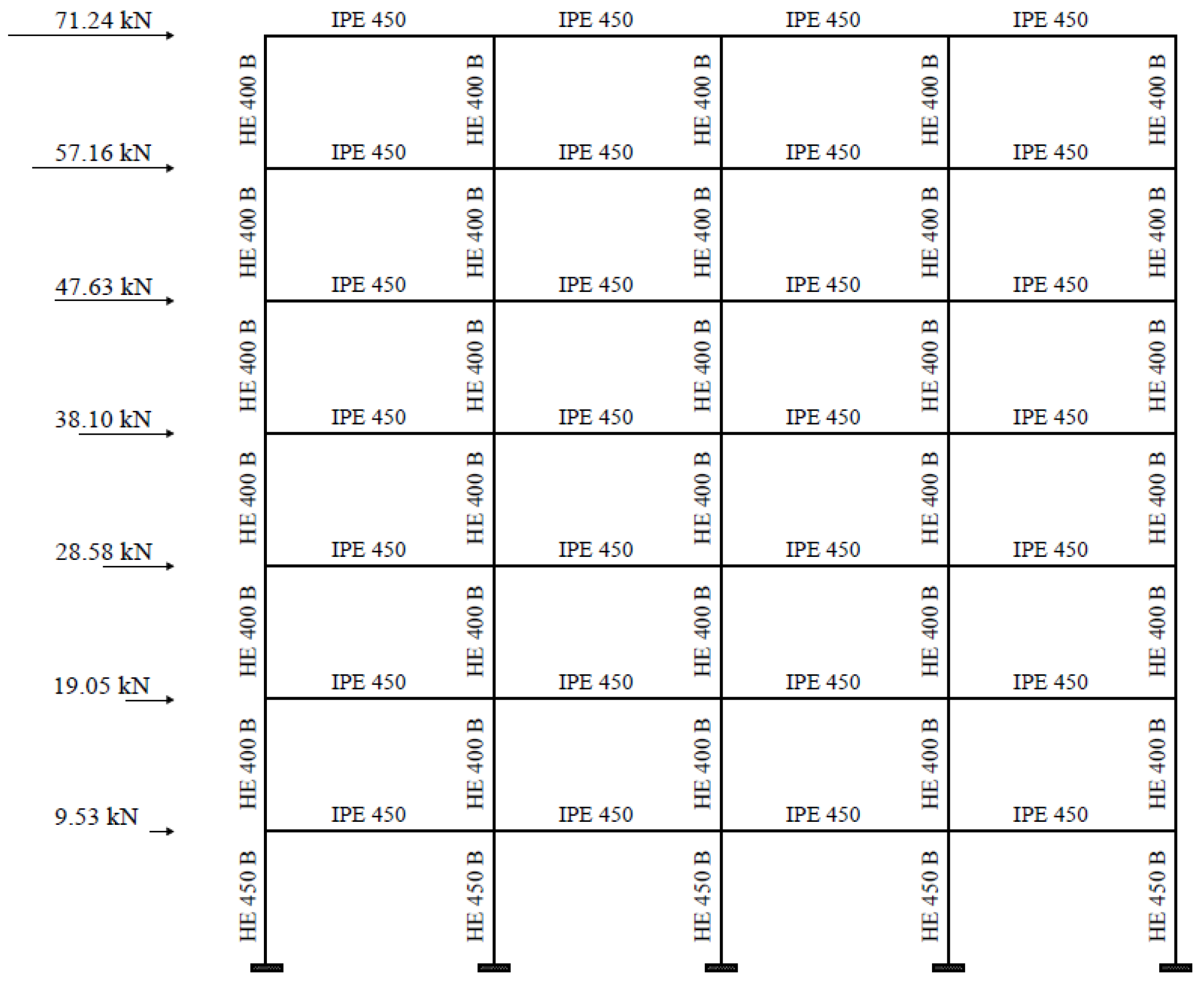

5.1. Ordinary Moment Resisting Frame

Ordinary moment resisting frames are designed without any seismic prescription. The beams and column sections are reported in

Figure 4.

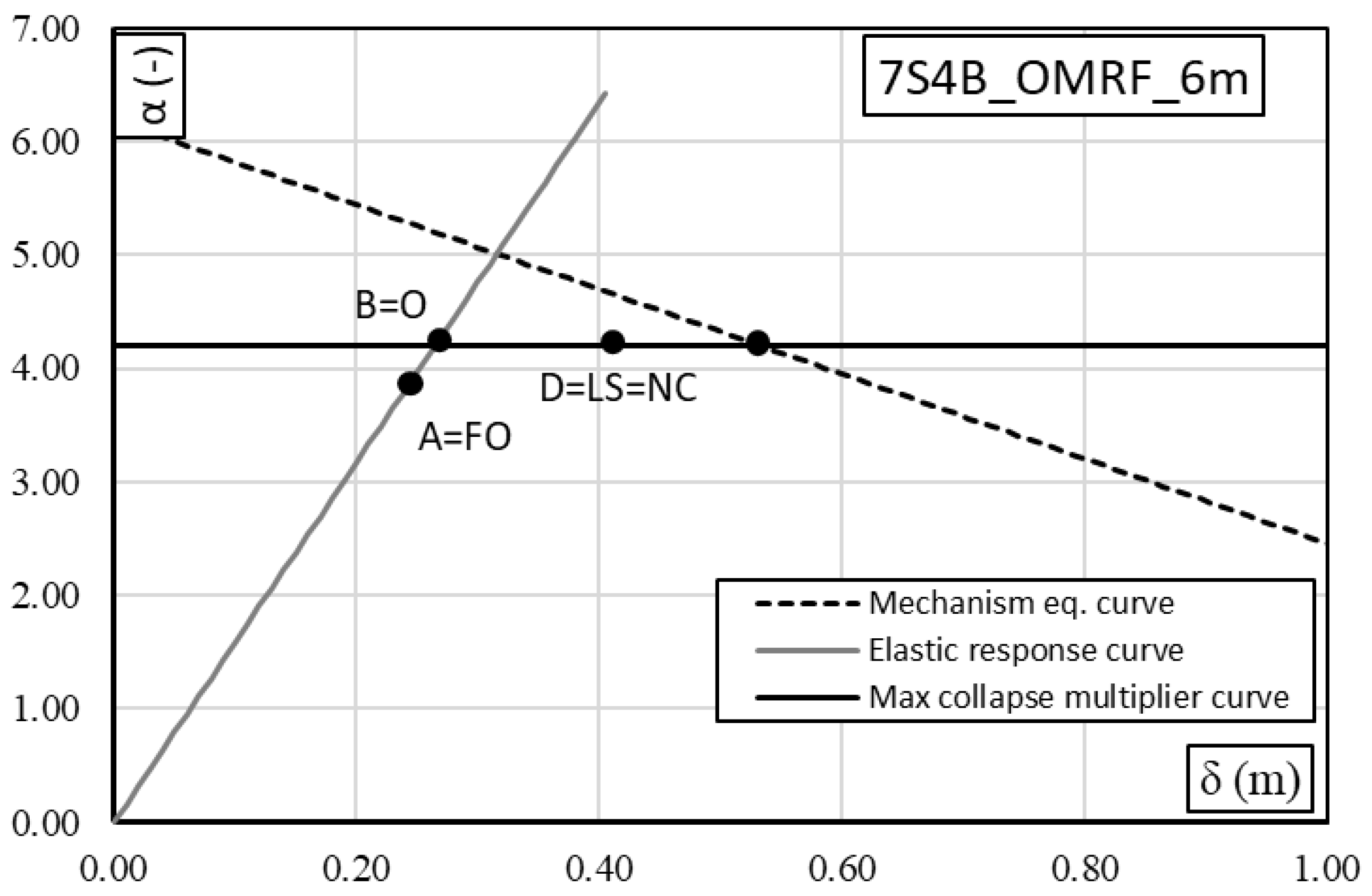

The trilinear capacity curve is shown in

Figure 5, which also shows the characteristic performance points of the model.

Parameters obtained from the elastic analysis:

δ1(α = 1) = 0.06305 m

k = 15.8605 m−1

δA = δy = 0.2602 m

αA = αy = kδy = 4.128

Parameters obtained from the rigid-plastic analysis:

α0 = 5.219

γs = 3.729 m−1

α = α0 − γS(δ − δy) → α = 5.219 − 3.729(δ − 0.2602)

α(δ = 0) = α0 + γsδy = 6.1888

H0 = 3.5 m(collapse mechanism Type 3, im = 3)

Evaluation of the maximum multiplier using the calibrated Merchant−Rankine formula:

where:

and consequently

and

=

.

Evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism for the first plasticized element (first storey beams):

The calculation of the corresponding capacity provides a final plastic rotation value of 8θy = 8 × 0.008257 = 0.06605 rad.

Evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism for the critical element (the mechanism is partial type 3 im = 3, so the critical element is a third storey column):

The calculation of the corresponding capacity, in the case of the third storey columns, provides a value of the ultimate plastic rotation equal to 8θy = 8 × 0.005568 = 0.04454 rad. Therefore, the ultimate conditions are governed by the columns of the third storey.

Considering the plastic rotation capacity, the ultimate displacement is given by:

Since the plastic rotation capacity of the third storey columns is lower than that necessary for the complete development of the kinematic mechanism, the points C and D corresponding to the limit states “Life Safety” and “Near Collapse” are coincident and correspond to the aforementioned last displacement (δu).

All the verification procedures considered the use of the transformation of the MDOF system into an equivalent SDOF system using the participation coefficient of the main vibration mode Γ. For this reason, it is necessary to define:

The eigenvector ɸ = {ɸ1, ɸ2, ɸ3, ɸ4, ɸ5, ɸ6}that, assuming , is:

The modal participation factor Γ:

being:

The dynamic parameters of the equivalent SDOF system are reported in

Table 2.

Therefore, the characteristic points of the capacity curve are defined in the planes

α −

δ,

Fb −

dc,

F* −

D*,

Sα −

SD assessing the capacity in terms of accelerations for the Nassar and Krawinkler approach and ADRS spectrum approach. In

Table 3, the results based on the use of the ADRS spectrum, and in

Table 4, the results based on the use of the Nassar and Krawinkler formulation, are reported. The numbers in bold identify the values of spectral acceleration and displacement to be used in the capacity-demand assessment procedure.

Seismic performance verification requires that, for each limit state, the inequality Sα.ls(T*)capacity ≥ Sα.ls(T*)demand is satisfied.

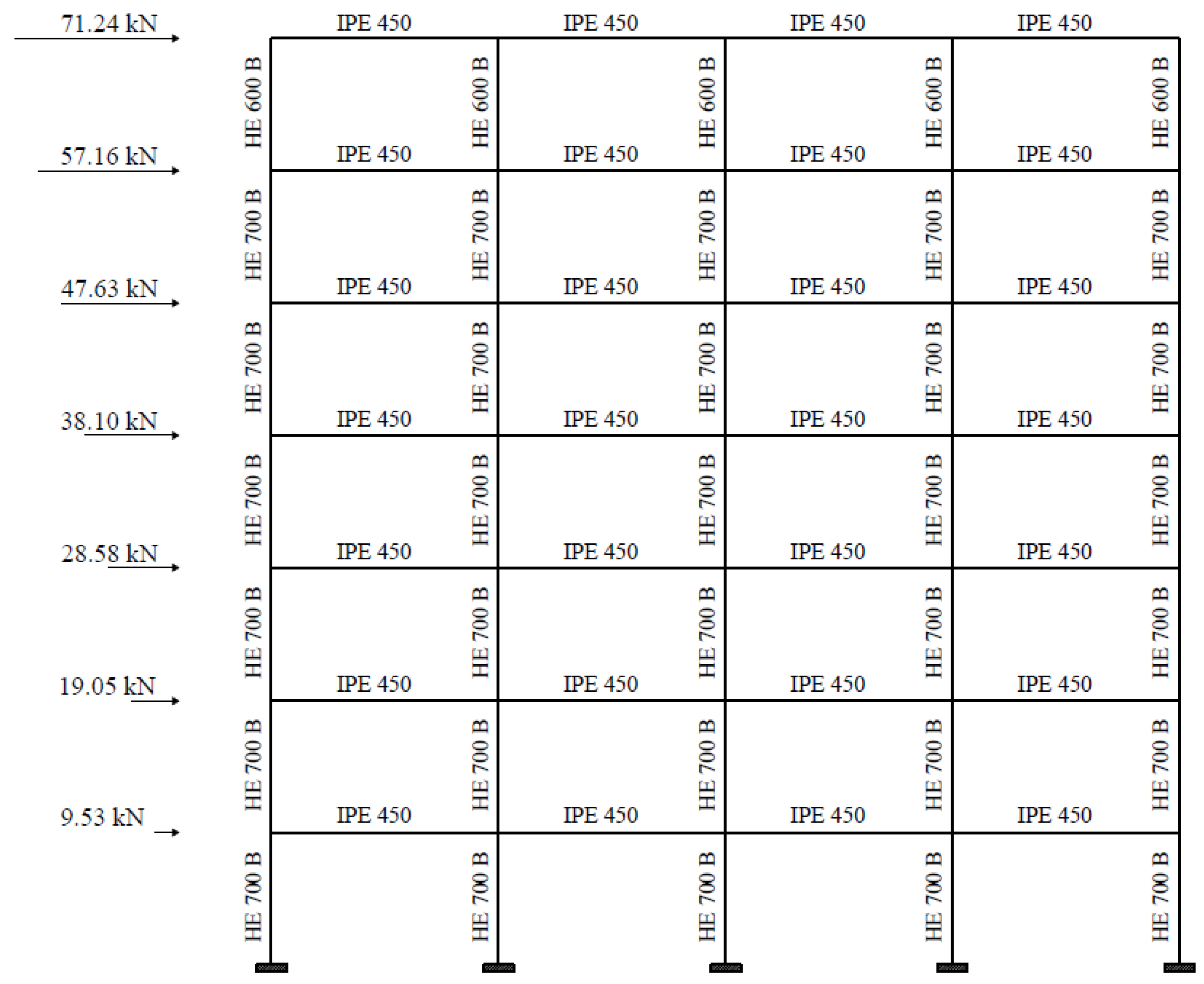

5.2. Special Moment Resisting Frame

Special moment resisting frames are designed to fulfil the Eurocode 8 seismic provisions. The selected case study with the definition of the beam and column dimension is reported in

Figure 6.

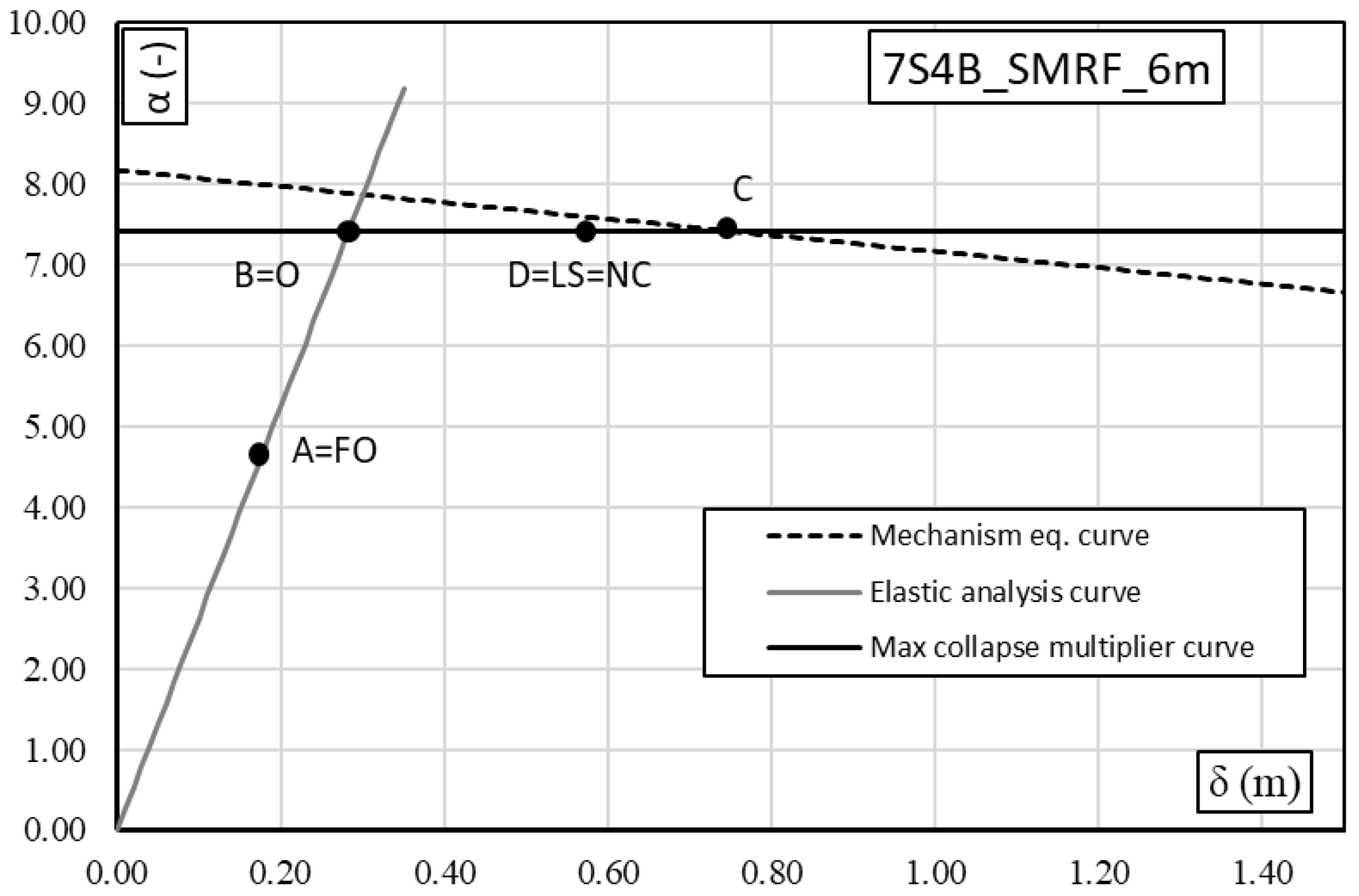

The trilinear capacity curve is shown in

Figure 7, which also shows the characteristic performance points of the model.

Parameters obtained from the elastic analysis:

δ1(α = 1) = 0.03814 m

k = 15.8605 m−1

δA = δy = 0.1802 m

αA = αy = kδy = 4.736

Parameters obtained from the rigid-plastic analysis:

α0 = 7.989

γs = 1.006 m−1

α = α0 − γs(δ − δy) → α = 7.989 − 1.006(δ − 0.1802)

α(δ = 0) = α0 + γsδy = 8.1704

H0 = 14.0 m (collapse mechanism Type 1, im = 4)

Evaluation of the maximum multiplier using the calibrated Merchant−Rankine formula:

where:

and consequently

and

=

.

Evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism for the first plasticized element (first storey beams):

The calculation of the corresponding capacity provides a final plastic rotation value of 8θy = 8 × 0.008257 = 0.06605 rad.

Evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism for the critical element (the mechanism is partial type 1 im = 4, so the critical element is a first storey column):

The calculation of the corresponding capacity, in the case of the third storey columns, provides a value of the ultimate plastic rotation equal to 8θy = 8 × 0.004212 = 0.033699 rad. Therefore, the ultimate conditions are governed by the columns of the first storey.

Considering the plastic rotation capacity, the ultimate displacement is given by:

Since the plastic rotation capacity of the third storey columns is lower than that necessary for the complete development of the kinematic mechanism, the points C and D corresponding to the limit states “Life Safety” and “Near Collapse” are coincident and correspond to the aforementioned last displacement (δu).

All the verification procedures considered the use of the transformation of the MDOF system by means of the participation coefficient of the main vibration mode Γ. For this reason, it is necessary to define:

The eigenvector

ɸ = {ɸ

1, ɸ

2, ɸ

3, ɸ

4, ɸ

5, ɸ

6}that, assuming

, is:

The modal participation factor Γ:

being:

The dynamic parameters of the equivalent SDOF system are reported in

Table 5.

Therefore, the characteristic points of the capacity curve are defined in the planes

α −

δ,

Fb −

dc,

F* −

D*,

Sα −

SD assessing the capacity in terms of accelerations for the Nassar and Krawinkler approach and ADRS spectrum approach. In particular, in

Table 6, the results based on the use of the ADRS spectrum, and in

Table 7, the results based on the use of the Nassar and Krawinkler formulation, are reported.

Seismic performance verification requires that, for each limit state, the inequality Sα.ls(T*)capacity ≥ Sα.ls(T*)demand is satisfied.

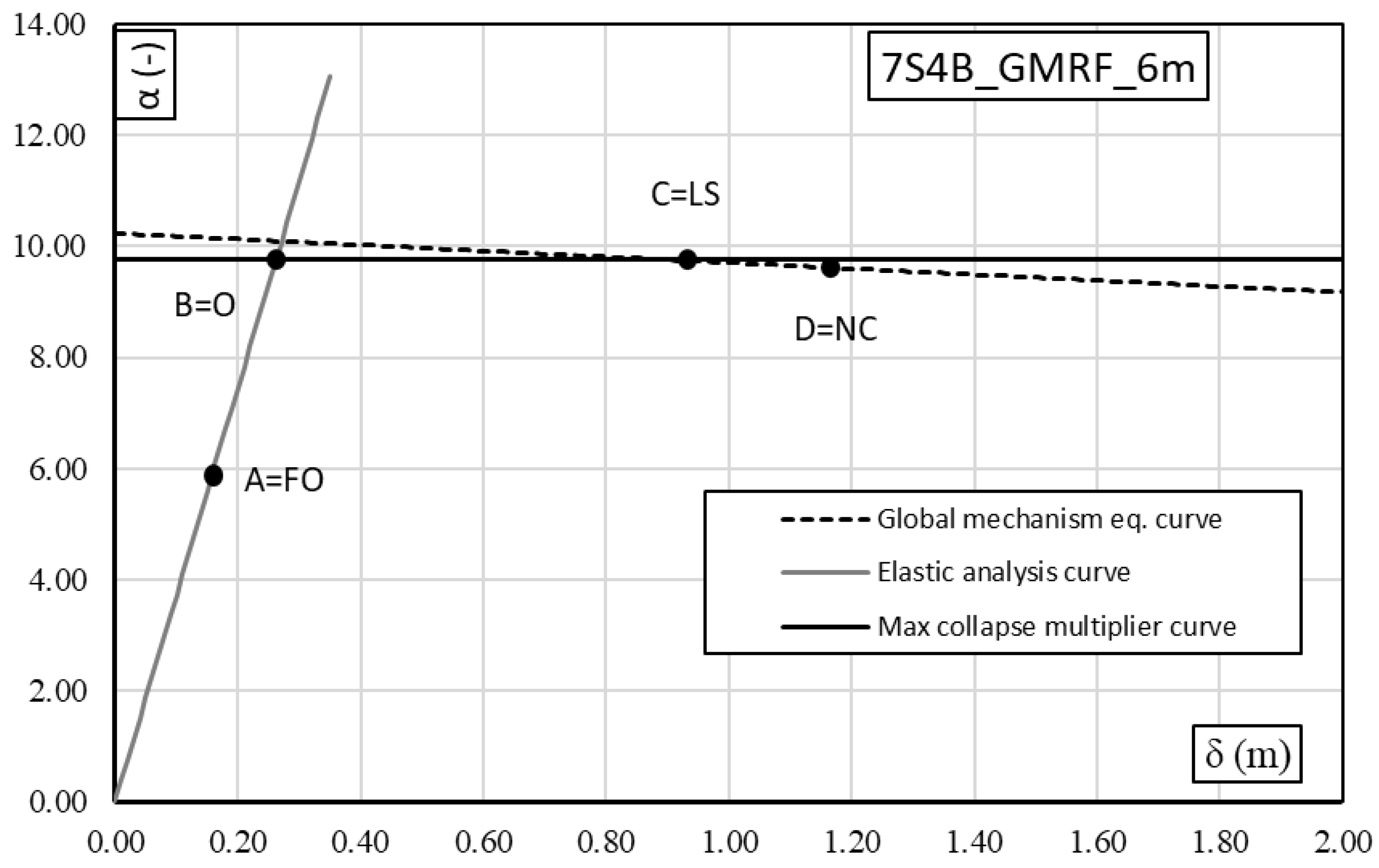

5.3. Global Moment Resisting Frame

Global moment resisting frames are designed according to the TPMC. The design results are reported in

Figure 8.

The trilinear capacity curve is shown in

Figure 9, which also shows the characteristic performance points of the model.

Parameters obtained from the elastic analysis:

δ1(α = 1) = 0.02684 m

k = 37.2606 m−1

δA = δy = 0.1602 m

αA = αy = kδy = 5.999

Parameters obtained from the rigid-plastic analysis:

α0 = 10.149

γs = 0.53 m−1

α = α0 − γs(δ − δy) → α = 10.149 − 0.53(δ − 0.1602)

α(δ = 0) = α0 + γsδy = 10.234

H0 = 24.5 m (Global collapse mechanism)

Evaluation of the maximum multiplier using the calibrated Merchant−Rankine formula:

where:

and consequently

and

=

.

Evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism for the first plasticized element (first storey beams):

The calculation of the corresponding capacity provides a final plastic rotation value of 8θy = 8 × 0.008257 = 0.06605 rad.

Evaluation of the plastic rotation demand corresponding to the development of the collapse mechanism for the critical element (the mechanism is global, so the critical element is one of the first storey columns):

The calculation of the corresponding capacity, in the case of the third storey columns, provides a value of the ultimate plastic rotation equal to 8θy = 8 × 0.003714 = 0.02971 rad. Therefore, the ultimate conditions are governed by the columns of the first storey.

Considering the plastic rotation capacity, the ultimate displacement is given by:

All the verification procedures considered the use of the transformation of the MDOF system by means of the participation coefficient of the main vibration mode Γ. For this reason, it is necessary to define:

The eigenvector ɸ = {ɸ1, ɸ2, ɸ3, ɸ4, ɸ5, ɸ6} that, assuming , is:

The dynamic parameters of the equivalent SDOF system are reported in

Table 8.

Therefore, the characteristic points of the capacity curve are defined in the planes

α −

δ,

Fb −

dc,

F* −

D*,

Sα −

SD assessing the capacity in terms of accelerations for the Nassar and Krawinkler approach and ADRS spectrum approach. In particular, in

Table 9, the results based on the use of the ADRS spectrum, and in

Table 10, results based on the use of the Nassar and Krawinkler formulation, are reported.

Seismic performance verification requires that, for each limit state, the inequality Sα.ls(T*)capacity ≥ Sα.ls(T*)demand is satisfied.

6. Conclusions

In this paper, some numeric examples explaining the application of a new assessment method are reported. As can be seen from the given numerical examples, the methodology is of easy and rapid application. The methodology is also completely analytical since the equations of the branches constituting the trilinear model can be obtained uniquely, given the horizontal seismic actions and the sections of beams and columns of the analyzed frame. The speed of application and the uniqueness show that this methodology is strongly indicated for the evaluation of seismic performances in the immediate post-earthquake or the large-scale assessment of the seismic vulnerability of the built heritage. Furthermore, it constitutes a suitable tool to check the capacity of the buildings designed with the new seismic code prescriptions. The reliability of the procedure is testified by the extensive regression analysis, carried out on 420 frames designed with different approaches. The feasibility of the procedure is very high and makes it suitable to be applied indiscriminately to frames belonging to different historical periods.

Table 11 shows a comparison between the results in terms of the percentage scatter between the values computed from pushover analysis and the proposed method of the maximum bearing multiplier α and the displacement corresponding to the collapse and formation of the plastic mechanism. It can be observed that the scatter is always lower than 10%, thus testifying the accuracy of the proposed formulations. Moreover, the results achieved by the simplified assessment procedure are on the safe side.

The assessment of structure performances, in terms of comparing capacity-demand, has been performed using the Nassar and Krawinkler approach, characterized by a wide generality because it does not discriminate between high and low periods of vibration and accounts for second-order effects. Finally, is important to note that the discretization of the trilinear model in characteristic performance points makes it easy to compare the capacity and demand for each limit state given by codes.