Featured Application

The work may be of great practical importance due to the use of EM cultivation technology that reduces the consumption of fertilizers and pesticides, allowing for not only economic but also environmental effects.

Abstract

The aim of the work is to develop innovative technology for potato cultivation aimed at potato food processing with the use of effective microorganisms (EMs), limiting the chemicalization of agriculture. The basis for the research was a field experiment established by the randomized subblock method, in three repetitions, where two factors were examined: cultivation technologies (3) and potato varieties (14). The influence of experimental factors on the quality of French fries (FF) and potato chips (PC) was investigated. The water content was assessed by the drying method, and the fat content by the Soxhlet method. The sensory assessment was performed by a team of 10 panelists in accordance with EN ISO methodology. In the production of both FF and PC, cultivation technologies using EMs contributed to a significant reduction in the absorption of fats and a significant reduction in the disadvantages of FF, the so-called “dark ends”, and the sensory characteristics of these products have not deteriorated. Potato obtained from cultivation in the EM system is a better raw material for the production of FF and PC than potato from plantations without the use of effective microorganisms. The beneficial effects of these preparations depended on the exposure time to EMs and the potato variety.

1. Introduction

Continuous and excessive use of chemical fertilizers and pesticides causes ecological and health hazards, and it also worsens the physicochemical condition of the soil, causing a decrease in yields [1]. Organic sources play an important role in improving soil fertility and crop productivity. Recently, effective microorganism technology has been used in agriculture and forestry. This technology is completely natural and environmentally friendly. The products of this technology contain photosynthetic lactic acid bacteria, ferments, and products that arise as a result of the metabolism of these ferments and bacteria (enzymes, vitamins, etc.) [2]. Microorganisms metabolize organic matter, accumulating humus substances, which lead to the mineralization of organic compounds, thanks to which they re-circulate elements necessary for plant production. The technology of effective microorganisms (EMs) was developed in the 1970s at Ryukyus University, Okinawa, Japan. EMs comes in a liquid form that consists of naturally occurring beneficial microorganisms such as: lactic acid bacteria, actinomycetes, yeast, and photosynthetic bacteria [3,4,5]. The advent of multicultural technology of beneficial anaerobic and aerobic microorganisms is now gaining popularity due to its environmentally friendly nature. This effective microorganism (EM) technology uses naturally occurring microorganisms that are able to cleanse and enliven nature. Applications of EMs using a formula known as Effective Microbial Activated Solution (EMAS) have been researched in Japan, China, Malaysia, Russia, Poland, the Czech Republic etc., depending on scale, location, physical and geographic conditions, with the main goal of improving and improving water, soil, and food quality [3,4,5,6,7,8,9,10,11,12]. Atmospheric nitrogen-fixing bacteria play the most important role in this process, converting non-digestible forms of nitrogen into a form available to plants. Microorganisms contribute significantly to the improvement of soil structure. The mucus substances they produce stick to humus and mineral particles, creating a lumpy structure [13]. Microorganisms also produce bioactive material useful for plants, such as hormones and growth stimulants, which trigger cell division. In the group of biopreparations, the best known and most commonly used in agricultural practice are vaccines containing bacteria (rhizobia), which bind atmospheric nitrogen in symbiosis with the roots of legumes [13,14]. The technology of producing these vaccines involves collecting a collection of various strains of microorganisms and controlling their purity and quality (symbiotic effectiveness), which is a multi-stage process.

In Poland, the consumption of “fast food” products, which are rich in fat and include French fries (FF) and potato chips (PC), has increased significantly in recent years. Bearing in mind the health problem of overweight and obesity, we should look for ways to reduce the fat content of fried foods, including FF. Potato cultivation technologies can modify both the chemical composition of tubers and the quality of products obtained from them; however, there are no scientific reports on whether and to what extent these technologies, especially EM technologies, modify the quality characteristics of potato tubers, which determine their processing value [15].

Potatoes for food processing, especially for PC and FF, should be round to oval in shape and 40–75 mm in size. A particularly important parameter is the even distribution of reducing sugars on the surface of the cut tuber. Potatoes accumulating sugars around the vascular bundles or in the stolon or top part should not be processed into refined products [15,16,17]. In the case of FF production, tubers of oblong and oval shape, with a length according to classes: over 75 mm and over 90 mm, are the most desirable. An important feature is the even distribution of sugars in the tubers, because the so-called sugar end effect (brown FF ends) may not appear until after the second frying stage. The raw material for the production of FF should have a low darkening tendency of the raw flesh, because the FF technological process is much longer than that of PC, so that the shredded raw material may undergo enzymatic graying before it is blanched. Moreover, a potato intended for these purposes should be able to be stored for a long time [17,18,19,20,21]. Due to the negative impact of excessive chemization on the quality of the raw material, alternative solutions have also been sought in the agri-food processing industry [11,22,23,24]. Some of them are already used in industry and in households, e.g., yeast is used for the production of alcohol (wine, beer) and baking bread. Other known microorganisms are lactic acid bacteria, used in dairy processing to produce, among other things, cheese, and acetic acid bacteria, which are used to produce vinegar [25]. As a result of the use of EM technology, it is possible to neutralize, for example, food waste by decomposing it and deionizing heavy metal ions [11].

The use of EM-Farming biotechnology in agricultural processing ensures higher standards, while reducing the burden of work, which leads to a significant reduction in production costs [26]. Moreover, EM cultures have a high antioxidant potential. They are used in food processing, among other things, for the production of pectinases used for the clarification of fruit juices or of proteinases used in the processing of milk. EMs can also be helpful in processing potatoes into a refined product. Hence, research has been undertaken on the use of EMs in the production of potatoes for food processing into enriched products. The aim of this work is to develop innovative technology for potato cultivation useful for food processing, introducing the use of EMs while, at the same time, limiting the chemization of agriculture (consumption of mineral fertilizers and plant protection products). Moreover, the aim of the study was to determine the effect of EM application in potato production on the physico-chemical and organoleptic characteristics of selected potato cultivars and to assess their suitability for consumption and processing purposes. The article verifies an alternative hypothesis that utilizing EM technology in pre-emergence facilities by (A) soaking seed potatoes in EM-Farming solution for 10 min and (B) soaking the seed potatoes in EM-Farming solution for 20 min will ensure:

(a) a broader spectrum of EM antioxidant activity and will improve the parameters of potato raw material suitable for food processing into FF and PC;

(b) the reduction of environmental pollution and provide better pre-emergence treatments by reducing the use of mineral fertilization and pesticides, contrary to the null hypothesis that there are no differences between the EM variants and the no EM variants in potato cultivation.

2. Materials and Methods

The test results were based on a field experiment carried out in Parczew (51°38′24″ N; 22°54′02″ E; altitude above sea level: 148 m) in 2015–2017. Parczew is located in the mesoregion of southeast Poland, called West Polesie. The field experiment was carried out using the randomized block method in a split-plot, in triplicate, on soils made of medium or strong loamy sands with a good rye complex [27]. The 1st order factor was EM technology: (A) soaking the seed potatoes in a solution of the EM-Farming preparation before planting for 10 min (exposure I); (B) soaking the seed potatoes in EM arming solution for 20 min (exposure II); (C) a control facility, soaking seed potatoes in distilled water. The second order factor consisted of fourteen potato cultivars of all age groups: ‘Krasa’ (very early), ‘Bellarosa’, ‘Ewelina’, ‘Korona’, ‘Nora’, ‘Vineta’ (early), ‘Roxana’, ‘Nicola’, ‘Red Fantasy’, ‘Zuzanna’ (mid-early), ‘Czapla’, ‘Jelly’, ‘Oktan’ (mid-late), and ‘Hinga’ (late).

EM-Farming is a biological mixture of microorganisms of natural origin, which include lactic acid bacteria, photosynthetic bacteria, yeasts, actinomycetes, and mold fungi. This vaccine was developed by a microbiologist, professor Higa and Okumoto [5]. The EM preparation consists of lactic acid bacteria (Lactobacillus casei, Streptococcus lactis), photosynthetic bacteria (Rhodopseudomonas palustrus, Rhodobacter spae), yeast (Saccharomyces albus, Candida utilis), actinomycetes (Streptomyces albus, S. griseus), and molds (Aspergillus oryzae hiemalis) [3,7]. The EM-Farming preparation was used in the concentration recommended by the manufacturer.

2.1. Cultivation Conditions

The potato was grown annually after winter rape. In autumn, stubble plowing was used, then manure was brought in the amount of 30 t·ha−1, and it was plowed with deep plowing. In spring, the field was ground and harrowed, and the following mineral fertilization was applied: 100 kg N, 43.6 kg P, and 124.5 kg K ha−1, according to the abundance of these components in the soil. All fertilizers were applied once, before planting. Nitrogen was used in the form of 46% urea, phosphorus—in the form of granular superphosphate, 19%, and potassium—in the form of a potassium salt, 60%. Propagation material was in the C/A qualification. The tubers were planted from 24 to 26 April at a spacing of 67.5 × 33 cm. The area of plots to harvest was 17.8 m2. All treatments were carried out in accordance with the requirements of Good Agricultural Practice [28]. Weeds were destroyed by mechanical and chemical method. Mechanical treatments were applied to the emergence of potatoes and consisted of rolling and single dredging combined with harrowing. Just before emergence, the herbicide Dispersive Afalon 450 SC (1.5 dm3 ha−1) (2°–7° in the 99° scale of BBCH for potato) was applied, and in the phase of 2–3 leaves of monocotyledons (12°–13° in the 99° scale of BBCH), Fusilade Forte 150 EC (1.5 dm ha−1) or another herbicide that destroyed monocotyledonous weeds was applied. After that, no beauty treatments were carried out. During the growing season, sprayings were performed against of the Colorado potato beetle, which were combined with the destruction of late blight. Chemical plant protection treatments were applied using the pest harmful thresholds (98° in the 99° scale of BBCH) (Supplementary Materials, Table S1).The tubers were harvested with an elevator digger, in the period of technical maturity, in the groups of earliness varieties. For the assessment of FF and PC quality, 20 potato tubers, each with a diameter of over 55 mm and a length of about 7 cm, were collected from 10% of plants of each combination of a field experiment that were not green and were undamaged. For the evaluation of the PC, 20 tubers with a diameter of 45–55 mm, that were not green and were undamaged, were also collected [29].

The characteristics of potato varieties in terms of culinary suitability and resistance to viral, fungal, and potato cystic diseases are presented in Supplementary Materials (Table S2) [30,31].

2.2. Methodology for the Sampling and Assessment of Soil Sample

Before setting up the experiment, representative soil samples were taken annually, 20 from each field experiment, in order to determine the content of humus and soil pH and the content of basic macro- and micronutrients in the soil. Soil samples were collected with Egner’s stick [32]. The collected samples were homogenized. In the soil samples, the following parameters were determined: soil granulometric composition by laser method [32], pH—in 1 mol KCl dm−3 [33]; organic carbon content (Corganic)—by the Tiurin method [34], and, on its basis, the content of humus in the soil was determined. The content of available P2O5 and K2O were determined by the Egner–Riehm method [35,36], magnesium content—by the Schachtschabel method [37]—in the soil was also determined. The content of Cu, Mn, Zn, Fe, and B was determined in 1 mol of HCl [38,39], and the abundance was determined according to the limit numbers established for this extractant [40]. The chemical and physicochemical properties of the soil were determined in a certified laboratory of the District Chemical and Agricultural Station in Lublin according to the methods in force at chemical and agricultural stations in Poland.

2.3. Soil Conditions

The experiment was carried out on fallow soil with a sandy loam grain composition (World Reference Base for Soil Resources (WRB), 2014). In terms of the percentage of sand, silt, and clay fractions, it is a granulometric subgroup—clay sand (light soil). The sand fraction was 67.0%, the dust fraction was 30.6%, and the clay was 2.4%. This proportion of individual fractions corresponds to the composition of clay dust. The agronomic category of soils, based on the granulometric analysis, was defined as clay sand [40]. The content of humus in the arable layer of soil, determined by the Tiurin method, was 1.02%. This soil is classified in the agronomic category as light mineral. The experiment was carried out on soil made of light clay sands, weak rye complex, and valuation class IVb. The pH of the soil was slightly acidic to neutral. The soil was characterized by high to very high abundance in available phosphorus, moderate in potassium, very low in magnesium, high in boron, very high in iron, low in copper, average in manganese, and very high in zinc [40] (Table 1).

Table 1.

Physicochemical characteristics of the soil before establishing the experiment in 2015–2017.

2.4. Methodology of Assessing PC

Tubers to be assessed for PC were first washed thoroughly, the eyes were punched out, and the tubers were then sliced into 1.5 mm slices in a food processor. They were then rinsed with water to wash out the starch granules from disrupted cells, and then excess water was drained on filter paper. The research program was prepared on the basis of the Polish Standard “Potato products. Fried potato snacks” [41]. The PC was fried in vegetable oil, heated to 180 °C for 2 min in a fryer that met the requirements of Directive 2006/95/EC relating to electrical equipment intended for use within certain voltage limits. It was equipped with a thermal fuse to protect it from overheating. Sensory analyzes were performed by a team of 10 assessors. The panelists were selected and trained in accordance with the methodology contained in the EN ISO standard [42]. The assessment was carried out in the Laboratory of Plant Commodity Science, appropriately adapted to this type of research. Color, smell and taste, appearance, and humidity, as well as PC defects, were assessed, including the number of wet areas, local damage, and discoloration. The PC color was assessed according to the 9 color scale developed by the European Association for Potato Research in Wageningen, where: 9—light color, 8—gold color, 7—light gold color, 6—dark gold color, 5—golden brown color; 4—brown color, 3—dark brown color, 2—brown color, 1—burnt color. The remaining sensory assessments of PC were performed on a 5° scale. The water content in the crisps was determined by drying in an oven at 105 °C to constant weight [43], and the fat content was determined by the Soxhlet method [44]. The results of each evaluation were the mean of the ten laboratory replicates.

2.5. FF Testing Methodology

The tubers to be assessed (FF) were first washed, then peeled and sliced in a blender. FF were characterized by the following dimensions: 5 × 5 mm and a length greater than 7 cm. After rinsing in cold water, the cut pieces were blanched in water at 75–85 °C for 5 min. After drying on tissue paper, the FF was fried in an LFE BN type electric fryer. Liquid frying, produced on the basis of rapeseed oil, was used for frying. ‘Maestro Sol’, produced by ZT Kruszwica S.A., was used for frying. ‘Maestro Sol’ is produced from refined, domestic rapeseed oil and is characterized by a high smoke point, above 235 °C; a high resistance to transformations in fat during frying at high temperatures; and by a neutral taste and smell, which allows the natural character and aroma of fried products to be brought out. The portion for one frying cycle was 100 g FF per 3 L of frying product. FF was fried in one stage at 165 °C for 10 min. The frying time was selected in a trial experiment so as to obtain fries with an even dry matter content. The temperature of the frying process was controlled using a CIE 307 temperature recorder, equipped with a K-type thermocouple. Each sample was evaluated immediately after frying. Each trial was examined in ten technological repetitions. The samples of the fried fries were drained of excess fat on filter paper and tested. The organoleptic evaluation of the finished product was carried out at a consumption temperature of +65 °C by a team of ten, who were all properly trained, meeting the formal requirements. The assessment was carried out in the Laboratory of Plant Commodity Science, appropriately adapted to this type of research. In the sensory evaluation, the ISO point method was used [45], which consists of expressing the intensity of the perceived impression in the form of points on a scale. A large number of points corresponds to a high intensity of the sensory feature. Color, taste, smell, texture, moisture, fat content, and dark ends were assessed. The evaluation was carried out in a group of 10 trained persons according to the ISO standard [46]. Each sample was evaluated immediately after frying. Color evaluation was carried out according to the following scoring: 5—golden color, 3—slightly red-brown color, 1—dark brown color. The FF consistency was assessed on a 5° scale where: 5°—the surface is very crispy, the flesh is delicate; 4°—delicate surface, brittle flesh, very loose; 3°—the surface is sufficiently crunchy, the flesh is slightly grainy or slightly greasy; 2°—the surface is not very crunchy, the flesh is grainy or greasy; 1°—wrong surface, wrong a flesh, sticky. The FF humidity measurement was performed in accordance with the Polish Standard [47]. The fat content of FF was determined by the weight extraction method using a Soxhlet apparatus. Each rating was the mean of ten laboratory replicates.

2.6. Meteorological Conditions

The results of meteorological observations come from the experimental station in Uhnin, located 5 km south of Parczew. The meteorological conditions during the years of the study were varied. The highest rainfall during the potato vegetation period was recorded in 2015. Their distribution was not favorable for the potato because, during the vegetation period, there was a significant water shortage, especially in the period June–August. The Sielianinov hydrothermal coefficient defines the months of 2016 as: May, quite dry; June, optimal; July, quite humid; August, dry; and September, extremely dry. In 2017, the meteorological conditions changed dramatically. Optimal water supply of potato plants alternated, with a large shortage in the next month of vegetation. The Sielianinov hydrothermal coefficient defines May as optimal, June as very dry, July as humid, August as very dry, and September as fairly wet. The latter rainfall, however, did not affect the tuber yield formed earlier (Table 2, Figure 1).

Table 2.

Hydrothermal coefficient of Sielianinov * in vegetation periods (2015–2017) according to the meteorological station in Uhnin.

Figure 1.

Rainfall and air temperature during the potato growing season in the years 2015–2017, compared with the average long-term rainfall and air temperatures in the years 1971–2014, according to data from the Hydrological and Meteorological Station of the station in Uhnin.

2.7. Statistical Analysis

Statistical analyses were based on two-factor analysis of variance and T-Tukey’s multiple tests, with the assumed significance level p = 0.05. The models of analysis of variance with the main effects of the factors studied and their interactions were used. The detailed analysis only dealt with the main effects. The calculations were made with the SAS/STAT 9.2 software [49]. T-Tukey’s multiple comparison tests enabled detailed comparative analyses of averages by isolating statistically homogeneous medium groups and determining the so-called least significant mean differences, which, in Tukey’s tests, are marked by Tukey’s Honest Significant Difference (HSD) [50]. The calculated p-values determine the significance and magnitude of the impact of the studied factors on the differentiation of the results of the analyzed variables by comparing them with the most frequently accepted levels of significance (p = 0.05). In the case of detailed analyses based on T Tukey’s multiple tests, the assumed significance level was p = 0.05. The SPSS Statistics program was also used, which allows for conducting analyzes aimed at statistical description. The results of the work include the relative standard deviation (RSD), which is a special form of standard deviation. The formula for the relative standard deviation was used:

where s = sample standard deviation and = sample mean [50].

In addition, in order to determine the share of individual sources of variation in the total variability of the examined features, an assessment of variance components was carried out using the following symbols:

- −

- σs2 e—this is the assessment of environmental variability associated with repeated observations or measurements over three years of research;

- −

- σs2 G—assessment of genotypic (varietal) variability;

- −

- σs2 T—evaluation of technological (agrotechnical) variability;

- −

- σs2 p—assessment of phenotypic (total) variability.

The empirical of mean square values obtained from the analysis of variance were compared with their expected values. Solving the systems of equations in this way, an estimate of the variance components corresponding to individual sources of variability was obtained. Mutual relations between the determined evaluations of variance components and their percentage structure formed the basis for the evaluation of the influence of varieties and years on the variability of the quality characteristics of PC and FF [50].

Normalizing transformations were used for the characteristics expressed as a percentage [50].

3. Results

3.1. Quality Assessment of PC

The evaluation of the quality of the PC was carried out by determining the color, organoleptic and visual evaluation, humidity, wet spots, defects, and discoloration and fat content. The RSD result says that the standard deviation is only a few percent of the mean, which is quite small. It tells us too that the data is tightly grouped around the mean. RSD is also sometimes used for convenience, but it also gives you an idea of how accurate the data is in an experiment. The more accurate the data, the lower the RSD. The color was the most stable characteristic of the chips, while the most variable characteristics of this product were its humidity and wet places. The average value of the PC color was 7.4° on a 9° scale. Technologies using EMs contributed to the improvement of PC color in both exposures of EMs. The decrease in moisture of the PC did not occur until after prolonged exposure to EMs (Table 3).

Table 3.

The quality assessment of PC and their variability (RSD in %).

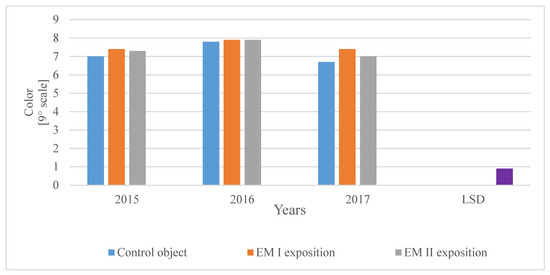

The effect of cultivation technology and the length of exposure to microorganisms (EMs) on the color of the potato chip (PC) depending on the meteorological conditions in the years of the study. Only in 2017, an unusual year in terms of the course of the weather, was a significant impact of the use of EM technology on the color of PC observed (Figure 2).

Figure 2.

Influence of EM technology and meteorological conditions in the years of research on the color of PC.

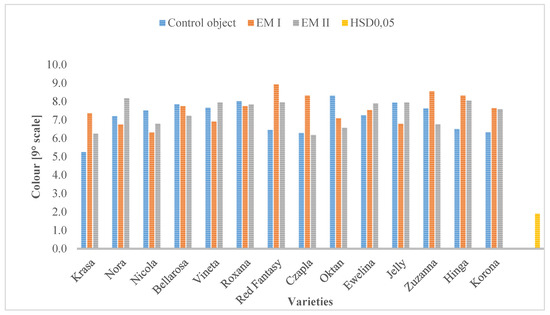

The features of individual varieties determined the value of PC to the greatest extent. The brightest PC color was that of the ‘Roxana’ variety, as it obtained the most desirable golden color. The following varieties turned out to be homogeneous in terms of the value of this feature: ‘Ewelina’, ‘Jelly’, ‘Zuzanna’, ‘Bellarosa’, ‘Vineta’, ‘Nora’, ‘Oktan’, and ‘Korona’. Th cultivars ‘Krasa’, ‘Czapla’, Bellarosa’, ‘Vineta’, ‘Czapla’, ‘Roxana’, ‘Red Fantasy’, ‘Jelly’, and ‘Hinga’ showed inadequate PC color (Table 3).A different reaction of individual varieties to the use of EM technology was found (Figure 3).

Figure 3.

Influence of EM exposure and meteorological conditions in the research years on the color of PC.

The cultivars ‘Krasa’, ‘Red Fantasy’, ‘Czapla’, ‘Zuzanna’, and ‘Hinga’ reacted with a significant improvement in the color of PC to the shorter EM exposure, compared to the control object. Among the examined cultivars, only ‘Oktan’ showed a negative reaction to a longer exposure of EMs, compared to the control object (Figure 3).

In the assessment of taste and smell, the PCs produced from the tested potato varieties scored 3.8° on a 5° scale. EM technology with pre-planting procedures did not deteriorate the value of this feature as compared to the control object (Table 3). The genetic properties of the tested potato cultivars determined the taste and smell of PC to the greatest extent. The highest, very good, grade was obtained by the ‘Jelly’ variety, while the cultivars ‘Red Fantasy’, ‘Nora’, ‘Oktan’, ‘Bellarosa’, ‘Roxana’, ‘Czapla’, ‘Hinga’, ‘Vineta’, and ‘Zuzanna’ turned out to be homogeneous in terms of the value of this feature. The worst taste and smell assessment were achieved by PC produced from the very early variety ‘Krasa’ (Table 3).

Assessment of the general appearance of PC was, on average, 3.7° on the 5° scale (Table 3). In both objects using EM, an improvement in the visual assessment of the PC was observed, but this fact can only be noted as a positive trend; however, it is not statistically proven. The hereditary features of the studied varieties significantly influenced the assessment of the PC appearance. The “Jelly” variety obtained a very good evaluation in terms of the value of this feature. The following cultivars turned out to be homogeneous in terms of the value of this trait: ‘Red Fantasty’, ‘Hinga’, ‘Oktan’, ‘Bellarosa’, ‘Czapla’, ‘Roxana’, and ‘Zuzanna’. The worst assessment of appearance was given to PC produced from the varieties ‘Krasa’ and ‘Nicola’, but the varieties ‘Korona’, ‘Nora’, ‘Vineta’, and ‘Ewelina’ were also included in the same homogeneous group (Table 3).

The average humidity of the potato PC was 2.1%. It should be added that the PC should be fried to a moisture content of 0.7–2%. The EM technology did significantly affect the value of this feature, but only the variants with longer EM exposure significantly reduced the humidity of the PC (Table 3). The PC obtained from the ‘Nicola’ and ‘Krasa’ cultivars had the highest humidity. The following turned out to be homogeneous in terms of this feature: ‘Bellarosa’, ‘Nora’, ‘Red Fantasty’, ‘Roxana’, ‘Ewelina’, ‘Zuzanna’, and ‘Korona’, while the lowest humidity was noted for those potato products produced from tubers of the ‘Vineta’ variety; ‘Hinga’, ‘Vineta’, ‘Czapla’, ‘Oktan’, and ‘Jelly’ turned out to be homogeneous due to the value of this feature (Table 3).

The average share of wet places in this potato product was at the level of 2.6%. Very good quality PC should have no more than 2% with this disadvantage. The 1st order factor, which was the technology that used EM biopreparation on the tubers before planting, increased the occurrence of wet places in objects with shorter exposure to EM, but in the variants with longer exposure to the application of pre-planting treatments with EM, compared to the control object, there was a reduction in the share of wet places in this product. The value of this trait was influenced by the differentiating genetic properties of the studied varieties. Only PC produced from the ‘Czapla’ variety did not have moist places, while the largest share in this product was observed for the chips produced from the ‘Nora’ variety. The following cultivars turned out to be homologous in this respect: ‘Hinga’, ‘Jelly’, ‘Red Fantasy’, ‘Oktan’, ‘Roxana’, ‘Vineta’, ‘Zuzanna’, ‘Ewelina’, ‘Krasa’, ‘Nicola’, and ‘Korona’ (Table 3).

The average fat content of the PC was 24.6%. The EM technology, in both exposures with the use of the EM-Farming biopreparation, significantly reduced fat absorption. Among the examined cultivars, the highest fat content was found in the chips obtained from the cultivars ‘Czapla’ and ‘Krasa’. On the other hand, the following varieties were characterized by the lowest fat absorption: ‘Red Fantasy’ and ‘Roxana’, while the remaining ones turned out to be varieties in the third, homogeneous group in terms of the value of this feature (Table 3).

The proportion of PC with defects and discoloration was, on average, 5%, while a good quality product should have no more than 3% of defects in the case of small chips, and 0% in the case of large ones. The use of EM technology contributed to an increase in the share of PC with discoloration, both in shorter and longer exposures, compared to the control object (Table 3). The varietal features significantly determined the value of the share of PC with defects and discoloration. The highest share of PC with this unfavorable feature, in terms of processing, was noted for the medium late variety of Czapla’, and the lowest was noted for the late ‘Hinga’; the cultivars ‘Zuzanna’, ‘Jelly’, and ‘Nora’ turned out to be homogeneous in this respect and can be classified as cultivars with little tendency towards defects and discoloration. The other varieties belonged to the group with an average share of discoloration in the chips (Table 3).

In general, the best results in terms of color, taste, smell, and absorbency of fat were obtained by the chips made from tubers of the ‘Red Fantasy’ variety, followed by the ‘Roxana’ variety (Table 3).The influence of meteorological conditions during the years of the research did not play a significant role in the assessment of PC quality features such as color, taste and smell, general appearance, and humidity; however, the remaining quality characteristics of this product were significantly related to the weather conditions during the years of the experiment. These features were the fat content of the PC, wet places, and their defects and discoloration. The highest fat absorption by PC and the highest share of products with discoloration were obtained in the last year of the study, which had unfavorable weather conditions for the growth and development of potato plants (Table 3). The highest participation of PC with the disadvantage of wet places was recorded in 2016–2017, compared to the favorable course of the weather in 2015.

The evaluation of the variance components (Table 4) indicates that the share of genotypic variation was the highest for the color of the chips and the fat content in this product. The EM cultivation technologies had a significant impact on the following quality characteristics: color, wet places, defects and discolorations, and fat content. The share of technological (agrotechnical) variability in the overall phenotypic variability ranged from 10.1% to 13.7%. The participation of the random factor, which is years, had a share from 3.7% to 24.6% in the total variance. The highest share of this factor was found in the case of the oiliness of the PC (24.6%), and the lowest was in the case of the PC appearance (4.6%). The interaction of EM technologies × varieties had a significant effect only on the color of the PC, and the share of variability for this interaction in the total variance was 20.8%. The interaction of EM technologies × years had a significant effect only on the color of this product and accounted for 12.1% of the overall phenotypic variability. The interaction of variety × years × technologies had the largest share in the total variance among all chip quality characteristics (30.9–44.2%). This proves that the conditions of the growing season in cooperation with genotypic and technological variability were the dominant source of variability for such traits as taste and smell, general appearance, moisture, damage, and discoloration of PC (Table 4).

Table 4.

The influence of varieties, technology, years and their interaction on the color, consistency, appearance, taste and smell, moisture, wet places, defects and discolorations, and fat content of PC and the percentages of participation of varieties, technology, years, and interaction cultivar x technology years in total variance.

3.2. FF Quality Evaluation

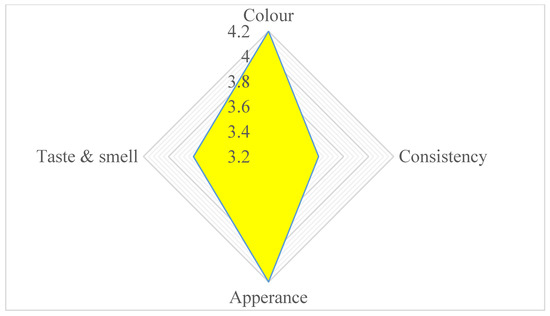

For the commodity assessment of FF features such as color, texture, taste and smell, general appearance, moisture, fat content, and dark ends were considered. The results of the FF assessment, regardless of the cultivation system, showed that this product, obtained from potato tubers, had the desired color and interior mealiness, while the taste, smell, and texture turned out to be less desirable (Figure 4). Relative standard deviation (RSD), also known by some as the coefficient of variation, is a convenient measure, independent of the scale of units and allows us to compare the examined features with each other in terms of stability. In the case of FF, the fat content were the most stable and the most variable were the share of dark tips of the FF (Table 5).

Figure 4.

Assessment of major features of French fries (FF) on a 1–5° scale.

Table 5.

FF quality evaluation and their variability (relative standard deviation (RSD) in %).

The color of FF, as one of the basic features of fried products, turned out to depend only on the genetic characteristics of the varieties tested. The brightest, desired color was obtained by the ‘Oktan’ variety; the cultivars ‘Zuzanna’, ‘Red Fantasy’, ‘Ewelina’, ‘Roxana’, ‘Vineta’, ‘Nicola’, ‘Nora’, ‘Czapla’, ‘Hinga’, and ‘Jelly’ turned out to be homogeneous in terms of the value of this features (Table 5).

EM technology had a significant impact on only the three quality features of FF, i.e., moisture, fat content, and “dark ends”. Only the technology with longer exposure to EM contributed to an increase in the moisture content of the produced FF and the reduction of oil absorption by FF, but both EM technologies resulted in a 2-fold reduction in the proportion of FF with dark ends (Table 4).

The consistency of FF was 3.6° on the 5° scale. The most desirable rating for this products is 4–5° on a 5° scale. Variety features turned out to be the factor that significantly differentiated the consistency of FF. The most favorable consistency was obtained by FF produced from the ‘Oktan’ and ‘Zuzanna’ varieties; the varieties ‘Jelly’ and ‘Hinga’ were homogeneous with regard to this feature. Similarly, the appearance of FF was related to the varietal properties of the potato. The most favorable assessment of the appearance was given to the ‘Zuzanna’ variety, while the worst was given to the very early variety of ‘Krasa’. Taste and smell are the basic characteristics of fried products, including FF. The best quality indicators of this trait were distinguished by FFs made from ‘Zuzanna’ and ‘Oktan’ varieties. The following varieties turned out to be homogeneous: ‘Hinga’, ‘Ewelina’, ‘Roxana’, ‘Vineta’, and ‘Ewelina’. The lowest humidity was noted for FF produced from the ‘Zuzanna’ and ‘Hinga’ varieties; the following varieties turned out to be homogeneous due to this feature: ‘Bellarosa’, ‘Roxana’, and ‘Vineta’. The ‘Hinga’ variety had the lowest tendency to absorb fats, while the ‘Korona’ was the most prone to fat absorption. There were two homogeneous classes in the group of the studied varieties, in relation to the varieties ‘Korona’ and ‘Hinga’. The most varied quality feature of the FF was the product’s disadvantages known as “dark ends”. The variety of ‘Krasa’ was characterized by their greatest participation, and the smallest was seen in the varieties of ‘Red Fantasy’ and ‘Jelly’ (Table 5).

Generally, the ‘Zuzanna’ variety was characterized by the most advantageous sensory features of FF in terms of color, texture, appearance, and taste and smell; the ‘Oktan’ variety turned out to be homogeneous in this respect. The fries made from tubers of the ‘Hinga’ variety absorbed the least amount of fat, while the fries made from tubers of the early ‘Korona’ and ‘Nora’ and mid-late ‘Oktan’ and ‘Jelly’ varieties were characterized by high fat absorbtion. The smallest number of defects in the form of ‘dark ends’ were seen in the ‘Red Fantasy’ variety (Table 5).

The meteorological conditions in the years of the study, regardless of other factors of the experiment, significantly differentiated the FF humidity, their fat content, and their share of ‘dark ends’. The highest values of these features were found in the last, atypical year of the research, characterized by a variable amount of rainfall in the months most important for the accumulation of tuber yield (Table 5).

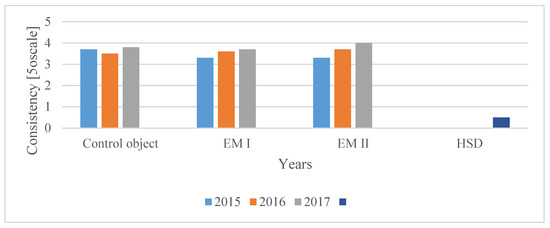

The FF response to EM technologies turned out to be related to the conditions of the potato growing season. In the years with dry and extremely dry periods during the potato growing season, a favorable reaction of FF produced from potato to EM technologies was observed, visible in the form of improvement in the consistency of this product (in 2016–2017), especially under the influence of longer exposure to EM (Figure 5).

Figure 5.

Effect of EM on the consistency of FF over the years of the research.

The quality of FF was first determined by the interaction of the variety × technologies × years (18.1–44.2, average 33.1%), followed by variety (23.7–37.9%, average 32.9%), then by only EM technologies (3.8–13.7%, average 10.3%), then the years (4.1–20.7%, mean 9.9%), and then by the interaction of cultivar × years (5.1–9.8, mean 6.6%), and the lowest share in the total variance was that of cultivar × technologies (4.0–7.3%, average 5.5%) (Table 6).

Table 6.

The influence of varieties, technology, and years, and their interaction on color, consistency, appearance, taste and smell, moisture, fat content, and dark ends of FF and the percentages of participation of varieties, technology, years, and the interaction of cultivar x years in total variance.

4. Discussion

Currently, biotechnology solves many problems in agriculture and broadly understood food processing. One of these solutions is EM technology (technology of effective microorganisms), which has recently been widely used in organic farming [2,9,12,51,52,53].

Allahverdiyev et al. [2] reports that there are microbial materials behind EM technology (“Baikal EM1”). They contain lactic acid groups, nitrogen-fixing bacteria, photosynthetic bacteria, and yeasts in their structure. Lactic acid bacteria, found mainly in fermented food and in the digestive tract of healthy people and animals, such as: Lactobacillus plantarum, Lactobacillus casei, Lactobacillus fermentum, Lactobacillus salivarius, Lactobacillus delbrueckii, and yeasts: Saccharomyces cerevisiae, which have a beneficial effect, distinguishes them from other microbial organisms. They also play an important role in processing technologies [11,23,24].

The quality requirements for potatoes intended for food processing, and especially for FF and PC, are constantly increasing, so the knowledge of the causes of changes in the chemical composition of tubers, which is the main factor determining their quality, is very important. There are no good solutions in Poland in the field of standardization of raw material for the production of FF and PC. The PN-R-74462: 1996 standard “Root crops—Potatoes for food processing” [54] was withdrawn on August 10, 2007, and there is still no information on its replacement or renewal. Accordingly, various potato processing plants have set their own internal standards. According to Zgórska [15], Lisińska [17], Zgórska and Frydecka-Mazurczyk [55], and Mozolewski [56], the optimal dry matter content should be at the level of 22–23%, the starch content should be within 15–17%, and reducing sugars should be up to 0.25% of the tuber fresh weight (acceptable level, 0.5%). In order to extend or accelerate production, the minimum dry matter content in tubers of early potato varieties intended for FF production should not be less than 18%, and starch should be no less than 12%, and the content of reducing sugars should not be higher than 0.25%. According to Lisińska [17], FF produced from tubers with a higher dry matter content are characterized by a greater crunchiness and brighter color. According to Tajner-Czopek et al. [57], the starch content in potato tubers intended for FF should be between 14 and 18%. Too high content of this component in tubers leads to unfavorable color changes and FF “crimping” during the frying process, while too little causes the tubers to absorb more fat during frying. The color of FF is closely related to the content of reducing sugars and, with them, the content of acrylamide [58]. This compound is produced by the reaction of asparagine with reducing sugars. Acrylamide is formed at a temperature higher than 120 °C, and its amount depends on the final temperature of heat treatment and its duration, the amount of asparagine, and the content of reducing sugars in the tubers [20,57,59]. Due to the high requirements for potato refined products, very high demands are also placed on the varieties suitable for processing into refined products, especially FF and PC. Most of the varieties tested met the expected requirements.

The obtained data prove that the technology implemented with the use of EM-Farming influenced the quality of fried products by optimizing physiological processes (respiration, transpiration, and enzymatic systems), ensuring the resistance of tubers to pathogenic organisms and stressors in their environment [10,60]. According to Allahverdiyev et al. [2], EM preparations are natural products that do not pollute the soil. According to Boligłowa and Gleń [60] and Allahverdiyev et al. [2], effective microorganisms not only enrich food with important amino acids such as lysine, valine, methionine, leitsin, isoleicin, tyrosine, phenylalanine, histidine, and threonine, but also eliminate gastrointestinal problems. Kondratowicz-Pietruszka et al. [61] examined the changes in the Totox index during frying by determining the oxidative stability of fats. Moreover, they determined the constant rates of fat oxidation processes and proved that the dynamics of fat oxidation during frying is very diverse, because rapeseed oil, used as a frying medium, oxidized 1.35 times faster than ordinary frying, 1.55 times faster than lard, and 1.72 times faster than coconut oil. As a result, they can be used as a criterion for selecting an appropriate frying medium. In the experiment performed, rapeseed oil was used as the frying medium, which was replaced after each batch of FF or PC was fried.

Deep-fat frying causes poor perception of fried products as it generates thermo-oxidants and is associated with the problem of excess weight, leading to further health problems [10]. Hence, fracture technologies are highly desirable to dramatically reduce oil absorption. Patsiuora et al. [62] demonstrated the mechanisms of oil absorption by cellular materials such as FF. They also proved the relationship between pressure and oil uptake and the key role of the potato structure. The dynamics of oil absorption in potato flesh cells confirms simulations of oil and gas filtration. Groundbreaking experiments show deviations from conventional descriptions of oil absorption mechanisms. It has been shown that in frozen, pre-fried products, internal evaporation and internal overpressure are delayed, which reduces fat absorption by FF or PC [56,62].

An increasingly weaker consumer perception of fried products encourages the development of both cracking technology in the frying process and the application of new innovative cultivation technologies to reduce oil absorption by raw potatoes. The currently available descriptions of oil sampling mechanisms are still incomplete, and they ignore the critical role of the total pressure gradient inside hygroscopic materials during cooling, as well as the coupling between mechanical fractures and oil sampling paths and various configurations of the two-phase air flow inside the raw material: co-currents and countercurrents. Using high-resolution, dynamic, non-invasive techniques, including X-ray micro-tomography, UV-VIS laser, or synchrotron source microscopy, as well as next-generation three-dimensional percolation models tailored to digitized structures, emphasizes the critical role of air in hindering/preventing oil absorption. The reasons for the increased fat intake during FF frying are, according to Barbaś and Sawicka [20] and Vauvre et al. [63], cell damage and starch grain damage, which has a significant impact on the formation of cavities and oil absorption in fried FFs subjected to various pretreatments.

One of the most important parameters characterizing the quality of fried products is their color. Regardless of the method of producing potato fries, color should be light and golden, without brown discoloration, black spots, or streaks [15,17,18,19]. The color of FF is related to the content of reducing sugars in potatoes and their distribution over the tuber cross-section [57]. Uneven distribution of sugars in the tuber (higher sugar content in the apical and stolon parts) causes the browning effect at the ends in the obtained fries—the so-called “Sugar end”. This effect is visible in the finished product as a result of the Maillard reaction occurring between reducing sugars and free amino acids [17,19,63]. The Maillard reaction that takes place during the frying of the fries contributes not only to the brown color, but also to the bitter taste of the finished product [56,57]. Many authors [15,16,17,18,19,20,63] have stated that the content of reducing sugars has a direct impact on the color of FF and PC, and that this is related to genetic features of potato varieties. The group of cultivars with a stable FF color includes the cultivars ‘Oktan’, ‘Zuzanna’, ‘Red Fantasy’, ‘Roxana’, ‘Vineta’, ‘Ewelina’, ‘Nicola’, ‘Jelly’, ‘Hinga’, ‘Czapla’, and ‘ Nora ‘, but a less numerous group of varieties had a very good consistency and included the varieties ‘Zuzanna’, Oktan, ‘Jelly’, and ‘Hinga’, and the group of varieties with the best taste and smell included ‘Zuzanna’, ‘Oktan’, ‘Ewelina’, ‘Roxana’, ‘Vineta’, ‘Red Fantasy’, ‘Hinga’, ‘Nicola’, ‘Nora’, ‘Bellarosa’, and ‘Korona’.

Another important quality feature of FF is their texture. The texture of the fries is determined by the crispness of the outside and the dryness of the inside. The exterior of the fries should be crunchy and tender, with no hard, rubbery, or leathery texture. On the other hand, its interior should be characterized by mealiness, without feeling watery or sticky, and should not separate from the outside. After breaking the fries, its surface should be even and without cracks [56]. A product with such a texture can be obtained only from a few potato varieties with appropriate physical properties and chemical composition [55]. In the conducted research, the best texture was obtained for the FF made from the ‘Oktan’ and ‘Zuzanna’ varieties. The texture of the finished product may be influenced not only by the dry matter and starch content in the tubers, but also by the qualitative characteristics of the starch, i.e., the ratio of amylose to amylopectin and the size of the starch balls [55,57]. Additionally, in the opinion of Mozolewski [56] and Tajner-Czopek [57], consistency is one of the most important features affecting the consumer acceptance of potato fries, which can be modified in a properly conducted technological process but mainly depends on the chemical composition of the raw materials, and this in turn depends on the genetic properties. All the above-mentioned features of FF significantly affect the quality of the finished product. The variability of technological characteristics of the researched potato varieties turned out to be closely dependent on the variety and less on the weather conditions during the growing season. However, there is no research regarding the technological aspect of fried products. Significant varietal differentiation was also found in terms of the general appearance of fries, their taste and smell, moisture, fat absorption and defects, and the so-called ‘dark ends’. The late varieties were the least wet, while the very early and early varieties were the most wet. Oil absorption is a very important feature of FF, determining the acceptability of this product by consumers. High-starch varieties such as ‘Hinga’ or ‘Red Fantasy’ had the lowest absorbency. The greatest variety, however, concerned the ‘dark ends’ of FF. The largest number of FF with defects were produced from very early and early varieties, which, at the same time, have the lowest dry matter and starch content in tubers [31].

One of the important sensory features of fried products is their crunchy, delicate texture [20,21]. In the literature, you can find two concepts: texture and consistency. These concepts are broadly understood and still not fully defined, but many authors [17,18,19,20,21,56,58] try to provide the most correct definition. Tajner-Czopek [57] states that consistency determines the rheological properties of heterogeneous, non-Newtonian systems, while the texture determines the physico-mechanical properties of food products, which are assessed using the sense of touch (skin and mouth). The latter two terms do not have a strict distinction, and in the literature and in colloquial speech, the terms ‘consistency’ and ‘texture’ can be interchangeable. Currently, texture can be marked as sensory and instrumentally [57,63]. The consistency of the tested products was highly rated, but was mainly related to the varietal characteristics. Tajner-Czopek [57] proved that, after heat treatment of potatoes, lignin (39%) had the greatest impact on the consistency of fried products, followed by hemicellulose (18%) and protopectin (17%).

The EM technology had a significant impact on only three FF quality features: moisture, grease absorption, and “dark ends”. EM technology with longer exposure to EM contributed, on the one hand, to an increase in the moisture content of the FF produced, and on the other hand, to a reduction in oil absorption, but both EM technologies contributed to a 2-fold reduction in the share of FF with dark ends, which generate large losses in the production of this range of refined products. There is no research on these mechanisms in the available literature yet, and they should be explained in the future.

Dhital et al. [64] predict that the microstructure of foods and their response to deformation and hydration is a key factor affecting texture and taste sensation during grinding and processing of oral PC. Using a wide variety of microscopic techniques and labeling methods, they captured potato cell structure and fat distribution at various length scales and assessed the hydration effects of sliced potatoes and PC formed during the production process. While both types of potato PC are a packed set of potato cells (they are microstructurally similar), when hydrated, the potato cells in the produced samples separate and disperse in the suspension, while the tissue structure of traditional PC remains substantially intact. These authors proved that a significant proportion of the fat in PC is bound in a thin film to the potato cell walls, both on the surface and within the tissue structure, while it is still present as droplets on the surface of the produced PC. When over-hydrated, the oil in the PC coalesces into larger droplets. Frying isolated cells or tissues damages the cell walls and allows oil to flow into the potato cells, which can also be the case with fried products. Our own research emphasizes the similarities in the microstructure of intact chips. We assessed the following fractions of the total oil content (TO) in potato slices: construction oil (STO), penetrated surface oil (PSO), and surface oil (SO). PSO constituted the largest fraction of the total oil content, and this was the case for the control object as well as for the blanched slices, which proves that the absorption of oil in the chips is mainly a physical, surface phenomenon, but may be modified by abiotic and biotic factors, as confirmed by our own research [56,57].

Deep-fat frying of FF or PC usually takes place in temperate climate conditions at temperatures close to 190 °C [65]. The most common problem is excessive darkening or burning of the product, even before the product is completely fried. In addition, some oil breakdown products can have adverse health effects as fried oils degrade with continued use. The tested products (FF and PC) were fried according to the rules contained in the national standard [41]; each batch of the product was fried after changing the oil. According to Arias-Mendez et al. [66], increasing the oil temperature and heating time when frying potato PC in deep-fat may improve texture quality but deteriorate the chemical safety of acrylamide formation. They formulated the optimal, complex frying process as a non-linear, constrained optimization problem, the aim of which is to calculate an oil temperature profile that guarantees the desired final moisture content, while minimizing the final acrylamide content, subject to technological constraints and process dynamics. The dynamics of the frying process uses a multi-component and multi-phase model of potato transport as a porous medium [56,65]. Five heating zones provide a good compromise between the process duration (the shorter the better) and the safety in terms of less acrylamide formation [10,66]. The high temperature zone at the beginning, with the progressive decrease of temperature in further zones, was considered optimal. Multi-zone optimal working conditions show a significant advantage over nominal constant temperature processes, opening up new possibilities for optimizing the frying temperature [10]. Vacuum frying is an alternative to traditional atmospheric deep-fat frying that provides the health benefits of lower acrylamide concentrations and less oil quality impact while maintaining the natural color and flavor of the product [10,66]. Additionally, the degree of frying fat degradation as well as the porosity and “roughness” of the surface of the fried product may affect the fat content of fried products [63].

The conducted research proved the assumed research hypothesis that EM technology applied before emergence by (A) soaking the seed potatoes in the EM-Farming solution for 10 min as well as by (B) soaking seed potatoes in the EM-Farming solution for 20 min provides a broader spectrum of EM antioxidant activity and improves the parameters of potato raw material suitable for food processing for FF and PC by reducing humidity and the share of the moist places in the potato chips (PC); reducing the absorption of fat by PC and FF, thus reducing the disadvantages of FF while not significantly affecting the color, flavor, or appearance; and reducing environmental pollution by reducing the use of fertilizers and plant protection products, which will ensure better effectiveness of EM technology by using pre-emergence treatments in the form of soaking seed potatoes in EM solution. The null hypothesis has therefore been refuted.

EM-FarmingTM preparations, in the opinion of Dithal and al. [64], have a great potential for biological interaction through specialized enzymes capable of transforming troublesome chemical compounds into their useful forms. Effective microorganisms help, among other things, in the production of disaccharide, which is trehalose, which has the ability to protect the entire plant when it is exposed to hazardous conditions, e.g., drought or high salinity. Trehalose prevents the formation of water crystals because hydrogen bonds are formed in it. On the other hand, its aqueous solutions, when dried, create enamel, which is an ideal compound for protecting plants against drought and high temperature [11,52,53]. In agriculture, effective organisms can be used, inter alia, to soak seed potatoes, spray plants, or irrigate them, without affecting human, plant, and animal health; for grafting plant seedlings before planting, with the aim of reducing or eliminating plant protection products against pathogens and diseases; for pest control of crops to complement the action of other pest control measures; when storing vegetable raw materials in cold stores and warehouses to improve the quality and durability of fruits and vegetables; to increase the biological activity of the soil; and to improve insect pest control [1,2,11,60]. The future direction in this field of science should go towards a thorough examination of the impact of EM technology on the quality of raw materials and processed food products, as this is directly related to human health.

Some researchers believe that experimenting consists only in manipulating the level of independent variables and observing the response of dependent variables [52]. Independent variables for which factor levels are forced or determined by the researcher are said to reflect the influence of fixed effects. However, there is also a second group of effects that scientists are also often interested in, and these are random effects. They represent classification effects where it is assumed that their levels are randomly selected from infinite population levels. Many of the independent variables, within one’s own discipline and interests, are not fully controllable (experimentally controlled), yet they can be considered as reflecting the influence of random effects. For example, cultivation technology regarding the genetic structure of a single variety of a given species, in this case potato, cannot be fully controlled experimentally. For example, geneticists are interested in the problem of estimating the share of a genetic factor in the case of individual variability of features such as disease resistance and organoleptic and sensory features such as taste, smell, and flesh color, and their changes over time [12]. Statistical analysis of random effects can be carried out using a model with random effects in cases where, for all independent variables, it can be assumed that they determine the impact of random effects or by using a mixed model, but only if some of the independent variables define the influence of random effects and the others evaluate the influence of fixed effects.

Some [9,49,50] believe that experimenting consists only of manipulating the level of independent variables and observing the response of dependent variables. Independent variables for which levels are dictated or set by the experimenter are said to reflect the influence of fixed effects. However, there is also a second group of effects that researchers are very interested in. Random effects are classification effects whose levels are assumed to be randomly selected from an infinite population of levels. Many of the independent variables within our discipline and interest are not fully controllable (experimentally controlled), but may be considered to reflect the influence of random effects. For example, the genetic structure of a single species variety, in this case potato, cannot be completely experimentally controlled. The problem of estimating the share of the genetic factor in the case of individual variability of such features as disease resistance, sensory features, e.g., taste, smell, palatability, and flesh color, and their changes over time, arouses great interest in geneticists. Statistical analysis of random effects is carried out using a model with random effects in a situation where, for all independent variables, it can be assumed that they determine the influence of random effects, or by using a mixed model, in the case when some of the independent variables determine the influence of random effects and other effects of fixed effects [48,50,56]. In the case of our experiment, the impact of the random effects, or rather the interaction of these random effects with the fixed effects, largely determines their contribution to the total variance.

The interaction of potato variety x technologies x years (12.1–44.2% for crisps and 12.6–42.2%—for FF) played a dominant role in the phenotypic variability of PC and FF. The genetic factor was from 23.6 to 37.6%—in the case of PC—from 25.1 to 35.9%—in the case of FF in the total variance. Interaction: varieties × years accounted for from 6.1 to 12.1% (PC) and 5.1 to 8.5% (FF) of the variance share in the total variance. In the case of crisps, EM technologies accounted for only 5.1 to 13.7% (PC) and 4.5 to 14.2% (FF) in the total variance. The research of Pszczółkowski et al. [11] confirms the diversified share of potato quality traits in the phenotypic variability. The obtained research results can be used in a decision-making system for breeding new potato varieties.

Consumer demands for the sensory quality of fried products (chips and fries) are high and are constantly growing. Thus, the attention of both scientists and the producers of these products is focused on obtaining FF and PC with the best texture; even, bright color; and the lowest possible fat content. Out of concern for the health of consumers, extensive research has been conducted on the possibility of reducing the content of anti-nutritional substances in food products. Therefore, it is necessary to conduct research on little known cultivation technologies, in particular on the possibility of improving the quality and reducing the fat content in fried potato products without deteriorating the organoleptic properties of the finished product.

5. Conclusions

Society strives to improve the condition of the environment and restore its natural balance. All steps taken in this direction may be easier to implement using EM technology. The EM cultivation system contributed to a significant reduction in the absorption of fats for FF and PC, and a significant reduction of the greatest disadvantage of FF, the ‘dark ends’. In the case of PC production, cultivation technology with the application of EM contributed to the lower absorption of fat by the PC but did not significantly affect their taste, smell, or general appearance. This suggests that potatoes from EM plantations are a better raw material for the production of FF and PC than potatoes from plantations without the use of these microorganisms. Among the sensory features of FF, the fat content was the most stable and the moisture content was the most variable. The genetic features of the tested potato varieties were the most decisive factor in the physicochemical and sensory properties of the improved products produced on the basis of the tested potato varieties. This will make it possible to determine their suitability for processing into refined products, such as PC or FF. The taste and smell is one of the key quality features of these products. The highest value of this feature in the case of FF was obtained by the cultivars ‘Oktan’ and ‘Zuzanna’. The ‘Red Fantasy’ variety obtained the best sensory and physicochemical assessments of PC. The use of EM preparations in favorable growing seasons, with higher soil moisture, as well as higher air temperatures, generally had a positive effect on the quality of raw material for the production of enriched products, although the beneficial effects of these preparations depended on the duration of exposure and potato variety. The use of an innovative technology of potato cultivation with the application of EM will allow us to obtain better quality products ennobled to the potato processing.

The interaction of potato cultivars × technologies × years played a dominant role in the phenotypic variability of PC and FF. The genetic factor was in the second order, and the years were the third factor that shaped phenotypic variability. The interaction of cultivar × technologies and EM technologies were in fourth and fifth place, and cultivar × years was in sixth places in terms of percentage share in the total variance.

Supplementary Materials

The following are available online at https://www.mdpi.com/2076-3417/11/4/1415/s1, Table S1: Agrotechnical procedures in a field experiment, Table S2: Characteristics of potato varieties.

Author Contributions

Conceptualization, B.S. and P.P.; methodology, B.S. and P.B.; software, A.K-D.; validation, A.K.-D., P.P., and A.K.-D.; formal analysis, M.Ć., B.S., and B.K.-M.; resources, M.Ć. and B.K.-M.; data curation, B.S. and P.B.; writing—original draft preparation, B.S. and P.P.; writing—review and editing, B.S., P.P., A.K.-D., and B.K.-M.; visualization, P.P., B.S., and M.Ć.; supervision, B.S.; project administration, B.S. and P.P.; funding acquisition, B.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding—own financing.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| BBCH | Biologische Bundesanstalt, Bundessortenamt und CHemische Industrie |

| EM | Effective microorganisms |

| FF | French fries |

| HSD | Honestly Significant Difference |

| PC | potato chips |

| WRB | World Reference Base for Soil Resources |

| TO | total oil content of potato slices |

| STO | construction oil |

| PSO | penetrated surface oil |

| SO | surface oil |

References and Note

- Al-Taweil, H.I.; Bin Osman, M.; Hamid, A.A.; Yusoff, W.M. Development of microbial inoculants and the impact of soil application on rice seedlings growth. Am. J. Agric. Biol. Sci. 2009, 4, 79–82. [Google Scholar] [CrossRef][Green Version]

- Allahverdiyev, S.R.; Kırdar, E.; Gunduz, G.; Kadimaliyev, D.; Revin, V.; Filonenko, V.; Rasulova, D.A.; Abbasova, Z.I.; Gani-Zade, S.I.; Zeynalova, E.M. Effective Microorganisms (EM) Technology in Plants. Technology 2011, 14, 103–106. [Google Scholar]

- Zakaria, Z.; Gairola, S.; Shariff, N.M. Effective Microorganisms (EM) Technology for Water Quality Restoration and Potential for Sustainable Water Resources and Management. In Proceedings of the 2010 International Congress on Environmental Modelling and Software Modelling for Environment’s Sake, Fifth Biennial Meeting, Ottawa, ON, Canada, 5–8 July 2010; David, A., Swayne, Wanhong, Y., Voinov, A.A., Rizzoli, A., Filatova, T., Eds.; International Environmental Modelling and Software Society (iEMSs): Manno, Switzerland. Available online: http://www.iemss.org/iemss2010/index.php?n=Main.Proceedings (accessed on 20 November 2020).

- Li, X.; Guo, Q.; Wang, Y.; Xu, J.; Wei, Q.; Chen, L.; Liao, L. Enhancing Nitrogen and Phosphorus Removal by Applying Effective Microorganisms to Constructed Wetlands. Water 2020, 12, 2443. [Google Scholar] [CrossRef]

- Okumoto, S.; Shintani, M.; Higa, T. The use of effective microorganisms and biochar inhibits the transfer of radioactive cesium from soil to plant during continuous komatsuna cultivation. In Proceedings of the International Scientific Conference "Radiobiology: Present", Institute of Radiobiology of the NAS of Belarus, Gomel, Belarus, 26–27 September 2019. [Google Scholar]

- Kaczmarek, Z.; Owczarzak, W.; Mrugalska, L.; Grzelak, M. Effect of effective microorganisms on selected physical and water properties of arable-humus levels of mineral soils. J. Res. Appl. Agric. Eng. 2007, 52, 73–77. (In Polish) [Google Scholar]

- Kaczmarek, Z.; Wolna-Murawska, A.; Jakubas, M. Change in the number of selected groups of soil microorganisms and enzymatic activity in soil inoculated with effective microorganisms (EM). J. Res. Appl. Agric. Eng. 2008, 53, 122–128. [Google Scholar]

- Zarzecka, K.; Gugała, M. Effect of UGmax soil fertilizer on the potato yield and its structure. Bull. IHAR 2013, 267, 107–112. (In Polish) [Google Scholar]

- Kołodziejczyk, M. Effect of nitrogen fertilization and microbial populations on potato yielding. Plant Soil Environ. 2014, 60, 379–386. [Google Scholar]

- Sawicka, B.; Mohammed, A.; Umachandran, K. Food Safety of Potato Processed in the Aspect of Acrylamide Risk. MOJ Food Process. Technol. 2018, 6, 00151. [Google Scholar] [CrossRef]

- Sawicka, B.; Pszczółkowski, P.; Noaema, A.H.; Krochmal-Marczak, B.; Kiełtyka-Dadasiewicz, A. Effective Microorganisms in Agriculture and Food Processing. Modern Research on the State of the Environment and the Therapeutic Use of Plants; Chwil, M., Skoczylas, M.M., Eds.; Publishing House of the University of Life Sciences in Lublin: Lublin, Poland, 2019; pp. 45–64. [Google Scholar] [CrossRef]

- Pszczółkowski, P.; Sawicka, B.; Danilčenko, H.; Jarienė, E. The role of microbiological preparations in improving the quality of potato tubers. In Proceedings of the International Scientific Conference ‘New trends in food safety and quality’, Aleksandras Stulginskis University, Akademija, Lithuania, 5–7 October 2017; pp. 22–23. [Google Scholar]

- Van Vliet, P.C.J.; Bloem, J.; De Goede, R.G.M. Microbial diversity, nitrogen loss and grass production after addition of effective microorganisms (EM) to slurry manure. Appl. Soil Ecol. 2006, 32, 188–198. [Google Scholar] [CrossRef]

- Martyniuk, S. Production of microbiological preparations on the example of symbiotic bacteria in legumes. J. Res. Appl. Agric. Eng. 2010, 55, 20–23. (In Polish) [Google Scholar]

- Zgórska, K. Quality of edible potatoes and potatoes for food processing. Polish Potato 2002, 4, 14–20. (In Polish) [Google Scholar]

- Zgórska, K. Quality requirements for potato varieties for food processing. Earth Half 2004, 4, 26–28. (In Polish) [Google Scholar]

- Lisińska, G. Technological value and consumption quality of Polish potato varieties. Zesz. Probl. Post. Sci. Agric. 2006, 511, 81–94. (In Polish) [Google Scholar]

- Lisińska, G. Food processed potato: Production volume, nutritional value. Zesz. Probl. Post. Agric. Sci. 2004, 500, 57–68. (In Polish) [Google Scholar]

- Rytel, E.; Nemś, A.; Kułakowska, K. Effect of pre-drying temperature on content of glycoalcaloids and nitrates (v) during laboratory production of dehydrated cooked potatoes. Żywność. Nauka. Technologia. Jakość 2013, 1, 191–203. [Google Scholar] [CrossRef]

- Sawicka, B.; Barbaś, P. Dependence of French fries quality on the chemical composition of potato tubers in organic and integrated cultivation system. Sci. Przyr. Technol. 2011, 5, 1–18. [Google Scholar]

- Zgórska, K.; Grudzińska, M. Changes in selected quality characteristics of potato tubers during storage. Acta Agrophys. 2012, 19, 203–214. (In Polish) [Google Scholar]

- Kolasa-Więcek, A. Will Effective Microorganisms Revolutionize the World? Post. Technol. Convert Spoz. 2010, 1, 66–69. (In Polish) [Google Scholar]

- Vaitkevičienė, N. The Effect of Biodynamic Preparations on the Accumulation of Biologically Active Compounds in the Tubers of Different Genotypes of Ware Potatoes. Ph.D. Thesis, Agricultural Sciences, Agronomy (01A), ASU, Akademija, Kaunas, Lithuania, 2016; p. 212. [Google Scholar]

- Vaitkevičienė, N.; Jariene, E.; Danilcenko, H.; Sawicka, B. Effect of biodynamic preparations on the content of some mineral elements and starch in tubers of three colored potato cultivars. J. Elem. 2016, 21, 927–935. [Google Scholar] [CrossRef]

- Mrugalska, L.; Świerk, D. Effective Microorganisms—A revolutionary technology? Por. Gosp. 2012, 5, 33–35. (In Polish) [Google Scholar]

- Szembowski, B. Experiences of a Farm in Trankwice with the EM-FarmingTM Biotechnology. Natural Probiotic Microorganisms; Associate Ecosystem: Lichen, Poland, 2009; pp. 56–58. (In Polish) [Google Scholar]

- WRB. World Reference Base for Soil Resources 2014 International Soil Classification System for Naming Soils and Creating Legends for Soil Maps; World Soil Resources Reports 106; Food and Agriculture Organization of The United Nations: Rome, Italy, 2014. [Google Scholar]

- Duer, I.; Fotyma, M.; Madej, A. Code of Good Agricultural Practice; MRiRW: Warsaw, Poland, 2004. (In Polish)

- Roztropowicz, S.; Czerko, Z.; Głuska, A.; Goliszewski, W.; Gruczek, T.; Lis, B.; Lutomirska, B.; Nowacki, W.; Rykaczewska, K.; Sowa-Niedziałkowska, G.; et al. Methodology of Observation, Measurement and Sampling in Agrotechnical Experiments with Potatoes; IHAR Radzików, Branch: Jadwisin, Poland, 1999; pp. 1–50. (In Polish) [Google Scholar]

- Peeten, H.M.G.; Shipper, E.; Shipper, J.K.; Baarveld, H.R. Netherlands Catalogue of Potato Varieties; NIVAP: Den Haag, The Netherlands, 2007. [Google Scholar]

- Lenartowicz, T. Descriptive List of Agricultural Plant Varieties 2020; COBORU: Słupia Wielka, Poland, 2020; pp. 11–41. (In Polish)

- Ryzak, M.; Bartmiński, P.; Bieganowski, A. Methods of determination of granulometric distribution of mineral soils. Acta Agroph. Theses Monogr. 2009, 175, 97. [Google Scholar]

- PN-R-BS 0403: 1997. Chemical and Agricultural Analysis of Soil. Sampling; Polish Committee for Standardization: Warsaw, Poland; Polish Accreditation Committee: Warsaw, Poland, 1997. [Google Scholar]

- KQ/PB-34 version 04 from 07.10.2011, 2011.

- PN-R-04023: 1996. Chemical and Agricultural Analysis of Soil. Determination of Available Phosphorus Content in Mineral Soils; Polish Committee for Standardization: Warsaw, Poland, 1996. [Google Scholar]

- PN-R-04022: 1996 + AZ1: 2002. Chemical and Agricultural Analysis of Soil. Determination of Available Potassium Content in Mineral Soils; Polish Committee for Standardization: Warsaw, Poland, 2002. [Google Scholar]

- PN-R-04017: 1992. Content of Copper Soluble in HCl in Mineral soil; Polish Committee for Standardization: Warsaw, Poland, 1992. [Google Scholar]

- PN-R-04019: 1993. Content of Manganese Soluble in HCl in Mineral Soil; Polish Committee for Standardization: Warsaw, Poland, 1993. [Google Scholar]

- PN-R-04021: 1994. The Content of Iron Soluble in HCl in Mineral Soil; Polish Committee for Standardization: Warsaw, Poland, 1994. [Google Scholar]

- Nawrocki, S. Zalecenia Nawozowe. Część I. Liczby Graniczne do Wyceny Zawartości w Glebach Makro-i Mikroelementów; Wyd. IUNG: Puławy, Poland, 1985; 38p. [Google Scholar]

- PN-A-74780:1996. Potato Products. Fried Potato Snacks; Polish Accreditation Committee: Warsaw, Poland, 1996. [Google Scholar]

- EN ISO 8586:2014-03. Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Sensory Evaluation Experts. Available online: https://sklep.pkn.pl/pn-en-iso-8586-2014-03e.html (accessed on 20 November 2020).

- PN-A-74702:1978. Potato Food Products. Testing Methods; Polish Accreditation Committee: Warsaw, Poland, 1978. [Google Scholar]

- PN-A-74780. Processed Potatoes. They Have Potato Snacks; Polish Accreditation Committee: Warsaw, Poland, 1996. [Google Scholar]

- ISO 4121:2003. Sensory Analysis—Guidelines for the Use of Quantitative Response Scales. Available online: https://www.iso.org/standard/33817.html (accessed on 20 November 2020).

- ISO 8589:2007. Sensory Analysis—General Guidelines for the Design of Test Rooms. Available online: https://www.iso.org/standard/36385.html (accessed on 20 November 2020).

- PN-EN 12145:2001—Fruit and Vegetable Products—Preparation of Samples and Physicochemical Test Methods—Determination of Dry Matter Content by Gravimetry; Polish Accreditation Committee: Warsaw, Poland, 2001.

- Skowera, B.; Kopcińska, J.; Kopeć, B. Changes in thermal and precipitation conditions in Poland in 1971–2010. Ann. Warsaw Univ. Life Sci.—SGGW Land Reclam. 2014, 46, 153–162. [Google Scholar] [CrossRef]

- SAS Institute Inc. SAS/STAT®9.2 User’s Guide; SAS Institute Inc.: Cary, NC, USA, 2008. [Google Scholar]

- Pripp, A.H. Statistics in Food Science and Nutrition, SpringerBriefs in Food, Health, and Nutrition; Richard, W.H., Ed.; Springer: New York, NY, USA; Berlin/Heidelberg, Germany; Dordrecht, The Netherlands; London, UK, 2013; p. 72. ISBN1 978-1-4614-5009. ISBN2 978-1-4614-5010-8. [Google Scholar] [CrossRef]

- Kołodziejczyk, M. Effect of nitrogen fertilization and microbial preparations on quality and storage losses in edible potato. Acta Agroph. 2016, 23, 67–78. [Google Scholar]

- Pszczółkowski, P.; Sawicka, B. The effect of application of biopreparations and fungicides on the yield and selected parameters of seed value of seed potatoes. Acta Agroph. 2018, 25, 239–255. [Google Scholar] [CrossRef]

- Pszczółkowski, P.; Sawicka, B. Influence of the use of fungicides, microbiological preparations and herbal extracts on the shaping of the potato yield. Fragm. Agron. 2018, 35, 17–28. (In Polish) [Google Scholar]

- PN-R-74456: 1999. Root Crops—Potato Quality Test; Polish Accreditation Committee: Warsaw, Poland, 1999. (In Polish) [Google Scholar]

- Zgórska, K.; Frydecka-Mazurczyk, A. Usefulness of new Polish potato varieties for food processing. Zeszyty Problemowe PostępówNauk Rolniczych 2002, 489, 347–354. (In Polish) [Google Scholar]

- Mozolewski, W. Research on Relations between the Quality of Potato Varieties and the Quality of PC and FF; Spread. Monogr.; Uniwersytet Warmińsko-Mazurski: Olsztyn, Poland, 2005; p. 77. (In Polish) [Google Scholar]

- Tajner-Czopek, A.; Kita, A.; Lisińska, G. Acrylamide content in French fries depending on the temperature and frying time. Zeszyty Problemowe Postępów Nauk Rolniczych 2008, 530, 371–379. (In Polish) [Google Scholar]