Featured Application

The results of this work quantitatively confirm the significant shelf-life extension, even at potentially deviating cold chain conditions, of high quality meat products, by post packaging high pressure processing, resulting in meat products loss and waste reduction.

Abstract

Vacuum packed Bratwurst type cooked sausages and sliced or cubed meat products that have limited shelf-life of few days in chilled storage were HP processed (5 min, 600 MPa, 25 °C) and stored at different temperatures (0–15 °C). Color, texture, and microbiological and sensory evaluation were kinetically studied for control and HP treated samples. HP treatment did not alter the color and texture of the treated samples when compared to untreated ones. Lactic acid bacteria were found to be the main spoilage index. The rates of microbiological and organoleptic deterioration were estimated, and their temperature dependence was modeled by the Arrhenius equation. An increase of their shelf life of five to eight times was estimated, compared to untreated ones. A sensory survey on HP treated cooked ham showed that the consumers could not distinguish differences between control and processed samples immediately after processing. Obtained results were used along with appropriate tools relevant to cold chain management to demonstrate that HP treated products are less perishable compared to control ones, allowing for short exposure to temperature deviations during transportation and storage. This has a positive impact on the reduction of the frequency of spoiled products before consumption, acting as a useful tool for the meat product’s loss and waste reduction.

1. Introduction

Vacuum packed meat products such as sliced cooked ham, sliced cooked turkey, ready to eat cooked ham cubes, etc., have a limited shelf-life of a few days in chilled storage. Cold chain management in meat supply is of utmost importance for the maintenance of quality and safety of meat/meat products [1]. Shelf-life extension has been considered by addition of preservatives such as nitrites, necessary to be added to meat products. Nitrites play various roles in the development of characteristic features of cured meat products. Nitrites, as undissociated nitrous acid, inhibit microbial growth, especially under anaerobic conditions [2,3]. Nevertheless, their addition is not always wanted, especially for products in which color fixation is not required such as typical cooked sausages (i.e., Bratwurst sausages). Nitrite combined with myoglobin, the main pigment of meat, produces pink nitric oxide myoglobin [4], which during heating is converted to the pink or red and quite stable nitrosohemochrome [5].

One of the most efficient technologies that is already applied as an established process by the meat industry globally is high pressure (HP) technology [6,7]. At the end of 2018, 385 HP units (representing a global volume of about 95,000 L) were in production, and one third of the global volume capacity of high pressure equipment was processing meat [8,9]. High pressure (HP) processing is a preservation technology that in combination with mild or low temperatures can adequately reduce pathogenic and spoilage microorganisms [10,11] and detrimental food enzyme activity [12]. HP processing of meat products is an active topic of research, because of its potential to extend shelf-life and produce safer meat products [11,13,14,15]. Application of HP at pressures as high as 600 MPa has demonstrated the potential of most pathogenic and spoilage bacteria inactivation, thus resulting in shelf life extension of RTE meat products (i.e., low-fat pastrami, Strasburg beef, export sausage, Cajun beef, cooked ham, dry cured ham, and marinated beef loin) [13,16]. Shelf-life of sliced ham treated at 400 MPa for 15 min was extended from 19 (control samples) to 85 days [14]. Diez et al. [17] efficiently investigated the effect of HP treatment at 600 MPa for 10 min to extend the shelf life of Spanish blood sausages (Morcilla de Burgos). Pietrasik et al. [18] reported that HP maintains the sensory acceptability of products such as reduced sodium naturally cured wieners, successfully extending the shelf life up to 12 weeks. Garriga et al. [19] reported microorganisms inactivation on cooked ham applying HP at 600 MPa, resulting in 6 log CFU/g lower lactic acid bacteria (LAB) count in HP cooked ham compared to untreated samples after 60 days of storage. Huang et al. [20] reported that treatment at 414 MPa and 50 °C for 2 min is sufficient for the production of fresh pork sausages safe from Listeria monocytogenes.

HP technology has established efficiency as an in-pack cold pasteurization technique, as an additional final processing step, offering prolonged preservation and increased safety of meat products. Due to the development of highly efficient HP machines, processing costs have been reduced to acceptable levels [21], and this has led to wider application of this technology in the food industry [8]. As an environmentally friendly and waste-free technology, HP has a high acceptance among industries, and it is expected to be more widely applied in the near future.

In this work, HP processing at ambient temperature was applied to several vacuum packed meat products with short shelf life. The objective was to investigate the effect of HP on spoilage microbial population and quality characteristics of sliced cooked ham, sliced cooked turkey, cooked ham cubes, and Bratwurst sausages. The benefit of HP treatment on the shelf life extension of these products was modeled and validated through simulation scenarios based on real cold chain data. It is demonstrated that cold chain management and spoiled meat products waste were significantly improved, by increased remaining shelf life for HP treated products along the whole cold chain.

2. Materials and Methods

2.1. Meat Products Preparation

Sliced cooked ham (slice weight 15 g, 15% protein, 3% fat, 4% carbohydrates, 78% moisture), sliced cooked turkey (slice weight 14 g, 13% protein, 2% fat, 6% carbohydrates, 79% moisture), and ham cubes (2 g per cube, 15% protein, 3% fat, 4% carbohydrates, 78% moisture), vacuum packed in polyethylene pouches, were provided directly from the production and packing line of a meat processing plant of the market leading manufacturer in Greece. Sliced cooked ham and turkey are the top-selected meat products in Greece for consumption at home, while the ham cubes are the top-selected one for food services, usually used in salad preparations. Pork (shoulder) Bratwurst type sausages (the most popular German sausage delicacy consumed throughout Germany and abroad), 50 g each, 12–15 cm long and 2 cm in diameter (13% protein, 21% fat, 1% carbohydrates, 65% moisture) were also produced in a leading meat processing plant in Greece. Two different batches of sausages were prepared. The first batch comprised sodium nitrite (150 ppm), and the second one was prepared without the addition of sodium nitrite. Typical commercial shelf life for vacuum packed sliced cooked ham, turkey, and Bratwurst sausages (containing nitrites) is 28 days at 4 °C, while for diced ham cubes, it is only seven days.

2.2. High Pressure Processing

HP experiments were conducted at various pressures (400–600 MPa) and temperature 25 °C, for various processing times (ranging from 5 to 15 min). The temperature of 25 °C was selected mainly to show that low temperatures are not necessary for the treatment of that kind of product, significantly reducing the energy consumption of the cooling units for reducing the temperature of the pressure medium (usually water). The high pressure unit (Food Pressure Unit FPU 1.01, Resato International BV, Roden, Holland) used included a pressure intensifier and a 1.5 L vessel, (7 cm diameter and 40 cm length), operating at a maximum pressure of 1000 MPa and temperature of 90 °C. Polyglycol ISO viscosity class VG 15 (Resato International BV, Roden, Holland) was the pressure transmitting fluid used. Pressure release time was very low (trelease < 3 s). Temperature in the vessel was monitored and recorded during pressure build up and holding. The adiabatic temperature increase due to pressure increase was taken into consideration for the selected vessel temperature during the treatment. Pre-cooled samples were used so as to reach the target temperature after pressure build up (adiabatic heating—approximately 3 °C/100 MPa). Preset conditions of 600 MPa pressure and 25 °C temperature resulted in 12 °C increase during pressure build-up; nevertheless, after 2 min processing, the temperature equilibrated with the temperature of the vessel jacket (25 °C). Mean time for 600 MPa pressure build up ranged from 54 to 58 s.

2.3. Storage Conditions

Sliced cooked ham and turkey and ham cubes samples (control and HP treated) as well as Bratwurst sausages (untreated nitrite-free samples, untreated samples with nitrites added, and the HP treated nitrite-free samples) were stored at temperatures ranging from 0 to 15 °C (Sanyo MIR 153, Sanyo electric co., Ora-Gun, Gunma, Japan). At pre-selected times (at least eight different sampling points up to a total storage duration of three months for Bratwurst sausages, five months for diced ham cubes, and eight months for sliced cooked ham and turkey) microbiological, sensory, color, and textural analyses for each type of product were performed.

2.4. Microbiological Analysis

Analysis of each sample was performed by diluting 25 g of meat product in 225 mL of sterile Ringer solution (1.15525 Merck, Darmstadt, Germany). Then, homogenization (Stomacher Lab Blender, Seward, London, UK) for 1 min in sterile plastic bags took place. Total viable count was enumerated on Plate Count agar (1.05463, Merck, Darmstadt, Germany) (spread-plate method, three days incubation at 25 °C). MRS agar (1.10660, Merck, Darmstadt, Germany) was used for the lactic acid bacteria enumeration (aerobic, pour-plate method, five days incubation at 25 °C), while Pseudomonas agar base (CM 559, Oxoid Ltd., Cambridge, UK) with appropriate CFC supplement (SR 103 Oxoid Ltd., Cambridge, UK) was used for Pseudomonas counts (incubation for up to four days at 30 °C). All the results were expressed as log CFU/g (CFU: Colony Forming Units). Violet Red Bile Glucose Agar (VRBGA, Oxoid) was used for the detection of Enterobacteriaceae colonies (pour plate method, 24 h incubation at 37 °C). Rose-Bengal Chloramphenicol Agar (RBC, Oxoid) was used for the enumeration of yeasts colonies (spread-plate method, five days incubation at 25 °C). Streptomycin sulphate, Thallous acetate, and Cycloheximide (Actidione) Agar (STAA, Biolife) with the appropriate supplement (STAA Selective Supplement) were used for Brochothrix thermosphacta cells enumeration (spread-plate method, incubation at 25 °C for three days).

2.5. pH Measurement

The sample’s pH value was measured after blending 25 g of the products with 225 mL of sterile Ringer solution for 1 min. At least two different samples of same batch and storage temperature were measured. Amel 338 pH-meter (0.005 accuracy) (Amel Instruments, Milano, Italy) was the instrument used.

2.6. Instrumental Color Analysis

The colorimeter Minolta CR-200 (Konica Minolta Holdings INC, Tokyo, Japan) was used for the evaluation of the surface color of the sausages. The CIELab scale was used, with L (lightness), a (red–green color), and b (yellow–blue color) values. Two different samples of same batch and storage temperature were used for the measurement, at five different spots for each sample, estimating the mean value of all these measurements. The total color difference (ΔΕ) (Equation (1)) was estimated:

where Lo, ao, and bo are the values at time 0.

ΔE = [(Lo − L)2 + (ao − a)2 + (bo − b)2]1/2

2.7. Instrumental Texture Analysis

The Texture Analyzer TA-XT2i (Stable MicroSystems, Godalming, UK) was used for the analysis of the samples texture profile, after being equilibrated to 25 °C. Analysis was performed for at least two different samples for each storage temperature and for each batch. Samples were compressed to the center of their length. The two-cycle compression protocol was applied, using a 1 cm diameter cylindrical compression probe and by recording the force during compression. The parameters of the analysis include a test speed of 1 mm/s, pre-test and post-test speeds of 2 mm/s, and penetration depth of 1 cm. Hardness, cohesiveness, and chewiness were the main characteristics estimated instrumentally, based on Peleg, 1976 [22].

2.8. Sensory Evaluation

Organoleptic scoring of all products was performed by a seven-member trained sensory panel. All ready to eat samples were tested after temperature equilibrium to approximately 25 °C. For Bratwurst sausages, the evaluation was performed in cooked samples. Sausages (at least two samples from each storage temperature and each batch) were enwrapped in thin aluminum layer, for moisture loss flavor alteration avoidance (steam broiled in an oven at 220 °C for 35 min). A nine-grade hedonic scale was used for the assessment of all products organoleptic characteristics such as appearance, taste, texture, flavor, and overall impression. The acceptance limit of the hedonic scale was 5. More extensive organoleptic evaluation simulating the consumers’ acceptance test was performed for sliced cooked hams. Approximately 100 different packs of sliced cooked ham were treated at 600 MPa, 25 °C for 5 min and were transferred to a sensory evaluation laboratory, where all the tests were performed. Untrained panelists (87 randomly selected students) organoleptically evaluated the treated samples on the same day of HP treatment, along with control samples for comparison purposes. They were asked to grade the samples with regards to the odor, texture, color, total appearance, and general impression on a hedonic scale from 1 to 9. The color, texture (hardness), and odor of the products were scored in terms of intensity (score 1—low intensity; score 9—high intensity), while the appearance and overall impression were scored in terms of likeliness (score 1—low likeliness; score 9—high likeliness). In the case of the latter, the score of 5 corresponded to the characterization “neither like nor dislike” and was considered the limit for product acceptability. All of the above were explained to the untrained consumer–students. After 25 days of storage at 0 °C of both HP treated and control samples, the same students were asked to re-evaluate the samples.

2.9. Data Analysis

Values of quality indices (average of three measurements ± standard deviation) (total viable count, lactic acid bacteria) were plotted versus time for different storage conditions. The results of microbiological analysis were fitted to the Baranyi model for microbial growth [23], where:

y(t) = lnx(t) with x(t) the cell concentration (CFU/mL), y0 = lnx0, and ymax = lnxmax with x0 being the initial and xmax the asymptotic cell correlation, respectively. The growth rates (μmax) were estimated, and they are presented with the corresponding standard errors. The Arrhenius equation was used to estimate the activation energy values, quantifying the effect of storage temperature on the growth rates:

where kT: growth rate at a storage temperature T (K), kref: growth rate at a reference storage temperature Tref = 277.15 K (4 °C), Ea: activation energy (J/mol), and R: universal gas constant (8.314 J·mol−1·K−1). A linear equation was used to model the organoleptic deterioration of the samples versus time.

kT = kref exp[−Ea/R(1/T − 1/Tref)]

2.10. Remaining Shelf Life Determination—Cold Chain Management

Cold chain management is required in order to reduce meat products’ quality failure and thus reduce food loss and food waste while offering consumers high quality, safe food products. The Cold Chain Database and Cold Chain Predictor software developed within the FRISBEE project could be applied for the building of a representative profile for meat products based on approximately 4500 records of contributed profiles with real time–temperature data measured at different cold chain stages from production to domestic storage [24]. A sequence of real cold chain stages could be used to build a representative t–T profile for meat products such as sliced cooked ham and turkey, as presented in Gogou et al. [24]. The remaining shelf life (SLR) after each stage was calculated considering that microbial growth follows first order kinetics (exponential growth), using Equation (4):

where NF: maximum microbial load before rejection, N0: the microbial count at the beginning of the cold chain stage, kref: growth rate at a reference storage temperature Tref = 277.15 K (4 °C), Teff is the effective temperature, a constant temperature resulting in the same effect expected by the real t–T data from the database, Ea: activation energy (J/mol), R: universal gas constant (8.314 J·mol−1·K−1), and t: the duration of the stage.

2.11. Statistical Analysis

At each sampling point, all studied quality parameters were measured (at least two replicates for each sample and sampling measurement). The deviation among the measurements (standard deviation, average ± stdev), along with the deviation among the calculated values of the constant rates (k) (standard error, st. error) were estimated. The 95% confidence upper and lower values were also estimated via a regression statistical routine. All the received data were analyzed statistically by one-way ANOVA using least significant difference (LSD) at p < 0.05 to evaluate differences between samples. Significant differences among data were assessed by Duncan’s multiple range test.

3. Results and Discussion

3.1. Preliminary Experiments for Selection of HP Treatment Conditions

Preliminary experiments were conducted at 25 °C for the selection of the shelf life treatment conditions, at the following combinations of pressure and time: 400 MPa for 10 min, 500 MPa for 10 min, 550 MPa for 10 min, and 600 MPa for 5 and 10 min (Table 1). More intense treatment conditions (higher pressure process or higher treatment time) resulted in alteration of the samples characteristics (softening, water extraction, and flavor modification). It was established that a treatment at 600 MPa and 25 °C for 5 min induces adequate bacterial inactivation (at least about 2 log reduction of total microflora) without significant modification (p < 0.05) of product organoleptic characteristics (sensory scoring of these samples was equal to the scoring of untreated samples). This HP treatment (600 MPa/25 °C/5 min) was used in subsequent studies.

Table 1.

Sensory evaluation and total microflora reduction (log CFU/g) of meat products treated at different combinations of pressure and time at 25 °C.

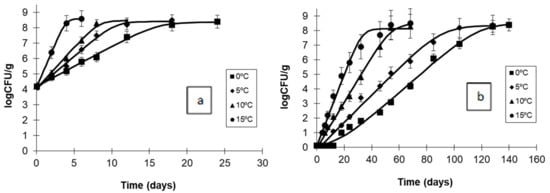

3.2. Effect of HP Treatment on Microbial Growth of Bratwurst Sausages

The effect of storage temperature (0–15 °C) on the growth of total viable count (TVC) for all samples was studied. High Pressure processing induced a reduction of initial total microbial count up to 4.2 log CFU/g, depending on the product studied (by 4.2 log CFU/g for Ham cubes, 3.2 log CFU/g for sliced turkey, 3.8 log CFU/g for sliced ham). For Bratwurst sausages, the initial count of nitrite containing samples (4.2 log CFU/g) was less by 0.9 log CFU/g compared to nitrite-free, whereas after HP treatment, it was less by 1.7 log CFU/g than the respective of control samples. Growth rates (μmax) at different storage temperatures are presented in Table 2. HP-treated samples were spoiled slower compared to control and nitrite-free sausages. Storage at 0 °C resulted in growth rates of total aerobic count of approximately 0.040, 0.092, and 0.197 days−1 for HP treated, with nitrites and control samples, respectively. After 80 days storage at 0 °C, total microbial count of HP-treated samples was lower than 6 log CFU/g, while nitrite containing and control samples reached 6 log CFU/g at 25 and 10 days, respectively (Figure 1). HP treatment in combination with low storage temperatures provided a significant (p < 0.05) inhibition of total aerobic count. The effect of storage temperature on the growth rates of total microflora was expressed through the activation energy (Ea) value, estimated as 69, 94, and 123 kJ/mol for control, nitrite containing, and HP treated samples, respectively. Higher Ea values denote higher dependence of the growth rate to storage temperature increase. Thus, at 10 °C, the growth rate increase by 2.4, 4.3, and 9.1 times, respectively, compared to growth rates at 0 °C. However, the growth in the HP treated samples is still the lowest (0.364 compared to 0.474 and 0.403 for the control and nitrite containing samples, respectively). Lactic acid bacteria (LAB) are the predominant spoilage microflora in meat products under vacuum and at refrigeration conditions [25,26], while at those conditions, Pseudomonas are significantly inhibited [27]. During the whole storage period studied, Pseudomonas spp. population was below the detection limit (<102 CFU/g). Growth rates of LAB for all treatments and temperature conditions are presented in Table 2. The effect of storage temperature was expressed by the Ea values (Table 2). LAB are relatively resistant to sodium nitrite [28]. Nitrite did not sufficiently prevent the growth of LAB, especially for storage temperatures higher than 10 °C, where LAB populations of nitrite-made sausages are similar to those of control samples (Figure 2). In contrast, HP treatment induced a significant (p < 0.05) reduction of LAB initial count from 2.4 to 1 log CFU/g, compared to the control and nitrite-containing samples. During storage at 0 and 5 °C, growth of LAB on HP-treated samples was very slow; LAB counts did not reach the level defined as the spoilage level (108 CFU/g, [29]), remaining below 3.6 log CFU/g even after 80 days at 0 °C and 5.9 log CFU/g after 40 days at 5 °C. Storage at higher temperatures (10 and 15 °C) allowed LAB on HP-treated samples to reach a population of approximately 8 log CFU/g after 30 days and 10 days, respectively. Control and nitrite enriched samples reached the level of 108 CFU/g after storage at 10 and 15 °C for approximately nine and five days, respectively. The inhibition of lactic acid bacteria, which have been reported as the dominant spoilage bacteria in vacuum-packed sausages, by high pressure treatment, in combination with storage temperature lower than 5 °C, leads to a significant (p < 0.05) extension of shelf life of those products.

Table 2.

Growth rates (days−1) for the total viable count and the lactic acid bacteria of Bratwurst sausages, stored at temperatures ranging from 0 to 15 °C, for control samples, nitrite-enriched samples, and HP-treated (600 MPa/25 °C/5 min) samples. The effect of temperature on the rates is expressed through the activation energy values, which are also presented.

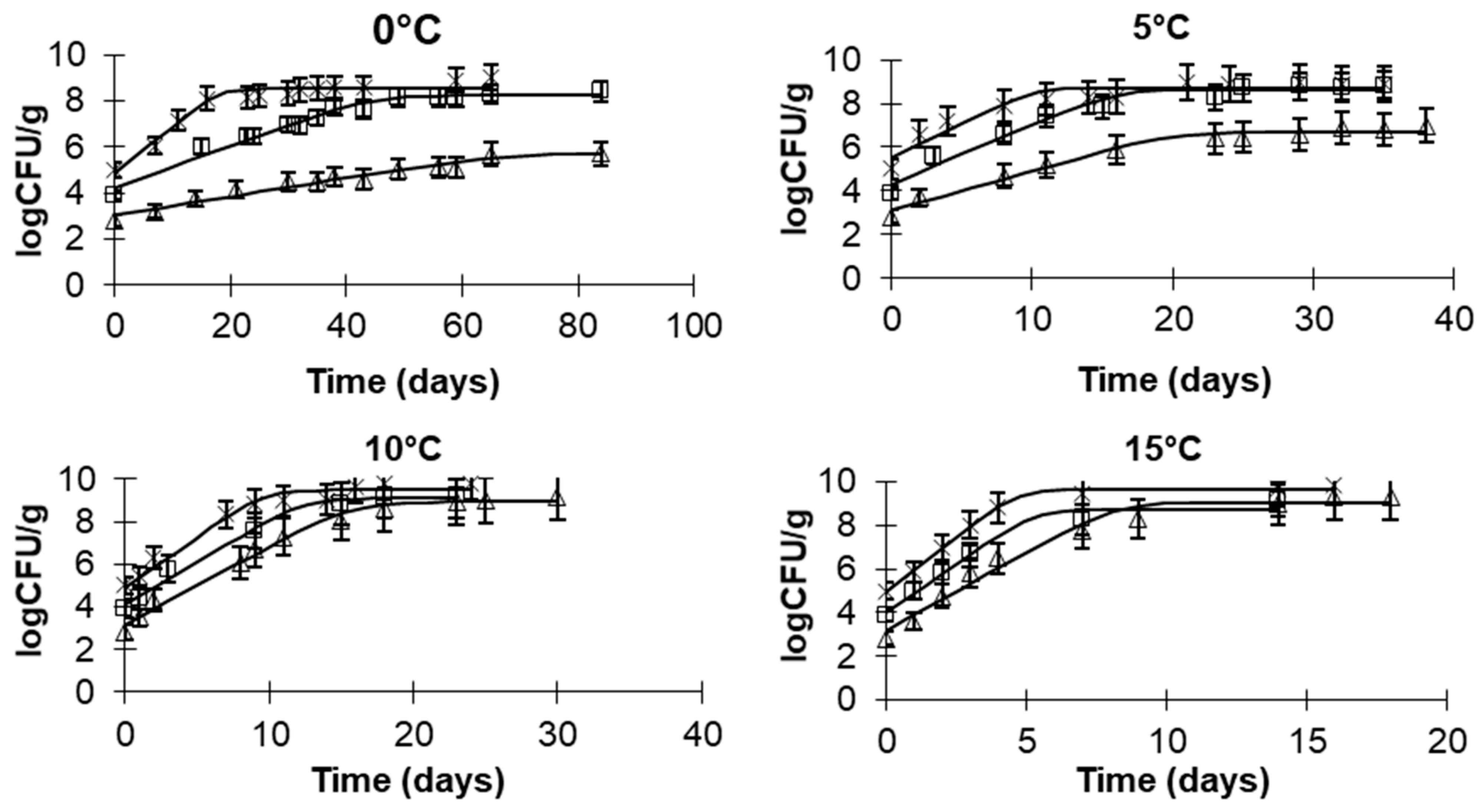

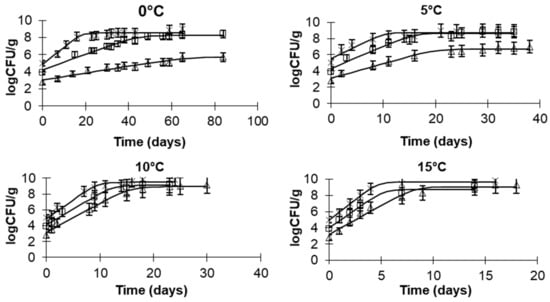

Figure 1.

Growth of total viable count of Bratwurst sausages during storage at 0, 5, 10, and 15 °C; (x): control samples, (□): nitrite-made samples, (∆): HP-treated samples at 600 MPa and 25 °C for 5 min.

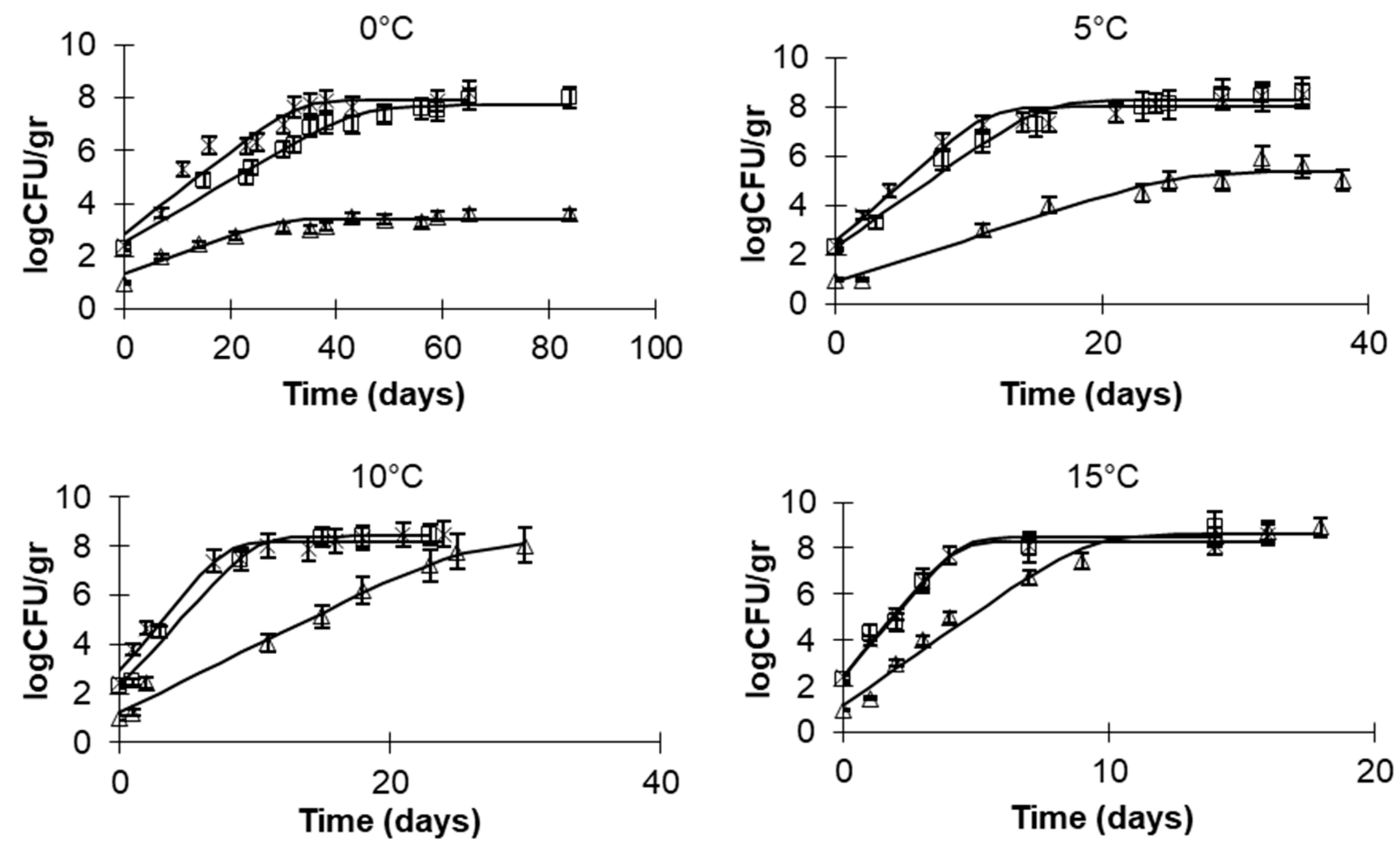

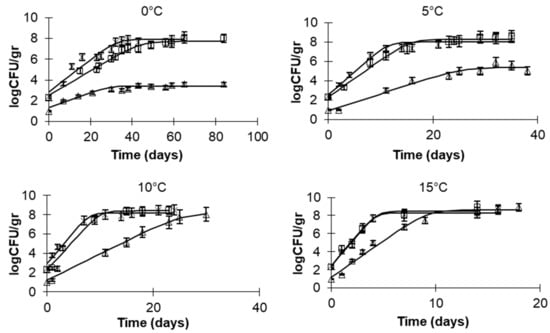

Figure 2.

Growth of lactic acid bacteria of Bratwurst sausages during storage at 0, 5, 10, and 15 °C; (x): control samples, (□): nitrite-made samples, (∆): HP-treated samples at 600 MPa and 25 °C for 5 min.

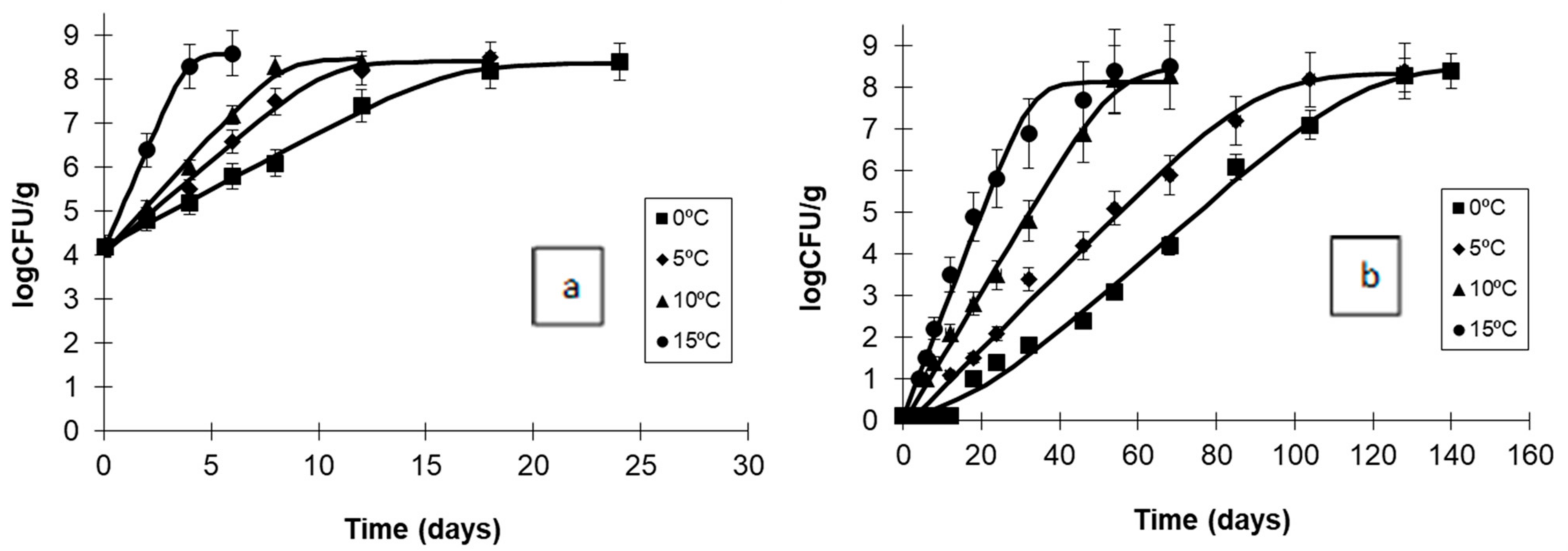

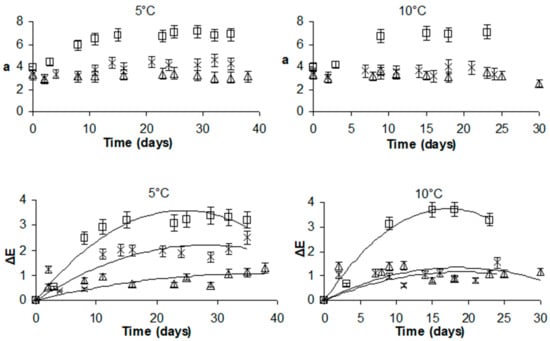

3.3. Effect of HP Treatment on Microbial Growth of Sliced Cooked Ham

For vacuum packed sliced cooked ham, LAB were also the dominant spoilage microorganisms, and their growth rates were estimated for control untreated samples and for HP treated at 500 and 600 MPa (5 min at 25 °C) (Figure 3, Table 3). Processing of sliced cooked ham at the higher pressure (600 MPa) resulted in significantly (p < 0.05) lower growth rates. At 0 °C storage, the LAB rate was approximately five times lower compared to the rate of control samples. All the other measured microorganisms (Pseudomonas spp., Enterobacteriaceae, Yeasts and molds, Staphylococcus spp., Brochothrix thermosphacta) were below the detection limit for HP treated samples throughout the whole storage period at all storage temperatures. Pseudomonas spp. growth was recorded at all storage temperatures for control samples. Nevertheless, their maximum population never exceeded the 5.2 log CFU/g up to a storage of 40 days (for all studied temperatures) (Figure 4).

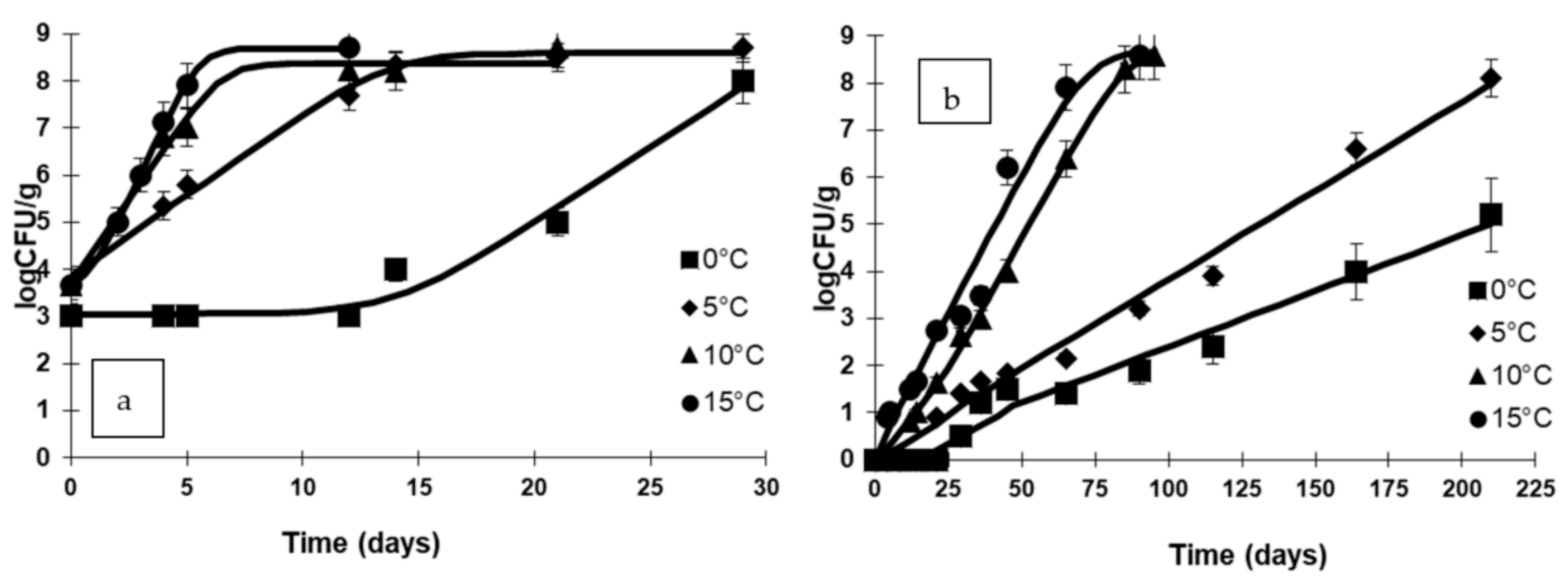

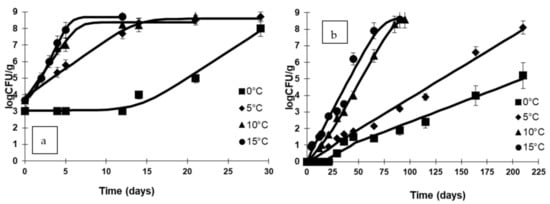

Figure 3.

Growth of lactic acid bacteria of sliced cooked ham during storage at 0, 5, 10, and 15 °C, for control (a) and HP treated samples at 600 MPa and 25 °C for 5 min (b).

Table 3.

Growth rate constants (days−1) for the lactic acid bacteria of meat products, stored at temperatures ranging from 0 to 15 °C, for each type of product. The activation energy values are also presented.

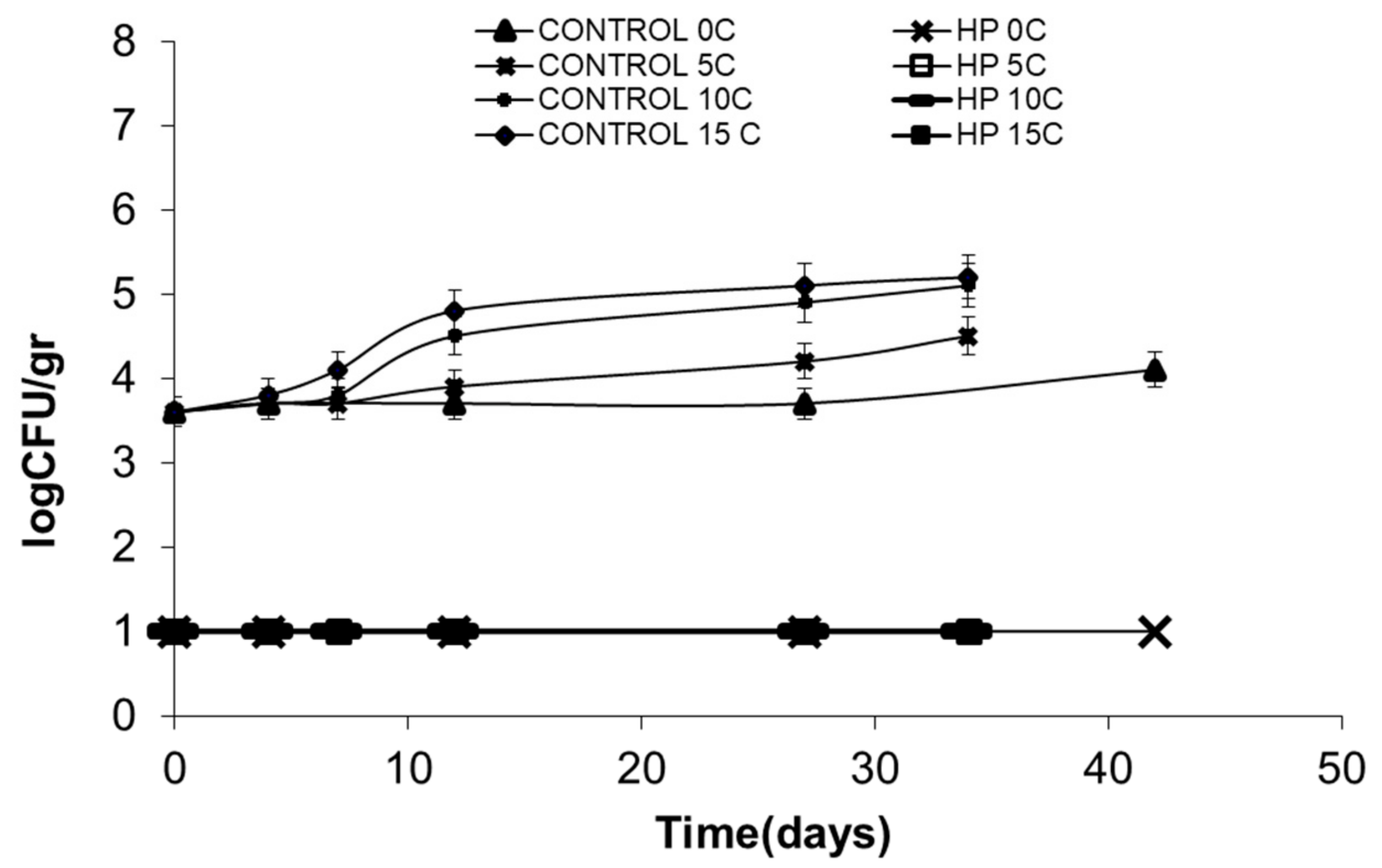

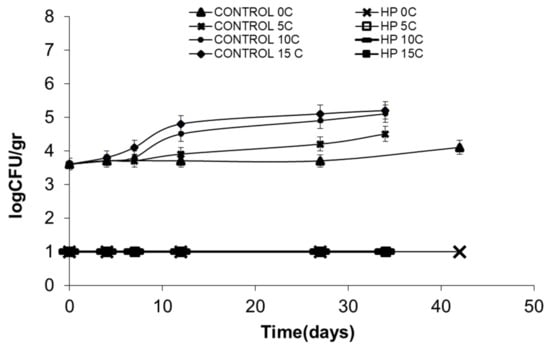

Figure 4.

Growth of Pseudomonas spp. sliced cooked ham during storage at 0, 5, 10, and 15 °C, for control and HP treated samples at 600 MPa and 25 °C for 5 min.

3.4. Effect of HP Treatment on Microbial Growth of Sliced Cooked Turkey

Similar results were obtained for vacuum packed sliced cooked turkey, HP treated in pack at 600 MPa. LAB were the pre-dominant spoilage microorganisms at all storage temperatures. HP cold pasteurization resulted in a more than 3-log reduction of initial LAB population (from 3.1 logCFU/gr of control samples to not detectable values for HP treated samples) and a significant lag phase (up to 25 days lag-phase with no microbial growth for sliced cooked ham, 10 days for sliced cooked turkey, and 15 days for diced ham cubes) at the lower storage temperatures. An up to eight-fold increase of control samples growth rate was estimated for the lower temperatures (0.188 days−1 at 0 °C), compared to the corresponding values of HP treated samples (0.025 days−1 at 0 °C) (Table 3).

3.5. Effect of HP Treatment on Microbial Growth of Cooked Ham Cubes

Vacuum packed cooked ham cubes (Figure 5) were, as expected, more perishable products compared to sliced cooked ham (Figure 4) and turkey, having a higher initial LAB load due to the dicing process. The growth rates of LAB were estimated as 0.2601, 0.4183, 0.5358, and 1.1428 d−1 for samples stored at 0, 5, 10, and 15 °C, respectively. Processing at 600 MPa resulted in significant (p < 0.05) reduction of the LAB growth rates (Figure 3; Figure 5, Table 3).

Figure 5.

Growth of lactic acid bacteria of diced cooked ham (ham cubes) during storage at 0, 5, 10, and 15 °C, for control (a) and HP treated samples at 600 MPa and 25 °C for 5 min (b).

3.6. Effect of Storage Temperature on Meat Products Microbial Growth Rate Constants

The effect of storage temperature on the growth rate constants of all studied microorganisms for all samples was expressed through the activation energy value, Ea, of the Arrhenius equation. All Ea values were estimated (Table 3) and ranged from 80 to 106 kJ/mol for sliced cooked ham and from 44 to 94 kJ/mol for cooked turkey. For ham cubes, the corresponding values were 61 and 49 kJ/mol for control and HP treated samples, respectively. The R2 values for the determination of Ea values were higher than 0.92 in all cases.

3.7. Effect of HP Treatment on pH Values of Meat Products

Initial pH value of all meat products was approximately 6.5; HHP treatment did not alter the pH value of the vacuum-packed meat products. During storage, all control samples exhibited pH decrease, while for HP treated ones the pH values were slightly affected. Reduction of pH value in foods and more specifically in meat products is usually correlated to lactic acid bacteria population [30,31]. After 60 days of storage at 0 °C, the pH values of control and HP treated samples were 5.7 and 6.1, respectively, for cooked ham. For the ham cubes at 10 °C, pH of HP treated samples was above 6.2 after 18 days of storage, while for control samples, the values decreased to 5.2. For Bratwurst sausages, after storage at 0 °C for 60 days, the pH values of control and nitrite-made samples were 5.7 and 5.8, respectively, while for the HP-treated samples, the pH value was 6.1.

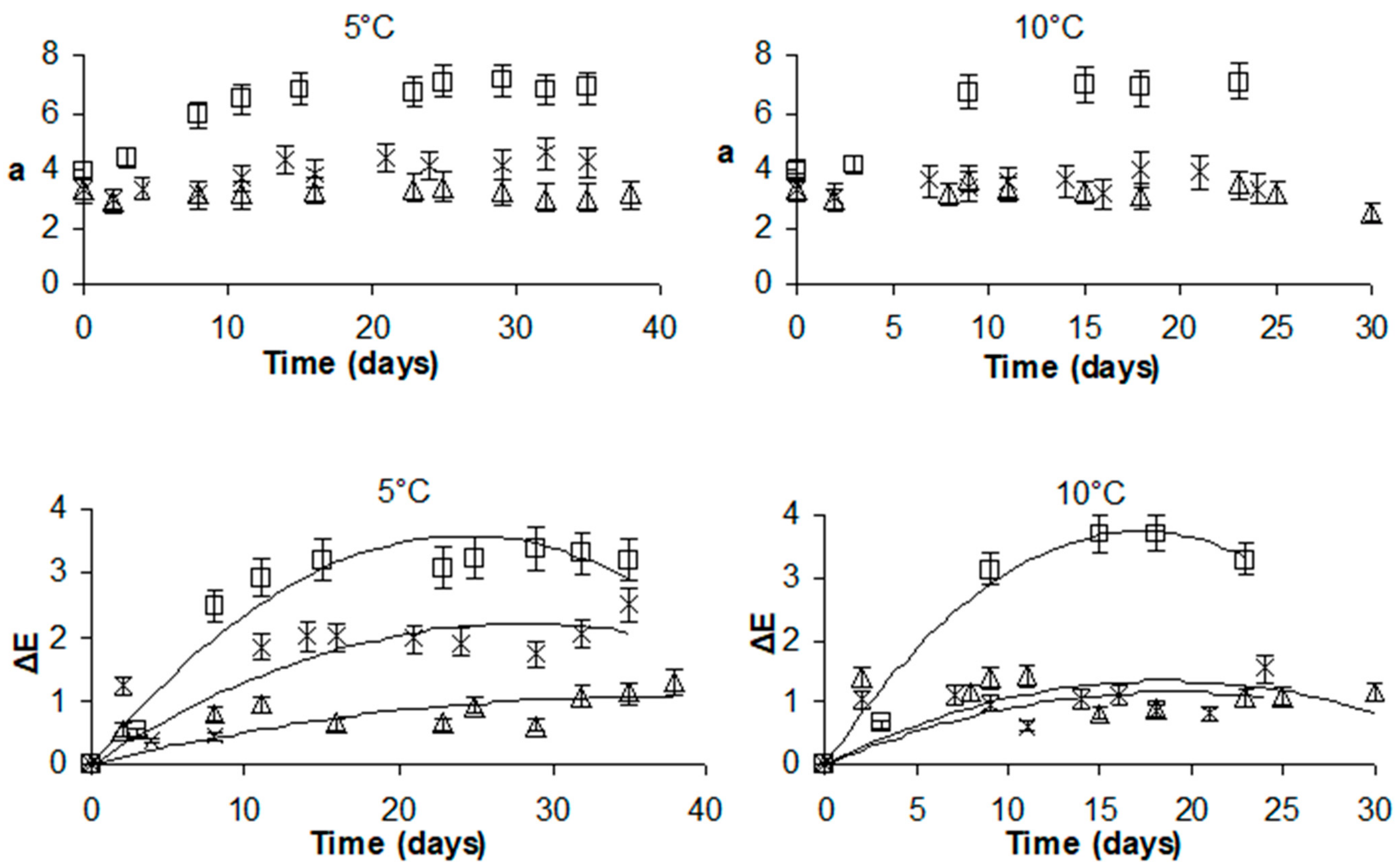

3.8. Effect of HP Treatment on Color of Meat Products

Nitrites are responsible for the characteristic pink color of the cured meat products [32]. Bratwurst sausage is a traditionally white colored meat product. Change of color from white to red (addition of nitrites) is undesirable for this specific product. On the other hand, use of nitrites can provide some extent of microbial inhibition. As it is shown in Figure 6, nitrite enriched samples exhibited an observable increase of redness (“a” value increased to 7), after 10 and 15 days of storage at 5 and 10 °C, respectively. For control and HP-treated samples, the value of redness (a) was not significantly changed (“a” equal to approximately 3.5) during the whole storage period. The same pattern was also observed for samples stored at 0 and 15 °C. Values of lightness slightly increased (L-value ranged from 72 to 73) in nitrite-made sausages and decreased (L-value ranged from 68 to 70) in HP-treated samples, compared to the control samples (corresponding L-value equal to 70–72). Yuste et al. [33] observed an increase in lightness and a decrease in redness and yellowness in HP-treated poultry and minced pork meat, while Jimenez-Colmenero et al. [34] reported a decrease in lightness, redness, and yellowness in HP-treated chicken batters. For all other studied samples (cooked ham in slices and cubes and sliced cooked turkey, both HP treated and control samples) the value of redness (a) and yellowness (b) did not significantly change during the whole storage period, at all studied temperatures. Values of lightness slightly decreased (from 71 to 68) in HP-treated sliced cooked turkey samples, while no effect was observed to all other samples studied.

Figure 6.

Redness (a) values of Bratwurst sausages’ surface during storage at 5 and 10 °C vs. time for; (x): control samples, (□): nitrite-made samples, (∆): HP-treated samples.

3.9. Effect of HP Treatment on Texture of Meat Products

In general, HP treatment did not significantly modify the hardness of all meat products samples compared to the untreated ones. For Bratwurst sausages, the nitrite-made ones were the less cohesive (value equal to 0.5) and the ones with the higher hardness measured (1650 g at time t = 0), compared to the nitrite-free (cohesiveness value equal to 0.75 and hardness value estimated at 850 g at time t = 0) and the HP-treated ones (corresponding values equal to 0.82 for cohesiveness and 1100 g for the hardness). Values of hardness and cohesiveness were not altered for any of the three different Bratwurst samples throughout the studied storage period. Nitrite-made samples exhibited higher gumminess and chewiness, during the whole storage period, at all storage temperatures. At time t = 0, gumminess and chewiness of nitrite-made samples was 276 g and 737 g·s, respectively, while the respective values of control samples was 179 g and 507 g·s. HP treatment did not modify gumminess and chewiness of Bratwurst sausages. Similar results about the effect of high pressure treatment on the texture of sausages have been reported by other authors. Yuste et al. [33] and Mor-Mur and Yuste [35], observed higher cohesiveness; lower gumminess, chewiness, and hardness; and unaffected adhesiveness and springiness in pressured sausages. HP-treated ham cubes exhibited higher gumminess and chewiness during the whole storage period, at all storage temperatures compared to untreated samples. At time t = 0, gumminess and chewiness of HP-treated ham cubes were 276 g and 737 g·s, respectively, while the respective values of control samples were 179 g and 507 g·s. HP treatment did not modify the hardness of the sliced cooked ham and turkeys (i.e., hardness of sliced cooked hams equal to 820 g for the control samples and 805 g for the HP-treated ones at time t = 0). Other measured parameters such as gumminess and chewiness of sliced cooked meat products were not affected at all by either the HP treatment or the storage time and temperature. Overall, storage temperature did not alter texture characteristics of any of the tested meat products.

3.10. Effect of HP Treatment on Organoleptic Properties of Meat Products

Sensory evaluation of all samples showed lower acceptance for nitrite-made samples compared to control and HP-treated samples, mainly attributed to their appearance and texture. It was noticed that nitrite-made sausages were harder, springier, and less juicy (results in accordance with Dong et al. [36]). Cooking caused shrinkage of nitrite-made samples’ surface, resulting in lower scoring during the evaluation. HP treatment did not modify organoleptic characteristics of sausages. During storage, HP-treated samples were scored with the higher values. It was noticed that HP-treated samples were juicier and had a more pleasant taste, and their surface was more smooth, compared to the nitrite-made samples. The deterioration of sensory characteristics of the sausages during storage was expressed through the scoring of the samples by the sensory panel. Scoring results were fitted to a linear model, and the rates of organoleptic deterioration (overall impression) for each storage temperature were estimated (Table 4) (R2 values were higher than 0.968 for all temperatures and all samples). Sensory evaluation showed that organoleptic characteristics of sausages degraded rapidly for control samples. Sensory deterioration of control samples was mainly attributed to microbial growth. HP-treated samples exhibited significantly (p < 0.05) lower rates of sensory deterioration: deterioration rate constant was 0.072 days−1 at 5 °C, while for nitrite-enriched and control samples, the corresponding values were 0.156 and 0.259 days−1. Sensory deterioration was also strongly dependent on storage temperature. The effect of storage temperature on the deterioration rate was expressed through the Ea value. HP treatment significantly affected the Ea value of organoleptic deterioration compared to the control samples (Ea value of HP treated samples was double the Ea value of control samples) (Table 4).

Table 4.

Organoleptic deterioration rates (days−1) for meat products, stored at temperatures ranging from 0 to 15 °C, for each type of product. The activation energy values are also presented.

Sensory evaluation of all other samples showed similar acceptance between control and HP-treated samples exactly after processing (time t = 0). After extended storage (more than 15 days) HP treated samples were evaluated with a higher scoring compared to control samples, mainly attributed to their appearance and texture. It was noticed that control meat products (ham cubes and sliced cooked ham and turkey) were harder, stringier, and less juicy, while HP treated ones were juicier, with more pleasant taste and with a smooth surface, compared to the control samples. Sensory evaluation showed that characteristics of ham cubes degraded rapidly for control samples. Sensory deterioration was mainly attributed to microbial growth, so it is directly correlated to the spoilage bacteria populations. HP-treated samples exhibited the lower rates of sensory deterioration: deterioration rate constant was 0.072 days−1 at 5 °C, while for control samples, the corresponding value was 0.259 days−1. The same pattern was established for sliced cooked ham and turkey. The corresponding sensory deterioration rates were significantly (p < 0.05) lower compared to the rates obtained for ham cubes, probably due to the lower microbial growths estimated. High pressure treatment may potentially extend the shelf life of meat products. Sensory deterioration was also strongly dependent to storage temperature. The effect of storage temperature on the deterioration rate was expressed through the Ea value. HP treatment significantly affected the Ea value of sensory deterioration compared to the control samples (Ea value of HP treated samples was approximately two-fold the Ea value of control samples) (Table 4). Ea values for the sensory rates of ham and turkey products were in the same order as the Ea values for the LAB growth rates.

3.11. Effect of HP Treatment on Shelf Life of Meat Products

The shelf life was defined based on both the microbiological growth of LAB and the sensory deterioration of the samples. The time in which the microbial counts reached 108 CFU/g or when the sensory scoring was lower than 5 defined the shelf life of the products. For HP treated Bratwurst sausages, the shelf life was estimated as 113, 51, 28, and nine days for storage at 0, 5, 10 and 15 °C, respectively. At all temperatures, the HP treated samples showed more than a two-fold shelf life increase compared to samples with nitrites (Table 5). For HP treated (600 MPa) sliced cooked hams, the shelf life was estimated as 286, 187, 45, and 30 days for storage at 0, 5, 10, and 15 °C, respectively (Table 5). The most pronounced shelf life increase was observed for the extremely perishable ham cubes. For ham cubes stored at 5 °C, the shelf life of HP treated samples is more than two months, compared to the corresponding value obtained for control samples that is less than 10 days. In all temperatures, the HP-treated samples’ shelf life increased by two-fold up to 10-fold compared to the shelf life of control samples. This demonstrates the effectiveness of HP in pack cold pasteurization for the shelf-life extension of meat products.

Table 5.

The shelf life (days) of meat products stored at temperatures ranging from 0 to 15 °C.

3.12. Consumers’ Acceptance of HP Treated Sliced Cooked Ham

A survey of the orghanoleptic acceptance of HP treated sliced cooked ham was performed. Samples processed at 600 MPa, 25 °C for 5 min and control samples were evaluated for their overall impression by approximately 87 untrained consumers. Evaluation was performed at day 0, a few hours from HP processing of the samples. The panelists were not informed about the differences in the samples, so the samples were named as 1 and 2. At day 0, the consumers could not determine significant (p > 0.05) differences between HP treated and untreated samples (48% preference for HP treated samples compared to 52% for control samples), indicating that HP processing does not alter the perceived flavor and texture of the products. The same survey was performed after 25 days of storage of control and HP treated samples at 0 °C. The same organoleptic panel evaluated the products. For 89% of the consumers, the HP-treated sample was significantly better than the control one. They indicated that after 25 days of storage, the HP-treated samples were preferred compared to the untreated ones and were characterized as fresh compared to the respective control samples.

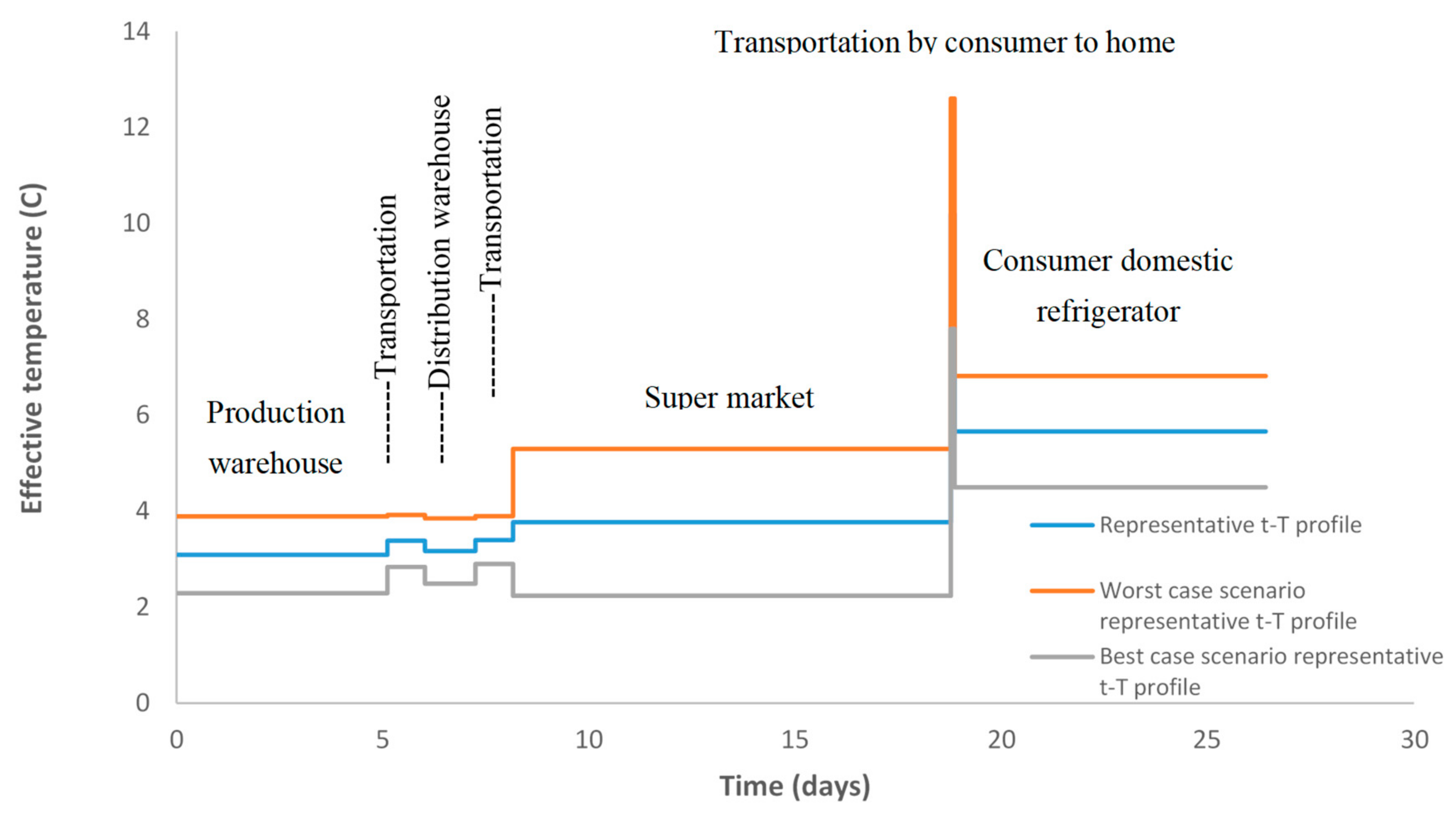

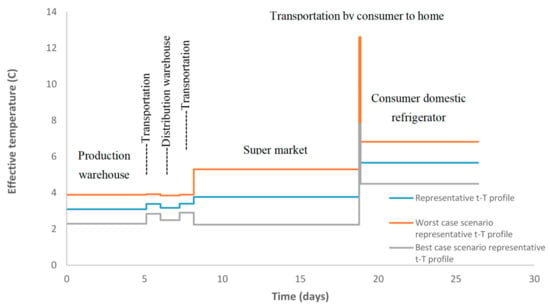

3.13. Cold Chain Management of HP Treated Meat Products

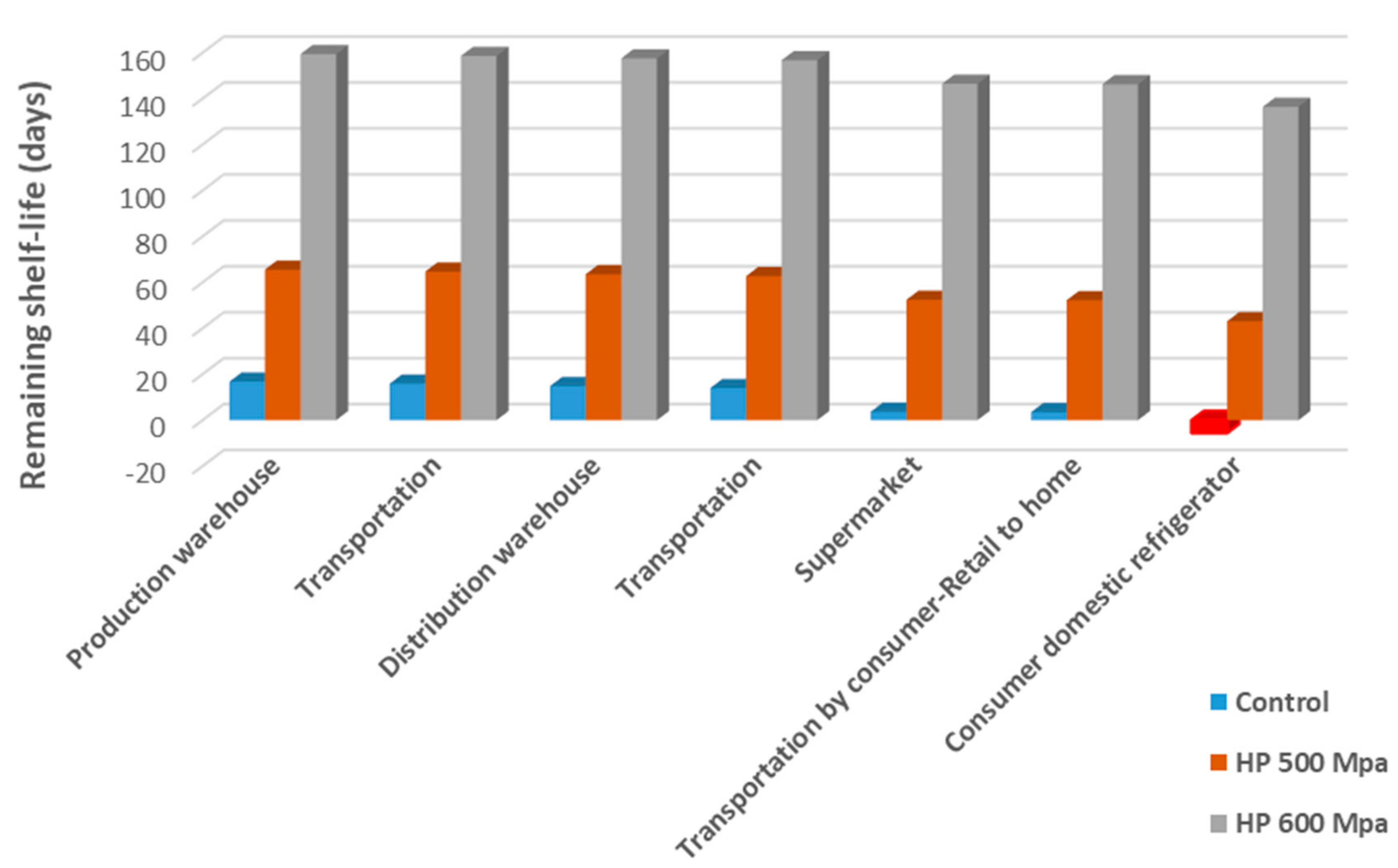

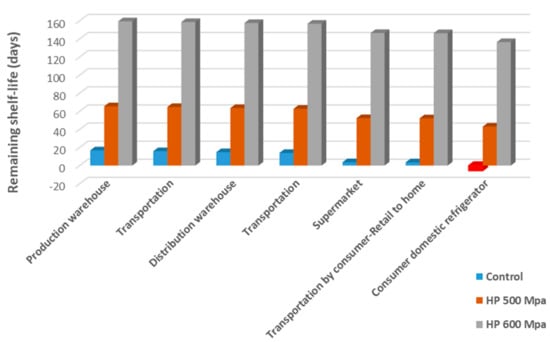

Overall, HP treatment offers significant the shelf life extension of meat products as evidenced above (Table 5). Storage and distribution are the weakest links in the food management. The effective control of temperature conditions is important for the commercial viability of the products, since they often deviate from specifications. Using Cold Chain Database and Cold Chain Predictor software, a sequence of real cold chain stages could be used to build a representative t–T profile for meat products. This sequence consists of the production warehouse, transportation, distribution warehouse, transportation, supermarket, transportation by consumer to home, and consumer domestic refrigerator (Figure 7). The effective temperature (Teff) (defined as the constant temperature that results in the same quality value as the variable temperature distribution over the same time period, based on the Arrhenius model and integrating in a single value the effect of the variable temperature profile) [37] estimated based on the records of contributed profiles is also presented in Figure 7, along with the worst case and the best case t–T profile scenario based on real data. Following the procedure described by Gogou et al. [24] and combining the representative profile (Figure 8) with the kinetic deterioration data presented above for sliced cooked products, assuming that the Lactic acid bacteria (LAB) are the dominant spoilage microorganisms, the remaining shelf life (SLR) of meat products may be estimated at any stage of the built representative profile. This profile was not applied to cooked ham cubes, since it is a product available only for food service and not for home consumption with a significantly short shelf life, while for Bratwurst sausages, the profile is similar to the one of the sliced meat products, but significantly shorter (the whole duration is 15 days, compared to the 27 days profile of sliced meat products depicted in Figure 7). The results validate that HP treatment offers significantly in the reduction of spoiled meat products during storage and transportation and before storage in domestic refrigerators. For untreated sliced cooked hams, the prediction indicates that products are expected to have past their nominal shelf-life even before being stored in domestic refrigerators. Application of HP at 500 and 600 MPa significantly improves this prediction. More specifically, HP at 500 MPa will provide an SLR of 20 days and HP at 600 MPa an SLR of more than six months in consumers’ refrigerators (Figure 8).

Figure 7.

Representative time–temperature profile, best case scenario t–T profile, and worst case scenario t–T profile, all generated by the CCP software based on the records of contributed actual profiles.

Figure 8.

Remaining shelf life after exposure to the time and temperature conditions of the representative profile for sliced cooked ham.

Combining all the above data, the remaining shelf life, SLR, for sliced cooked ham and turkey may be estimated in the consumers’ refrigerator considering a duration of the handling of the products for a total time of 19 days up to the point it starts being stored in the domestic refrigerator (Figure 7). Table 6 presents the SLR of cooked ham and turkey in slices during the storage in the consumer refrigerator if (a) the recommended storage conditions are applied throughout the whole cold chain (samples should be kept during storage and transportation at 2–4 °C, based on the producer recommendations), (b) the representative t–T profile of Figure 7 is applied for the cold chain stages before the consumer refrigerator, (c) the best case scenario for the t–T profile is applied (Figure 7) before the consumer refrigerator, and (d) when the worst case scenario for the t–T profile is applied before storage at the domestic refrigerator (Figure 7). The results validate that proper temperature handling is necessary for untreated samples throughout the whole cold chain, while HP treatment results in longer duration of the products in consumers’ refrigerators, allowing for unplanned temperature deviations from the recommended ones, thus minimizing the food waste (spoiled products before their consumption that would be discarded). Even for the worst case scenario t–T profile, the HP treated products would still have a very long SLR and would be very unlikely to fail. Considering all the above, three months is a satisfactory shelf life of commercially available HP-treated sliced meat products, and although technically it is achievable to have longer times, the meat industry would not be necessary to claim for it.

Table 6.

The remaining shelf life, SLR (days), of sliced cooked meat products (ham and turkey) if stored in consumers’ refrigerators with a constant temperature of 4 °C, after 19 days in the cold chain.

4. Conclusions

High hydrostatic pressure in pack cold pasteurization was demonstrated to be effective in extending the shelf life of four different meat products, i.e., sliced cooked ham and turkey, ham in cubes, and Bratwurst sausages. Growth of lactic acid bacteria, the predominant spoilage microflora for these products, was significantly delayed by application of HP technology. The growth rates were estimated and compared for HP treated samples and control ones, demonstrating the efficacy of this technology to decrease the bacterial count. Texture of HP treated samples was not significantly modified, while the HP-treated samples exhibited improved sensory characteristics and limited color changes compared to control samples. The delayed microbial growth for HP samples resulted in significant (p < 0.05) shelf life extension for all products, equal to more than two-fold and up to 10-fold the shelf life of control samples. For the cooked ham in slices, a sensory evaluation was performed by untrained consumers, showing that the obtained products are not distinguishable immediately after processing, while after several weeks, the control ones are scored significantly lower than the HP treated ones, offering the sense of being freshly produced. The obtained kinetic data were applied to a useful tool for shelf-life prediction of the products when exposed to a time–temperature profile as more representative as possible based on real t–T data. The output of the software validated that HP treated samples are less perishable compared to control ones and allow for short exposure to temperature deviations during transportation and storage. High pressure treatment can therefore lead to meat products of high quality throughout their prolonged shelf life, satisfying consumers’ demands for products with “fresh” attributes and long durability.

Author Contributions

Conceptualization: P.T.; methodology: G.K. and P.T.; software: G.K. and P.T.; validation: G.K. and P.T.; formal analysis: G.K.; investigation: G.K.; resources: P.T.; data curation: G.K.; writing—original draft preparation: G.K.; writing—review and editing: P.T.; supervision: P.T.; project administration: P.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors acknowledge Kostianna Karoussi for performing part of experiments reported in this publication, during her studies for the Chemical Engineering diploma.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nastasijevic, I.; Lakicevic, B.; Petrović, Z. Cold Chain Management in Meat Storage, Distribution and Retail: A Review. IOP Conf. Ser. Earth Environ. Sci. 2017, 85, 012022. [Google Scholar] [CrossRef]

- Rahman, S. Nitrites in Food Preservation. In Handbook of Food Preservation; Shafiur Rahman, M., Ed.; CRC Press, Inc.: Boca Raton, FL, USA, 1999; pp. 421–436. [Google Scholar]

- Holley, R.A. Brochothrix. In Encyclopedia of Food Microbiology, 2nd ed.; Batt, C.A., Tortorello, M.L., Eds.; Academic Press: London, UK, 1981; pp. 331–334. [Google Scholar]

- Andersen, H.J.; Bertelson, G.; Skibsted, L.H. Salt effect on acid-catalyzed autoxidation of oxymyoglobin. Acta Chem. Scand. 1988, A42, 226. [Google Scholar] [CrossRef][Green Version]

- Lee, S.H.; Cassens, R.G. Nitrite binding sites on myoglobin. J. Food Sci. 1976, 41, 969. [Google Scholar] [CrossRef]

- Gassiot, M.; Masoliver, P. Commercial high pressure processing of ham and other sliced meat products at Esteban Espuña, SA. In Case Studies in Novel Food Processing Technologies: Innovations in Processing, Packaging, and Predictive Modelling; Doona, C.J., Kustin, K., Feeherry, F.E., Eds.; Woodhead Publishing: Sawston/Cambridge, UK, 2010; pp. 21–33. [Google Scholar]

- Pottier, L.; Villamonte, G.; de Lamballerie, M. Applications of high pressure for healthier foods. Curr. Opin. Food Sci. 2017, 16, 21–27. [Google Scholar] [CrossRef]

- Tonello-Samson, C. High Pressure Processing Commercial Developments: Global Market, Equipment and Applications in the Meat Industry. Eur. Symp. Food Saf. 2017. [Google Scholar] [CrossRef]

- Hiperbaric—Blog: Global Trends in High Pressure Processing (HPP) for 2019. Available online: https://blog.hiperbaric.com/en/global-trends-in-hpp-for-2019 (accessed on 29 December 2020).

- Cheftel, J.C. Review: High-pressure, microbial inactivation and food preservation. Food Sci. Technol. Intern. 1995, 1, 75–90. [Google Scholar] [CrossRef]

- Sukmanov, V.; Hanjun, M.; Li, Y.-P. Effect of high pressure processing on meat and meat products. A review. Ukr. Food J. 2019, 8, 448–469. [Google Scholar] [CrossRef]

- Katsaros, G.J.; Alexandrakis, Z.S.; Taoukis, P.S. Kinetic assessment of high pressure inactivation of different plant origin pectinmethylesterase enzymes. Food Eng. Rev. 2017, 9, 170–189. [Google Scholar] [CrossRef]

- Jofré, A.; Aymerich, T.; Grèbol, N.; Garriga, M. Efficiency of high hydrostatic pressure at 600 MPa against food-borne microorganisms by challenge tests on convenience meat products. LWT 2009, 42, 924–928. [Google Scholar] [CrossRef]

- Slongo, A.P.; Rosenthal, A.; Quaresma Camargo, L.M.; Deliza, R.; Mathias, S.P.; Falcão de Aragão, G.M. Modeling the growth of lactic acid bacteria in sliced ham processed by high hydrostatic pressure. LWT 2009, 42, 303–306. [Google Scholar] [CrossRef]

- O’Neill, C.M.; Cruz-Romero, M.C.; Duffy, G.; Kerry, J.P. Shelf life extension of vacuum-packed salt reduced frankfurters and cooked ham through the combined application of high pressure processing and organic acids. Food Pack. Shelf. Life 2018, 17, 120–128. [Google Scholar] [CrossRef]

- Hayman, M.M.; Baxter, I.; O’Riordan, P.J.; Stewart, C.M. Effects of high-pressure processing on the safety, quality, and shelf life of ready-to-eat meats. J. Food Prot. 2004, 67, 1709–1718. [Google Scholar] [CrossRef] [PubMed]

- Diez, A.M.; Santos, E.M.; Jaime, I.; Rovira, J. Effectiveness of combined preservation methods to extend the shelf life of Morcilla de Burgos. Meat Sci. 2009, 81, 171–177. [Google Scholar] [CrossRef] [PubMed]

- Pietrasik, Z.; Gaudette, N.J.; Johnston, S.P. The impact of high hydrostatic pressure on the functionality and consumer acceptability of reduced sodium naturally cured wieners. Meat Sci. 2017, 129, 127–134. [Google Scholar] [CrossRef]

- Garriga, M.; Grèbol, N.; Aymerich, M.T.; Monfort, J.M.; Hugas, M. Microbial inactivation after high-pressure processing at 600 MPa in commercial meat products over its shelf life. Innov. Food Sci. Emerg. Technol. 2004, 5, 451–457. [Google Scholar] [CrossRef]

- Huang, M.; Moreira, R.G.; Murano, E. Use of hydrostatic pressure to produce high quality and safe fresh pork sausage. J. Food Process. Preserv. 1999, 23, 265–284. [Google Scholar] [CrossRef]

- Cacace, F.; Bottani, E.; Rizzi, A.; Vignali, G. Evaluation of the economic and environmental sustainability of high pressure processing of foods. Innov. Food Sci. Emerg. 2020, 60, 102281. [Google Scholar] [CrossRef]

- Peleg, M. Texture Profile Analysis Parameters Obtained by an Instron Universal Testing Machine. J. Food Sci. 1976, 41, 721–722. [Google Scholar] [CrossRef]

- Baranyi, J.; Roberts, T.A. A dynamic approach to predicting bacterial growth in food. Int. J. Food Microbiol. 1994, 23, 277–294. [Google Scholar] [CrossRef]

- Gogou, E.; Katsaros, G.; Derens, E.; Alvarez, G.; Taoukis, P.S. Cold chain database development and application as a tool for the cold chain management and food quality evaluation. Int. J. Refrig. 2015, 52, 109–121. [Google Scholar] [CrossRef]

- Koutsoumanis, K.; Taoukis, P.S.; Nychas, G.J.E. Development of a Safety Monitoring and Assurance System for chilled food products. Int. J. Food Microbiol. 2005, 100, 253–260. [Google Scholar] [CrossRef] [PubMed]

- Cayré, M.E.; Garro, O.; Vignolo, G. Effect of storage temperature and as permeability of packaging film on the growth of lactic acid bacteria and Brochothrix thermosphacta in cooked meat emulsions. Food Microbiol. 2005, 22, 505–512. [Google Scholar] [CrossRef]

- Borch, E.; Kant-Muermans, M.L.; Blixt, Y. Bacterial spoilage of meat and cured meat products. Int. J. Food Microbiol. 1996, 33, 103–120. [Google Scholar] [CrossRef]

- Korkeala, H.J.; Björkroth, K.J. Spoilage and contamination of vacuum-packaged cooked sausages: A review. J. Food Prot. 1997, 60, 724–731. [Google Scholar] [CrossRef]

- Sofos, J.N. Microbial growth and its control in meat, poultry and fish. In Quality Attributes and Their Measurement in Meat, Poultry, and Fish Products; Pearson, A.M., Dutson, T.R., Eds.; Blackie Academic and Professional: Glasgow, UK, 1994; pp. 359–403. [Google Scholar]

- Hitchener, B.J.; Egan, A.F.; Rogers, P.J. Characteristics of lactic acid bacteria isolated from vacuum-packaged beef. J. Appl. Bacter. 1982, 52, 31–37. [Google Scholar] [CrossRef]

- García-Lopéz, M.L.; Prieto, M.; Otero, A. The Microbiology of Meat and Poultry; Davies, A., Board, R., Eds.; Blackie Academic and Professional: London, UK, 1998; pp. 1–34. [Google Scholar]

- Eakes, B.D.; Blumer, N.N.; Monroe, R.J. Effect of nitrate and nitrite on color and flavor of country-style ham. J. Food Sci. 1975, 40, 973–976. [Google Scholar] [CrossRef]

- Yuste, J.; Mor-Mur, M.; Capellas, M.; Pla, R. Listeria innocua and aerobic mesophiles during chill storage of inoculated mechanically recovered poultry meat treated with high hydrostatic pressure. Meat Sci. 1999, 53, 251–257. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F.; Fernandez, P.; Carballo, J.; Fernandez-Martin, F. High-pressure-cooked low-fat pork and chicken batters as affected by salt levels and cooking temperature. J. Food Sci. 1998, 63, 656–659. [Google Scholar] [CrossRef]

- Mor-Mur, Μ.; Yuste, J. High pressure processing applied to cooked sausage manufacture: Physical properties and sensory analysis. Meat Sci. 2003, 65, 1187–1191. [Google Scholar] [CrossRef]

- Dong, Q.; Tu, K.; Guo, Y.; Yang, J.; Wang, H.; Chen, Y. The effect of sodium nitrite on the textural properties of cooked sausage during cold storage. J. Texture Stud. 2007, 38, 537–554. [Google Scholar] [CrossRef]

- Taoukis, P.S.; Labuza, T.P.; Saguy, I.S. Kinetics of food deterioration and shelf life prediction. In Handbook of Food Engineering Practice; Valentas, K.J., Rotstein, E., Singh, R.P., Eds.; CRC: New York, NY, USA, 2007. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).