Proposal of a Tool for Determining Sub- and Main Dimension Indicators in Assessing Internal Logistics Readiness for Industry 4.0 within a Company

Abstract

:1. Introduction

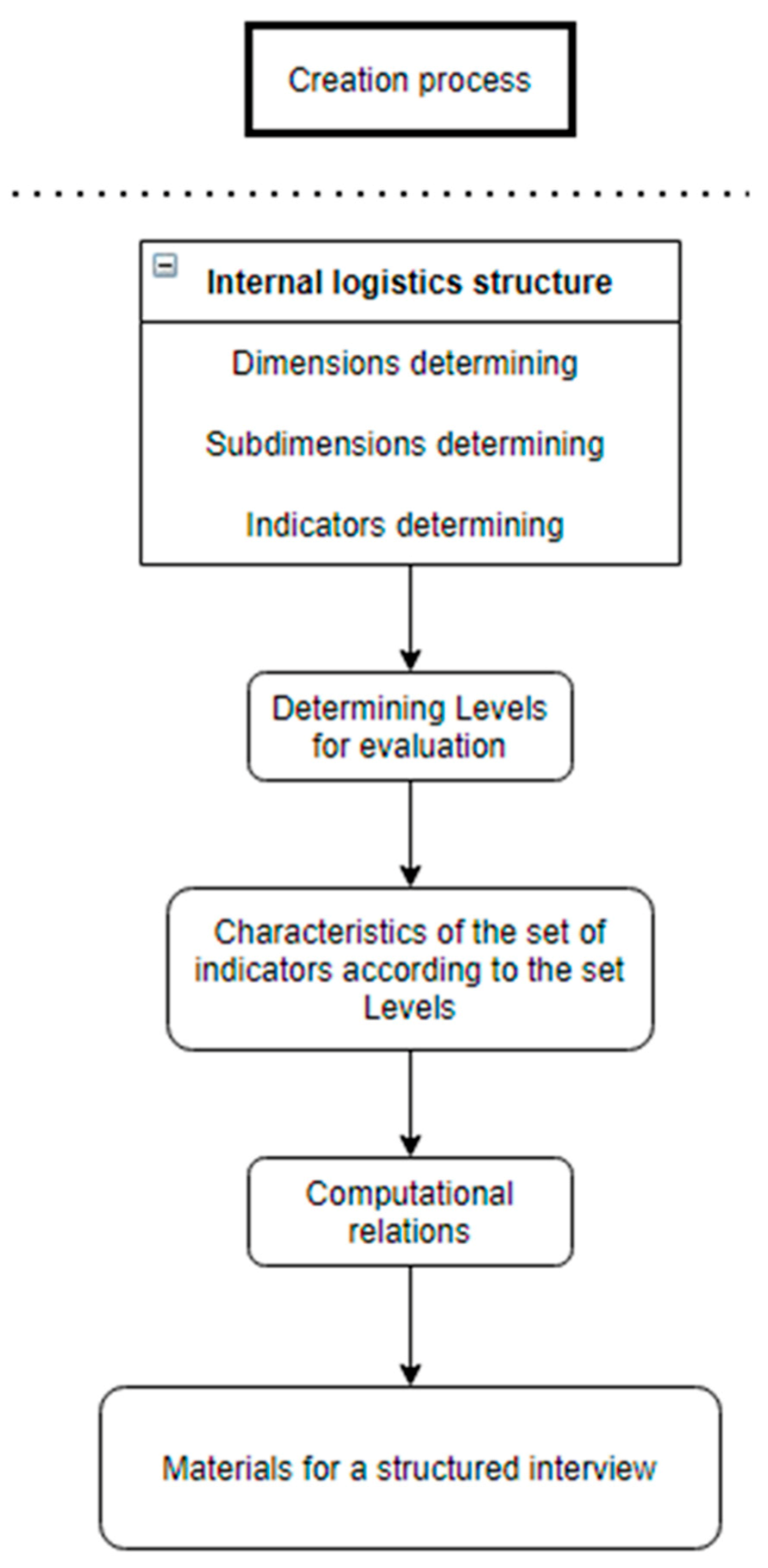

2. Materials and Methods

- What is Industry 4.0 and what are the tangible benefits it could bring?

- What is the level of readiness of the company, sub-areas or individual facilities?

- How can a company gradually and purposefully improve and increase its level?

- 1.

- Initial: Teams at this level do not perform defined processes or only partially.

- 2.

- Managed: Project management is established and activities are planned.

- 3.

- Defined: Procedures are defined, documented and controlled.

- 4.

- Quantitatively controlled: Products and processes are quantitatively controlled.

- 5.

- Optimizing: The team is constantly optimizing its activities [40].

Analyzed Models of Readiness

- 1.

- 2.

- SIMMI 4.0—A Maturity Model for Classifying the Enterprise [43].

- 3.

- PwC Maturity Model 4.0: Building the Digital Enterprise [44].

- 4.

- A Maturity Model for Assessing Industry 4.0 Readiness and Maturity.

- 5.

- A Maturity Model for Assessing the Digital Readiness of Manufacturing [45].

- 6.

- Development of an Assessment Model for Industry 4.0: Industry 4.0-MM [46].

- 7.

- M2DDM—A Maturity Model for Data-Driven Manufacturing [47].

- 8.

- The Singapore Smart Industry Readiness Index [48].

- 9.

- Rockwell—The Connected Enterprise Maturity Model [49].

- 10.

- Model according to the Working Group of the company firma4.cz [50].

- 11.

- Digitalization Degree in the Manufacturing Industry in Germany [51].

- 12.

- Digital Maturity & Transformation Study St. Gallen [52].

- 13.

- Capgemini-Asset Performance Management Maturity Model [53].

- 14.

- Towards a Smart Manufacturing Maturity Model for SMEs [54].

- 15.

- Preliminary Maturity Model for Leveraging Digitalization in Manufacturing [55].

- 16.

- The Logistics 4.0 Maturity Model [56].

- 17.

- Cybersecurity in the context of Industry 4.0 [57].

- 18.

- Study based analysis on the current digitalization degree in the manufacturing [58]

- 19.

- Concept for an evolutionary maturity based Industry 4.0 migration model [58].

- 20.

- Roadmapping towards industrial digitization based on an Industry 4.0 [59].

- 21.

- Contextualizing the outcome of a maturity assessment for Industry 4.0 [60].

- 22.

- The Reference Architectural Model Industrie 4.0 [61].

- 23.

- A Categorical Framework of Manufacturing for Industry 4.0 and Beyond [62].

- 24.

- Acatech Industrie 4.0 Maturity Index [63].

- 25.

- An Overview of a Smart Manufacturing System Readiness Assessment [64].

- 26.

- Maturity and Readiness Model for Industry 4.0 Strategy [65].

- 27.

- A Smartness Assessment Framework for Smart Factories [66].

- 28.

- Three stage maturity model in SME’s toward Industry 4.0 [67].

- 29.

- Intelligent Logistics For Intelligent Production Systems [68]

- 30.

- Logistics maturity of the service industry [69].

- 31.

- Defining and assessing industry 4.0 maturity levels—Case of the defence sector [70].

- 32.

- Maturity Levels For Logistics 4.0 Based On Nrw’S Industry 4.0 Maturity Model [71].

- 33.

- Logistics 4.0 Maturity in Service Industry: Empirical Research Results [72].

3. Results

- The main dimensions of internal logistics;

- Subdimensions of the main dimensions;

- A set of indicators covering a given subdimension.

Calculation Relationships for Evaluation

- Subdimension level values;

- Dimension level values.

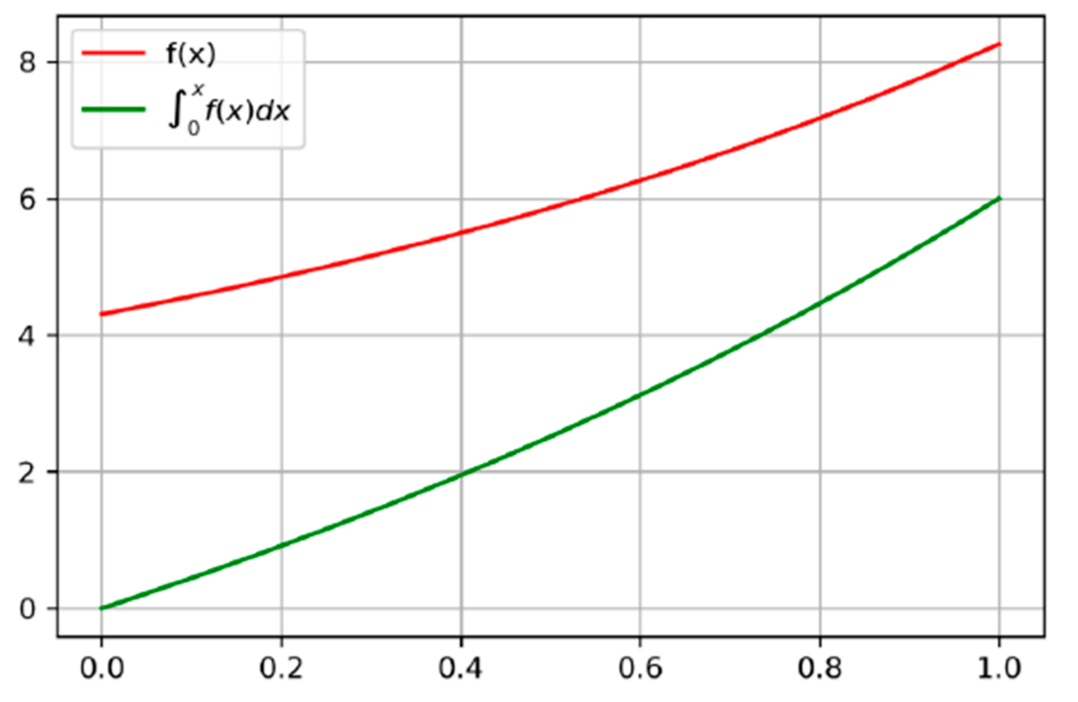

Computational Formulations

- 1.

- System of evaluation and determination of final levels

- 𝑏𝑖—number of points achieved in question 𝑖.

- 𝐵𝑖—maximum possible number of points of the question 𝑖.

- 2.

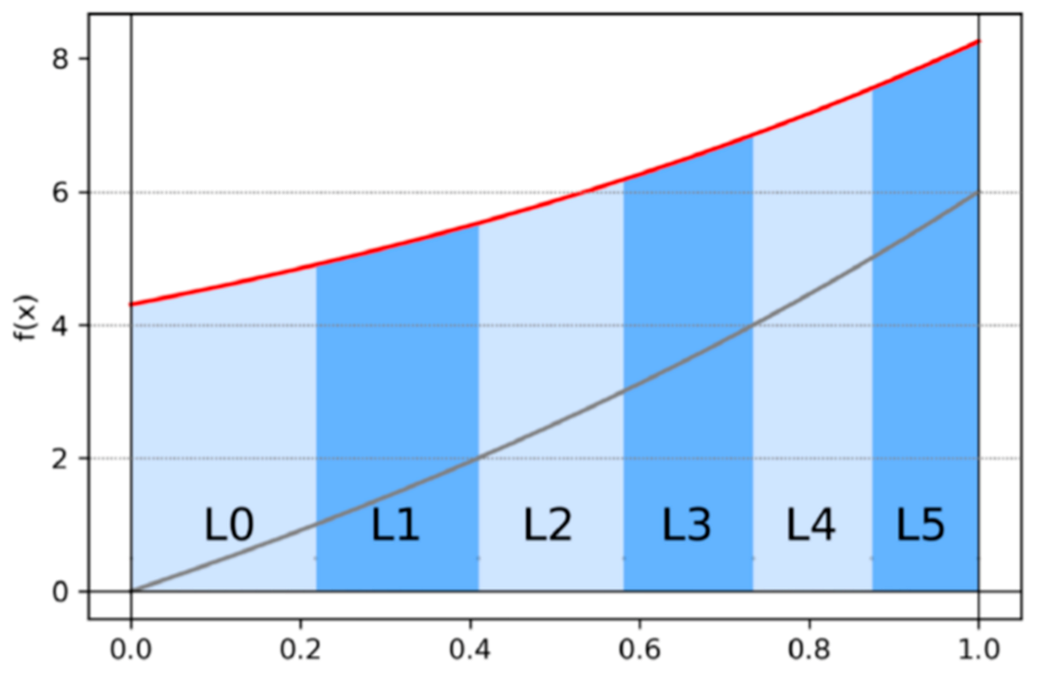

- Division of the interval into values.

- 𝐾 is the basis where 𝐾 ≠ 1.

- 𝑥 is the exponent, 𝑥∈𝑅.

- A, B and C—function parameters (constants).

- 3.

- Function properties

- —calculated value of readiness level (value of integral);

- —the resulting value of the readiness level;

- —lower limit for a certain level;

- —upper limit for a certain level.

- 4.

- Interval division

- 𝐴 = 2.862, 𝐵 = 2.381, 𝐶 = 1.4448.

- 5.

- Function f(x) graph and proposed intervals

4. Discussion

- A new method of evaluation, which is based on set six levels (0–5) for the evaluation of indicators, sub-dimensions, and dimensions;

- Evaluation, which uses a suitable mathematical basis applicable for the entire field of internal logistics;

- An innovative scoring system based on a point system divided into six intervals using an exponential function.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. A Table with All Companies with the Main Description and Their Readiness for Industry 4.0.

| Company Size | Employees Number | Production Type According to Repeatability | Production Type | Company Strategy towards Industry 4.0 | Implementation of Industry 4.0 into Internal Logistics | Shifts |

|---|---|---|---|---|---|---|

| Large | 1250 | Large series | Electronic components | Partly-Projects fit into the concept of Industry 4.0 | No | 3 |

| Medium | 65 | Small series | Production of metal components–couplings | No-The projects do not concern the Industry 4.0 concept | No | 3 |

| Large | 1000 | Serial | Assembly of car seats | Yes | Yes | 3 |

| Small | 49 | Small series | Production of weldments, other metal production | No-The projects do not concern the Industry 4.0 concept | No | 2 |

| Large | 600 | Serial | Door panels and car interiors | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3 |

| Large | 1900 | Serial | Car locking systems | Yes | Yes | 3–4 |

| Large | 650 | Serial | Chassis parts | Partly-Projects fit into the concept of Industry 4.0 | No | 3–4 |

| Large | 400 | Large series | Production of steel bumpers | Yes | Yes | 3 |

| Large | 1050 | Large series | Room heat pumps | Yes | Yes | 3 |

| Large | 500 | Serial | Components for fluid systems and car seats | Partly-Projects fit into the concept of Industry 4.0 | No | 2 |

| Large | 1120 | Small series | Aerospace industry-assembly | Partly-Projects fit into the concept of Industry 4.0 | Yes | 3 |

| Medium | 230 | Serial | Propulsion and control systems for VZV | Yes | Yes | 3 |

| Large | 1100 | Serial | Car seats and electrical systems | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3 |

| Large | 1650 | Serial | Headrests and seat frames | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3 |

| Large | 1200 | Large series | PCB connectors | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3 |

| Large | 480 | Serial | Manufacture of washing equipment | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3–4 |

| Large | 850 | Serial | Manufacture of bus bodies | No-The projects do not concern the Industry 4.0 concept | No | 3 |

| Large | 1200 | Large series | Manufacturer of OLED and LCD TVs | Yes | Yes | 3 |

| Large | 1300 | Serial | Air conditioning units | Partly-Projects fit into the concept of Industry 4.0 | Yes | 3 |

| Small | 50 | Small series | Burning, pressing, machining of metal parts | No-The projects do not concern the Industry 4.0 concept | No | 2 |

| Medium | 220 | Small series | Welded parts, other metal production | No-The projects do not concern the Industry 4.0 concept | No | 3 |

| Medium | 240 | Small series | Welded parts, other metal production, assembly | No-The projects do not concern the Industry 4.0 concept | No | 3 |

| Large | 1400 | Serial | Textile elements of car trim | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3 |

| Large | 900 | Serial | Production of car control systems | Partly-Projects fit into the concept of Industry 4.0 | Yes | 3 |

| Large | 670 | Small series | Fans, conveyors, flaps, and closures | No-The projects do not concern the Industry 4.0 concept | No | 3 |

| Large | 3100 | Large series | Seat structures, door locks | Yes | Yes | 3 |

| Small | 50 | Small series | Manufacture of tools | No-The projects do not concern the Industry 4.0 concept | No | 2 |

| Large | 400 | Serial | Production of cutting tools | Partly-Projects fit into the concept of Industry 4.0 | Partly | 3 |

| Medium | 250 | Large series | Electronic components | No-The projects do not concern the Industry 4.0 concept | No | 3 |

| Company Number | Company 1 | Company 2 | Company 3 | Company 4 | Company 5 | Company 6 | Company 7 | Company 8 | Company 9 | Company 10 | Company 11 | Company 12 | Company 13 | Company 14 | Company 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U1 | 1 | 1 | 3 | 1 | 1 | 3 | 0 | 3 | 4 | 2 | 2 | 3 | 3 | 2 | 1 |

| U2 | 2 | 2 | 3 | 0 | 3 | 3 | 0 | 3 | 4 | 1 | 2 | 3 | 3 | 2 | 1 |

| U3 | 1 | 1 | 4 | 0 | 2 | 3 | 1 | 4 | 4 | 1 | 2 | 3 | 2 | 2 | 1 |

| U4 | 2 | 2 | 3 | 1 | 3 | 3 | 2 | 3 | 4 | 2 | 3 | 3 | 3 | 2 | 2 |

| U5 | 2 | 2 | 3 | 0 | 3 | 4 | 3 | 4 | 4 | 3 | 3 | 4 | 3 | 3 | 4 |

| U6 | 2 | 2 | 3 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 2 | 2 | 2 | 2 |

| U7 | 2 | 1 | 3 | 1 | 3 | 2 | 1 | 3 | 3 | 2 | 3 | 3 | 3 | 2 | 2 |

| U8 | 2 | 1 | 3 | 0 | 2 | 3 | 1 | 4 | 4 | 2 | 3 | 4 | 3 | 2 | 2 |

| U9 | 3 | 2 | 4 | 0 | 3 | 3 | 2 | 4 | 4 | 2 | 2 | 4 | 3 | 2 | 3 |

| U10 | 1 | 0 | 1 | 1 | 2 | 3 | 2 | 2 | 3 | 2 | 4 | 3 | 2 | 3 | 3 |

| U11 | 1 | 0 | 3 | 1 | 2 | 3 | 3 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| U12 | 2 | 0 | 1 | 1 | 3 | 3 | 2 | 3 | 3 | 2 | 4 | 3 | 2 | 3 | 3 |

| U13 | 2 | 0 | 1 | 0 | 2 | 3 | 2 | 2 | 2 | 2 | 3 | 3 | 2 | 3 | 3 |

| U14 | 2 | 1 | 2 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 |

| U15 | 2 | 0 | 1 | 2 | 2 | 3 | 2 | 2 | 2 | 2 | 3 | 3 | 2 | 2 | 2 |

| U16 | 2 | 0 | 3 | 2 | 2 | 3 | 3 | 2 | 2 | 2 | 3 | 2 | 3 | 3 | 3 |

| U17 | 2 | 1 | 2 | 1 | 3 | 3 | 2 | 3 | 2 | 2 | 3 | 3 | 2 | 3 | 3 |

| U18 | 1 | 0 | 2 | 1 | 1 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 1 | 3 |

| U19 | 2 | 0 | 4 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 2 | 3 |

| U20 | 3 | 1 | 2 | 2 | 2 | 4 | 3 | 3 | 3 | 3 | 4 | 3 | 3 | 3 | 4 |

| U21 | 2 | 1 | 4 | 0 | 2 | 2 | 2 | 2 | 4 | 1 | 2 | 2 | 1 | 2 | 2 |

| U22 | 2 | 2 | 4 | 0 | 2 | 3 | 2 | 3 | 4 | 2 | 3 | 3 | 3 | 2 | 2 |

| U23 | 2 | 2 | 4 | 0 | 3 | 3 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 3 | 2 |

| U24 | 2 | 1 | 4 | 1 | 3 | 2 | 2 | 2 | 3 | 2 | 3 | 2 | 2 | 2 | 2 |

| U25 | 2 | 1 | 3 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 2 | 3 | 2 | 3 | 2 |

| U26 | 2 | 1 | 2 | 1 | 3 | 2 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 2 | 2 |

| U27 | 2 | 2 | 2 | 1 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 2 |

| U28 | 4 | 1 | 4 | 1 | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 2 | 3 | 3 | 3 |

| U29 | 1 | 1 | 3 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| U30 | 2 | 1 | 3 | 1 | 2 | 3 | 1 | 4 | 4 | 2 | 2 | 4 | 1 | 4 | 2 |

| U31 | 2 | 1 | 3 | 2 | 3 | 4 | 3 | 3 | 4 | 3 | 3 | 4 | 2 | 4 | 3 |

| U32 | 2 | 1 | 3 | 1 | 2 | 3 | 1 | 4 | 4 | 2 | 3 | 3 | 1 | 3 | 2 |

| U33 | 2 | 1 | 3 | 1 | 3 | 3 | 4 | 4 | 4 | 3 | 3 | 3 | 2 | 4 | 3 |

| U34 | 2 | 1 | 3 | 1 | 3 | 4 | 2 | 4 | 4 | 2 | 3 | 4 | 1 | 4 | 2 |

| U35 | 3 | 1 | 3 | 0 | 3 | 3 | 1 | 3 | 3 | 2 | 4 | 3 | 1 | 3 | 2 |

| U36 | 3 | 1 | 3 | 1 | 3 | 4 | 2 | 4 | 4 | 3 | 3 | 4 | 2 | 4 | 3 |

| U37 | 3 | 2 | 3 | 1 | 3 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 4 | 3 |

| U38 | 2 | 1 | 2 | 1 | 2 | 2 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 3 | 2 |

| U39 | 2 | 2 | 3 | 1 | 3 | 3 | 2 | 3 | 4 | 3 | 4 | 4 | 2 | 3 | 3 |

| U40 | 2 | 1 | 3 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 2 | 2 |

| U41 | 2 | 1 | 4 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 3 | 2 |

| U42 | 2 | 1 | 4 | 1 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 3 | 2 |

| U43 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 3 | 4 | 1 | 3 | 3 | 1 | 2 | 2 |

| U44 | 2 | 1 | 4 | 0 | 2 | 3 | 2 | 3 | 4 | 2 | 3 | 3 | 2 | 3 | 2 |

| U45 | 2 | 2 | 4 | 1 | 3 | 4 | 2 | 4 | 4 | 4 | 4 | 4 | 3 | 4 | 3 |

| U46 | 2 | 2 | 3 | 0 | 2 | 3 | 2 | 3 | 3 | 2 | 4 | 3 | 2 | 3 | 2 |

| Company Number | Company 16 | Company 17 | Company 18 | Company 19 | Company 20 | Company 21 | Company 22 | Company 23 | Company 24 | Company 25 | Company 26 | Company 27 | Company 28 | Company 29 | |

| U1 | 2 | 1 | 4 | 2 | 0 | 1 | 1 | 2 | 3 | 1 | 3 | 1 | 3 | 2 | |

| U2 | 3 | 1 | 3 | 3 | 0 | 0 | 0 | 2 | 3 | 1 | 4 | 2 | 2 | 2 | |

| U3 | 2 | 1 | 4 | 3 | 1 | 1 | 1 | 1 | 3 | 1 | 4 | 1 | 2 | 3 | |

| U4 | 1 | 2 | 4 | 4 | 2 | 2 | 2 | 2 | 3 | 2 | 3 | 1 | 3 | 2 | |

| U5 | 2 | 2 | 4 | 4 | 2 | 2 | 1 | 3 | 2 | 2 | 4 | 1 | 3 | 2 | |

| U6 | 2 | 2 | 3 | 3 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 1 | 2 | 2 | |

| U7 | 2 | 2 | 3 | 3 | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 1 | 3 | 3 | |

| U8 | 2 | 1 | 3 | 3 | 1 | 1 | 1 | 2 | 3 | 1 | 4 | 1 | 3 | 2 | |

| U9 | 2 | 2 | 3 | 3 | 0 | 2 | 0 | 2 | 3 | 2 | 4 | 1 | 3 | 4 | |

| U10 | 4 | 1 | 2 | 4 | 1 | 0 | 1 | 2 | 4 | 2 | 5 | 1 | 2 | 1 | |

| U11 | 4 | 3 | 2 | 3 | 1 | 1 | 1 | 2 | 3 | 3 | 4 | 2 | 2 | 1 | |

| U12 | 4 | 1 | 3 | 4 | 1 | 0 | 1 | 3 | 3 | 2 | 5 | 1 | 2 | 2 | |

| U13 | 4 | 2 | 2 | 4 | 0 | 0 | 0 | 3 | 4 | 2 | 5 | 1 | 3 | 2 | |

| U14 | 3 | 2 | 3 | 3 | 1 | 1 | 1 | 2 | 3 | 2 | 4 | 1 | 2 | 1 | |

| U15 | 3 | 2 | 3 | 3 | 1 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 1 | 1 | |

| U16 | 3 | 3 | 3 | 4 | 2 | 1 | 1 | 2 | 4 | 2 | 4 | 1 | 3 | 2 | |

| U17 | 2 | 2 | 3 | 4 | 1 | 1 | 1 | 2 | 3 | 2 | 4 | 2 | 3 | 3 | |

| U18 | 2 | 1 | 3 | 3 | 1 | 1 | 1 | 2 | 3 | 1 | 4 | 2 | 2 | 1 | |

| U19 | 3 | 3 | 3 | 3 | 2 | 1 | 1 | 3 | 4 | 2 | 3 | 2 | 4 | 2 | |

| U20 | 3 | 2 | 4 | 4 | 2 | 1 | 1 | 3 | 3 | 3 | 4 | 1 | 4 | 3 | |

| U21 | 1 | 2 | 4 | 3 | 0 | 1 | 1 | 2 | 3 | 2 | 3 | 0 | 0 | 1 | |

| U22 | 2 | 2 | 4 | 3 | 0 | 2 | 2 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | |

| U23 | 3 | 2 | 3 | 3 | 0 | 2 | 1 | 2 | 2 | 2 | 3 | 1 | 1 | 1 | |

| U24 | 1 | 1 | 3 | 3 | 1 | 3 | 1 | 2 | 2 | 1 | 4 | 1 | 2 | 2 | |

| U25 | 2 | 2 | 4 | 3 | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 1 | 2 | 2 | |

| U26 | 3 | 1 | 3 | 3 | 1 | 1 | 2 | 2 | 2 | 0 | 3 | 1 | 2 | 1 | |

| U27 | 2 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 0 | 2 | 1 | |

| U28 | 2 | 1 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 2 | 4 | 0 | 1 | 2 | |

| U29 | 2 | 2 | 2 | 3 | 0 | 2 | 1 | 2 | 2 | 0 | 4 | 0 | 2 | 1 | |

| U30 | 2 | 1 | 3 | 4 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 1 | 2 | 2 | |

| U31 | 3 | 1 | 2 | 3 | 1 | 1 | 1 | 3 | 3 | 2 | 4 | 3 | 2 | 2 | |

| U32 | 2 | 1 | 3 | 3 | 1 | 0 | 1 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | |

| U33 | 3 | 1 | 2 | 4 | 1 | 1 | 1 | 3 | 2 | 2 | 4 | 1 | 3 | 2 | |

| U34 | 2 | 2 | 3 | 3 | 1 | 1 | 1 | 3 | 3 | 2 | 4 | 2 | 3 | 2 | |

| U35 | 3 | 1 | 3 | 2 | 0 | 1 | 0 | 2 | 3 | 1 | 3 | 2 | 3 | 2 | |

| U36 | 3 | 2 | 3 | 3 | 1 | 0 | 2 | 3 | 4 | 2 | 4 | 2 | 2 | 3 | |

| U37 | 2 | 2 | 3 | 3 | 2 | 2 | 2 | 3 | 3 | 2 | 4 | 1 | 3 | 3 | |

| U38 | 2 | 2 | 4 | 3 | 1 | 1 | 1 | 2 | 3 | 2 | 4 | 2 | 3 | 3 | |

| U39 | 3 | 3 | 3 | 4 | 2 | 2 | 1 | 3 | 3 | 1 | 5 | 2 | 2 | 4 | |

| U40 | 2 | 2 | 3 | 2 | 1 | 1 | 2 | 2 | 3 | 1 | 3 | 1 | 2 | 2 | |

| U41 | 2 | 2 | 3 | 3 | 1 | 1 | 2 | 2 | 2 | 1 | 4 | 1 | 2 | 2 | |

| U42 | 2 | 2 | 4 | 3 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 1 | 1 | 2 | |

| U43 | 1 | 2 | 4 | 3 | 1 | 1 | 1 | 2 | 2 | 1 | 3 | 2 | 1 | 2 | |

| U44 | 1 | 2 | 3 | 3 | 0 | 0 | 1 | 2 | 2 | 2 | 4 | 2 | 1 | 2 | |

| U45 | 2 | 2 | 4 | 3 | 1 | 2 | 2 | 2 | 3 | 2 | 4 | 2 | 2 | 3 | |

| U46 | 2 | 2 | 4 | 3 | 1 | 1 | 1 | 2 | 3 | 1 | 3 | 1 | 1 | 2 |

| Company Number | Subdimension | Dimension | Final Value of Intermal Logistics | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SD1 | SD2 | SD3 | SD4 | SD5 | SD6 | SD7 | SD8 | SD9 | SD10 | SD11 | SD12 | SD13 | SD14 | D1 | D2 | D3 | D4 | D5 | ||

| Company 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 2 | 2 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | 1 |

| Company 2 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 |

| Company 3 | 3 | 3 | 3 | 1 | 1 | 2 | 4 | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 1 | 3 | 2 | 3 | 3 |

| Company 4 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| Company 5 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 3 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Company 6 | 3 | 3 | 2 | 3 | 2 | 3 | 2 | 2 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 3 |

| Company 7 | 0 | 2 | 1 | 2 | 2 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 |

| Company 8 | 3 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 4 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 |

| Company 9 | 4 | 3 | 3 | 2 | 2 | 2 | 3 | 3 | 1 | 4 | 3 | 3 | 3 | 4 | 4 | 2 | 2 | 4 | 3 | 3 |

| Company 10 | 1 | 2 | 1 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 2 | 2 |

| Company 11 | 1 | 3 | 2 | 3 | 3 | 3 | 2 | 2 | 1 | 2 | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 3 | 3 | 3 |

| Company 12 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 2 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 |

| Company 13 | 2 | 2 | 3 | 2 | 2 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 1 | 1 | 2 |

| Company 14 | 1 | 2 | 1 | 3 | 2 | 1 | 2 | 2 | 2 | 4 | 3 | 3 | 2 | 3 | 2 | 2 | 2 | 3 | 2 | 2 |

| Company 15 | 0 | 2 | 2 | 3 | 2 | 3 | 1 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 1 | 3 | 2 | 2 | 2 | 2 |

| Company 16 | 2 | 1 | 1 | 4 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 3 | 1 | 2 | 1 | 2 |

| Company 17 | 0 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 0 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Company 18 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 1 | 2 | 3 | 3 | 3 | 4 | 3 | 2 | 3 | 2 | 3 | 3 |

| Company 19 | 2 | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 3 | 2 | 3 | 3 | 3 | 2 | 3 | 2 | 3 |

| Company 20 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 |

| Company 21 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 1 |

| Company 22 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 |

| Company 23 | 1 | 2 | 1 | 2 | 1 | 2 | 2 | 1 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 1 | 2 |

| Company 24 | 3 | 2 | 2 | 3 | 3 | 3 | 2 | 1 | 2 | 2 | 3 | 3 | 2 | 2 | 2 | 3 | 2 | 2 | 2 | 2 |

| Company 25 | 0 | 1 | 1 | 2 | 1 | 1 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 |

| Company 26 | 3 | 3 | 4 | 5 | 4 | 3 | 3 | 3 | 4 | 3 | 3 | 4 | 3 | 3 | 3 | 4 | 3 | 4 | 3 | 4 |

| Company 27 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 |

| Company 28 | 2 | 2 | 3 | 2 | 2 | 3 | 0 | 1 | 1 | 2 | 2 | 2 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 2 |

| Company 29 | 2 | 1 | 2 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 2 | 3 | 1 | 2 | 2 | 1 | 1 | 2 | 2 | 1 |

References

- Krajcovic, M.; Bulej, V.; Kuric, I.; Sapietova, A. Intelligent manufacturing systems in concept of digital factory. Commun.-Sci. Lett. Univ. Zilina 2013, 15, 77–87. [Google Scholar]

- Ancarani, A.; Di Mauro, C.; Mascali, F. Backshoring strategy and the adoption of Industry 4.0: Evidence from Europe. J. World Bus. 2019, 54, 360–371. [Google Scholar] [CrossRef]

- Hoyer, C.; Gunawan, I.; Reaiche, C.H. The Implementation of Industry 4.0–A Systematic Literature Review of the Key Factors. Syst. Res. Behav. Sci. 2020, 37, 557–578. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking Int. J. 2019, 27, 2213–2232. [Google Scholar] [CrossRef]

- Zoubek, M.; Koubovská, M.; Šimon, M. A New Approach for the Evaluation of Internal Logistics Processes and Their Readiness for the Industry 4.0 Concept. In Design, Simulation, Manufacturing: The Innovation Exchange; Springer: Cham, Switzerland, 2021; pp. 275–285. [Google Scholar]

- Allen, W.B. The logistics revolution and transportation. ANNALS Am. Acad. Polit. Soc. Sci. 1997, 553, 106–116. [Google Scholar] [CrossRef]

- Klaus, P. Logistics research: A 50 years’ march of ideas. Logist. Res. 2009, 1, 53–65. [Google Scholar] [CrossRef]

- Zvirgzdiņa, B.; Tolujevs, J. Simulation-Based Metaheuristic Optimization of Logistics Systems. In Proceedings of the 12th International Conference Reliability and Statistics in Transportation and Communication, Riga, Latvia, 17–20 October 2012; pp. 17–20. [Google Scholar]

- Curcio, D.; Longo, F. Inventory and internal logistics management as critical factors affecting the supply chain performances. Int. J. Simul. Process. Model. 2009, 5, 278–288. [Google Scholar] [CrossRef]

- Jiang, C.; Chau, K.T.; Liu, C.; Lee, C.H.; Han, W.; Liu, W. Move-and-charge system for automatic guided vehicles. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Herrero-Perez, D.; Martinez-Barbera, H. Modeling distributed transportation systems composed of flexible automated guided vehicles in flexible manufacturing systems. IEEE Trans. Ind. Inform. 2010, 6, 166–180. [Google Scholar] [CrossRef]

- Simons, J.; Brussel, H.; De Schutter, J.; Verhaert, J. A self-learning automaton with variable resolution for high precision assembly by industrial robots. IEEE Trans. Autom. Control 1982, 27, 1109–1113. [Google Scholar] [CrossRef]

- Antonio, P.; Gianluca, E.; Christian, C.; Sirio, C.R. Interconnection System with Software Able to Interconnect 4.0 Generation Machines with the Whole Enterprise System. Contemput. Eng. Sci. 2018, 11, 3109–3127. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yang, S. Design of Enterprise Network Information System Based on Industrial Interconnection. In Data Processing Techniques and Applications for Cyber-Physical Systems (DPTA 2019); Springer: Singapore, 2020; pp. 799–807. [Google Scholar]

- Zhao, S.; Li, Z.; Zhou, L. Construction of logistics network system based on Internet+. J. Phys. Conf. Ser. 2019, 1176, 022027. [Google Scholar] [CrossRef]

- Kuhn, H.; Sternbeck, M.G. Integrative retail logistics: An exploratory study. Oper. Manag. Res. 2013, 6, 2–18. [Google Scholar] [CrossRef]

- Sternad, M.; Lerher, T.; Gajšek, B. Maturity levels for logistics 4. In 0 based on NRW’s Industry 4.0 maturity model. In Proceedings of the Business Logistics in Modern Management, Osijek, Croatia, 11–12 October 2018. [Google Scholar]

- Skapinyecz, R.; Illés, B.; Bányai, Á. Logistic aspects of Industry 4.0. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 448, p. 12014. [Google Scholar]

- Strandhagen, J.W.; Alfnes, E.; Strandhagen, J.O.; Vallandingham, L.R. The fit of Industry 4.0 applications in manufacturing logistics: A multiple case study. Adv. Manuf. 2017, 5, 344–358. [Google Scholar] [CrossRef] [Green Version]

- Mourtzis, D.; Vlachou, E.; Milas, N.J.P.C. Industrial big data as a result of IoT adoption in manufacturing. Procedia CIRP 2016, 55, 290–295. [Google Scholar] [CrossRef] [Green Version]

- Zoubek, M.; Simon, M. Evaluation of the Level and Readiness of Internal Logistics for Industry 4.0 in Industrial Companies. Appl. Sci. 2021, 11, 6130. [Google Scholar] [CrossRef]

- Rakic, S.; Pavlovic, M.; Marjanovic, U. A Precondition of Sustainability: Industry 4.0 Readiness. Sustainability 2021, 13, 6641. [Google Scholar] [CrossRef]

- Trstenjak, M.; Opetuk, T. Industry 4.0 Readiness Factor Calculation and Process Planning: State-of-the-Art Review. Trans. FAMENA 2020, 44. [Google Scholar] [CrossRef]

- Rejikumar, G.; Arunprasad, P.; Persis, J.; Sreeraj, K.M. Industry 4.0: Key findings and analysis from the literature arena. Benchmarking Int. J. 2019, 26, 2514–2542. [Google Scholar]

- Nick, G.; Kovács, T.; Kő, A.; Kádár, B. Industry 4.0 readiness in manufacturing: Company Compass 2.0, a renewed framework and solution for Industry 4.0 maturity assessment. Procedia Manuf. 2021, 54, 39–44. [Google Scholar] [CrossRef]

- Temur, G.T.; Bolat, H.B.; Gözlü, S. Evaluation of industry 4.0 readiness level: Cases from Turkey. In the International Symposium for Production Research; Springer: Cham, Switzerland, 2018; pp. 412–425. [Google Scholar]

- Kohnová, L.; Papula, J.; Salajová, N. Internal factors supporting business and technological transformation in the context of Industry 4.0. Bus. Theory Pract. 2019, 20, 137–145. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process. Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Jodlbauer, H.; Schagerl, M. Reifegradmodell Industrie 4.0—Ein Vorgehensmodell zur Identifikation von Industrie 4.0 Potentialen. Informatik 2016, 259, 1473–1487. [Google Scholar]

- Zoubek, M. Methodology for Evaluating the Readiness of Internal Logistics Processes for Industry 4.0, Dissertation Work; Faculty of Mechanical Engineering, Department of Industrial Engeneering and Management, University of West Bohemia: Pilsen, Czech Republic, 2021. [Google Scholar]

- Chrissis, M.B.; Konrad, M.; Shrum, S. CMMI for Development: Guidelines for Process Integration and Product Improvement; Pearson Education: London, UK, 2011. [Google Scholar]

- Torrecilla-Salinas, C.J.; Sedeño, J.; Escalona, M.J.; Mejías, M. Agile, Web Engineering and Capability Maturity Model Integration: A systematic literature review. Inf. Softw. Technol. 2016, 71, 92–107. [Google Scholar] [CrossRef]

- Kneuper, R. CMMI: Improving Software and Systems Development Processes Using Capability Maturity Model Integration; Rocky Nook: San Rafael, CA, USA, 2008. [Google Scholar]

- Kim, D.Y.; Grant, G. E-government maturity model using the capability maturity model integration. J. Syst. Inf. Technol. 2010, 12, 230–244. [Google Scholar] [CrossRef]

- Gibson, D.L.; Goldenson, D.R.; Kost, K. Performance Results of CMMI-Based Process Improvement; Software Engineering Institute: Pittsburgh, PA. USA, 2006. [Google Scholar]

- Mutafelija, B.; Stromberg, H. Process Improvement with CMMI v1. 2 and ISO Standards; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- CMMI Product Team. CMMI for Software Engineering, Version 1.1, Continuous Representation (CMMI-SW, V1.1, Continuous); CMU/SEI-2002-TR-028; Software Engineering Institute, Carnegie Mellon University: Pittsburgh, PA, USA, 2002. [Google Scholar]

- Paulk, M.C.; Curtis, B.; Chrissis, M.B.; Weber, C.V. Capability maturity model for software, version 1.1. In Software Engineering Institute (No. 52.219617), CMU/SEI-93-TR-24, DTIC Number ADA263403; IEEE: Piscataway, NJ, USA, 1993; Volume 10. [Google Scholar]

- Amaral, A.; Jorge, D.; Peças, P. Small Medium Enterprises and Industry 4.0: Current Models’ Ineptitude and The Proposal of a Methodology to Successfully Implement Industry 4.0 In Small Medium Enterprises. Procedia Manuf. 2020, 41, 1103–1110. [Google Scholar] [CrossRef]

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millack, A.; Schröter, M. Industrie 4.0-Readiness Online Self-Check for Businesses. Recuper. Em 2015, 10, 1–12. [Google Scholar]

- VDMA. German Mechanical Engineering Industry Association 2020. VDMA Members. Available online: https://www.vdma.org/en/mitglieder (accessed on 13 November 2021).

- Leyh, C.; Bley, K.; Schäffer, T.; Forstenhäusler, S. SIMMI 4.0-a maturity model for classifying the enterprise-wide it and software landscape focusing on Industry 4.0. In Proceedings of the 2016 Federated Conference on Computer Science and Information Systems (Fedcsis), Gdansk, Poland, 11–14 September 2016; pp. 1297–1302. [Google Scholar]

- Geissbauer, R.; Vedso, J.; Schrauf, S. Industry 4.0: Building the Digital Enterprise. 2016. Available online: https://www.pwc.com/gx/en/industries/industries-4.0/landing-page/industry-4.0-building-your-digital-enterprise-april-2016.pdf (accessed on 12 November 2021).

- De Carolis, A.; Macchi, M.; Negri, E.; Terzi, S. Guiding manufacturing companies towards digitalization a methodology for supporting manufacturing companies in defining their digitalization roadmap. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation (ICE/ITMC), Madeira, Portugal, 27–29 June 2017; pp. 487–495. [Google Scholar]

- Gökalp, E.; Şener, U.; Eren, P.E. Development of an assessment model for industry 4.0: Industry 4.0-MM. In International Conference on Software Process Improvement and Capability Determination; Springer: Cham, Switzerland, 2017; pp. 128–142. [Google Scholar]

- Weber, C.; Königsberger, J.; Kassner, L.; Mitschang, B. M2DDM–A Maturity Model for Data-Driven Manufacturing. Procedia CIRP 2017, 63, 173–178. [Google Scholar] [CrossRef]

- Singapore EDB. The Singapore Smart Industry Readiness Index; Singapore EDB: Raffles City, Singapore, 2018. [Google Scholar]

- Rong, H.; Automation, R. The-Connected-Enterprise-Maturity Model, Doctoral Dissertation. 2014. Available online: https://www.gov.sg/~/sgpcmedia/media_releases/edb/press_release/P-20171113-1/attachment/The%20Singapore%20Smart%20Industry%20Readiness%20Index%20-%20Whitepaper_final.pdf (accessed on 12 November 2021).

- Firma4: Pracovní Skupina pro Implementaci Průmyslu 4.0. Available online: http://firma4.cz/hodnoceni-digitalni-zralosti-firmy/ (accessed on 12 November 2021).

- Bogner, E.; Voelklein, T.; Schroedel, O.; Franke, J. Study based analysis on the current digitalization degree in the manufacturing industry in Germany. Procedia CIRP 2016, 57, 14–19. [Google Scholar] [CrossRef]

- Back, A.; Berghaus, S.; Kaltenrieder, B. Digital Maturity Transformation Studie; Institut für Wirtschaftsinformatik: St. Gallen, Switzerland, 2015. [Google Scholar]

- Dennis, M.; Ramaswamy, C.; Ameen, M.N.; Jayaram, V. Asset Performance Management Maturity Model Strategic Roadmap to Digital Manufacturing; Capgemini: Paris, France, 2018. [Google Scholar]

- Mittal, S.; Romero, D.; Wuest, T. Towards a smart manufacturing maturity model for SMEs (SM 3 E). In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Swizerland, 2018; pp. 155–163. [Google Scholar]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation. Res.-Technol. Manag. 2018, 61, 22–31. [Google Scholar] [CrossRef] [Green Version]

- Oleśków-Szłapka, J.; Stachowiak, A. The framework of logistics 4.0 maturity model. In International Conference on Intelligent Systems in Production Engineering and Maintenance; Springer: Cham, Switzerland, 2018; pp. 771–781. [Google Scholar]

- Corallo, A.; Lazoi, M.; Lezzi, M. Cybersecurity in the context of industry 4.0: A structured classification of critical assets and business impacts. Comput. Ind. 2020, 114, 103165. [Google Scholar] [CrossRef]

- Stefan, L.; Thom, W.; Dominik, L.; Dieter, K.; Bernd, K. Concept for an evolutionary maturity based Industrie 4.0 migration model. Procedia CIRP 2018, 72, 404–409. [Google Scholar] [CrossRef]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards industrial digitalization based on an Industry 4.0 maturity model for manufacturing enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- Colli, M.; Madsen, O.; Berger, U.; Møller, C.; Wæhrens, B.V.; Bockholt, M. Contextualizing the outcome of a maturity assessment for Industry 4.0. IFAC-Pap. 2018, 51, 1347–1352. [Google Scholar] [CrossRef]

- Hankel, M.; Rexroth, B. Industrie 4.0: The Reference Architectural Model Industrie 4.0 (RAMI 4.0). Frankfurt am Main, Germany: ZVEI-German Electrical and Electronic Manufacturers’ Association. ZVEI 2015, 2, 4–9. [Google Scholar]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Zeller, V.; Hocken, C.; Stich, V. Acatech Industrie 4.0 Maturity Index-A Multidimensional Maturity Model. In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Swizerland, 2018; pp. 105–113. ISBN 978-3-319-99707-0. [Google Scholar]

- Jung, K.; Kulvatunyou, B.; Choi, S.; Brundage, M.P. An Overview of a Smart Manufacturing System Readiness Assessment. IFIP Adv. Inf. Commun. Technol. 2017, 488, 705–712. [Google Scholar]

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and Readiness Model for Industry 4.0 Strategy. In Industry 4.0: Managing The Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Lee, J.; Jun, S.; Chang, T.W.; Park, J. A Smartness Assessment Framework for Smart Factories Using Analytic Network Process. Sustainability 2017, 9, 794. [Google Scholar] [CrossRef] [Green Version]

- Jaione, G.; Nekane, E. Three stage maturity model in SME’s toward industry 4.0. J. Ind. Eng. Manag. (JIEM) OmniaScience Barc. 2016, 9, 1119–1128. [Google Scholar]

- Krajcovic, M.; Grznar, P.; Fusko, M.; Skokan, R. Intelligent Logistics for Intelligent Production Systems. Commun.-Sci. Lett. Univ. Zilina 2018, 20, 16–23. [Google Scholar] [CrossRef]

- Werner-Lewandowska, K.; Kosacka-Olejnik, M. Logistics maturity of the service industry—Research results. Prace Nauk. Uniw. Ekon. We Wrocławiu 2019, 63, 233–248. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels—Case of the defence sector. Prod. Plan. Control 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2020, 12, 86. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.S.; Veelenturf, L.P. The strategic role of logistics in the industry 4.0 era. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 1–11. [Google Scholar] [CrossRef]

- Birkel, H.S.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability–A systematic literature review. J. Clean. Prod. 2020, 289, 125612. [Google Scholar] [CrossRef]

- Lassnig, M.; Müller, J.M.; Klieber, K.; Zeisler, A.; Schirl, M. A digital readiness check for the evaluation of supply chain aspects and company size for Industry 4.0. J. Manuf. Technol. Manag. 2021. [Google Scholar] [CrossRef]

- Jovčić, S.; Průša, P.; Dobrodolac, M.; Švadlenka, L. A proposal for a decision-making tool in third-party logistics (3PL) provider selection based on multi-criteria analysis and the fuzzy approach. Sustainability 2019, 11, 4236. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, P.; Kovalainen, A. Qualitative Methods in Business Research: A Practical Guide to Social Research; Sage: Newcastle upon Tyne, UK, 2015. [Google Scholar]

- Kjaer, L.L.; Høst-Madsen, N.K.; Schmidt, J.H.; McAloone, T.C. Application of environmental input-output analysis for corporate and product environmental footprints—Learnings from three cases. Sustainability 2015, 7, 11438–11461. [Google Scholar] [CrossRef] [Green Version]

- Behzadian, M.; Kazemzadeh, R.B.; Albadvi, A.; Aghdasi, M. Promethee: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2010, 200, 198–215. [Google Scholar] [CrossRef]

- Wang, K. Applying data mining to manufacturing: The nature and implications. J. Intell. Manuf. 2007, 18, 487–495. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Evaluating the barriers to specific industrial energy efficiency measures: An exploratory study in small and medium-sized enterprises. J. Clean. Prod. 2014, 82, 70–83. [Google Scholar] [CrossRef]

- Matana, G.; Simon, A.; Godinho Filho, M.; Helleno, A. Method to assess the adherence of internal logistics equipment to the concept of CPS for industry 4.0. Int. J. Prod. Econ. 2020, 228, 107845. [Google Scholar] [CrossRef]

- Kostrzewski, M.; Varjan, P.; Gnap, J. Solutions dedicated to internal logistics 4.0. In Sustainable Logistics and Production in Industry 4.0; Springer: Cham, Swizerland, 2020; pp. 243–262. [Google Scholar]

- Colli, M.; Berger, U.; Bockholt, M.; Madsen, O.; Møller, C.; Wæhrens, B.V. A maturity assessment approach for conceiving context-specific roadmaps in the Industry 4.0 era. Annu. Rev. Control 2019, 48, 165–177. [Google Scholar] [CrossRef]

- Todorovic, T.; Lalic, B.; Majstorovic, V.; Marjanovic, U.; Tasic, N. General Readiness Assessment of Industry 4.0: Evidence from Serbian Manufacturing Industry. In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Swizerland, 2020; pp. 139–146. [Google Scholar]

- Götz, M.; Jankowska, B. Adoption of Industry 4.0 Technologies and Company Competitiveness: Case Studies from a Post-Transition Economy. Foresight STI Gov. 2020, 14, 61–78. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 technologies: Critical success factors for implementation and improvements in manufacturing companies. Prod. Plan. Control 2021, 1, 1–21. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Jafarnejad, H. The smart SME technology readiness assessment methodology in the context of industry 4.0. J. Manuf. Technol. Manag. 2021, 32, 1037–1065. [Google Scholar] [CrossRef]

- Sadeghi-Niaraki, A. Industry 4.0 development multi-criteria assessment: An integrated fuzzy DEMATEL, ANP and VIKOR methodology. IEEE Access 2020, 8, 23689–23704. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M. Readiness of enterprises in Czech Republic to implement industry 4.0: Index of industry 4.0. Appl. Sci. 2019, 9, 5405. [Google Scholar] [CrossRef] [Green Version]

- Basl, J.; Doucek, P. A metamodel for evaluating enterprise readiness in the context of Industry 4.0. Information 2019, 10, 89. [Google Scholar] [CrossRef] [Green Version]

- Mrugalska, B.; Stasiuk-Piekarska, A. Readiness and maturity of manufacturing enterprises for industry 4.0. In International Conference on Applied Human Factors and Ergonomics; Springer: Cham, Swizerland, 2020; pp. 263–270. [Google Scholar]

- Hajoary, P.K.; Akhilesh, K.B. Conceptual framework to assess the maturity and readiness towards Industry 4.0. In Industry 4.0 and Advanced Manufacturing; Springer: Singapore, 2021; pp. 13–23. [Google Scholar]

| Level | Interval Range | |

|---|---|---|

| From | To | |

| 0 | 0 | 0.2176 |

| 1 | 0.2176 | 0.4096 |

| 2 | 0.4096 | 0.5806 |

| 3 | 0.5806 | 0.7342 |

| 4 | 0.7342 | 0.8731 |

| 5 | 0.8731 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poor, P.; Zoubek, M.; Simon, M. Proposal of a Tool for Determining Sub- and Main Dimension Indicators in Assessing Internal Logistics Readiness for Industry 4.0 within a Company. Appl. Sci. 2021, 11, 11817. https://doi.org/10.3390/app112411817

Poor P, Zoubek M, Simon M. Proposal of a Tool for Determining Sub- and Main Dimension Indicators in Assessing Internal Logistics Readiness for Industry 4.0 within a Company. Applied Sciences. 2021; 11(24):11817. https://doi.org/10.3390/app112411817

Chicago/Turabian StylePoor, Peter, Michal Zoubek, and Michal Simon. 2021. "Proposal of a Tool for Determining Sub- and Main Dimension Indicators in Assessing Internal Logistics Readiness for Industry 4.0 within a Company" Applied Sciences 11, no. 24: 11817. https://doi.org/10.3390/app112411817

APA StylePoor, P., Zoubek, M., & Simon, M. (2021). Proposal of a Tool for Determining Sub- and Main Dimension Indicators in Assessing Internal Logistics Readiness for Industry 4.0 within a Company. Applied Sciences, 11(24), 11817. https://doi.org/10.3390/app112411817