The Archaeometallurgical Evaluation of Three Bronze Socketed Axes, Discovered in Eastern Romania

Abstract

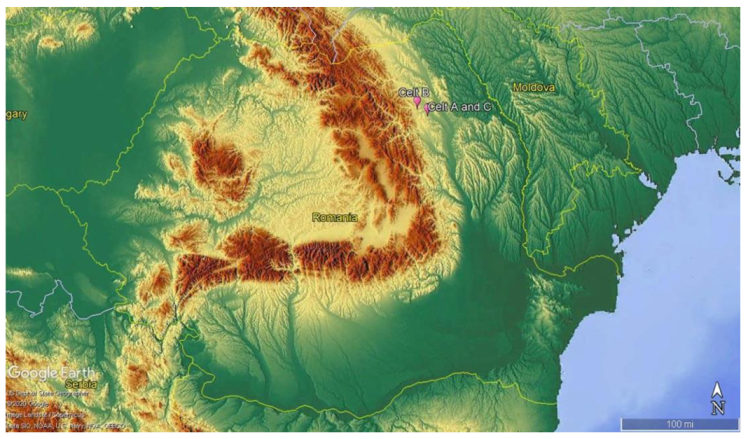

:1. Introduction

2. Materials and Methods

2.1. Description of the Artifacts

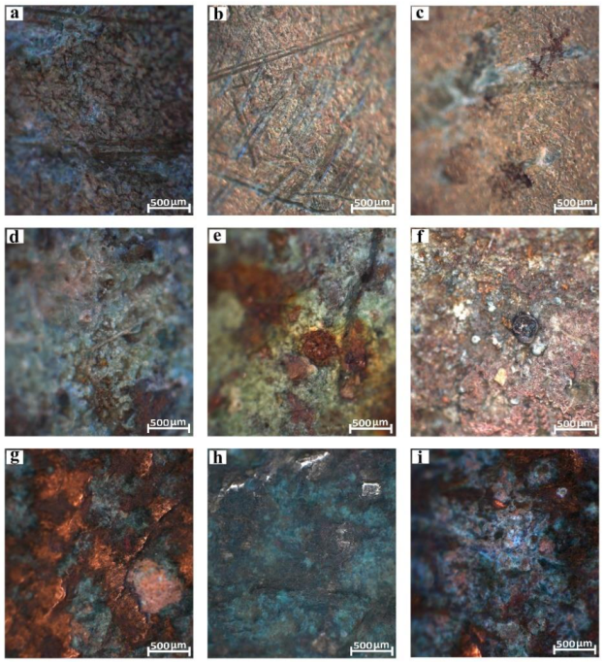

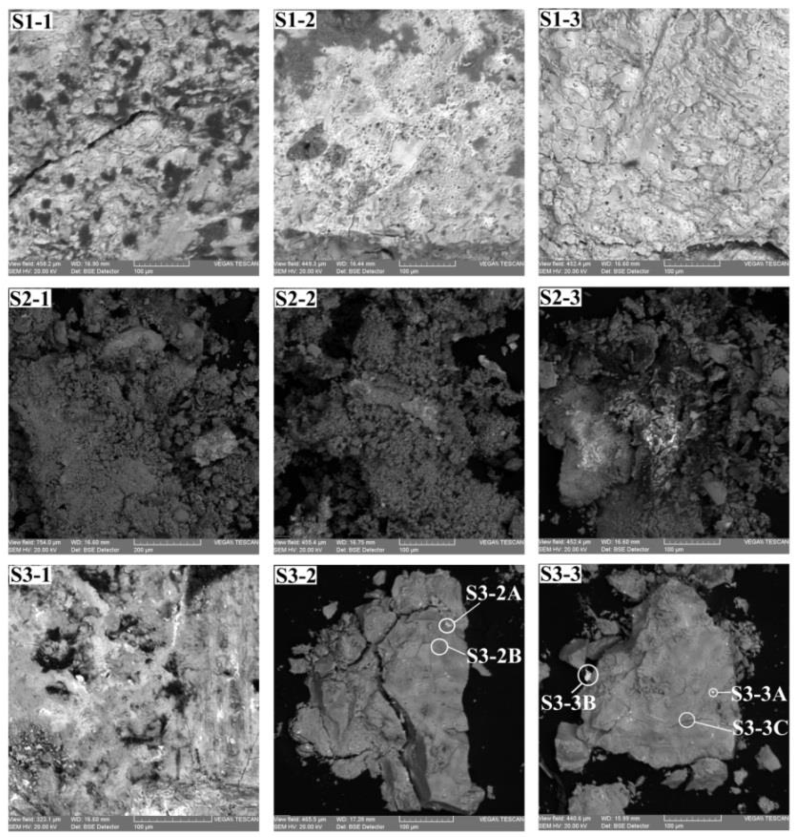

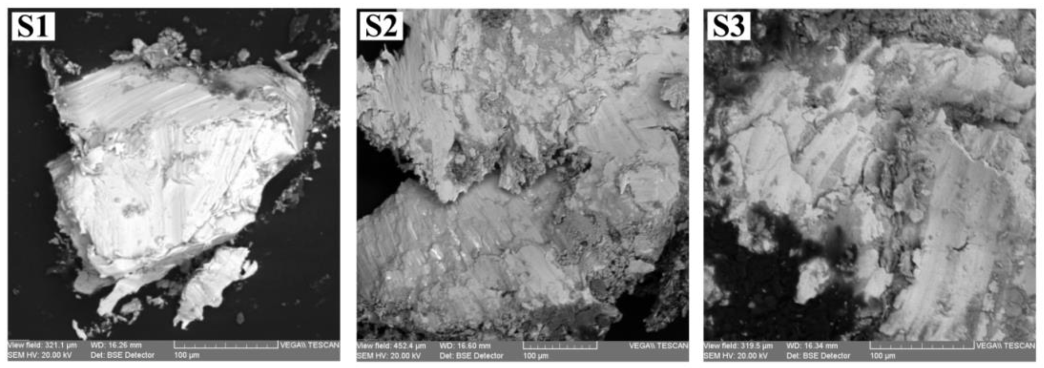

2.2. Methods of Analysis

2.3. Areas of Analyses

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandu, I. Deteriorarea și Degradarea Bunurilor de Patrimoniu Cultural; Universitatii “Al. I. Cuza”: Iași, Romania, 2008. [Google Scholar]

- Domenech-Carbo, A. Tracing, authenticating and dating archaeological metal using the voltammetry of microparticles. Anal. Methods 2011, 3, 2181–2188. [Google Scholar] [CrossRef]

- Doménech-Carbó, A.; Doménech-Carbó, M.T.; Peiró-Ronda, M.A. Dating archaeological lead artifacts from measurement of the corrosion content using the voltammetry of microparticles. Anal. Chem. 2011, 83, 5639–5644. [Google Scholar] [CrossRef] [PubMed]

- Doménech-Carbó, A.; Doménech-Carbó, M.T.; Peiró-Ronda, M.A.; Osete-Cortina, L. Electrochemistry and Authentication of Archaeological Lead Using Voltammetry of Microparticles: Application to the Tossal de Sant Miquel Iberian Plate. Archaeometry 2011, 53, 1193–1211. [Google Scholar] [CrossRef]

- Goffer, Z. Archaeological Chemistry, 2nd ed.; Wiley-Interscience a John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Robbiola, L.; Blengino, J.M.; Fiaud, C. Morphology and mechanisms formation of natural patinas on archaeological Cu-Sn alloys. Corros Sci. 1998, 40, 2083–2111. [Google Scholar] [CrossRef]

- Robbiola, L.; Portier, R. A global approach to the authentication of ancient bronzes based on the characterization of the alloy—Patina—Environment system. J. Cult. Heritage 2006, 7, 1–12. [Google Scholar] [CrossRef]

- Scott, D.A. Copper and Bronze in Art; Getty Publications: Los Angeles, CA, USA, 2002. [Google Scholar]

- Mircea, O.; Sandu, I.; Sarghie, I.; Sandu, A.V. The Identified Effects of Degradation in Archaeological Artifacts with Overlapped Metals Used in Authentication. Int. J. Conserv. Sci. 2011, 1, 27–40. [Google Scholar]

- Mircea, O.; Sandu, I.; Vasilache, V.; Sandu, A.V. Study of the Atypical Formations in the Corrosion Bulks of an Ancient Bronze Shield, by Optical and Electron Microscopy. Microsc. Res. Tech. 2012, 75, 1467–1474. [Google Scholar] [CrossRef] [PubMed]

- Mircea, O.; Sandu, I.; Vasilache, V.; Sandu, A.V. Research on Atypical Formations from Corrosion Bulks of an Ancient Bronze. Rev. Chim. 2012, 63, 893–899. [Google Scholar]

- Sandu, I.; Ursulescu, N.; Sandu, I.G.; Bounegru, O.; Sandu, I.C.A.; Alexianu, A. The pedological stratification effect of corrosion and contamination products on byzantine bronze artefacts. Corros. Eng. Sci. Technol. 2008, 43, 256–266. [Google Scholar] [CrossRef]

- Sandu, I.; Mircea, O.; Sandu, I.G.; Vasilache, V.; Sandu, A.V. Study of the Liesegang Chemical Effects in Antique Bronze Artefacts During Their Stay Within an Archaeological Site. Rev. Chim. 2014, 65, 311–319. [Google Scholar]

- Sandu, I.G.; Sandu, I.; Dima, A. Restaurarea şi Conservarea Obiectelor din Metal; Corson: Iași, Romania, 2002. [Google Scholar]

- Sandu, I.G.; Mircea, O.; Vasilache, V.; Sandu, I. Influence of the Archaeological Environment on Ancient Copper Alloy Artifacts. Microsc. Res. Tech. 2012, 75, 1646–1652. [Google Scholar] [CrossRef] [PubMed]

- Vasilache, V.; Aparaschivei, D.; Sandu, I. A Scientific Investigation of the Ancient Jewels Found in the Ibida Site, Romania. Int. J. Conserv. Sci. 2011, 2, 117–126. [Google Scholar]

- Vasilache, V.; Sandu, I.; Lazanu, C.C.; Sandu, I.G. Archaeometallurgical evaluation of two spearheads from the bronze age. Int. J. Conserv. Sci. 2015, 6, 633–642. [Google Scholar]

- Monah, D.; Dumitroaia, G.; Weller, O.; Chapman, J. L’exploitation du sel a Travers le Temps (Actes du Colloque International, Piatra Neamț, Roumanie, Oct. 2004); BMA XVIII, C; Matasă: Piatra Neamț, Romania, 2007. [Google Scholar]

- Cavruc, V.; Harding, A. Prehistoric production and exchange of saltin the Carpathian-Danube Region. In Salz und Gold: Die Rolle des Salzes im Prähistorischen Europa/Saltand Gold: The Role of Salt in Prehistoric Europe; Nikolov, V., Bacvarov, K., Eds.; Provadia & Veliko: Tarnovo, The Republic of Bulgaria, 2012; pp. 173–200. [Google Scholar]

- Brigand, R.; Weller, O. Neolithic and Chalcolithic settlement pattern in central Moldavia (Romania). Doc. Praehist. 2013, 40, 195–207. [Google Scholar] [CrossRef]

- Weller, O. Firt salt making in Europe: An overview from Neolithic times. Doc. Praehist. 2015, XLII, 185–196. [Google Scholar]

- Dergačev, V. Topory-kel’ty pozdnej bronzy Karpato-Podynav’ja, Vyšysk II, Kel’ty i serpy nižnego Podynav’ja; Čentral’naja: Moldova, 2010. [Google Scholar]

- Dumitroaia, G. Obiecte de aramă şi bronz descoperite pe teritoriul judeţului Neamţ. Mem. Ant. 1985, IX–XI, 465–482. [Google Scholar]

- Petrescu-Dîmboviţa, M. Contribuţii la problema sfârşitului epocii bronzului şi începutului epocii fierului în Moldova. SCIV 1953, 4, 443–486. [Google Scholar]

- Rusu, M. Depozitul de bronzuri de la Balşa. Sargetia 1966, 4, 17–40. [Google Scholar]

- Petrescu-Dîmboviţa, M. Date noi relativ la descoperirile de obiecte de bronz de la sfârşitul epocii bronzului şi începutul Hallstattului în Moldova. ArhMold 1964, II–III, 251–272. [Google Scholar]

- Sandu, I.G.; Tencariu, F.A.; Vornicu, D.M.; Sandu, A.V.; Vornicu, A.; Vasilache, V.; Sandu, I. Establishing the archaeo-metallurgic ornamentation process of an axe from the bronze age by OM, SEM-EDX and micro-FTIR. Microsc. Res. Tech. 2014, 77, 918–927. [Google Scholar] [CrossRef] [PubMed]

- Uşurelu, E. Consideraţii cu Privire la Celturile de Tip Cozia-Saharna. In Interferenţe Cultural-Cronologice în Spaţiul Nord-Pontic; Sava, E., Ed.; Centrul Editorial al Universității de Stat Moldova: Chişinău: Moldova, 2003; pp. 211–219. [Google Scholar]

- Petrescu-Dîmboviţa, M. Depozitele de Bronzuri din România; Academia Română: Bucureşti, Romania, 1977. [Google Scholar]

- László, A. Începuturile Epocii Fierului la est de Carpaţi: Culturile Gava-Holihrady și Corlăteni Chișinău pe Teritoriul României, B.THR. VI; Publirom: Bucureşti, Romania, 1994. [Google Scholar]

- Udrescu, T. Descoperiri arheologice în jumătatea sudică a Moldovei cu privire la cultura Noua. Carpica 1974, VI 1973–1974, 17–42. [Google Scholar]

- Ciugudean, H.; Luca, S.A.; Georgescu, A. Depozite de Bronzuri de Bronzuri Preistorice din Colecţia BRUKENTHAL (I); ALTIP: Sibiu, Romania, 2008. [Google Scholar]

- Ciugudean, H. Noi descoperiri arheologice pe teritoriul judeţului Alba (I). Apulum 1978, 16, 39–53. [Google Scholar]

- Soroceanu, T.; Lakó, E. Der zwiete Depotfund von Dragu, Kr. Sălaj. Zu den Tüllenbeiledepotfunde in Rumänien. In Bronzefunde aus Rumänien; Soroceanu (Hrsg.), T., Ed.; PAS: Berlin, Germany, 1995; pp. 187–195. [Google Scholar]

- Żurowski, K. Zabytki brązove z młodszej epoki brązu i wczesnego okresu żelaza z dorzecza górnego Dniestru. PrzArch 1949, 8, 155–284. [Google Scholar]

- Mozsolics, A. Bronzefunde aus Ungarn. Depotfundhorizonte von Aranyos, Kurd und Gyermely; Akadémiai Kiadó: Budapesta, Hungary, 1985. [Google Scholar]

- Mozsolics, A. Bronzefunde aus Ungarn. Depotfundhorizonte Hajdúböszörmény; Románd und Bükkszentlászló: Verlag Oetket/Voges Kiel, Germany, 2000. [Google Scholar]

- Figueiredo, E.; Silva, R.J.C.; Fátima Araújo, M.; Senns-Martinez, J.C. Identification of ancient gilding technology and Late Bronze Age metallurgy by EDXRF, Micro-EDXRF, SEM-EDS and metallographic techniques. Microchim Acta 2010, 168, 283–291. [Google Scholar] [CrossRef]

- Sandu, I.; Mircea, O.; Sandu, A.V.; Sarghie, I.; Sandu, I.G.; Vasilache, V. Non-invasive Techniques in the Analysis of Corrosion Crusts formed on Archaeological Metal Objects. Rev. Chim 2010, 61, 1054–1058. [Google Scholar]

| Samples | Elemental Composition—Weight Percent (%) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Pb | Fe | Ag | Ni | Si | Al | Ca | Mg | K | O | S | C | P | Cl | |

| S1-1 | 17.07 | 21.69 | 0.14 | 1.69 | - | - | 1.84 | 0.40 | - | 0.12 | - | 40.61 | 0.15 | 14.30 | 1.34 | 0.63 |

| S1-2 | 16.03 | 24.59 | 0.09 | 2.66 | - | - | 3.99 | 1.70 | - | 0.31 | - | 44.37 | 0.13 | 4.93 | 1.07 | 0.13 |

| S1-3 | 21.11 | 23.45 | 0.11 | 1.49 | - | - | 1.19 | 0.10 | - | 0.35 | - | 45.25 | 0.07 | 4.88 | 1.91 | 0.09 |

| S2-1 | 64.59 | 3.11 | 0.14 | 1.71 | - | 1.38 | 0.01 | 0.01 | - | 0.04 | - | 26.51 | 0.01 | 2.34 | 0.15 | - |

| S2-2 | 23.39 | - | - | 14.23 | - | - | 0.45 | 0.23 | 0.75 | - | 0.47 | 42.71 | 0.27 | 17.00 | 0.17 | 0.33 |

| S2-3 | 68.43 | 1.57 | 0.14 | 0.83 | - | 1.36 | 0.02 | 0.03 | - | - | - | 25.69 | 0.02 | 1.89 | 0.02 | - |

| S3-1 | 32.31 | 17.38 | 1.09 | 0.72 | - | - | 1.98 | 0.52 | - | 0.67 | - | 37.30 | - | 6.35 | 1.30 | 0.38 |

| S3-2A | 34.99 | 11.07 | 1.09 | - | 5.65 | - | 0.82 | 0.09 | - | 0.72 | - | 39.75 | 0.66 | 4.61 | 0.55 | - |

| S3-2B | 46.17 | 11.81 | 0.49 | - | - | - | 0.91 | 0.02 | - | 0.40 | - | 36.44 | 0.02 | 3.17 | 0.57 | - |

| S3-3A | 33.35 | 16.48 | 0.29 | - | 4.44 | - | 1.14 | 0.14 | - | 0.78 | - | 40.12 | 0.43 | 1.87 | 0.96 | - |

| S3-3B | 9.24 | - | - | - | 35.41 | - | 0.42 | 0.09 | - | 0.31 | - | 28.28 | 4.63 | 21.62 | - | - |

| S3-3C | 36.12 | 12.95 | 1.15 | - | - | - | 1.44 | 0.27 | - | 0.89 | - | 40.59 | - | 3.55 | 1.09 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasilache, V.; Diaconu, V.; Mircea, O.; Drob, A.; Sandu, I. The Archaeometallurgical Evaluation of Three Bronze Socketed Axes, Discovered in Eastern Romania. Appl. Sci. 2021, 11, 1811. https://doi.org/10.3390/app11041811

Vasilache V, Diaconu V, Mircea O, Drob A, Sandu I. The Archaeometallurgical Evaluation of Three Bronze Socketed Axes, Discovered in Eastern Romania. Applied Sciences. 2021; 11(4):1811. https://doi.org/10.3390/app11041811

Chicago/Turabian StyleVasilache, Viorica, Vasile Diaconu, Otilia Mircea, Ana Drob, and Ion Sandu. 2021. "The Archaeometallurgical Evaluation of Three Bronze Socketed Axes, Discovered in Eastern Romania" Applied Sciences 11, no. 4: 1811. https://doi.org/10.3390/app11041811

APA StyleVasilache, V., Diaconu, V., Mircea, O., Drob, A., & Sandu, I. (2021). The Archaeometallurgical Evaluation of Three Bronze Socketed Axes, Discovered in Eastern Romania. Applied Sciences, 11(4), 1811. https://doi.org/10.3390/app11041811