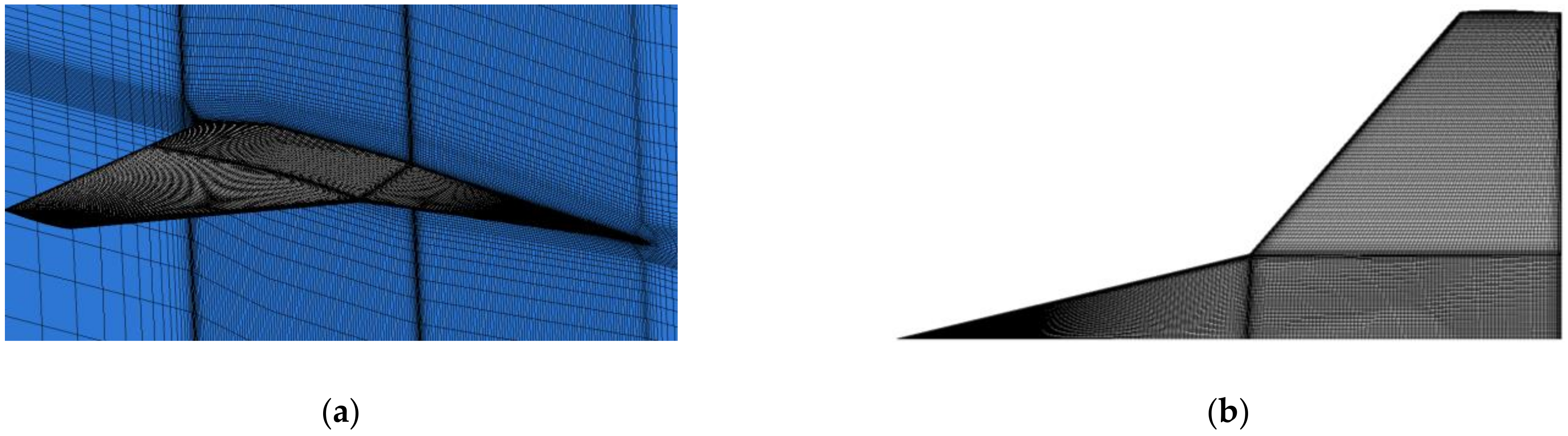

Figure 2.

The grid topology of LSSDW: (a) Volume grid; (b) Surface grid of LSSDW.

Figure 2.

The grid topology of LSSDW: (a) Volume grid; (b) Surface grid of LSSDW.

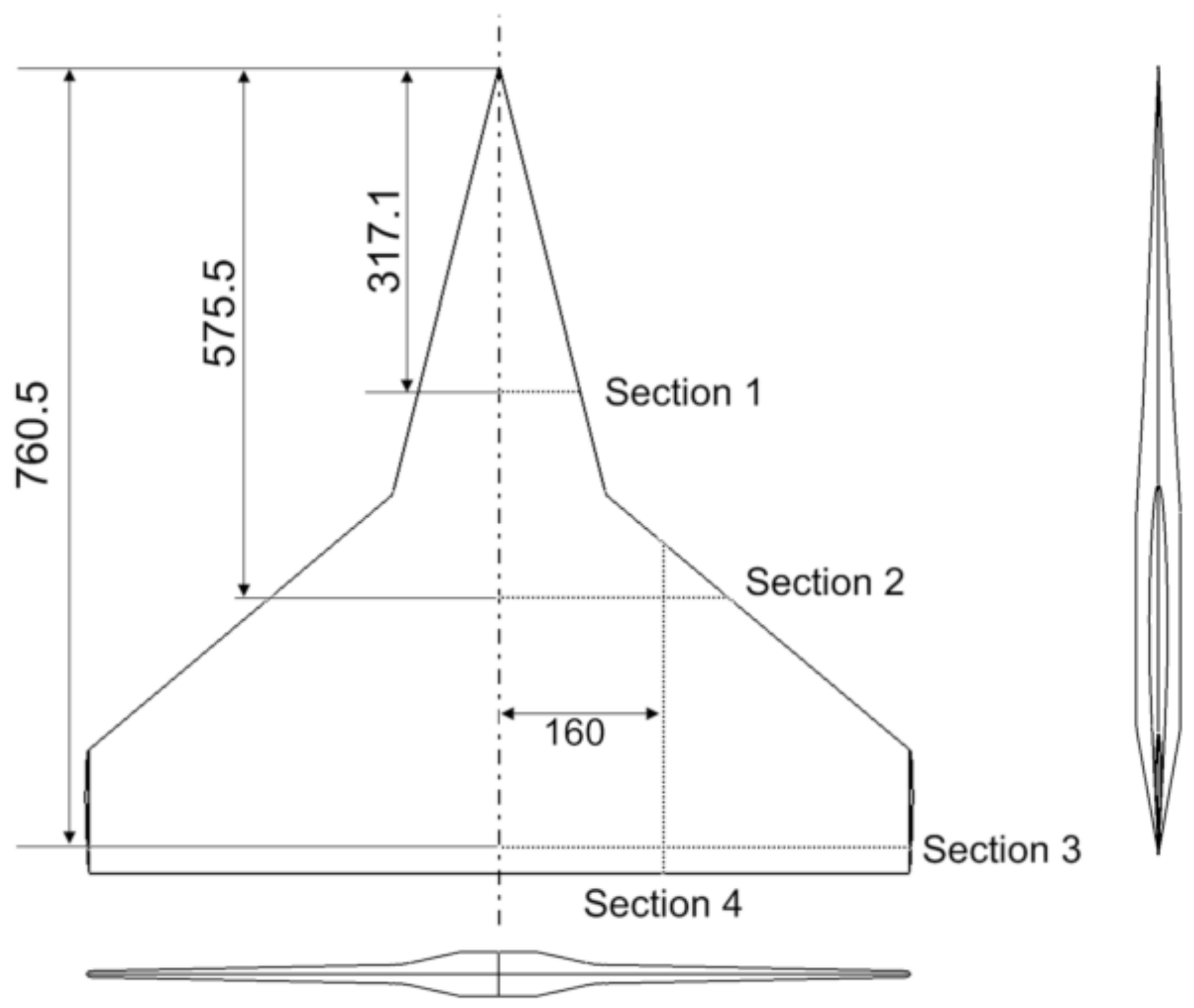

Figure 3.

Pressure coefficients comparisons of the experiment [

24] and numerical calculation on the upper surface of LSSDW at typical sections for Ma = 0.225, Re = 3.7 × 10

6: (

a) Section 1; (

b) Section 2; (

c) Section 3; (

d) Section 4.

Figure 3.

Pressure coefficients comparisons of the experiment [

24] and numerical calculation on the upper surface of LSSDW at typical sections for Ma = 0.225, Re = 3.7 × 10

6: (

a) Section 1; (

b) Section 2; (

c) Section 3; (

d) Section 4.

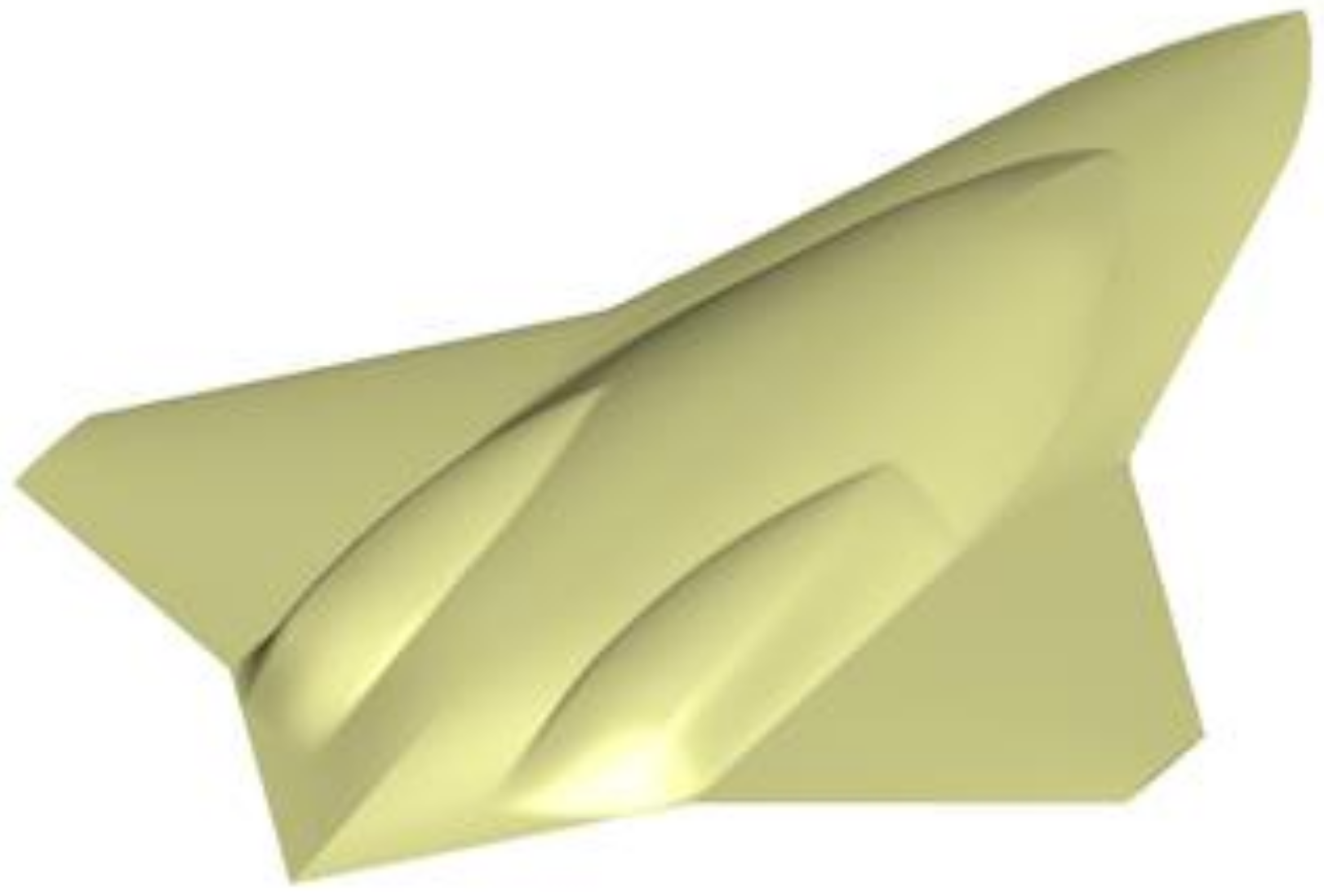

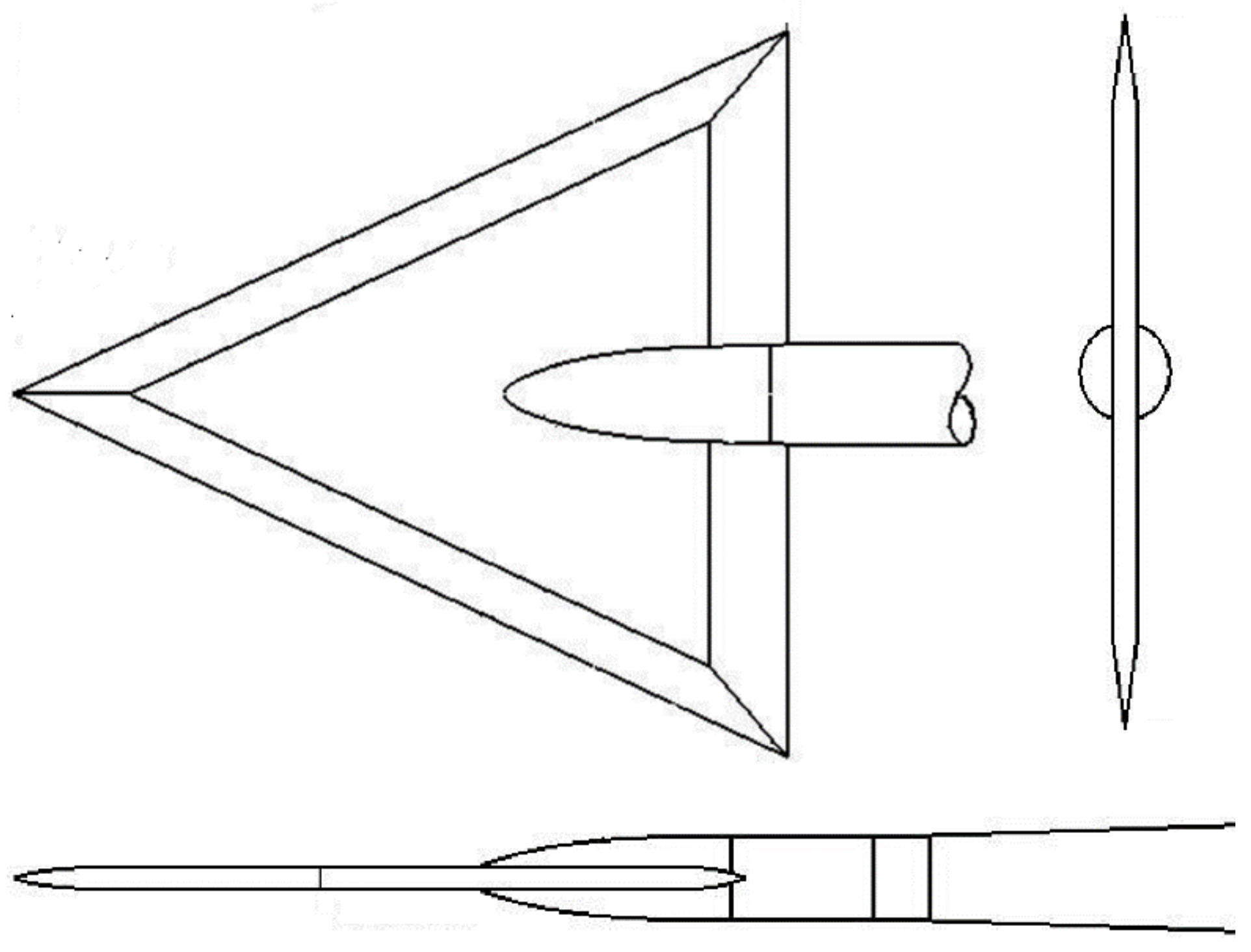

Figure 4.

Delta wing model.

Figure 4.

Delta wing model.

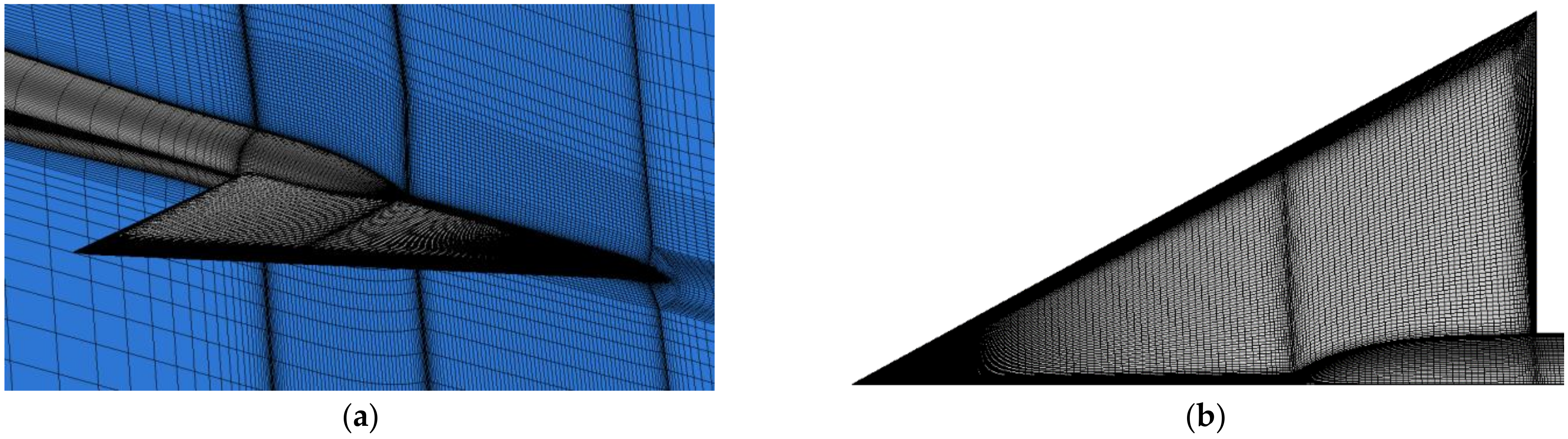

Figure 5.

The grid of delta wing. (a) Volume grid; (b) Surface grid.

Figure 5.

The grid of delta wing. (a) Volume grid; (b) Surface grid.

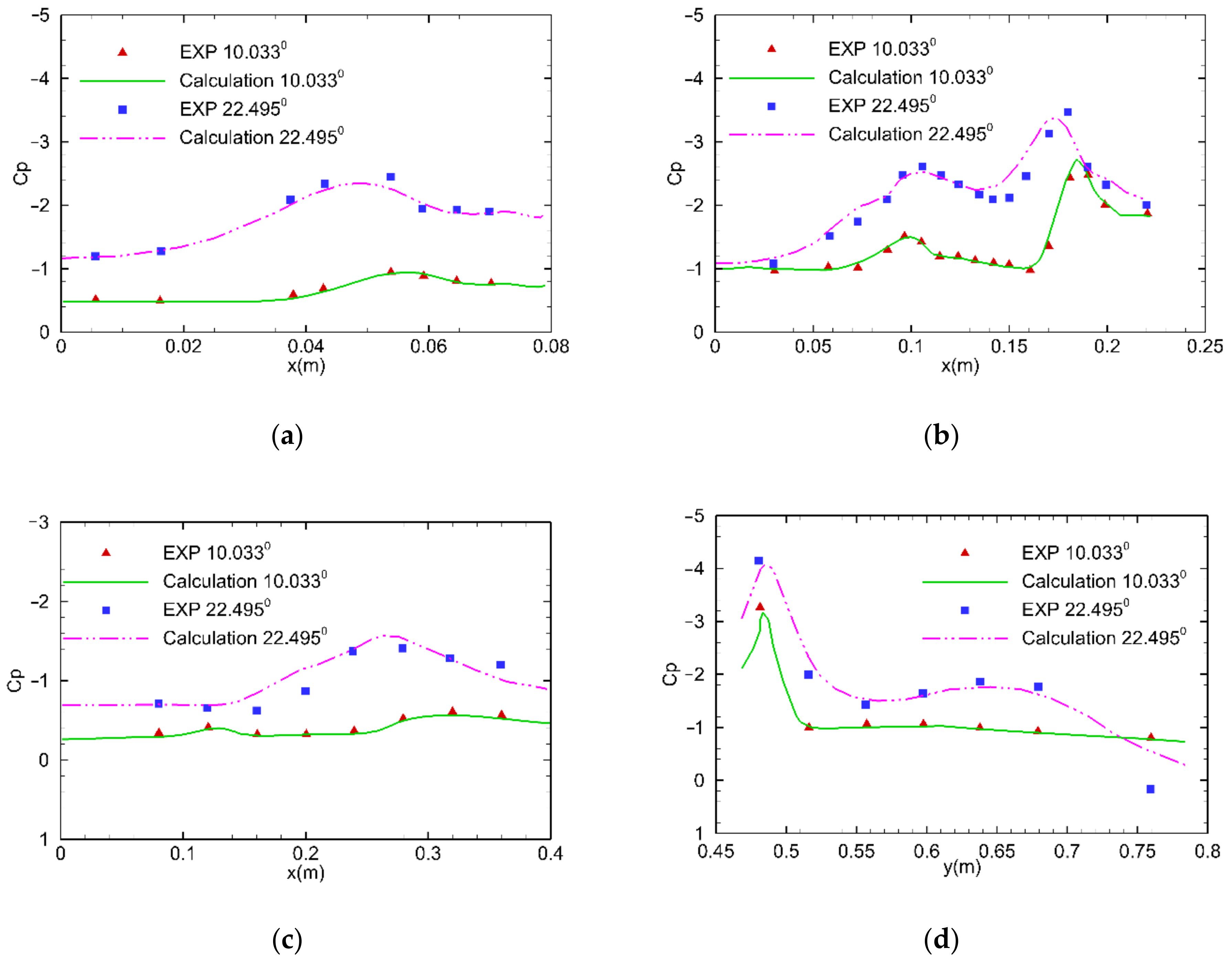

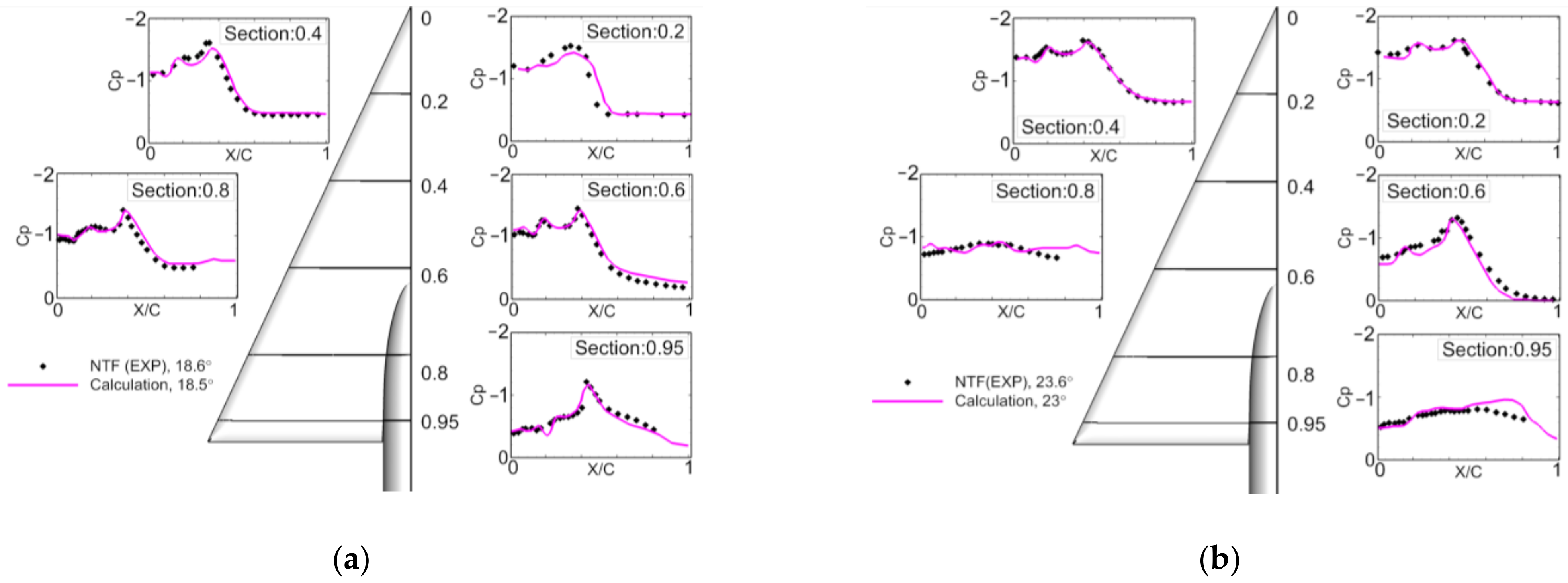

Figure 6.

Pressure comparisons of the experiment [

25] and CFD calculation on the upper surface of the delta wing at typical sections for Ma = 0.85, Re = 6 × 106. (

a)

; (

b)

.

Figure 6.

Pressure comparisons of the experiment [

25] and CFD calculation on the upper surface of the delta wing at typical sections for Ma = 0.85, Re = 6 × 106. (

a)

; (

b)

.

Figure 7.

Pressure coefficients distribution contours by CFD herein on the upper surface of delta wing, Ma = 0.85, Re = 6 × 106.

Figure 7.

Pressure coefficients distribution contours by CFD herein on the upper surface of delta wing, Ma = 0.85, Re = 6 × 106.

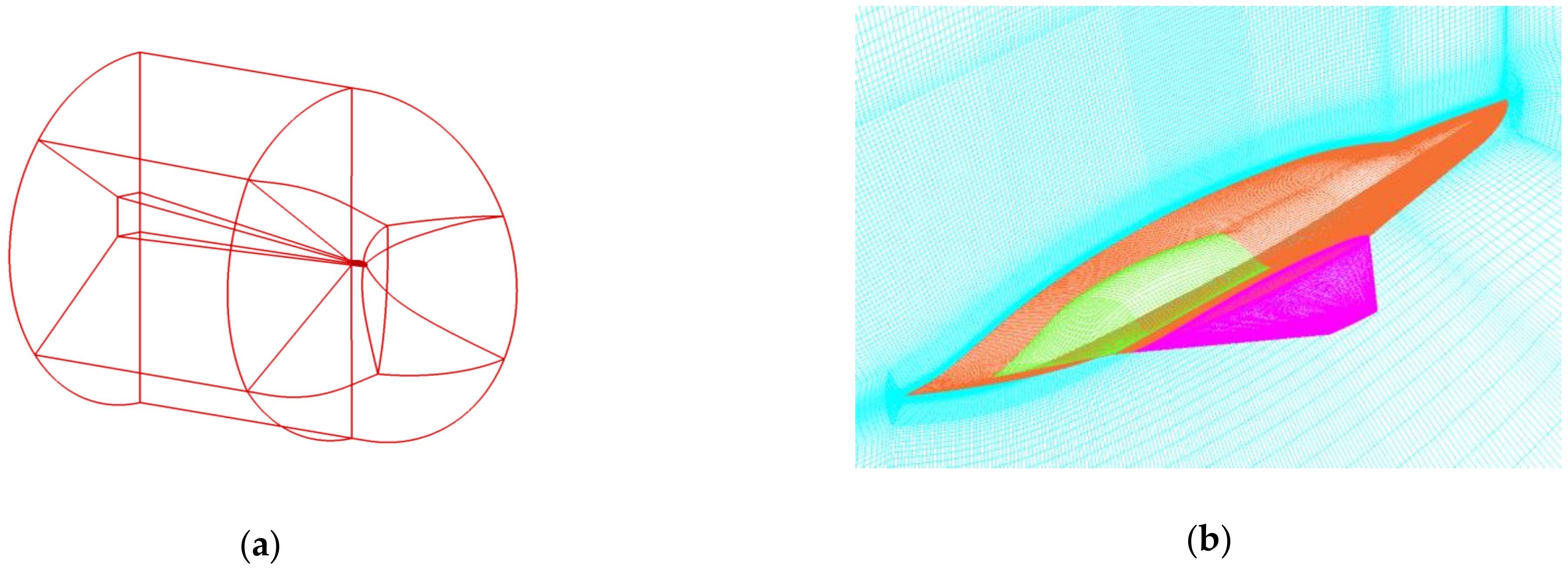

Figure 9.

The grid of the model. (a) Grid topology. (b) Mesh around the model.

Figure 9.

The grid of the model. (a) Grid topology. (b) Mesh around the model.

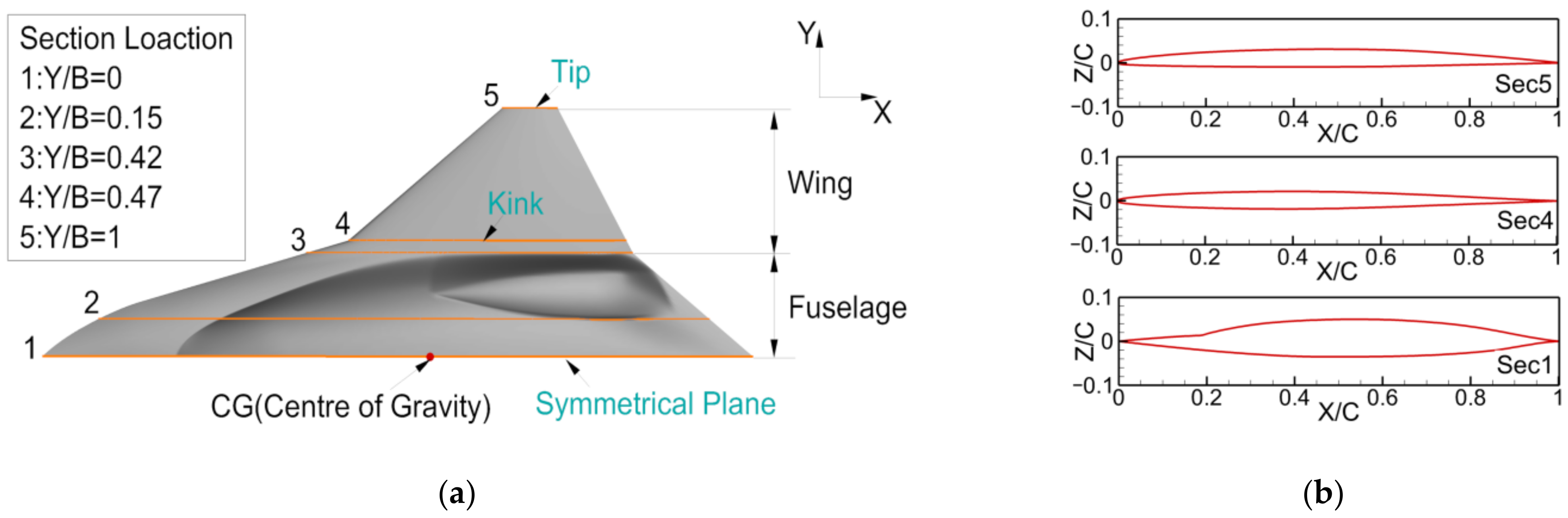

Figure 10.

(a) Planform and typical sections locations; (b) Geometrical shapes of typical section airfoils.

Figure 10.

(a) Planform and typical sections locations; (b) Geometrical shapes of typical section airfoils.

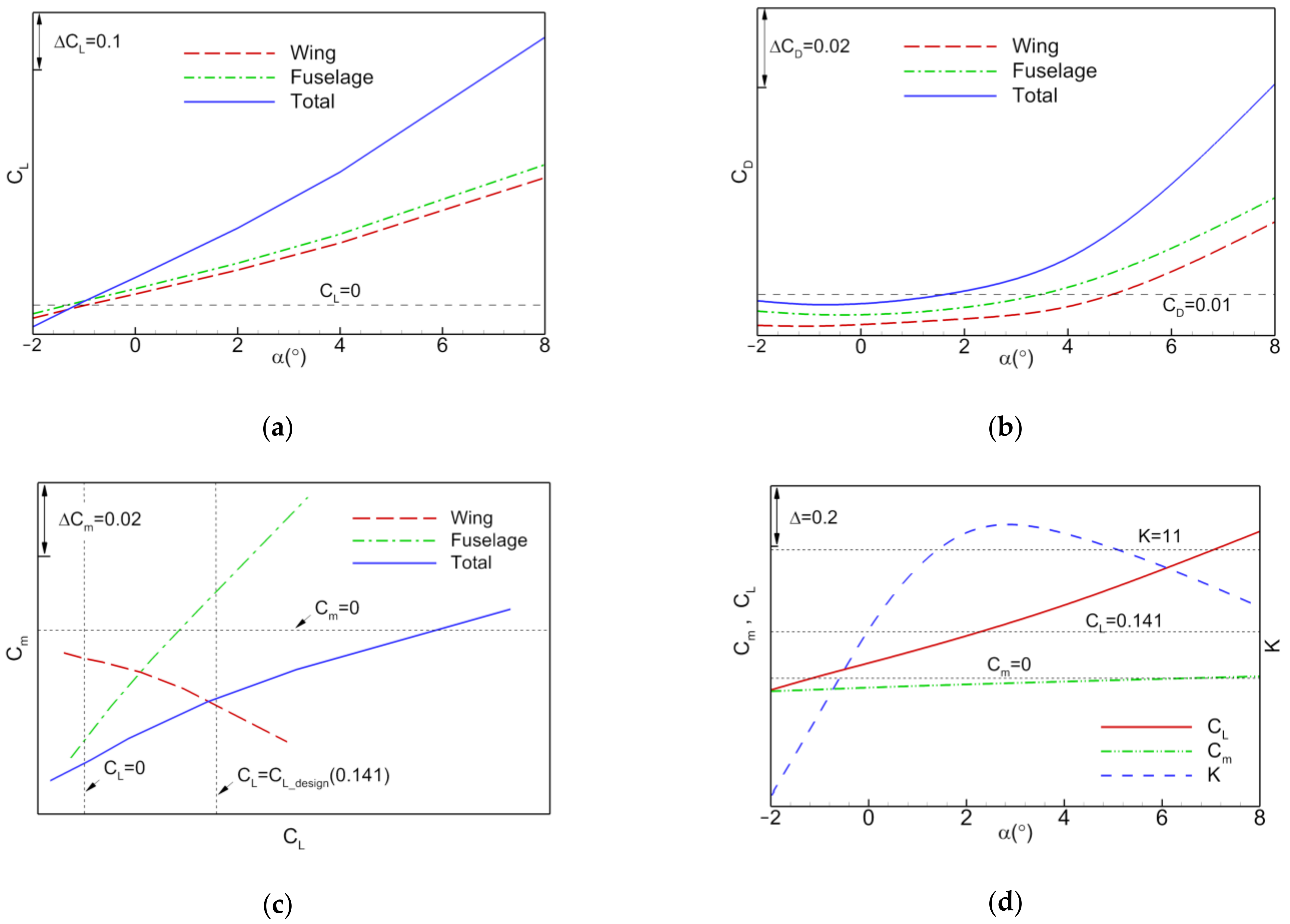

Figure 11.

Aerodynamic characteristic of each component and the initial configuration, Ma = 0.85, H = 11 km, . (a) Lift coefficient; (b) Drag coefficient; (c) Pitching moment coefficient; (d) Aerodynamic characteristic of the initial configuration.

Figure 11.

Aerodynamic characteristic of each component and the initial configuration, Ma = 0.85, H = 11 km, . (a) Lift coefficient; (b) Drag coefficient; (c) Pitching moment coefficient; (d) Aerodynamic characteristic of the initial configuration.

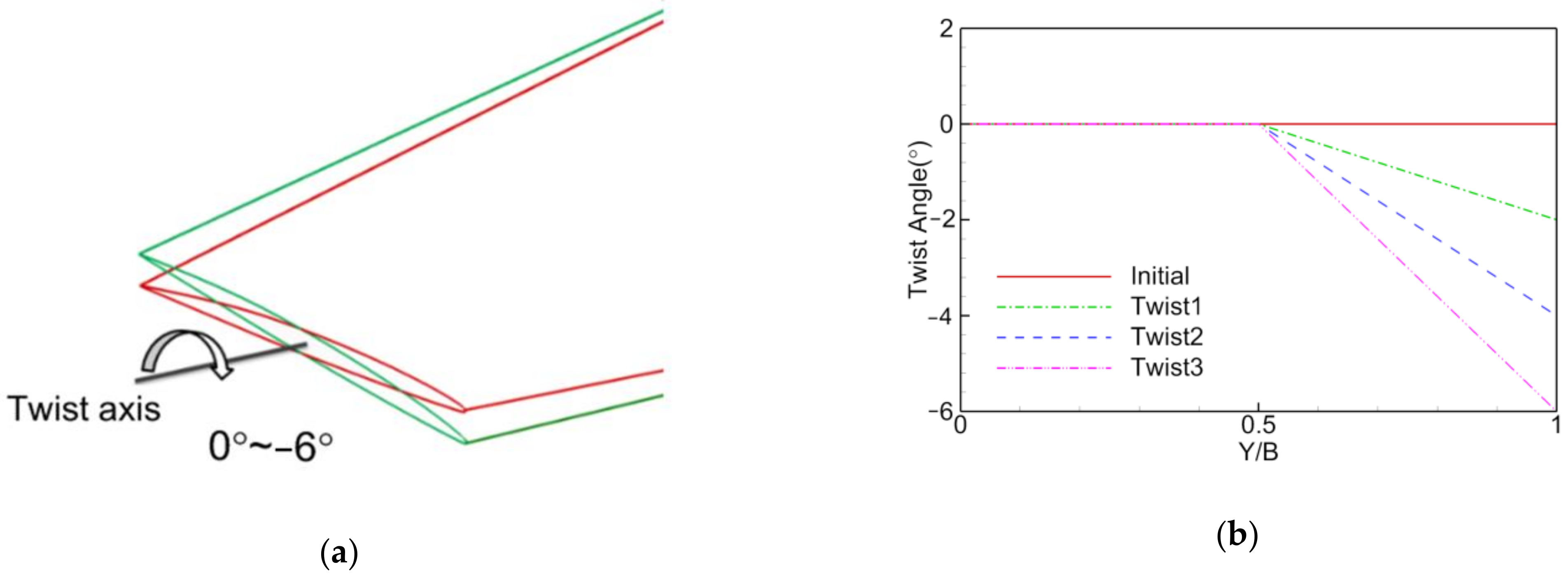

Figure 12.

Wing twist: (a) Wing twist method; (b) Twist distribution in spanwise direction.

Figure 12.

Wing twist: (a) Wing twist method; (b) Twist distribution in spanwise direction.

Figure 13.

Aerodynamic characteristic of the configurations with different twist angles. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

Figure 13.

Aerodynamic characteristic of the configurations with different twist angles. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

Figure 14.

The increments of Cm,c and K obtained by twisting the wing at cruise state.(a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 14.

The increments of Cm,c and K obtained by twisting the wing at cruise state.(a) Pitching moment coefficient; (b) Lift-to-drag ratio.

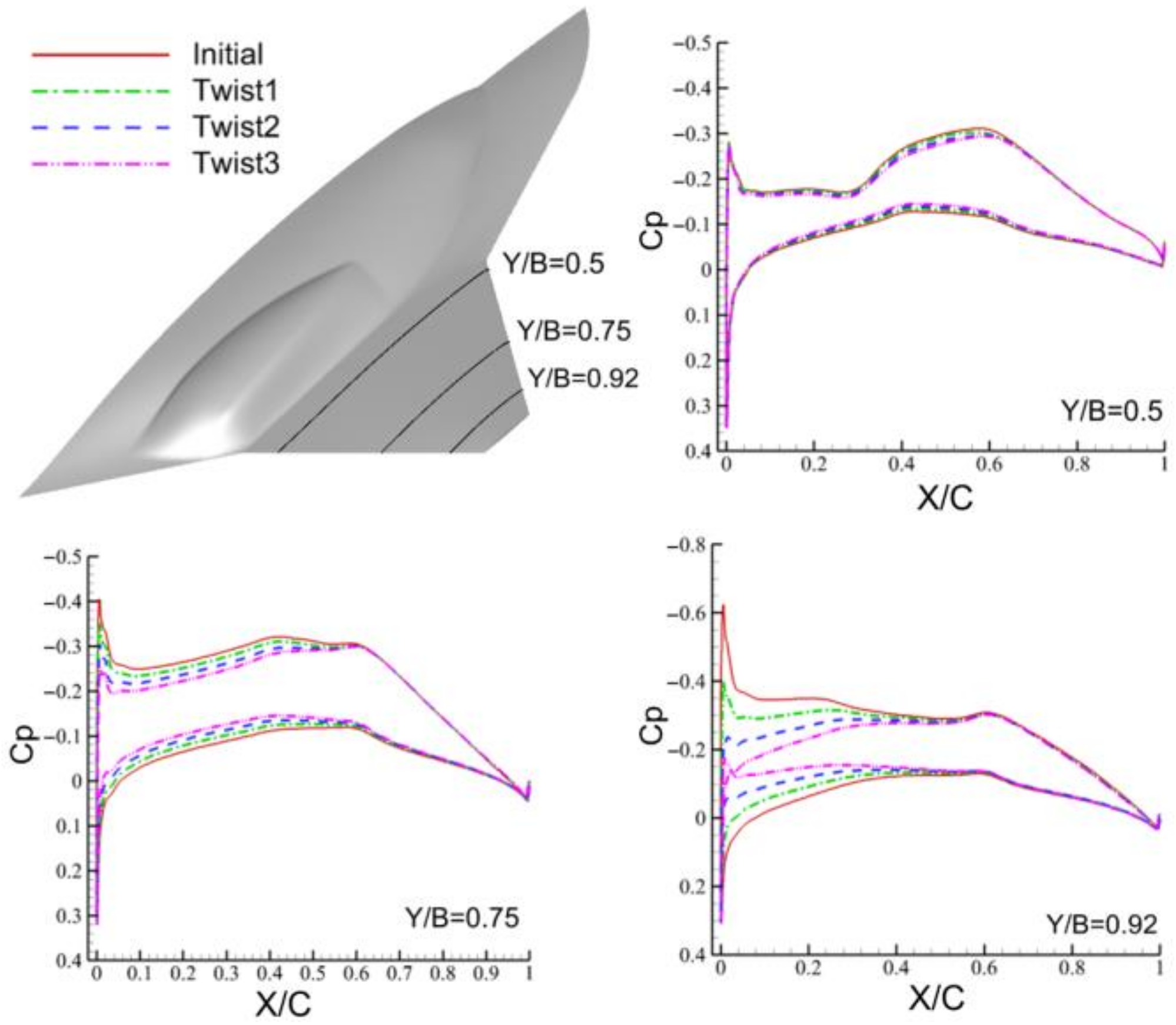

Figure 15.

The positions and pressure coefficient distributions at typical sections of the different twisted configurations. Ma = 0.85, α = 2°.

Figure 15.

The positions and pressure coefficient distributions at typical sections of the different twisted configurations. Ma = 0.85, α = 2°.

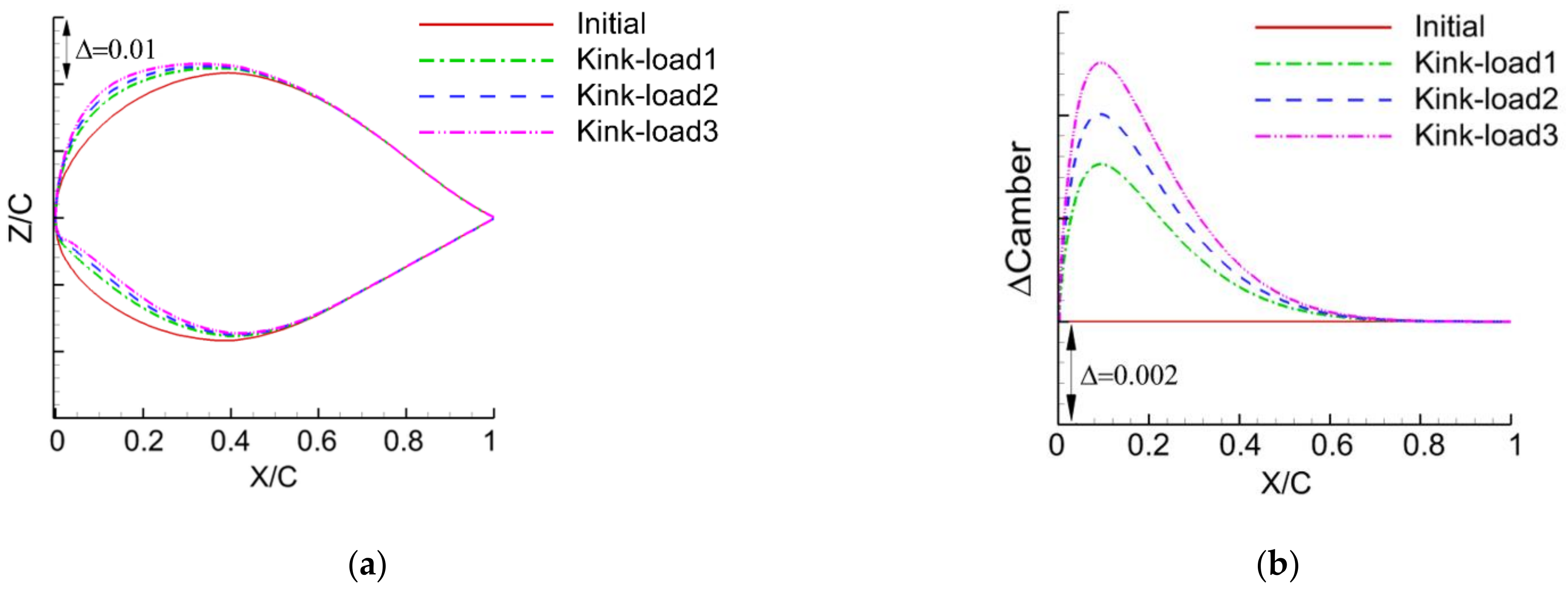

Figure 16.

The fore-loading modification of kink airfoil. (a) Airfoils comparison; (b) Different camber increments.

Figure 16.

The fore-loading modification of kink airfoil. (a) Airfoils comparison; (b) Different camber increments.

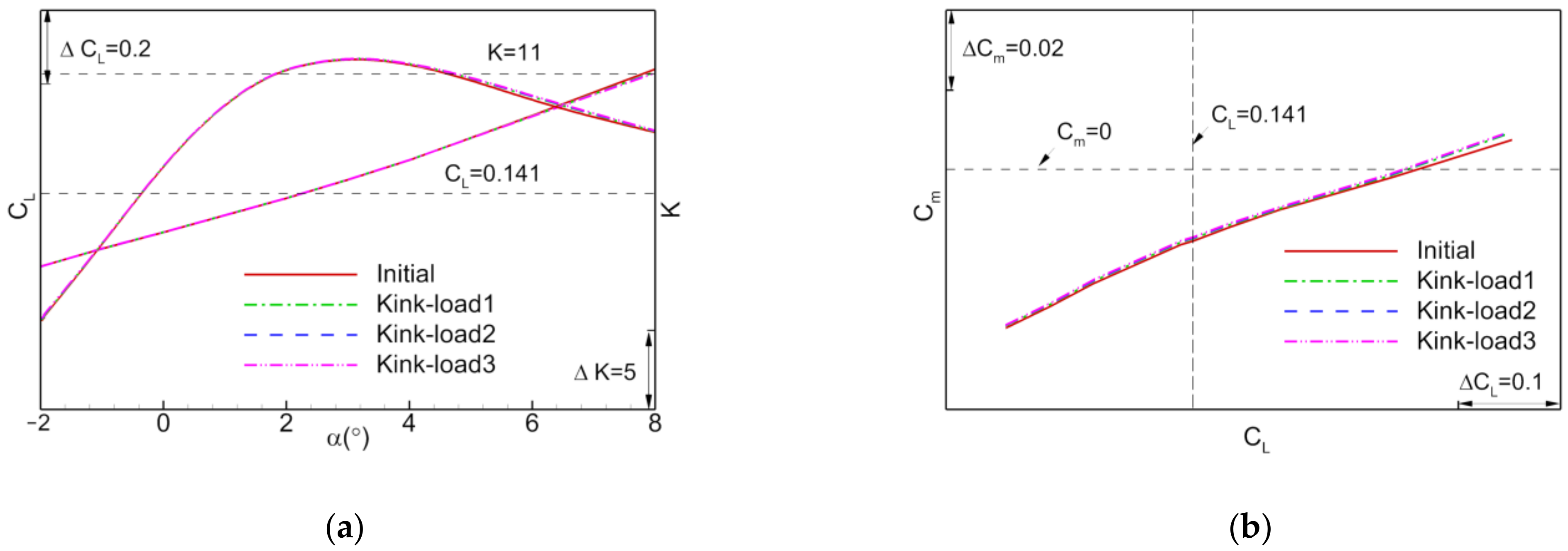

Figure 17.

Aerodynamic characteristic of the configurations with different fore-loading kink airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

Figure 17.

Aerodynamic characteristic of the configurations with different fore-loading kink airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

Figure 18.

The increments of Cm,c and K obtained by fore-loading the kink airfoil at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 18.

The increments of Cm,c and K obtained by fore-loading the kink airfoil at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 19.

The positions and pressure coefficient distributions at typical sections of the different fore-loaded configurations. Ma = 0.85, α = 2°.

Figure 19.

The positions and pressure coefficient distributions at typical sections of the different fore-loaded configurations. Ma = 0.85, α = 2°.

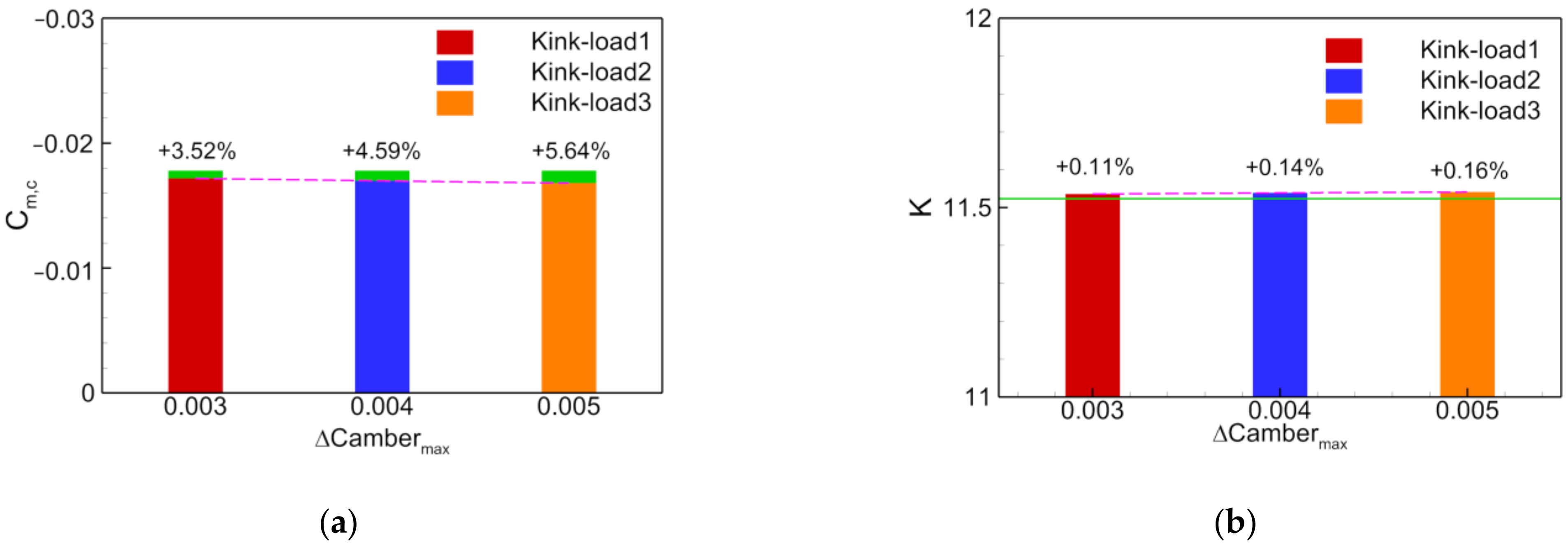

Figure 20.

The aft-reflexing modification of kink airfoil. (a) Airfoils comparison; (b) Different camber increments.

Figure 20.

The aft-reflexing modification of kink airfoil. (a) Airfoils comparison; (b) Different camber increments.

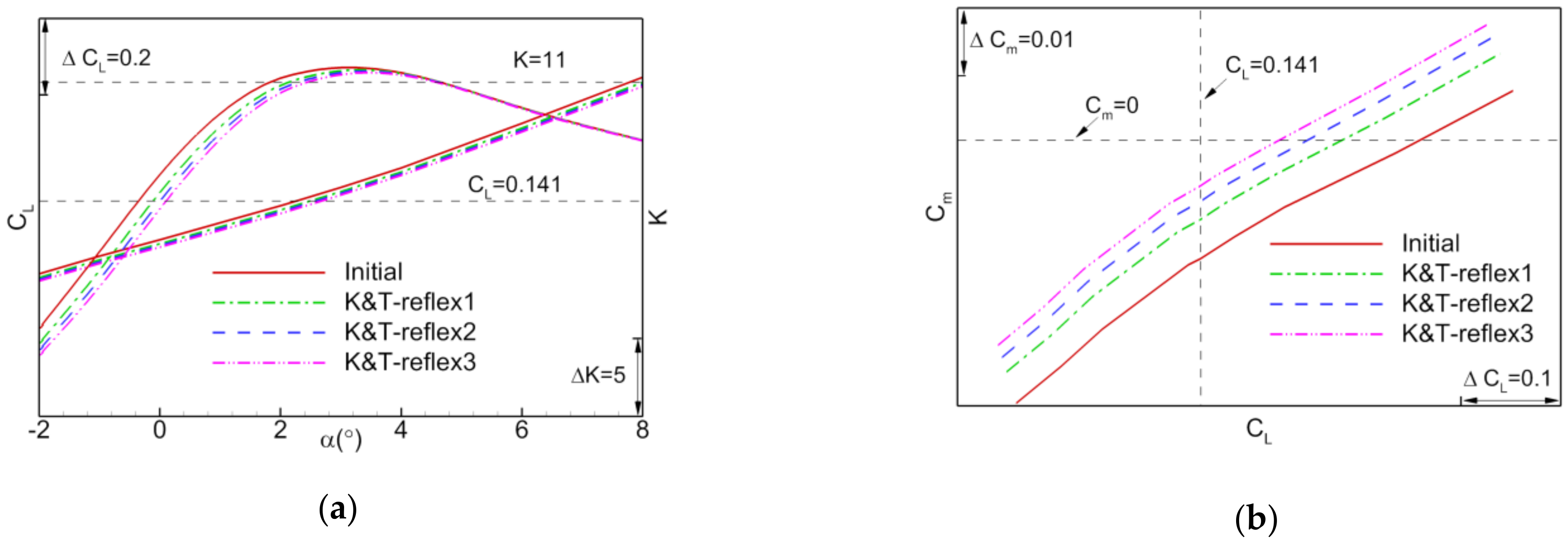

Figure 21.

Aerodynamic characteristic of the configurations with different aft-reflexing kink airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

Figure 21.

Aerodynamic characteristic of the configurations with different aft-reflexing kink airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

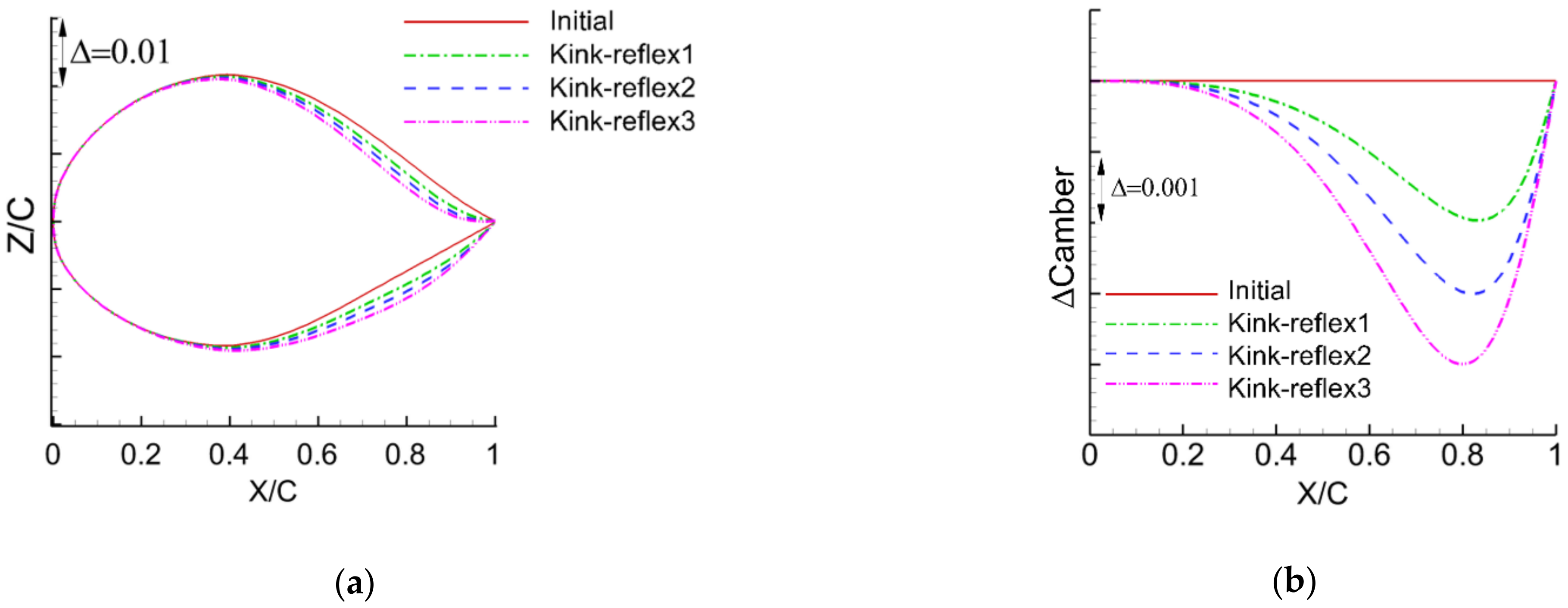

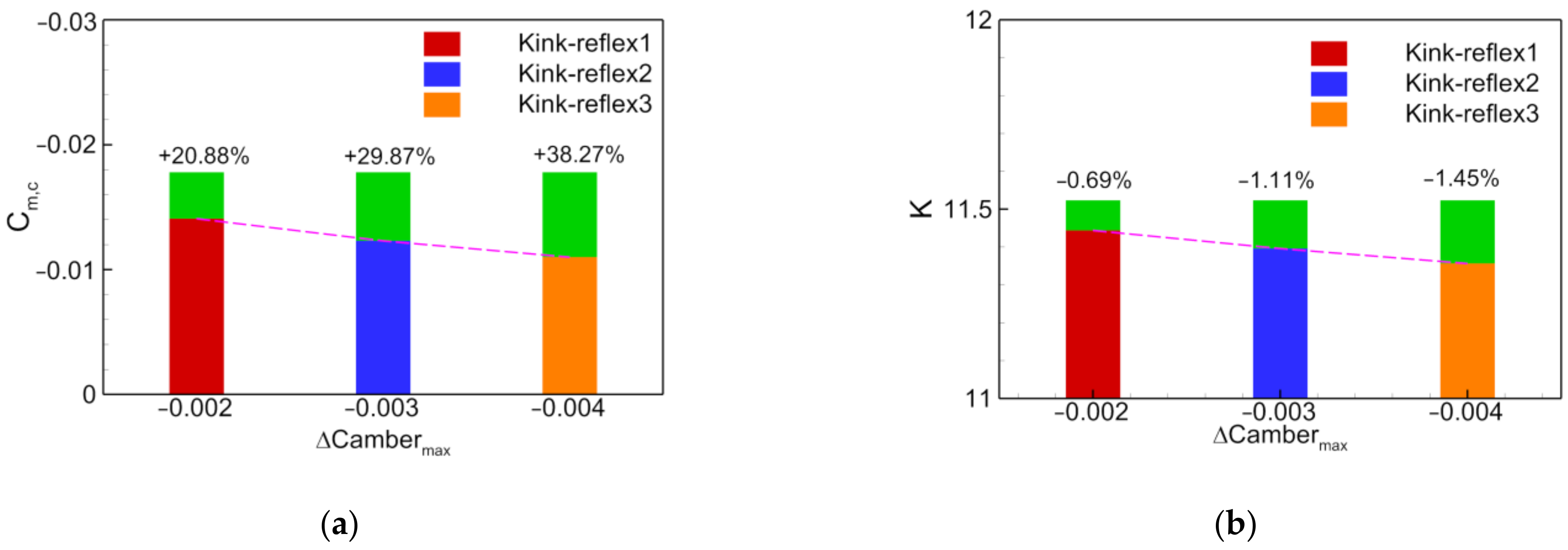

Figure 22.

The increments of Cm,c and K obtained by aft-reflexing the kink airfoil at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 22.

The increments of Cm,c and K obtained by aft-reflexing the kink airfoil at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

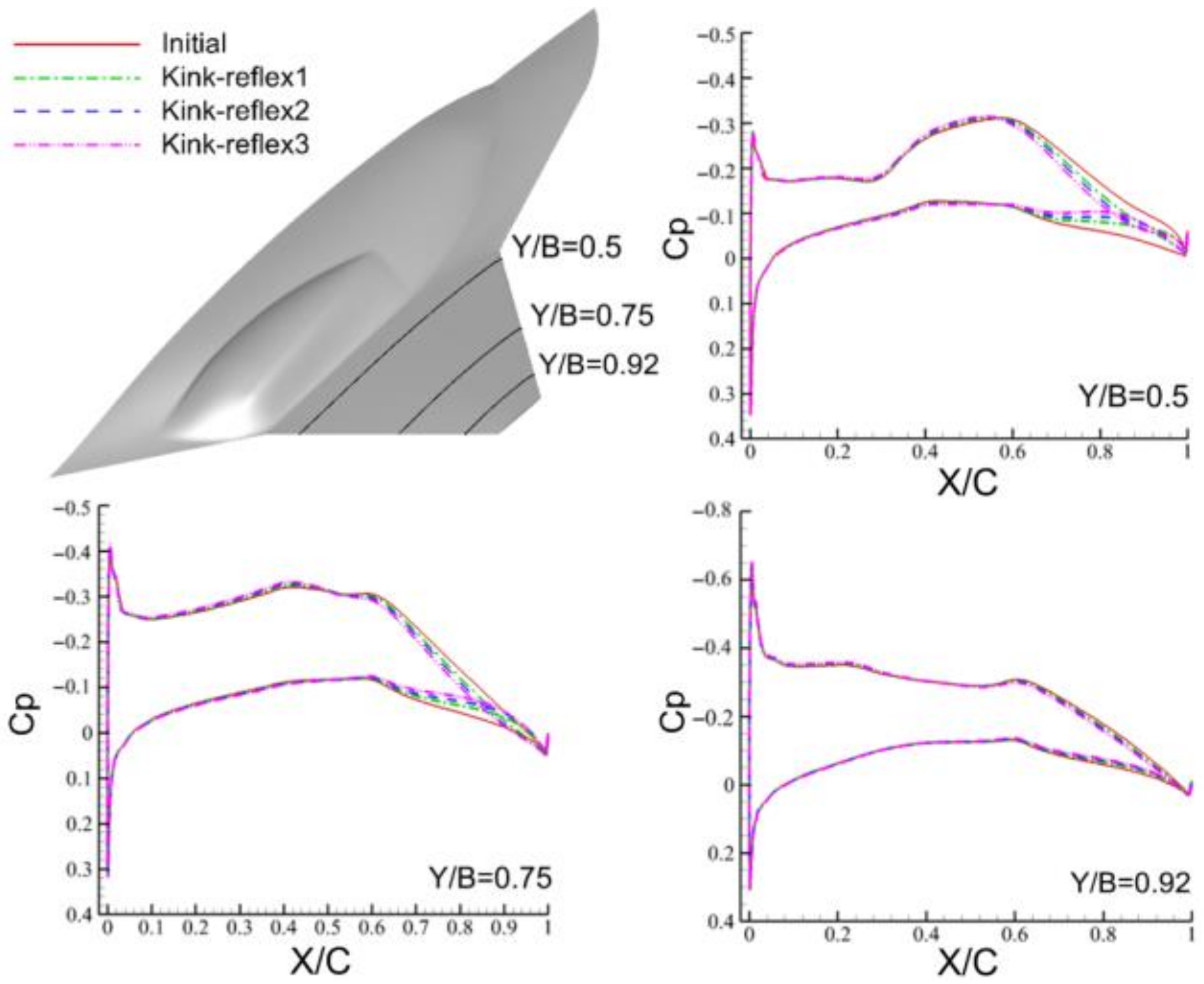

Figure 23.

Pressure coefficient distributions at typical sections of the different aft-reflexed configurations. Ma = 0.85, α = 2°.

Figure 23.

Pressure coefficient distributions at typical sections of the different aft-reflexed configurations. Ma = 0.85, α = 2°.

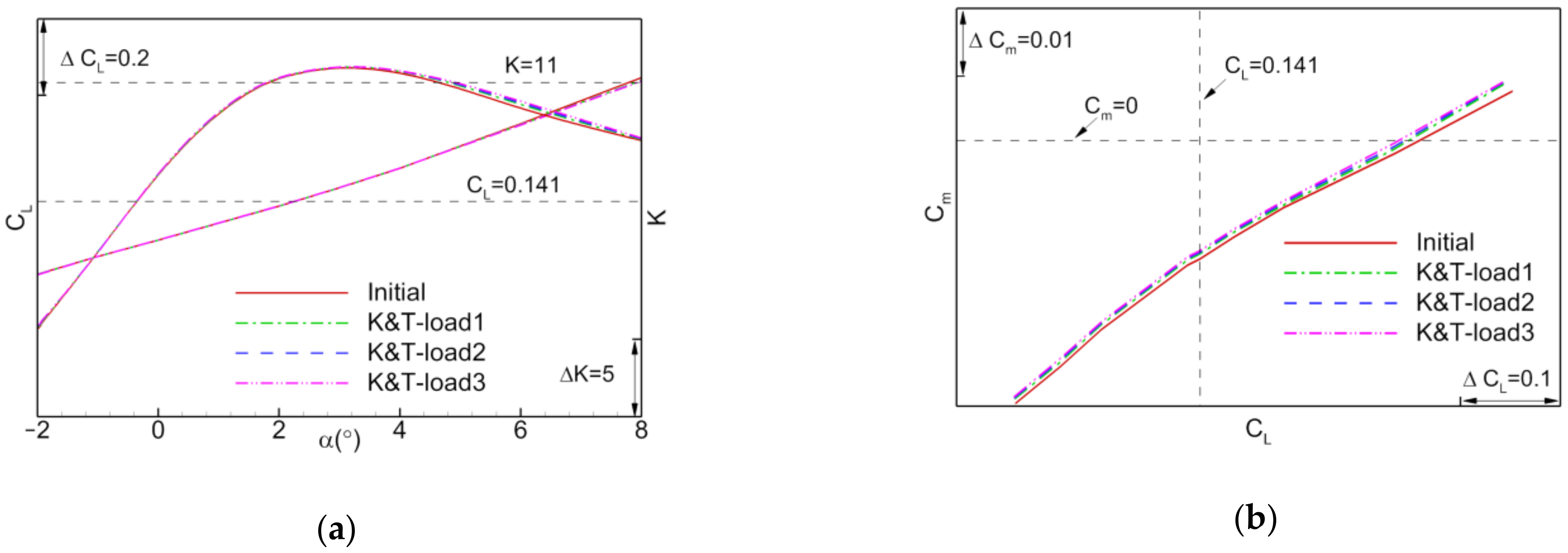

Figure 24.

Aerodynamic characteristic of the configurations with different fore-loading kink and tip airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

Figure 24.

Aerodynamic characteristic of the configurations with different fore-loading kink and tip airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) Pitching moment.

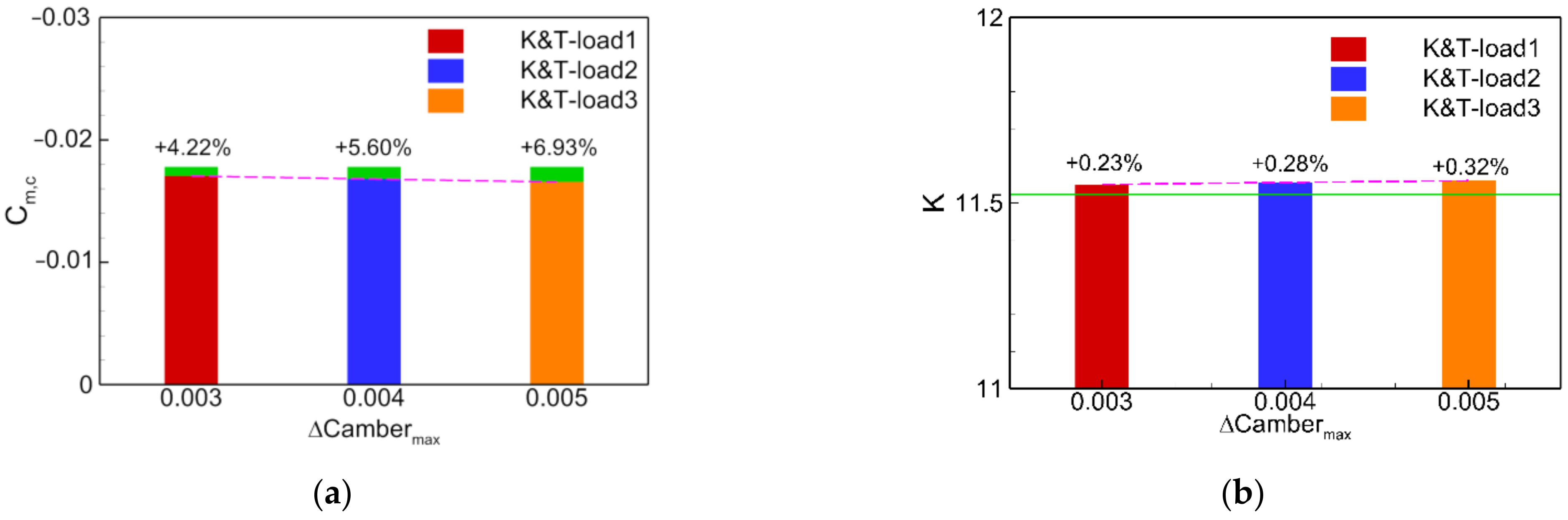

Figure 25.

The increments of Cm,c and K obtained by fore-loading the kink and tip airfoils at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 25.

The increments of Cm,c and K obtained by fore-loading the kink and tip airfoils at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 26.

Aerodynamic characteristic of the configurations with different aft-reflexing kink and tip airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) pitching moment.

Figure 26.

Aerodynamic characteristic of the configurations with different aft-reflexing kink and tip airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) pitching moment.

Figure 27.

The increments of Cm,c and K obtained by aft-reflexing the kink and tip airfoils at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

Figure 27.

The increments of Cm,c and K obtained by aft-reflexing the kink and tip airfoils at cruise state. (a) Pitching moment coefficient; (b) Lift-to-drag ratio.

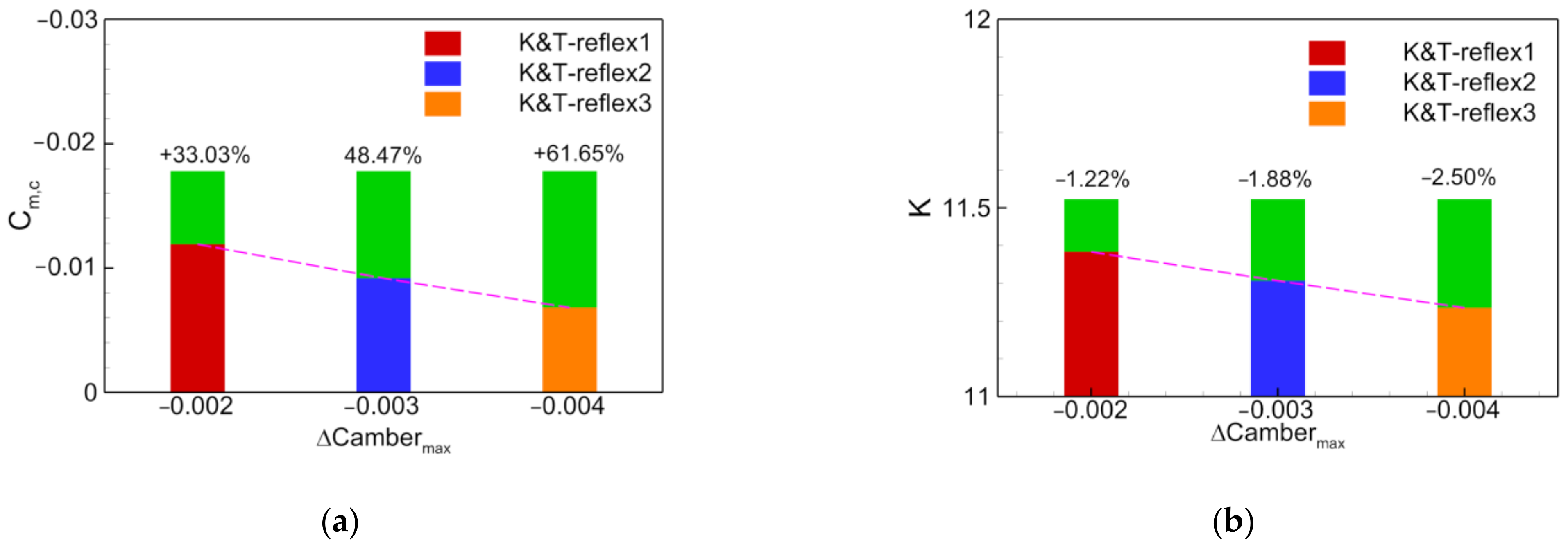

Figure 28.

The fore-loading and aft-reflexing modification of symmetrical plane airfoil. (a) Airfoils comparison. (b) Camber increments distributions.

Figure 28.

The fore-loading and aft-reflexing modification of symmetrical plane airfoil. (a) Airfoils comparison. (b) Camber increments distributions.

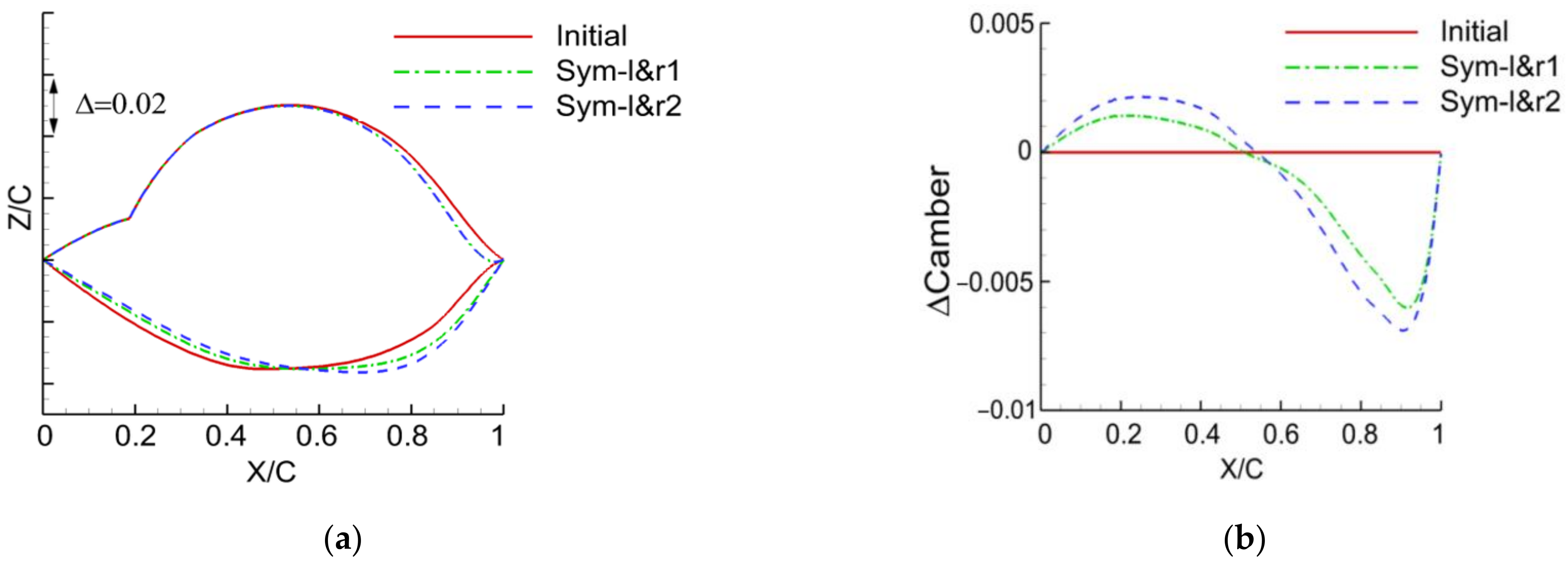

Figure 29.

Aerodynamic characteristic of the configurations with different symmetrical plane airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) pitching moment.

Figure 29.

Aerodynamic characteristic of the configurations with different symmetrical plane airfoils. Ma = 0.85, H = 11 km, . (a) Lift coefficient, lift to drag ratio; (b) pitching moment.

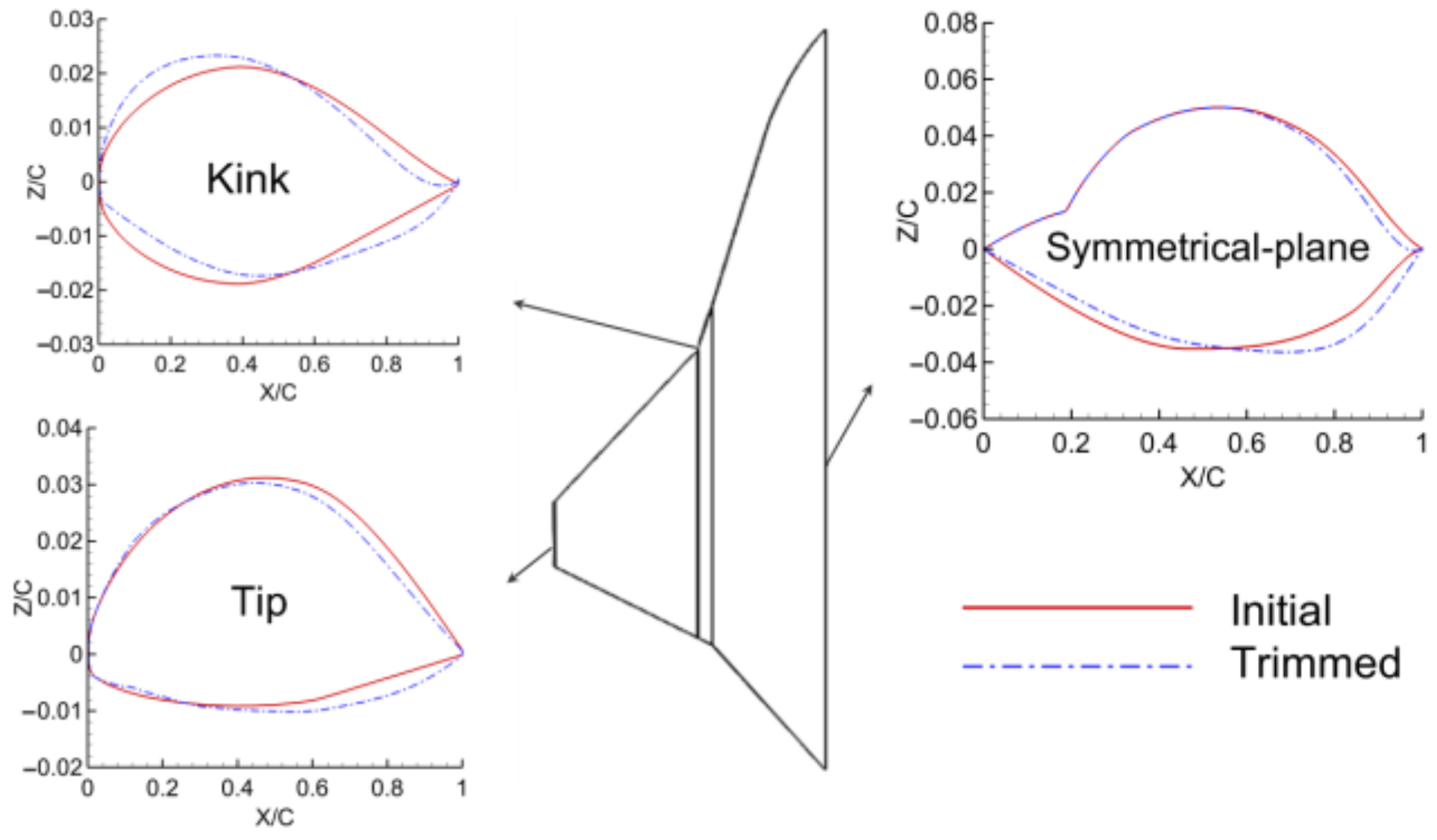

Figure 30.

The difference between the initial and the trimmed configuration.

Figure 30.

The difference between the initial and the trimmed configuration.

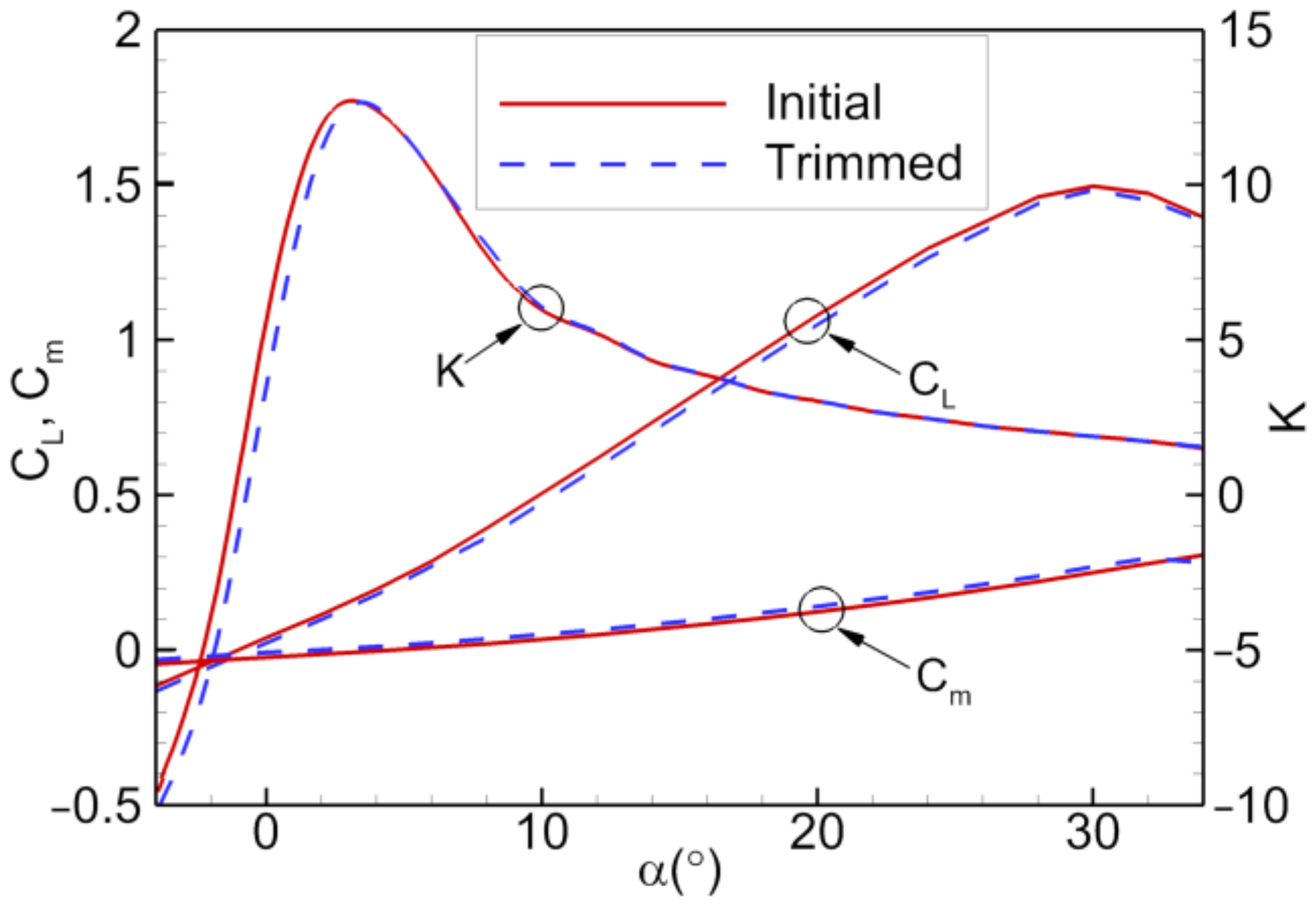

Figure 31.

Aerodynamic characteristic of the initial and trimmed configurations. Ma = 0.85, H = 11 km, .

Figure 31.

Aerodynamic characteristic of the initial and trimmed configurations. Ma = 0.85, H = 11 km, .

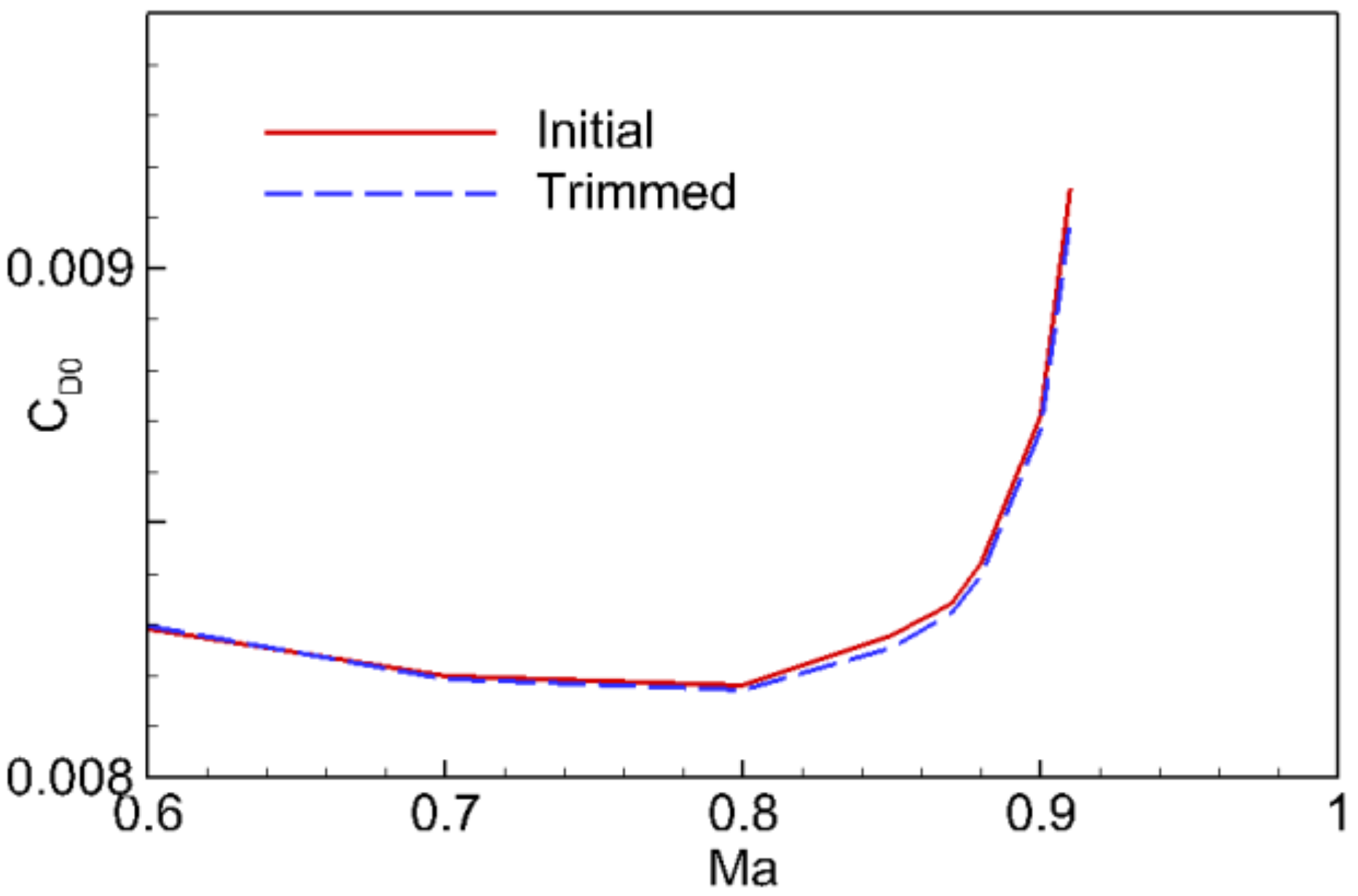

Figure 32.

The drag divergence characteristics of the initial and the trimmed configuration.

Figure 32.

The drag divergence characteristics of the initial and the trimmed configuration.

Figure 33.

The zero-lift pitching moment comparison of the initial and the trimmed configuration.

Figure 33.

The zero-lift pitching moment comparison of the initial and the trimmed configuration.

Figure 34.

Aerodynamic characteristic of the trimmed configurations at low-speed state. Ma = 0.2, H = 0 km, .

Figure 34.

Aerodynamic characteristic of the trimmed configurations at low-speed state. Ma = 0.2, H = 0 km, .

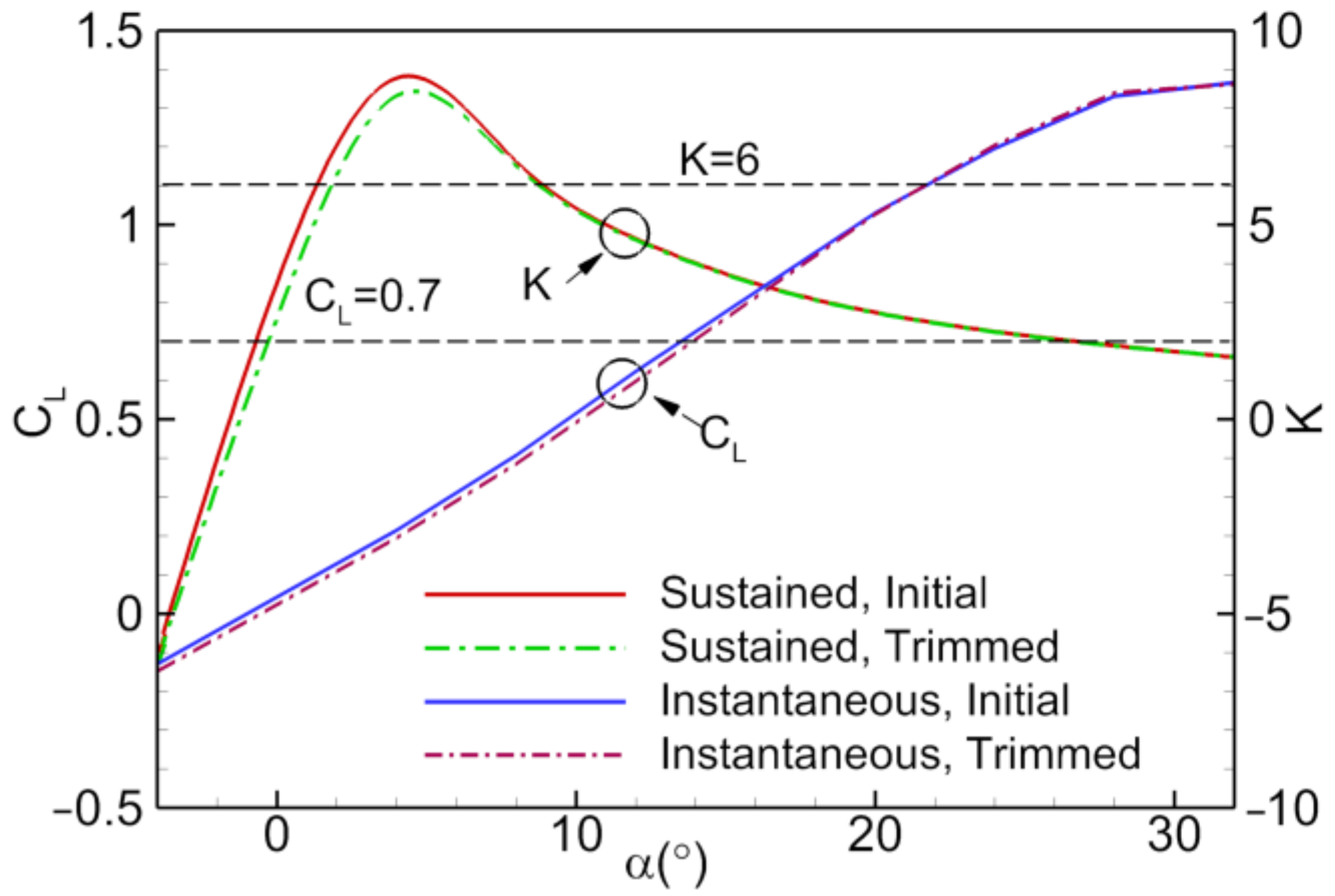

Figure 35.

Aerodynamic characteristic of the trimmed configurations at maneuvering state. Sustained turn state: H = 5 km, Ma = 0.9; Instantaneous turn state: H = 5 km, Ma = 0.6..

Figure 35.

Aerodynamic characteristic of the trimmed configurations at maneuvering state. Sustained turn state: H = 5 km, Ma = 0.9; Instantaneous turn state: H = 5 km, Ma = 0.6..

Figure 36.

Comparison of the wind tunnel and numerical results on the trimmed configuration. Ma = 0.85, Re = 7.1 × 106, . (a) Lift coefficient; (b) Drag coefficient; (c) Lift to drag ratio; (d) Pitching moment.

Figure 36.

Comparison of the wind tunnel and numerical results on the trimmed configuration. Ma = 0.85, Re = 7.1 × 106, . (a) Lift coefficient; (b) Drag coefficient; (c) Lift to drag ratio; (d) Pitching moment.

Table 1.

Computing states of LSSDW.

Table 1.

Computing states of LSSDW.

| Ma | Re | α | Description |

|---|

| 0.225 | 3.7 × 106 | 10.033° | strake/wing vortexes develop independently |

| 0.225 | 3.7 × 106 | 22.495° | vortexes interact; trailing edge vortex breakdown |

Table 2.

Forces results of Exp and CFD.

Table 2.

Forces results of Exp and CFD.

| States | Method | CN | CN%

| CT | CT%

| Cm | Cm%

|

|---|

| 10.033° | Calculation | 0.5027 | −0.06% | −0.0045 | −12.50% | 0.0315 | −4.26% |

| EXP | 0.5030 | 0 | −0.0040 | 0 | 0.0329 | 0 |

| 22.495° | Calculation | 1.1604 | 0.70% | −0.0189 | 5.50% | 0.0880 | −5.22% |

| EXP | 1.1523 | 0 | −0.0200 | 0 | 0.0923 | 0 |

Table 3.

Computing states of delta wing.

Table 3.

Computing states of delta wing.

| Ma | Re | α | Description |

|---|

| 0.85 | 6 × 106 | 18.5° | Pre-breakdown case |

| 0.85 | 6 × 106 | 23° | Post-breakdown case |

Table 4.

Results of different grids.

Table 4.

Results of different grids.

| Grid Name | Cell Number | CL | CD | Cm | Simulation Time (Hour) |

|---|

| Grid 1 | 1,064,960 | 0.03320 | 0.00583 | −0.01999 | 1.08 |

| Grid 2 | 2,075,008 | 0.03296 | 0.00579 | −0.01992 | 2.08 |

| Grid 3 | 4,013,056 | 0.03259 | 0.00571 | −0.01972 | 4.07 |

| Grid 4 | 8,160,896 | 0.03256 | 0.00569 | −0.01968 | 8.90 |

| Grid 5 | 15,883,677 | 0.03255 | 0.00567 | −0.01962 | 18.63 |

Table 5.

The pitching moment of each component.

Table 5.

The pitching moment of each component.

| Moment | Wing | Fuselage | Total |

|---|

| Cm0 | −0.0075 | −0.0284 | −0.0359 |

| Cm,c | −0.0112 | −0.0066 | −0.0178 |

Table 6.

The efficiency factor κ of fore-loading and aft-reflexing the kink airfoil.

Table 6.

The efficiency factor κ of fore-loading and aft-reflexing the kink airfoil.

| Method | κ |

|---|

| fore-loading | 0.0067 |

| aft-reflexing | 1.8 |

Table 7.

The efficiency factor κ of fore-loading and aft-reflexing the tip airfoil.

Table 7.

The efficiency factor κ of fore-loading and aft-reflexing the tip airfoil.

| Method | κ |

|---|

| fore-loading | 0.02 |

| aft-reflexing | 1.00 |

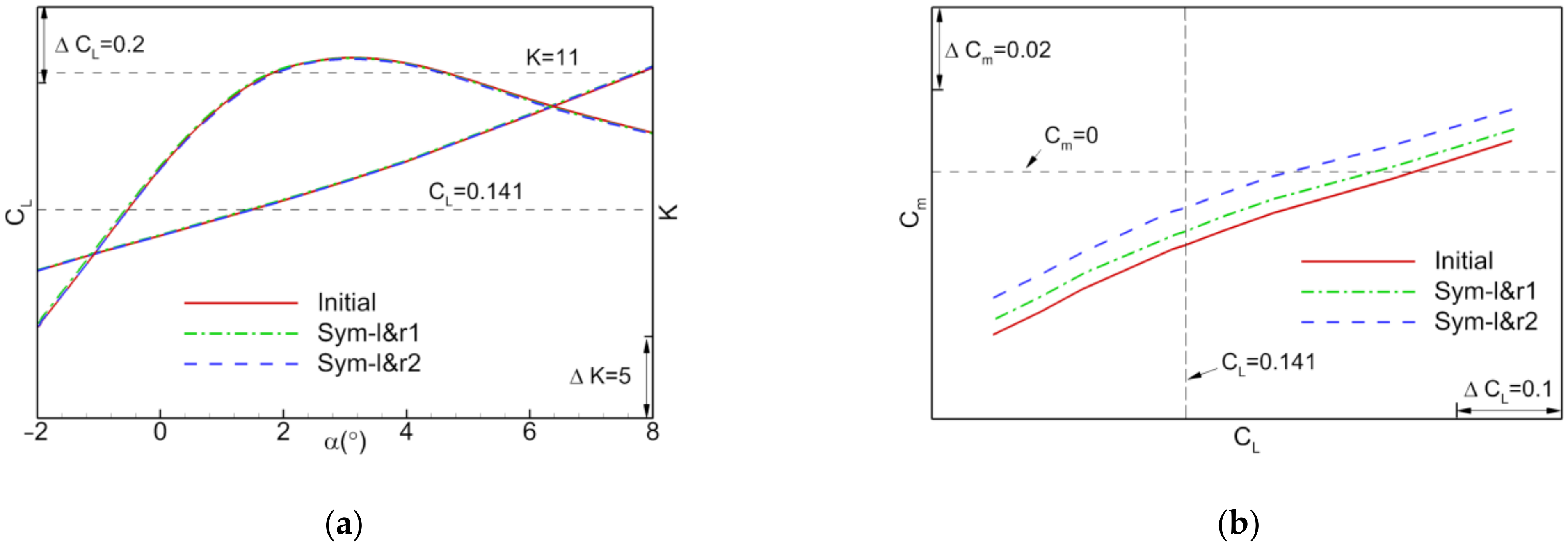

Table 8.

The pitching moment and lift-to-drag ratio of each configuration at cruise.

Table 8.

The pitching moment and lift-to-drag ratio of each configuration at cruise.

| Case

| Cruise Angle

| Cm,c | ΔCm,c%

| K

| ΔK%

|

|---|

| Initial | 2.26° | −0.0178 | - | 11.52 | - |

| Sym-L&R1 | 2.21° | −0.0144 | 19.10 | 11.49 | −0.23 |

| Sym-R&L2 | 2.28° | −0.0088 | 51.12 | 11.47 | −0.40 |