1. Introduction

Buildings account for the largest share of total EU final energy consumption (40%) and produce about 35% of all greenhouse emissions. More than ever, we need to apply circular economy and resource efficiency principles to buildings to reduce resource use in the future. The European Commission has reaffirmed this message by means of the European Green Deal [

1].

Recycling nonwoven textile waste as building components could help reducing environmental impacts [

2]. In the past few decades, the fiber production increased enormously. Several application fields can be counted from the industrial sector to the home furnishing. Wang [

3] stated that the textile waste can be divided into three different categories: the short term (e.g., disposables), medium term (e.g., apparel and carpet), and long term (e.g., textiles for buildings). Bilal et al. [

4] stated that the textile by-products represent an excellent opportunity for the production of high performances building composites. Several researchers demonstrated that these materials can be excellent when used for the production of thermal insulators [

2,

5,

6].

However, a low thermal mass value characterizes these materials. Thus, in order to improve their thermal performances the addition of phase change materials (PCMs) can be considered an efficient method as clearly represented by the many literature reviews on this topic [

7,

8,

9,

10]. In particular, Soares et al. [

7] compiled one of the first comprehensive review on PCMs used in latent heat thermal energy storage (LHTES) systems, in order to improve building’s energy performance. Such LHTES systems can increase indoor thermal comfort; reduce energy consumption; decrease the conditioning power needed, and contribute to the reduction of CO

2 emissions in heating and cooling.

PCMs can be included in building materials through different ways (i.e., direct incorporation, immersion, encapsulation, and stabilization), ensuring in all cases a reduction of extreme temperatures and lower temperature fluctuations. Encapsulation is the most frequently used technique and, in particular, microencapsulation, which involves the incorporation of PCMs in microcapsules with a protective shell which prevents material dispersion during the liquid phase and, in addition, makes the PCM to be directly used in the mixing process of the construction materials [

10]. Several studies showed that such approach allowed a straightforward use of microencapsulated PCMs in concretes [

11], which proved to ensure long-term durability and performance stability [

12]. However, as stated above, it is with low thermal mass materials that PCMs prove to be more effective and the most frequent, cheapest, and easiest use of microcapsules filled with paraffin, is their incorporation into gypsum-based plasters paste for internal walls or plasterboard panels [

13,

14,

15]. These solutions have been experimented for years [

9]. The main purpose of integrating PCMs into lightweight building materials is to increase their thermal energy storage capability and consequently reduce temperature fluctuations, economically, and effectively, both in case of renovations of existing buildings and in case of new ones. Peippo et al. [

16] discussed the use of walls containing PCMs (fatty acids, to be precise) for the short-term storage of latent heat in passive solar applications. After defining guidelines for the ideal determination of the melting temperature and the wall thickness, in order to optimize the amount of stored energy, they estimated an energy saving varying between 5% and 20%. In Feldman et al.’s experiment [

14], a tenfold increase in the heat storage capacity of a classic plasterboard panel was found, following the direct incorporation of PCM.

The current framework deriving from scientific literature about PCMs incorporation in gypsum-based plasters (and cement-based too) confirms many advantages deriving from this application [

15,

17,

18]. The most significant, among them, include a considerable increase in specific heat, an increase in thermal mass, with a consequent reduction in temperature peaks and their amplitude, and an improvement (albeit non-linear) in the overall performance of the compound according to the amount of paraffin embodied. Recently, the potential of multiple melting ranges has been also successfully investigated [

19].

In this work the use of PCM within insulating materials obtained from textile waste was investigated. Textile fibers and PCMs were bonded with gum arabic solution, at minimum cost and very limited environmental impact, to improve thermal properties of the product.

2. Materials and Methods

2.1. Sheep Wool

In recent years, the use of textile waste in the construction sector has been explored as an economic and sustainable alternative to the traditional insulating materials used so far, especially those deriving from the shearing or textile industry [

5,

20,

21]. Sheep wool is one of the oldest thermal insulators in the world, it is a natural thermoregulator and has interesting characteristics [

22]. Wool contributes to improve the indoor air quality, filtering the air from any harmful chemicals present in the walls, such as formaldehyde (CH

2O), nitrogen dioxide (NO

2), and sulfur dioxide (SO

2). Wool is hygroscopic and hydrophobic, i.e., it is difficult to wet but, at the same time, it is able to control and absorb humidity, minimizing surface condensation. It prevents mold and fungi formation, due to the keratin. Wool effectively absorbs sound waves and, if used as disconnecting layer between massive layers, may contribute to provide excellent acoustic insulation. Wool is naturally fire resistant, as it is self-extinguishing and in case of fire it does not burn but it melts. Finally, it is elastic and breathable, valid against both cold and heat, and it is entirely renewable and sustainable.

In this work, 100% pure merino wool extracted from pieces of tailoring waste deriving from the manufacturing process was used (

Figure 1). Merino wool is the fiber obtained by shearing the homonymous sheep, a particular breed highly appreciated for its fleece. In fact, it is a type of wool highly sought-after because of its fineness, which, added to the qualities of common wool, makes it a very valuable fiber.

2.2. Phase Change Materials

For the subsequently described investigation Micronal

® DS 5001 X was chosen, an organic PCM produced by the German company BASF. It is a dry powder PCM, microencapsulated with highly crosslinked polymethylmethacrylate polymer wall, formaldehyde-free. The particle size varies from 0.1 to 0.3 mm, with a bulk density ranging from 250 to 350 kg/m

3. Its 26 °C melting temperature falls within the range of average operating temperatures that characterize a Mediterranean climate, making the Micronal

® DS 5001 X suitable for construction applications through direct incorporation into building materials for the purpose of improving interior comfort conditions [

22,

23,

24]. Once this melting point is reached, the material inside the microcapsules will maintain a slightly constant temperature for a more or less significant period depending on the amount of PCM used, and this because all the absorbed thermal energy is used to break the chemical bonds and make the phase change happen. This thermal energy is called latent heat of fusion, and for this PCM is about 110 kJ/kg, with an overall storage capacity of 145 kJ/kg in temperature range 10–30 °C.

More detailed information about the properties of the Micronal

® DS 5001 X can be found in Giro-Paloma et al. [

25]. According to these authors this material shows a phase-change temperature between 26.09 °C and 27.81 °C, a melting enthalpy between 114.98 kJ/kg and 142.55 kJ/kg and a solidification enthalpy between 117.85 kJ/kg and 137.85 kJ/kg.

A dynamic Differential Scanning Calorimetry (DSC) analysis (

Figure 2) with constant heating rates of 0.5 °C/min was performed in order to characterize the thermal behavior of the PCM. The analysis was carried out on a 5.5 mg sample of PCM by using a DSC 1 Star System Mettler Toledo device, according to ISO 11357-1 [

26].

The first endothermic transformation at

T = 0 °C refers to the phase change of the water present within the sample, therefore it is not to be taken into consideration. Data resulting from the second endothermic process, on the other hand, refer exclusively to Micronal

® DS 5001 X: area is 632.09 mJ, melting enthalpy is 114.93 kJ/kg, with

Tonset = 24.72 °C,

Tpeak = 29.19 °C, and

Tendset = 33.71 °C. The melting enthalpy of the PCM (

Figure 3) is consistent with that indicated by the manufacturer on the data sheet (110 kJ/kg). On the contrary, the peak temperature can be wrongly compared with the phase change temperature. In fact,

Tpeak depends on the measurement conditions, including heating speed and mass of the sample used, so it is not an intrinsic value of the material and it is generally unreliable for comparison purposes [

25]. Thus, the discrepancy of about 3 °C compared to the nominal value of the melting temperature (26 °C) can be explained in the light of the above differences.

2.3. Gum Arabic

Gum arabic is considered as a biopolymer as it is a hardened sap from the Acacia tree and is therefore commonly used as a natural gum. Its chemical composition is a complex polysaccharide with high molecular weight, water soluble, and its solution gives a slight yellow to reddish color [

5]. Gum arabic shows an important mineralizing ability thanks to its rich content of calcium, magnesium, and potassium salts, while its antibacterial potential is ensured by the presence of tannins in the plant [

27].

Although gum arabic is widely used as dispersant in the food industry, it has great potential for application in building materials. Zhao et al. [

28] tested the disperse-holding capacity of the gum arabic in Portland cement paste, proving a decrease in the viscosity and an increase in the fluidity. The dispersing effects on concrete particles were confirmed by Elinwa et al. [

29] who also observed an improvement of the mechanical properties of the cement with natural biopolymer. Mohamed et al. [

30] tested the antibacterial capacity of the gum arabic, evaluating its positive effects on the durability of concrete in aggressive ambient. In fact, cement samples including the biopolymer showed better resistance to the acid attack, achieving lower mass lost than samples without it. The bio-adhesive capacity of the gum arabic has been also investigated. Abuarra et al. [

31] studied the effects of the gum arabic addition in particleboards made from stems of a typical mangrove tree of the tropical and subtropical coasts regions. Results revealed that the gum arabic bonded panels resulted in smooth surfaces, rigid texture, and good internal bonding strength. Dieye et al. [

32] investigated the thermal properties of innovative boards made from a mixture of powder Typha leaves and gum arabic as binder, observing a promising thermal insulating behaviour. Liuzzi et al. [

33] used gum arabic aqueous solution as binder of almond skin wastes for high hygrothermal and acoustic performances building panels.

In this work, powdered gum arabic produced by BiOrigins (Hampshire, UK) was used, with a very fine consistency and a color tending to white. Its gluing power resulting once the gum is diluted in water was used to produce fully sustainable building materials.

2.4. Samples Preparation

Several test samples were made in the Building Physics Lab of the Polytechnic University of Bari, in order to identify the best proportions of wool, binder and PCM. The starting point for all the samples was wool carding, a manual process performed by two hand carders and through which cloth strips were decomposed into its elementary fibers. The carded wool is soaked into a water and gum arabic solution (

Figure 4) and suitably squeezed by passing small quantities through two rollers in order to eliminate the excess binder. Then, tufts of wool are placed inside a cylindrical mold, with a diameter of 10 cm and a height of 5 cm. During this step, PCM powder is homogeneously added between the various layers of wool, so that it can remain trapped between the meshes of the sample. The latter is finally dried in an oven for about 12 h at 60 °C.

Three specimens were made (

Figure 5), one being the reference (without PCM) and the other two having different weight percentages of phase change material (

Table 1 and

Table 2). The amount of wool and binder always remained the same, so that, with equal volumes, when PCM increased the total weight, sample density increased too.

From the analysis of scanning electron microscope (SEM) images of the specimen surface, with a magnification rate of 200 and 500×, the interaction between the PCM microcapsules, the wool fibers and the gum arabic was observed (

Figure 6), showing that microcapsules often tended to cluster rather than being uniformly distributed among the fibers, possibly having implications on making phase change less efficient because of lower surface-to-volume ratio.

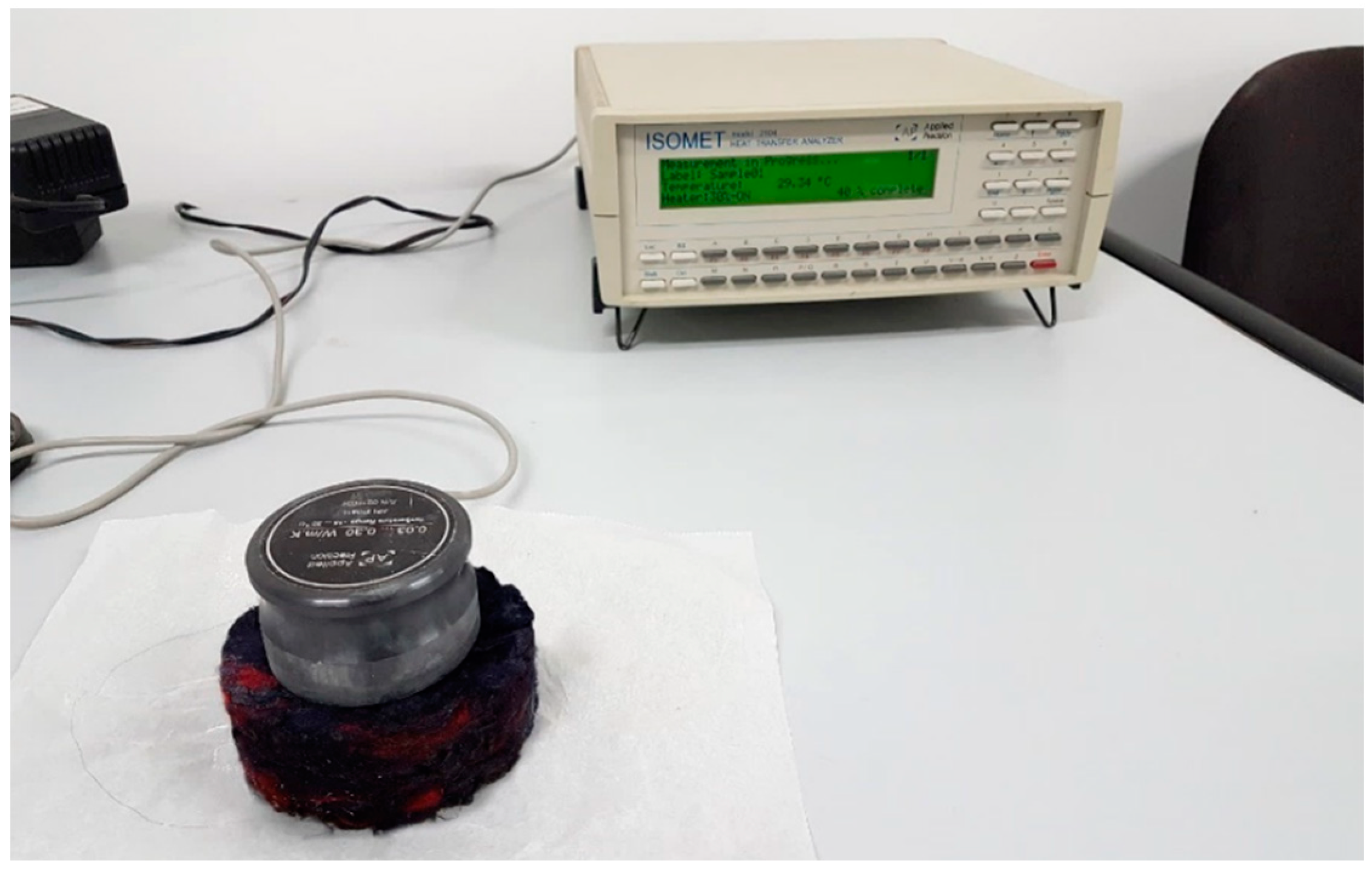

2.5. Measurements of Thermal Properties

The thermal properties of the specimens, i.e., thermal conductivity, thermal diffusivity and volumetric heat capacity, were evaluated with the dynamic plane source method (

Figure 7), using the ISOMET 2104 instrument (Applied Precision Ltd., Bratislava, Slovakia). The measurement is based on the analysis of the material thermal response to a heat flow impulse generated by the electrical resistance of a probe, directly in contact with the sample surface [

34]. The error in the measurement of thermal conductivity, thermal diffusivity, and volumetric heat capacity is estimated to be within ±4%, ±5%, and ±7%, respectively [

35].

However, at room temperature this test was performed only for the sample without PCM. In fact, the presence of phase change material could interfere with the measurement. The instrument, generating a heat flow at temperatures around 26 °C, would cause a phase change from solid to liquid state in the PCM, without any change in temperature which could consequently bias the measurement.

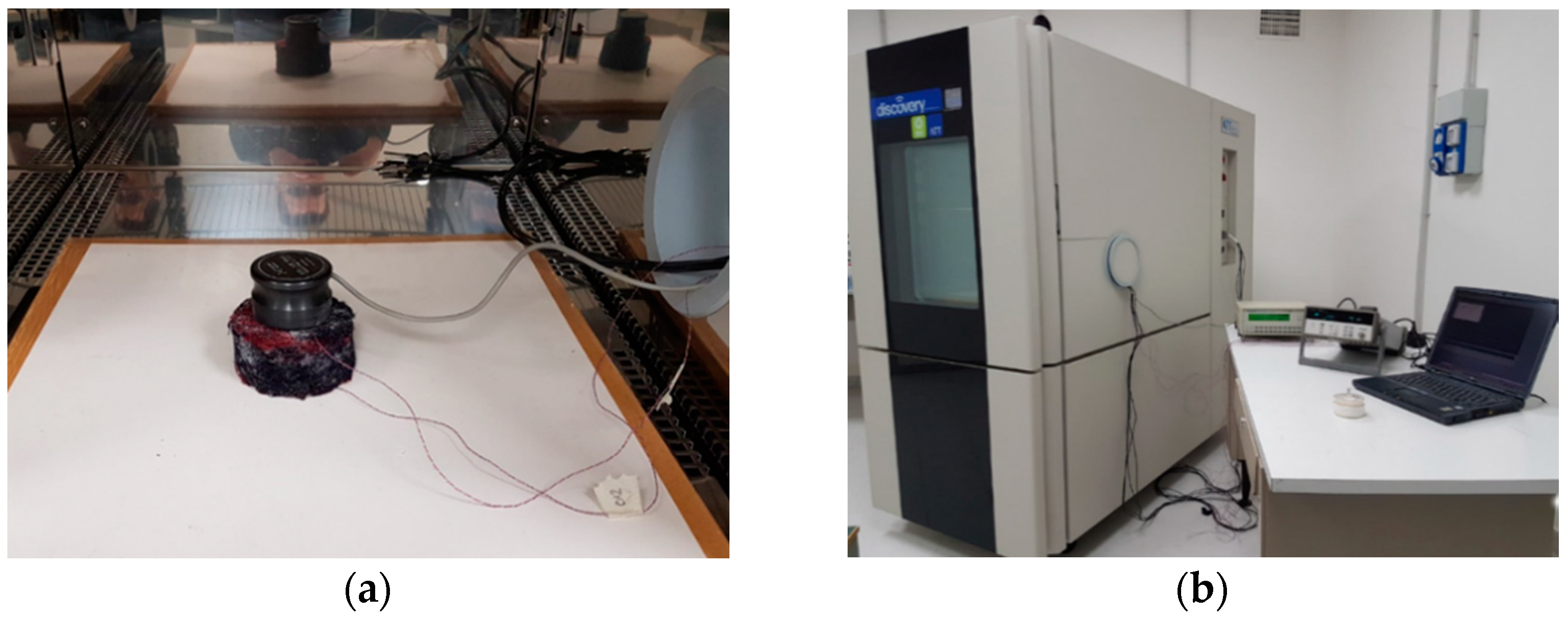

For this reason, measurements of thermal properties of the specimens with PCMs were carried out in a climatic chamber (Angelantoni DY340), under controlled hygrothermal conditions, setting temperature values far from the phase change zone (

Figure 8). Two configurations were chosen: (16 °C, 50% RH) and (36 °C, 50% RH). When the hygrothermal conditions in the climatic chamber reached constant values of temperature and relative humidity, the measurement was started.

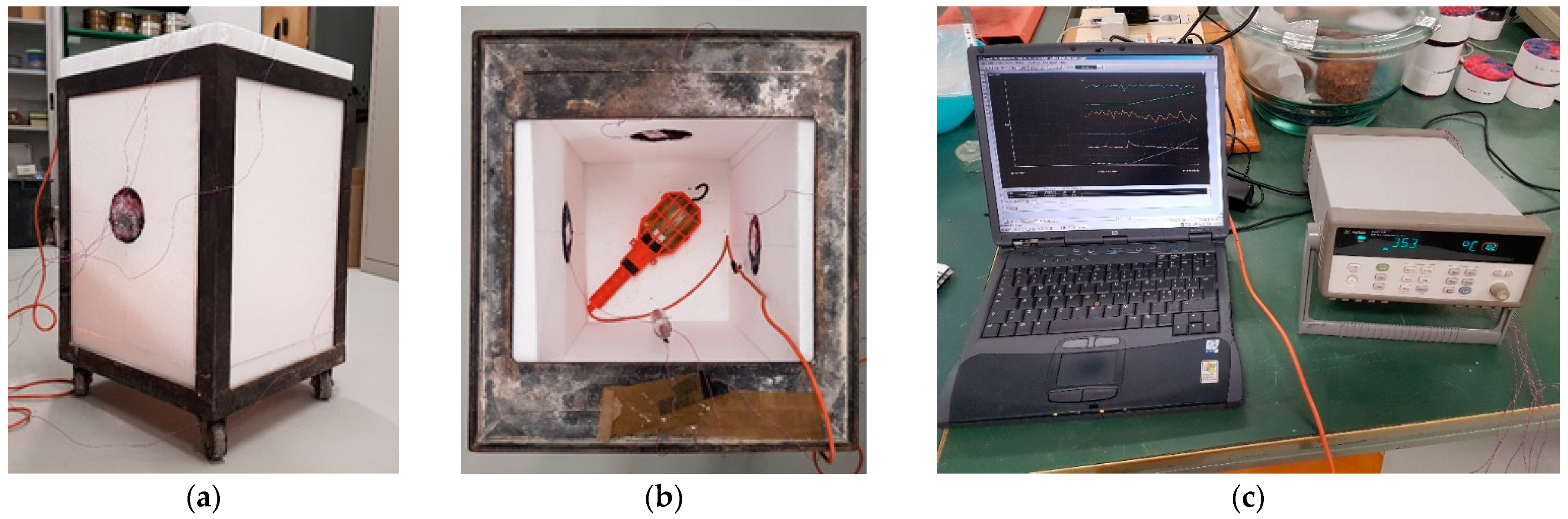

In order to investigate the thermal behaviour of the specimens under dynamic regime, a dynamic thermal response test [

36] was carried out using a small Hot Box (

Figure 9). The Hot Box had a parallelepiped shape with dimensions of 40 × 43 × 53 cm, with a metal frame, inside which six polystyrene panels (4.85 cm thick) were placed and carefully fitted together. Polystyrene panels had a thermal conductivity of 0.0351 W·m

−1·K

−1. In the center of three of the four side surfaces, circular holes with a 10 cm diameter were cut out in order to put in the three samples. Finally, a simple 28 W halogen bulb was placed inside the box as heat source.

For each specimen, two T-type thermocouples were used to monitor the internal and external surface temperatures, while two more thermocouples were used to monitor the internal and external air temperature. All the thermocouples were connected to an Agilent 34970A data acquisition multiplexer, which scanned and stored the temperature values read by each thermocouple at regular intervals of 10 s through its proprietary software (Agilent BenchLink Data Logger).

The test lasted about 5 h and was divided into two heating cycles (60 min each) and two cooling cycles (90 min each).

3. Results

Results of thermal properties evaluated using the ISOMET 2014 are shown in

Table 3, where the “mean temperature” is given by the mean test temperature that occurred at the interface between the probe and the specimen surface during the measurement. It can be observed that thermal conductivity showed a predictable increase as a function of temperature (considering that air filling pores increases its own conductivity by about 6% from 20 to 40 °C). Similarly, the thermal conductivity is strictly related to the amount PCM due to the increased connections among fibers and the reduction of pore volume. The latter consideration is clearly supported also by the significant increase in density resulting from PCM addition.

Regarding the specific heat capacity, it is noted that the values are much greater than the literature values. For example, Schiavoni et al. [

37] reported a value of 1800 J·kg

−1·K

−1 for sheep’s wool with a density of 20 kg·m

−3. In the present work, the wool sample under test (PCM_00) has a density of 103.7 kg·m

−3 and a specific heat capacity of about 3 kJ·kg

−1·K

−1. The influence of thickening due to the binding action of gum arabic present for 26.81% by mass is evident.

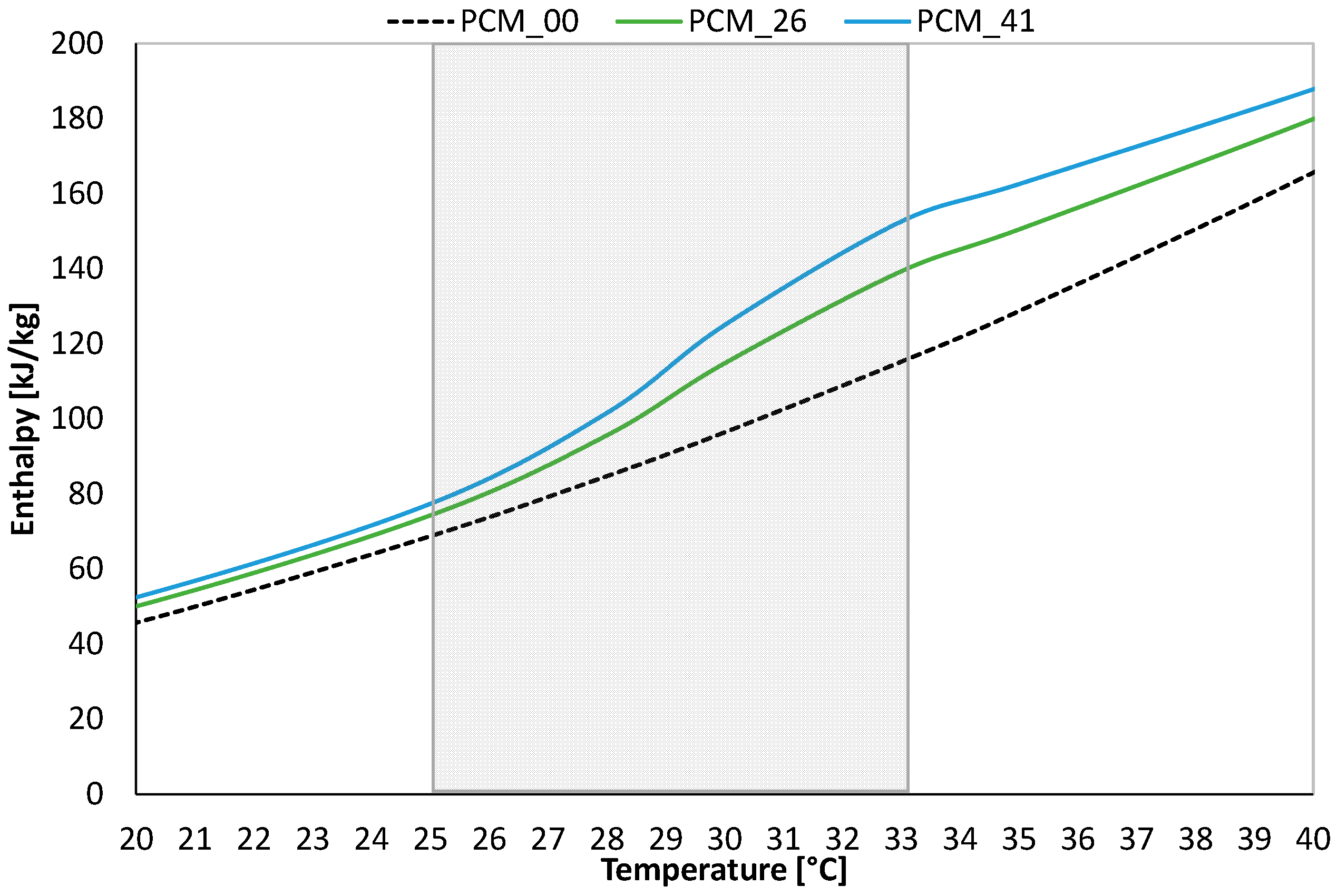

Taking into account the results from the DSC measurements, the enthalpy variation as a function of temperature was determined according to the following equation:

where

- -

fw is the weight percent fraction of the mixture wool-gum arabic (PCM_00);

- -

cw(

T) = 92.827·

T + 427.5 (J·kg

−1·K

−1) is the specific heat capacity of PCM_00 sample obtained with a linear interpolation on the values in

Table 3;

- -

fPCM is the weight percent fraction of PCM;

- -

hPCM(

T) is the enthalpy vs temperature of the pure PCM as obtained from the DSC diagram (

Figure 2 and

Figure 3).

The resulting enthalpy vs. temperature

h(

T) plots for the three mixtures are shown in

Figure 10, where the grey zone shows the temperature range in which phase change takes place.

The analysis of the temperatures resulting from the Hot Box test (

Figure 11) provides interesting insights. In fact, both the samples embodying PCMs showed a much slower temperature variation on the interior face (with instantaneous differences up to 2 °C compared to PCM_00 configuration) both during heating and cooling. During heating both the samples have lower temperatures than the reference (suggesting a clear energy storage inside the samples). Similarly, during cooling, temperatures are higher than the reference and the air, suggesting an unloading of the stored energy. Differences between the three samples are even more emphasized when temperature values on the outside face were considered. The heat flows exchanged on the internal and external faces of the specimens were evaluated through an estimate of the surface heat exchange coefficients. These coefficients were measured on the fourth vertical wall of the Hot Box by measuring the surface temperatures with T-type thermocouples under quasi steady-state conditions. Once the surface temperatures are known, as well as the thickness of the polystyrene plate (4.85 cm) and its thermal conductivity (0.0351 W·m

−1·K

−1), the heat flux was estimated from the following equation:

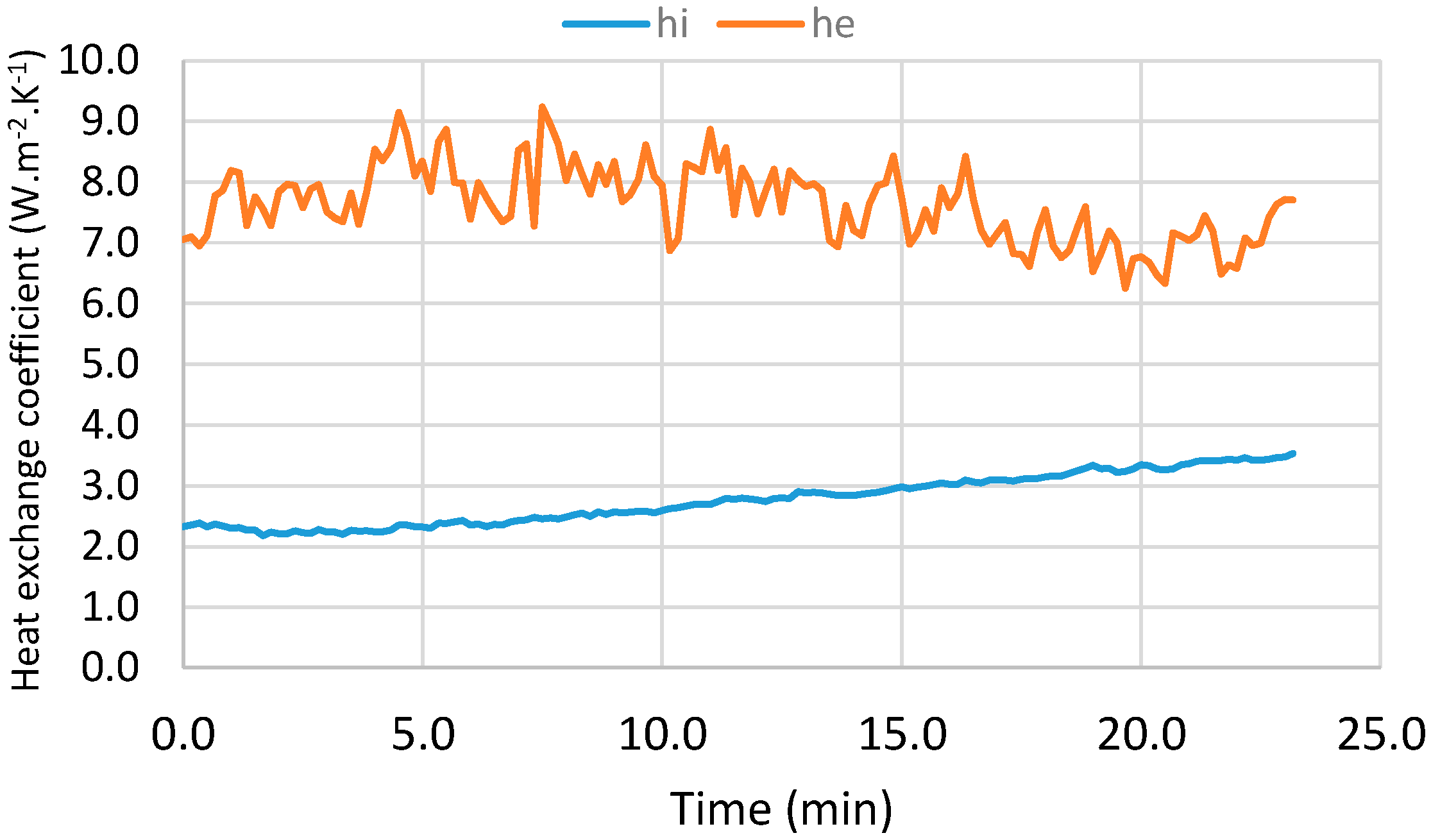

and the internal and external surface heat exchange coefficients were:

The mean values were 2.8 W·m

−2·K

−1 for

hi, and 7.6 W·m

−2·K

−1 for

he (

Figure 12). The lower value for the coefficient on the internal side was due to the negligible contribution of the exchange by radiation, since the internal surfaces of the Hot Box are practically isothermal. The value of

hi is very close to that which can be calculated with the ASHRAE formula [

38] for natural convection heat flux between a heated or cooled wall panel surface and indoor air, for vertical surface with height H = 0.53 m:

Figure 13 shows time variation of heat flux on the internal and external faces of the specimens and it shows how clearly the PCM affects the phase shift of heat flux on the external face.

The PCM influence is more evident in

Figure 14, where the difference between the thermal flow entering through the internal face of the specimen and the thermal flux exiting from the external face is reported, as a function of the mean temperature (average between the internal surface temperature and the external surface one). Compared to the PCM_00 trend (green line), the PCM presence make the heat flow imbalance greater (about four times), and the peak shifts to the temperature range typical of the phase change.

The apparent hysteresis that is evident in the material with PCM that leads the unloading cycle not to resume the initial conditions of the loading one, can be explained by the fact that the PCM used might not have the same latent heat of solidification and liquefaction [

39] (thus suggesting a different storage capacity in heating or in cooling), or that the solidification process might not be completed when the new heating cycle starts, thus reducing the heat that can be stored.

4. Case Study

The tested materials were applied to a mobile operating unit in meeting office and/or secretarial configuration, made in the form of multifunctional shelter, potentially installed on a road trailer. The shelter had a parallelepiped geometry of 6 × 2.5 × 2.4 m. The envelope was assumed to be made up of expandable sandwich panels, consisting of two aluminum sheets of 10/10 thickness each, and an insulator among them. On one side there were two glazed windows, one square meter each, with a movable sun screen.

Figure 15 shows the render produced by the software DesignBuilder [

40].

Four kinds of insulation were compared: polyurethane foam, wool board, wool with 26% in weight of PCM and wool with 41% in weight of PCM.

The performance comparison was carried out while keeping constant the thermal transmittance of the opaque wall (

U = 0.626 W·m

−2·K

−1), and therefore with variable insulation thicknesses due to the different thermal conductivity of the considered insulators (

Table 4). The reference

U-value was taken from Apulian regional standard procurement specifications for this kind of shelter [

41].

Windows model consisted of a double-glazed unit with air cavity (6/6/6 mm). Internal screens had high reflectivity slats operated by solar control with 120 W·m−2 set point. Their thermal transmittance was 3.094 W·m−2·K−1. The door on the short side had the identical structure of the opaque wall.

The shelter was supposed to be occupied by two adults from 8 to 19 from Monday to Friday. During the occupation period, there was 200 W heat input for lighting and electrical appliances, and a natural ventilation of 10 l/s per person.

The air conditioning system was defined through a “Simple HVAC”, so that DesignBuilder could automatically calculate heating and cooling capacity in the zone. The HVAC sizing option was set to “Adequate”, that means that the heating and cooling equipment had unlimited capacity to meet demands, always maintaining set point temperatures.

In order to highlight the local climate influence on structure thermal behavior depending on the insulating material used for the opaque envelope, the energy performances were simulated in three locations with three different climates. Some characteristic climatic parameters of these locations (Palermo, Bari, and Bolzano) are shown in

Table 5 and

Table 6.

The simulations were carried out with internal set point temperature of 20 °C in the heating period and 25 °C in the cooling period, and only during the occupation hours.

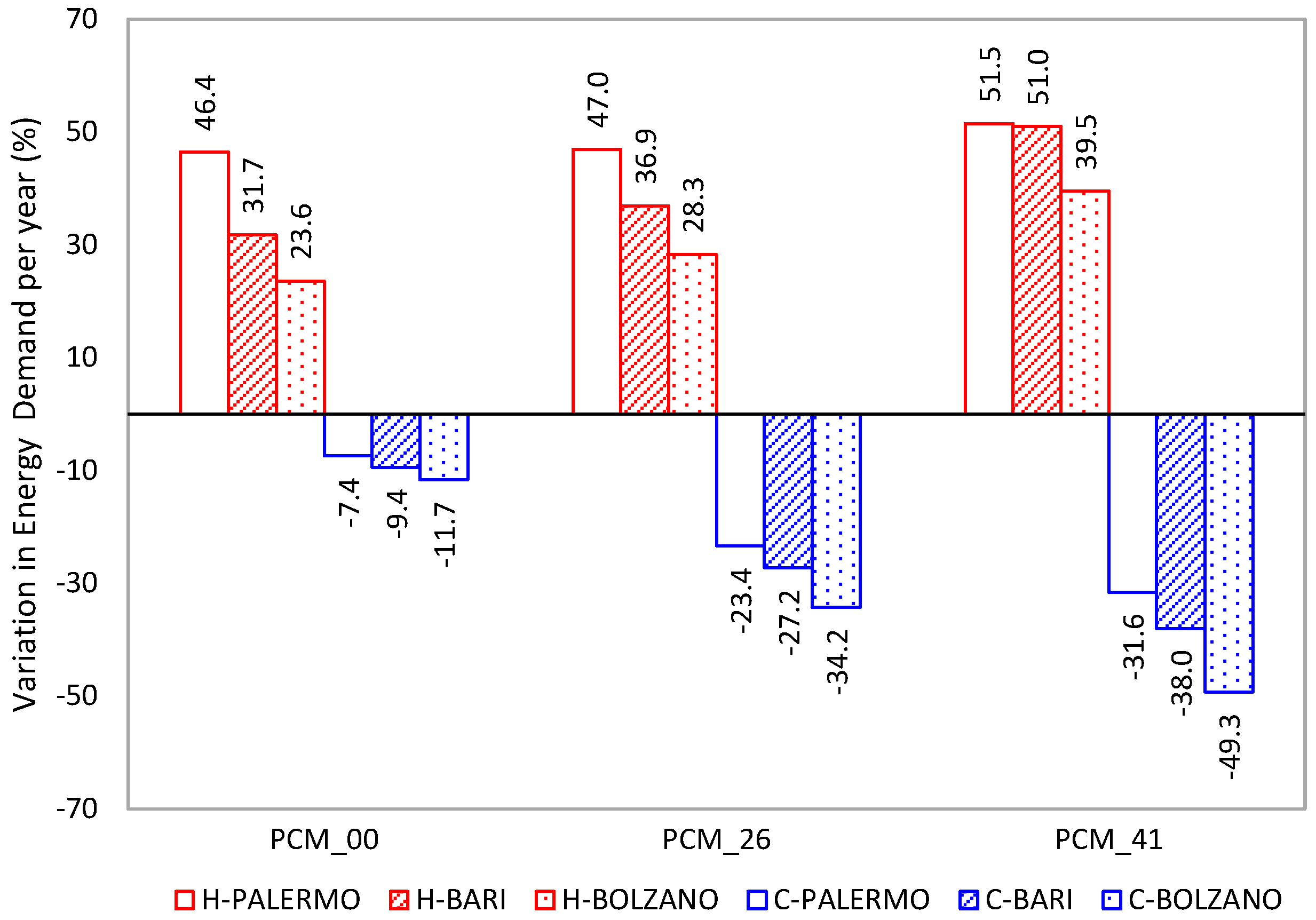

Figure 16 shows the annual energy requirement for air conditioning system (heating and cooling) for those locations.

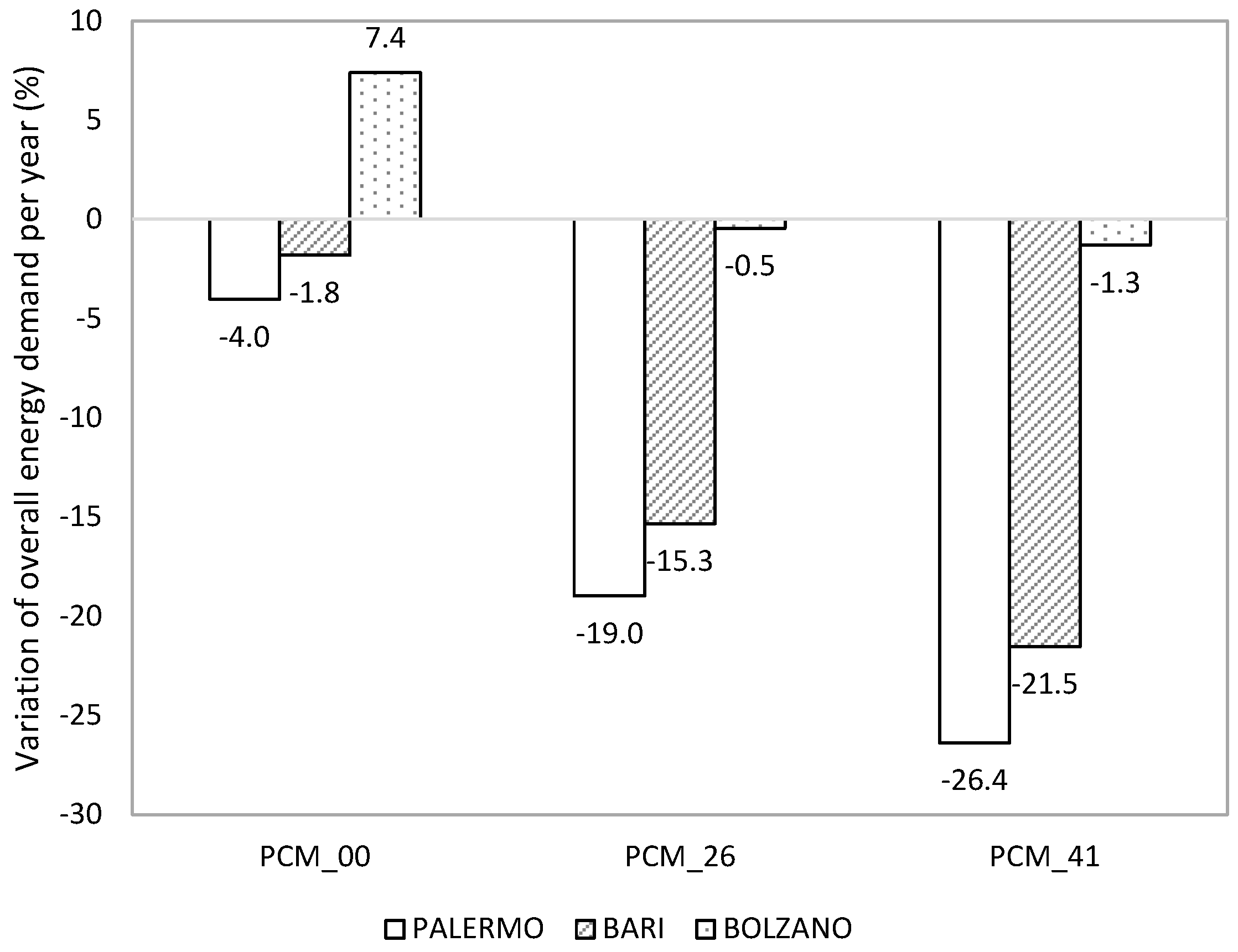

Figure 17 shows the percentage change of annual energy requirement for air conditioning system of the studied wool-based materials compared to polyurethane foam (reference). The higher thermal inertia of the wool-PCM materials produces an increase in consumption for heating and a reduction in consumption for cooling. This leads to a substantial annual need decrease (

Figure 18) for air conditioning system in temperate climates (Palermo and Bari), and a limited increase in predominantly cold climates (Bolzano).

5. Discussion

The use of textile waste for wool-based insulation panels production proved to be a sustainable and efficient solution. It is sustainable because it contributes to solve the disposal problem of textile waste with a view to a circular economy and minimum usage of additional resources for the panel fabrication, and it is efficient as it allows a significant reduction in the energy requirements for air conditioning. In fact, in active cooling mode, the wool-based material, with or without PCM, has a better performance in terms of energy requirements for air conditioning system than the polyurethane foam.

However, considering the air conditioning energy requirement over the whole year by adding both heating and cooling contributions, the advantage of using wool-PCM based insulation was impressive in warmer locations, but greatly reduced in locations with a longer and severe winter season. On annual basis, in temperate climate locations like Palermo the wool-based insulation with 41% in weight of PCM requires 26% less annual energy for air conditioning system and 31.6% less for cooling than the polyurethane foam insulation.

6. Conclusions

An innovative thermal insulation for buildings was studied. It consists of wool obtained from textile waste, treated with a natural binder solution made of gum arabic and thermally improved by the addition of a phase change material, a microencapsulated paraffinic mixture called Micronal® DS 5001 X, produced by BASF. A DSC test allowed to verify the performance declared by the PCM manufacturer, while a series of thermal conductivity measurements through the dynamic plane source method allowed to evaluate the characteristic thermal parameters of the tested materials as a function of temperature.

The performance of the studied insulation was evaluated with DesignBuilder software assuming an application in a mobile shelter type structure, usually made with a layer of polyurethane foam between two metal sheets.

The structure was simulated in three different locations, Palermo, Bari, and Bolzano, with different climatic characteristics. The simulation results showed a better performance of the proposed insulators compared to the traditional polyurethane foam, especially in the cooling season. The advantage in terms of energy requirements for air conditioning system throughout the year is considerable for warmer climate locations, much less for colder one.

The experimental study conducted so far has taken into consideration only the thermal properties of the material studied. Its application has been tested in a particular condition, that of the shelter structure, which, due to its construction, does not expose the layer of insulating material to problems of a hygrometric nature. For use in construction on a larger scale, a thorough experimental campaign is required to measure the hygrometric properties of the wool-PCM insulation.

Author Contributions

Conceptualization, C.R., S.L., F.M., P.S. (Pierfrancesco Straziota), and P.S. (Pietro Stefanizzi); Methodology, C.R., S.L., F.M., P.S. (Pierfrancesco Straziota), and P.S. (Pietro Stefanizzi); Investigation, P.S. (Pierfrancesco Straziota) and P.S. (Pietro Stefanizzi); Formal analysis, C.R., S.L., F.M., P.S. (Pierfrancesco Straziota), and P.S. (Pietro Stefanizzi); Data curation, S.L., C.R., and F.M.; Writing—original draft preparation, P.S. (Pierfrancesco Straziota) and P.S. (Pietro Stefanizzi); Writing—review and editing C.R., S.L., F.M., P.S. (Pierfrancesco Straziota), and P.S. (Pietro Stefanizzi); Visualization, F.M., P.S. (Pierfrancesco Straziota), and P.S. (Pietro Stefanizzi); Software, P.S. (Pierfrancesco Straziota) and P.S. (Pietro Stefanizzi); Supervision, P.S. (Pietro Stefanizzi) and F.M.; Funding acquisition, P.S. (Pietro Stefanizzi) and F.M. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out within the framework of the Italian PRIN (“Progetto di Ricerca di Rilevante Interesse Nazionale) Project “SUSTAIN/ABLE—SimultaneoUs STructural And energetIc reNovAtion of BuiLdings through innovativE solutions”, ERC Sector PE8, ID 20174RTL7W_007.

Conflicts of Interest

The authors declare no conflict of interest.

References

- EUROPEAN COMMISSION, COM (2019) 640 Final. The European Green Deal. Brussels. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1579087430180&uri=CELEX:52019DC0640 (accessed on 5 December 2020).

- Rubino, C.; Bonet Aracil, M.; Liuzzi, S.; Stefanizzi, P.; Martellotta, F. Wool waste used as sustainable nonwoven for building applications. J. Clean. Prod. 2021, 278, 123905. [Google Scholar] [CrossRef]

- Wang, Y. Fiber and Textile Waste Utilization. Waste Biomass Valor 2010, 1, 135–143. [Google Scholar] [CrossRef]

- Bilal, M.; Ahmad Khan, K.I.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Rubino, C.; Bonet-Aracil, M.; Gisbert-Payá, J.; Liuzzi, S.; Zamorano Cantó, M.; Martellotta, F.; Stefanizzi, P. Composite eco-friendly sound absorbing materials made of recycled textile waste and biopolymers. Materials 2019, 12, 4020. [Google Scholar] [CrossRef] [PubMed]

- Del Rey, R.; Uris, A.; Alba, J.; Candelas, P. Characterization of Sheep Wool as a Sustainable Material for Acoustic Applications. Materials 2017, 10, 1277. [Google Scholar] [CrossRef] [PubMed]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- De Gracia, A.; Cabeza, L.F. Phase change materials and thermal energy storage for buildings. Energy Build. 2015, 103, 414–419. [Google Scholar] [CrossRef]

- Delgado, J.P.Q.; Martinho, J.C.; Sá, A.V.; Guimarães, A.S.; Abrantes, V. Thermal Energy Storage with Phase Change Materials: A Literature Review of Applications for Buildings Materials; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Pisello, A.L.; Fabiani, C.; Ubertini, F.; Cabeza, L.F.; Cotana, F. Multifunctional smart concretes with novel phase change materials: Mechanical and thermo-energy investigation. Appl. Energy 2018, 212, 1448–1461. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Navarro, L.; Pisello, A.L.; Olivieri, L.; Bartolomé, C.; Sánchez, J.; Álvarez, S.; Tenorio, J.A. Behaviour of a concrete wall containing micro-encapsulated PCM after a decade of its construction. Sol. Energy 2020, 200, 108–113. [Google Scholar] [CrossRef]

- Serrano, S.; Barreneche, C.; Inés Fernández, A.; Farid, M.M.; Cabeza, L.F. Composite gypsum containing fatty-ester PCM to be used as constructive system: Thermophysical characterization of two shape-stabilized formulations. Energy Build. 2015, 86, 190–193. [Google Scholar] [CrossRef]

- Feldman, D.; Banu, D.; Hawes, D.; Ghanbari, E. Obtaining an energy storing building material by direct incorporation of an organic phase change material in gypsum wallboard. Sol. Energy Mater. 1991, 22, 231–242. [Google Scholar] [CrossRef]

- Toppi, T.; Mazzarella, L. Gypsum based composite materials with micro-encapsulated PCM: Experimental correlations for thermal properties estimation on the basis of the composition. Energy Build. 2013, 57, 227–236. [Google Scholar] [CrossRef]

- Peippo, K.; Kauranen, P.; Lund, P.D. A multicomponent PCM wall optimized for passive solar heating. Energy Build. 1991, 17, 259–270. [Google Scholar] [CrossRef]

- Franquet, E.; Gibout, S.; Tittelein, P.; Zalewski, L.; Dumas, J.-P. Experimental and theoretical analysis of a cement mortar containing microencapsulated PCM. Appl. Therm. Eng. 2014, 73, 32–40. [Google Scholar] [CrossRef]

- Jaworski, M.; Wnuk, R. Determination of Thermal Properties and Characteristics of PCM-Based Heat Storage Elements for Application in Building Envelope. In Proceedings of the EuroSun 2010, International Conference on Solar Heating, Cooling and Buildings, Graz, Austria, 28 September–1 October 2010. [Google Scholar] [CrossRef]

- Frota de Albuquerque Landi, F.; Fabiani, C.; Pisello, A.L. Palm oil for seasonal thermal energy storage applications in buildings: The potential of multiple melting ranges in blends of bio-based fatty acids. J. Energy Storage 2020, 29, 101431. [Google Scholar] [CrossRef]

- Korjenic, A.; Klarić, S.; Hadžić, A.; Korjenic, S. Sheep Wool as a Construction Material for Energy Efficiency Improvement. Energies 2015, 8, 5765–5781. [Google Scholar] [CrossRef]

- Corscadden, K.W.; Biggs, J.N.; Stiles, D.K. Sheep′s wool insulation: A sustainable alternative use for a renewable resource? Resour. Conserv. Recycl. 2014, 86, 9–15. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; Mastellone, M.; Vanoli, G.P. Phase Change Materials for Reducing Cooling Energy Demand and Improving Indoor Comfort: A Step-by-Step Retrofit of a Mediterranean Educational Building. Energies 2019, 12, 3661. [Google Scholar] [CrossRef]

- Kośny, J. PCM-Enhanced Building Components: An Application of Phase Change Materials in Building Envelopes and Internal Structures; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Oncins, G.; Barreneche, C.; Martínez, M.; Fernández, A.I.; Cabeza, L.F. Physicochemical and mechanical properties of microencapsulated phase change material. Appl. Energy 2013, 109, 441–448. [Google Scholar] [CrossRef]

- UNI EN ISO 11357-1:2016. Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles; UNIPLAST - Italian National Body for Plastics Standardisation: Milan, Italy, 2016. [Google Scholar]

- Ahmed, A.A. Health Benefits of Gum Arabic and Medical Use. In Gum Arabic Structure, Properties, Application and Economics; Mariod, A.A., Ed.; Academic Press: London, UK, 2018; pp. 183–210. [Google Scholar]

- Zhao, C.; Zhao, Q.; Zhang, Y.; Zhou, M. The effect of gum Arabic on the dispersion of cement paste. In Proceedings of the 11th International Congress for Applied Mineralogy (ICAM), Mianyang, China, 5–10 July 2013; Dong, F., Ed.; Springer Geochemistry/Mineralogy: Cham, Switzerland, 2015; pp. 483–494. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Abdulbasir, G.; Abdulkadir, G. Gum Arabic as an admixture for cement concrete production. Constr. Build. Mater. 2018, 176, 201–212. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Ariffin, M.A.M.; Smaoui, H.; Osman, M.H. Performance evaluation of concrete with Arabic gum biopolymer. Mater. Today 2020, in press. [Google Scholar] [CrossRef]

- Abuarra, A.; Hashim, R.; Bauk, S.; Kandaiya, S.; Tousi, E.T. Fabrication and characterization of gum Arabic bonded Rhizophora spp. Particleboards. Mater. Des. 2014, 60, 108–115. [Google Scholar] [CrossRef]

- Dieye, Y.; Toure, P.M.; Gueye, P.M.; Sambou, V.; Bodian, S.; Tigampo, S. Thermomechanical Characterization of Particleboards From Powder Typha Leaves. J. Sustain. Constr. Mater. Technol. 2019, 4, 306–317. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Martellotta, F. Performance Characterization of Broad Band Sustainable Sound Absorbers Made of Almond Skins. Materials 2020, 13, 5474. [Google Scholar] [CrossRef] [PubMed]

- Log, T.; Gustafsson, S.E. Transient plane source (TPS) technique for measuring thermal transport properties of building materials. Fire Mater. 1995, 19, 43–49. [Google Scholar] [CrossRef]

- Bouguerra, A.; Aït-Mokhtar, A.; Amiri, O.; Diop, M.B. Measurement of thermal conductivity, thermal diffusivity and heat capacity of highly porous building materials using transient plane source technique. Int. Commun. Heat Mass 2001, 28, 1065–1078. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Martorell, I.; Miró, L.; Sari-Bey, S.; Fois, M.; Anghel, E.M. Unconventional experimental technologies available for phase change materials (PCM) characterization. Part 1. Thermophysical properties. Renew. Sustain. Energy Rev. 2015, 43, 1399–1414. [Google Scholar] [CrossRef]

- Schiavoni, S.; D′Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook–HVAC Systems and Equipment; ASHRAE: Peachtree Corners, GA, USA, 2016. [Google Scholar]

- Soares, N.M.L. Thermal Energy Storage with Phase Change Materials (PCMs) for the Improvement of the Energy Performance of Buildings. Ph.D. Thesis, Mechanical Engineering Deptartment, University of Coimbra, Coimbra, Portugal, 2016. [Google Scholar]

- DesignBuilder Software Ltd (6.1). Available online: https://designbuilder.co.uk//software (accessed on 5 December 2020).

- REGIONE PUGLIA. Area Politiche Per Riqualificazione, La Tutela E La Sicurezzaambientale E Per L′attuazione Delle Opere Pubblicheservizio Protezione Civile. Available online: http://www.empulia.it/tno-a/empulia/bandi/49378846C7/Documenti/allegato%201_%20%20ufficio.pdf (accessed on 12 October 2020).

- Weather Data. Available online: https://energyplus.net/weather (accessed on 5 December 2020).

Figure 1.

Merino wool, pre and post-carding process.

Figure 1.

Merino wool, pre and post-carding process.

Figure 2.

Differential Scanning Calorimetry (DSC) curve of Micronal® DS 5001 X obtained using nitrogen at 50 mL/min as purge gas.

Figure 2.

Differential Scanning Calorimetry (DSC) curve of Micronal® DS 5001 X obtained using nitrogen at 50 mL/min as purge gas.

Figure 3.

Enthalpy variation with temperature for Micronal® DS 5001 X.

Figure 3.

Enthalpy variation with temperature for Micronal® DS 5001 X.

Figure 4.

Materials: (a) Carded wool; (b) Gum arabic; (c) phase change material (PCM); (d) Water.

Figure 4.

Materials: (a) Carded wool; (b) Gum arabic; (c) phase change material (PCM); (d) Water.

Figure 5.

From left to right: PCM_00, PCM_26, PCM_41.

Figure 5.

From left to right: PCM_00, PCM_26, PCM_41.

Figure 6.

SEM images of PCM_41 specimen with magnification 200× (a) and 500× (b).

Figure 6.

SEM images of PCM_41 specimen with magnification 200× (a) and 500× (b).

Figure 7.

Measurement of thermal properties of PCM_00 specimen.

Figure 7.

Measurement of thermal properties of PCM_00 specimen.

Figure 8.

Measurement setup of thermal properties: (a) the sample inside the climatic chamber; (b) the ISOMET 2104, Agilent 34970A data acquisition unit and notebook outside the climatic chamber.

Figure 8.

Measurement setup of thermal properties: (a) the sample inside the climatic chamber; (b) the ISOMET 2104, Agilent 34970A data acquisition unit and notebook outside the climatic chamber.

Figure 9.

The Hot Box seen from the outside (a), from the inside (b) and data acquisition setup (c).

Figure 9.

The Hot Box seen from the outside (a), from the inside (b) and data acquisition setup (c).

Figure 10.

Enthalpy variation as a function of temperature for the three mixtures.

Figure 10.

Enthalpy variation as a function of temperature for the three mixtures.

Figure 11.

Air and surface temperatures in the Hot Box: Internal side (bottom) and external side (top).

Figure 11.

Air and surface temperatures in the Hot Box: Internal side (bottom) and external side (top).

Figure 12.

Internal (hi) and external (he) surface heat exchange coefficients.

Figure 12.

Internal (hi) and external (he) surface heat exchange coefficients.

Figure 13.

Specific heat flux through the internal (int) and external (ext) specimen side.

Figure 13.

Specific heat flux through the internal (int) and external (ext) specimen side.

Figure 14.

Heat flux imbalance vs the mean temperature of the specimen.

Figure 14.

Heat flux imbalance vs the mean temperature of the specimen.

Figure 15.

DesignBuilder render of the shelter.

Figure 15.

DesignBuilder render of the shelter.

Figure 16.

Annual energy need for heating (H) and cooling (C).

Figure 16.

Annual energy need for heating (H) and cooling (C).

Figure 17.

Percent variation of annual energy need for heating and cooling respect to Reference.

Figure 17.

Percent variation of annual energy need for heating and cooling respect to Reference.

Figure 18.

Percent variation of annual energy need for heating plus cooling respect to Reference.

Figure 18.

Percent variation of annual energy need for heating plus cooling respect to Reference.

Table 1.

Quantity of materials used in the specimens.

Table 1.

Quantity of materials used in the specimens.

| | PCM_00 | PCM_26 | PCM_41 |

|---|

| Wool (g) | 25 | 25 | 25 |

| Gum arabic (g) | 20 | 20 | 20 |

| Water (mL) | 100 | 100 | 100 |

| PCM (g) | / | 12.50 | 25 |

Table 2.

Weigh percentage of the materials present in the specimens after squeezing.

Table 2.

Weigh percentage of the materials present in the specimens after squeezing.

| | PCM_0 | PCM_26 | PCM_41 |

|---|

| Wool (%) | 73.19 | 52.55 | 40.72 |

| Gum arabic (%) | 26.81 | 21.17 | 18.57 |

| PCM (%) | / | 26.28 | 40.72 |

Table 3.

Mean values of thermal properties.

Table 3.

Mean values of thermal properties.

| Sample | Mean Temperature (°C) | Thermal Conductivity λ (W·m−1·K−1) | Volumetric Heat Capacity ρc (106 J·m−3·K−1) | Thermal Diffusivity α

(10−6 m2·s−1) | Density ρ (kg·m−3) | Specific Heat Capacity c (J·kg−1·K−1) |

|---|

| PCM_00 | 27.3 | 0.053 | 0.307 | 0.172 | 103.7 | 2961.7 |

| PCM_00 | 37.8 | 0.069 | 0.446 | 0.191 | 103.7 | 3936.4 |

| PCM_26 | 19.8 | 0.060 | 0.287 | 0.209 | 136.7 | 2099.7 |

| PCM_26 | 39.4 | 0.064 | 0.402 | 0.160 | 136.7 | 2941.0 |

| PCM_41 | 19.5 | 0.077 | 0.341 | 0.226 | 173.1 | 1969.8 |

| PCM_41 | 37.7 | 0.085 | 0.446 | 0.191 | 173.1 | 2576.3 |

Table 4.

Properties of the insulation (at 24 °C).

Table 4.

Properties of the insulation (at 24 °C).

| Insulation | Thermal Conductivity

W·m−1·K−1 | Thicknesscm

cm |

|---|

| Polyurethane foam (30 kg·m−3) | 0.028 | 4.0 |

| PCM_00 | 0.049 | 7.0 |

| PCM_26 | 0.061 | 8.6 |

| PCM_41 | 0.080 | 11.4 |

Table 5.

Site climatic properties (EnergyPlus weather data [

42]).

Table 5.

Site climatic properties (EnergyPlus weather data [

42]).

| | Palermo | Bari | Bolzano |

|---|

| Max site air-dry bulb temperature (°C) | 34.6 (5 August) | 39.0 (10 August) | 34.6 (9 July) |

| Min site air-dry bulb temperature (°C) | 5.9 (22 December) | 0.0 (11 January) | −11.6 (15 January) |

| Max daily thermal excursion (°C) | 13.2 (26 April) | 16.2 (15 August) | 20.1 (22 May) |

| Max Direct Normal Solar Rad (Wh·m−2) | 7997 (22 June) | 7708 (25 May) | 7595 (26 June) |

| Köppen–Geiger climate classification | Cfa | Cfa | Dfb |

Table 6.

Site climatic properties (Italian regulations).

Table 6.

Site climatic properties (Italian regulations).

| | Palermo | Bari | Bolzano |

|---|

| Climatic Zone (D.P.R. 412/93) | B | C | E |

| Heating period | 01/12–31/03 | 15/11–31/03 | 15/10–15/04 |

| Heating Degrees Day (°C·d/yr) | 751 | 1185 | 2791 |

| Design external temperature (°C) | 5 | 0 | −15 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).