Influence of Cracking on the Durability of Reinforced Concrete with Carbon Nanotubes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Concrete Production

2.3. Sampling and Curing

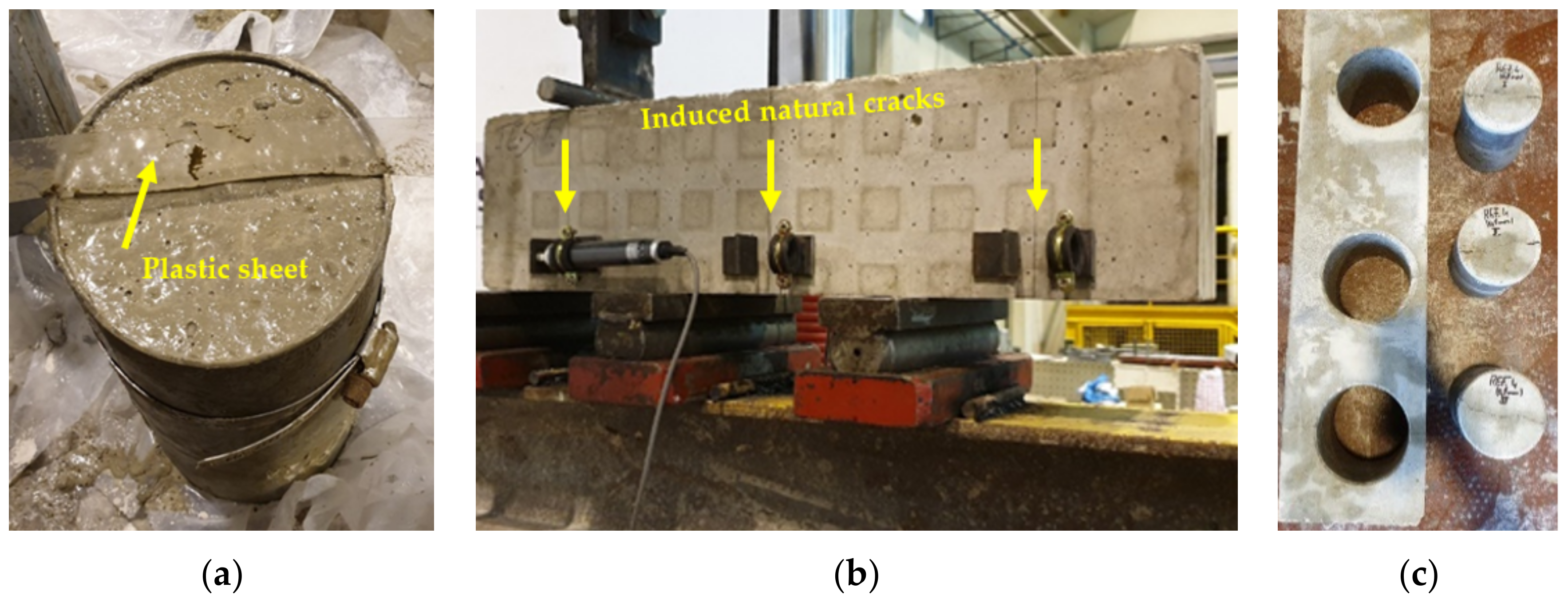

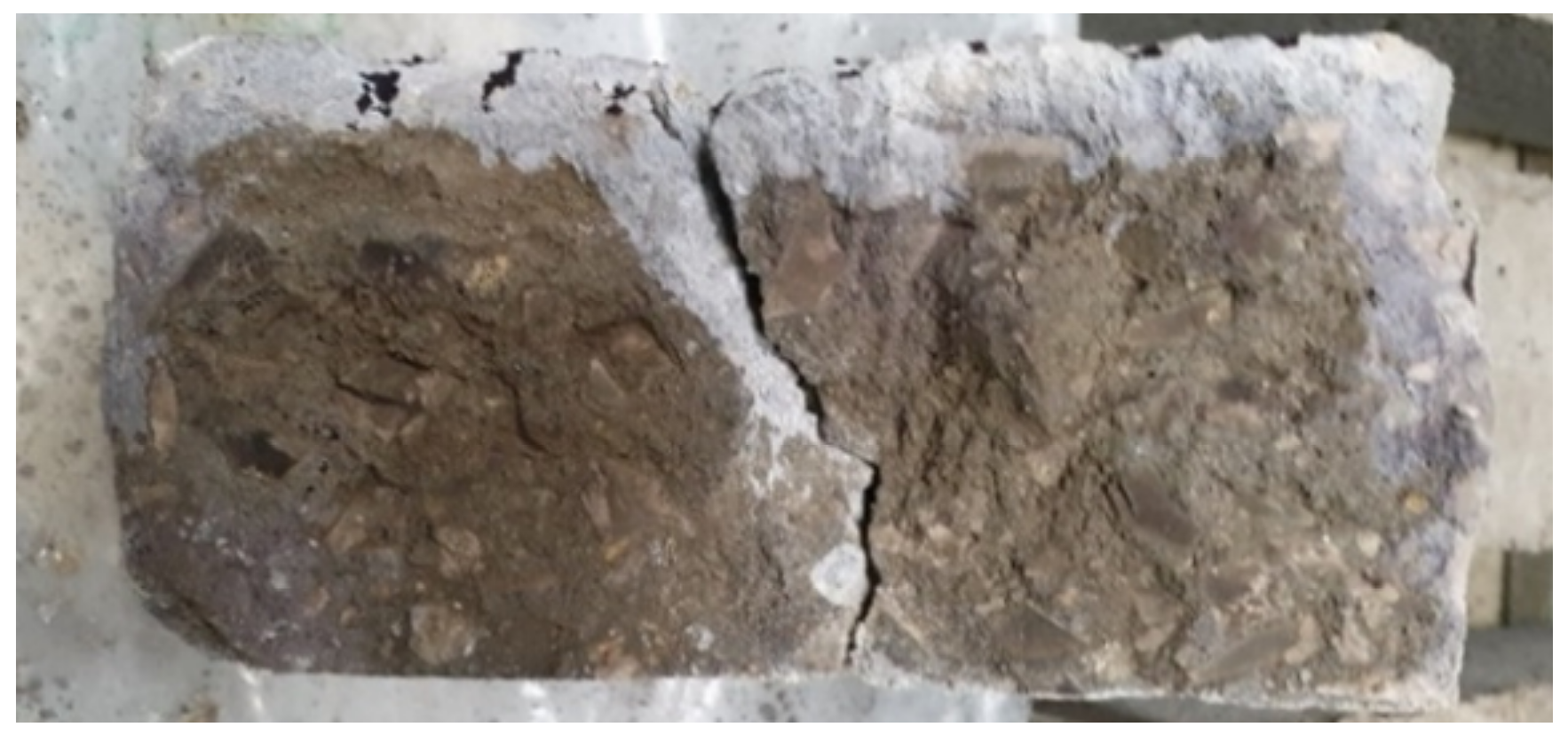

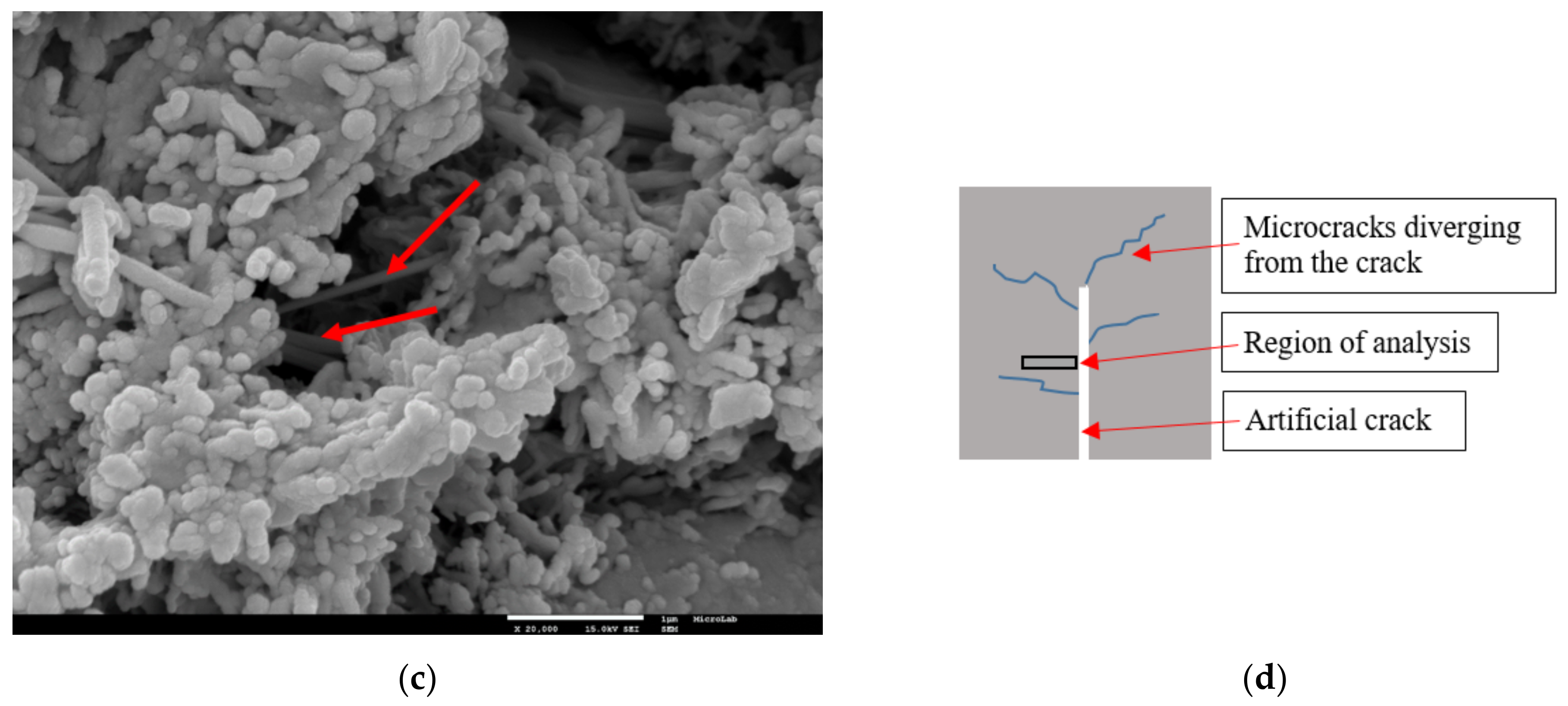

2.4. Pre-Cracking Concrete

2.5. Testing Procedeurs

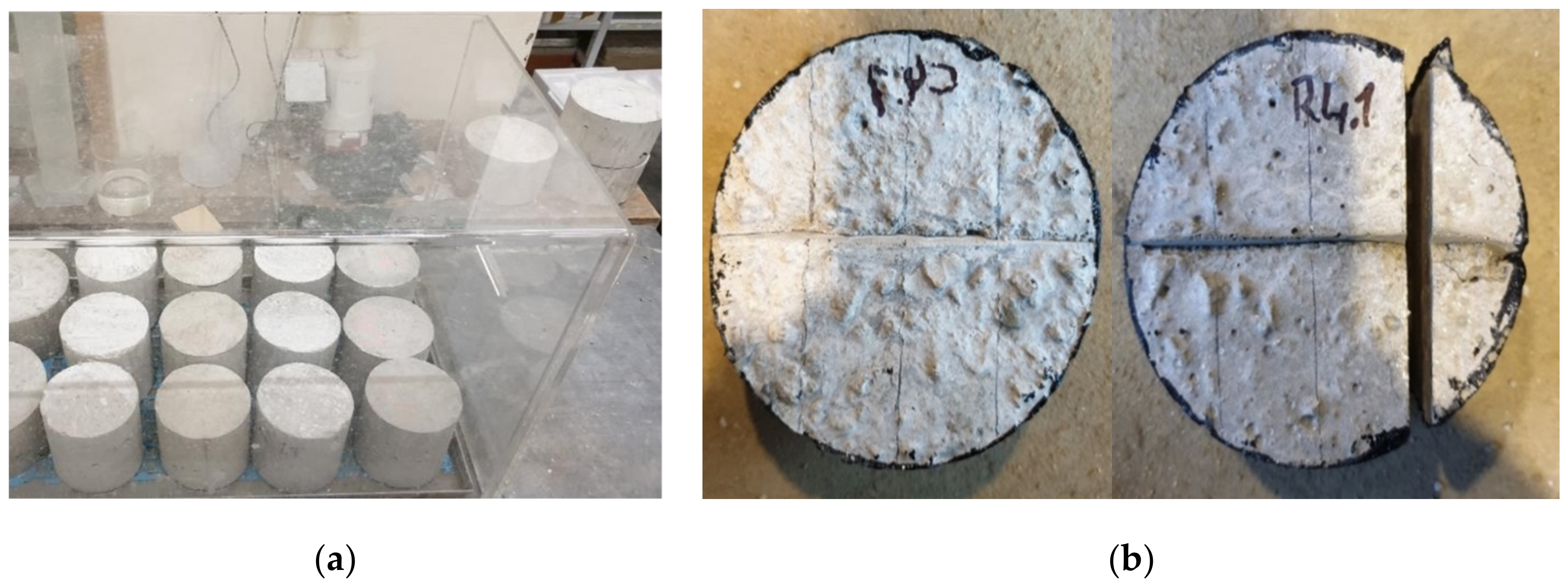

2.5.1. Capillary Absorption

2.5.2. Carbonation Resistance

2.5.3. Chloride Penetration Resistance

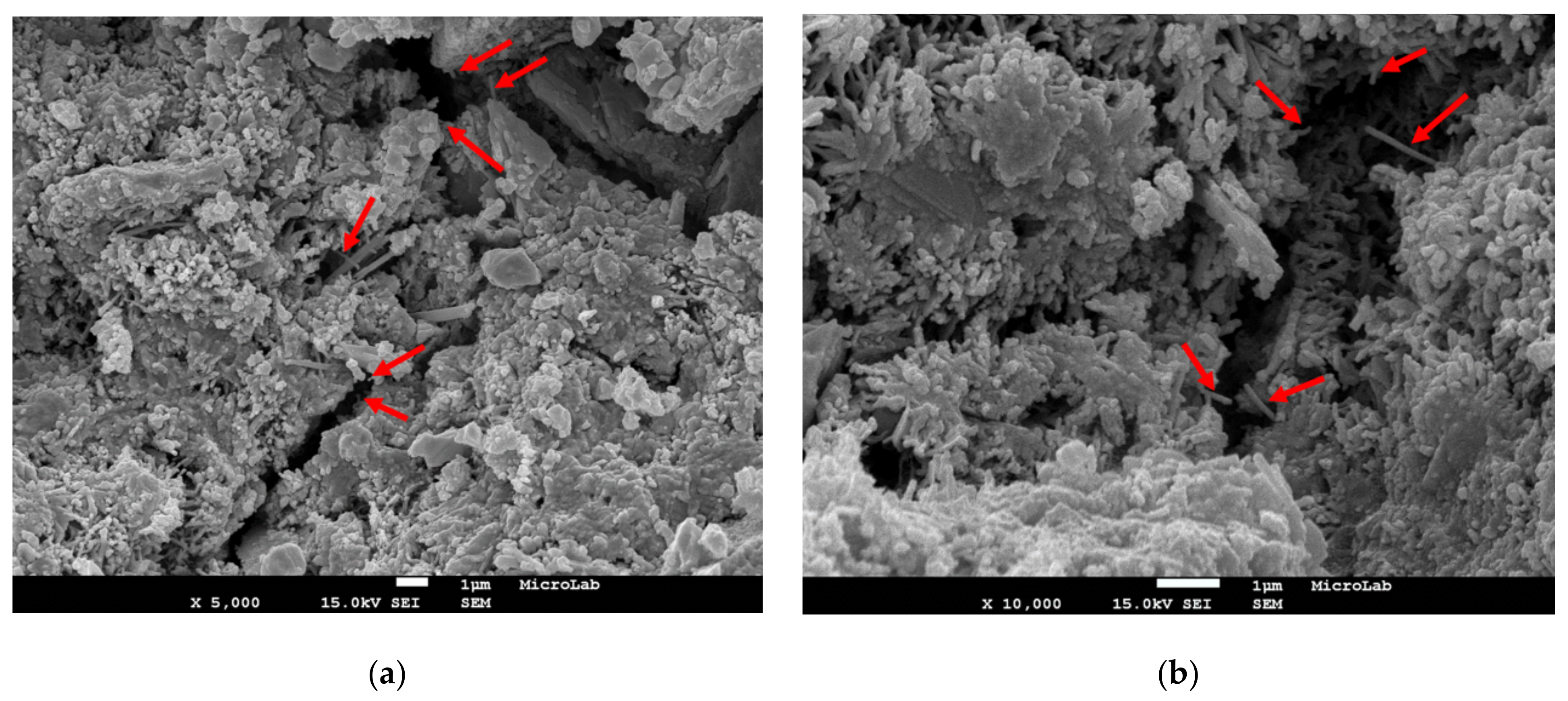

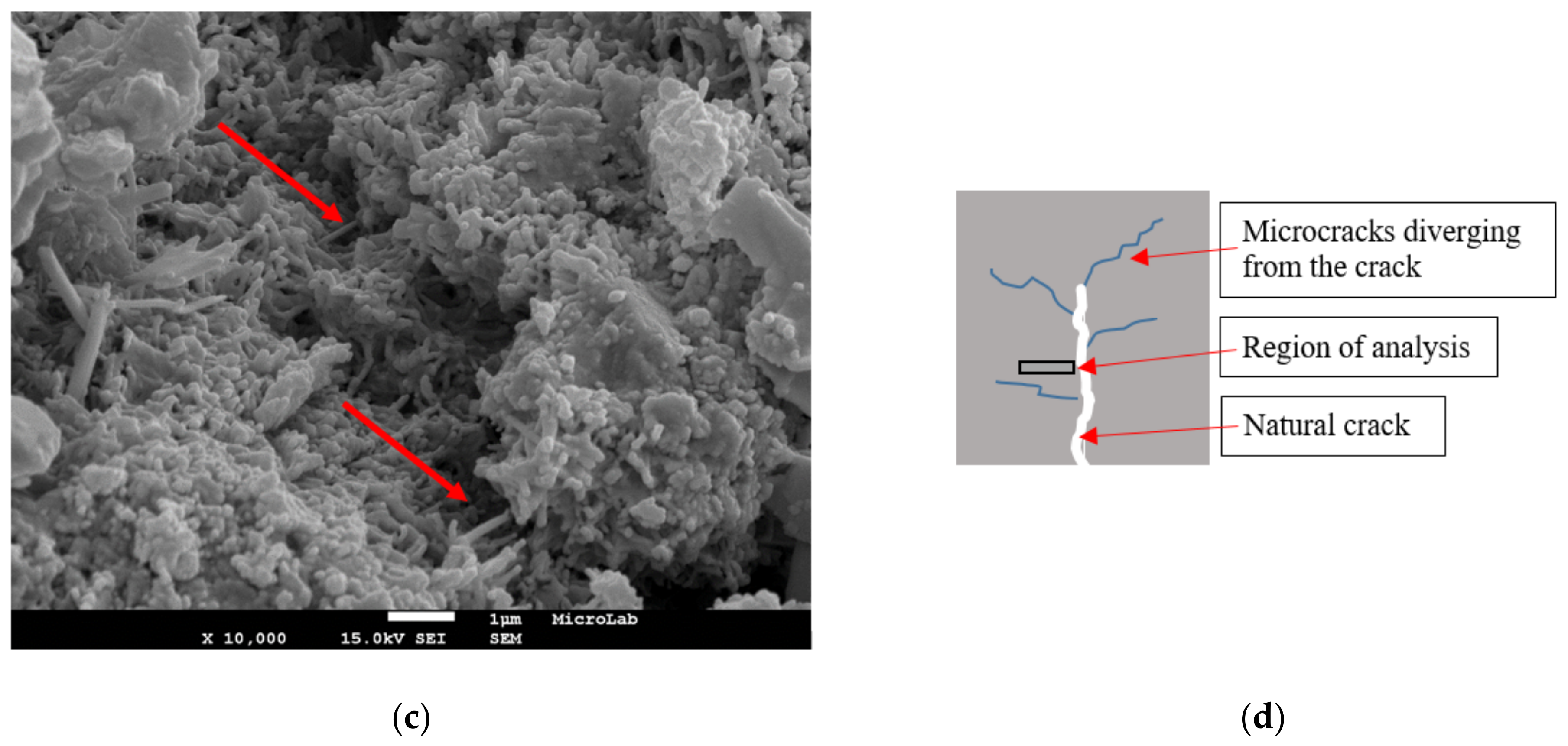

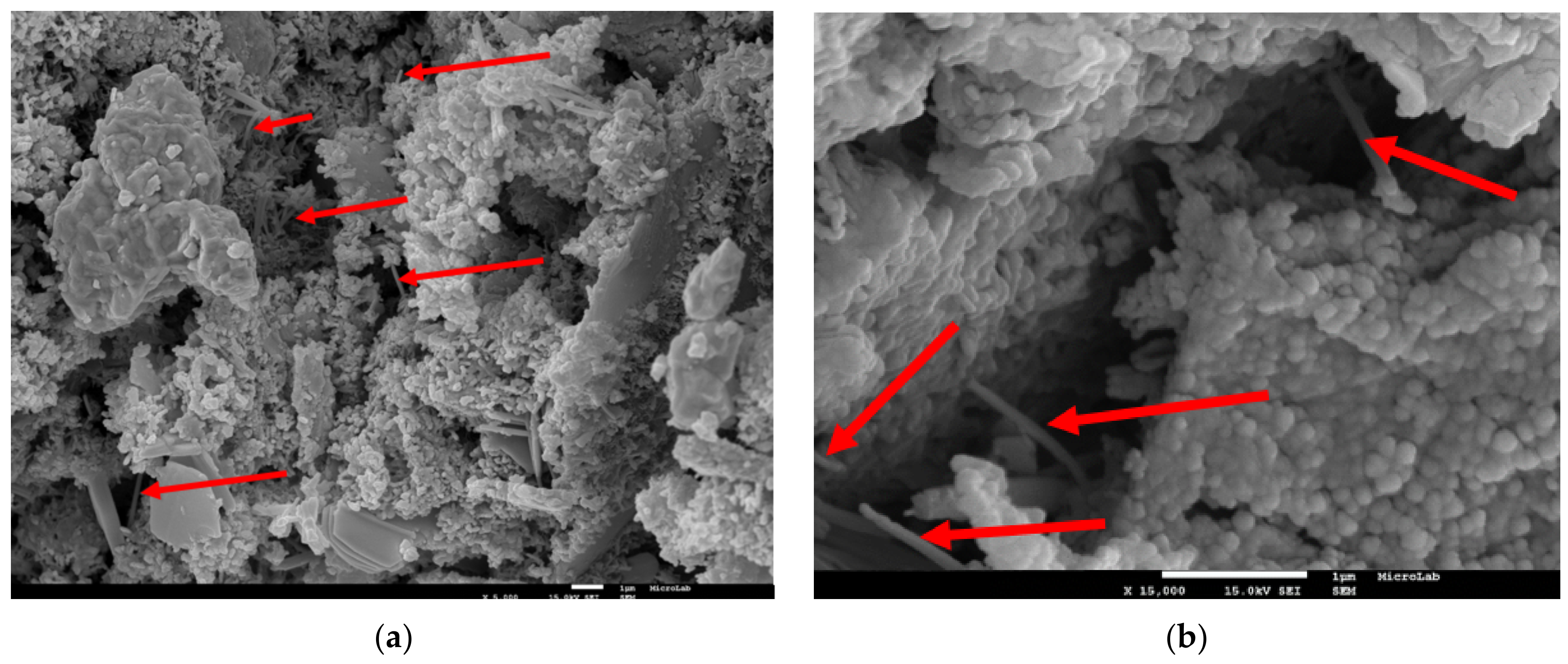

2.5.4. Microscopic Analysis

3. Results and Discussion

3.1. Fresh-State Properties, Hardened Density and Compressive Strength

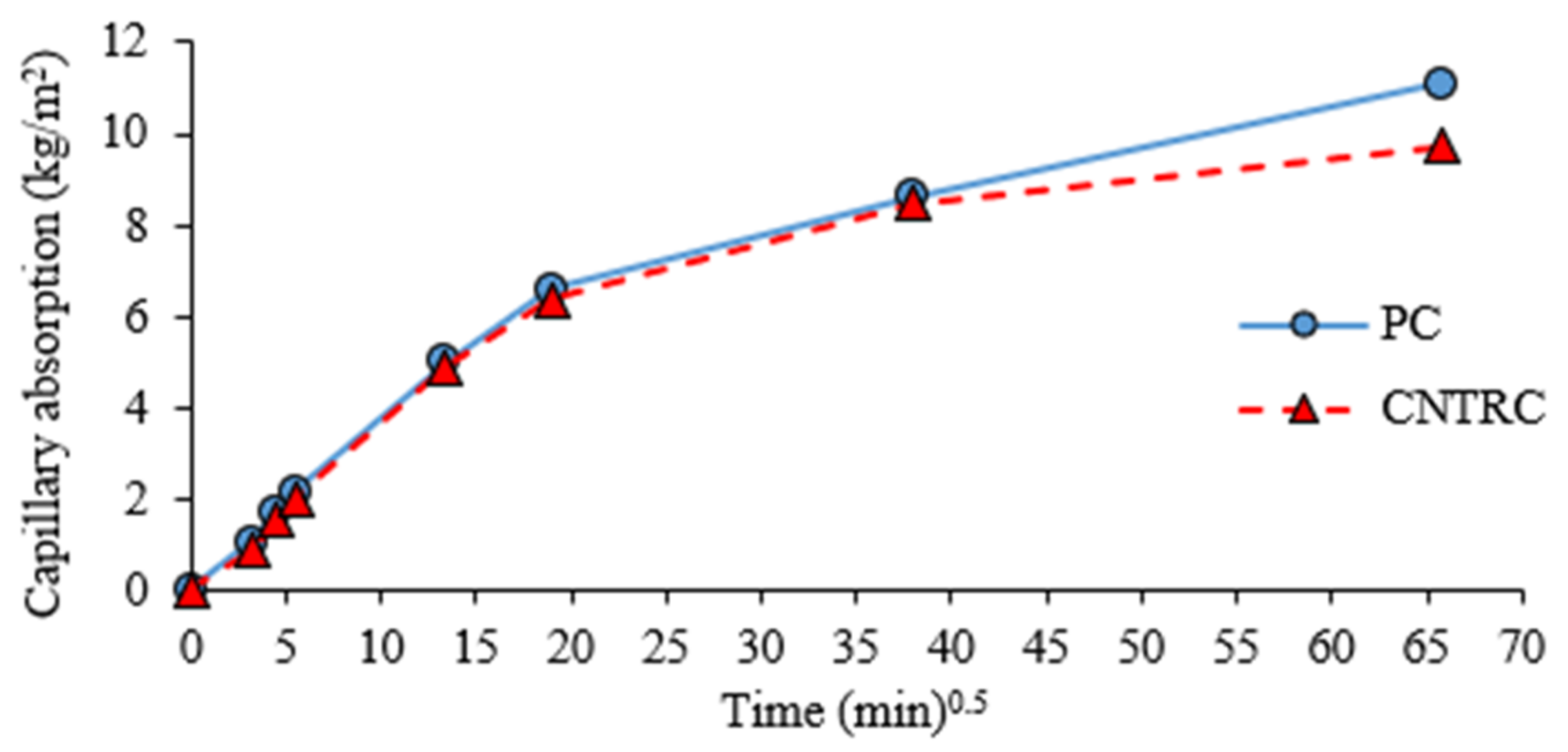

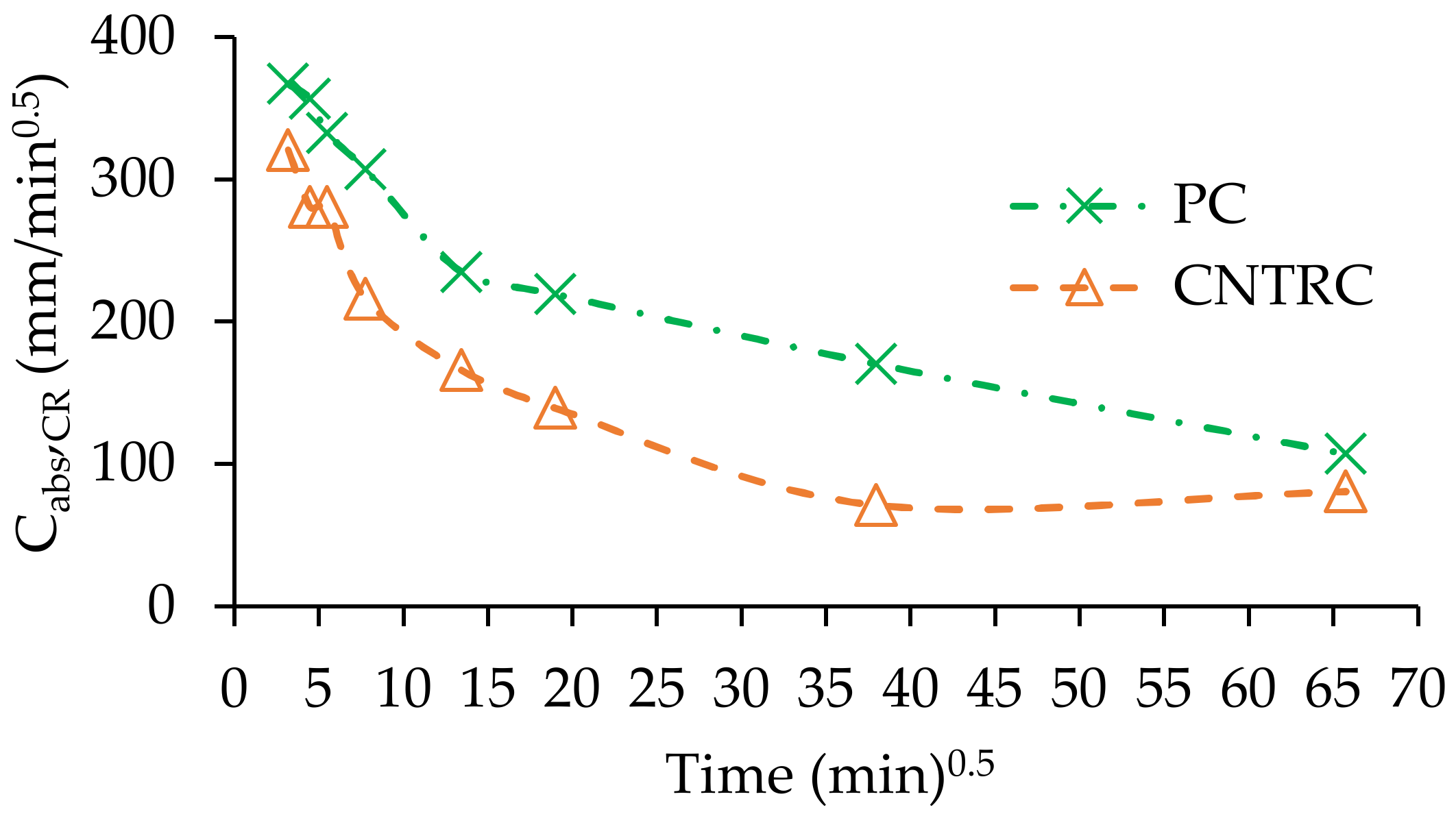

3.2. Capillary Absorption

3.3. Carbonation Resistance

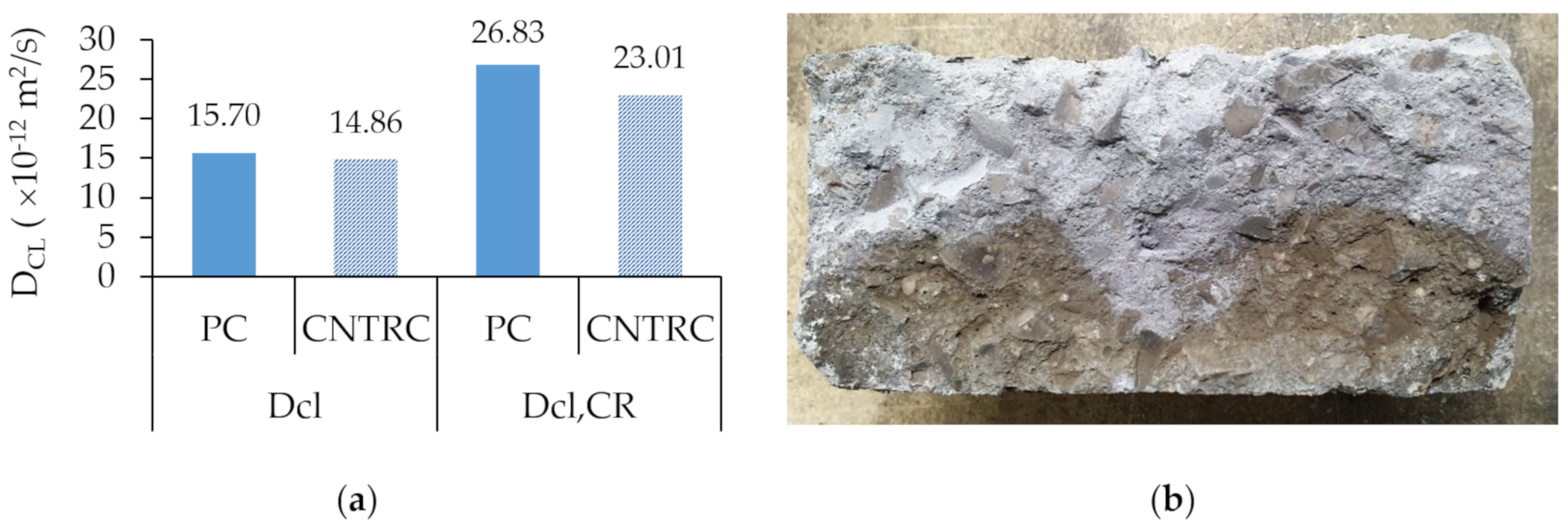

3.4. Chloride Ion Penetration

3.5. Microscopic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Stang, H. Application of stress crack width relationship in predicting the flexural behaviour of fiber reinforced concrete. Cem. Concr. Res. 1998, 28, 439–452. [Google Scholar] [CrossRef]

- Komlos, K.; Babal, B.; Nurnbergerova, T. Hybrid fiber- reinforced concrete under repeated loading. Nucl. Eng. Des. 1995, 156, 195–200. [Google Scholar] [CrossRef]

- Eguchi, K.; Teranishi, K. Prediction equation of drying shrinkage of concrete based on composite model. Cem. Concr. Res. 2005, 35, 483–493. [Google Scholar] [CrossRef]

- Camacho, M.; Galao, O.; Baeza, F.; Zornoza, E.; Garcés, P. Mechanical Properties and Durability of CNT Cement Composites. Materials 2014, 7, 1640–1651. [Google Scholar] [CrossRef]

- De Schutter, G. Quantification of the influence of cracks in concrete structures on carbonation and chloride penetration. Mag. Concr. Res. 1999, 51, 427–435. [Google Scholar] [CrossRef]

- Wang, K.; Jansen, D.C.; Shah, S.P.; Karr, A.F. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Sullivan-Green, L. Effect of Crack Width on Carbonation: Implications for Crack-Dating; Northwestern University: Evanston, IL, USA, 2005. [Google Scholar]

- Aldea, C.M.; Shah, S.P.; Karr, A. Permeability of cracked concrete. Mater. Struct. 1999, 32, 370–376. [Google Scholar] [CrossRef]

- Ismail, M.; Toumi, A.; François, R.; Gagné, R. Effect of crack opening on the local diffusion of chloride in inert materials. Cem. Concr. Res. 2004, 34, 711–716. [Google Scholar] [CrossRef]

- Jang, S.Y.; Kim, B.S.; Oh, B.H. Effect of crack width on chloride diffusion coefficients of concrete by steady-state migration tests. Cem. Concr. Res. 2011, 41, 9–19. [Google Scholar] [CrossRef]

- Shin, K.J.; Bae, W.; Choi, S.W.; Son, M.W.; Lee, K.M. Parameters influencing water permeability coefficient of cracked concrete specimens. Constr. Build. Mater. 2017, 151, 907–915. [Google Scholar] [CrossRef]

- Alahmad, S.; Toumi, A.; Verdier, J.; François, R. Effect of crack opening on carbon dioxide penetration in cracked mortar samples. Mater. Struct. Constr. 2009, 42, 559–566. [Google Scholar] [CrossRef]

- Djerbi, A.; Bonnet, S.; Khelidj, A.; Baroghel-bouny, V. Influence of traversing crack on chloride diffusion into concrete. Cem. Concr. Res. 2008, 38, 877–883. [Google Scholar] [CrossRef]

- Hameed, R.; Turatsinze, A.; Duprat, F.; Sellier, A. Metallic fiber reinforced concrete: Effect of fiber aspect ratio on the flexural properties. Arpn. J. Eng. Appl. Sci. 2009, 4, 67–72. [Google Scholar]

- Majumdar, A.; Ryder, J. Glassfiber Reinforcement for Cement Products. Glass Technol. 1968, 9, 78–84. [Google Scholar]

- Bogas, A.H.J. Capillary Absorption and Oxygen Permeability of Concrete Reinforced with Carbon Nanotubes. Adv. Civ. Eng. Mater. 2019, 8, 307–326. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A.; Kurda, R. Mechanical Characterization of Concrete Reinforced with Different Types of Carbon Nanotubes. Arab J. Sci. Eng. 2019, 44, 8361–8376. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Bogas, A.; Hawreen, A.; Olhero, S.; Ferro, A.C.; Guedes, M. Selection of dispersants for stabilization of unfunctionalized carbon nanotubes in high pH aqueous suspensions: Application to cementitious matrices. Appl. Surf. Sci. 2019, 463, 169–181. [Google Scholar] [CrossRef]

- Ahmed, H.; Bogas, J.A.; Guedes, M.; Costa Pereira, M.F. Dispersion and reinforcement efficiency of carbon nanotubes in cementitious composites. Mag. Concr. Res. 2019, 71, 408–423. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Influence of carbon nanotubes on steel–concrete bond strength. Mater. Struct. 2018, 51, 155. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A.; Guedes, M. Mechanical Behavior and Transport Properties of Cementitious Composites Reinforced with Carbon Nanotubes. J. Mater. Civ. Eng. 2018, 30, 04018257. [Google Scholar]

- Hawreen, A.; Bogas, J.A.; Dias, A.P.S. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr. Build. Mater. 2018, 168, 459–470. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Gao, L.; Jiang, L.; Sun, J. Carbon nanotube-ceramic composites. J. Electroceram. 2006, 17, 51–55. [Google Scholar] [CrossRef]

- Samal, S.S.; Bal, S. Carbon Nanotube Reinforced Ceramic Matrix Composites—A Review. J. Min. Mater. Charact. Eng. 2008, 7, 355. [Google Scholar] [CrossRef]

- Yu, M.; Lourie, O.; Dyer, M.J.; Moloini, K.; Kelly, T.F. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J. Darwin Concrete, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2018. [Google Scholar]

- Monteiro, M.P. Concrete: Microstructure, Properties and Materials; McGraw-Hill Professional Publishing: New York, NY, USA, 2013. [Google Scholar]

- Nochaiya, T.A. Chaipanich Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

- EN 197-1:2012. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- EN 12350-2: 2009. Testing Fresh Concrete. Slump Test; European Committee for Standardization (CEN): Brussels, Belgium, 2009. [Google Scholar]

- EN 12350-6: 2009. Testing Fresh Concrete. Density; European Committee for Standardization (CEN): Brussels, Belgium, 2009. [Google Scholar]

- EN 12390-3: 2009. Testing Hardened Concrete. Compressive Strength of Test Specimens; European Committee for Standardization (CEN): Brussels, Belgium, 2009. [Google Scholar]

- Rilem. TC116-PCD Permeability of concrete as a criterion of its durability. Recomendations. Tests for gas permeability of concrete 1999, determination of the capillary absorption of water of hardened concrete. Mater. Struct. 1999, 32, 174–179. [Google Scholar]

- LNEC E391. Concrete. Carbonation resistance. LNEC Specification; Laboratório Nacional de Engenharia Civil (LNEC): Lisbon, Portugal, 1993. [Google Scholar]

- Bogas, J.A.; Carriço, A.; Pontes, J. Influence of cracking on the capillary absorption and carbonation of structural lightweight aggregate concrete. Cem. Concr. Compos. 2019, 104, 103382. [Google Scholar] [CrossRef]

- LNEC E393. Concrete. Capillary Absorption; Laboratório Nacional de Engenharia Civil (LNEC): Lisbon, Portugal, 1993. [Google Scholar]

- LNEC E463. Concrete—Determination of the Chloride Diffusion Coefficient by Non-Stationary Migration Test; Laboratório Nacional de Engenharia Civil (LNEC): Lisbon, Portugal, 2004. [Google Scholar]

- NTBUILD 492. Concrete Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiences; Nordtest Method: Espoo, Finland, 1999. [Google Scholar]

- Makar, J.; Margeson, J.; Luh, J. Carbon Nanotube/Cement Composites—Early Results and Potential Application. In Proceedings of the 3rd International Conference on Construction Materials: Performance, Innovations and Structural Implications, Vancouver, BC, Canada, 22–24 August 2005; pp. 1–10. [Google Scholar]

- Al-Rub, R.; Tyson, M.B.; Yazdanbakhsh, A.Z. Grasley Mechanical properties of nanocomposite cement incorporating surface-treated and untreated carbon nanotubes and carbon nanofibers. J. Nanomech. Micromech. 2012, 1, 3–8. [Google Scholar]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube—OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Zou, B.; Chen, S.; Korayem, A.; Collins, F.; Wang, C.; Duan, W. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 2015, 85, 21–220. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Martys, N.; Ferraris, C. Capillary transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

| Purity | Outer Diameter | Inner Diameter | Length | Specific Surface Area | Density |

|---|---|---|---|---|---|

| >98% | 20–80 nm | 5–15 nm | 10–20 μm | >60 m2/g | ~2.1 g/cm3 |

| Properties | Fine Aggregates | Coarse Aggregates | ||

|---|---|---|---|---|

| Fine Sand | Coarse Sand | Fine Gravel | Coarse Gravel | |

| Water absorption at 24 h (%) | 0.16 | 0.38 | 0.63 | 0.37 |

| Density of the dried particles (kg/m3) | 2577 | 2595 | 2591 | 2504 |

| Density of impermeable particles (kg/m3) | 2588 | 2621 | 2634 | 2528 |

| Density of saturated surface dried particles (kg/m3) | 2581 | 2605 | 2608 | 2513 |

| Bulk density (kg/m3) | 1573 | 1512 | 1313 | 1355 |

| Granulometric fraction (d15/D90) | 0.125/1 | 0.5/4 | 2/6.3 | 5.6/11.2 |

| Mix | w/c | Cement (kg/m3) | Water (kg/m3) | Fine Sand (kg/m3) | Coarse Sand (kg/m3) | Fine Gravel (kg/m3) | Coarse Gravel (kg/m3) | CNT (g/m3) |

|---|---|---|---|---|---|---|---|---|

| PC | 0.55 | 380 | 214 | 303 | 454 | 242 | 710 | |

| CNTRC | 0.55 | 380 | 210 | 303 | 454 | 242 | 710 | 4222 |

| Fresh Density | Slump | Hardened Density | Compressive Strength | ||||

|---|---|---|---|---|---|---|---|

| Mix | ρf (kg/m3) | Δ (%) | (cm) | ρ28d (kg/m3) | Δ (%) | fcm,28d (MPa) | Δ (%) |

| PC | 2290 | - | 17.5 | 2354 | - | 45.6 | - |

| CNTRC | 2303 | 0.6 | 18.0 | 2364 | 0.4 | 50.0 | 9.8 |

| Cracking Condition | Mix | Crack Width 1 | Crack Depth, Lc | Capillary Absorption | Water Absorption | |||

|---|---|---|---|---|---|---|---|---|

| Cabs,0–20min | Cabs,0–3h | Cabs,6–72h | βCR | at 72 h | ||||

| (mm) | (mm) | (mm/min0.5) | (kg/m2) | |||||

| uncracked | PC | - | - | 0.371 | 0.095 | 11.08 | ||

| CNTRC | - | - | 0.363 | 0.069 | 9.71 | |||

| artificially cracked | PC | 0.05 | 18 | 0.515 | 0.132 | 0.954 | ||

| CNTRC | 0.05 | 18 | 0.466 | 0.107 | 0.868 | |||

| naturally cracked | PC | 0.05 (0.1) | - | 0.264 | 0.017 | 2.42 | ||

| 0.1 (0.16) | - | 0.266 | 0.019 | 2.64 | ||||

| CNTRC | 0.05 (0.08) | - | 0.217 | 0.018 | 2.28 | |||

| 0.1 (0.2) | - | 0.251 | 0.016 | 2.34 | ||||

| Cracking Condition | Mix | Crack Width 1 | Crack Depth, Lc | Region of Testing | Carbonation Depth | Carbonation Coefficient | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| xc (mm) | Kc | R2 | ||||||||

| (mm) | (mm) | 7 Days | 28 Days | 56 Days | 90 Days | (mm/Year0.5) | ||||

| uncracked | PC | - | - | 7 | 10.2 | 12.7 | 25.7 | 0.99 | ||

| CNTRC | - | - | 5.6 | 9.1 | 9.9 | 21.1 | 0.98 | |||

| artificially cracked | PC | 0.05 | 18 | uncracked | 10.2 | 12.4 | 14.5 | 31.2 | 0.97 | |

| cracked | 17.2 | 19.3 | 23.2 | 67.1 | ||||||

| CNTRC | 0.05 | 18 | uncracked | 9.9 | 11.5 | 12.4 | 28.2 | 0.93 | ||

| cracked | 16.9 | 18.4 | 19.9 | 65.8 | ||||||

| naturally cracked | PC | 0.05 (0.06) | - | uncracked | 2.9 | 7.3 | 25.1 | 0.98 | ||

| cracked | 10.2 | 19.9 | 72.3 | 0.99 | ||||||

| 0.10 (0.19) | - | uncracked | 3.8 | 7.1 | 25.9 | 0.99 | ||||

| cracked | 13 | 21.4 | 80.7 | 0.98 | ||||||

| CNTRC | 0.05 (0.09) | - | uncracked | 2.5 | 6.9 | 23.6 | 0.97 | |||

| cracked | 9.1 | 18.2 | 65.6 | 1 | ||||||

| 0.10 (0.17) | - | uncracked | 3.5 | 7.1 | 25.5 | 0.99 | ||||

| cracked | 10.2 | 20.5 | 73.9 | 1 | ||||||

| Cracking Condition | Mix | Crack Width 1 (mm) | Crack Depth, Lc (mm) | Chloride Diffusion Coefficient | |

|---|---|---|---|---|---|

| Dcl (×10−12 m2/s) | Dcl,CR (×10−12 m2/s) | ||||

| Uncracked | PC | - | - | 15.81 | - |

| CNTRC | - | - | 14.74 | - | |

| Artificially cracked | PC | 0.05 | 20.1 | 15.7 | 26.83 |

| CNTRC | 0.05 | 18.8 | 14.86 | 23.01 | |

| Naturally cracked | PC | 0.05 (0.11) | 49.3 | 58.53 | 123.15 |

| CNTRC | 0.05 (0.07) | 48.5 | 37.17 | 113.01 | |

| PC | 0.1 (0.16) | 49.4 | 66.44 | 129.31 | |

| CNTRC | 0.1 (0.18) | 48.6 | 43.07 | 115.19 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogas, J.A.; Ahmed, H.H.; Diniz, T. Influence of Cracking on the Durability of Reinforced Concrete with Carbon Nanotubes. Appl. Sci. 2021, 11, 1672. https://doi.org/10.3390/app11041672

Bogas JA, Ahmed HH, Diniz T. Influence of Cracking on the Durability of Reinforced Concrete with Carbon Nanotubes. Applied Sciences. 2021; 11(4):1672. https://doi.org/10.3390/app11041672

Chicago/Turabian StyleBogas, Jose Alexandre, Hawreen Hasan Ahmed, and Tomás Diniz. 2021. "Influence of Cracking on the Durability of Reinforced Concrete with Carbon Nanotubes" Applied Sciences 11, no. 4: 1672. https://doi.org/10.3390/app11041672

APA StyleBogas, J. A., Ahmed, H. H., & Diniz, T. (2021). Influence of Cracking on the Durability of Reinforced Concrete with Carbon Nanotubes. Applied Sciences, 11(4), 1672. https://doi.org/10.3390/app11041672