Effects of Veneering Ceramic and Methods on Failure Load of Veneered Zirconia

Abstract

1. Introduction

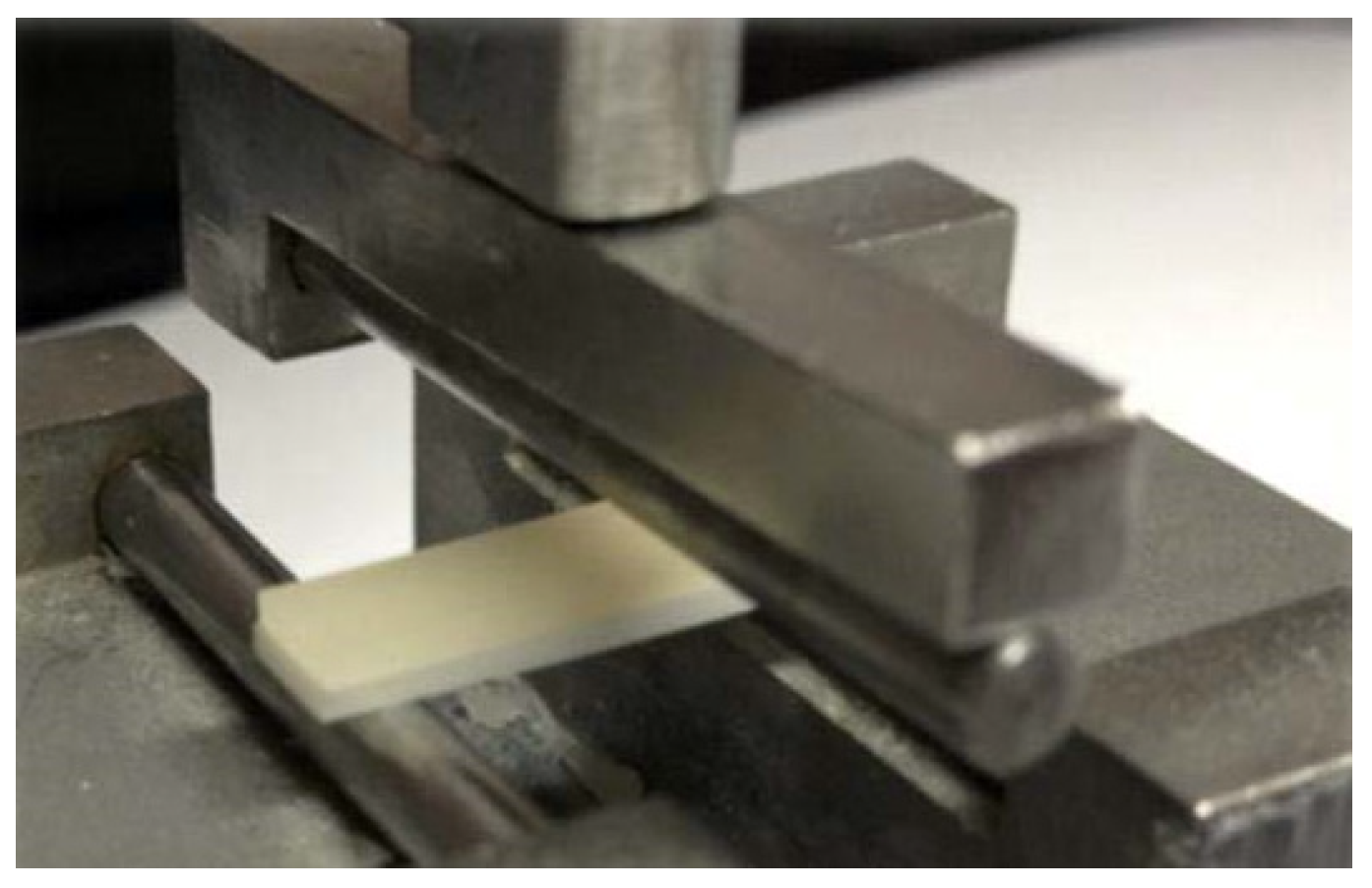

2. Materials and Methods

2.1. Hand-Layered Porcelain Groups

2.1.1. Group 1: Vita In-Ceram YZ + Vita VM9

2.1.2. Group 2: IPS e.max ZirCAD +IPS e.max Ceram

2.2. Pressed-on Ceramics Groups

Group 3: Vita In-Ceram YZ + Vita PM9 and Group 4: IPS e.max ZirCAD + IPS e.max Zirpress

2.3. Cemented Milled Ceramics Groups

2.3.1. Groups 5, 6, and 7: Vita In-Ceram YZ + Vitablocs Triluxe Forte + Resin Cement

2.3.2. Groups 8, 9, and 10: IPS e.max ZirCAD + IPS e.max CAD + Resin Cement

2.4. Fused Milled Ceramics Groups

2.4.1. Group 11: Vita In-Ceram YZ + Vita Triluxe Forte + IPS e.max CAD Crystall/Connect

2.4.2. Group 12: IPS e.max ZirCAD + IPS e.max CAD + IPS e.max CAD Crystall/Connect

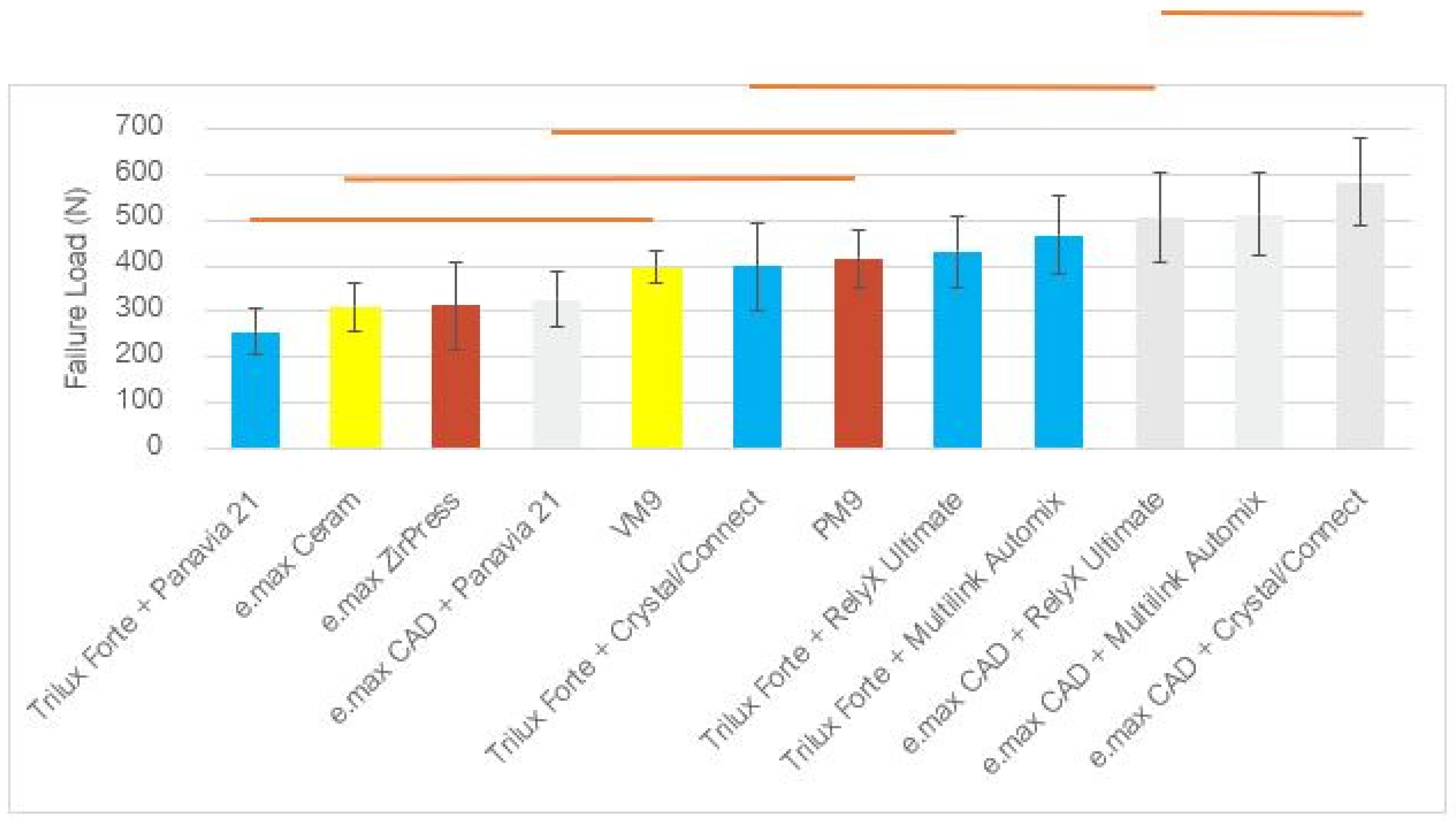

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

References

- Erdemir, U.; Sancakli, H.S.; Sancakli, E.; Eren, M.M.; Ozel, S.; Yucel, T.; Yildiz, E. Shear bond strength of a new self-adhering flowable composite resin for lithium disilicate-reinforced CAD/CAM ceramic material. J. Adv. Prosthodont. 2014, 6, 434–443. [Google Scholar] [CrossRef] [PubMed]

- Kumchai, H.; Juntavee, P.; Sun, A.F.; Nathanson, D. Comparing the Repair of Veneered Zirconia Crowns with Ceramic or Composite Resin: An in Vitro Study. Dent. J. 2020, 8, 37. [Google Scholar] [CrossRef]

- Tinschert, J.; Zwez, D.; Marx, R.; Anusavice, K.J. Structural reliability of alumina-, feldspar-, leucite-, mica- and zirconia-based ceramics. J. Dent. 2000, 28, 529–535. [Google Scholar] [CrossRef]

- Sailer, I.; Balmer, M.; Husler, J.; Hammerle, C.H.F.; Kanel, S.; Thoma, D.S. Comparison of Fixed Dental Prostheses with Zirconia and Metal Frameworks: Five-Year Results of a Randomized Controlled Clinical Trial. Int. J. Prosthodont. 2017, 30, 426–428. [Google Scholar] [CrossRef]

- Guess, P.C.; Schultheis, S.; Bonfante, E.A.; Coelho, P.G.; Ferencz, J.L.; Silva, N.R. All-ceramic systems: Laboratory and clinical performance. Dent. Clin. N. Am. 2011, 55, 333–352. [Google Scholar] [CrossRef]

- Pjetursson, B.E.; Sailer, I.; Makarov, N.A.; Zwahlen, M.; Thoma, D.S. Corrigendum to “All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part II: Multiple-unit FDPs” [Dental Materials 31 (6) (2015) 624-639]. Dent. Mater. 2017, 33, e48–e51. [Google Scholar] [CrossRef] [PubMed]

- D’Addazio, G.; Santilli, M.; Rollo, M.L.; Cardelli, P.; Rexhepi, I.; Murmura, G.; Al-Haj Husain, N.; Sinjari, B.; Traini, T.; Ozcan, M.; et al. Fracture Resistance of Zirconia-Reinforced Lithium Silicate Ceramic Crowns Cemented with Conventional or Adhesive Systems: An In Vitro Study. Materials 2020, 13, 2012. [Google Scholar] [CrossRef]

- Kumchai, H.; Juntavee, P.; Sun, A.F.; Nathanson, D. Effect of Glazing on Flexural Strength of Full-Contour Zirconia. Int. J. Dent. 2018, 2018, 8793481. [Google Scholar] [CrossRef] [PubMed]

- Tsalouchou, E.; Cattell, M.J.; Knowles, J.C.; Pittayachawan, P.; McDonald, A. Fatigue and fracture properties of yttria partially stabilized zirconia crown systems. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2008, 24, 308–318. [Google Scholar] [CrossRef] [PubMed]

- White, S.N.; Caputo, A.A.; Vidjak, F.M.; Seghi, R.R. Moduli of rupture of layered dental ceramics. Dent. Mater. Off. Publ. Acad. Dent. Mater. 1994, 10, 52–58. [Google Scholar] [CrossRef]

- Kelly, J.R.; Tesk, J.A.; Sorensen, J.A. Failure of all-ceramic fixed partial dentures in vitro and in vivo: Analysis and modeling. J. Dent. Res. 1995, 74, 1253–1258. [Google Scholar] [CrossRef] [PubMed]

- Thompson, J.Y.; Anusavice, K.J.; Naman, A.; Morris, H.F. Fracture surface characterization of clinically failed all-ceramic crowns. J. Dent. Res. 1994, 73, 1824–1832. [Google Scholar] [CrossRef]

- Kosmac, T.; Oblak, C.; Jevnikar, P.; Funduk, N.; Marion, L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent. Mater. Off. Publ. Acad. Dent. Mater. 1999, 15, 426–433. [Google Scholar] [CrossRef]

- Shilpa, P.; Narendra, R.; Sesha Reddy, S.R. Shear Bond Strength of Ceramic Bonded to Different Core Materials and Their Pattern of Failure: An In Vitro Study. Cureus 2019, 11, e6242. [Google Scholar] [CrossRef]

- Tinschert, J.; Natt, G.; Hassenpflug, S.; Spiekermann, H. Status of current CAD/CAM technology in dental medicine. Int. J. Comput. Dent. 2004, 7, 25–45. [Google Scholar]

- Tinschert, J.; Natt, G.; Mautsch, W.; Augthun, M.; Spiekermann, H. Fracture resistance of lithium disilicate-, alumina-, and zirconia-based three-unit fixed partial dentures: A laboratory study. Int. J. Prosthodont. 2001, 14, 231–238. [Google Scholar]

- Beuer, F.; Schweiger, J.; Eichberger, M.; Kappert, H.F.; Gernet, W.; Edelhoff, D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings—A new fabrication mode for all-ceramic restorations. Dent. Mater. 2009, 25, 121–128. [Google Scholar] [CrossRef]

- Aboushelib, M.N.; Kleverlaan, C.J.; Feilzer, A.J. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2006, 22, 857–863. [Google Scholar] [CrossRef]

- Guess, P.C.; Zhang, Y.; Thompson, V.P. Effect of veneering techniques on damage and reliability of Y-TZP trilayers. Eur. J. Esthet. Dent. Off. J. Eur. Acad. Esthet. Dent. 2009, 4, 262–276. [Google Scholar]

- Choi, Y.S.; Kim, S.H.; Lee, J.B.; Han, J.S.; Yeo, I.S. In vitro evaluation of fracture strength of zirconia restoration veneered with various ceramic materials. J. Adv. Prosthodont. 2012, 4, 162–169. [Google Scholar] [CrossRef]

- Ishibe, M.; Raigrodski, A.J.; Flinn, B.D.; Chung, K.H.; Spiekerman, C.; Winter, R.R. Shear bond strengths of pressed and layered veneering ceramics to high-noble alloy and zirconia cores. J. Prosthet. Dent. 2011, 106, 29–37. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Ozcan, M.; Roos, M.; Trottmann, A.; Sailer, I.; Hammerle, C.H. Load-bearing capacity and failure types of anterior zirconia crowns veneered with overpressing and layering techniques. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2011, 27, 1045–1053. [Google Scholar] [CrossRef]

- Eisenburger, M.; Mache, T.; Borchers, L.; Stiesch, M. Fracture stability of anterior zirconia crowns with different core designs and veneered using the layering or the press-over technique. Eur. J. Oral Sci. 2011, 119, 253–257. [Google Scholar] [CrossRef]

- Gakis, P.; Kontogiorgos, E.; Zeller, S.; Nagy, W.W. Effect of firing and fabrication technique on the marginal fit of heat-pressed lithium disilicate veneers. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef] [PubMed]

- Chaiyabutr, Y.; McGowan, S.; Phillips, K.M.; Kois, J.C.; Giordano, R.A. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J. Prosthet. Dent. 2008, 100, 194–202. [Google Scholar] [CrossRef]

- van Noort, R. The future of dental devices is digital. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2012, 28, 3–12. [Google Scholar] [CrossRef]

- Bindl, A.; Luthy, H.; Mormann, W.H. Strength and fracture pattern of monolithic CAD/CAM-generated posterior crowns. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2006, 22, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Strub, J.R.; Stiffler, S.; Scharer, P. Causes of failure following oral rehabilitation: Biological versus technical factors. Quintessence Int. 1988, 19, 215–222. [Google Scholar]

- Karlsen, C.A.; Schriwer, C.; Oilo, M. Damage tolerance of six dental zirconias with different translucencies. Biomater. Investig. Dent. 2020, 7, 126–133. [Google Scholar] [CrossRef] [PubMed]

- Swain, M.V. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2009, 5, 1668–1677. [Google Scholar] [CrossRef]

| Group | Zirconia Materials | Veneering Materials | Interface Materials |

|---|---|---|---|

| 1 | Vita In-Ceram YZ | Vita VM9 | |

| 2 | IPS e.max ZirCAD | IPS e.max Ceram | |

| 3 | Vita In-Ceram YZ | Vita PM9 | |

| 4 | IPS e.max ZirCAD | IPS e.max Zirpress | |

| 5 | Vita In-Ceram YZ | Vitablocs Triluxe Forte | Panavia 21 |

| 6 | Vita In-Ceram YZ | Vitablocs Triluxe Forte | Multilink Automix |

| 7 | Vita In-Ceram YZ | Vitablocs Triluxe Forte | RelyX Ultimate |

| 8 | IPS e.max ZirCAD | IPS e.max CAD | Panavia 21 |

| 9 | IPS e.max ZirCAD | IPS e.max CAD | Multilink Automix |

| 10 | IPS e.max ZirCAD | IPS e.max CAD | RelyX Ultimate |

| 11 | Vita In-Ceram YZ | Vitablocs Triluxe Forte | IPS e.max CAD Crystall/Connect |

| 12 | IPS e.max ZirCAD | IPS e.max CAD | IPS e.max CAD Crystall/Connect |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumchai, H.; Juntavee, P.; Sun, A.F.; Nathanson, D. Effects of Veneering Ceramic and Methods on Failure Load of Veneered Zirconia. Appl. Sci. 2021, 11, 2129. https://doi.org/10.3390/app11052129

Kumchai H, Juntavee P, Sun AF, Nathanson D. Effects of Veneering Ceramic and Methods on Failure Load of Veneered Zirconia. Applied Sciences. 2021; 11(5):2129. https://doi.org/10.3390/app11052129

Chicago/Turabian StyleKumchai, Hattanas, Patrapan Juntavee, Arthur F. Sun, and Dan Nathanson. 2021. "Effects of Veneering Ceramic and Methods on Failure Load of Veneered Zirconia" Applied Sciences 11, no. 5: 2129. https://doi.org/10.3390/app11052129

APA StyleKumchai, H., Juntavee, P., Sun, A. F., & Nathanson, D. (2021). Effects of Veneering Ceramic and Methods on Failure Load of Veneered Zirconia. Applied Sciences, 11(5), 2129. https://doi.org/10.3390/app11052129