Viability of Cupola Slag as an Alternative Eco-Binder and Filler in Concrete and Mortars

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of the Materials

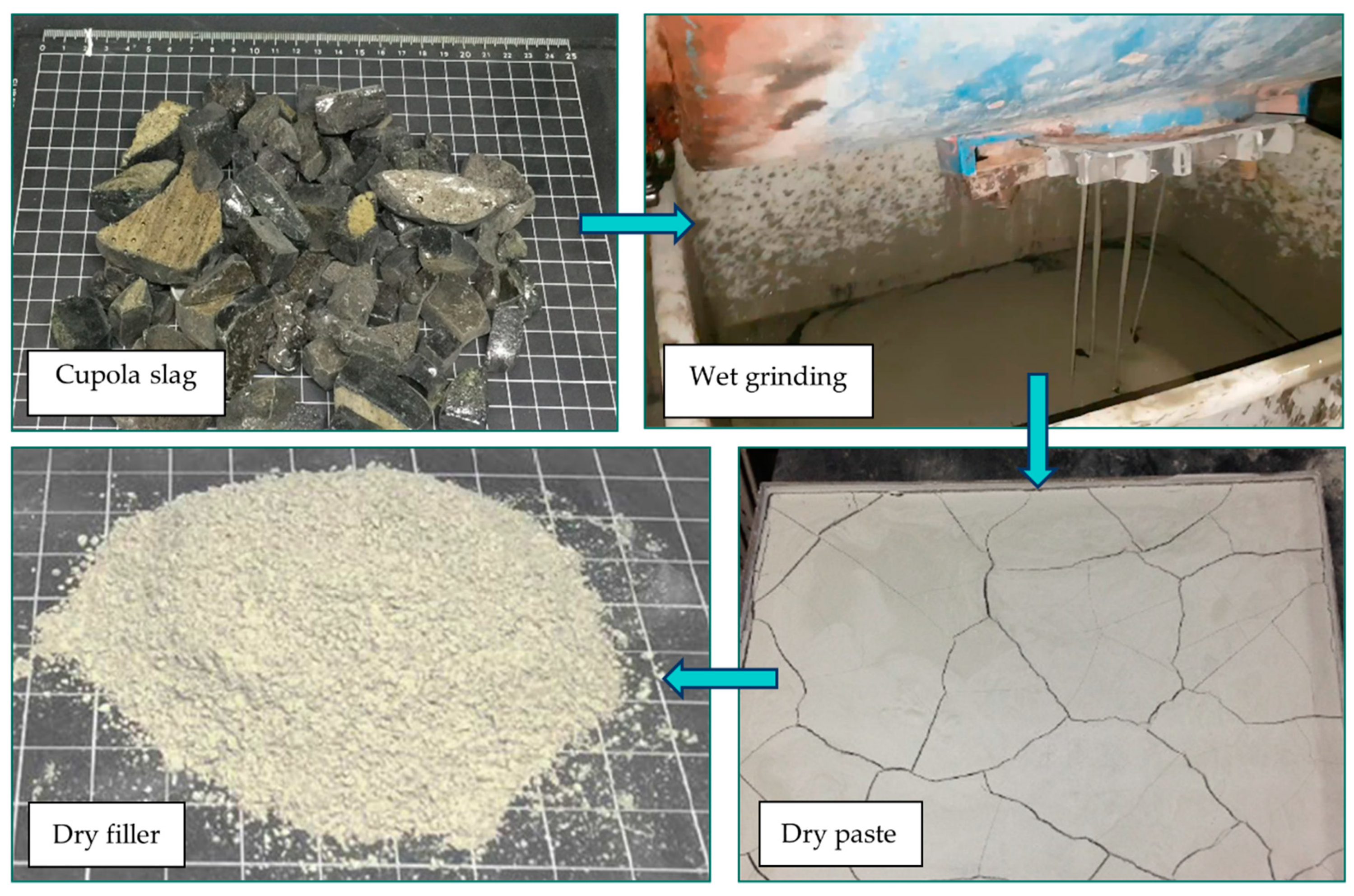

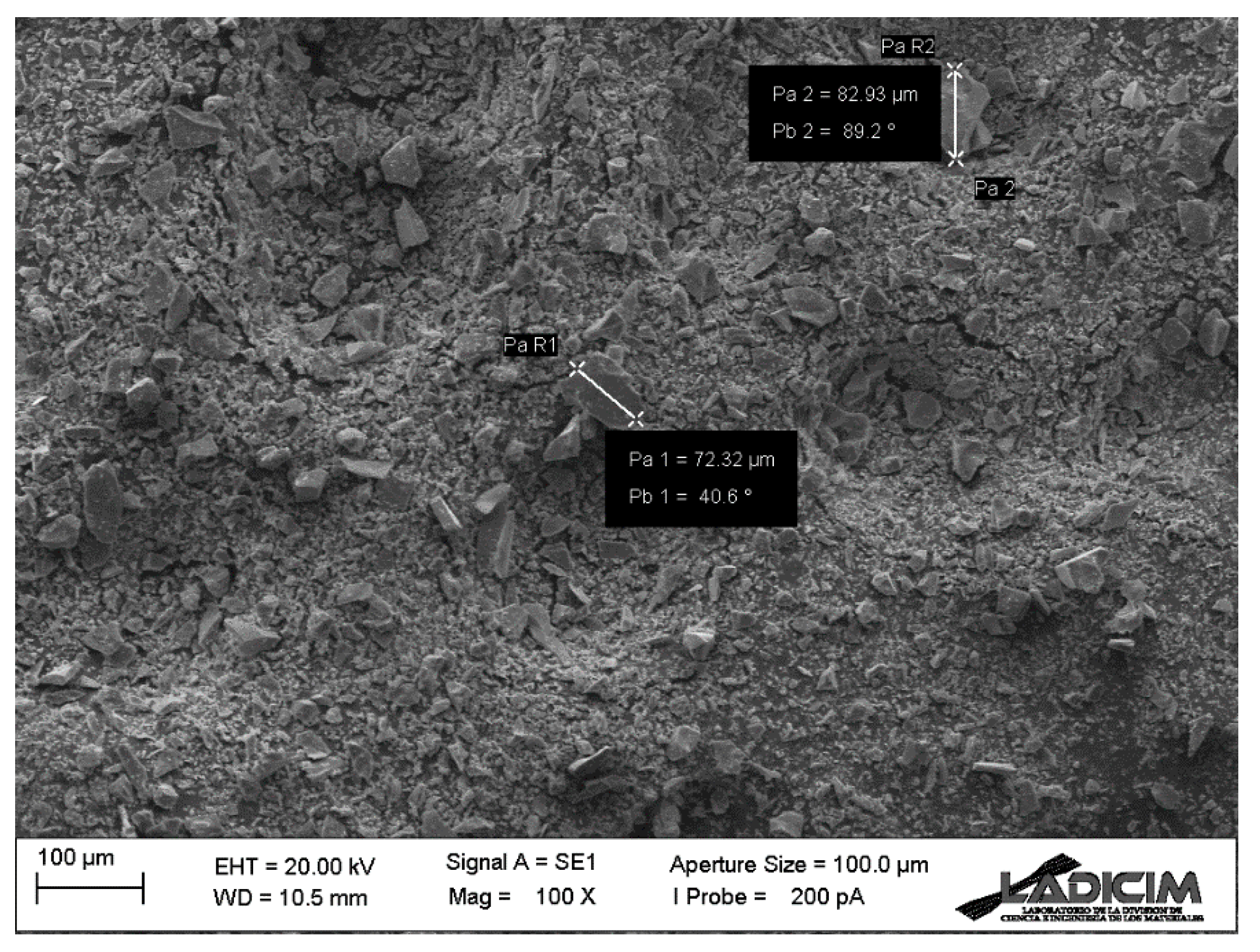

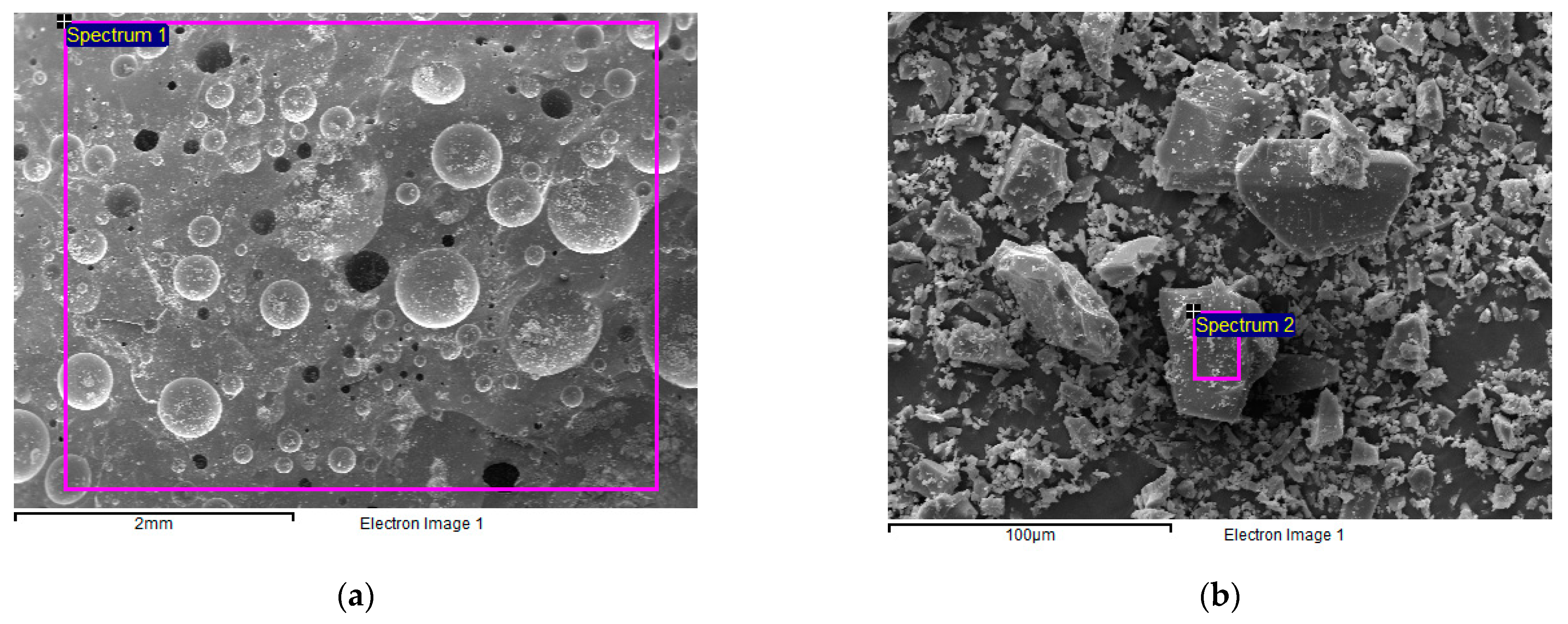

2.1.1. Valorization and Properties of the Cupola Slag

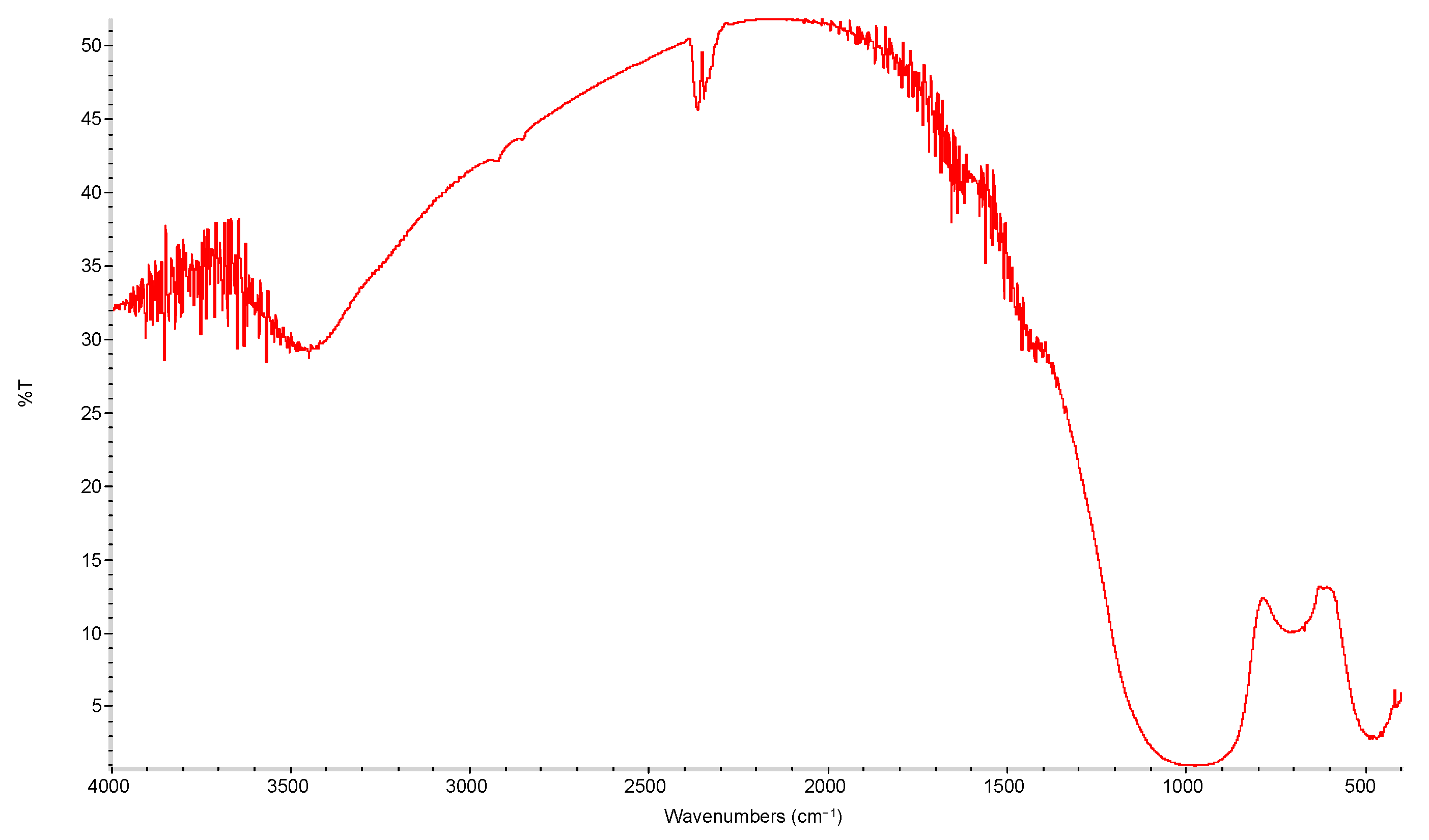

- Mainly silicates and aluminosilicates, with vibration bands in range 800–1100 cm−1 and 500 cm−1.

- Calcium oxide due to its peaks at frequencies around 1400–1500 cm−1 and at 910 cm−1.

- Iron oxides, peaks at 2400 cm−1, 1400–1500 cm−1, and 300–600 cm−1.

2.1.2. Other Mixing Materials

2.2. Design and Testing Methodology

2.2.1. Mix Design

2.2.2. Standardized Tests

3. Results

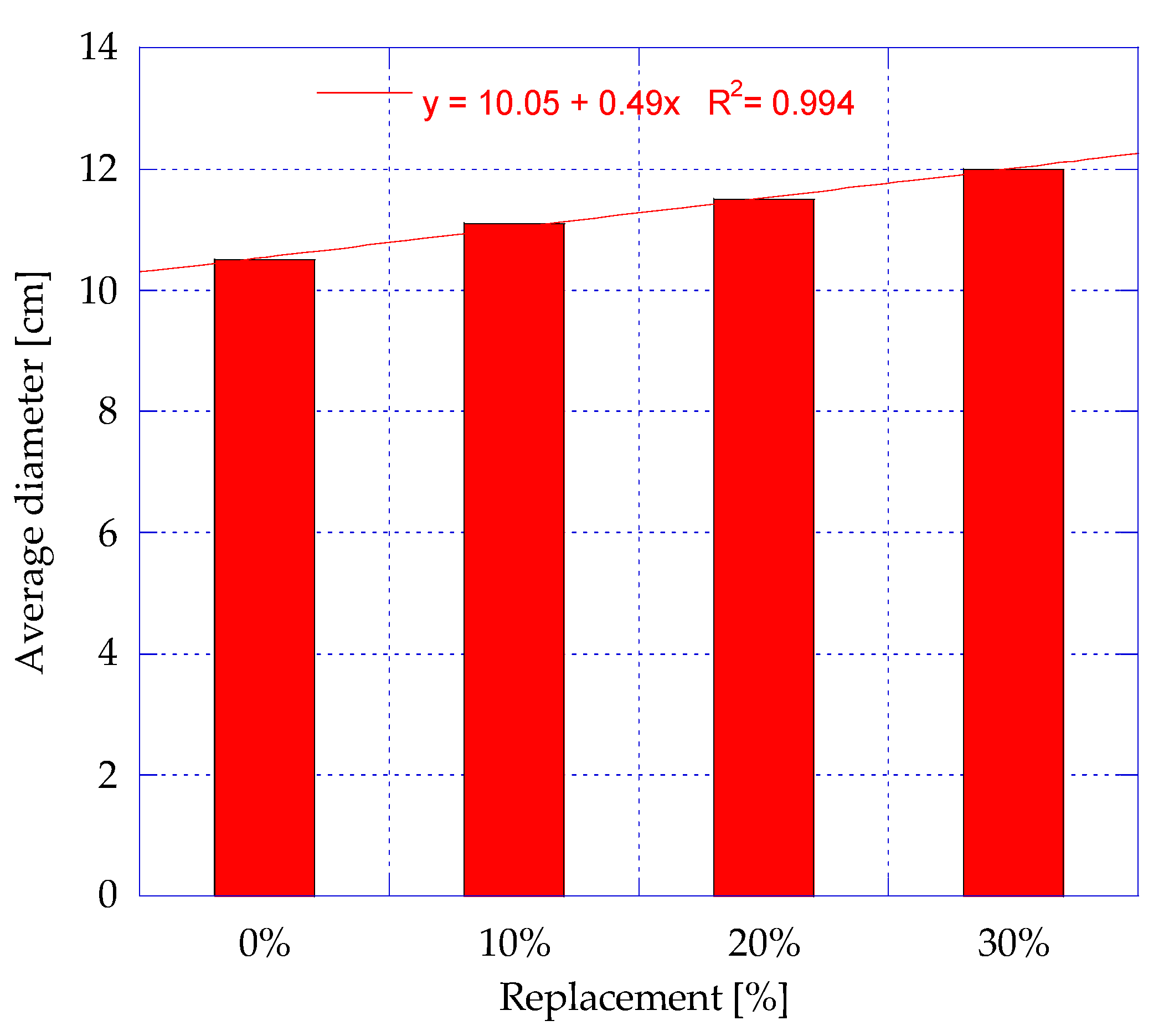

3.1. Consistence of Fresh Mortars

3.2. Mechanical Properties

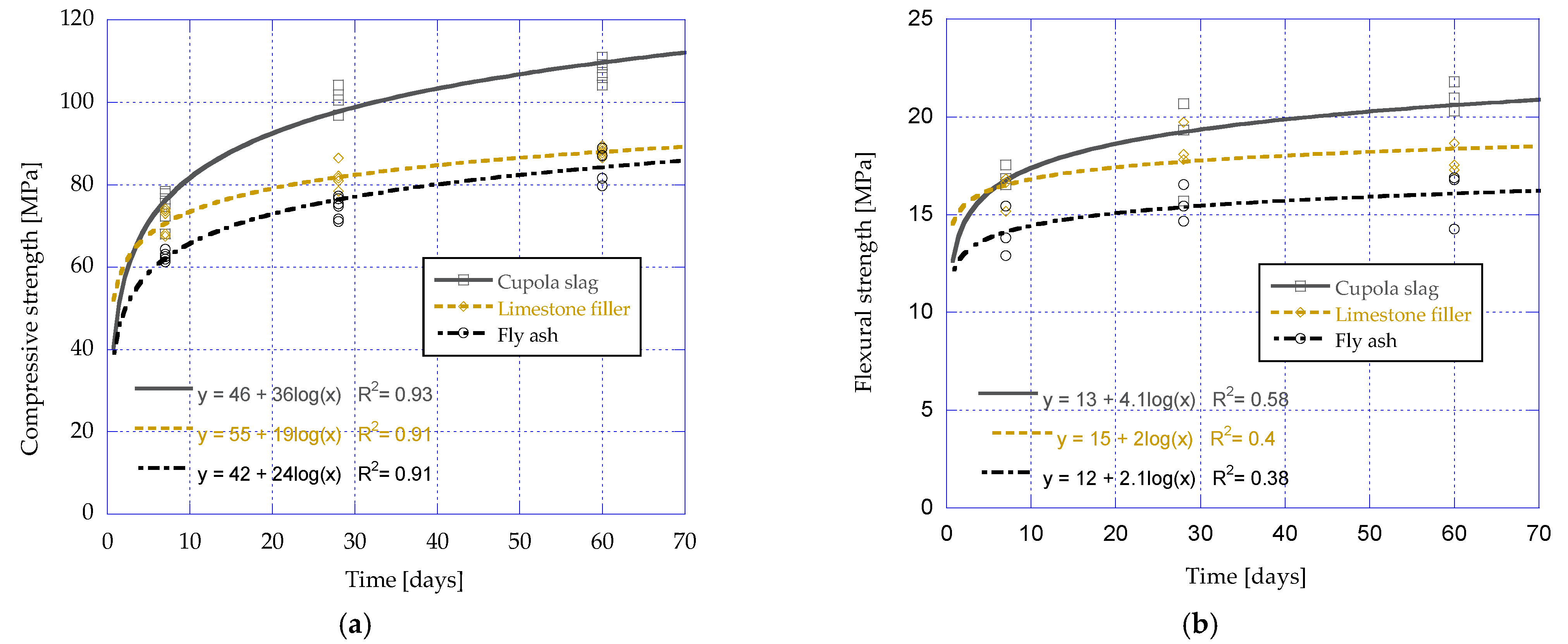

3.2.1. Mortars with Different Admixtures

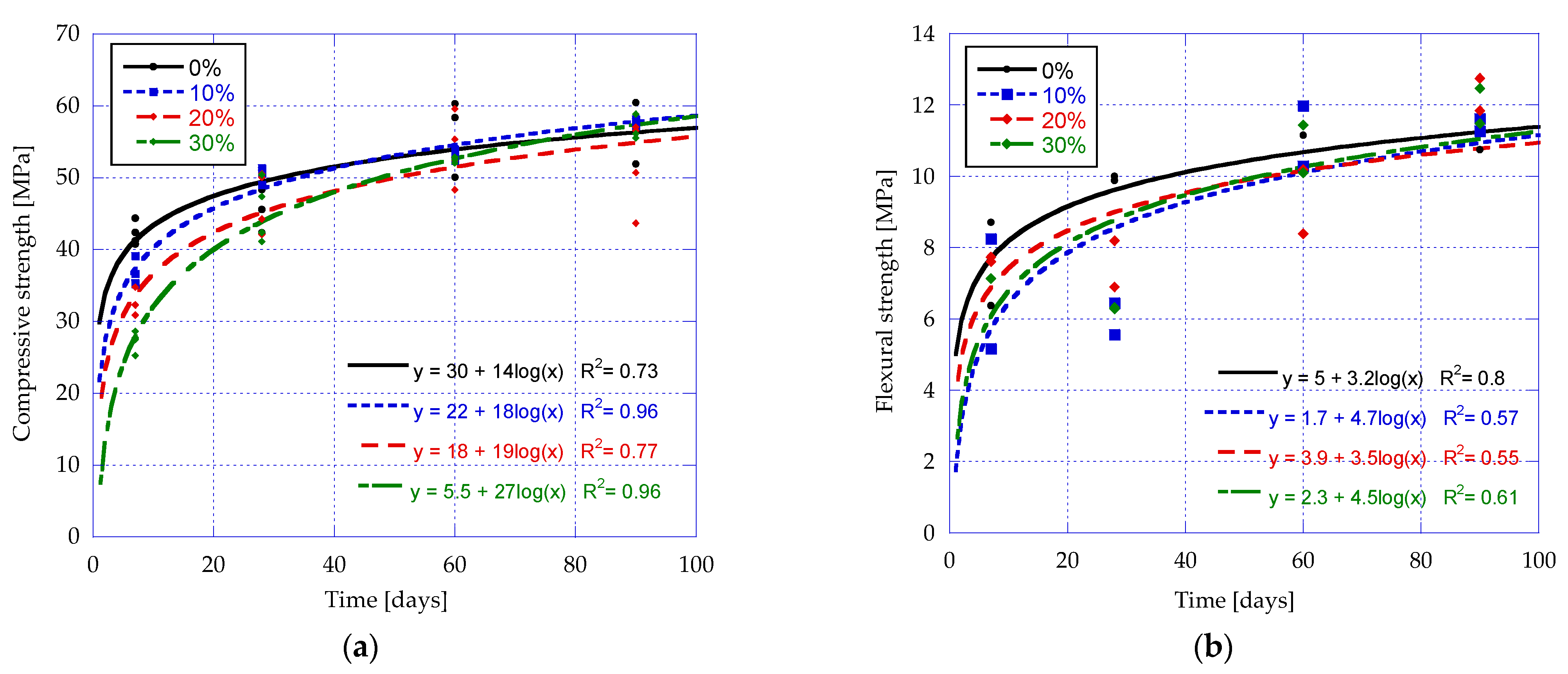

3.2.2. Mortars with Different Replacement Proportions

4. Conclusions

- The recovery of cupola slag and its use in construction materials means a reduction in CO2 emissions generated by the manufacturing of cement, and preventing this waste from going to landfills.

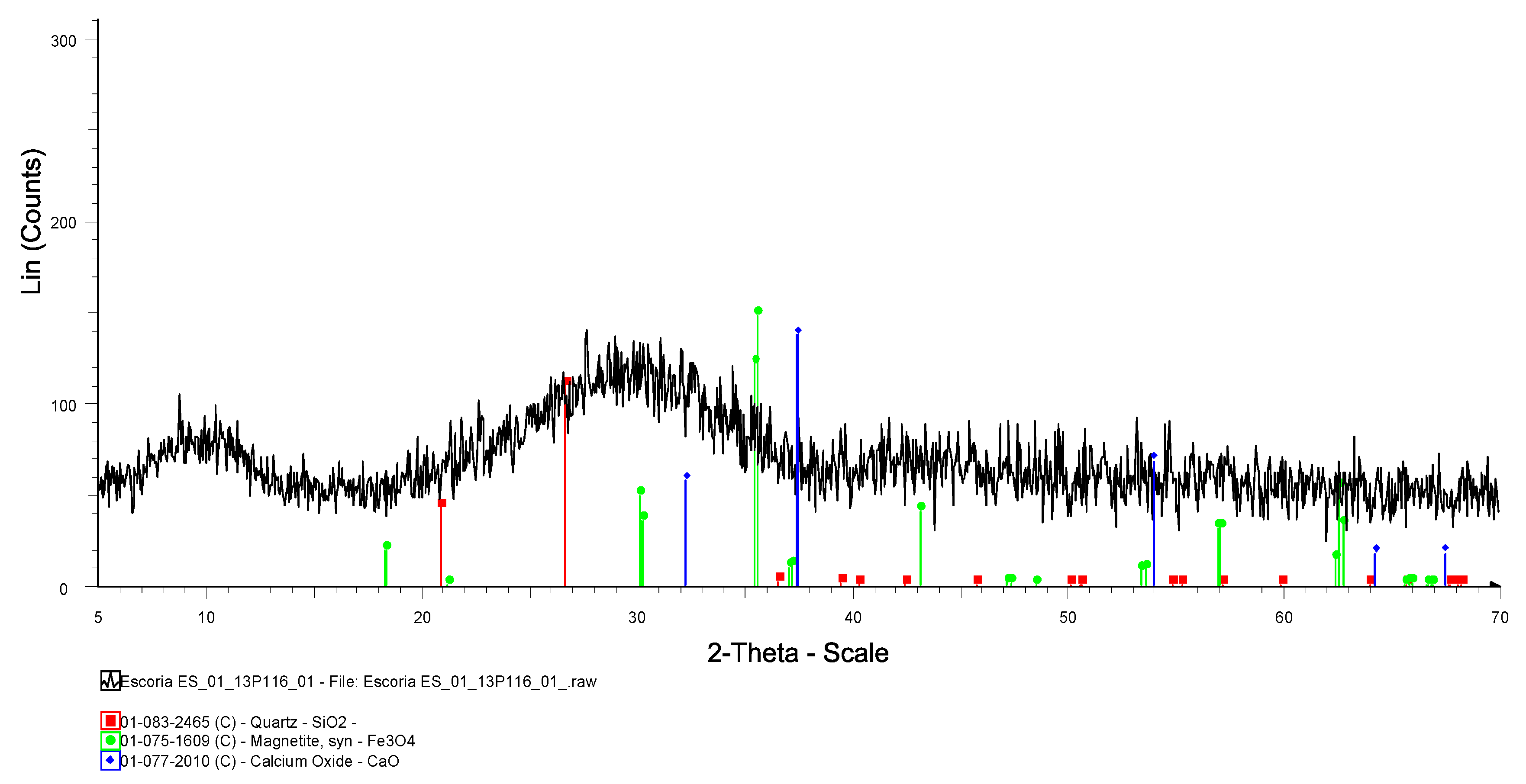

- The diffractogram, the chemical composition, and the infrared spectrum confirm the presence of an amorphous structure in the slag cupola that makes it susceptible to reacting.

- The cupola slag studied does not pose any environmental risk since concentrations of dangerous elements in the leachate test are very low.

- Compared to limestone filler and fly ash admixtures, the evolution of strength is similar up to ages close to 7 days, but more than 20% higher in the long-term, for ages close to 60 days. This shows a greater hydraulicity of the slag cupola with respect to the other admixtures used.

- A greater replacement of cupola slag by Portland cement produces a greater consistency in the fresh mortar, but a loss of compressive strength of up to 27% after 7 days. The slowness of the pozzolanic reactions makes the resistances tend to converge at 90 days for any replacement.

- Future work will attempt to quantitatively clarify the environmental and economic costs associated with the recovery process, which is very important to establish the sustainability of the material.

- The results obtained show that it is feasible to use the slag cupola in the manufacturing of mortars/concrete when high initial strengths are not required or when a binder that generates less heat of hydration than Portland cement is desired.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- American Foundry Society. Available online: https://www.afsinc.org/ (accessed on 19 October 2020).

- Raju, K.; Ganesh, M.P.; Murthy, N.; Anirudha, K.V.; Rao, P.R. Geotechnical characterization of miscellaneous wastes. In Proceedings of the GEOtrendz Indian Geotechnical Conference (IGC), II T Bombay, Mumbai, India, 16–18 December 2010; pp. 53–56. [Google Scholar]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Babu, K.G.; Kumar, V.S.R. Efficiency of GGBS in concrete. Cem. Concr. Res. 2000, 30, 1031–1036. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Rakhimov, R.Z.; Rakhimova, N.R.; Ojovan, M.I. Cementitious Materials for Nuclear Waste Immobilization; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Ministerio de Medio Ambiente y Medio Rural y Marino. Mejores Técnicas Disponibles de Referencia Europea Forja y Fundición; Government of Spain: Madrid, Spain, 2009.

- Aderibigbe, D.A.; Ojobo, A.E. Properties of cupola slag as a pozzolana and its effects on partial replacement of cement in a mortar. Conserv. Recycl. 1982, 5, 203–208. [Google Scholar] [CrossRef]

- Thomas, C.; Rosales, J.; Polanco, J.A.; Agrela, F. New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Sainz-Aja, J.; Carrascal, I.; Polanco, J.A.; Thomas, C.; Sosa, I.; Casado, J.; Diego, S. Self-compacting recycled aggregate concrete using out-of-service railway superstructure wastes. J. Clean. Prod. 2019, 230, 945–955. [Google Scholar] [CrossRef]

- Tamayo, P.; Pacheco, J.; Thomas, C.; de Brito, J.; Rico, J. Mechanical and Durability Properties of Concrete with Coarse Recycled Aggregate Produced with Electric Arc Furnace Slag Concrete. Appl. Sci. 2020, 10, 216. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Gil, V.; Sainz-Aja, J.A.; Cimentada, A. Multiple recycled aggregate properties analysed by X-ray microtomography, Constr. Build. Mater. 2018, 166. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; de Brito, J.; Fiol, F. Micro- and macro-porosity of dry- and saturated-state recycled aggregate concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Cimentada, A.I.; Medina, C. Influence of curing conditions on recycled aggregate concrete. Constr. Build. Mater. 2018, 172. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Carrascal, I.; Polanco, J.A.; Thomas, C. Fatigue failure micromechanisms in recycled aggregate mortar by μCT analysis. J. Build. Eng. 2020, 28. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; de Juan, M.S. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Baricová, D.; Pribulová, A.; Demeter, P. Comparison of possibilities the blast furnaceand cupola slag utilization by concrete production. Arch. Foundry Eng. 2010, 10, 15. [Google Scholar]

- Stroup, W.W.; Stroup, R.D.; Fallin, J.H. Cupola Slag Cement Mixture and Methods of Making and Using the Same. U.S. Patent 6,627,138 B2, 30 September 2003. [Google Scholar]

- Ceccato, D.; Masuero, A.; Moraes, C.; Vilela, A. Reciclaje de escoria granulada de fundición (EGF) como sustitución de parte del cemento en hormigón. Rev. Matéria 2009, 14, 737. [Google Scholar] [CrossRef]

- Alabi, S.A.; Afolayan, J.O. Investigation on the potentials of cupola furnace slag in concrete. Int. J. Integr. Eng. 2013, 5, 59–62. [Google Scholar]

- Sosa, I.; Thomas, C.; Polanco, J.A.; Setién, J.; Tamayo, P. High Performance Self-Compacting Concrete with Electric Arc Furnace Slag Aggregate and Cupola Slag Powder. Appl. Sci. 2020, 10, 773. [Google Scholar] [CrossRef]

- Domone, P.L. A review of the hardened mechanical properties of self-compacting concrete. Cem. Concr. Compos. 2006, 29, 1–12. [Google Scholar] [CrossRef]

- Rozière, E.; Granger, S.; Turcry, P.; Loukili, A. Influence of paste volume on shrinkage cracking and fracture properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 626–636. [Google Scholar] [CrossRef]

- Characterization of residues. Leaching. Compliance test for the leaching of granular residues and sludge. In Part 4: One-Stage Batch Test with a Liquid-Solid Ratio of 10 L/kg for Materials with a Particle Size Less than 10, UNE 12457-4. 2004. Available online: https://www.en.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0029596 (accessed on 22 July 2020).

- D. 104/2006 19 October. Valorización de escorias en la Comunidad Autónoma de Cantabria, BOC. 204; Government of Cantabria: Santander, Spain, 2006. [Google Scholar]

- Sosa, I. Incorporación de Escorias Siderurgicas en Hormigones Autocompactantes de Altas Prestaciones. Ph.D. Thesis, University of Cantabria, Santander, Spain, 2017. [Google Scholar]

- Ogirigbo, O.R. Influence of Slag Composition and Temperature on the Hydration and Performance of Slag Blends in Chloride Environments; University of Leeds: Leeds, UK, 2016. [Google Scholar]

- Wan, H.; Shui, Z.; Lin, Z. Analysis of geometric characteristics of GGBS particles and their influences on cement properties. Cem. Concr. Res. 2004, 34, 133–137. [Google Scholar] [CrossRef]

- Test Methods of Cements. Physical Analysis. Actual Density Determination, U.N.E. 80103:2013. 2013. Available online: https://infostore.saiglobal.com/en-us/Standards/UNE-80103-2013-22841_SAIG_AENOR_AENOR_50269/ (accessed on 22 July 2020).

- Methods of Testing Cement—Part 6: Determination of Fineness, E.N. 196-6:2010. 2010. Available online: https://webstore.ansi.org/standards/din/dinen1962010 (accessed on 22 July 2020).

- Sainz-Aja, J.A.; Carrascal, I.; Polanco, J.A.; Sosa, I.; Thomas, C.; Casado, J.; Diego, S. Determination of the optimum amount of superplasticizer additive for self-compacting concrete. Appl. Sci. 2020, 10, 3096. [Google Scholar] [CrossRef]

- Methods of Testing Cement—Part 1: Determination of Strength, E.N. 196-1:2018. 2018. Available online: https://www.en.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0060675 (accessed on 2 July 2020).

- Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar, E.N. 1015-11:2000. 2000. Available online: https://www.en.une.org/encuentra-tu-norma/busca-tu-norma/norma/?Tipo=N&c=N0022410 (accessed on 2 July 2020).

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and hardened characteristics of self compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar] [CrossRef]

- Felekoglu, B.; Baradan, B. Utilisation of limestone powder in self-levelling binders. Recycl. Reuse Waste Mater. 2003, 475–484. [Google Scholar]

- ASTM-C-311. Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

| Parameter | Unit | Limit Value | Obtained Value |

|---|---|---|---|

| Conductivity | µS/cm | - | 72.8 (20 °C) |

| Acidity | pH | - | 10.41 (21.6 °C) |

| Chemical oxygen demand | mg/kg m.s. | 500 | <50 |

| Chlorides | mg/kg m.s. | 800 | <50 |

| Phenols | mg/kg m.s. | 1 | <1 |

| Total solid solved | mg/kg m.s. | 4 | 480 |

| Sulfates | mg/kg m.s. | 1000 | 60.4 |

| Antimony | mg/kg m.s. | 0.06 | <0.01 |

| Arsenic | mg/kg m.s. | 0.5 | <0.02 |

| Barium | mg/kg m.s. | 20 | <0.10 |

| Cadmium | mg/kg m.s. | 0.04 | <0.01 |

| Copper | mg/kg m.s. | 2 | <0.17 |

| Total chromium | mg/kg m.s. | 0.5 | <0.06 |

| Mercury | mg/kg m.s. | 0.01 | <0.02 |

| Molybdenum | mg/kg m.s. | 0.5 | <0.20 |

| Nickel | mg/kg m.s. | 0.4 | <0.08 |

| Lead | mg/kg m.s. | 0.5 | <0.12 |

| Zinc | mg/kg m.s. | 4 | <0.55 |

| Selenium | mg/kg m.s. | 0.10 | <0.10 |

| Material | Fe2O3 | CaO | SiO2 | Al2O3 | MgO | MnO | Cr2O3 | TiO2 | Na2O | SO3 | K2O | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diabase sand | 13.7 | 11.1 | 46.5 | 13.6 | 12.4 | - | - | - | 2.8 | - | - | - |

| Silica sand | - | - | 96.0 | 4 | - | - | - | - | - | - | - | - |

| Cupola slag | 6.3 | 30.0 | 43.6 | 13.6 | 2.1 | 2.8 | - | 0.5 | - | - | - | <0.5 |

| Limestone filler | - | 100 | - | - | - | - | - | - | - | - | - | - |

| Fly ash | 7.0 | 6.1 | 55.0 | 20.4 | 2.6 | - | - | 0.9 | 1.2 | 4.0 | 2.0 | - |

| CEM I 52.5 R | 3.4 | 66.6 | 17.8 | 4.8 | 1.3 | - | - | 0.2 | - | 4.5 | 0.8 | - |

| Material | Real Density (g/cm3) | Blaine Surface (m2/kg) |

|---|---|---|

| Diabase sand | 2.89 | - |

| Silica sand | 2.61 | - |

| Cupola slag | 2.89 | 429.4 |

| Limestone filler | 2.65 | 274.1 |

| Fly ash | 2.13 | 400.3 |

| CEM I 52.5 R | 3.11 | 495.7 |

| Material | FA | LF | CS | M-0% | M-10% | M-20% | M-30% |

|---|---|---|---|---|---|---|---|

| Diabase sand | 435 | 435 | 435 | - | - | - | - |

| Silica sand | 390 | 390 | 390 | 1450 | 1450 | 1450 | 1450 |

| Cupola slag | - | - | 200 | - | 41.8 | 83.6 | 125.5 |

| Limestone filler | - | 200 | - | - | - | - | - |

| Fly ash | 200 | - | - | - | - | - | - |

| CEM I 52.5 R | 450 | 450 | 450 | 450 | 405 | 360 | 315 |

| Water | 211.5 | 193.5 | 180 | 225 | 225 | 225 | 225 |

| w/c ratio | 0.47 | 0.43 | 0.4 | 0.50 | 0.60 | 0.70 | 0.80 |

| SP | 9 | 9 | 9 | - | - | - | - |

| Admixture | W/c Ratio | Average Diameter (mm) | Diameter after 15 Strokes (mm) |

|---|---|---|---|

| Limestone filler | 0.43 | 155 | 190 |

| Fly ash | 0.47 | 160 | 215 |

| Cupola slag | 0.40 | 150 | 200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sosa, I.; Tamayo, P.; Sainz-Aja, J.A.; Cimentada, A.; Polanco, J.A.; Setién, J.; Thomas, C. Viability of Cupola Slag as an Alternative Eco-Binder and Filler in Concrete and Mortars. Appl. Sci. 2021, 11, 1957. https://doi.org/10.3390/app11041957

Sosa I, Tamayo P, Sainz-Aja JA, Cimentada A, Polanco JA, Setién J, Thomas C. Viability of Cupola Slag as an Alternative Eco-Binder and Filler in Concrete and Mortars. Applied Sciences. 2021; 11(4):1957. https://doi.org/10.3390/app11041957

Chicago/Turabian StyleSosa, Israel, Pablo Tamayo, Jose A. Sainz-Aja, Ana Cimentada, Juan Antonio Polanco, Jesús Setién, and Carlos Thomas. 2021. "Viability of Cupola Slag as an Alternative Eco-Binder and Filler in Concrete and Mortars" Applied Sciences 11, no. 4: 1957. https://doi.org/10.3390/app11041957

APA StyleSosa, I., Tamayo, P., Sainz-Aja, J. A., Cimentada, A., Polanco, J. A., Setién, J., & Thomas, C. (2021). Viability of Cupola Slag as an Alternative Eco-Binder and Filler in Concrete and Mortars. Applied Sciences, 11(4), 1957. https://doi.org/10.3390/app11041957