Featured Application

Applications of papercrete as new eco-friendly mortars for masonry panels.

Abstract

The manufacturing of Portland cement is responsible for a big amount of energy and greenhouse gas (GHG) emission. Therefore, to date, it is imperative to find alternative materials to replace a major part of cement for sustainable concrete constructions. The present study forms a part of an on-going research project on the application of new cementitious matrices produced using different types of recycled materials. In particular, it focuses on the use of pulp and waste paper to partially replace Portland cement at varying percentages for producing a new lightweight mortar, frequently named papercrete. The development of this economical and eco-friendly material may permit of recycling a big amount of waste paper leading to lower housing costs with also ecological benefits. To this scope, an experimental campaign in the laboratory is carried out to characterize this new innovative material from a physical and mechanical point of view. The preliminary results of this on-going experimental campaign are illustrated and commented on in this paper. The obtained results confirm the possibility of applying this partially-recycled material as a possible alternative for strengthening existing panels of masonry.

1. Introduction

“Sustainability” is nowadays one of the most used but least understood terms since usually there is the tendency to treat this matter in a superficial way interpreted under different points of view, and linked to “eco”, “green”, or “smart” rhetoric.

In general, the concept of sustainability is aimed at ensuring the quality of life and linked to three areas: environmental, sociocultural, and economic [1]. For these reasons, engineers have to consider a building’s “lifecycle” cost, from the building construction and maintenance to demolition and recycling, extended over the useful lifetime to comply with sustainable standards. In particular, to build in a sustainable manner there is the need to pay attention to physical, environmental, and technological resources, together with problems related to human health, energy conservation of new and existing buildings, and control of construction technologies and methods. Actually, there is the need for a new generation of ecological materials able to improve durability and energy efficiency and to allow waste recycling and cost savings [2].

The construction sector is not only the biggest economical sector deeply engrained in society and fulfilling basic needs. It is by large the biggest cause for CO2 emissions, both in construction materials production (±25%) and by the buildings’ use (±35%). For instance, concrete alone already emits more than 7.1 billion tons of CO2/year, increasing more and more [3].

In order to reduce dioxide emissions, in recent years several studies have been conducted for partially substituting cement with recycled components, obtaining in this way innovative composite materials to be applied in buildings construction/repairing. They have focused on paper recycling, developing the so-called “papercrete” where solid waste paper or else paper pulp is mixed with a cementitious mortar [4,5].

Papercrete was rediscovered in the 1980s, independently by Eric Patterson and Mike McCain (they called it respectively “padobe” and “fibrous cement”). It is recognized as an environment-friendly material due to significant recycled content and its ability to reduce the dead load for the main structure [6,7]. The manufacturing process of paper generally produces a large amount of solid waste. More than 450 million tons of paper is generated worldwide per annum and the demand predicted for paper will get to 500 million tons per annum by the end of 2020 [8]. To this, it should be added that paper fibers can be recycled only a limited number of times in the paper industry before becoming too short and weak, producing a decrease in strength and quality of the final product. It means that these inadequate and low-quality paper fibers are separated out to become waste sludge that every year fills a lot of space in local landfills [9]. Therefore, waste paper and paper sludge also deinked are suitable to become a future building material in the concrete industry for lightweight applications thanks to its low cost and high recycle paper content [10,11,12], presenting also different properties such as the ratio of the virgin-recycled paper used as the raw material, the ratio between organic (non-recovered cellulose) and inorganic (principally, kaolinite and limestone) components. Recently, experimental investigations [13] of masonry panels composed of mortars including cellulose fibers from deinked paper sludge were conducted in order to evaluate the influence of paper sludge on the compressive behavior of panels.

To this, it should be added that recently several efforts have also been conducted in order to propose integrated design approaches by applying innovative materials capable of producing several benefits on a building. For instance, in References [14,15], integrated interventions are investigated in upgrading at the same time thermal and structural performance of a building. Moreover, many researches have been also addressed to propose materials with different recycled components, such as: reinforced concrete with recycled steel fibers from tires waste [16,17], or nylon fibers from waste fishing nets [18]; sawdust-reinforced ice-filled flax FRP circular columns [19].

In this paper, preliminary results of an on-going experimental campaign addressed to physically and mechanically characterize papercrete mortar are presented. Several specimens are prepared and tested in different ways in the laboratory for measuring thermal conductivity, capillary absorption, and flexural and compressive strengths. At first, the tests conducted are separately illustrated and commented. Then, a first design criterion for dimensioning of papercrete strengthening layers is discussed as possible interventions in existing masonry panels. Two different papercrete mortars are investigated, by applying solid waste paper or paper pulp as recycled paper component, whose volumetric percentage is also varied in the specimens. Tests are addressed to provide specific information on the mechanical properties of papercrete, to date scarcely investigated, as well as on the physical properties. The preliminary results obtained show that even with modest quantities of recycled paper it is possible to obtain a material with acceptable mechanical and physical characteristics that can be used in civil constructions.

2. Materials and Specimens Preparation

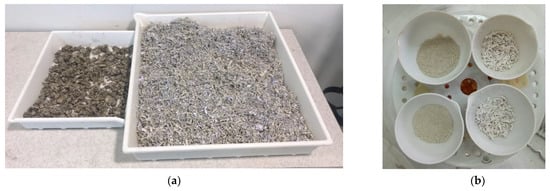

Waste paper and pulp used as recycled components in the papercrete specimens tested were derived as follows.

Waste paper was a common printed office paper that was first of all reduced into small pieces by using a paper cutter. Then, the shredded paper was soaked in water for 24 h and finally placed overnight in a ventilated oven at 50 °C in order to eliminate extra water content. At the end of this process, the paper was submitted to grinding by using a blender to obtain the required size.

The pulp used derived from the separation stage of the paper manufacturing process, resulting in a gray color and extremely humid. Before being added to the mortar, it was subjected to drying, mixing, and homogenization process. The drying process was conducted in a ventilated oven for a night at a temperature equal to 50 ± 5 °C to extract the excess humidity, followed by subsequent cooling at room temperature (23 °C). Once the material was removed from the oven, its dry conditions were verified by weight method: the aggregate was weighed after 24 h and it was observed that there were no variations in the mass [20].

Figure 1 shows the recycled paper in the form of waste paper and pulp before the drying process (Figure 1a), and after grinding and drying (Figure 1b). The grinding of the waste material was performed in a ball mill operating at 30 rotations per minute.

Figure 1.

(a) Pulp and waste paper utilized. (b) Pulp after grinding and waste paper after drying.

Once the recycled paper components were ready, papercrete specimens were prepared by mixing the following components:

- portland cement CEM III/A 32.5 R LH [21], with a compressive strength of 32.5 MPa assessed at 28 days of age;

- natural aggregates in a range between 0 and 4 mm [5] used for better packing of the incorporated mortar and for increasing mechanical strength reducing porosity [22];

- tap water in a quantity able to guarantee a water/cement ratio of 0.5, allowing appropriate mixture workability;

- waste paper and pulp prepared as previously described, added in different volumetric ratios.

All specimens were placed in appropriate molds and aged for 28 days in a controlled humidity ambient with a temperature of around 20 ± 2 °C, considering that the mortar fabrication temperature may influence the technical properties of the aged mortar [23].

As previously stated, the main research objective is to evaluate the effects of a partial substitution in the cementitious mortars of waste dry paper (named ‘PAPER’ specimens) or pulp (‘PULP’ specimens). To this scope, three different volumetric percentages for each recycled paper type have been considered: 2%, 5%, 10%. In addition, also specimens made only with cement have been cast as reference for the other papercrete specimens considered (indicated as ‘REF’ specimens). Future development will be focused on aging tests in order to study the behavior of the material under different humidity and temperature conditions that also simulate extreme climates. Table 1 summarizes the percentage of the components considered.

Table 1.

Components proportioning for obtaining the specimens to be tested.

For each volumetric percentage, a triplet of prismatic specimens was prepared, having dimensions 160 mm × 40 mm × 40 mm. Totally, 21 specimens were prepared: one triplet for ‘REF’ specimens, 3 triplets for ‘PAPER’ specimens, and 3 triplets for ‘PULP’ specimens. Prismatic specimens were subjected at first to flexural tests. Then, on the resulting two halves compression tests were conducted. In addition, a series of prismatic specimens was tested as well for capillary water absorption. In order to measure the thermal conductivity, 7 specimens having dimensions 300 mm × 300 mm × 20 mm were prepared (1 reference specimens, 3 with different waste paper percentage, and 3 with pulp). As an example, Figure 2 illustrates prismatic specimens before flexural tests.

Figure 2.

Some of the prepared specimens.

3. Results

In the following subsections, the experimental results obtained are illustrated and commented. It should be pointed out that, as stated in the introduction, they represent the preliminary results of an experimental campaign still in progress. Therefore, a statistical analysis of the data of obtained results will be conducted at the end of tests, where the strengths obtained will be defined in a probabilistic way, according to the current design philosophy for constructions adopted by the modern design codes.

3.1. Mechanical Tests

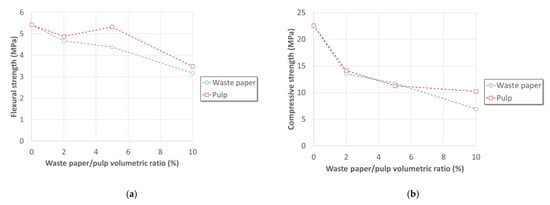

Mechanical strength test results, performed on the mortar specimens with a universal testing machine (model Dual Column Instron 3369) [24], were satisfactory and within the usual values present for blocks fixing, as well as ceiling and wall coating mortars. A typical specimen failure observed after a flexural test on pulp specimen is reported in Figure 3, while the results obtained with flexural and compressive tests are numerically reported in Table 2 and Figure 4. The values reported are the average values calculated for each triplet of prepared specimens.

Figure 3.

Pulp specimens after the flexural failure.

Table 2.

Average strengths of tested triplets.

Figure 4.

(a) Flexural strength and (b) compressive strength by varying the waste paper/pulp volumetric ratio.

As one may observe, flexural and compressive strength reduce if waste paper/pulp volumetric ratio increases, except for specimen PULP5 flexural strength. As for the flexural strength, for the same volumetric ratio, pulp papercrete specimen provides higher strength than the waste paper one. On the contrary, as far as the compressive strength is concerned, a negligible difference is observed between the two recycled paper types except for the 10% of volumetric ratio. In this latter case, the compressive strength of the papercrete with pulp is higher than the one with waste paper.

3.2. Thermal Tests

Thermals tests are conducted on seven specimens with dimensions 300 mm × 300 mm × 20 mm in order to determine thermal conductivity λ10 and thermal resistance. The apparatus used for thermal conductivity measurements consists of a heat flow meter in “single sample in a double configuration” (NETZSCH heat flow meter HFM 436/0/1), placed in a conditioned laboratory at a temperature of 23 ± 2 °C and relative humidity 50 ± 5% [25]. The results obtained with the thermal tests are reported in Table 3. As it is possible to understand, if the recycled paper amount increases, the bulk density and the thermal conductivity decrease. Among the two recycled paper types, for the same volumetric percentage, the waste paper is always more insulating than the pulp. This is due to the fact that, as known, low-density samples have low thermal conductivity because the extent of spaces and voids in the samples increases considerably. The thermal conductivity of a porous medium is inversely proportional to the extent of pores and gaps between the particles which prevent the passage of heat through [26].

Table 3.

Results of thermal tests.

3.3. Capillary Water Absorption Tests

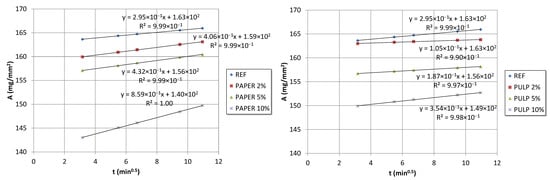

Water absorption is a crucial property for construction materials because it influences their durability. Water absorption coefficient C, expressed in [kg/(m2 × min0.5)], corresponds to the line slope joining the representative points measurements and represents the absorbent capacity of the material [27]. After 28 days of wet curing, the four long faces of the prismatic specimens were sealed with the paraffin and then they were broken into two halves. Hence, they were oven-dried up to constant mass at 60 °C and finally immersed in a shallow bath of water at a temperature equal to 20 °C and at a depth of about 6 mm.

For a more efficient evaluation of the coefficient C, tests were performed in a more complete procedure [28] with respect to the protocol indicated in Reference [27], taking into account more points for the linear regression representing the material adsorbent capacity. In particular, the uptake of water by capillary absorption was calculated through each specimen resulting weight, measured at the following times after the immersion beginning: 10, 30, 45, 90, 120 min. It should be noted that in Reference [27], only weighing at 10 and 90 min are indicated.

The equation used to model the absorption of water due to capillary action is the following:

where A [mg/mm2] is the water absorbed by the area unit since it is immersed in water; S [mg/(mm2 × min0.5)] is the material absorptivity; t [minutes] is the elapsed time; a0 [mg/mm2] is the water initially absorbed by the pores in contact with water.

Figure 5 shows the measured relationships between the water absorbed by the immerged specimen per unit area (measured as total weight at a certain time divided by 1600 mm2) and the time square root [27]. In particular, Figure 5a,b shows the results of ‘PAPER’ and ‘PULP’ specimens, respectively. In the same graphs, the linear regressions of the experimental values are reported, together with the correlation coefficient R2. In this way, the capillarity absorption coefficient S is calculated, summarized in Table 4 together with the absorption variation percentage calculated with respect to the ‘REF’ specimen [(SPAPER/PULP–SREF)/SREF × 100].

Figure 5.

Capillary absorption vs. time square root: (a) ‘PAPER’ specimens, (b) ‘PULP’ specimens.

Table 4.

Capillarity water absorption coefficient values and percentage variation.

As regards the waste paper, it is easy to note that the percentage of water absorption drastically increases as the recycled paper content increases. This is due to the fact that the spaces in the lower density samples are larger, allowing water to penetrate more easily into the specimen matrix. Water absorption is inversely proportional to the fiber cement density [29], and the presence of cellulose materials facilitates water absorption. This demonstrates the necessity to provide waterproofing behavior or an additional coating to the paper mixture in order to contrast the water absorption.

On the contrary, as regards the pulp, different behaviors are observed. As for 2% and 5% the higher the pulp percentage, the lower the water absorption with respect to the reference specimen. This may be partly due to the tubular form of cellulose fibers able to promote greater interfacial adhesion between the pulp and the cement paste in mortar with the effect of pore size reduction. In fact, internal pores are saturated with air and water from the cement hydration, so they lose their absorption capacity and ascension by capillarity (internal connection of the pores). Since absorption is a measure of the total water required to fill open voids within the net volume of a mortar, a capillarity reduction and a consequent durability improvement are obtained [30].

4. Masonry Panels Strengthened with External Papercrete Layers

The experimental results show that the new mortar produced using waste paper or paper pulp is capable of reaching mechanical strengths comparable with the ones provided by classical structural mortars applied in the masonry panels. For instance, for structural applications [31,32], mortars having compressive strengths higher than 1.0 and 2.5 N/mm2 are required, respectively. Moreover, compressive strengths higher than 20 N/mm2 may be reached. In this work, the results obtained from mechanical tests show that concrete with different volumetric percentages of paper/pulp reaches a compressive strength between 6.92 N/mm2 and 14.11 N/mm2, so it is suitable for structural applications.

In addition, due to its not negligible strength values, the papercrete should be applied also as external jacketing of masonry walls, alternatively to the traditional strengthening interventions steel jackets. To this scope, one may calculate the contribution of the external papercrete layers with the following analytical expression, as follows [33]:

where ft,rm is the reinforced masonry equivalent tensile strength; ft,um is the unreinforced masonry tensile strength; ft,plast is the papercrete plaster tensile strength; tum is the masonry thickness excluding reinforcement; tplast is plaster thickness; p is the reinforcing mesh size (if any); EAr is axial stiffness of a mesh wire (having transversal area Ar); is the mortar deformation in the uncracked condition, given by , where Eplast is the plaster elastic modulus; β is the coefficient taking into account the efficiency of the papercrete plaster on the tensile strength depending on the type of masonry, conservatively assumed in this study equal to 1. The previous equation has been derived by assuming that the external papercrete jacketing is applied on both faces of the masonry panel and that the maximum tensile strength of the reinforced masonry panel is attained at the first cracking of the external papercrete plaster.

Equation (2) reveals that the tensile strength of reinforced masonry panel is ideally provided by three terms: the tensile strength of unreinforced masonry, the one of the external layers, and the one offered by the additional reinforcing mesh. If this external reinforcement is not applied, then the third term of Equation (2) may be assumed equal to zero.

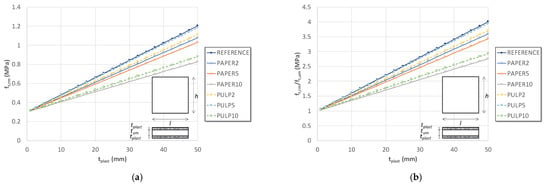

For instance, Figure 6a shows the equivalent tensile ft,rm plotted as a function of the papercrete jacketing tplast, by referring to the case of a brick masonry panel strengthened on the two faces with a papercrete layer, by assuming a fv0 = 0.2 N/mm2, and a compressive strength f = 3.45 N/mm2. ft,rm is calculated with Equation (2) where, according to the References [31,32], the unreinforced masonry tensile strength ft,um may be calculated starting from the fv0, that is the masonry shear strength, as ft,um = 1.5 fv0. It should be pointed out that in the case analyzed, fv0 refers to the shear strength associated with stair step cracks for masonry of good texture. According to the formulation adopted, it should be noted that the higher the tplast, the higher the ft,rm. For sake of completeness, in Figure 6b, the ratios ft,rm/ft,um are illustrated. It is clear to note that, in the range analyzed, due to the papercrete applied the tensile strength, ft,rm may be higher than 4 times the ft,um in the case of PULP5 specimen.

Figure 6.

(a) Equivalent tensile strength of reinforced masonry ft,rm, (b) ratio between the equivalent tensile strength of reinforced (ft,rm) and unreinforced (ft,um) masonry.

Therefore, papercrete could be applied as external jacketing of masonry panels with a suitable thickness according to the reinforced masonry equivalent tensile strength required.

Starting from the ft,rm, the equivalent shear strength of the reinforced masonry vrm may be calculated with the following expression [31,34]:

where Vrm is the shear strength of the reinforced masonry panel; l and tum are the length and thickness of the unreinforced panel, respectively; ft,rm is the equivalent tensile strength calculated with the Equation (2); σ0 is the mean of the vertical normal stress, (calculated on the as P/lt, assumed positive in compression); b is a correction coefficient related to the distribution of the stresses on the section, depending on the panel slenderness (it may be assumed that b = h/l, but not more than 1.5 and not less than 1, where h is the height of the panel).

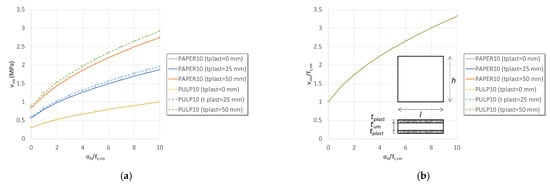

For instance, Figure 7a reports the equivalent shear strength of the reinforced masonry vrm plotted as function of the ratio σ0/ft,rm, by assuming this ratio in a range between 0 and 10, and considering three types of plaster thickness (0, 25, and 50 mm) and two types of papercrete (PAPER10 and PULP10). It should be noted, accordingly to the formulation adopted, the higher the ratio σ0/ft,rm the higher the vrm. Moreover, in this graph, pulp papercrete provides higher strength than waste paper one. Instead, in Figure 7b, the Equation (3) is plotted in a dimensionless way. As one may clearly observe, the ratio vrm/ft,rm depends only on the ratio σ0/ft,rm for any kind of papercrete, and independently on the papercrete thickness applied on the two faces.

Figure 7.

(a) Shear strength of the reinforced panel vrm, (b) ratio between the shear strength of the reinforced panel (vrm) and equivalent tensile strength of reinforced masonry (ft,rm).

5. Discussion

The experimental results obtained clearly have shown that papercrete, composed of cement mortar including a fraction of recycled paper, may be suitable as a strengthening material in the constructions. As proof of this, tests conducted on mortar specimens have revealed acceptable strengths if compared with the ones of classical mortars, in terms of both compressive and flexural strengths. The latter, as known, is directly related to tensile strength of the mortar. This partially recycled mortar may be applied in masonry panels for bed joints, or else as strengthening with external layers due to its not negligible tensile strength. The numerical evaluations conducted have confirmed this possible application, demonstrating that in the case examined of papercrete jacketing applied on both faces of a brick masonry panel, the shear strength may increase up to 3 times depending on the acting vertical stress. Finally, tests have demonstrated the necessity to provide waterproofing behavior, for instance, through the additional coating to the paper mixture, in order to contrast the water absorption.

6. Conclusions

In this paper, the experimental results obtained on prismatic papercrete specimens have been shown and discussed. Several tests have been conducted in order to measure thermal conductivity, capillary absorption, and flexural and compressive strength. Two different papercrete mixtures have been investigated by applying solid waste paper or paper pulp as recycled paper components varied in different volumetric percentages.

The preliminary results obtained, belonging to an experimental campaign still in progress have shown that:

- flexural and compressive strengths reduce if waste paper/pulp volumetric ratio increases;

- bulk density and thermal conductivity decrease if recycled paper amount increases;

- as regards the waste paper, the percentage of water absorption drastically increases as the recycled paper content increases. An opposite trend has been observed in the case of pulp applications.

This confirms that papercrete may be applied as new eco-friendly construction material, showing physical and mechanical properties adapt for being applied as the structural strengthening of existing masonry panels.

The completion of the experimental campaign will permit to analyze from a statistical point of view the observed data, including also mechanical investigations for different cycles of humidity and temperature and evaluating paper fraction size influence on the concrete strength (according to the work presented in Reference [35]).

Finally, in the future, integrated design approaches may be developed, where energetic and structural performances may be simultaneously assessed as a function of the papercrete thickness. In these interventions, as demonstrated by the experimental results shown, waterproofing behavior or an additional coating should be provided in order to contrast the water absorption.

Author Contributions

Conceptualization, T.C. and M.D.; formal analysis, M.D. and R.S.; investigation, T.C. and N.C.; methodology, T.C., M.D., and R.S.; writing—review and editing, T.C., M.D., and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ferrándiz-Mas, V.; Bond, T.; García-Alcocel, E.; Cheeseman, C.R. Lightweight mortars containing expanded polystyrene and paper sludge ash. Constr. Build. Mater. 2014, 61, 285–292. [Google Scholar] [CrossRef]

- Naik, T.R.; Moriconi, G. Environmental-friendly durable concrete made with recycled materials for sustainable concrete construction. In Proceedings of the International Symposium on Sustainable Development of Cement, Concrete and Concrete Structures, Toronto, ON, Canada, 5–7 October 2005; pp. 485–505. [Google Scholar]

- Frías, M.; Vegas, I.; Vigil de la Villa, R.; García Giménez, R. Recycling of Waste Paper Sludge in Cements: Characterization and Behavior of New Eco-Efficient Matrices. Integr. Waste Manag. 2011, 2, 301–318. [Google Scholar]

- Ghosh, A.K. A Review on Paper Crete: A Sustainable Building Material. Int. Res. J. Eng. Technol. 2018, 5, 1499–1510. [Google Scholar]

- UNI EN 13139: 2002; Aggregates for Mortar: Brussels, Belgium, 2002.

- Sangrutsamee, V.; Srichandr, P.; Poolthong, N. Re-pulped waste paper-based composite building materials with low thermal conductivity. J. Asian Archit. Build. Eng. 2012, 11, 147–151. [Google Scholar] [CrossRef]

- Birhane, S.; Mesfin, M.; Koshe, W. Experimental Study on Some Mechanical Properties of Papercrete Concrete. Adv. Mater. 2017, 6, 1–6. [Google Scholar] [CrossRef][Green Version]

- Akinwumi, I.I.; Olatunbosun, O.M.; Olofinnade, O.M.; Awoyera, P.O. Structural evaluation of lightweight concrete produced using waste newspaper and office paper. Civ. Environ. Res. 2014, 6, 160–167. [Google Scholar]

- Srinivasan, R.; Sathiya, K.; Palanisamy, M. Experimental Investigation in Developing Low Cost Concrete from Paper Industry Waste; The Bulletin of the Polytechnic Institute of Jassy, Construction; Architecture Section: Iasi, Romania, 2010; pp. 43–56. [Google Scholar]

- Gorgis, I.N.; Zaki, H.M.; Salih, S.A. Properties of papercrete. J. Eng. Appl. Sci. 2017, 12, 7400–7412. [Google Scholar]

- Cardinale, T.; Sposato, C.; Alba, M.B.; Feo, A.; De Fazio, P. Experimental evaluation of innovative cementitious materials containing waste paper. In Patrimonio in Divenire: Conoscere, Valorizzare, Abitare, Proceedings of the ReUSO VII Convegno Internazionale Sulla Documentazione, Conservazione e Recupero del Patrimonio Architettonico e Sulla Tutela Paesaggistica, Matera, Italia, 22–26 October 2019; Gangemi Editore International: Roma, Italy, 2019; pp. 343–354. [Google Scholar]

- Shermale, Y.D.; Varma, M.B. Papercrete: An Efficient Use of Waste Paper. Recent Trends Civ. Eng. Technol. 2015, 5, 54–59. [Google Scholar]

- Bencardino, F.; Cecchi, A.; Franceschi, M.; Nisticò, M.; Ombres, L.; Verre, S. Structural Behavior of Small-Scale Masonry Panel with Fiber Reinforced Mortar under Compressive Load. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2019; Volume 817, pp. 472–477. [Google Scholar]

- Negro, E.; D’Amato, M.; Cardinale, N. Non-Invasive Methods for Energy and Seismic Retrofit in Historical Building in Italy. Front. Built Environ. 2020. [Google Scholar] [CrossRef]

- Formisano, A.; Chiumiento, G.; Fabbrocino, F.; Landolfo, R. Comparative seismic evaluation between numerical analysis and Italian guidelines on cultural heritage applied to the case study of a masonry building compound. In AIP Conference Proceedings, Proceedings of the 14th International Conference of Numerical Analysis and Applied Mathematics–ICNAAM 2016, Rodhes, Greece, 19–25 September 2016; Simos, T., Tsitouras, C., Rodhes, G., Eds.; Volume 1863. [Google Scholar]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Experimental study on bond behavior in fiber-reinforced concrete with low content of recycled steel fiber. J. Mater. Civ. Eng. 2016, 28, 04016068. [Google Scholar] [CrossRef]

- Lu, S.; Koopialipoor, M.; Asteris, P.G.; Bahri, M.; Armaghani, D.J. A Novel Feature Selection Approach Based on Tree Models for Evaluating the Punching Shear Capacity of Steel Fiber-Reinforced Concrete Flat Slabs. Materials 2020, 13, 3902. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Wan, B.; Han, B. Compressive Behavior of Circular Sawdust-Reinforced Ice-Filled Flax FRP Tubular Short Columns. Materials 2020, 13, 957. [Google Scholar] [CrossRef] [PubMed]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues. Sustainability 2020, 12, 6120. [Google Scholar] [CrossRef]

- CEN. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1:2011; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Cardinale, T.; Sposato, C.; Alba, M.B.; Feo, A.; De Fazio, P. Energy Performance of Construction Materials Using Waste Recycled Polymer as Fine Aggregate Replacement. Int. J. Heat Technol. 2019, 37, 696–704. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Alexandre, J.; De, C.; Xavier, G.; Pedroti, L.G. Recycling paper industry effluent sludge for use in mortars: A sustainability perspective. J. Clean. Prod. 2018, 192, 335–346. [Google Scholar]

- CEN. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; EN 1015-11:2001; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- CEN. Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Dry and Moist Products of Medium and Low Thermal Resistance; EN 12664:2001; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- Selvaraj, R.; Priyanka, R.; Amirthavarshini, M.; Prabavathy, D.S. Evaluation of Papercrete: An innovative building material. Int. J. Eng. Adv. Res. Technol. 2015, 1, 52–56. [Google Scholar]

- CEN. Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar; EN 1015-18:2004; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Candamano, S.; De Luca, P.; Frontera, P.; Crea, F. Production of Geopolymeric Mortars Containing Forest Biomass Ash as Partial Replacement of Metakaolin. Environments 2017, 4, 74. [Google Scholar] [CrossRef]

- Frías, M.; Sanchez de Rojas, M.I.; Rodriguez, O.; García Giménez, R.; Vigil de la Villa, R. Characterisation of calcined paper sludge as an environmentally friendly source of metakaolin for manufacture of cementitious materials. Adv. Cem. Res. 2008, 20, 23–30. [Google Scholar] [CrossRef]

- Adesanya, E.; Ohenoja, K.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. One-part geopolymer cement from slag and pretreated paper sludge. J. Clean. Prod. 2018, 185, 168–175. [Google Scholar] [CrossRef]

- Standard, B. Eurocode 6—Design of Masonry Structures; British Standard Institution: London, UK, 2005. [Google Scholar]

- Ministerial Decree 17/01/2018. In Aggiornamento Delle “Norme Tecniche Per le Costruzioni”, di cui al Decreto Ministeriale 17 gennaio 2011”. Suppl. O. n. 8 alla Gazzetta Ufficiale del 20 Febbraio 2018; Ministero delle Infrastrutture e dei Trasporti: Rome, Italy, 2018. (In Italian)

- Zanello, E. Rinforzo Strutturale e Principi Della Conservazione: Un Esempio Applicativo su Edifici in Tufo Soggetti a Vincolo; Fibre Net S.R.L.: Jacopo Stellini, Italy, 2020; pp. 5–6. [Google Scholar]

- Commentary to the Ministerial Decree 17/01/2018—Circolare 21/01/2019 n. 7, 2019. In Istruzioni Per L’applicazione DELL’. Aggiornamento Delle “Norme Tecniche Per le Costruzioni” di Cui al Decreto Ministeriale 17 Gennaio 2011. Suppl. O. n. 5 Alla Gazzetta Ufficiale Del 11 Febbraio 2019; C.S.LL.PP; Consiglio Superiore: Rome, Italy, 2019. (In Italian)

- Nurek, T.; Gendek, A.; Roman, K. Forest Residues as a Renewable Source of Energy: Elemental Composition and Physical Properties. Bioresources 2019, 14, 6–20. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).