1. Introduction

Improvement of energy efficiency is one of the priority research areas for the construction engineers/scientists towards the mitigation of the socioeconomic challenges like climate change nowadays. Most countries have committed to the Paris Agreement by United Nations (UN) to pursue efforts to limit the extent of global average rise in temperature [

1]. European Union (EU) aims to achieve climate-neutrality by 2050 and wants to lead global efforts in this way. Buildings and the building sector as a whole are responsible for over 30% of the world’s total energy demand, and 40% of direct and indirect

emissions. The International Energy Agency (IEA) describes this sector to be a source of the enormous untapped potential of energy efficiency [

2]. A key part of the strategy is to maximize the energy efficiency of buildings [

3]. The increasing amount of research findings shows that the incorporation of PCMs in building/construction materials is an effective solution in new constructions and in retrofit solutions [

4]. PCMs are a promising passive cooling technology which can increase a building’s thermal mass in an effective way [

5,

6,

7,

8]. The use of thermal mass in the building envelope have been widely used historically as a thermal energy storage system (TES), and when utilized beneficially it can reduce heating and cooling loads, shift peak load hours as well as dampen the diurnal indoor temperature swings throughout the day [

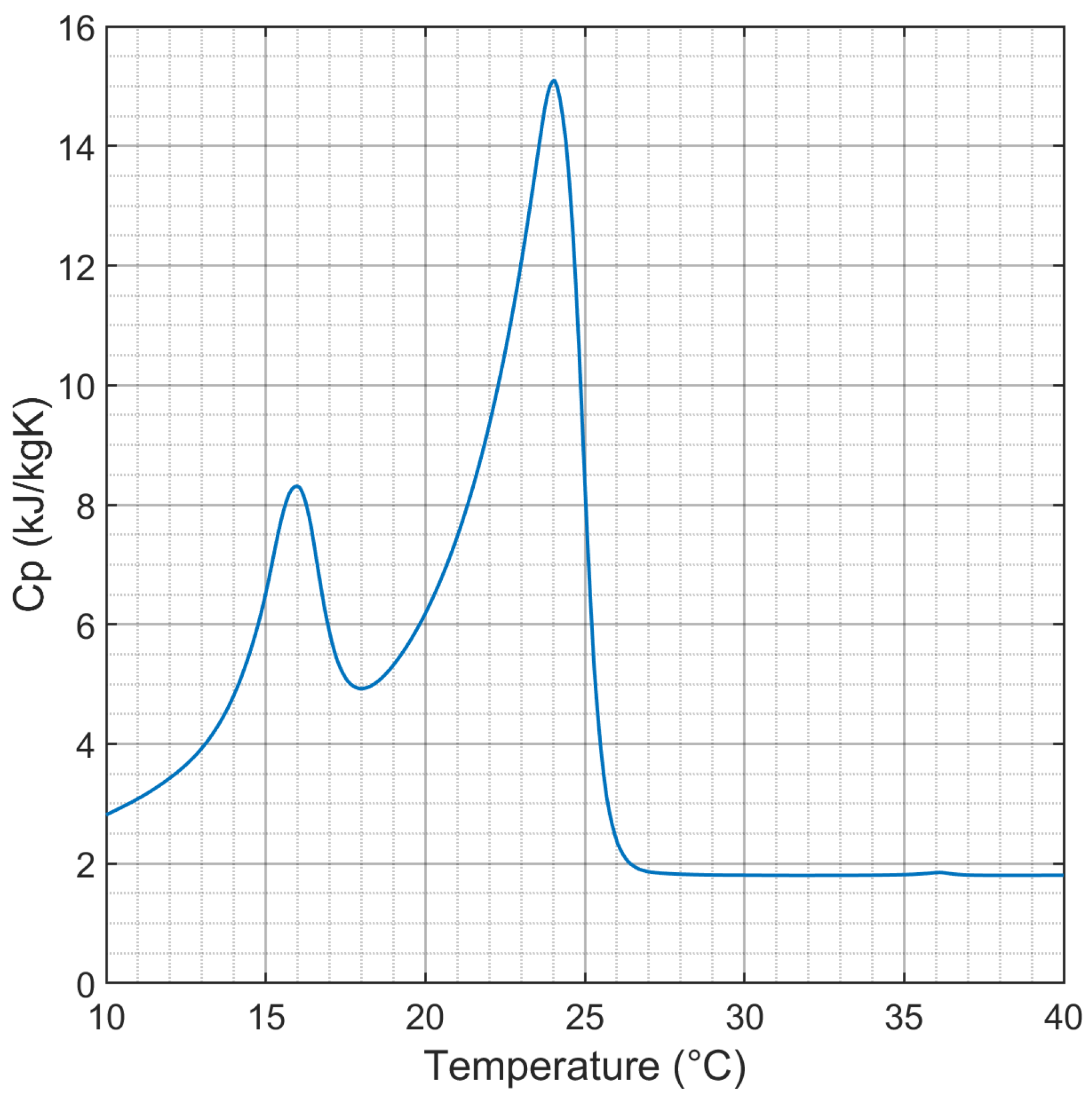

9]. The chemical composition of the PCM can be tailored to achieve suitable melting temperatures for a wide range of climates and environments, and this has been identified by numerous studies as the key design parameter for successful application of the material [

10,

11,

12,

13]. Indeed, PCMs are widely utilized in building materials. Among these, PCM enhanced wallboards/gypsum boards are one of the common techniques [

14,

15,

16,

17,

18,

19,

20,

21] used in the interior of the building.

However, several key challenges are to improve the thermo-physical properties, e.g., to increase thermal conductivity and latent heat of a PCM incorporated composite. Other important issues are to ensure complete melting-solidification cycle and to ensure the fire safety requirements. The benefits of heat storage in the PCM can be completely lost if incomplete charging occurs repeatedly [

10,

22]. Application of NV with PCM-integrated gypsum boards was investigated by Barzin et al. [

23] and a weekly electricity saving of 73% was reported in their study. The solidifying process can be assisted with enhanced convection, and a commonly proposed strategy is NV where air change rates are increased during night time to remove heat from the building. There is a great interest in coupling NV with free cooling by allowing cool ambient air into the building, which can enhance the heat transfer with the PCM considerably [

11,

12]. This is dependent on climatic conditions, and works best in locations with diurnal temperature variations of 12–15 °C [

24]. NV strategies utilizing free cooling can consist of mechanical ventilation solutions, natural solutions with window openings or hybrid systems which is a combination of both. While all variations can be equally adequate in priming the PCM for good performance, the highest energy savings benefit can be achieved in the natural strategy as ventilation fans can be shut off [

25]. Depending upon the building type, pure natural ventilation can often not be utilized efficiently. There are benefits by combining natural and mechanical ventilation strategies into hybrid NV and should be explored.

In their work, Geros et al. [

26] revealed three key parameters affecting the efficiency of strategies by experimental measurements in three office buildings in Greece, namely the indoor-outdoor air temperature differential, the useful air flow rate applied during night time and the thermal capacity of the building. Their results showed that during the night, the lower outdoor air temperature, and the higher supply airflow rate increase the efficiency of the NV. Additionally, the importance of thermal mass was clearly revealed in the experiments by increasing the buildings thermal inertia in cooperation with effective NV that produced a lower temperature development and delay in the peak indoor air temperature. Solgi et al. [

27] verified these conclusions in an experimental study that the key parameters for NV efficiency are the airflow rate, differential indoor-outdoor temperature and the thickness of the PCM layer, which is equivalent to an increase in thermal mass.

Simulations and experimental work on PCM wallboards installed in lightweight buildings are performed by Evola et al. [

28,

29]. They reported the air flow rate to be effective and one reaches a point of diminishing returns between 4 and 8 ACH. Zhou et al. [

30] simulated the effect of natural NV in a multilayered building with PCM and concluded that the number of ACHs should be as high as possible, where up to 40 ACH was tested. Whenever hybrid NV strategies are used, most studies report a critical value of airflow rates where the energy savings are starting to drop due to fan usage [

27]. In the recent study of Liu et al. [

31], the authors presented the climatic and seasonal suitability for the combination of PCM and NV. However, an important factor is the control mechanism for the NV strategy. Wang et al. [

32] analyzed three different control schemes in a similar climate and office building as in this report. It was reported that the most efficient strategy was the one which ventilated the office space excessively, where the NV control was not deactivated until the surface temperatures dropped below the outdoor air temperatures. Moreover, it was concluded that a strategy which prolonged the operational hours as long as possible, from 21:00–07:00 had a second-best effect. Roach et al. [

33] explored a custom control, which aimed at using NV until a certain set point temperature inside the building was reached. Setpoint temperatures of 13, 15, 17 and 19 °C was tested, and it was found that the strategy reaching the lowest indoor temperature was best for energy performance. However, this can lead to problems with overcooling in regards to thermal comfort for early working hours. They concluded that 15 °C could be the optimum set point temperature, but further research is needed. Upon researching more studies on control schemes, it’s noticed that no one-fits-all solution exists. Researchers explore different ideas based on the particular climate and building conditions of study. There is also a lack of recommendations in national standards on the details of NV control mechanisms.

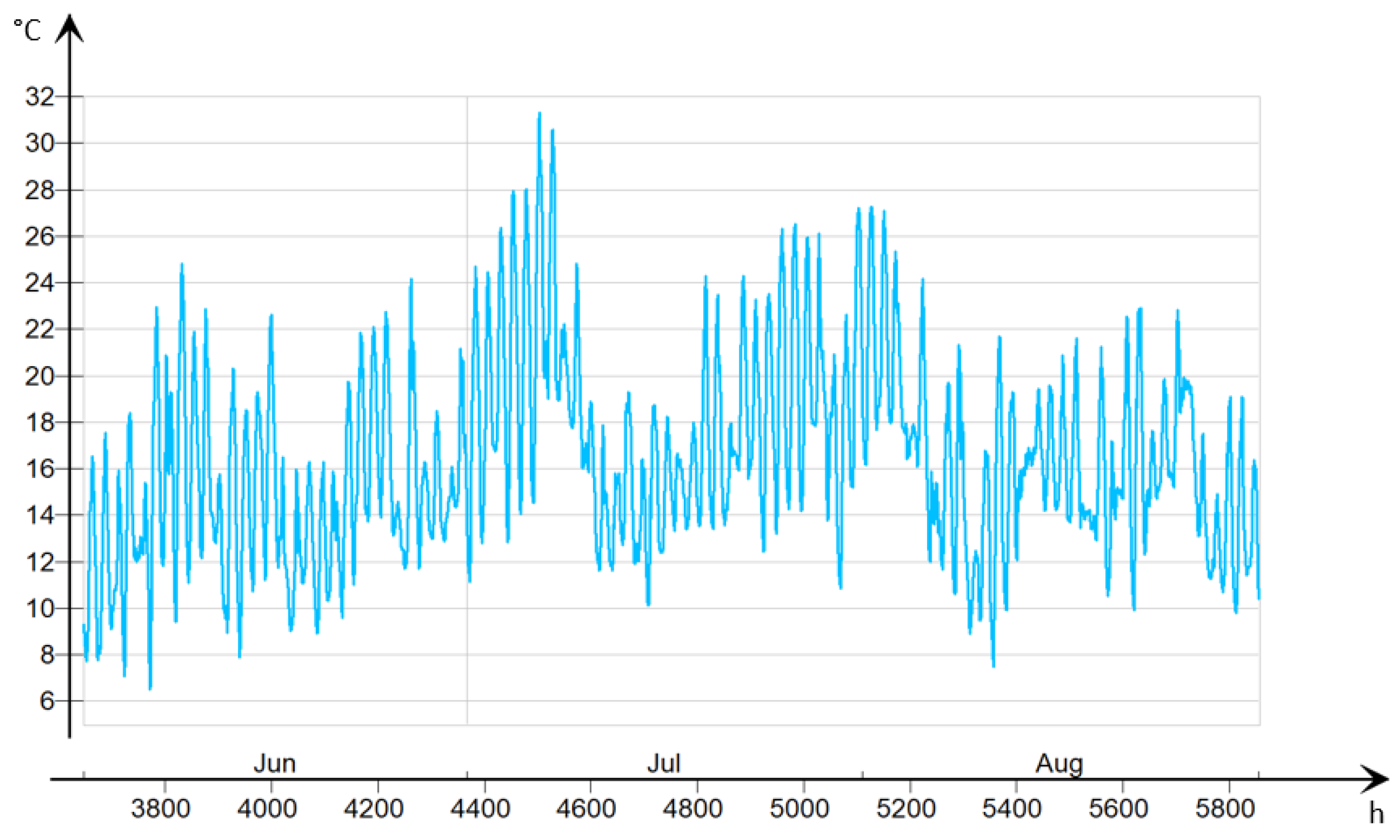

Studies related to quantification of the energy efficiency of buildings equipped with PCMs are not abundant in literature. This is partly due to the novelty of PCM enhanced building materials where few products are in a state to be readily incorporated in building applications, and partly due to the extent of study needed to properly analyze the energy efficiency. A sufficiently long time period with dynamic weather conditions should be investigated to produce reliable results. We summarize some relevant studies addressing the effectiveness of the PCMs for passive cooling in dynamic weather conditions in

Table 1. Note that the results are seldom directly comparable as the outcomes are dependent on many variables linked to the PCM, climatic conditions and test setup. The works presented in [

23,

34,

35,

36] showed high improvements to either cooling load power draw or reduction of accumulative energy usage by the combination of PCMs and natural NV. Mechanical cooling (air conditioning (AC) or heat pump) were used at night in [

37,

38,

39] to charge the PCMs. Although the results are lower in comparison with NV, significant improvements to the energy efficiency were still achieved. The remaining studies did not consider any cooling strategy of the PCM, and the benefits are subsequently lower.

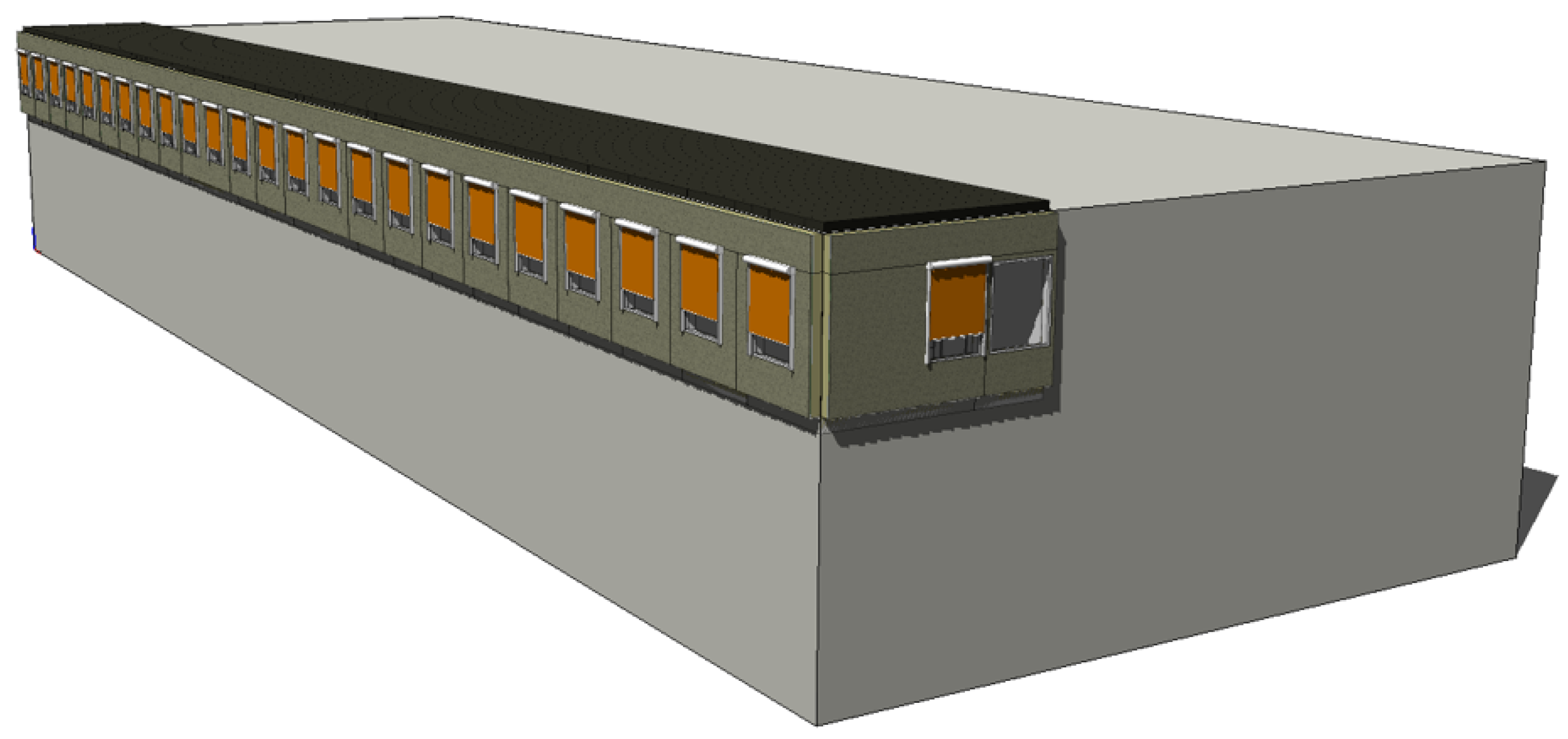

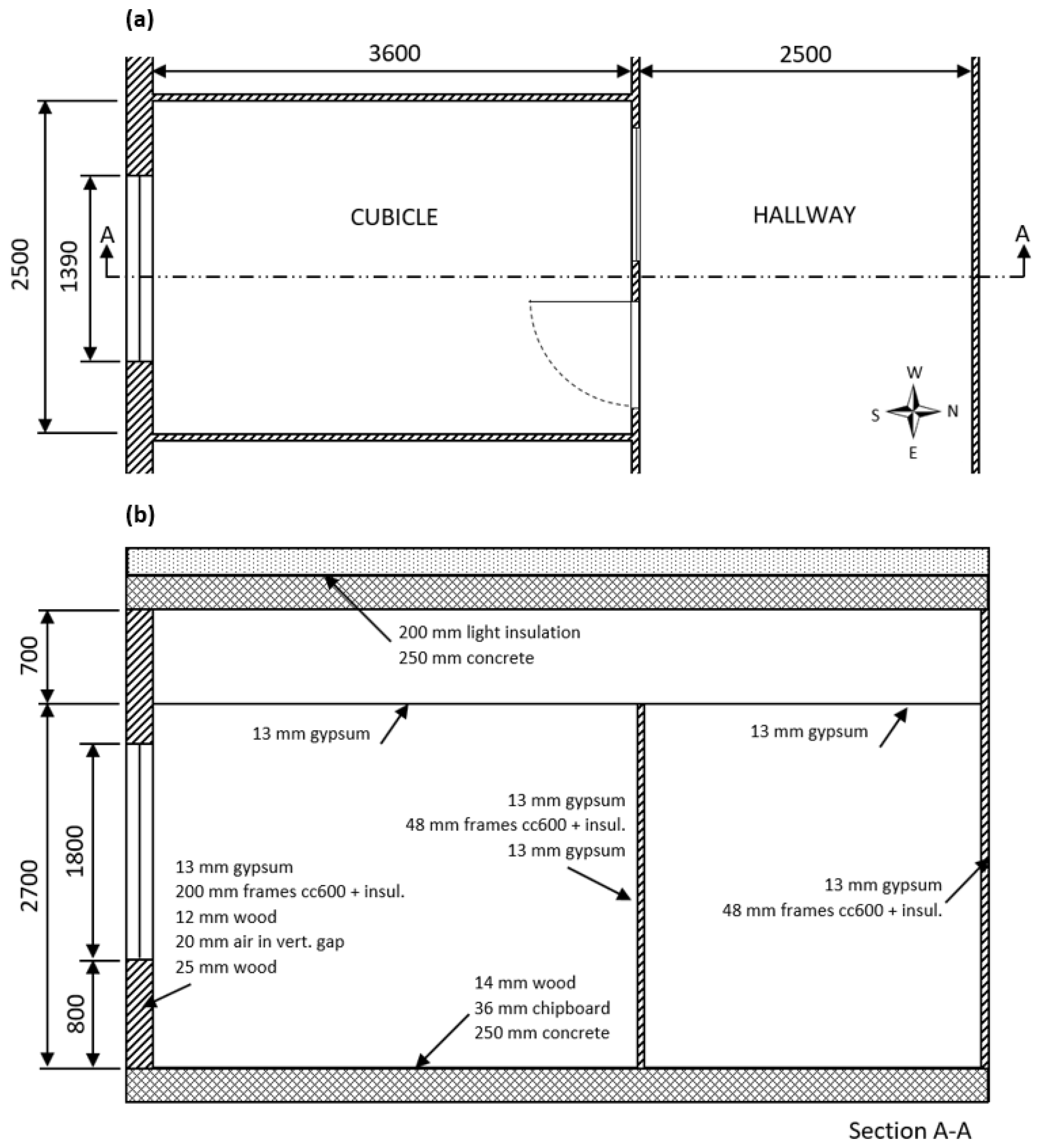

In the recent work [

43], the authors presented an experimental and a parametric study with a novel cost effective spackling material incorporated with microencapsulated PCM (MPCM) produced by Scanscap [

44]. It can be realized that a high production cost is involved in the process of making gypsum boards incorporated with MPCM. The spackling material (contains fillers, MPCM, rheological additives and binding agents) acts as a primer coating material at internal wall and ceiling surfaces of building envelopes for passive thermal management and is supposed to cover the entire surface. Additionally, the application of this coating material lies of the range of 1–4 mm at the internal wall and ceiling surfaces of a building. This can be achieved by very simple operations. One of the key advantages of this coating material is that a large surface area of the material can be available for direct and effective interaction with the air inside the building spaces. Moreover, spackling materials can easily be retrofitted into existing building mass as it can be applied to gypsum boards, plasterboards, concrete or bricks. In this work, we further investigate this novel MPCM enhanced spackling material in combination with NV in building applications. Summer conditions in the climate of Oslo, Norway, is chosen to study the spackling material mentioned above. A particular focus of this work is the realistic usage of the material in office environments, complying with the current Norwegian building code, TEK-17 [

45]. The work is organized as follows: in

Section 2 the methodology and the description of the case studies are presented. The detailed analysis of the results is given in

Section 3. Finally, the conclusions are drawn in

Section 4.

4. Conclusions

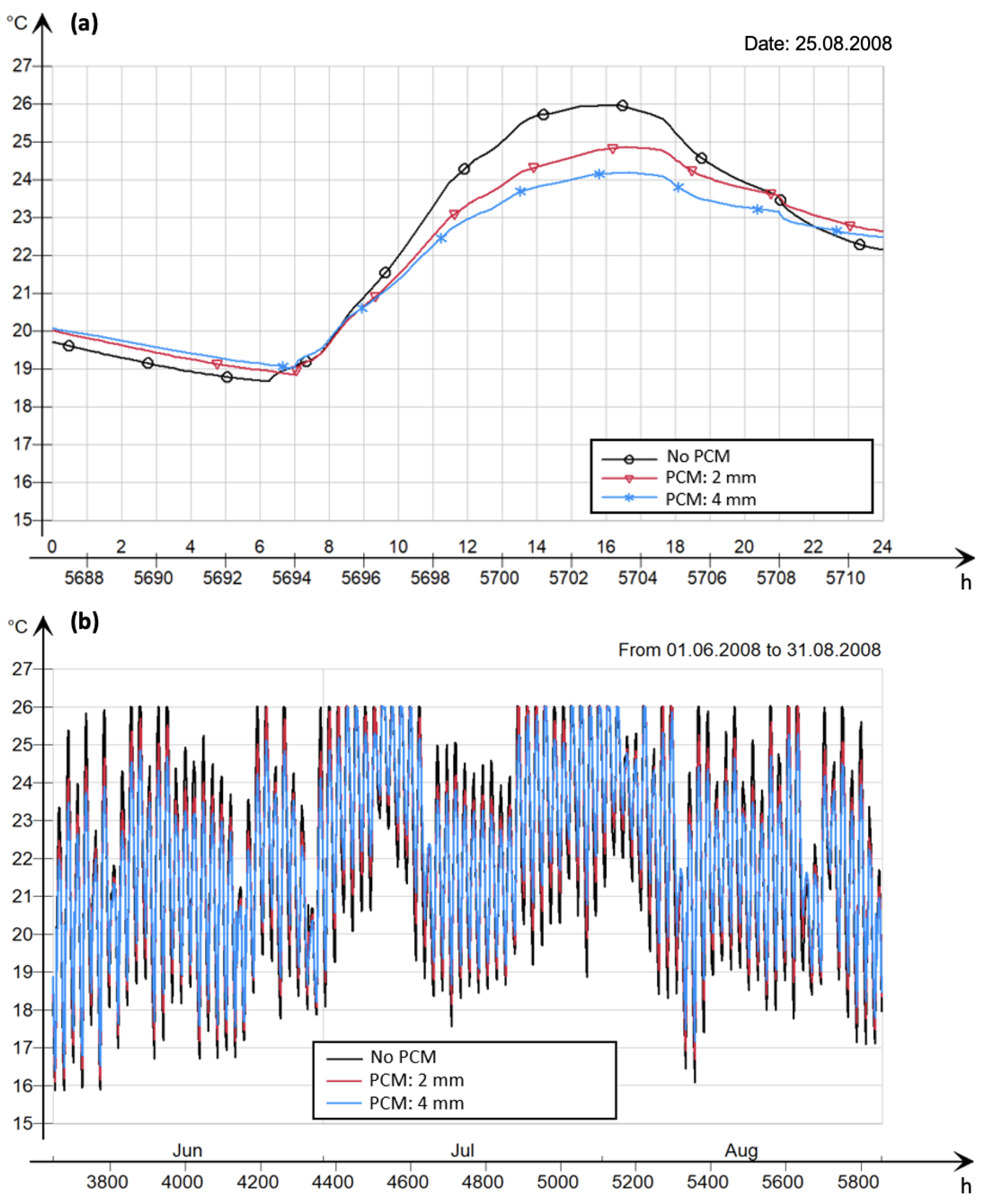

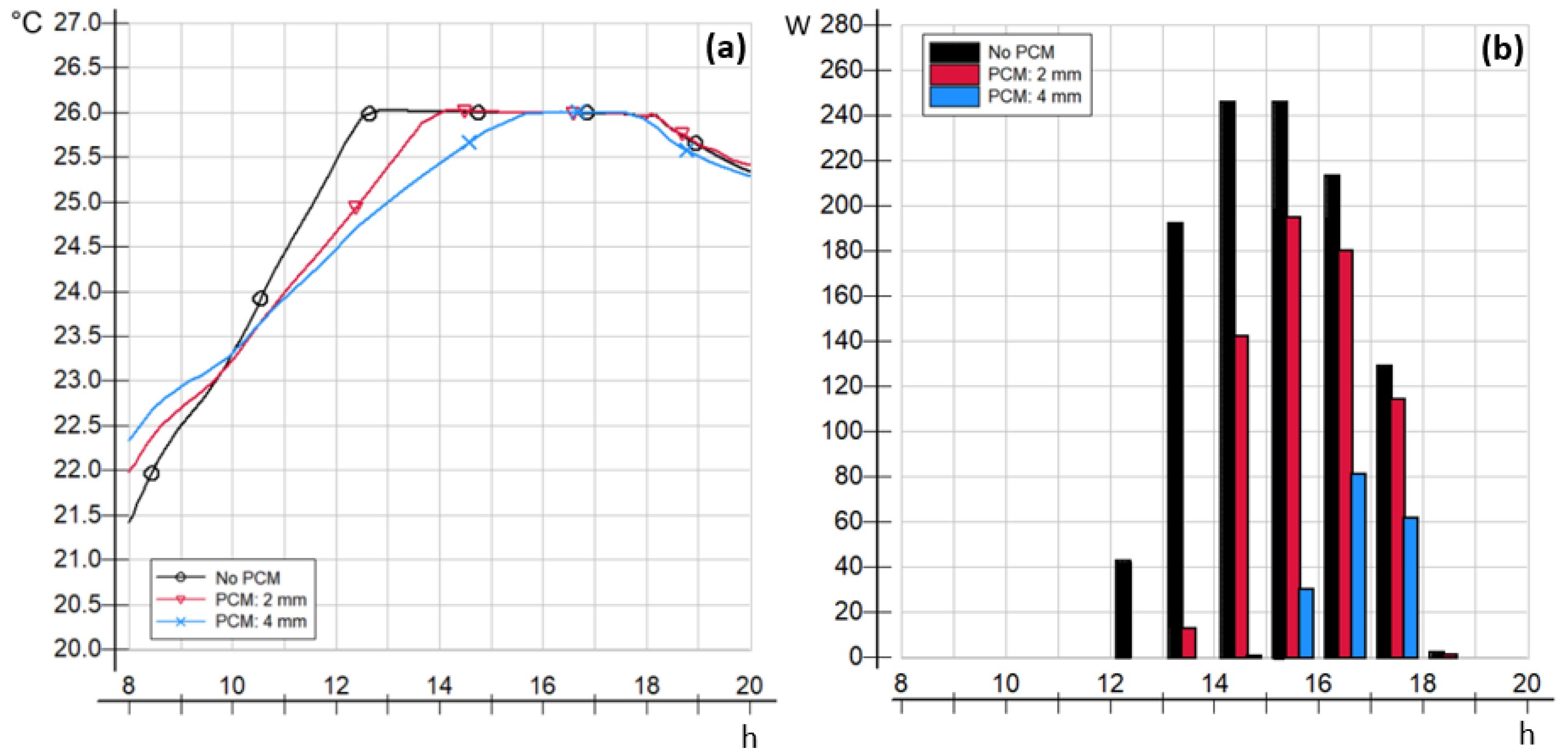

This study set out to investigate how a novel spackle material enhanced with microencapsulated PCM could improve thermal behaviour and cooling energy performance in an office building in a temperate cold climate during the summer. The studied application of the material is in the range of 2–4 mm on walls and ceiling surfaces in office cubicles coupled with NV as a strategy to charge the PCM during night time. The results reveal that although being applied only in thin layers it yields a significant boost to the thermal inertia of the environment, slowing down and reducing the indoor temperature development throughout the hot period of the day. This leads to better thermal comfort for the occupants by reducing the operative temperature, and also reducing the cooling load and energy requirement to maintain thermal comfort in buildings.

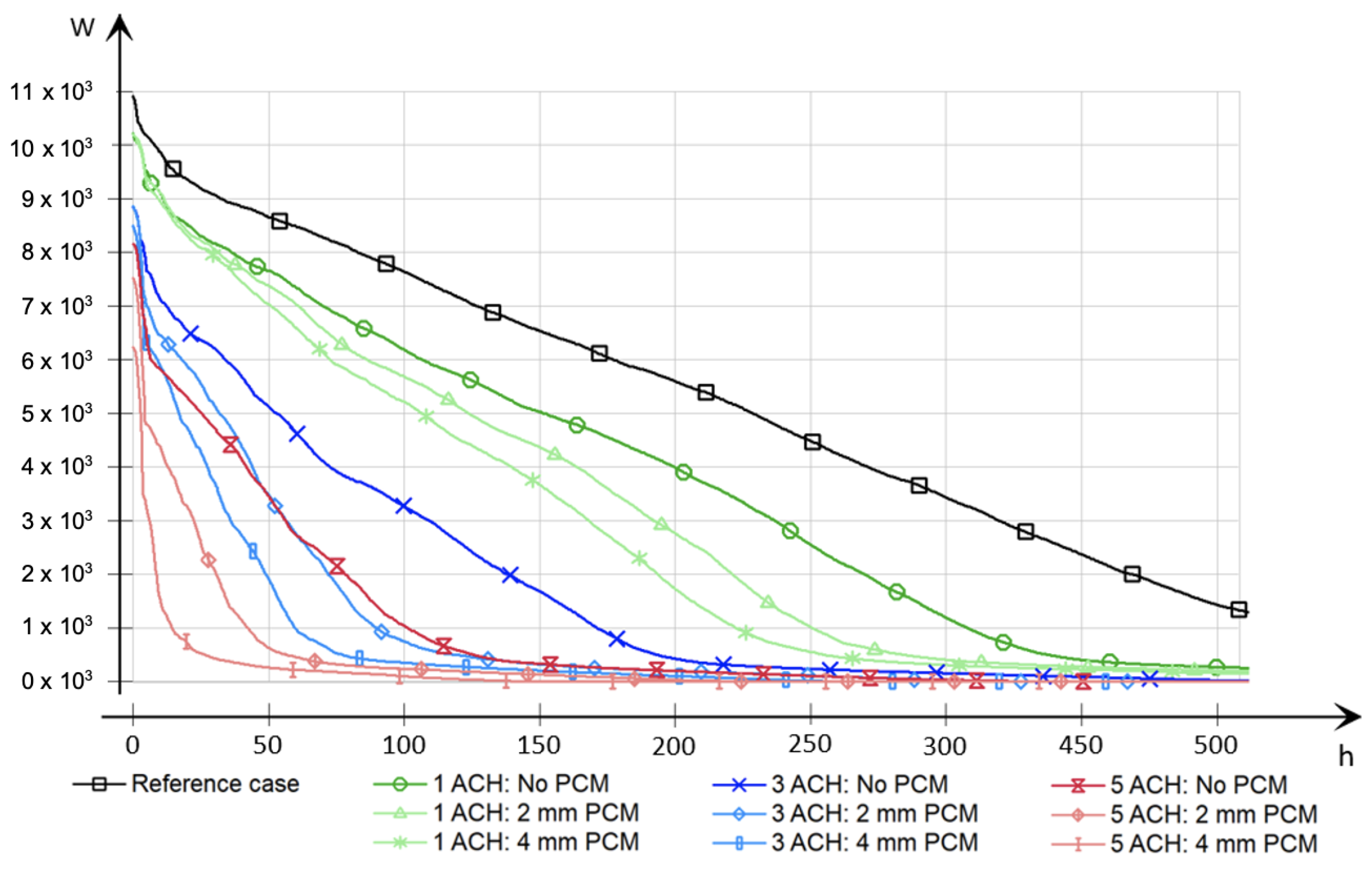

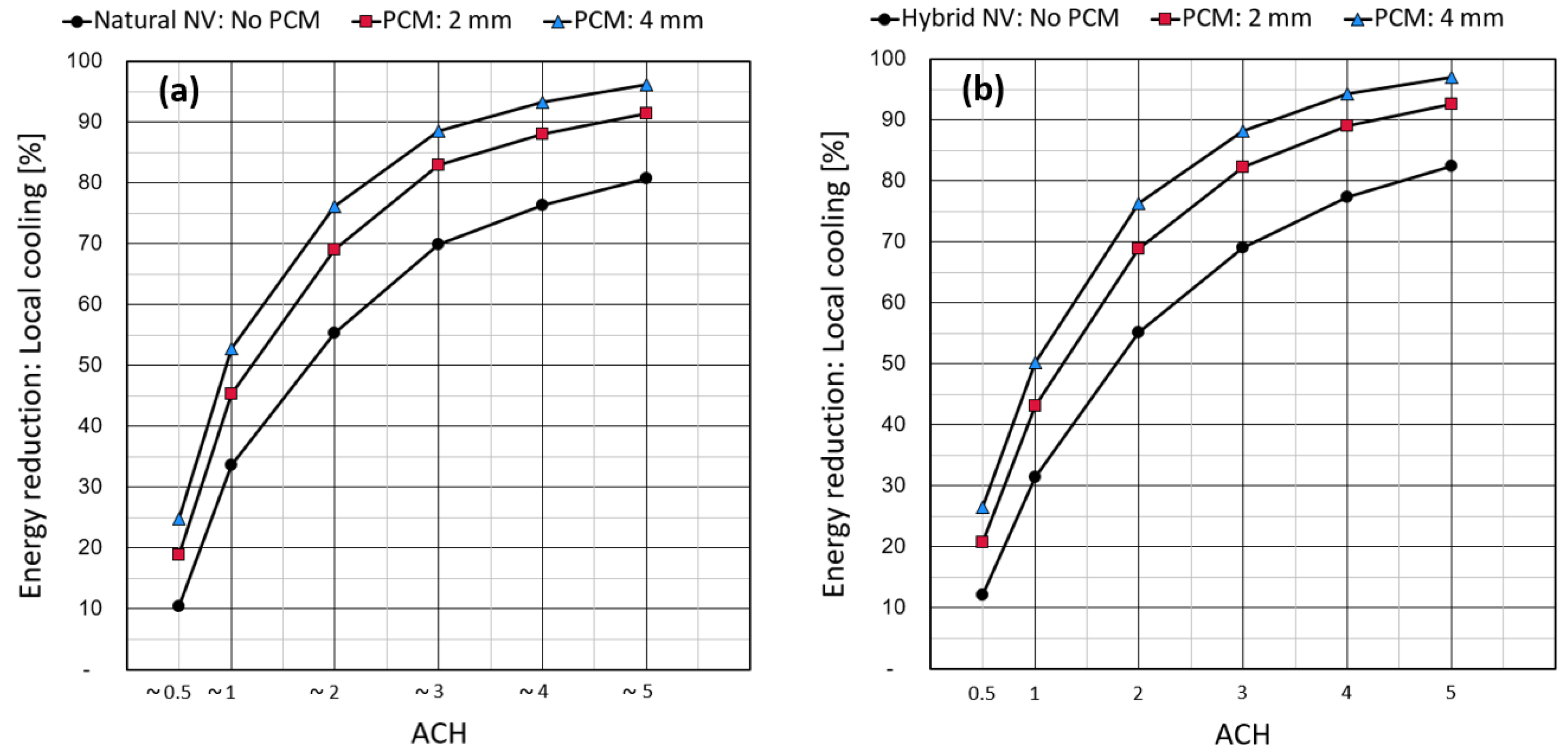

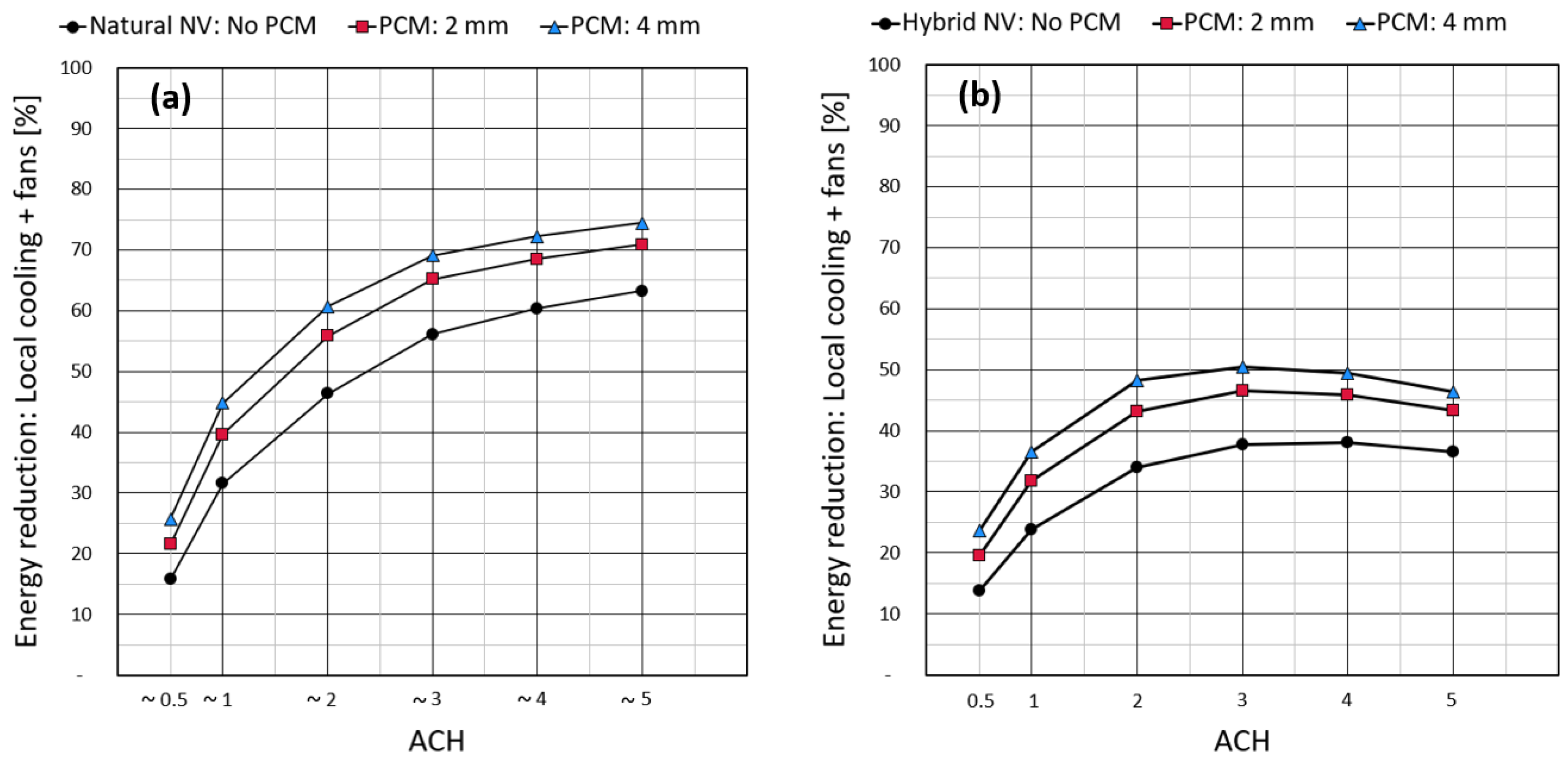

The analysis revealed that the application of 2 mm and 4 mm PCM spackling in each cubicle could contribute to a maximum of ≈14% and ≈21% additional energy savings for local cooling, respectively. These values are in addition to the very effective NV strategies which boosted the total energy savings to 70–95% from 2–5 ACH. However, going beyond 4 ACH gives diminishing returns in energy savings. When considering the total change in delivered energy to the building, we found that the natural strategy is more beneficial for energy savings for all the studied air flow rates, except for the very low air flow rate of 0.5 ACH where both strategies are equally effective. This is due to the ever increasing energy consumption of the exhaust fan in the hybrid strategy, and it is proven not to be worthwhile to pursue air flow rates higher than 2 ACH for this strategy. The energy savings would in fact start to decrease for the hybrid strategy when going beyond 3 ACH.

Overall, this study found that both PCM technology and NV strategies can contribute significantly to reduce the cooling demand and improve energy efficiency for office buildings in cold temperate climates. The high diurnal temperature variation during the summer is advantageous for utilizing NV and thus improve phase transition cycles of the PCM. The PCM spackling concerned in this study having a melting range of 20–24 °C is suitable for this climate, and the intended application of thin layers at inner building surfaces is favourable for heat exchange with the PCM. The authors recommend further work to investigate the effectiveness of the PCM at increasing layer thickness and perform multi-objective optimization considering different design parameters. In

Figure 10 and

Figure 11, it can be seen that increasing the PCM layer from 2 mm to 4 mm yields less returns in energy savings compared to the difference between no PCM and 2 mm PCM. This might indicate that the latent heat storage potential of the PCM is not fully exploited with 4 mm PCM in this case study. The methodology mentioned in [

28] for calculating PCM effectiveness can be a helpful method to correctly size the amount of PCM for a given building scenario. The PCM spackle can also be investigated with buildings geared towards passive house and nearly zero emission building (NZEB) standards as these thermal environments are known to have challenges with high indoor temperatures during the summer season. Use of PCMs in residential buildings will also be of interest, as the NV strategies designed in this study are better suited for commercial buildings that are vacant during nighttime.