1. Introduction

Drones are unmanned aerial vehicles, ranging from large ones that can fly thousands of kilometers to small ones that can fly in limited spaces [

1]. Early drones were developed for military purposes and to aid search and rescue operations, but drones have since been developed for various civilian purposes, such as transportation and fire suppression [

2]. In 2014, the global market size of drones reached 700 million USD, and it is expected to grow to approximately 1.7 billion USD by 2025 [

3]. Most studies on drones have focused on improving the flight time for practical commercial applications. Gattie et al. [

4,

5] estimated the weight of the drone and number of rotors depending on the maximum power demand of the battery and made suggestions regarding the propellers and some performance requirements underlying the design. In addition, an aerodynamic analysis method that improves durability by maintaining the balance is proposed. Abdilla et al. [

6] presented a capacity model for the lithium-polymer batteries used in commercial quad-rotors, resulting in maximum durability at the optimum mass value and an excellent propulsion system.

Drones are also employed in agricultural fields, because the aerial spraying technology reduces labor costs and removes the risk of physical damage to the crops and soil from the wheels or tracks of a machine. In addition to improving the durability of the battery life and propulsion, Primicerio et al. [

7] developed an agricultural drone that can generate management maps of vineyards through multispectral image analysis for ease of navigation. To improve the practical applications of agricultural drones in spraying water and pesticides, it is necessary to investigate the spraying system further.

Edward [

8] developed electrostatic spraying machines and presented system specifications to increase the effectiveness of the deposition of pesticides, and experimentally verified the possibility of spraying a volume median diameter of 50 µm. Rockwell et al. [

9] developed a variable speed direct spraying nozzle for uniform spraying. Murtadha et al. [

10] conducted experiments and COMSOL software simulations of spraying water on targets with different shapes to establish a direct relationship between water flow and current in electrostatic spraying methods. Sharda et al. [

11] proposed a local automatic selectivity control nozzle that can accurately control the amount of pesticide to reduce environmental pollution, while reducing the costs. However, these studies on optimizing the spraying system are only applicable to ground spraying systems.

Aerial spraying technology was first used in large manned aircraft to combat pests in early 1906. Later, in 1975, electrostatic spraying technology was applied to medium-sized aircraft [

12,

13,

14]. Xue et al. [

15] developed precision technologies that can adjust the spraying rate, such as variable-speed spraying technology and positioning technology. In 1990, the first unmanned aerial spraying technology was employed in the agricultural sector [

16,

17].

Most of the previous aerial spraying techniques had been applied to medium-sized unmanned aerial vehicles. However, recently, compact-sized small drones have received significant attention in the field of aerial spraying technology, owing to their high maneuverability. Even though different companies develop agricultural drones, the spraying system generally consists of a commercial pump and nozzle. In recent years, research has also been conducted to select suitable nozzles and pumps for use in agricultural drones. Yu et al. [

18] evaluated the performance of three types of pumps and 18 types of nozzles currently in use, by using a pressure-flow curve, injection flow rate, injection angle, and droplet size. Chen et al. [

19] compared the performance by selecting three nozzles, to extend the flight time of agricultural drones by reducing the amount of pesticide spraying per unit area. However, these studies have been limited to evaluating the nozzle performance, and research on the spray system is insufficient. Therefore, further research into spraying systems for agricultural drones is needed [

20,

21].

The spraying performance of agricultural drones can be evaluated through various factors, such as the effective spray width, spray uniformity, droplet size, spray droplet adhesion rate, and scattering characteristics. However, research on existing agricultural drones focuses mainly on improving the effective spray width. In addition to the spaying width, the important issue in agricultural spraying is to maintain an even liquid distribution and to avoid the drift of the droplets. Especially, drifting is an important and costly problem because it requires additional air flows in some applications. It is well-known that this drift problem depends on the droplet size. The droplet size also affects the penetration performance of the spray into the crops. Therefore, in this study, we developed a nozzle with a feedback channel for the spraying system of agricultural drones that can improve the effective spray width, droplet size, and spray uniformity.

2. Proposed Design of Agricultural Drone Nozzle

The fluidic oscillator can also be found in previous studies, and a number of visualization studies have been conducted to find out the flow characteristics of fluid vibrators. In this study, a new nozzle was designed, using the flow characteristics of a fluid vibrator [

22,

23,

24,

25]. A nozzle with a feedback channel generates an oscillating jet flow through the interaction of the feedback block and the chamber with the inner block, without additional external equipment. This oscillation can generate a uniform spraying, compared to a conventional nozzle. When fluid is supplied into the feedback channel, a Coanda effect occurs in which the airflow ejected in close proximity to a wall of the feedback chamber adheres to the wall. The nozzle with a feedback channel uses this effect to generate a cross-flow through the feedback flow path inside the nozzle, thereby causing the fluid to vibrate at the outlet.

Fan-shaped commercial nozzles are generally used in agricultural drones, owing to their wide spray width, but the nozzles provide low uniformity. To overcome this problem, we tried to improve the spraying uniformity of agricultural drones by the oscillating characteristic of the nozzle with a feedback channel.

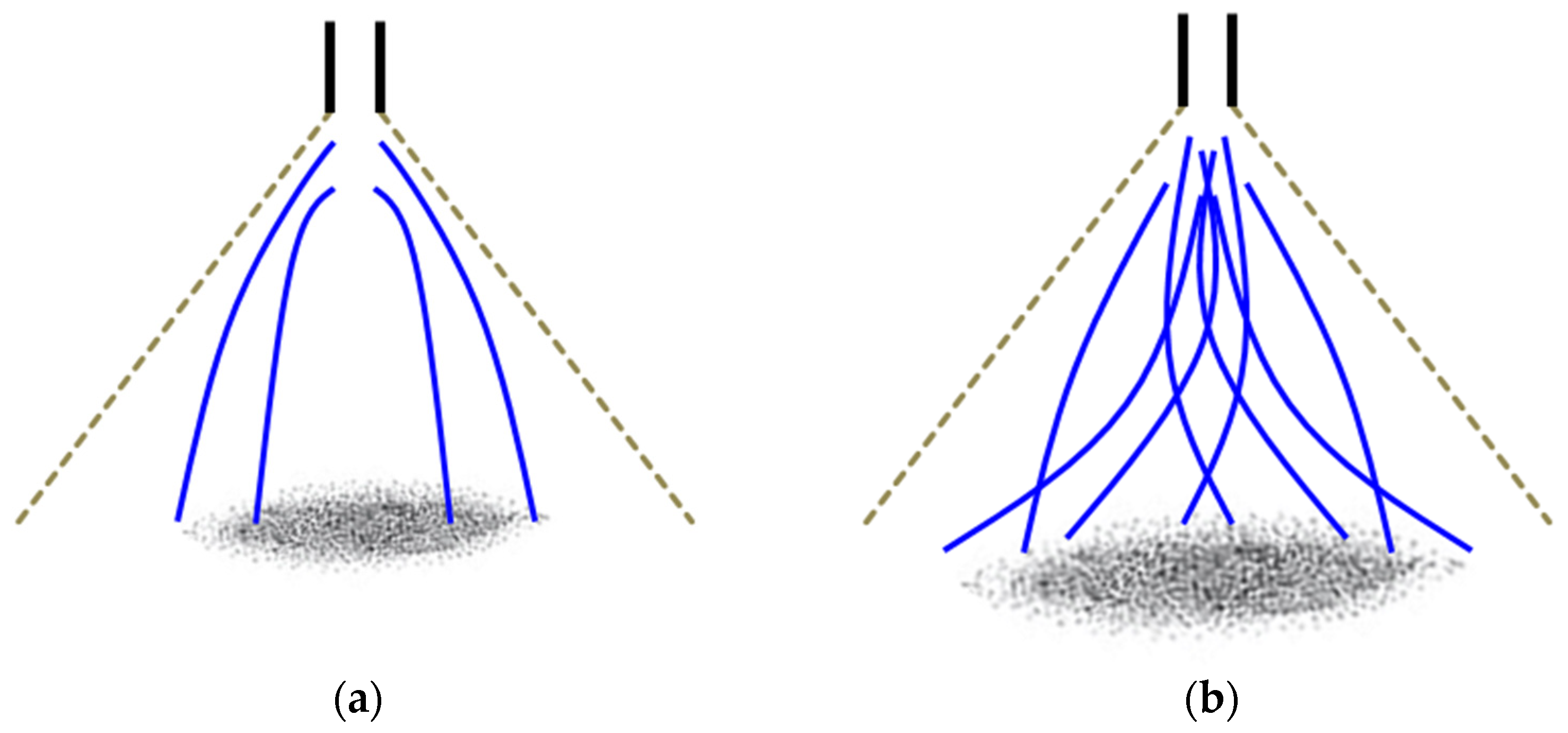

Figure 1 shows the expected spraying distributions with the conventional and the feedback channel nozzles.

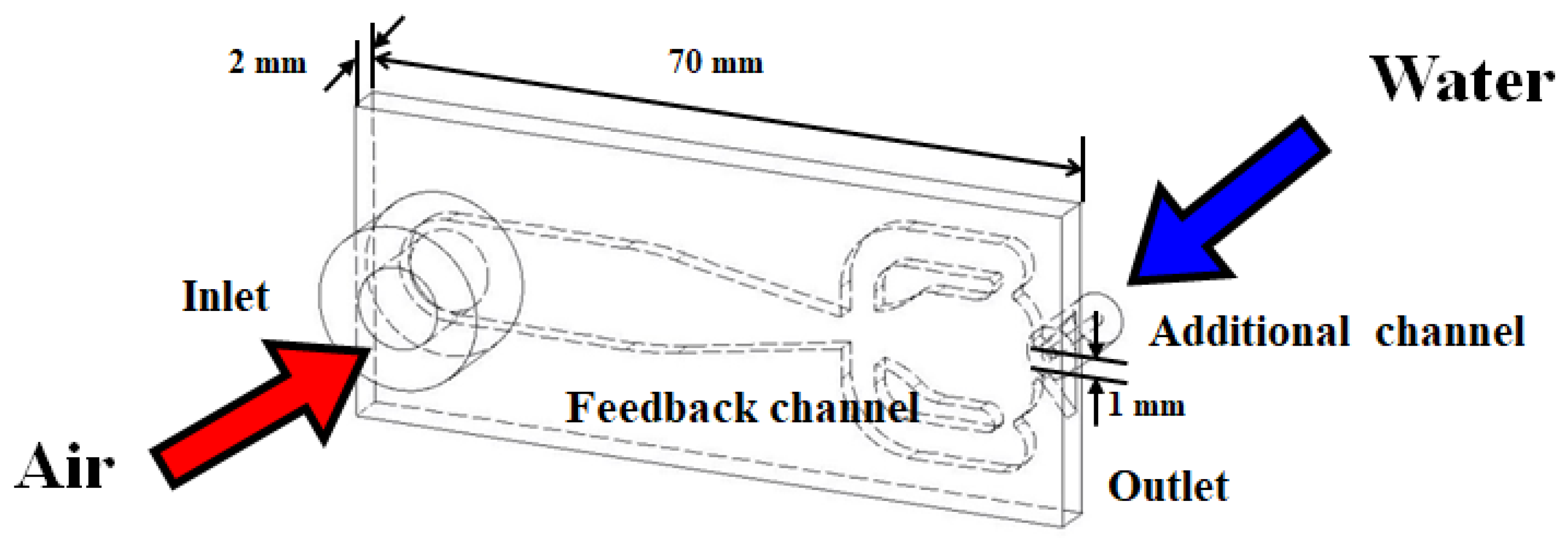

Figure 2 shows the proposed design for an agricultural drone nozzle that can generate periodic oscillation and improve the spraying uniformity. In general, fluid oscillation effectively occurs when a fluid is discharged into a space filled with the same phase fluid. By contrast, when a fluid is ejected on to a different phase, the oscillation is reduced, and the formation of atomized droplets becomes difficult. Therefore, in this study, in contrast to a conventional feedback channel nozzle, a certain amount of air is injected through the main inlet, and water is introduced through an additional channel installed at the outlet neck. The size of the feedback channel nozzle was 70 mm in length and 30 mm in width for application to small agricultural drones, the outlet height was 10 mm, and the nozzle height was 2 mm. The proposed nozzle was built, using digital light processing 3D printing to evaluate the spraying performance.

3. Experiment Methods

3.1. Spraying Performance

The spraying performance of an agricultural drone was evaluated, using parameters such as spraying uniformity, droplet size and speed, adhesion rate of spray particles, and scattering characteristics. The selected variables depend on the objective and evaluator. The Korean government uses spraying uniformity as a criterion for agricultural drone certification [

21]. Therefore, in this study, the spraying performance of the proposed and conventional drone types was compared, based on the spraying uniformity and droplet size. These parameters can evaluate the sole effect of the nozzle design on the spray performance without the influence of external factors, such as wind and temperature.

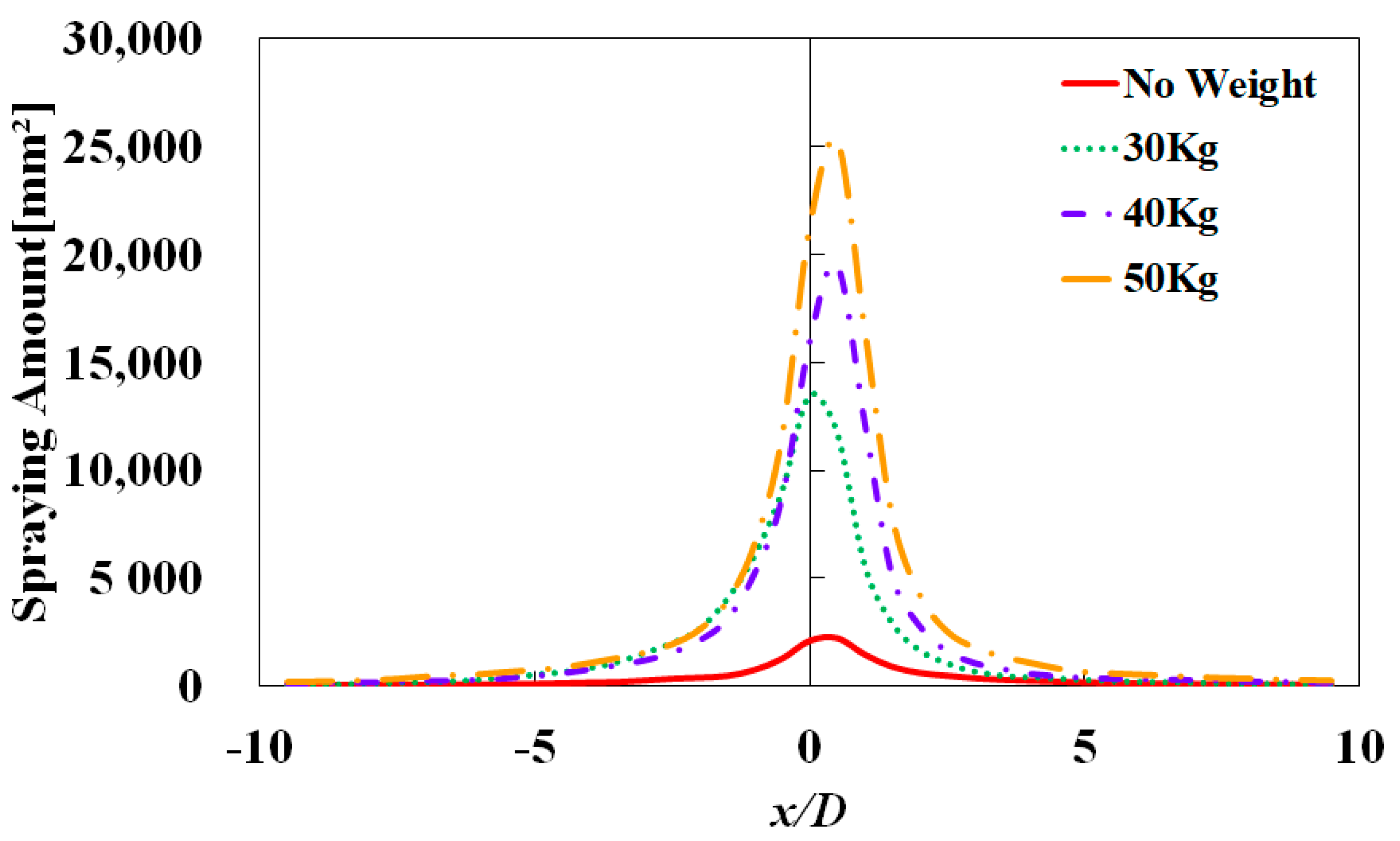

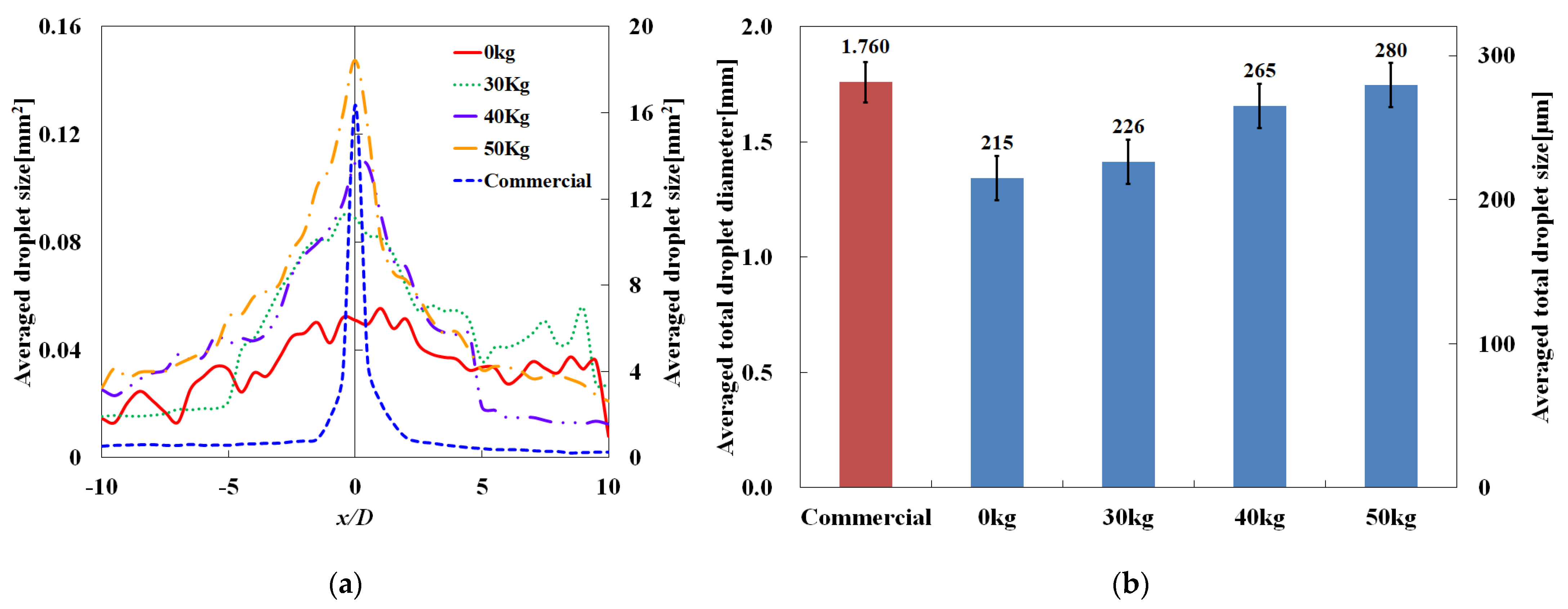

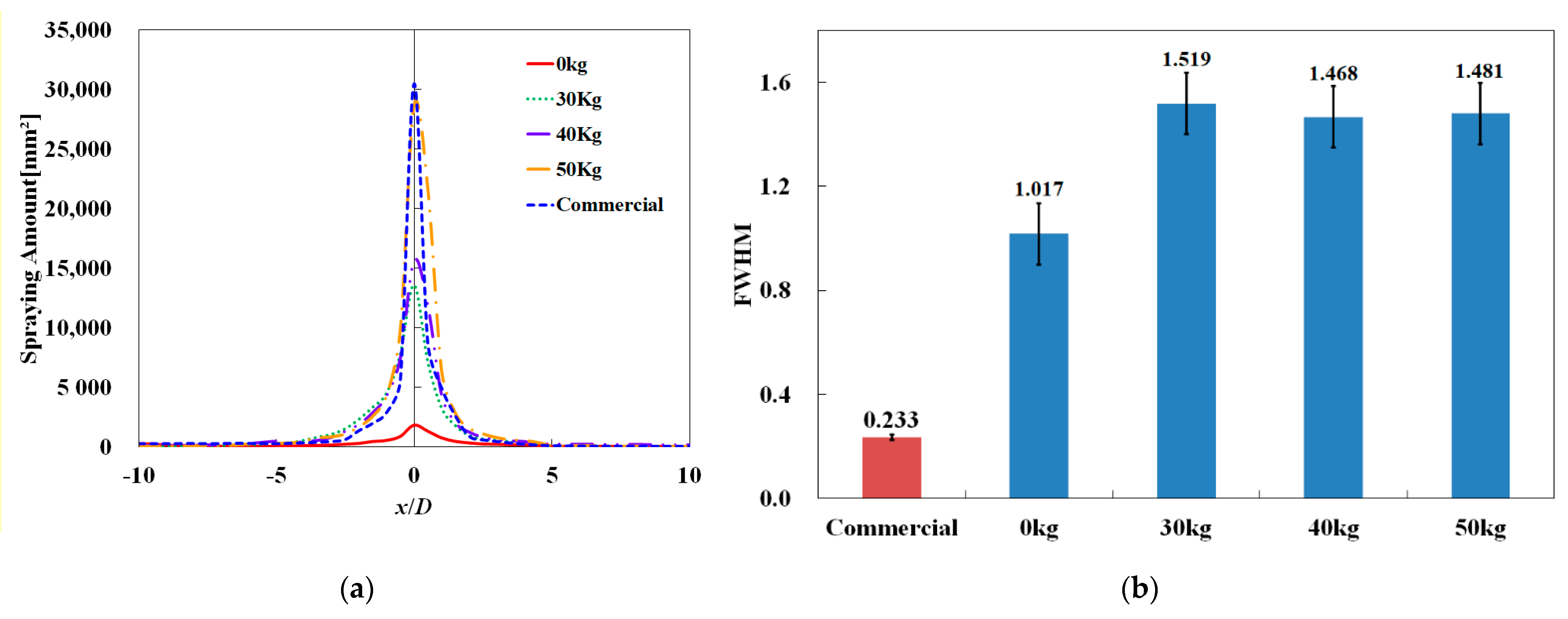

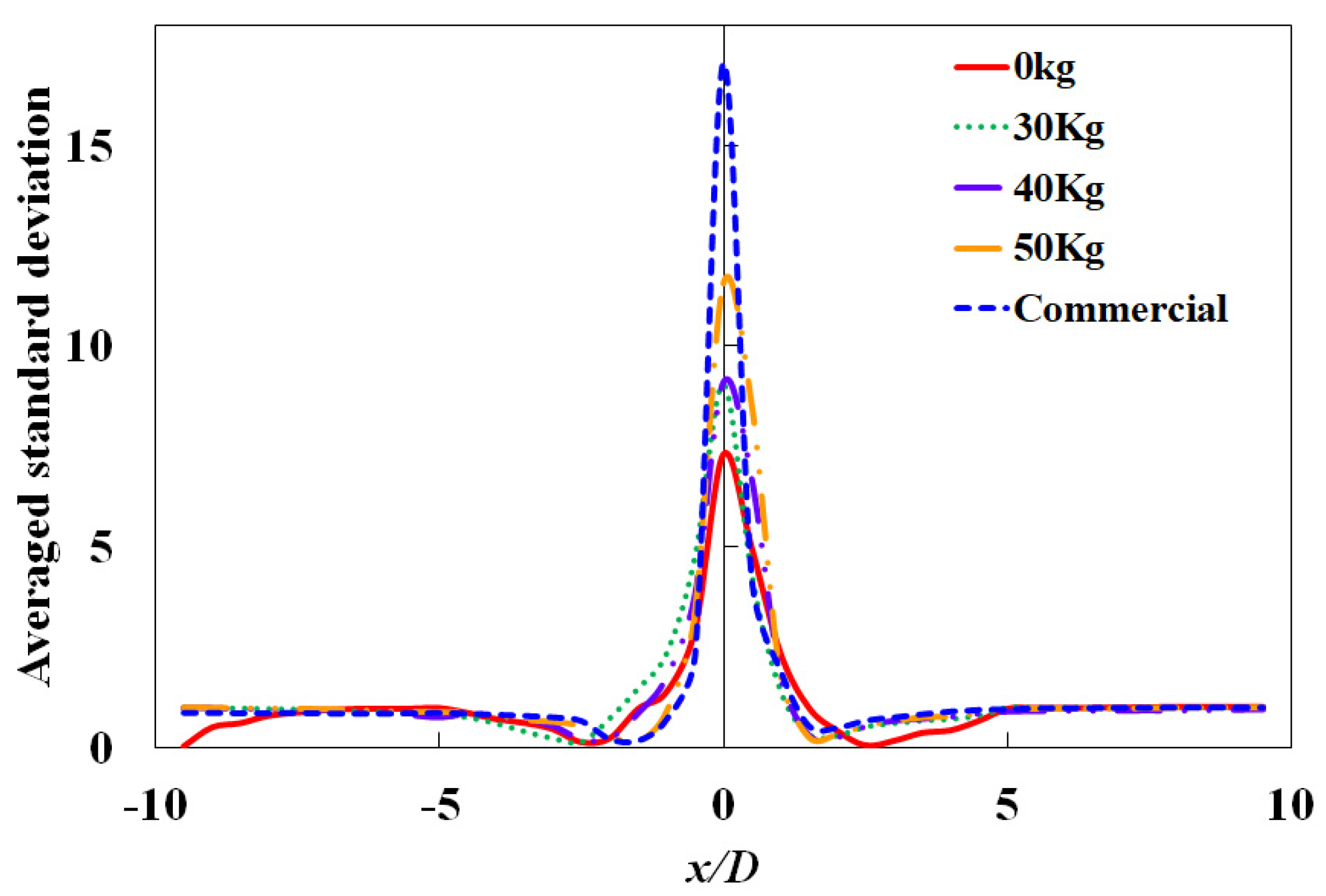

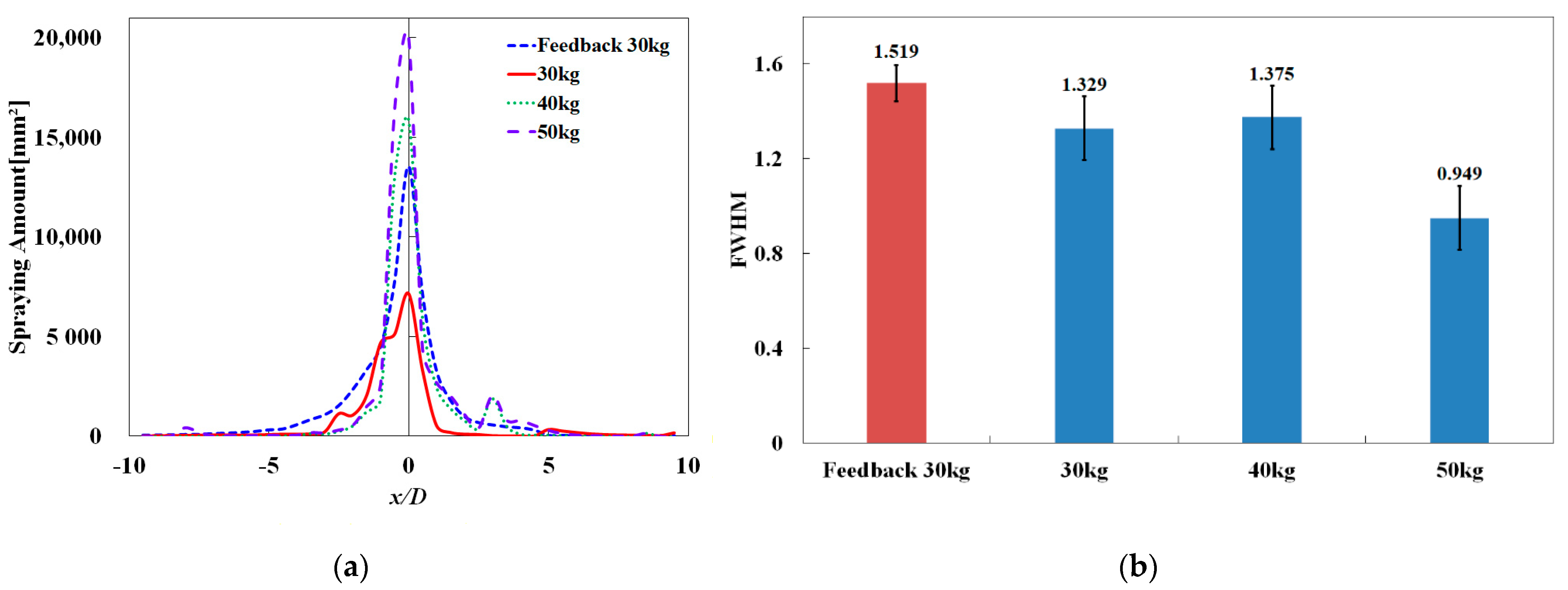

Actually, the spray uniformity in the agricultural drone certification means that the width has effective spraying amount within the maximum spraying width from one point. This effective width can be used to decide the distance between the cross-flights of the agricultural drone. The full width at half maximum (FWHM) is a value that represents the width of a curve between points on half of the maximum value and is used to indicate the size of the function for spaying distributions. In this study, FWHM was used to calculate the spraying width, and the spraying uniformity was compared in terms of the spraying amount and droplet size according to the radial position.

3.2. Tested Nozzles

The spraying performance of the proposed nozzle was compared with that of two other nozzles. The first was a fan-shaped commercial nozzle (TEEJET XR11002, Spray Systems), which is currently employed in commercial agricultural drones. The other was a nozzle without a feedback channel to confirm the feedback channel effect on the designed nozzle. Except for the feedback channel, the other physical dimensions were the same as those of the proposed nozzle. The flow rate for the nozzle test was determined at 500 mL/min, which was similar to the condition in real-world applications.

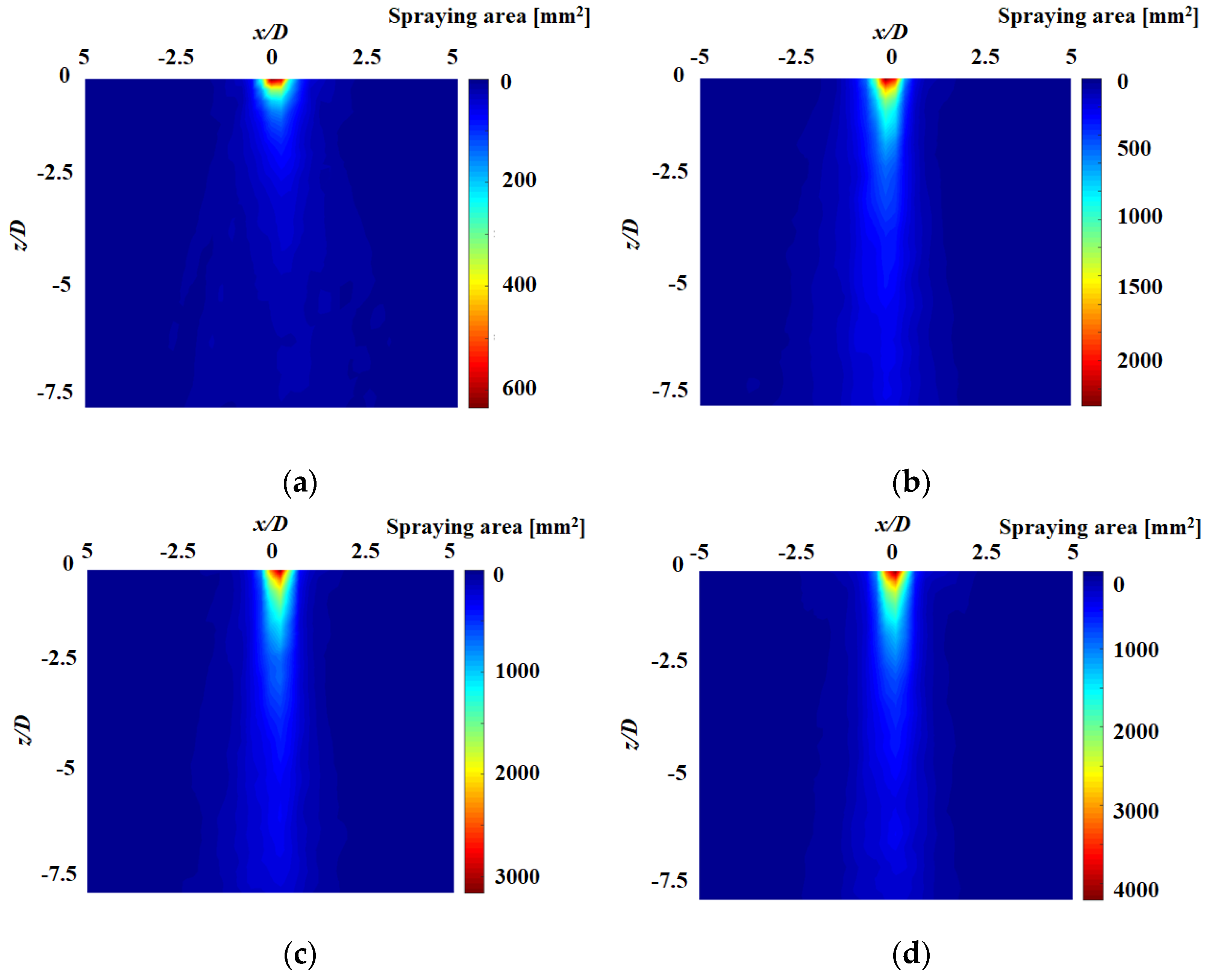

3.3. Measurement of Spraying Performance

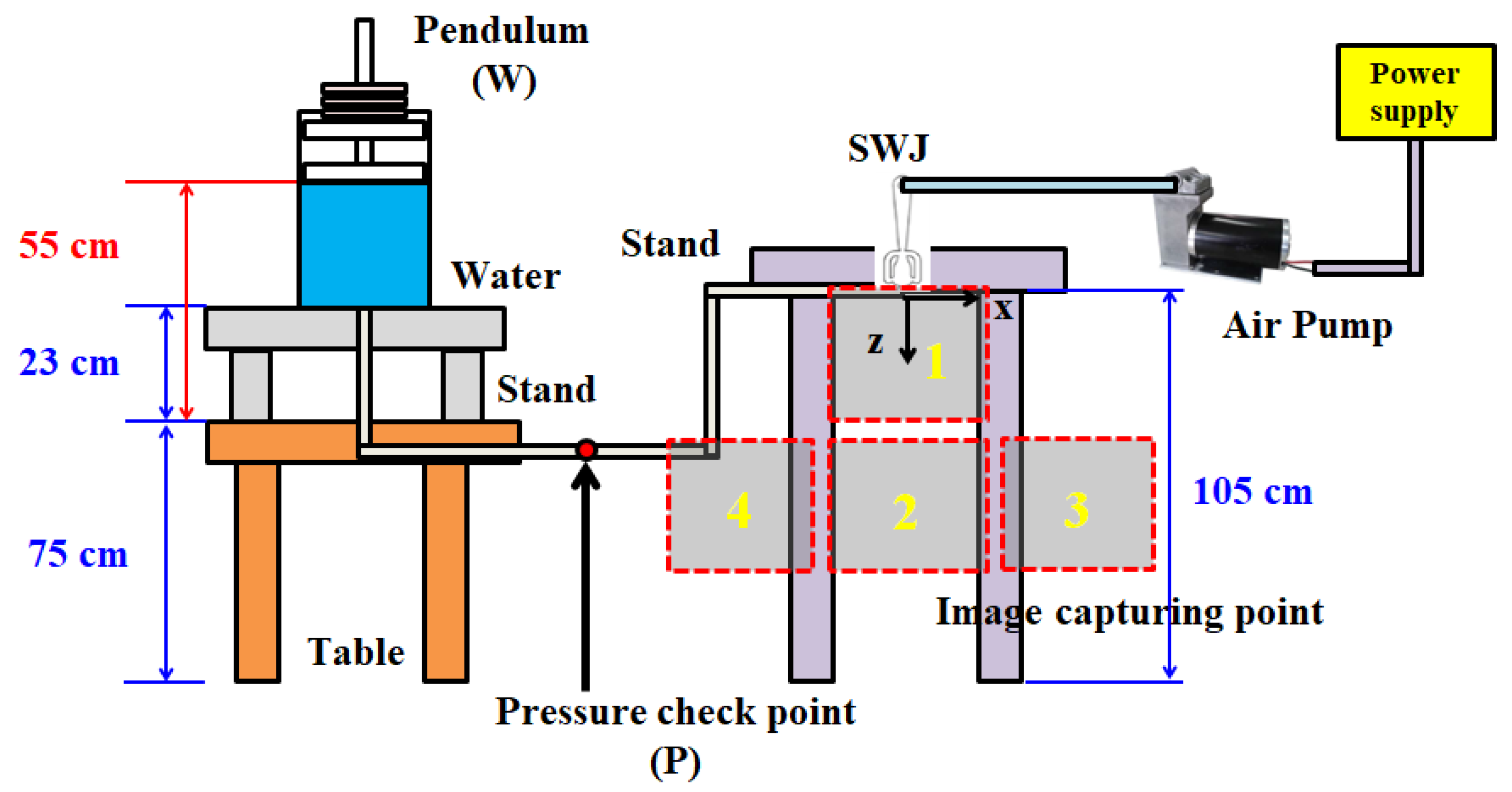

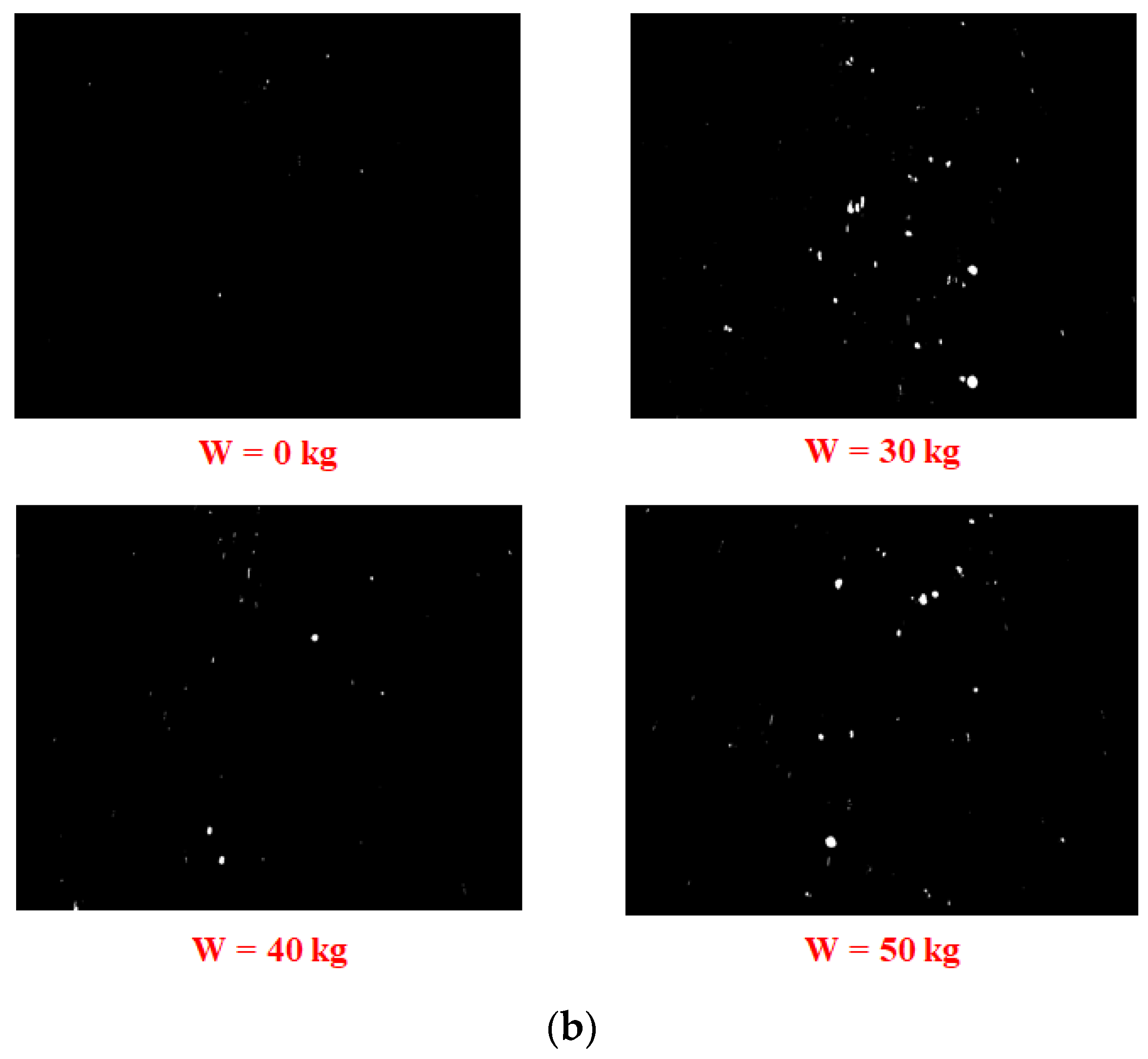

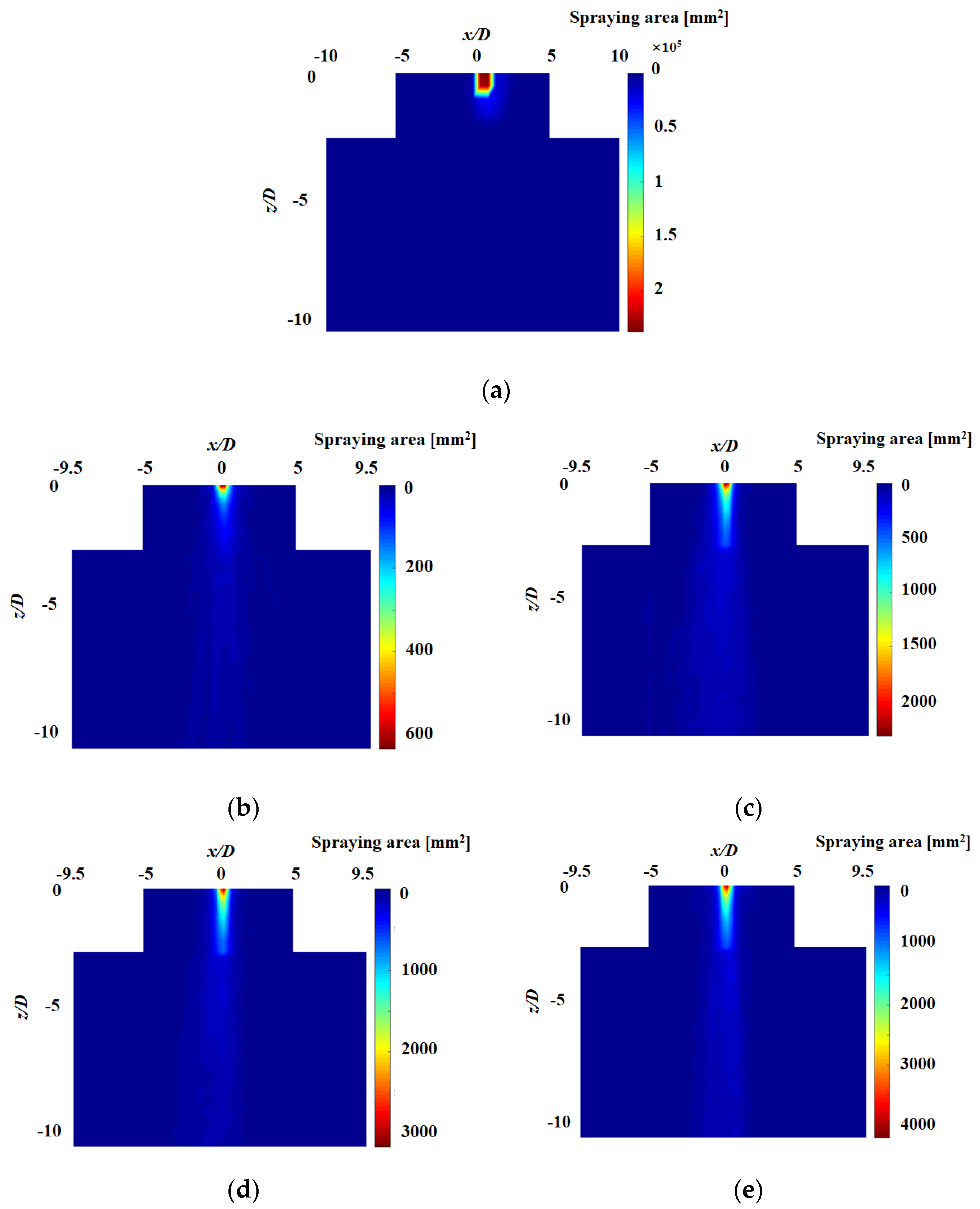

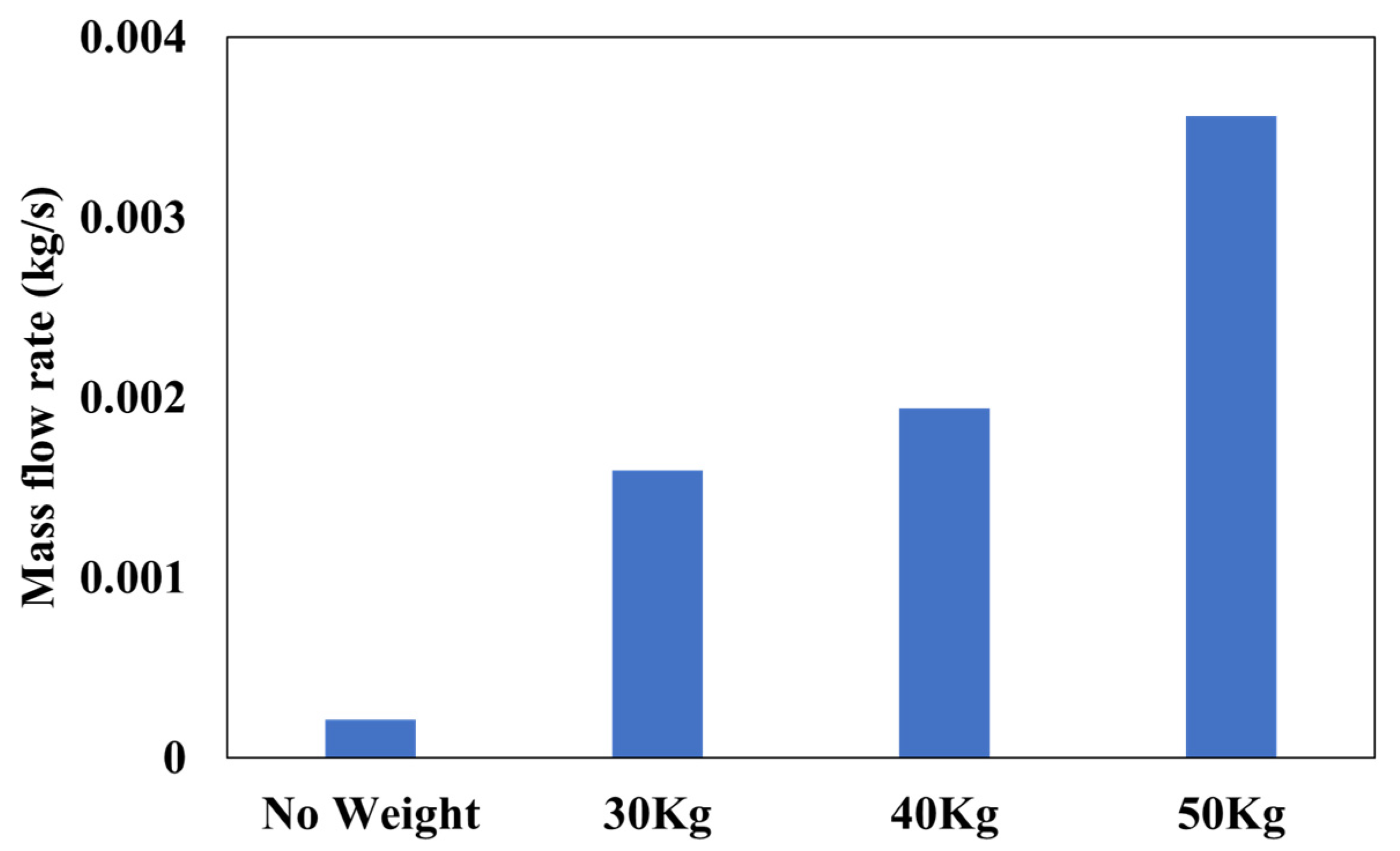

Figure 3 shows a schematic diagram of the experimental setup used to measure the spraying performance. The main flow was injected by using an air pump (Wob-L Piston Gas Pump WA80DC, YLKTECH), and the supply of water through the additional channel was controlled through hydrostatic pressure. After generating a main flow of 8.1 L/min at the main inlet by using an air pump, spraying was performed by applying hydrostatic pressure. For changing the hydrostatic pressure, a weight was added to the upper part of the water piston, and the spraying performance was confirmed by changing the weight from 0 to 50 kg, in 10 kg increments. The static pressure was measured at the point indicated in

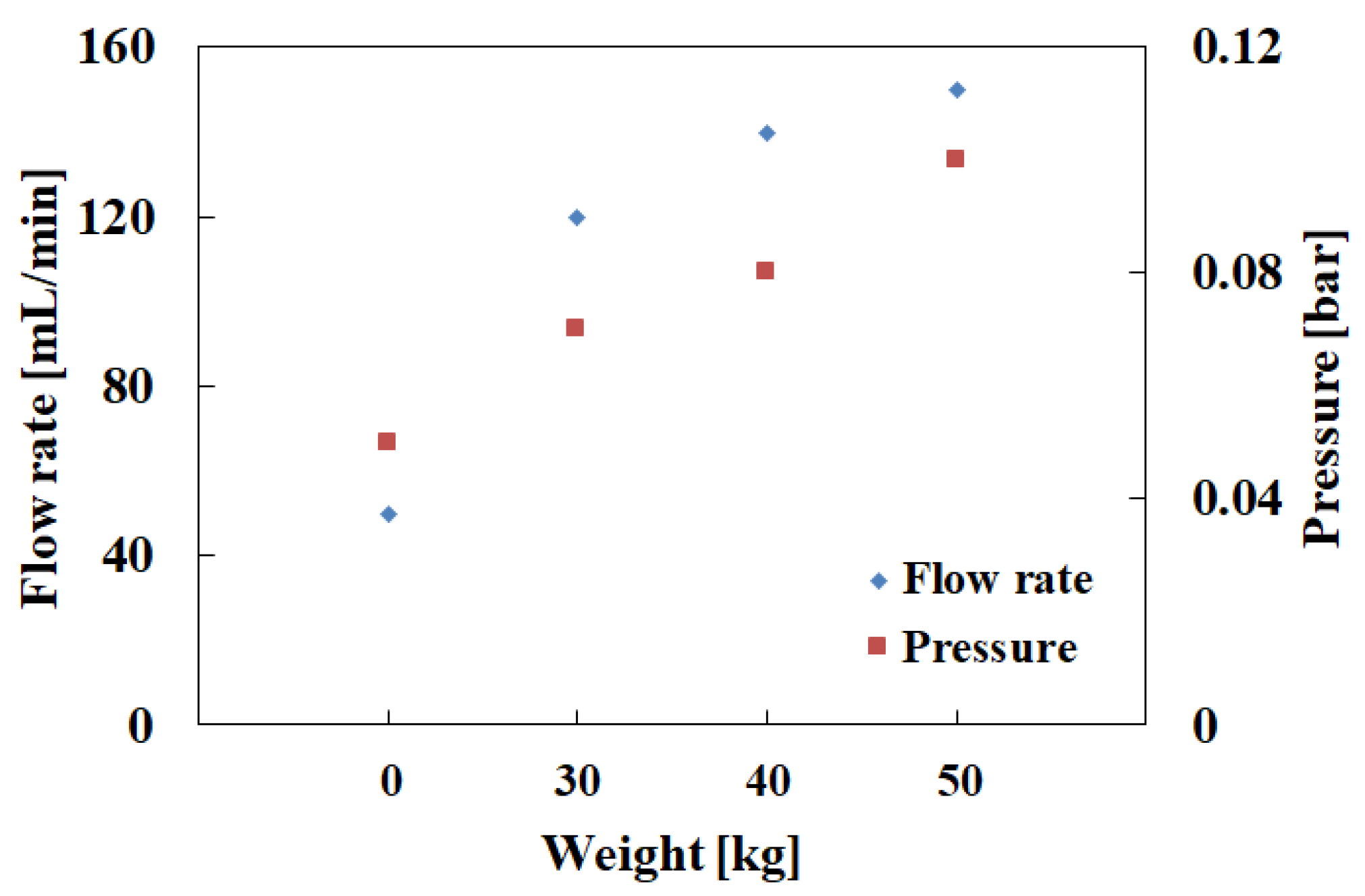

Figure 3. The pressure and flow rates corresponding to different loads on the water piston are summarized in

Figure 4. Without load, the pressure and flow rates were 0.05 bar and 50 mL/min, respectively. The pressure and flow rates are found to increase with increasing loads. The rate of change is found to increase further for loads heavier than 30 kg. When the load was higher than 30 kg, as the load increased, both the pressure and flow rate increased.

The images of spraying particles were captured at 2000 frames per second, with a high-speed camera (Fastcam Mini UX50, Photron, San Diego, CA, USA). The obtained images were analyzed, using a digital image-processing technique. The origin was set at the center of the nozzle exit in the analysis, and the

x-axis and

z-axis represent the radial and spraying directions, respectively. As shown in

Figure 3, to confirm the distribution of particles over a wide range, spraying water droplets were visualized in four areas and photographed by moving the camera ±50 mm in the

x-axis and 50 mm in the

z-axis.

The spray shape maintained a shape close to that of a curtain because the nozzle had a flat exit. In addition, the commercial nozzle used in this study was a fan-shaped nozzle having a curtain-type spaying distribution. Therefore, 2D measurement was sufficient to compare the results in terms of uniformity, because the spraying thickness is small enough to involve the depth of field of imaging; however, the spraying distribution had a thickness in depth because the thickness is small enough to involve the depth of field of imaging. Several blurred droplets, due to being out of focus, were removed by the threshold correction during image processing; however, almost particles were involved in the depth of field of imaging.

3.4. Measurement of Spraying Performance

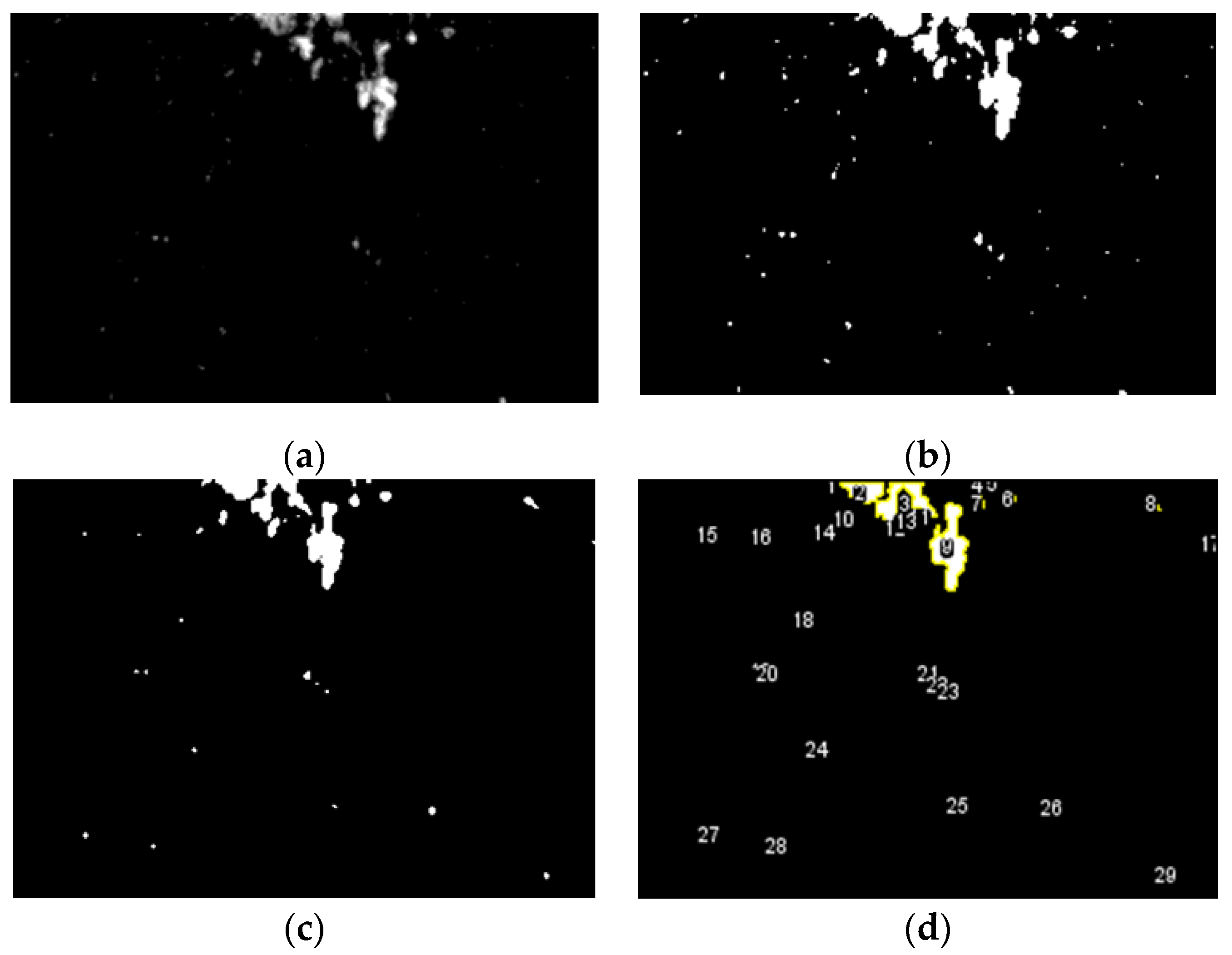

Figure 5 shows the image-processing procedure. The processed images were obtained by sequentially performing threshold correction and noise reduction on the original image, using Image J software. The particle-tracking function in Image J software was employed with the processed images for extracting spraying droplet information, including position and size. In order to check the reliability of the procedure for automatic obtaining the droplet size, we compared the value with a manual calculation for 100 droplets. The measurement accuracy in the size was about 5.3%.

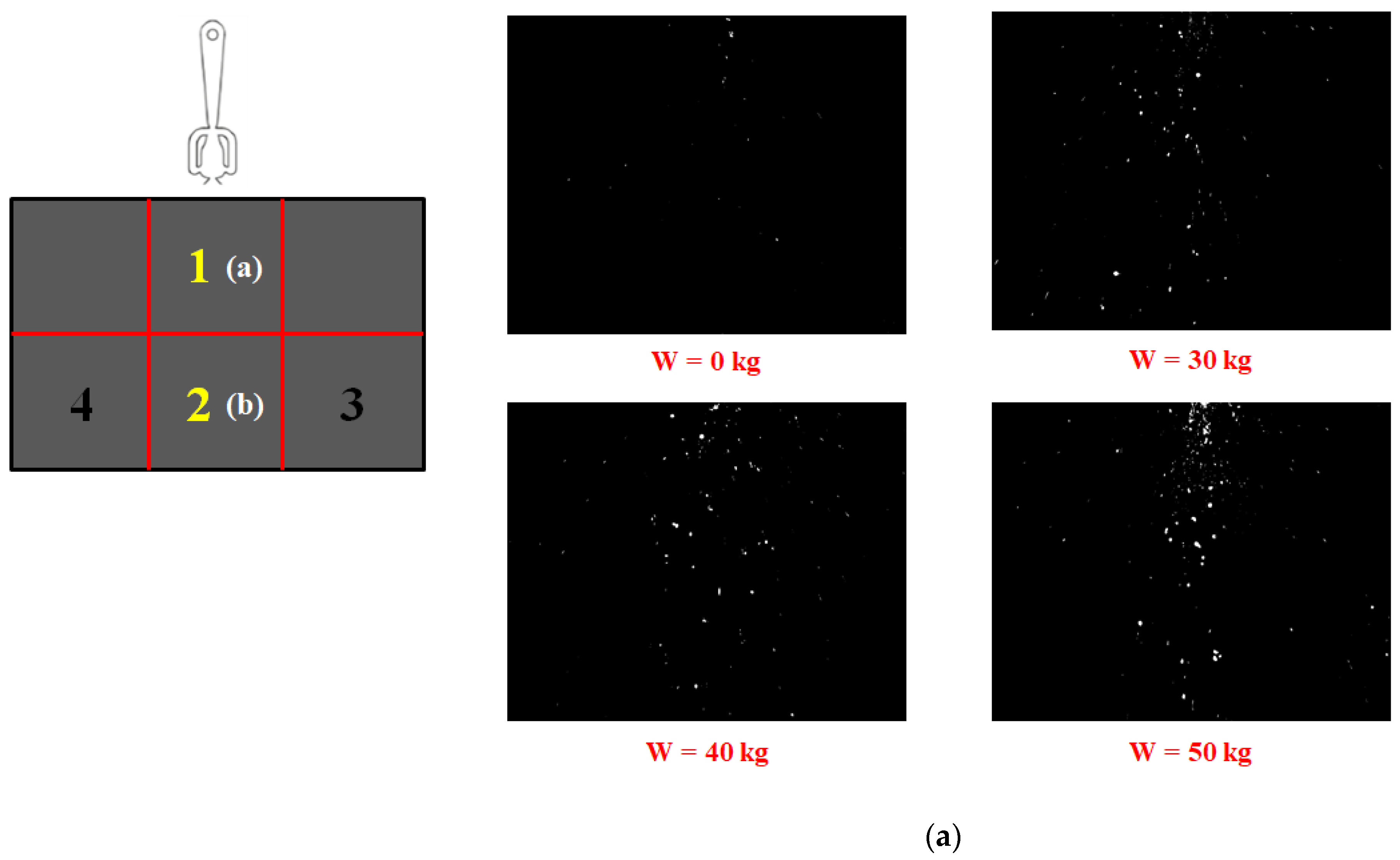

Figure 6 shows representative processed images for the newly proposed nozzle obtained at locations 1 and 2. For statistical analysis, spraying images were captured for 1 s, and the final droplet information was summed and averaged. From the droplet information, the spraying performances were compared by calculating various parameters, such as FWHM and droplet distributions, with respect to the radial position.

5. Conclusions

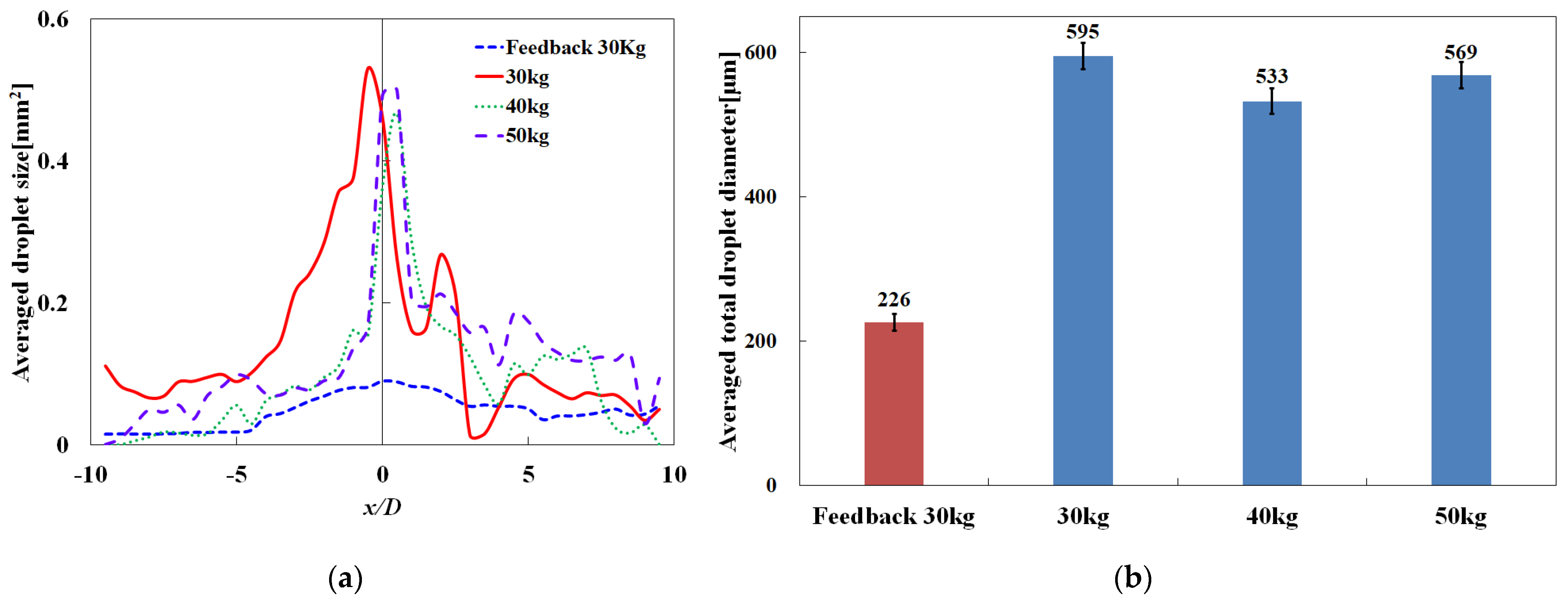

In this study, an advanced nozzle for an agricultural drone with a feedback channel was developed. The spraying performance was evaluated in terms of the droplet size and uniformity and compared with that of a fan-shaped commercial nozzle. The droplet size reduced by at least six to eight times with the proposed nozzle, making it suitable for use in sprayers. Variations in the spraying amount and the corresponding FWHM indicate that the developed nozzle has a better spraying uniformity than the commercial nozzle. To investigate the effect of the feedback channel, the spraying performance of the nozzle without the feedback channel was further investigated. Although the non-feedback nozzle diameter was smaller than that of the commercial nozzle, the droplet size increased as the feedback channel was removed, regardless of the load condition. The droplet diameter of the non-feedback nozzle was not appropriate for use in sprayers. In addition, the spraying uniformity of the non-feedback nozzle was lower than that with feedback. Considering both the droplet size and spraying uniformity, it was confirmed that the 30 kg load condition is optimal because the FWHM is almost independent of loads exceeding 30 kg, while the droplet size increased with increasing load. In addition to spraying performance, including droplet size and uniformity, the proposed nozzle reduces the consumption of water and pesticide. The flow rate for the developed nozzle with a 50 kg load is 150 mL/min, which is significantly lower than that of the commercial nozzle (500 mL/min). The developed nozzle would help improve the spraying performance and contribute to expanding the drone market in agricultural fields.