A Comparative Study of Energy Consumption and Recovery of Autonomous Fuel-Cell Hydrogen–Electric Vehicles Using Different Powertrains Based on Regenerative Braking and Electronic Stability Control System

Abstract

1. Introduction

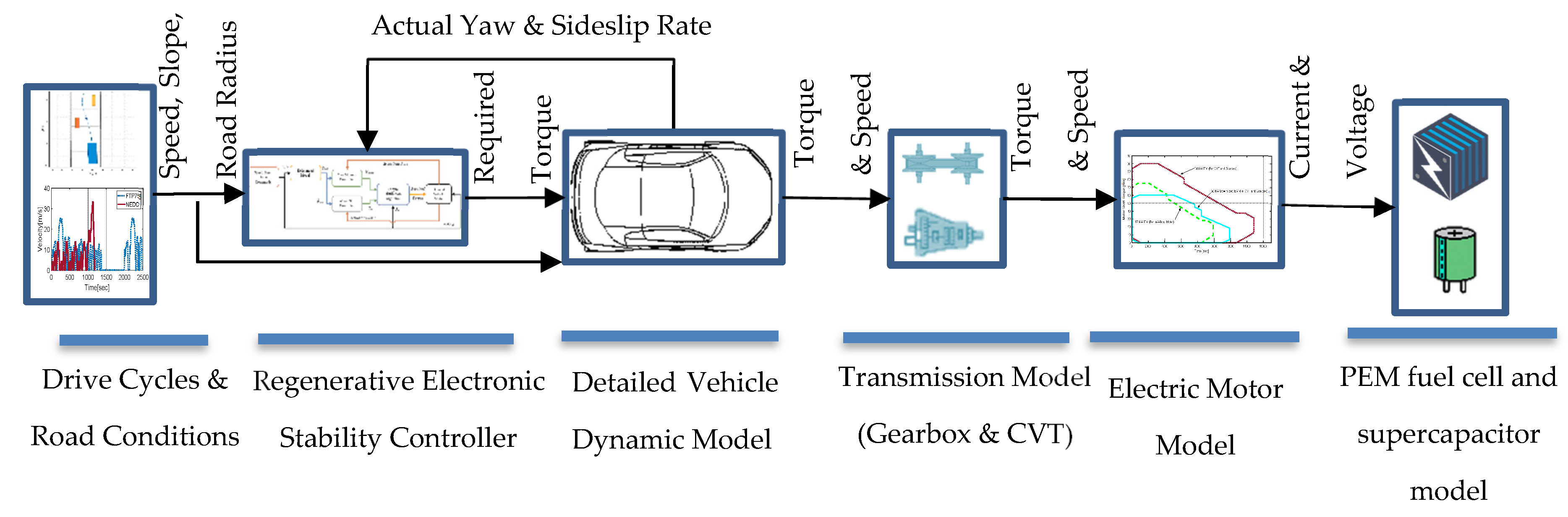

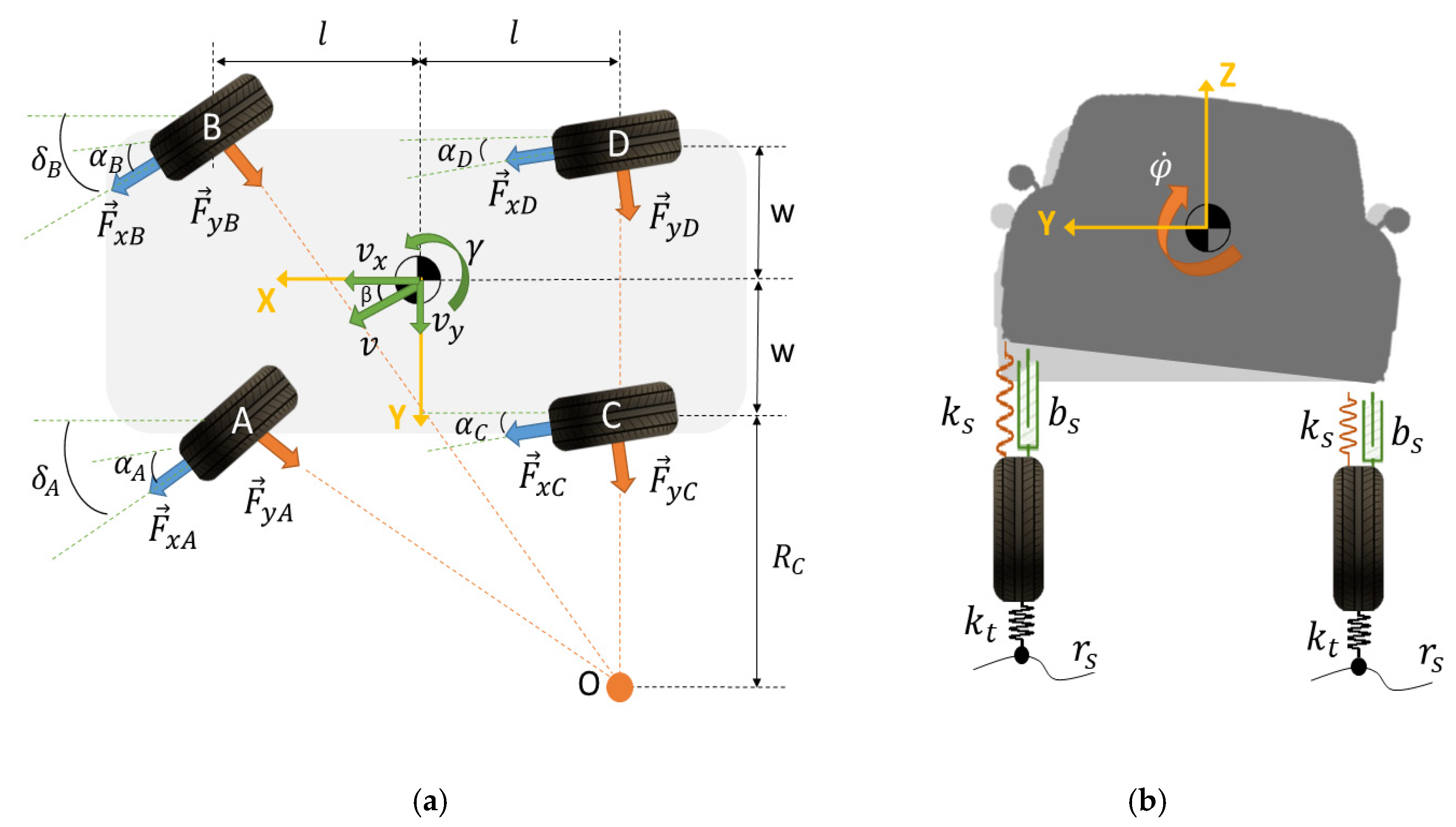

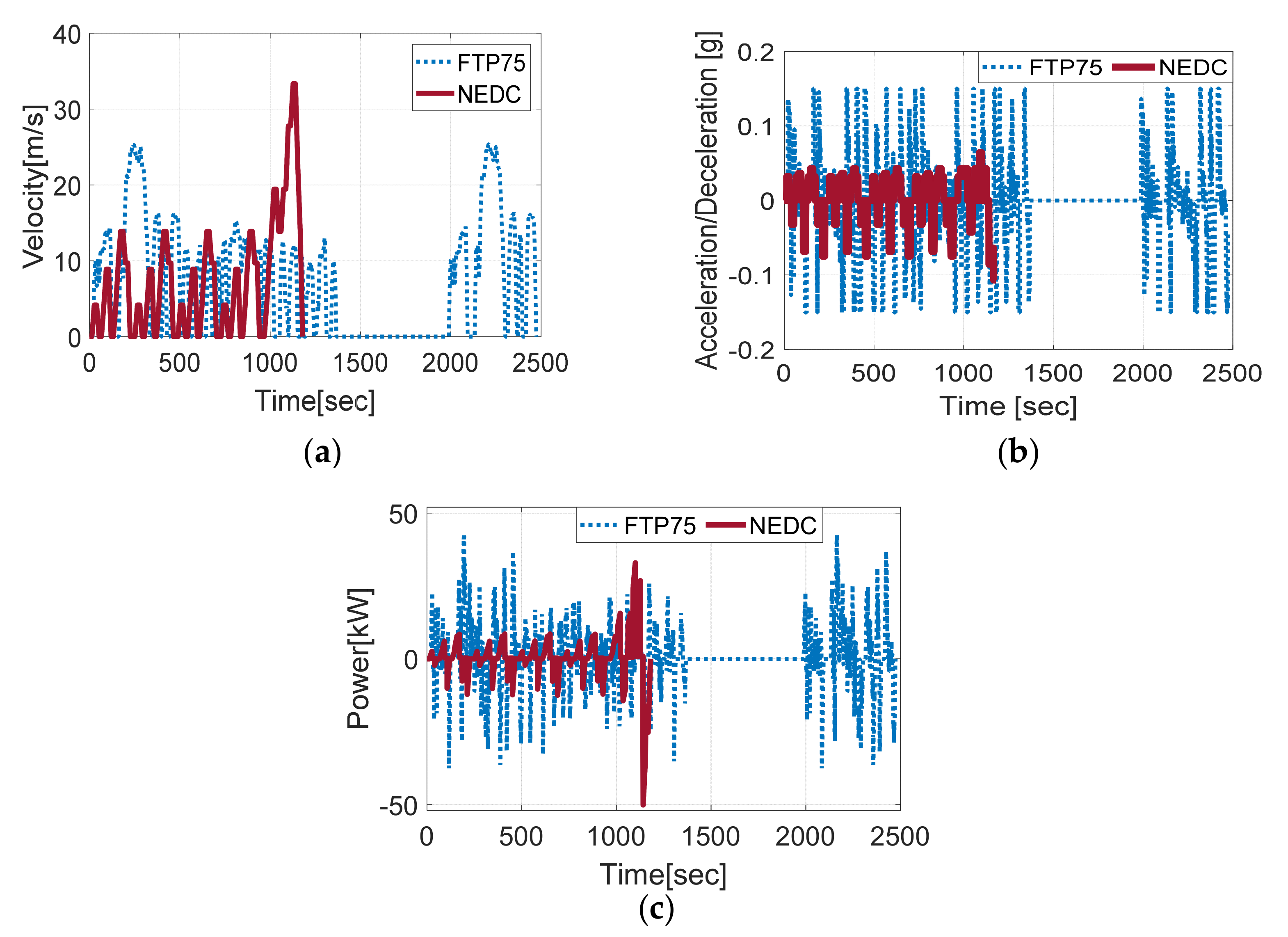

2. Developed Simulation Model for Different Powertrain Layouts

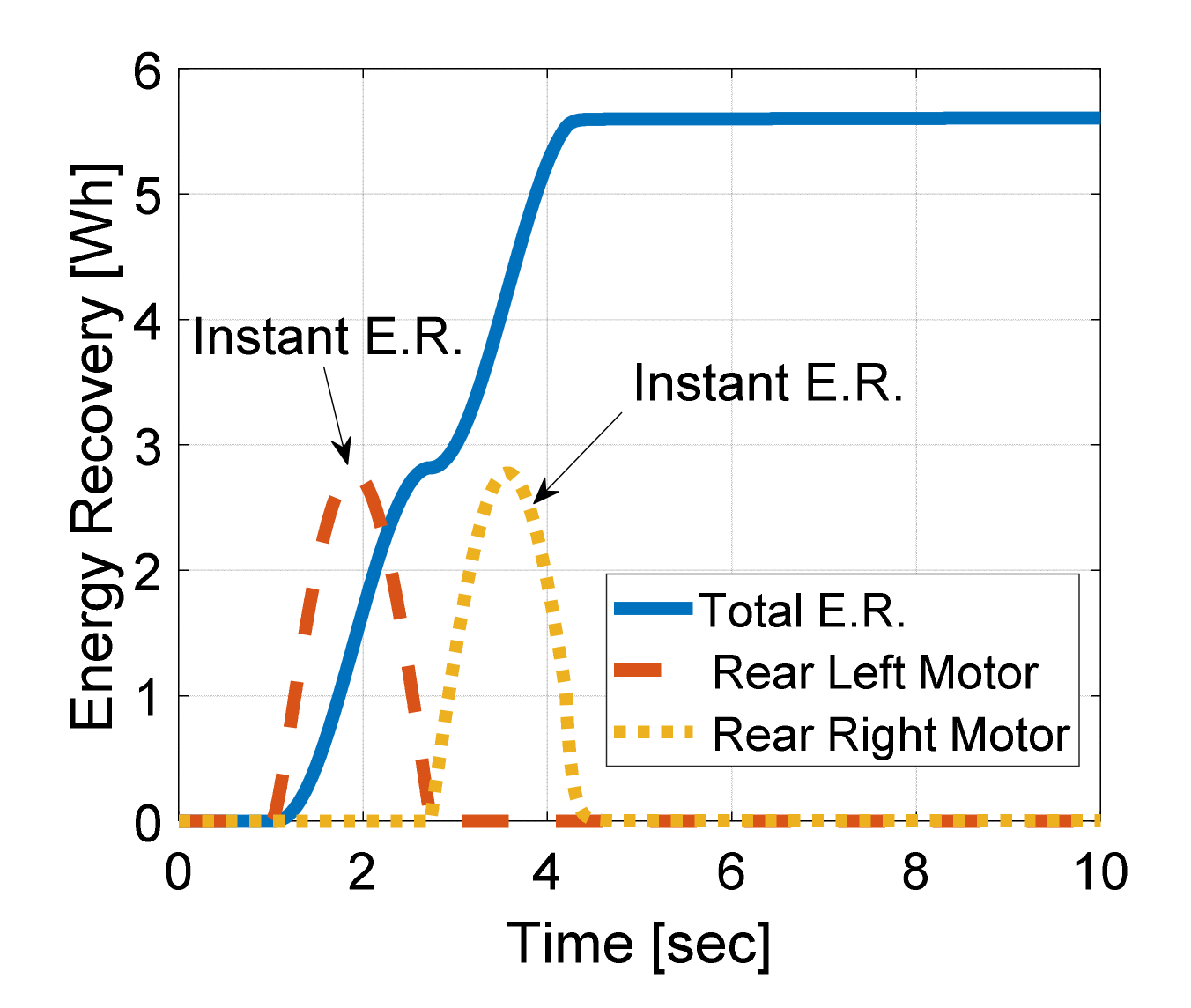

3. Regenerative Electronic Strategy and Stability Control Strategy

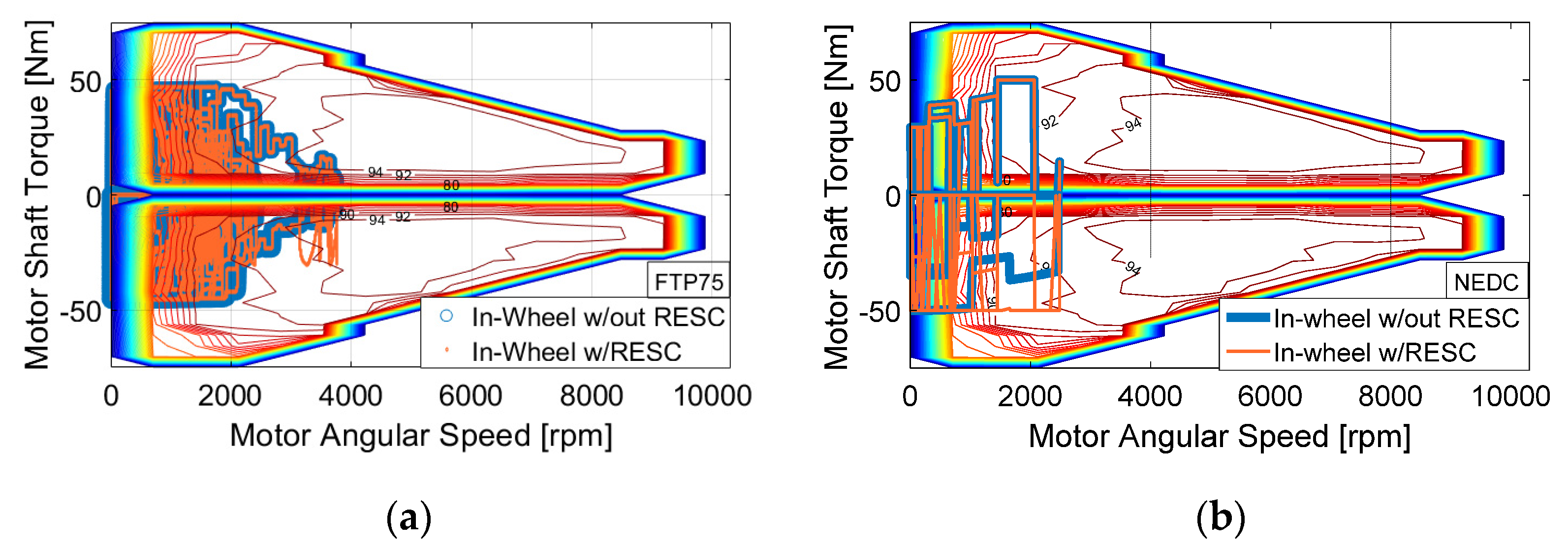

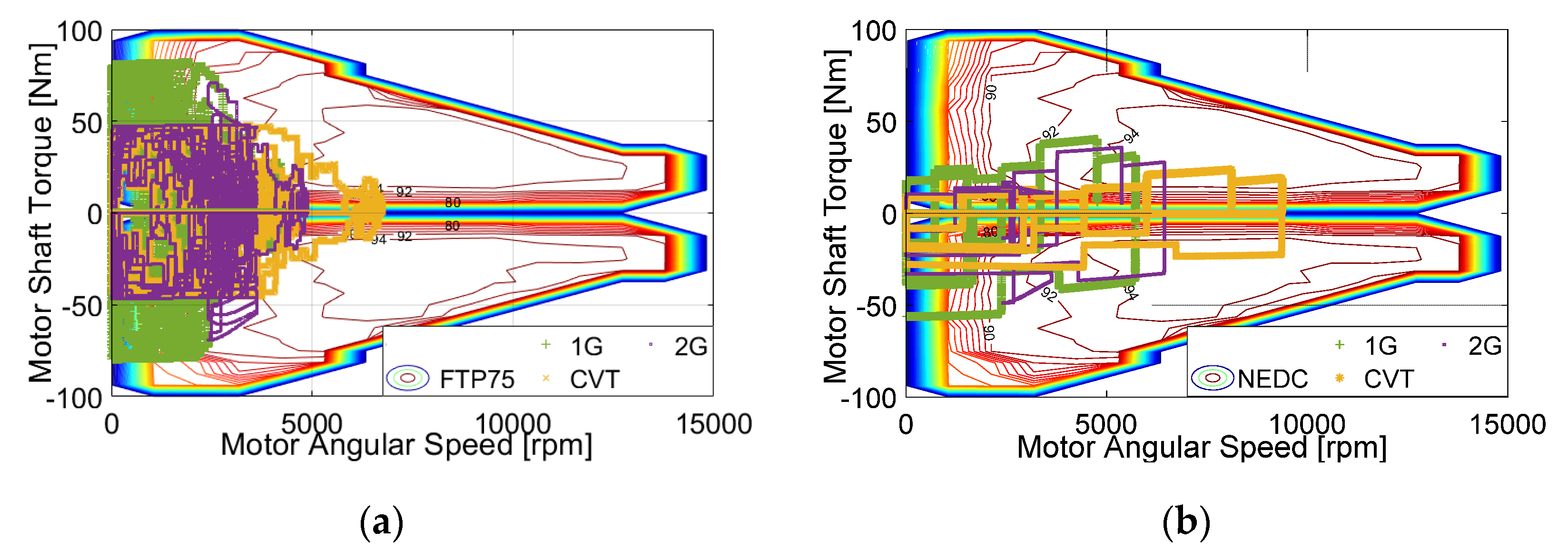

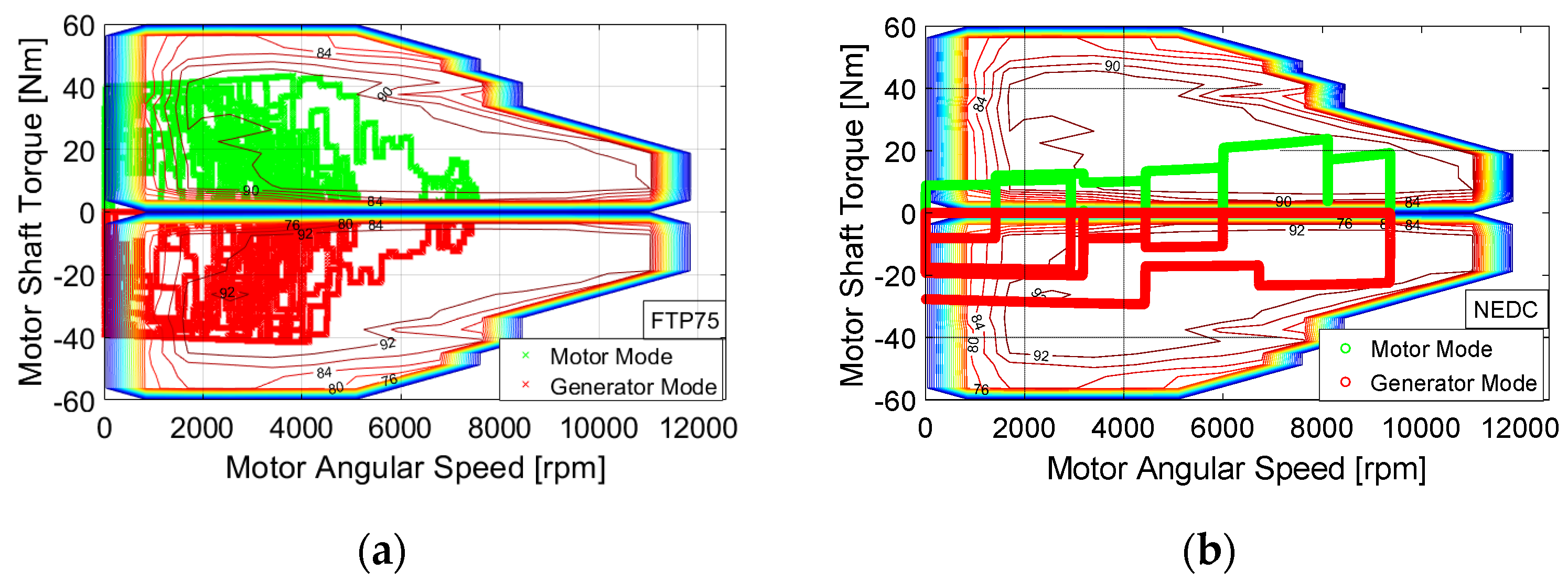

4. Model of Electric Motors and Concurrent Efficiency Maps

5. PEM Fuel Cell and Supercapacitor Model

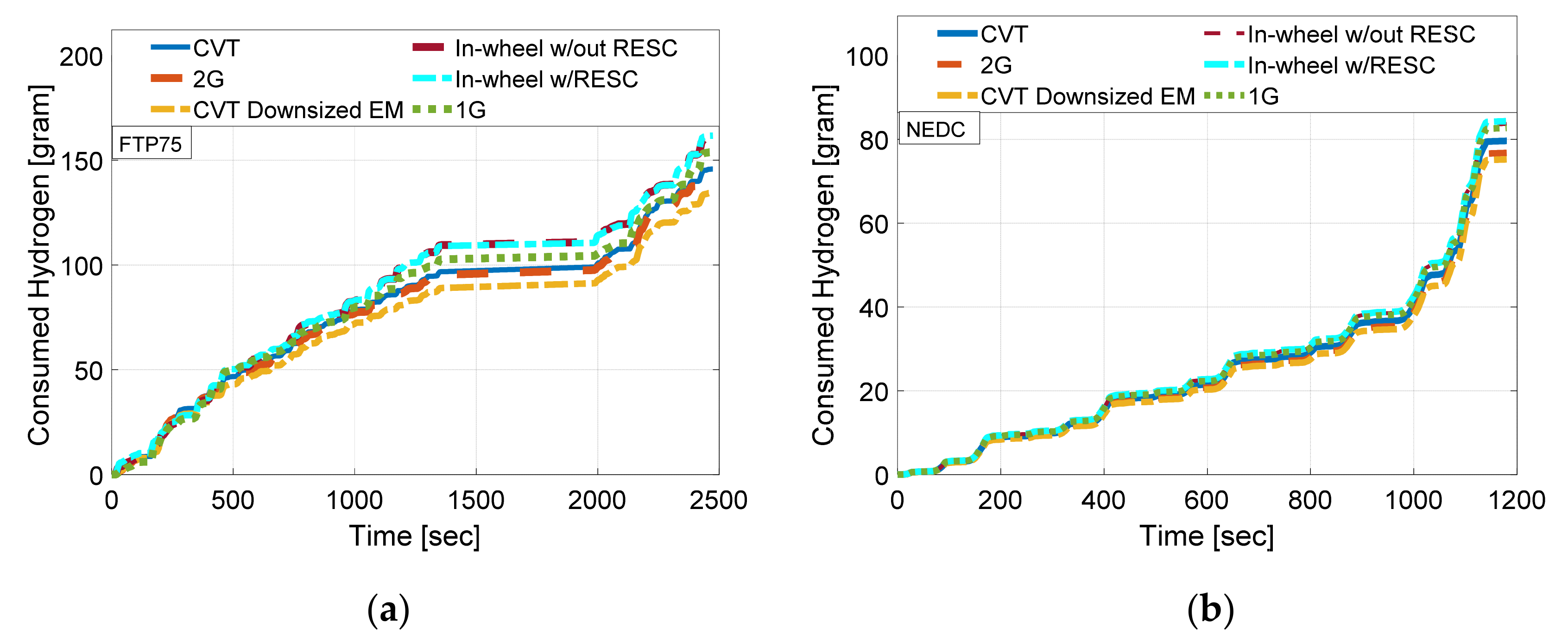

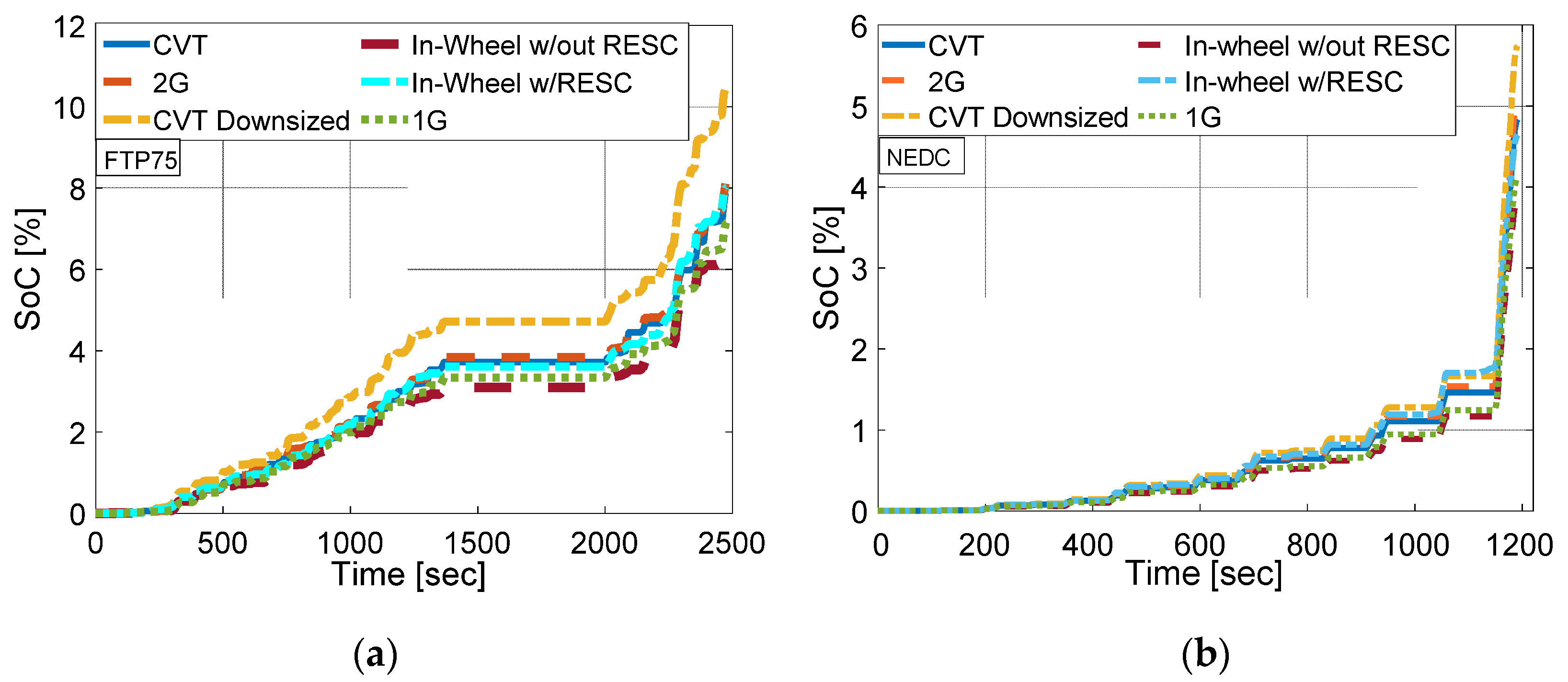

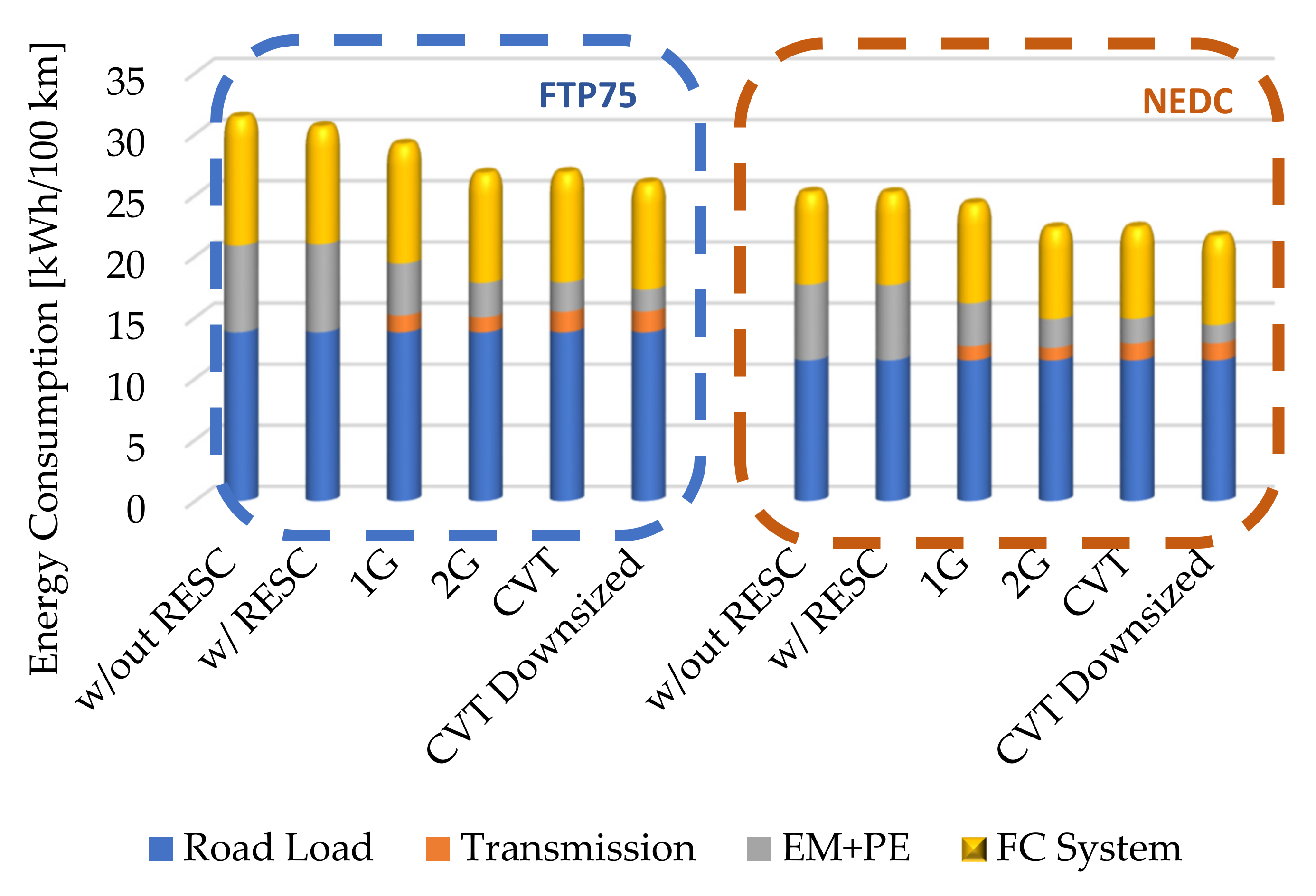

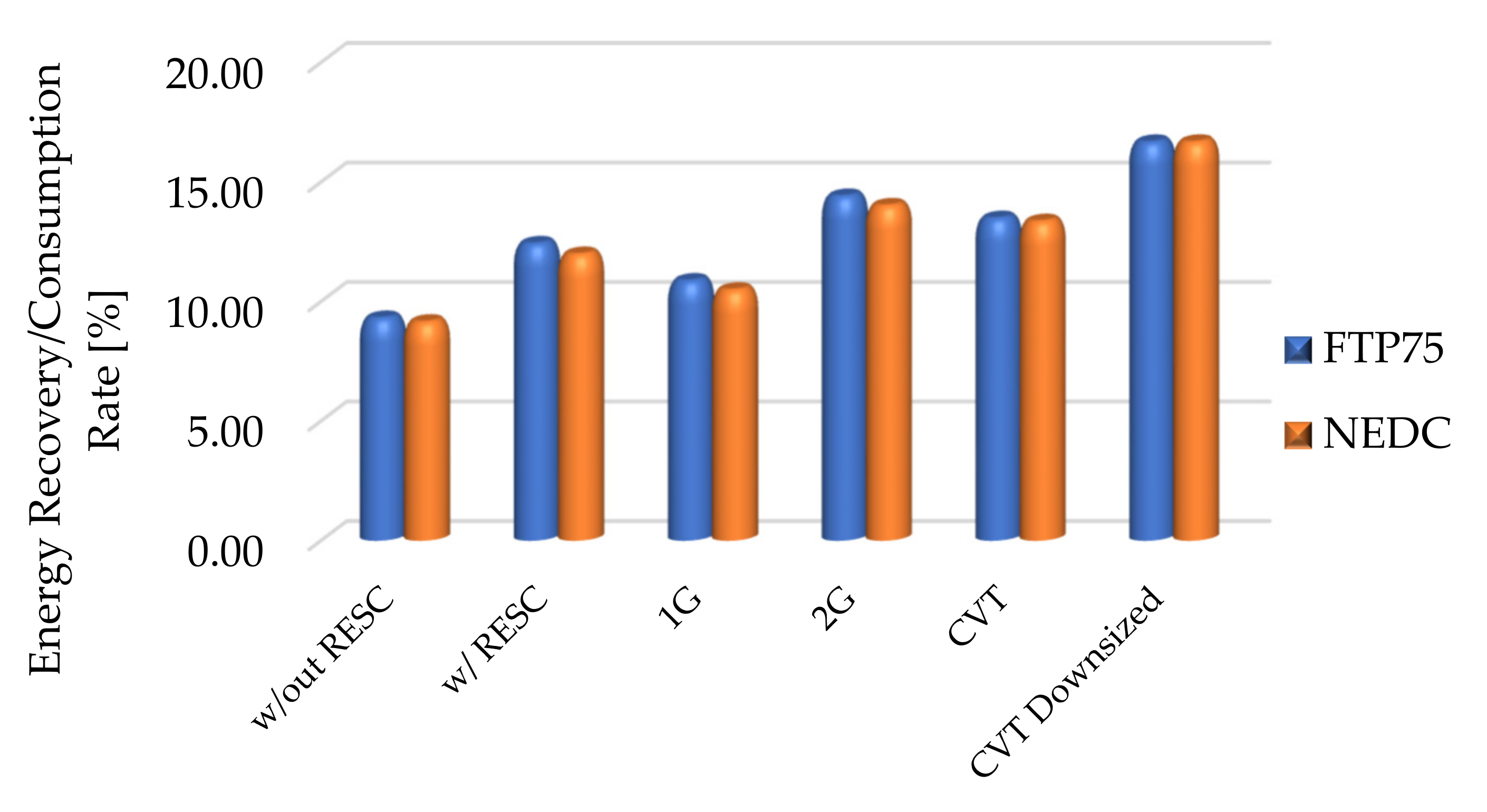

6. Results

7. Conclusions

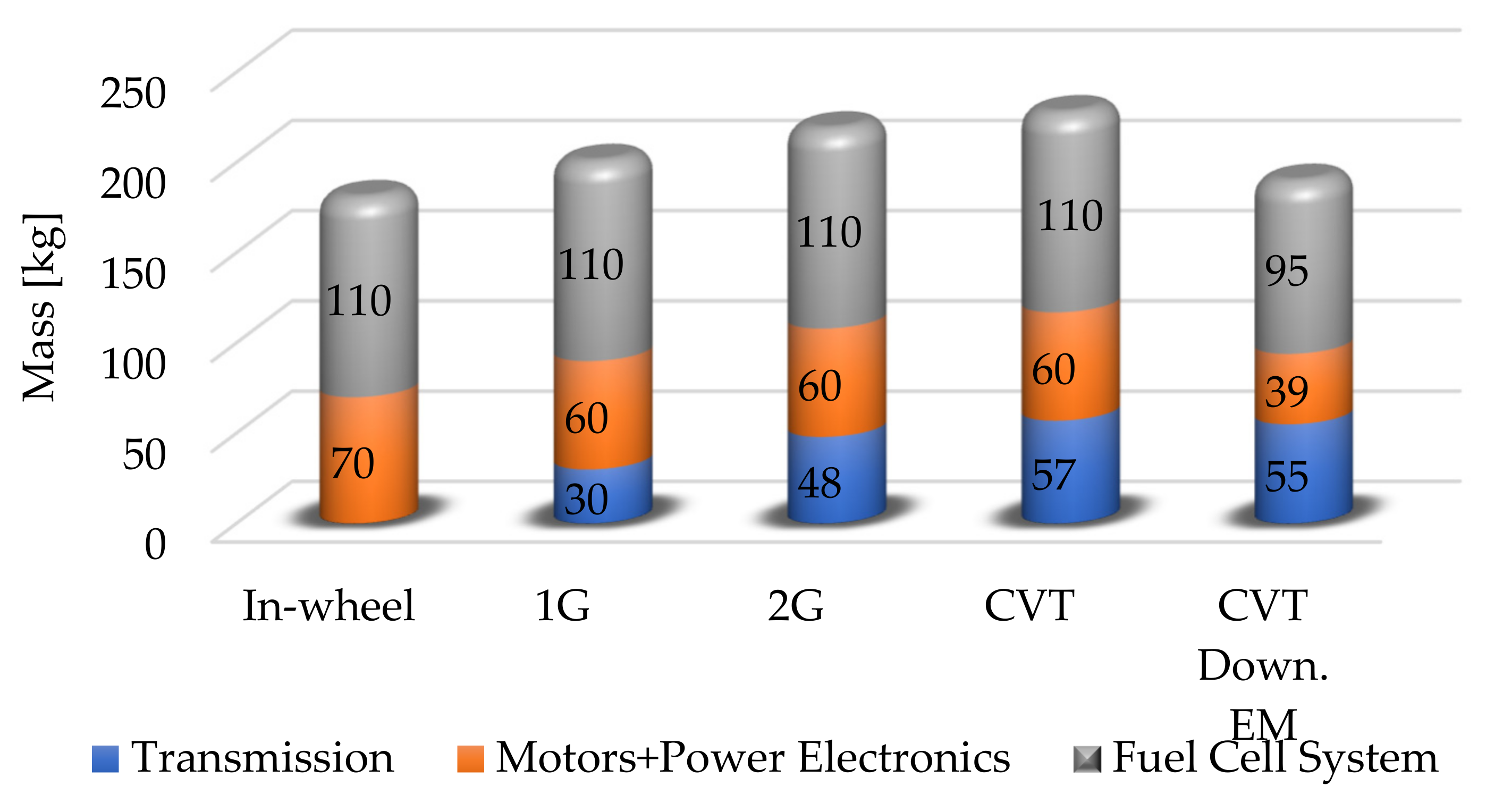

- A transmission system can reduce the energy consumption of HFCEVs tremendously as compared to other powertrain layouts, as it provides the optimum operating conditions for electric motors. If high torque capacity is required at low velocities of the vehicle, an automated transmission system must be used for improved energy consumption.

- An in-wheel motor layout is able to recover more energy if an RESC system is added to it. Overall, it spends less energy, except in the case of a downsized electric motor and two-stage automatic transmission. In addition, if the vehicle is used on a curved road, the in-wheel architecture with an RESC system can save a significant amount of energy.

- Using a CVT transmission, the required peak torque of the electric motor can be decreased; therefore, it is possible to downsize the electric motor. Downsizing helps to achieve a reduction in the weight of not only the motor but also its driver and other power units, which results in the lowest energy consumption rate as compared to the other layouts.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Parameter of Magic Formula for a Lateral and Longitudinal Slip

| Hydrogen Pressure | 1.5 [bar] | Oxygen Pressure | 1.5 [bar] | ||

|---|---|---|---|---|---|

| Front tire lateral stiffness | 41,000 [N/rad] | Rear tire lateral stiffness | 40,000 [N/rad] | ||

| Damping coefficient | 3500 [Ns/m] | Stiffness of tire | 193,000 [N/m] | ||

| Stiffness of spring | 35,000 [N/m] | Fixed power loss |

Appendix A.2. Efficiency Map for the Electric Motors

References

- Kim, I.; Kim, J.; Lee, J. Dynamic analysis of well-to-wheel electric and hydrogen vehicles greenhouse gas emissions: Focusing on consumer preferences and power mix changes in South Korea. Appl. Energy 2020, 260, 114281. [Google Scholar] [CrossRef]

- Wang, Q.; Xue, M.; Lin, B.; Lei, Z.; Zhang, Z. Well to wheel analysis of energy consumption, greenhouse gas and air pollutants emissions of hydrogen fuel cell vehicle in China. J. Clean. Prod. 2020, 275, 123061. [Google Scholar] [CrossRef]

- Lathia, R.; Dobariya, K.; Patel, A. Hydrogen Fuel Cells for Road Vehicles. J. Clean. Prod. 2017, 141, 462. [Google Scholar] [CrossRef]

- Ahmadi, P. Environmental impacts and behavioral drivers of deep decarbonization for transportation through electric vehicles. J. Clean. Prod. 2019, 225, 1209–1219. [Google Scholar] [CrossRef]

- Xiong, H.; Liu, H.; Zhang, R.; Yu, L.; Zong, Z.; Zhang, M.; Li, Z. An energy matching method for battery electric vehicle and hydrogen fuel cell vehicle based on source energy consumption rate. Int. J. Hydrogen Energy 2019, 44–56, 29733–29742. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Comparison between hydrogen and electric vehicles by life cycle assessment: A case study in Tuscany, Italy. Appl. Energy 2013, 101, 103–111. [Google Scholar] [CrossRef]

- Grüger, F.; Dylewski, L.; Robinius, M.; Stolten, D. Carsharing with fuel cell vehicles: Sizing hydrogen refueling stations based on refueling behavior. Appl. Energy 2018, 228, 1540–1549. [Google Scholar] [CrossRef]

- Wen, C.; Rogie, B.; Kaern, M.R.; Rothuizen, E. A first study of the potential of integrating an ejector in hydrogen fuelling stations for fuelling high pressure hydrogen vehicles. Appl. Energy 2020, 260, 113958. [Google Scholar] [CrossRef]

- Cao, S.; Alanne, K. The techno-economic analysis of a hybrid zero-emission building system integrated with a commercial-scale zero-emission hydrogen vehicle. Appl. Energy 2018, 211, 639–661. [Google Scholar] [CrossRef]

- Nagasawa, K.; Davidson, F.T.; Lloyd AC: Webber, M.E. Impacts of renewable hydrogen production from wind energy in electricity markets on potential hydrogen demand for light-duty vehicles. Appl. Energy 2019, 235, 1001–1016. [Google Scholar] [CrossRef]

- Hoskins, A.L.; Milican, S.L.; Czernik, C.E.; Alshankiti, I.; Netter, J.C.; Wendelin, T.J.; Musgrave, C.B.; Weimer, A.W. Continuous on-sun solar thermochemical hydrogen production via an isothermal redox cycle. Appl. Energy 2019, 249, 368–376. [Google Scholar] [CrossRef]

- Mastropasqua, L.; Pecenati, I.; Giostri, A.; Campanari, S. Solar hydrogen production: Techno-economic analysis of a parabolic dish-supported high-temperature electrolysis system. Appl. Energy 2020, 261, 114392. [Google Scholar] [CrossRef]

- Eckert, J.; Silva, L.; Santiciolli, F.; Costa, E.; Corrêa, F.; Dedini, F. Energy storage and control optimization for an electric vehicle. Int. J. Energy Storage 2018, 42, 3506–3523. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, X.; Zheng, L. Design and analysis of hybrid electric vehicle powertrain configurations considering energy transformation. Int. J. Energy Storage 2018, 42, 4719–4729. [Google Scholar] [CrossRef]

- Yang, X.; Taenaka, B.; Miller, T.; Snyder, K. Modeling validation of key life test for hybrid electric vehicle batteries. Int. J. Energy Storage 2010, 34, 171–181. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Changizian, S.; Ahmadi, P.; Raeesi, M.; Javani, N. Performance optimization of hybrid hydrogen fuel-cell electric vehicles in real driving cycles. Int. J. Hydrogen Energy 2020, 0360, 3199. [Google Scholar] [CrossRef]

- Alamili, A.; Xue, Y.; Anayi, F. An experimental and analytical study of the ultra-capacitor storage unit used in regenerative braking systems. Energy Procedia 2019, 159, 376–381. [Google Scholar] [CrossRef]

- Kaya, K.; Hames, Y. Two new control strategies: For hydrogen fuel saving and extending the life cycle in the hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2019, 44, 18967–18980. [Google Scholar] [CrossRef]

- Tanç, B.; Arat, H.T.; Conker, Ç.; Baltacioğlu, E.; Aydin, K. Energy distribution analyses of an additional traction battery on hydrogen fuel cell hybrid electric vehicle. Int. J. Hydrogen Energy 2019, 45, 26344–26356. [Google Scholar] [CrossRef]

- Ferreira, F.J.T.E.; Almeida, A.T. Induction motor downsizing as a low-cost strategy to save energy. J. Clean. Prod. 2012, 24, 117–131. [Google Scholar] [CrossRef]

- De Pinto, S.; Camocardi, P.; Chatzikomis, C.; Sorniotti, A.; Bottiglione, F.; Mantriota, G.; Perlo, P. On the Comparison of 2- and 4-Wheel-Drive Electric Vehicle Layouts with Central Motors and Single- and 2-Speed Transmission Systems. Energies 2020, 13, 3328. [Google Scholar] [CrossRef]

- Bottiglione, F.; De Pinto, S.; Mantriota, G.; Sorniotti, A. Energy consumption of a battery electric vehicle with infinitely variable transmission. Energies 2014, 7, 8317–8337. [Google Scholar] [CrossRef]

- Sluis, F.; Romers, L.; Spijk GHupkes, I. CVT, promising solutions for electrification. SAE Int. Conf. Pap. 2019, 1, 0359. [Google Scholar] [CrossRef]

- Liang, J.; Walker, P.D.; Ruan, J.; Yang, H.; Wu, J. Gear shift and brake distribution control for regenerative braking in electric vehicles with dual clutch transmission. Mech. Mach. Theory 2019, 133, 1–22. [Google Scholar] [CrossRef]

- Mo, W.; Walker, P.D.; Fang, Y.; Wu, J.; Ruan, J.; Zhang, N. A novel shift control concept for multi-speed electric vehicles. Mech. Syst. Signal Process. 2018, 112, 171–193. [Google Scholar] [CrossRef]

- Zhang, L.; Ca, X. Control strategy of regenetrative braking system in electric vehicles. Energy Procedia 2018, 152, 496–501. [Google Scholar] [CrossRef]

- Ruan, J.; Walker, P.; Zhang, N. A comparative study energy consumption and costs of battery electric vehicle transmissions. Appl. Energy 2016, 165, 119–134. [Google Scholar] [CrossRef]

- Yildiz, A.; Kopmaz, O.; Cetin, S.T. Dynamic modeling and analysis of a four-bar mechanism coupled with a CVT for obtaining variable input speeds. J. Mech. Sci. Technol. 2015, 29, 1001–1006. [Google Scholar] [CrossRef]

- Yildiz, A.; Piccininni, A.; Bottiglione, F.; Carbone, G. Modeling chain continuously variable transmission for direct implementation in transmission control. Mech. Mach. Theory 2016, 105, 428–440. [Google Scholar] [CrossRef]

- Yildiz, A.; Bottiglione, F.; Carbone, G. An experimental study on the shifting dynamics of the chain CVT. Int. Conf. Adv. Mech. Robot. Eng. 2015. [Google Scholar] [CrossRef]

- Yildiz, A.; Kopmaz, O. Control-oriented modelling with experimental verification and design of the appropriate gains of a PI speed ratio controller of chain CVTs. Stroj. Vestn. J. Mech. Eng. 2017, 63, 374–382. [Google Scholar] [CrossRef]

- Yildiz, A.; Bottiglione, F.; Piccininni, A.; Kopmaz, O.; Carbone, G. Experimental validation of the Carbone–Mangialardi–Mantriota model of continuously variable transmission. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232. [Google Scholar] [CrossRef]

- Yildiz, A.; Kopmaz, O. Dynamic analysis of a mechanical press equipped with a half-toroidal continuously variable transmission. Int. J. Mater. Product Technol. 2015, 50, 22–36. [Google Scholar] [CrossRef]

- Arango, I.; Muñoz Alzate, S. Numerical Design Method for CVT Supported in Standard Variable Speed Rubber V-Belts. Appl. Sci. 2020, 10, 6238. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, Y.; Zeng, Y.; Yu, J. Multi-Objective Optimization for Plug-In 4WD Hybrid Electric Vehicle Powertrain. Appl. Sci. 2019, 9, 4068. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Y.; Xiong, H.; Fu, B.; Huang, Z. Real-Time Control Strategy for CVT-Based Hybrid Electric Vehicles Considering Drivability Constraints. Appl. Sci. 2019, 9, 2074. [Google Scholar] [CrossRef]

- Mingyao, Y.; Datong, Q.; Xingyu, Z.; Sen, Z.; Yuping, Z. Integrated optimal control of transmission ratio and power split ratio for a CVT-based plug-in hybrid electric vehicle. Mech. Mach. Theory 2019, 136, 52–71. [Google Scholar] [CrossRef]

- Jain, M.; Williamson, S.S. Suitability analysis of in-wheel motor direct drives for electric and hybrid electric vehicles. IEEE Electr. Power Energy Conf. 2019, 988, 1–5. [Google Scholar] [CrossRef]

- Long, G.; Ding, F.; Zhang, N.; Zhang, J.; Qin, A. Regenerative active suspension system with residual energy for in-wheel motor driven electric vehicle. Appl. Energy 2020, 260, 114180. [Google Scholar] [CrossRef]

- Kulkarni, A.; Ranjha, S.A.; Kapoor, A. Fatigue analysis of a suspension for an in-wheel electric vehicle. Eng. Fail. Anal. 2016, 68, 150–158. [Google Scholar] [CrossRef]

- Najjari, B.; Mirzae, M.; Tahouni, A. Constrained stability control with optimal power management strategy for in-wheel electric vehicles. J. Multi-Body Dyn. 2019, 1–19. [Google Scholar] [CrossRef]

- Xu, W.; Chen, H.; Zhao, H.; Ren, B. Torque optimization control for electric vehicles with four in-wheel motors equipped with regenerative braking system. Mechatronics 2019, 57, 95–108. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Gay, S.E.; Emadi, A. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles Fundamentals, Theory, and Design; CRC Press: Boca Raton, FL, USA, 2005; ISBN 0-8493-3154-4. [Google Scholar]

- Tekin, G.; Unlusoy, Y.S. Design and simulation of an integrated active yaw control system for road vehicles. Int. J. Veh. Des. 2010, 52. [Google Scholar] [CrossRef]

| Drag coefficient | 0.32 | Half length of vehicle | 1.413 [m] | ||

| Frontal area | 1.4 [] | Half width of vehicle | 0.652 [m] | ||

| Vehicle mass inertia at x axis | 750 [kg/] | Wheel radius | 0.325 [m] | ||

| Rolling stiffness coefficient | 85,450 [Nm/rad] | Air density | 1.225 [kg/] | ||

| Height of the rolling axis | 0.27 [m] | Rolling damping coefficient | 4542 [Nms/rad] | ||

| Vehicle mass (without powertrain and motor) | 2300 [kg] | Vehicle mass inertia at z axis | 2707 [kg/] |

| Differential Ratio | 1:4 | |

| Differential efficiency | 0.9 | |

| Gear ratio of 1G | 1:3.625 | |

| Gear efficiency of 1G | 0.92 | |

| First gear ratio of 2G | 1:2.724 | |

| First gear efficiency of 2G | 0.92 | |

| Second gear ratio | 1:1.251 | |

| Second gear efficiency of 2G | 0.92 | |

| Minimum CVT speed ratio | 0.4 | |

| Maximum CVT speed ratio | 2.5 | |

| Maximum CVT efficiency | 0.96 | |

| Minimum CVT efficiency | 0.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yildiz, A.; Özel, M.A. A Comparative Study of Energy Consumption and Recovery of Autonomous Fuel-Cell Hydrogen–Electric Vehicles Using Different Powertrains Based on Regenerative Braking and Electronic Stability Control System. Appl. Sci. 2021, 11, 2515. https://doi.org/10.3390/app11062515

Yildiz A, Özel MA. A Comparative Study of Energy Consumption and Recovery of Autonomous Fuel-Cell Hydrogen–Electric Vehicles Using Different Powertrains Based on Regenerative Braking and Electronic Stability Control System. Applied Sciences. 2021; 11(6):2515. https://doi.org/10.3390/app11062515

Chicago/Turabian StyleYildiz, Ahmet, and Mert Ali Özel. 2021. "A Comparative Study of Energy Consumption and Recovery of Autonomous Fuel-Cell Hydrogen–Electric Vehicles Using Different Powertrains Based on Regenerative Braking and Electronic Stability Control System" Applied Sciences 11, no. 6: 2515. https://doi.org/10.3390/app11062515

APA StyleYildiz, A., & Özel, M. A. (2021). A Comparative Study of Energy Consumption and Recovery of Autonomous Fuel-Cell Hydrogen–Electric Vehicles Using Different Powertrains Based on Regenerative Braking and Electronic Stability Control System. Applied Sciences, 11(6), 2515. https://doi.org/10.3390/app11062515