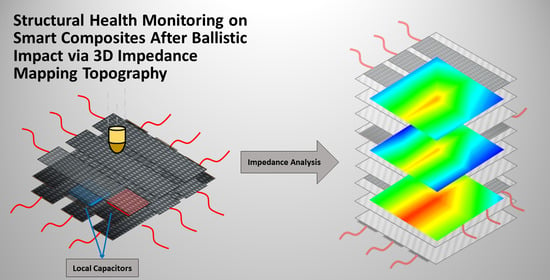

A Novel Composite with Structural Health Monitoring Functionality via 2D and 3D Impedance Mapping Topography

Abstract

:1. Introduction

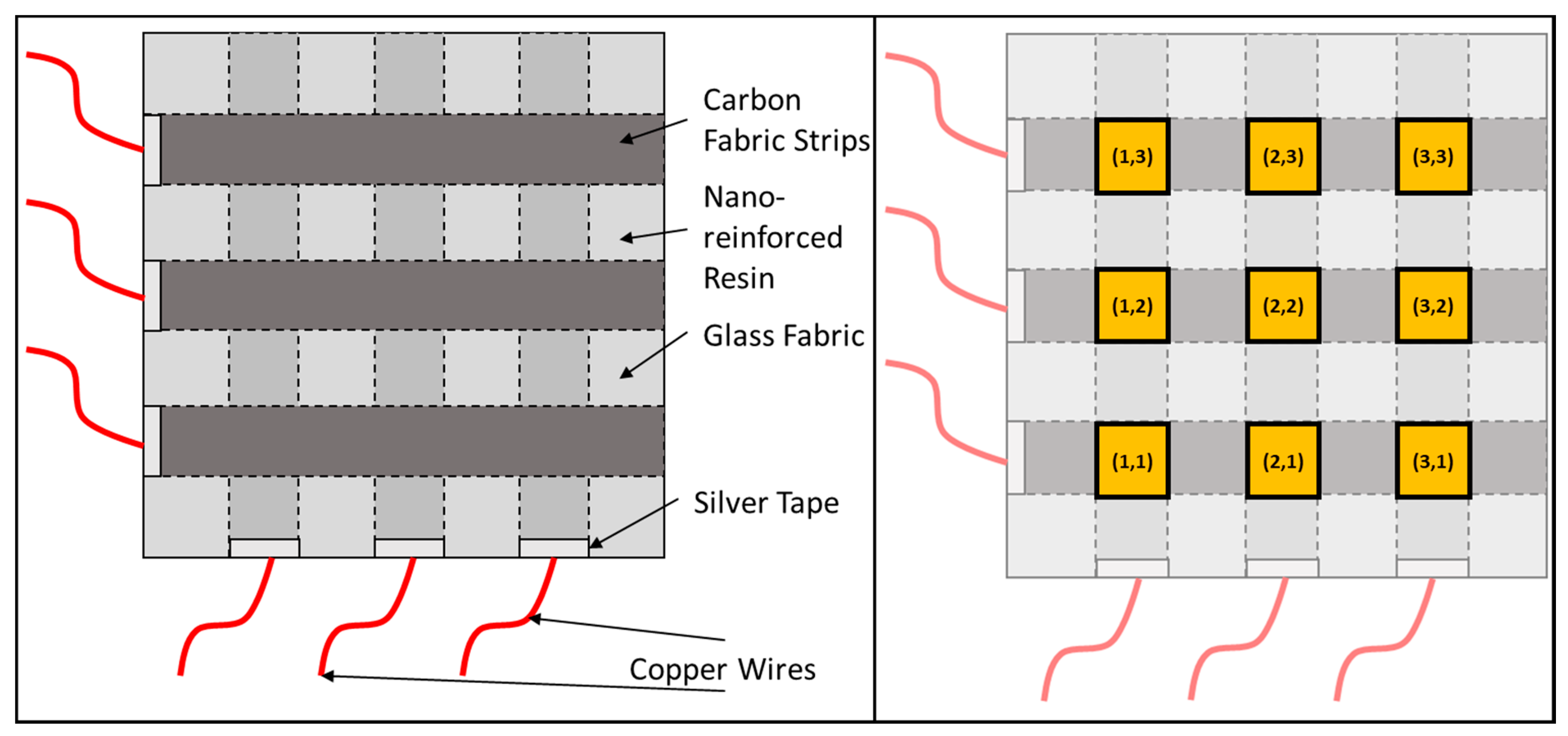

2. Materials and Methods

2.1. Materials

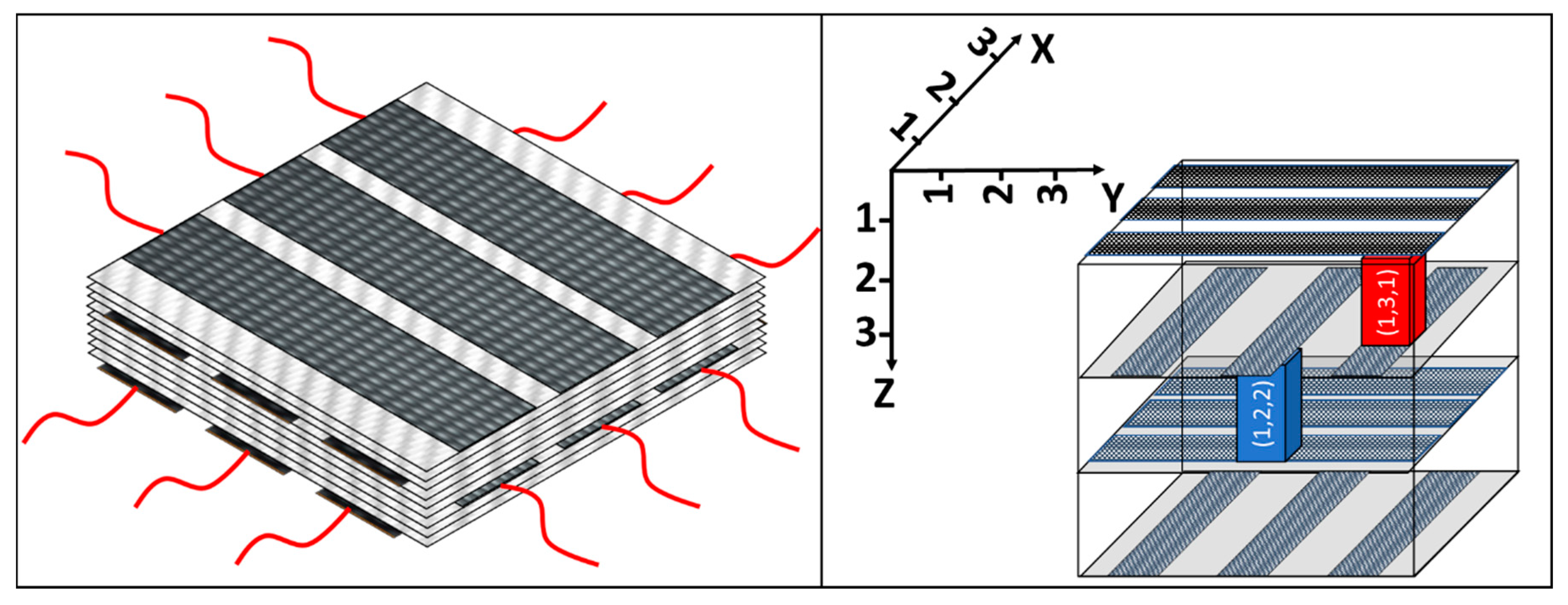

2.2. Composites Manufacturing

2.3. Characterisation Techniques

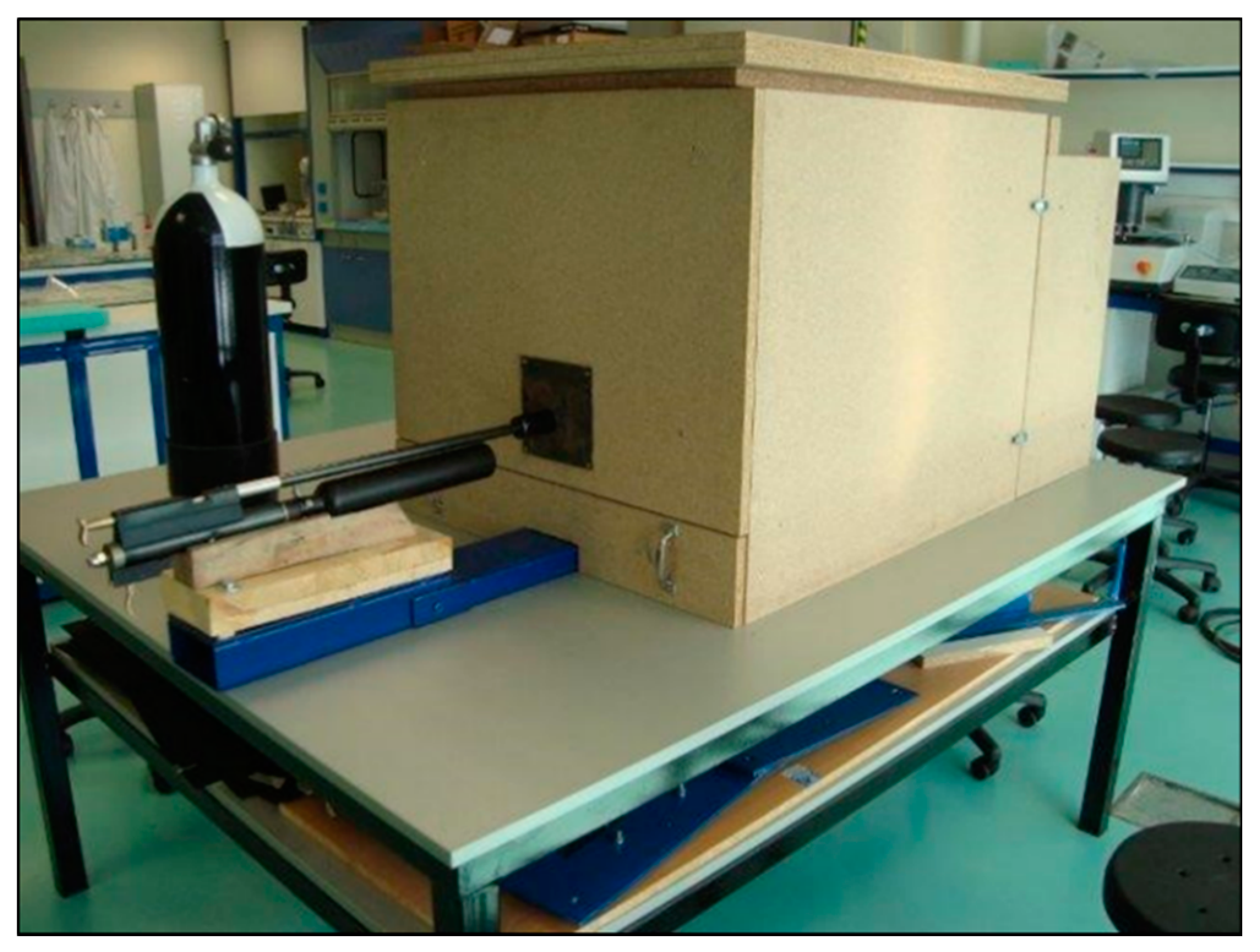

2.4. Impact Test

3. Results and Discussion

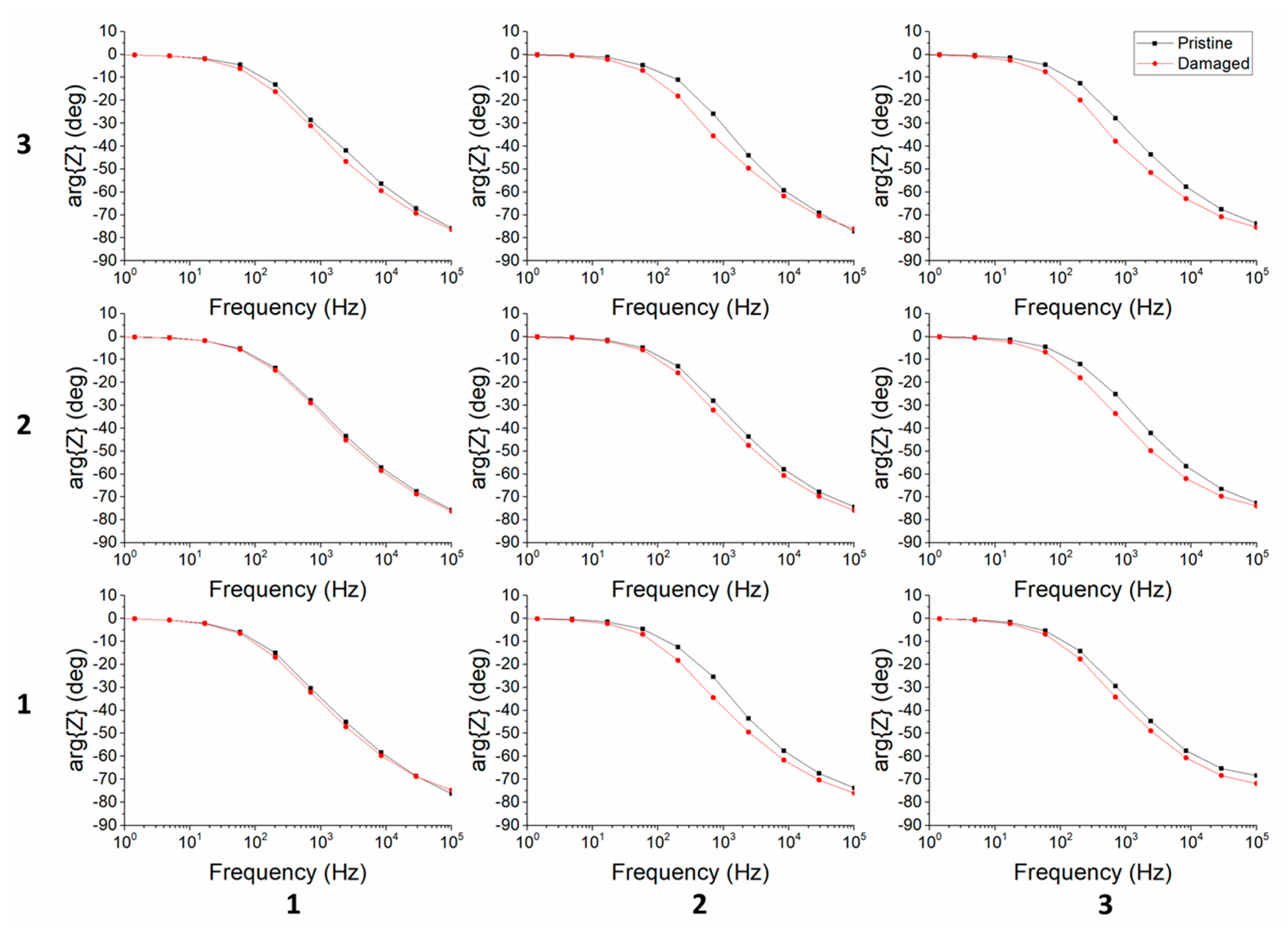

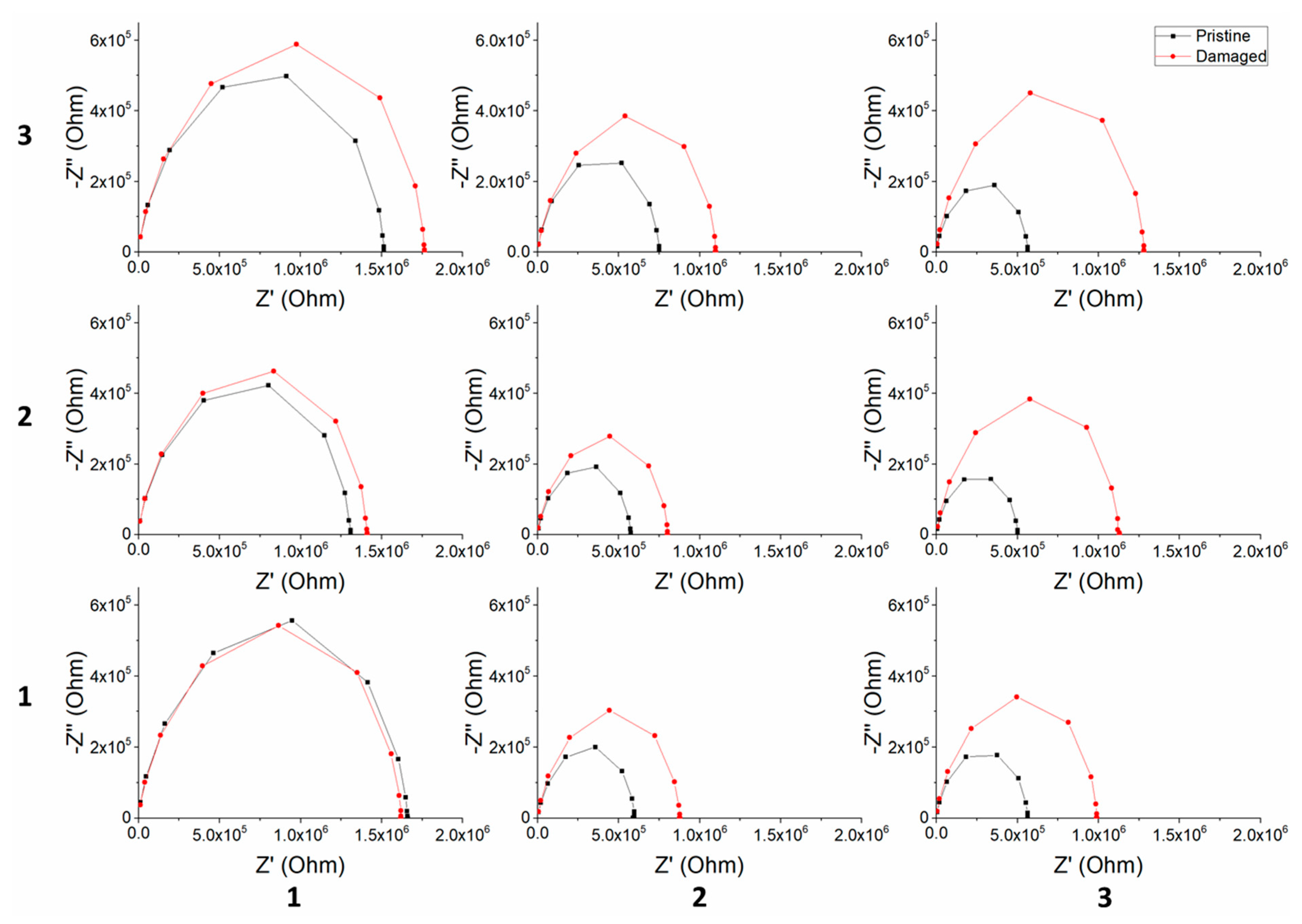

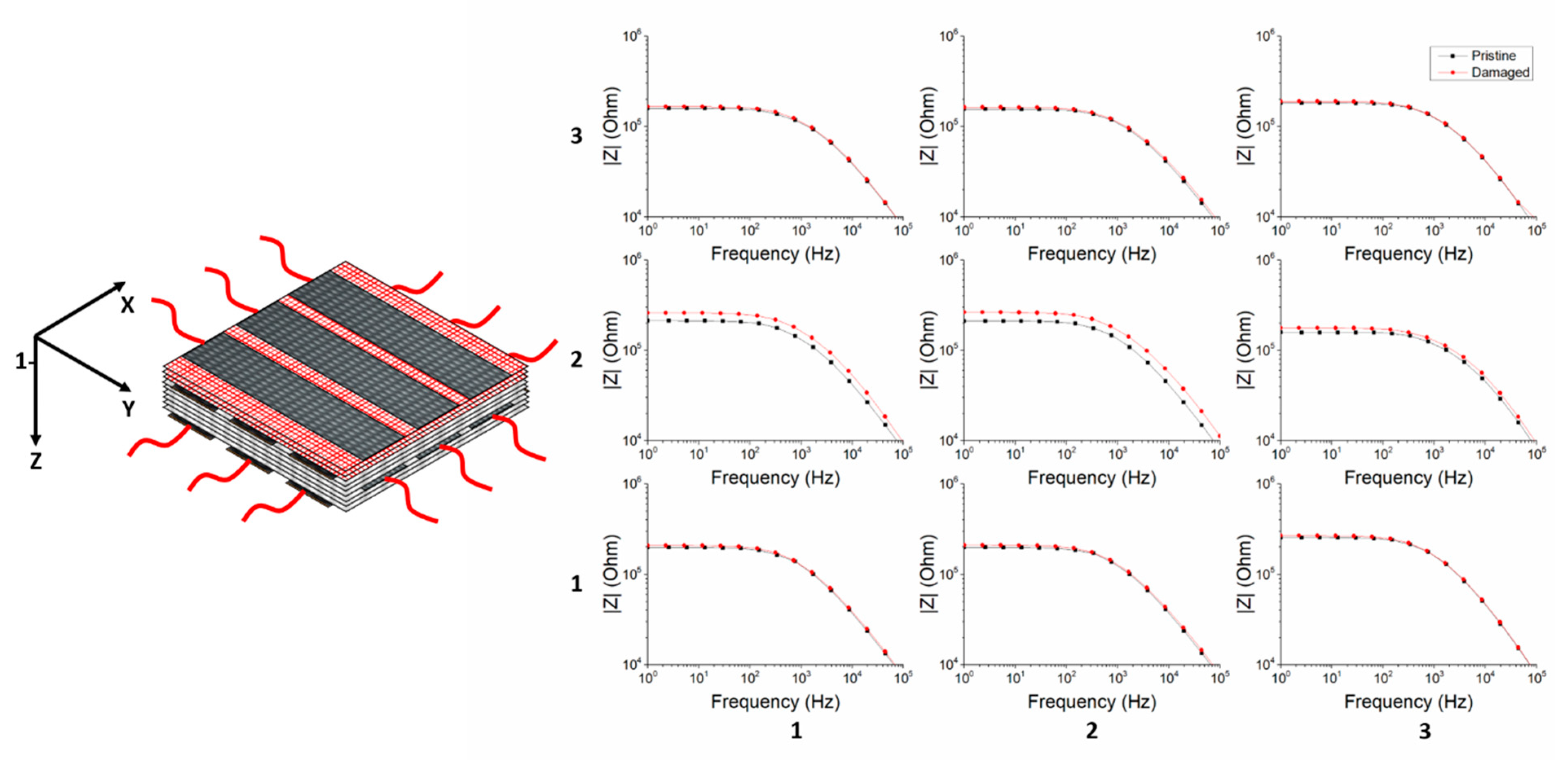

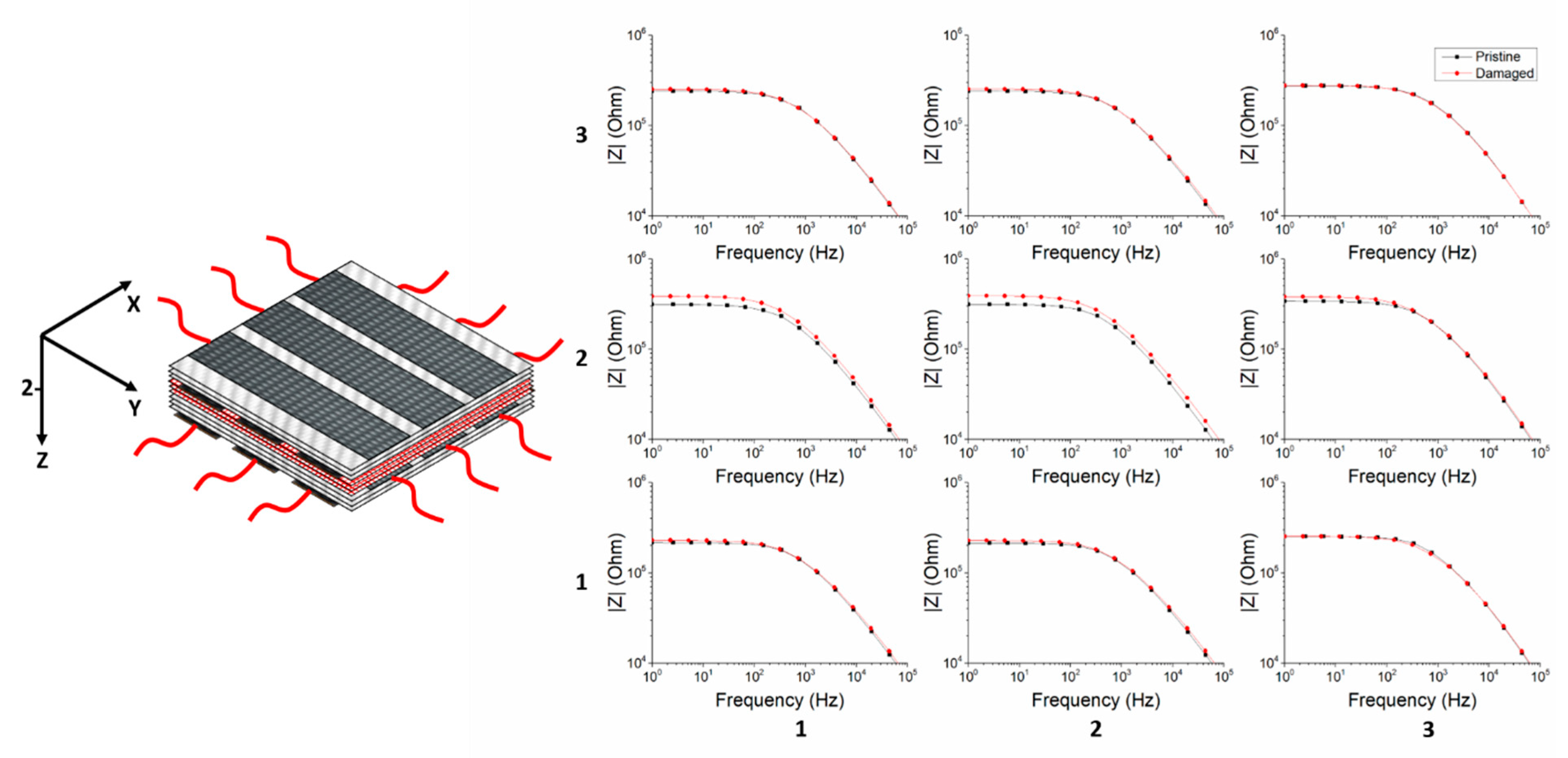

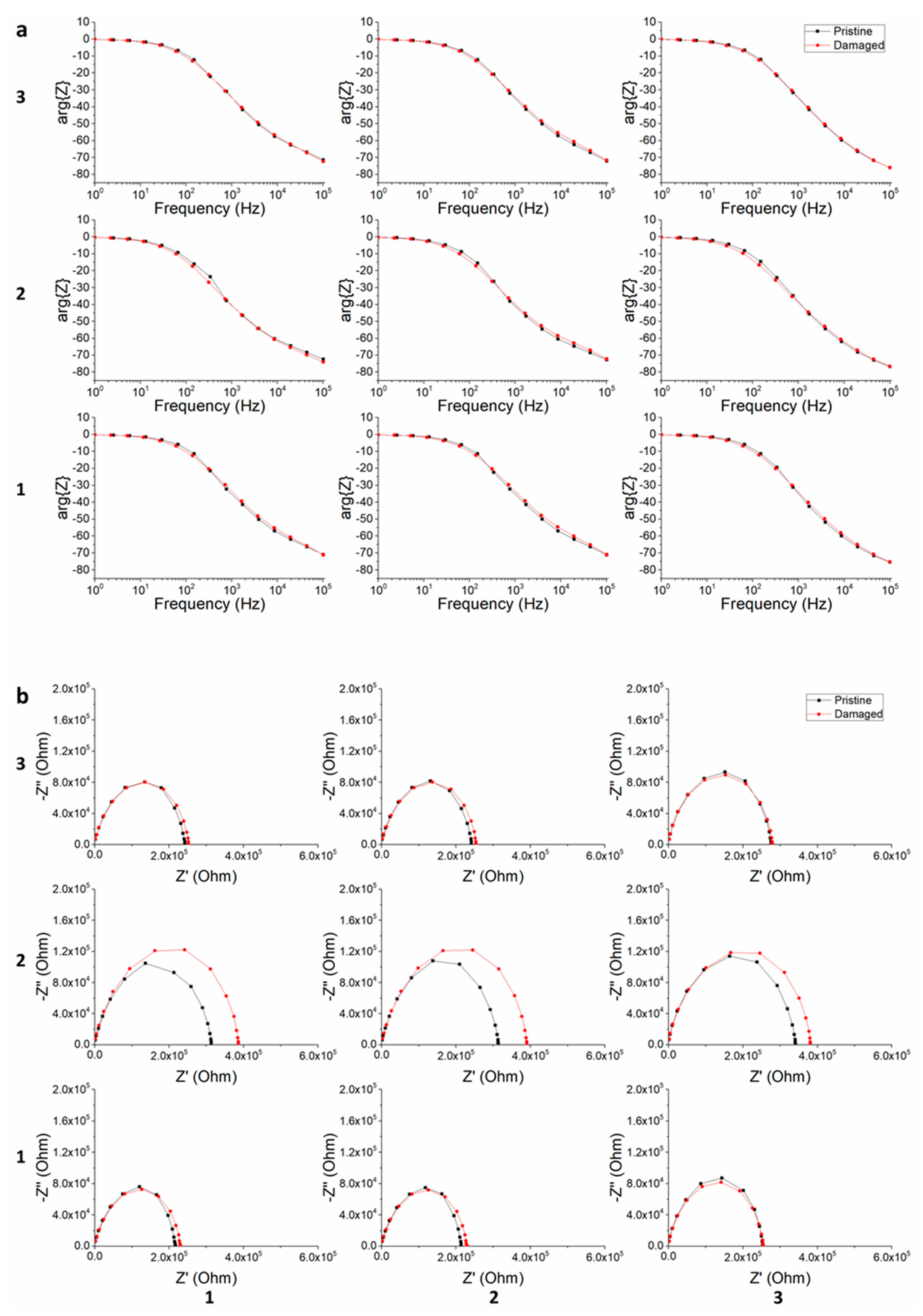

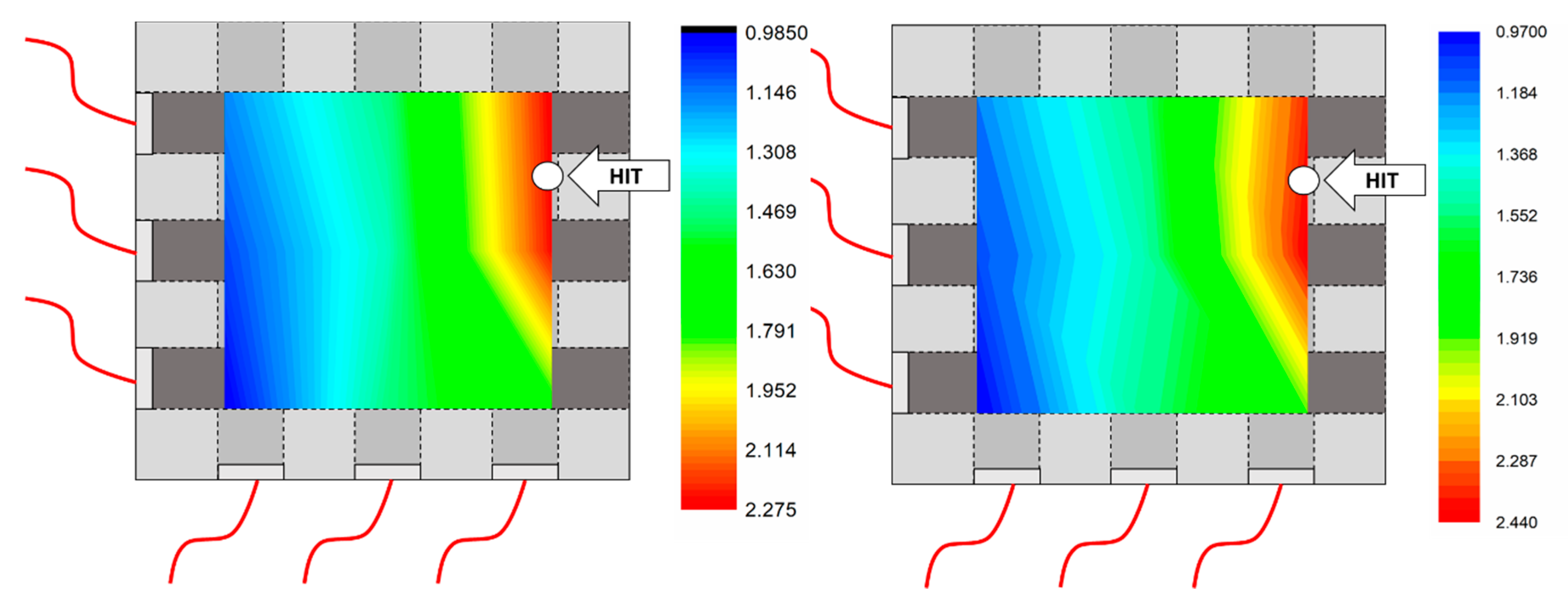

3.1. Impedance Analysis, 2D SHM Damage Localization

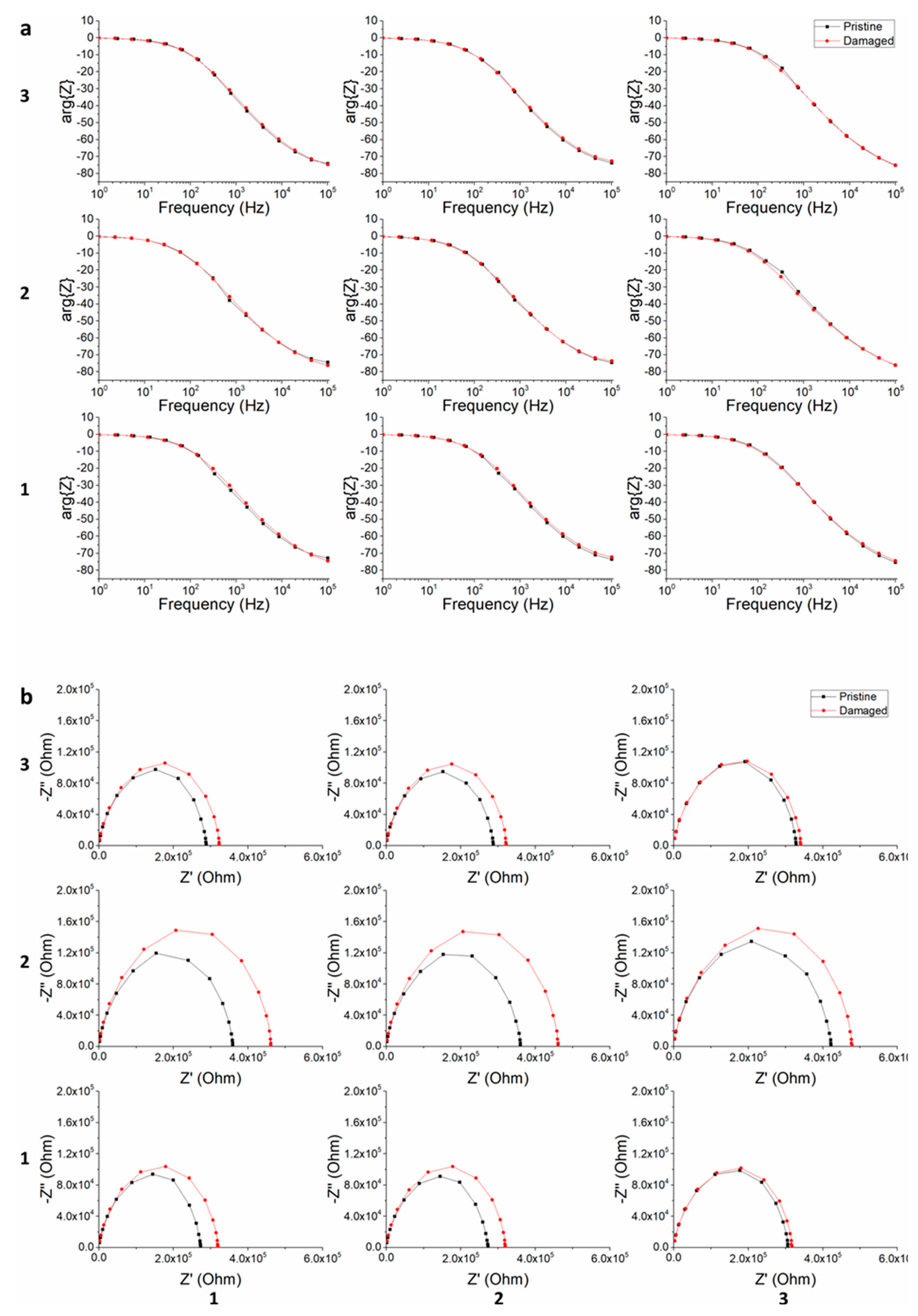

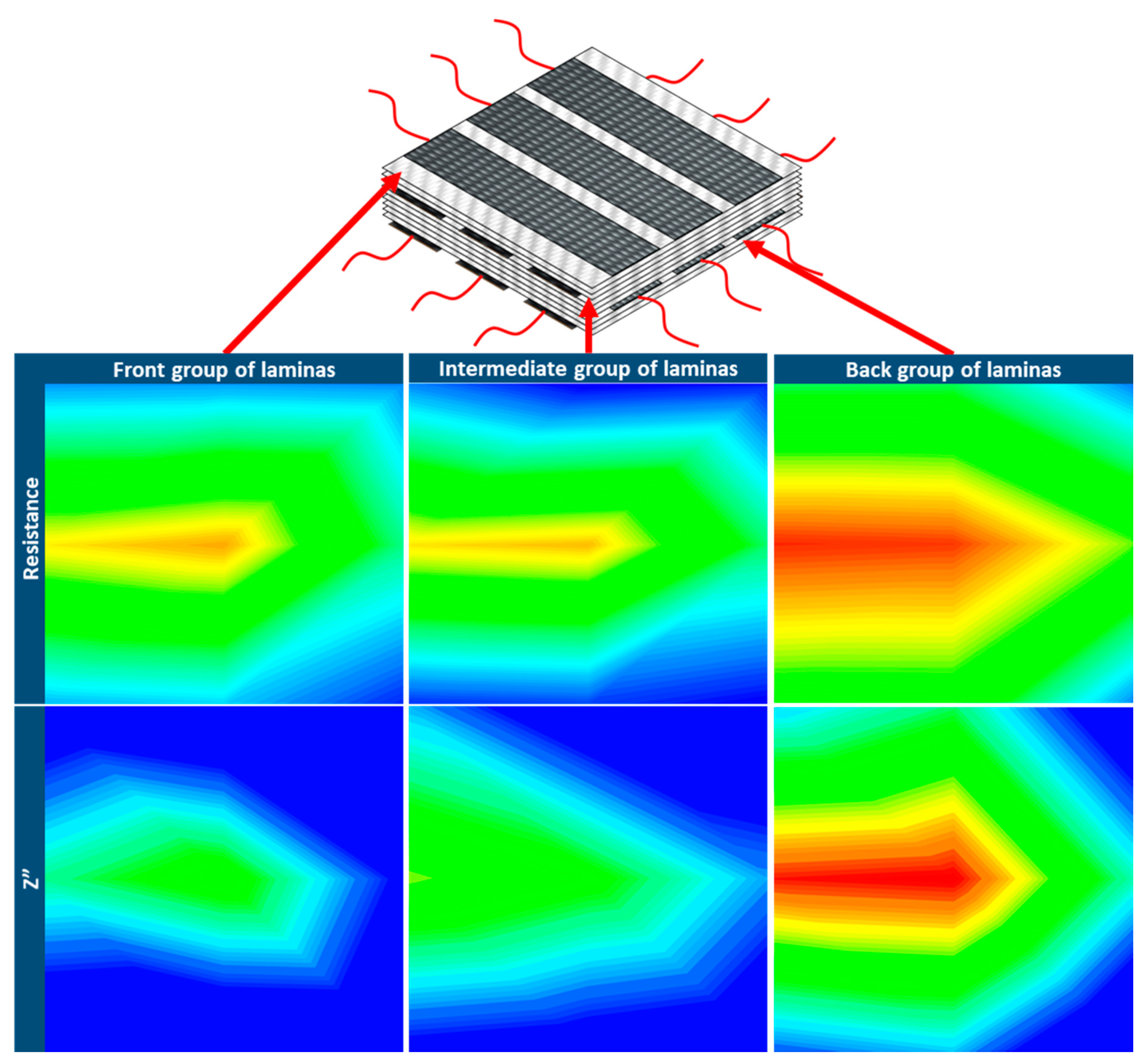

3.2. Impedance Analysis, 3D SHM Damage Localization

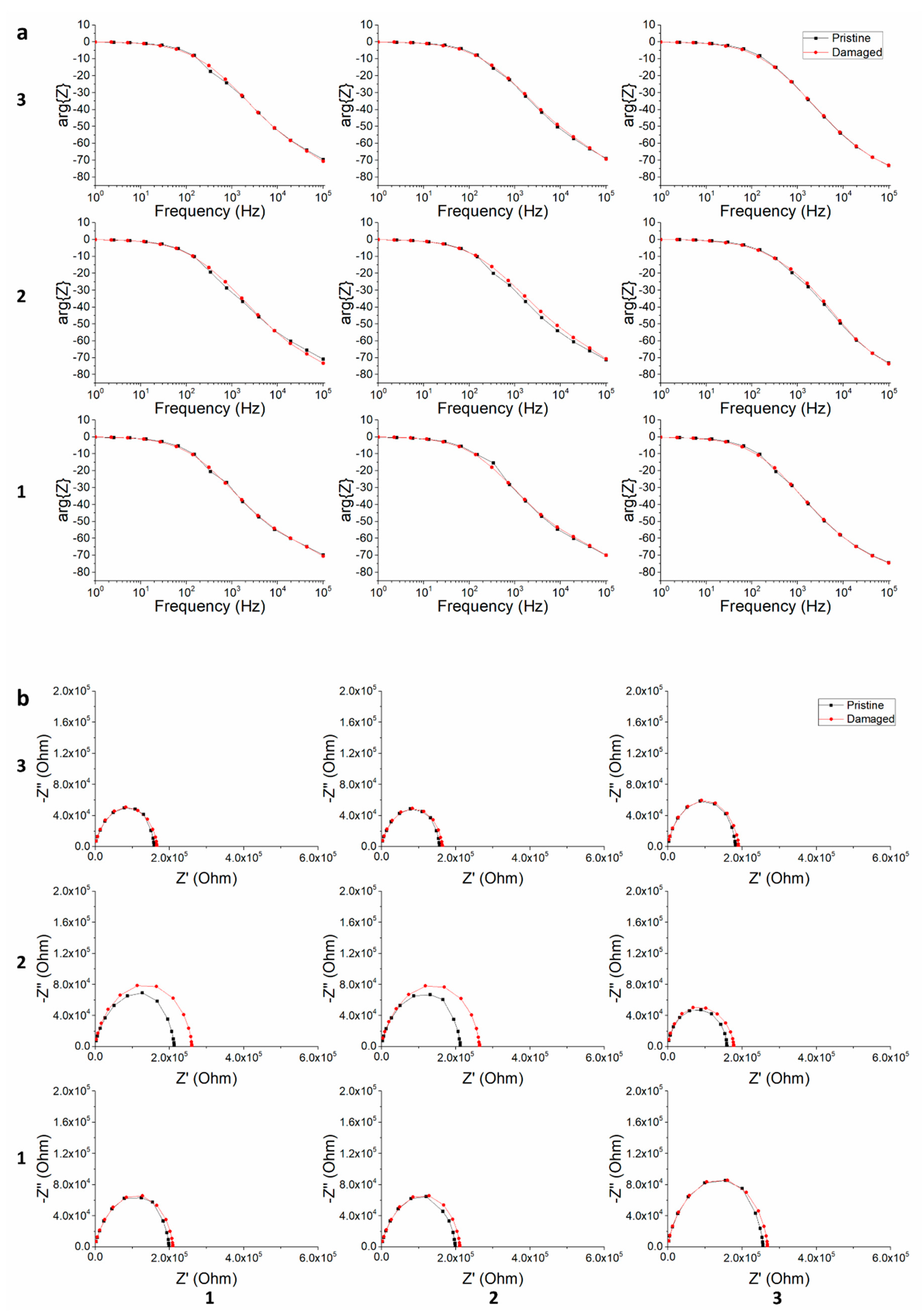

3.3. 2D and 3D Damage Localization by Utilising Equivalent Circuit

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abrate, S. Impact on Laminated Composite Materials. Appl. Mech. Rev. 1991, 44, 155–190. [Google Scholar] [CrossRef]

- Naik, N.K.; Shrirao, P. Composite structures under ballistic impact. Compos. Struct. 2004, 66, 579–590. [Google Scholar]

- Safri, S.; Sultan, M.; Yidris, N.; Mustapha, F. Low Velocity and High Velocity Impact Test on Composite Materials—A review. Int. J. Eng. Sci 2014, 3, 50–60. [Google Scholar]

- Mouritz, A.P. Ballistic impact and explosive blast resistance of stitched composites. Compos. Part B Eng. 2001, 32, 431–439. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Katunin, A.; Dragan, K.; Dziendzikowski, M. Damage identification in aircraft composite structures: A case study using various non-destructive testing techniques. Compos. Struct. 2015, 127, 1–9. [Google Scholar]

- Diamanti, K.; Soutis, C. Structural health monitoring techniques for aircraft composite structures. Prog. Aerosp. Sci. 2010, 46, 342–352. [Google Scholar] [CrossRef]

- Staszewski, W.J.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures—Active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

- Boller, C.; Chang, F.K.; Fujino, Y. Encyclopedia of Structural Health Monitoring; Jonh Wiley & Sons Ltd.: Hoboken, NJ, USA, 2009; p. 3. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Vavouliotis, A.; Karapappas, P.; Tsotra, P.; Paipetis, A. Damage monitoring of carbon fiber reinforced laminates using resistance measurements. Improving sensitivity using carbon nanotube doped epoxy matrix system. J. Intell. Mater. Syst. Struct. 2009, 20, 1025–1034. [Google Scholar]

- Vavouliotis, A.; Paipetis, A.; Kostopoulos, V. On the fatigue life prediction of CFRP laminates using the Electrical Resistance Change method. Compos. Sci. Technol. 2011, 71, 630–642. [Google Scholar] [CrossRef] [Green Version]

- Aggelis, D.G.; Barkoula, N.M.; Matikas, T.E.; Paipetis, A.S. Acoustic structural health monitoring of composite materials: Damage identification and evaluation in cross ply laminates using acoustic emission and ultrasonics. Compos. Sci. Technol. 2012, 72, 1127–1133. [Google Scholar] [CrossRef]

- Grammatikos, S.A.; Kordatos, E.Z.; Matikas, T.E.; Paipetis, A.S. On the fatigue response of a bonded repaired aerospace composite using thermography. Compos. Struct. 2018, 188, 461–469. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. Automatic detection of impact damage in carbon fiber composites using active thermography. Infrared Phys. Technol. 2013, 58, 36–46. [Google Scholar] [CrossRef]

- Frias, C.; Faria, H.; Frazão, O.; Vieira, P.; Marques, A.T. Manufacturing and testing composite overwrapped pressure vessels with embedded sensors. Mater. Des. 2010, 31, 4016–4022. [Google Scholar] [CrossRef] [Green Version]

- Bekas, D.G.; Sharif-Khodaei, Z.; Ferri Aliabadi, M.H. An innovative diagnostic film for structural health monitoring of metallic and composite structures. Sensors 2018, 18, 2084. [Google Scholar] [CrossRef] [Green Version]

- Bekas, D.G.; Sharif-Khodaei, Z.; Aliabadi, F.M.H. A smart multi-functional printed sensor for monitoring curing and damage of composite repair patch. Smart Mater. Struct. 2019, 28, 085029. [Google Scholar] [CrossRef]

- Bekas, D.G.; Paipetis, A.S. Damage monitoring in nanoenhanced composites using impedance spectroscopy. Compos. Sci. Technol. 2016, 134, 96–105. [Google Scholar] [CrossRef]

- Fazzino, P.D.; Reifsnider, K.L.; Majumdar, P. Impedance spectroscopy for progressive damage analysis in woven composites. Compos. Sci. Technol. 2014, 69, 2008–2014. [Google Scholar] [CrossRef]

- Raihan, R.; Adkins, J.M.; Baker, J.; Rabbi, F.; Reifsnider, K. Relationship of dielectric property change to composite material state degradation. Compos. Sci. Technol. 2014, 105, 160–165. [Google Scholar] [CrossRef] [Green Version]

- Hayes, S.A.; Swait, T.J.; Lafferty, A.D. Self-Sensing and Self-Healing in Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; ISBN 9781782422921. [Google Scholar]

- Todoroki, A.; Haruyama, D.; Mizutani, Y.; Suzuki, Y.; Yasuoka, T. Electrical Resistance Change of Carbon / Epoxy Composite Laminates under Cyclic Loading under Damage Initiation Limit. Open J. Compos. Mater. 2014, 4, 22–31. [Google Scholar] [CrossRef] [Green Version]

- Roh, H.D.; Lee, S.Y.; Jo, E.; Kim, H.; Ji, W.; Park, Y. Bin Deformation and interlaminar crack propagation sensing in carbon fiber composites using electrical resistance measurement. Compos. Struct. 2019, 216, 142–150. [Google Scholar] [CrossRef]

- Nonn, S.; Schagerl, M.; Zhao, Y.; Gschossmann, S.; Kralovec, C. Application of electrical impedance tomography to an anisotropic carbon fiber-reinforced polymer composite laminate for damage localization. Compos. Sci. Technol. 2018, 160, 231–236. [Google Scholar] [CrossRef]

- Grammatikos, S.A.; Kouli, M.; Gkikas, G.; Paipetis, A.S. Structural health monitoring of aerospace materials used in industry using electrical potential mapping methods. In Proceedings of the SPIE 8346, Smart Sensor Phenomena, Technology, Networks, and Systems Integration, San Diego, CA, USA, 26 April 2012; Volume 8346, pp. 1–7. [Google Scholar]

- Tzounis, L.; Zappalorto, M.; Panozzo, F.; Tsirka, K.; Maragoni, L.; Paipetis, A.S.; Quaresimin, M. Highly conductive ultra-sensitive SWCNT-coated glass fiber reinforcements for laminate composites structural health monitoring. Compos. Part B Eng. 2019, 169, 37–44. [Google Scholar] [CrossRef]

- Bekas, D.G.; Paipetis, A.S. Study of the Effect of Damage on the Electrical Impedance of Carbon Nanotube Reinforced Epoxy Nanocomposites. J. Sens. 2015, 2015, 805303. [Google Scholar] [CrossRef] [Green Version]

- Hernández-Pérez, A.; Avilés, F.; May-Pat, A.; Valadez-González, A.; Herrera-Franco, P.J.; Bartolo-Pérez, P. Effective properties of multiwalled carbon nanotube/epoxy composites using two different tubes. Compos. Sci. Technol. 2008, 68, 1422–1431. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Allaoui, A.; Bai, S.; Cheng, H.M.; Bai, J.B. Mechanical and electrical properties of a MWNT/epoxy composite. Compos. Sci. Technol. 2002, 62, 1993–1998. [Google Scholar]

- Burmistrov, I.; Gorshkov, N.; Ilinykh, I.; Muratov, D.; Kolesnikov, E.; Anshin, S.; Mazov, I.; Issi, J.P.; Kusnezov, D. Improvement of carbon black based polymer composite electrical conductivity with additions of MWCNT. Compos. Sci. Technol. 2016, 129, 79–85. [Google Scholar] [CrossRef]

- Foteinidis, G.; Tsirka, K.; Tzounis, L.; Baltzis, D.; Paipetis, A.S. The Role of Synergies of MWCNTs and Carbon Black in the Enhancement of the Electrical and Mechanical Response of Modified Epoxy Resins. Appl. Sci. 2019, 9, 3757. [Google Scholar] [CrossRef] [Green Version]

- Baltopoulos, A.; Polydorides, N.; Pambaguian, L.; Vavouliotis, A.; Kostopoulos, V. Exploiting carbon nanotube networks for damage assessment of fiber reinforced composites. Compos. Part B Eng. 2015, 76, 149–158. [Google Scholar] [CrossRef] [Green Version]

- Isaac-Medina, B.K.S.; Alonzo-García, A.; Avilés, F. Electrical self-sensing of impact damage in multiscale hierarchical composites with tailored location of carbon nanotube networks. Struct. Health Monit. 2019, 18, 806–818. [Google Scholar] [CrossRef]

- Stauffer, D.; Ammon, A. Introduction to Percolation Theory, 2nd ed.; Taylor and Francis: Abingdon, UK, 1994. [Google Scholar]

- Baltzis, D.; Bekas, D.G.; Tzachristas, G.; Parlamas, A.; Karabela, M.; Zafeiropoulos, N.E.; Paipetis, A.S. Multi-scaled carbon reinforcements in ternary epoxy composite materials: Dispersion and electrical impedance study. Compos. Sci. Technol. 2017, 153, 7–17. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foteinidis, G.; Paipetis, A.S. A Novel Composite with Structural Health Monitoring Functionality via 2D and 3D Impedance Mapping Topography. Appl. Sci. 2021, 11, 1647. https://doi.org/10.3390/app11041647

Foteinidis G, Paipetis AS. A Novel Composite with Structural Health Monitoring Functionality via 2D and 3D Impedance Mapping Topography. Applied Sciences. 2021; 11(4):1647. https://doi.org/10.3390/app11041647

Chicago/Turabian StyleFoteinidis, Georgios, and Alkiviadis S. Paipetis. 2021. "A Novel Composite with Structural Health Monitoring Functionality via 2D and 3D Impedance Mapping Topography" Applied Sciences 11, no. 4: 1647. https://doi.org/10.3390/app11041647

APA StyleFoteinidis, G., & Paipetis, A. S. (2021). A Novel Composite with Structural Health Monitoring Functionality via 2D and 3D Impedance Mapping Topography. Applied Sciences, 11(4), 1647. https://doi.org/10.3390/app11041647